Abstract

Control of the porous structure and particle size is essential for improving the properties of polysilsesquioxane (PSQ) microspheres. Herein, using the strategy combining inverse suspension polymerization, two-step sol–gel- and polymerization-induced phase separation processes, micron-sized thiol-containing macroporous PSQ (TMPSQ) microspheres with controllable morphologies, adjustable particle diameters (4.9–17.3 μm), and pore sizes (40–3774 nm) were prepared. The morphology and size of the TMPSQ microspheres were characterized by SEM. The mercury intrusion method was employed to analyze the porous structure of the microspheres. The effects of the composition of the sol–gel disperse phase, the mass ratio of the sol–gel disperse phase to the oil continuous phase (WRW/O), and the Span 80 mass content in the oil continuous phase on the morphology, particle diameter and pore size of the TMPSQ microspheres were investigated. Results indicated that the composition of the sol–gel disperse phase determines the morphology and porous structure of the microspheres, and WRW/O and Span 80 content have remarkable impacts on the morphology and particle size of the microspheres. This study is beneficial to the design and fabrication of functional PSQ microspheres with desired properties and promising application prospects.

1. Introduction

Owing to the inorganic –Si–O–Si– framework and variable organic groups, polysilsesquioxane (PSQ) microspheres have unique and beneficial features, such as great mechanical performance, stability, biocompatibility, temperature resistance, and easy functionalization [1]. Therefore, PSQ microspheres are ideal materials for light-scattering agents [2], pollutant adsorbents [3], chromatographic stationary phases [4], catalyst supports [1], and biosensors [5]. To satisfy the needs for diverse applications, controlling particle size and size distribution has become the focus in the area of PSQ microspheres [6,7,8].

In the past few decades, porous materials have attracted considerable interest from industries and researchers. Due to their advantages of large surface area, low density, and unique structure, porous materials have better performance than nonporous materials in many fields. Until now, researchers have always endeavored to obtain porous materials with tunable porous structures to improve their properties and meet different requirements, which depend on the desired speed of mass transfer or release of substances with target molecular sizes [9,10,11,12]. Macropores, with the pore size over 50 nm, can facilitate mass transfer and enhance interactions between the active sites on the surface and the substances outside the materials [13]. Additionally, the movement of large molecules along the macropore channels is allowed, which expands the application potential of porous materials [14]. Yet introducing macropores into various functional materials and adjusting the pore sizes are still challenging.

The functionality of PSQ microspheres can be enhanced by porous structures, but there is little research on porous PSQ microspheres compared to porous silica-based microspheres with a similar –Si–O–Si– skeleton. Multiple methods have been employed to fabricate porous silica-based microspheres, such as template [15,16], colloid aggregation [17], self-assembly [18], spray drying [19], aerosol [20], and polymerization-induced phase separation [13,21] methods. However, the synthesis of macroporous PSQ microspheres generally resorts to emulsion or suspension systems—such as W/O [22], O/W [23,24], and W/O/W [1] systems—as illustrated in Figure 1 because of their mild synthetic conditions and moderate post-treatment processes. In our previous study, a new strategy combining inverse suspension polymerization, two-step sol–gel and polymerization-induced phase separation processes was developed to synthesize thiol-containing open macroporous polysilsesquioxane (TMPSQ) microspheres, and the formation mechanism of the bicontinuous structure was revealed through the following processes of spinodal decomposition, coarsening, gelation, and the removal of solvent [25]. Tuning the pore size and pore structure of TMPSQ microspheres can control the surface area, active sites on the surface, and the mass transfer rate. The design and preparation of TMPSQ microspheres with different pore sizes and morphologies are beneficial to broaden their application fields. Nevertheless, control synthesis of TMPSQ microspheres with tunable pore sizes has not been achieved yet.

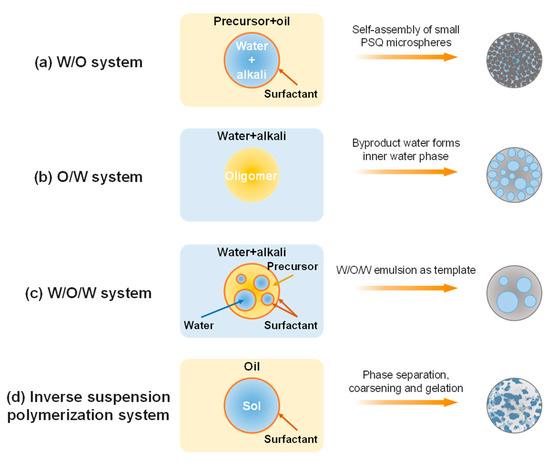

Figure 1.

Schematic illustration of preparing porous PSQ microspheres in various emulsion or suspension systems. (a) W/O system [22], (b) O/W system [23,24], (c) W/O/W system [1], and (d) inverse suspension polymerization system [25].

In this study, the TMPSQ microspheres with controllable morphology, particle diameter, and pore size were prepared via the same strategy as above using the mixture of H2O, MeOH, methyltrimethoxysilane (MTMS), (3-mercaptopropyl)trimethoxysilane (MPTMS) and catalyst solutions as the sol–gel disperse phase and liquid paraffin and Span 80 as the oil continuous phase. The effects of the composition of the polymerization system on the morphology, particle diameter, and pore size of the microspheres were systematically investigated.

2. Results and Discussion

2.1. Effects of the Composition of the Sol–Gel Disperse Phase

2.1.1. Effect of the Molar Ratio of H2O to Total Precursors (MRH2O/Si)

The siloxane skeletons and organic side groups of TMPSQ microspheres were confirmed by FTIR, Raman spectroscopy (Figure S1a,b) [25] and the solid-state 29Si NMR (Figure S2), and details were given in Supplementary Information.

In the labels of all samples in this article, the alphabetical order is the order of the factor being investigated; the numerical order reflects the value of the respective factor, and the higher the order, the higher the value.

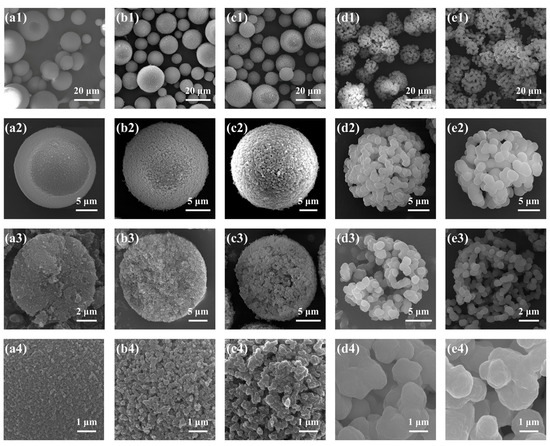

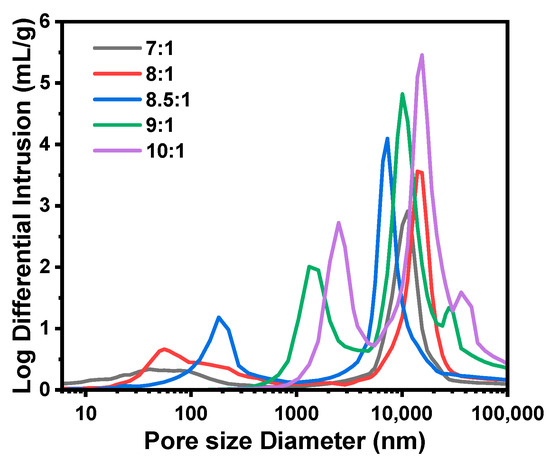

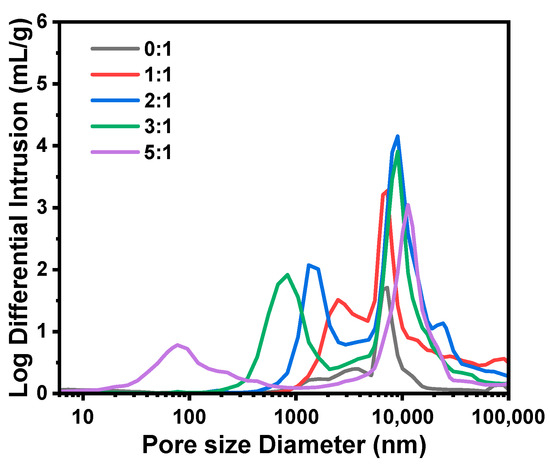

Samples A1–A5 were prepared with the increase in MRH2O/Si from 7:1 to 10:1. Effect of the MRH2O/Si in the sol–gel disperse phase was investigated by varying Water-A and Water-B, and the recipe and properties of TMPSQ microspheres are listed in Table 1. Here, the water amount of the mixture of 0.01 M HCl (aq) and Water-A was equal to that of the mixture of NH4OH (aq, 10 wt.%) and Water-B. As presented in Figure 2, all samples had open porous structures. In this study, pore characteristics of the TMPSQ microspheres were determined using the mercury intrusion method, and the log differential intrusion versus pore size curves were used to assess the pore size distributions. According to Figure 3, all samples were of bimodal distributions, indicating the coexistence of intraparticle pores and interparticle voids. When the MRH2O/Si was 7:1 (sample A1), Dintra was only 40 nm, suggesting that the pores were mesopores rather than macropores. With the increase in MRH2O/Si, Vpore, Ptotal, Dintra, Vintra, and Ptotal all increased, while SMIP decreased, which suggested that the pore in the microspheres became larger. Under lower MRH2O/Si (from 7:1 to 8.5:1), the particles had higher sphericity (samples A1–A3). When this ratio reached 9:1 (sample A4), some microspheres were slightly damaged. With a higher MRH2O/Si at 10:1 (sample A5), the sphericity of particles was poorer, and some non-spherical fragments were observed in Figure 2(e1), indicating that the microspheres were partly broken during preparation.

Table 1.

Influence of the MRH2O/Si on the properties of TMPSQ microspheres a.

Figure 2.

SEM photographs of the TMPSQ microspheres prepared with different MRH2O/Si at different magnifications: (a1–a4) 7:1 (sample A1), (b1–b4) 8:1 (sample A2), (c1–c4) 8.5:1 (sample A3), (d1–d4) 9:1 (sample A4), and (e1–e4) 10:1 (sample A5).

Figure 3.

Pore size distributions of the TMPSQ microspheres prepared with different MRH2O/Si.

It has been demonstrated that H2O content has a great impact on phase separation in the sol–gel process of alkoxysilanes [26]. With more water in the disperse phase, the polarity of the solvent becomes higher, which causes lower compatibility between the oligomers and the solvent and results in a stronger phase separation in the disperse phase. Thus, with higher MRH2O/Si, the oligomer and solvent phases caused by spinodal decomposition grew fully and both the skeletons and pores in microspheres became larger. However, when the MRH2O/Si was over 9:1, the coarsening process became remarkable and the fragmentation of the oligomer phase started [26,27]. In this case, the skeletons of microspheres became weakly connected and were partly broken by washing and drying. For the sample A5 with the highest MRH2O/Si of 10:1, the more significant coarsening process caused the further breakup of the oligomer phase. Hence, more broken microspheres and fragments were observed in Figure 2(e1). Even though microspheres with similar structures as sample A5 had larger pores, their disadvantages would limit their application potential. On the one hand, their specific surface areas became lower, and as a result, some properties—such as loading and adsorption capacities—would be weakened. On the other hand, this type of microsphere was more fragile and easily broken into smaller particles and fragments, which made it more difficult to recover and reuse the microsphere.

2.1.2. Effect of the Molar Ratio of MeOH to Total Precursors (MRMeOH/Si)

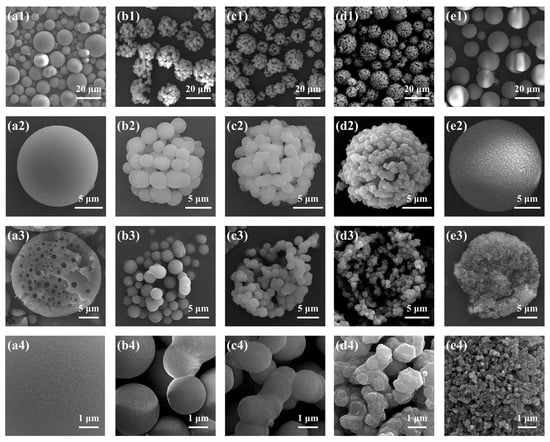

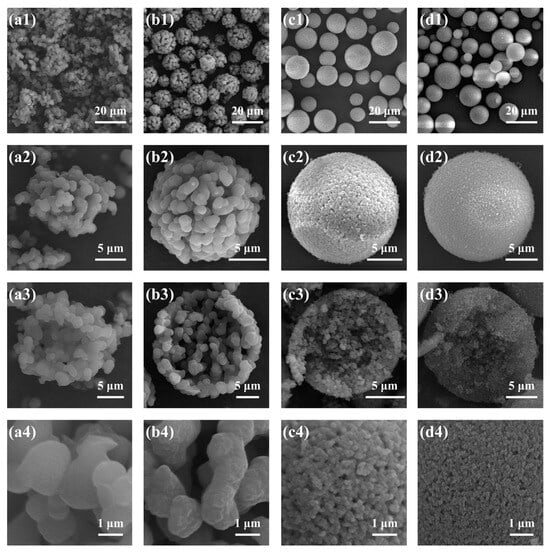

Samples B1–B6, with gradually increasing MRMeOH/Si from 0:1 to 5:1, were synthesized with varying amounts of MeOH, and the results are presented in Table 2 and Figure 4 and Figure 5, respectively. In comparison with other samples, sample B1 (MRMeOH/Si = 0:1) was rather special. The surface was smooth, and no open pore was found (Figure 4(a4)), and only one main peak attributed to the interparticle spaces existed in Figure 5, indicating the absence of open macropores in the microspheres. Nevertheless, closed pores with an average diameter of 1.06 ± 0.30 μm were formed inside the microspheres (Figure 4(a3)). The reason is that when no MeOH was added, the composition of the sol–gel disperse phase was off-critical and located in the metastable region in the equilibrium phase diagram [27], and the phase separation in sample B1 conformed to the nucleation-growth mode, forming the isolated multiple cavities inside microspheres [28]. For the samples from B2 to B6, open porous structures and bimodal pore size distributions were observed. With the increase in MRMeOH/Si from 1:1 to 5:1, Dintra decreased and SMIP increased dramatically, suggesting a reduction in pore size. The phase separation was suppressed to generate finer bicontinuous structures inside the microspheres with higher MeOH content, which is consistent with the previous studies [26,29]. Despite the macroporous structure, the morphology of sample B2 (MRMeOH/Si = 1:1) was still different from that of samples B3–B6 (with the MRMeOH/Si from 2:1 to 5:1). The skeletons of sample B2 consisted of numerous isolated or weakly connected smaller microspheres (Figure 4(b4)), but the bicontinuous structures were generated in samples B3–B6 (Figure 2(c4) and Figure 4(c4–e4)). With the MRMeOH/Si of 1:1 (sample B2), the composition was also off-critical but still in the unstable region in the phase diagram, and the coarsening process was rather remarkable, which caused the fragmentation and spheroidization of the oligomer domain and resulted in the aggregation of smaller spherical particles [30]. Additionally, this weak connection between spherical units was partly ruined during washing and drying, and some fragments could be seen in the SEM photograph (Figure 4(b1)).

Table 2.

Influence of the MRMeOH/Si on the properties of TMPSQ microspheres a.

Figure 4.

SEM photographs of the TMPSQ microspheres prepared with different MRMeOH/Si at different magnifications: (a1–a4) 0:1 (sample B1), (b1–b4) 1:1 (sample B2), (c1–c4) 2:1 (sample B3), (d1–d4) 3:1 (sample B4), and (e1–e4) 5:1 (sample B6).

Figure 5.

Pore size distributions of the TMPSQ microspheres prepared with different MRMeOH/Si.

2.1.3. Effect of the Molar Ratio of NH4OH to Total Precursors (MRNH4OH/Si)

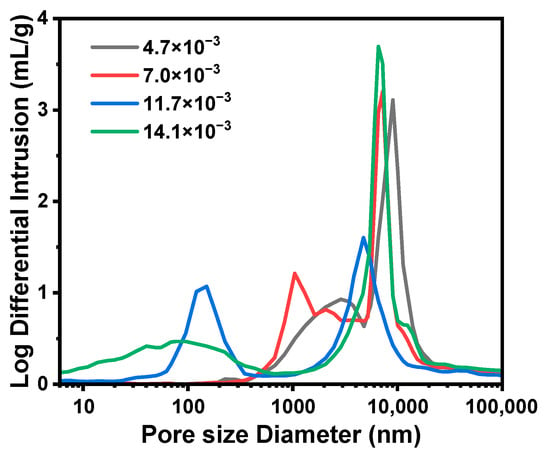

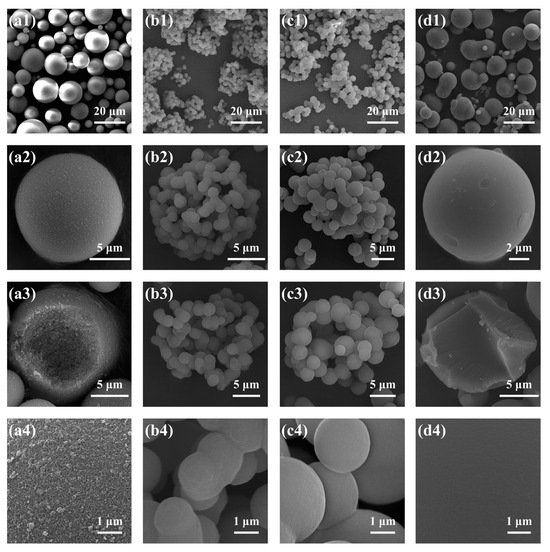

Table 3 summarizes the results of TMPSQ microspheres (samples C1–C5) prepared with the increase in MRNH4OH/Si from 4.7 × 10−3:1 to 14.1 × 10−3:1. In preparation, with the same MRH2O/Si at 8.5:1, the dosages of NH4OH (aq, 10 wt.%) and Water-B were varied to change the MRNH4OH/Si. The morphologies and pore size distributions of the TMPSQ microspheres are presented in Figure 6 and Figure 7. Results showed that with the increase in MRNH4OH/Si, Dintra, Vintra, and Ptotal decreased, and SMIP increased. All the samples had open pores and bimodal pore size distributions, and both the domains of skeletons and pores became narrower with higher MRNH4OH/Si. Note that Dmean of sample C1 (MRNH4OH/Si = 4.7 × 10−3:1) was lower than that of the others, and there were numerous small particles (Figure 6(a1)), which came from the broken microspheres and fragments of the skeletons.

Table 3.

Influence of the MRNH4OH/Si on the properties of TMPSQ microspheres a.

Figure 6.

SEM photographs of the TMPSQ microspheres prepared with different MRNH4OH/Si at different magnifications: (a1–a4) 4.7 × 10−3:1 (sample C1), (b1–b4) 7.0 × 10−3:1 (sample C2), (c1–c4) 11.7 × 10−3:1 (sample C4), and (d1–d4) 14.1 × 10−3:1 (sample C5).

Figure 7.

Pore size distributions of the TMPSQ microspheres prepared with different MRNH4OH/Si.

In this series of TMPSQ microspheres, since MRH2O/Si and MRMeOH/Si remained constant, the compatibility between the solvent and oligomers was considered to be unchanged, and the change in MRNH4OH/Si did not significantly affect the phase separation. However, the increase in MRNH4OH/Si can greatly accelerate the condensation rate and reduce the gelation time. With a higher MRNH4OH/Si, the interconnected structure was frozen in earlier stages of spinodal decomposition, and the coarsening process was inhibited. In this case, both the oligomer phase and the solvent phase became finer, resulting in smaller pore sizes inside the microspheres.

2.1.4. Effect of the MPTMS/MTMS Molar Ratio (MRMPTMS/MTMS)

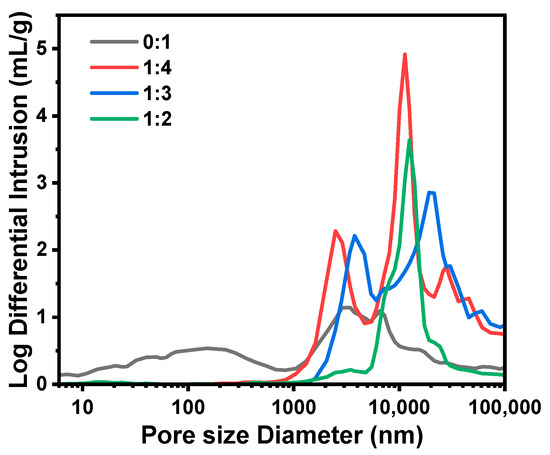

The hydrophobicity of the precursors strongly affects the phase separation in the sol–gel system [26]. Here, MPTMS has a longer carbon chain in the side groups and is thus more hydrophobic than MTMS. In order to investigate the effect of MRMPTMS/MTMS, Samples D1–D5 were prepared with MRMPTMS/MTMS of 0:1, 1:5, 1:4, 1:3, 1:2, and 1:1, respectively, but the same 0.06 mol of total precursors, and the results are summarized in Table 4, Figure 8 and Figure 9.

Table 4.

Influence of the MRMPTMS/MTMS on the properties of TMPSQ microspheres a.

Figure 8.

SEM photographs of the TMPSQ microspheres prepared with different MRMPTMS/MTMS at different magnifications: (a1–a4) 0:1 (sample D1), (b1–b4) 1:4 (sample D3), (c1–c4) 1:3 (sample D4), and (d1–d4) 1:2 (sample D5).

Figure 9.

Pore size distributions of the TMPSQ microspheres prepared with different MRMPTMS/MTMS.

The microspheres prepared with only MTMS (sample D1) were complete spheres (Figure 8(a1–a4)) with the lowest Dintra (151 nm) and the highest SMIP (70.8 m2/g) among samples D1–D5. Due to the less hydrophobic methyl, MTMS-derived oligomers were more compatible with the solvent than MTMS–MPTMS-derived oligomers, and the phase separation was less remarkable. Thus, the skeletons and pores of the microspheres became finer. When the MRMPTMS/MTMS increased to 1:4 (sample D3), Dintra drastically increased to 2485 nm, SMIP decreased to 2.1 m2/g, and the microspheres started to be broken and non-spherical (Figure 8(b1)). Obviously, the phase separation was quite sensitive to MPTMS content, and a small amount of MPTMS could cause a noticeable coarsening process. When the MRMPTMS/MTMS reached 1:3 (sample D4), Dintra further increased to 3774 nm, SMIP decreased to 1.3 m2/g, and the skeletons were made up of weakly connected small particles (Figure 8(c1–c4)), meaning that fragmentation and spheroidization occurred during the coarsening process. Since the structure was relatively loose, the microspheres were easily broken during washing and drying. Surprisingly, when the MRMPTMS/MTMS reached 1:2 (sample D5), the solid microspheres with the smallest Dmean (8.3 μm) were obtained. As shown in Figure 8(d1–d4), there existed no obvious macroporous structure, and only a main peak was observed in Figure 9. With an intense phase separation at a higher MPTMS content, the coarsening process proceeded quickly and thoroughly, and the sol was separated into two totally dissociative phases [27], and the isolated oligomer droplets were eventually converted into the solid microspheres.

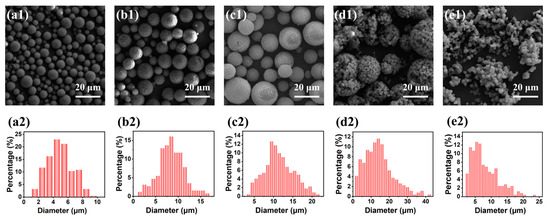

2.2. Effect of the Mass Ratio of Sol–Gel Disperse Phase to Oil Continuous Phase (WRW/O)

A series of TMPSQ microspheres (samples E1–E5) were synthesized by varying WRW/O from 0.11:1 to 0.54:1 with the same compositions of sol–gel disperse phase and oil continuous phase, and results were presented in Table 5 and Figure 10. For the samples E1–E3 (with the WRW/O from 0.11:1 to 0.32:1), the microspheres had great sphericity and integrity, and the interconnected macroporous structures were observed. Additionally, their size distributions were unimodal (Figure 10(a2–c2)), suggesting that the inverse suspension polymerization process was stable enough, and the integrity of droplets and the resultant microspheres was preserved. With the increase in the WRW/O, Dmean increased from 4.9 to 11.4 μm, but CV and Dintra did not change remarkably, which indicated that adjusting the WRW/O is an effective method of tuning particle size.

Table 5.

Influence of the WRW/O on the properties of TMPSQ microspheres a.

Figure 10.

(a1–e1) SEM photographs and (a2–e2) particle size histograms of the TMPSQ microspheres prepared with different WRW/O: (a1,a2) 0.11:1 (sample E1), (b1,b2) 0.22:1 (sample E2), (c1,c2) 0.32:1 (sample E3), (d1,d2) 0.43:1 (sample E4), and (e1,e2) 0.54:1 (sample E5).

However, when the WRW/O increased to 0.43:1 (sample E4), Dmean reached the maximum (14.4 μm), but CV and Dintra dramatically increased to 56.0% and 1606 nm, respectively, and partially broken large microspheres and small fragments were observed in Figure 10(d1). Further increasing WRW/O to 0.54:1 (sample E5), the value of Dmean sharply reduced to 7.9 μm, and the products were non-spherical and fragmented (Figure 10(e1)). In the case of a higher WRW/O, larger sol–gel disperse phase droplets were generated, and the polymerization system became unstable. During polymerization process, the breakup and coalescence of droplets co-existed, and the loose structure instantly formed inside the droplets could be easily destroyed by these two dynamic processes, resulting in non-spherical products.

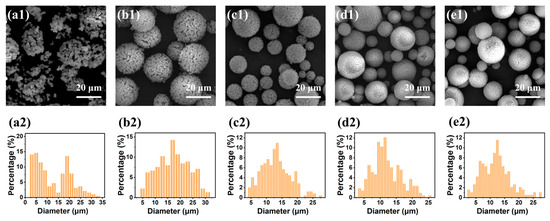

2.3. Effect of the Span 80 Mass Content in the Oil Continuous Phase

As a stabilizer, adequate Span 80 dosage was a key factor in controlling the size and integrity of the dispersed phase droplets. A series of TMPSQ microspheres (samples F1–F6) was prepared with increasing Span 80 mass contents in the oil phase from 1 wt.% to 10 wt.%, and the results are given in Table 6 and Figure 11. When the Span 80 content was as low as 1 wt.% (sample F1), the obtained microspheres were cracked and non-spherical (Figure 11(a1)), the size distribution was bimodal (Figure 11(a2)), and the peaks were at around 5 μm and 19 μm, respectively. This indicated that the amount of Span 80 was not enough to stabilize the droplets against breakup and coalescence and that the droplets were easily destroyed by stirring. For samples F2–F4 with Span 80 contents from 2 wt.% to 6 wt.%, all the microspheres were of high sphericity and integrity, and as expected, both Dmean and CV decreased with the increase in Span 80 content. When the Span 80 content further increased to 8 wt.% (sample F5) and 10 wt.% (sample F6), the values of Dmean and Dintra fluctuated slightly, but CV increased to 37.5% and 41.0%, respectively. These results suggested that excessive Span 80 caused the dispersity of TMPSQ microspheres to widen.

Table 6.

Influence of the Span 80 content on the properties of TMPSQ microspheres a.

Figure 11.

(a1–e1) SEM photographs and (a2–e2) particle size histograms of the TMPSQ microspheres prepared with different Span 80 mass contents in the oil continuous: (a1,a2) 1 wt.% (sample F1), (b1,b2) 2 wt.% (sample F2), (c1,c2) 4 wt.% (sample F3), (d1,d2) 8 wt.% (sample F5), and (e1,e2) 10 wt.% (sample F6).

3. Materials and Methods

3.1. Materials

MTMS (AR) and MPTMS (AR) were obtained from 3A Chemicals Scientific Co., Ltd. (Shanghai, China). MeOH (AR) was supplied by Beijing Tongguang Fine Chemicals Inc. (Beijing, China). Hydrochloric acid (HCl, 35–37 wt.%, AR) was purchased from Modern Oriental Fine Chemistry Co., Ltd. (Beijing, China). Ammonium hydroxide (NH4OH, 25–28 wt.%, AR), ethanol (AR), and cyclohexane (AR) were obtained from Shanghai Titan Scientific Co., Ltd. (Shanghai, China). Liquid paraffin (AR, 0.83–0.86 g/mL of density, ≥300 °C of distillation temperature at atmospheric pressure) was purchased from Sinopharm Group Chemical Reagent Co., Ltd. (Shanghai, China). Span 80 (CP) was obtained from Shanghai Macklin Biochemical Technology Co., Ltd. (Shanghai, China). Water was deionized using a RO DI digital water purification system (Shanghai, China).

3.2. Preparation of TMPSQ Microspheres

The TMPSQ microspheres were prepared according to our previous report [25].

First, certain amounts of Span 80 and liquid paraffin were charged into a three-necked 250 mL flask to form the oil continuous phase by stirring, and the total mass of the two components was fixed at 80 g.

Then, certain amounts of MTMS, MPTMS, MeOH, 0.01 M HCl (aq), and water (Water-A) were first added to a round-bottom 50 mL flask equipped with a magnetic stirrer. After stirring for 2 h, an alkaline catalyst solution prepared from NH4OH (aq, 10 wt.%) and water (Water-B) was added to form the sol–gel disperse phase.

Finally, the sol–gel disperse phase was dropwise charged into the oil continuous phase, and the system was mechanically stirred at 500 rpm for 16 h in a water bath at 25 °C. To obtain the TMPSQ microspheres, the product was collected by centrifugation, washed with cyclohexane twice and by ethanol twice, and dried at 40 °C for 2 d.

3.3. Characterization

The morphology and internal structure of the TMPSQ microspheres were observed by an ULTRA 55 scanning electron microscope (SEM, ZEISS, Jena, Germany), operating at a 15 kV accelerating voltage. To obtain the internal structure information, the TMPSQ microsphere samples were ground in advance. Before characterization, the samples were sputtered with platinum. The particle sizes and size distributions were measured via a software called Nano Measurer 1.2 (Fudan University, Shanghai, China) based on SEM photos. The numerical mean diameter (Dmean) and standard deviation (σ) were calculated by measuring 200 microspheres. The coefficient of variation (CV), which is an index of the polydispersity of particles, was calculated as follows:

The macroporous structures of the TMPSQ microspheres were analyzed using an AutoPore V 9620 porosimeter (Micromeritics, Norcross, GA, USA), operating at pressures from 0.001 to 410 MPa. The samples were dried at 100 °C for 2 h in advance using a vacuum drying oven (DZF-6020, Shanghai Honghua Instruments, Shanghai, China). Through the mercury intrusion method, the pore size distributions were determined, and total pore volumes (Vpore), total porosities (Ptotal), and surface areas (SMIP) were quantified.

The minimal points in the middle of the bimodal pore size distribution curves were used to distinguish interparticle spaces and intraparticle macropores, and the maximal points of the peaks at smaller pore sizes were considered to represent the intraparticle pore sizes (Dintra). Based on the cumulative intrusion volume at different pressures, the volume of interparticle spaces (Vinter) and the volume of intraparticle pores (Vintra) were determined. The total volume of the sample (Vsample) was calculated by dividing Vpore by Ptotal, and after subtraction of Vinter from Vsample, the total volume of microspheres (Vmicrosphere) was estimated using Equation (2):

Then, the intraparticle porosity (Pintra) was obtained from Equation (3):

4. Conclusions

In summary, the macroporous TMPSQ microspheres with controllable diameter and pore size were successfully synthesized via a facile strategy that integrated inverse suspension polymerization, two-step sol–gel, and phase separation processes. The composition of the sol–gel disperse phase had remarkable effects on the morphology and pore size of the TMPSQ microspheres. Higher MRH2O/Si and MRMPTMS/MTMS, and lower MRMeOH/Si and MRNH4OH/Si would cause larger pores but less sphericity and integrity. By varying the above four ratios, the pore size, specific surface area, total porosity, and intraparticle porosity could be adjusted from 40 nm to 3774 nm, from 1.3 m2/g to 71.3 m2/g, from 47.9% to 74.7%, and from 29.1% to 51.3%, respectively. The size and morphology of the TMPSQ microspheres were significantly impacted by WRW/O and Span 80 content, and excessive WRW/O or insufficient Span 80 content would result in the damage to the TMPSQ microspheres. We believe that this work will provide insights into the controllable synthesis and property improvement of new functional PSQ microspheres and accelerate the application of such microspheres in different fields.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/molecules29122841/s1, Figure S1: (a) FTIR and (b) Raman spectra of the TMPSQ microspheres; Figure S2: Solid-state 29Si NMR spectrum of the TMPSQ microspheres. References [8,25,31] are cited in the supplementary materials.

Author Contributions

Conceptualization, L.H.; methodology, L.H.; validation, L.H. and Z.N.; formal analysis, L.H., Z.N. and R.G.; investigation, L.H., Z.N. and R.G.; resources, C.K.; data curation, L.H., Z.N. and R.G.; writing—original draft preparation, L.H.; writing—review and editing, Z.N., R.G. and C.K.; visualization, L.H.; supervision, C.K.; project administration, C.K.; funding acquisition, C.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Strategic Priority Research Program A of the Chinese Academy of Sciences (Grant XDA22010203).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Du, G.Q.; Peng, J.X.; Zhang, Y.Y.; Zhang, H.X.; Lü, J.L.; Fang, Y. One-step synthesis of hydrophobic multicompartment organosilica microspheres with highly interconnected macro-mesopores for the stabilization of liquid marbles with excellent catalysis. Langmuir 2017, 33, 5223–5235. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, X.; Lei, S.; Liu, X.F.; Chen, D.Z.; Tang, J.N. Preparation of refractive-index-controlled silicone microspheres and their application in polycarbonate light diffusing materials. Polym.-Plast. Technol. Mater. 2019, 58, 1766–1780. [Google Scholar] [CrossRef]

- Lu, X.; Yin, Q.F.; Xin, Z.; Zhang, Z.Q. Powerful adsorption of silver(I) onto thiol-functionalized polysilsesquioxane microspheres. Chem. Eng. Sci. 2010, 65, 6471–6477. [Google Scholar] [CrossRef]

- Shi, J.J.; Zhang, L.X.; Huo, Z.X.; Chen, L. High stability amino-derived reversed-phase/anion-exchange mixed-mode phase based on polysilsesquioxane microspheres for simultaneous separation of compound drugs. J. Pharm. Biomed. Anal. 2021, 203, 114187. [Google Scholar] [CrossRef] [PubMed]

- Miller, C.R.; Vogel, R.; Surawski, P.P.T.; Corrie, S.R.; Rühmann, A.; Trau, M. Biomolecular screening with novel organosilica microspheres. Chem. Commun. 2005, 41, 4783–4785. [Google Scholar] [CrossRef] [PubMed]

- Han, L.; Nie, Z.Y.; Gao, R.S.; Kan, C.Y. Facile synthesis of micron-sized thiol-functional polysilsesquioxane microspheres through a one-step sol-gel method. J. Sol-Gel Sci. Technol. 2023, 109, 330–345. [Google Scholar] [CrossRef]

- Matsumoto, T.; Takayama, Y.; Wada, N.; Onoda, H.; Kojima, K.; Yamada, H.; Wakabayashi, H. Acid-free synthesis of poly-organo-siloxane spherical particles using a W/O emulsion. J. Mater. Chem. 2003, 13, 1764–1770. [Google Scholar] [CrossRef]

- Lu, X.; Hou, Y.H.; Zha, J.; Xin, Z. Size-controlled synthesis of monodispersed poly(3-mercaptopropylsilsesquioxane) microspheres by a two-step sol–gel method. Ind. Eng. Chem. Res. 2014, 53, 14659–14663. [Google Scholar] [CrossRef]

- Li, J.; Xu, L.; Shi, Z.G. Waxberry-like hierarchically porous ethyl-bridged hybrid silica microsphere: A substrate for enzyme catalysis and high-performance liquid chromatography. J. Chromatogr. A 2019, 1587, 79–87. [Google Scholar] [CrossRef]

- Qu, Q.S.; Si, Y.; Xuan, H.; Zhang, K.H.; Chen, X.M.; Ding, Y.; Feng, S.J.; Yu, H.Q.; Abdullah, M.A.; Alamry, K.A. Dendritic core-shell silica spheres with large pore size for separation of biomolecules. J. Chromatogr. A 2018, 1540, 31–37. [Google Scholar] [CrossRef]

- Li, T.; Wang, S.W.; Gao, J.Q.; Wang, R.Q.; Gao, G.F.; Ren, G.M.; Na, S.N.; Hong, M.; Yang, S.H. Spherical binderless 4A/5A zeolite assemblies: Synthesis, characterization, and adsorbent applications. Molecules 2024, 29, 1432. [Google Scholar] [CrossRef] [PubMed]

- Strangfeld, C.; Wiehle, P.; Munsch, S.M. About the dominance of mesopores in physisorption in amorphous materials. Molecules 2021, 26, 7190. [Google Scholar] [CrossRef] [PubMed]

- Vale, M.; Loureiro, M.V.; Ferreira, M.J.; Marques, A.C. Silica-based microspheres with interconnected macroporosity by phase separation. J. Sol-Gel Sci. Technol. 2020, 95, 746–759. [Google Scholar] [CrossRef]

- Steinbach, J.C.; Fait, F.; Mayer, H.A.; Kandelbauer, A. Sol–gel-controlled size and morphology of mesoporous silica microspheres using hard templates. ACS Omega 2023, 8, 30273–30284. [Google Scholar] [CrossRef] [PubMed]

- Bai, J.Q.; Zhu, Q.Y.; Tang, C.W.; Liu, J.W.; Yi, Y.K.; Bai, Q. Synthesis and application of 5 μm monodisperse porous silica microspheres with controllable pore size using polymeric microspheres as templates for the separation of small solutes and proteins by high-performance liquid chromatography. J. Chromatogr. A 2022, 1675, 463165. [Google Scholar] [CrossRef]

- Xia, H.J.; Wan, G.P.; Zhao, J.L.; Liu, J.W.; Bai, Q. Preparation and characterization of monodisperse large-porous silica microspheres as the matrix for protein separation. J. Chromatogr. A 2016, 1471, 138–144. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.M.; Wang, Y.J.; Sun, Y.W.; Luo, G.S.; Dai, Y.Y. Synthesis of micrometer-sized hard silica spheres with uniform mesopore size and textural pores. J. Colloid Interface Sci. 2006, 299, 823–830. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Xiao, Q.; Zhou, H.; Sun, P.; Yuan, Z.; Li, B.; Ding, D.; Shi, A.C.; Chen, T. Budded, mesoporous silica hollow spheres: Hierarchical structure controlled by kinetic self-assembly. Adv. Mater. 2006, 18, 3284–3288. [Google Scholar] [CrossRef]

- Abdullah, M.; Iskandar, F.; Shibamoto, S.; Ogi, T.; Okuyama, K. Preparation of oxide particles with ordered macropores by colloidal templating and spray pyrolysis. Acta Mater. 2004, 52, 5151–5156. [Google Scholar] [CrossRef]

- Min, K.; Choi, C.H.; Kim, M.Y.; Choi, M. Aerosol-assisted controlled packing of silica nanocolloids: Templateless synthesis of mesoporous silicates with structural tunability and complexity. Langmuir 2015, 31, 542–550. [Google Scholar] [CrossRef]

- Shi, Z.G.; Feng, Y.Q. Synthesis and characterization of hierarchically porous silica microspheres with penetrable macropores and tunable mesopores. Microporous Mesoporous Mater. 2008, 116, 701–704. [Google Scholar] [CrossRef]

- Han, C.L.; Ma, L.; Tang, T.Y.; Deng, J.; Luo, G.S. Microdroplet-based synthesis of polymethylsilsesquioxane microspheres with controllable size, surface morphology, and internal structure. Chem. Eng. Sci. 2022, 262, 118054. [Google Scholar] [CrossRef]

- Johnston, A.P.R.; Battersby, B.J.; Lawrie, G.A.; Trau, M. Porous functionalised silica particles: A potential platform for biomolecular screening. Chem. Commun. 2005, 7, 848–850. [Google Scholar] [CrossRef]

- Johnston, A.P.R.; Battersby, B.J.; Lawrie, G.A.; Lambert, L.K.; Trau, M. A mechanism for forming large fluorescent organo-silica particles: potential supports for combinatorial synthesis. Chem. Mater. 2006, 18, 6163–6169. [Google Scholar] [CrossRef]

- Han, L.; Nie, Z.Y.; Gao, R.S.; Jiang, Z.Y.; Kan, C.Y. Micron-sized thiol-functional polysilsesquioxane microspheres with open and interconnected macropores: Preparation, characterization and formation mechanism. Molecules 2024, 29, 1204. [Google Scholar] [CrossRef] [PubMed]

- Nakanishi, K.; Kanamori, K. Organic-inorganic hybrid poly(silsesquioxane) monoliths with controlled macro- and mesopores. J. Mater. Chem. 2005, 15, 3776–3786. [Google Scholar] [CrossRef]

- Nakanishi, K.; Soga, N. Phase-separation in gelling silica organic polymer-solution—Systems containing poly(sodium styrenesulfonate). J. Am. Ceram. Soc. 1991, 74, 2518–2530. [Google Scholar] [CrossRef]

- Cai, W.W.; Yang, H.; Guo, X.Z. A facile one-step route to synthesize titania hollow microspheres with incontinuous multicavities. Chin. Chem. Lett. 2014, 25, 441–446. [Google Scholar] [CrossRef]

- Nakanishi, K. Pore structure control of silica gels based on phase separation. J. Porous Mater. 1997, 4, 67–112. [Google Scholar] [CrossRef]

- Marques, A.C.; Vale, M. Macroporosity control by phase separation in sol-gel derived monoliths and microspheres. Materials 2021, 14, 4247. [Google Scholar] [CrossRef]

- Lu, X.; Hou, Y.; Zha, J.; Xin, Z. Facile synthesis of Rhodamine B-doped poly(3-mercaptopropylsilsesquioxane) fluorescent microspheres with controllable size. Ind. Eng. Chem. Res. 2013, 52, 5880–5886. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).