Liquid–Liquid Equilibrium of Sesame Fatty Acid (Ethyl and Methyl) Ester + Glycerol + Ethanol/Methanol Mixtures at Different Temperatures

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Production of Methyl and Ethyl Biodiesel from Sesame Oil (Sesamum indicum)

| Compound | Fatty Acid | Cx:y a | Molar Mass (g. gmol−1) | Content 100.w | |||

|---|---|---|---|---|---|---|---|

| This Study b | Carvalho et al. [22] | Corso et al. [23] | Andresa et al. [24] | ||||

| 1 | Palmitic acid | 16:0–C16H32O2 | 256.43 | 10.5 | 11.5 | 10.3 | 9.7 |

| 2 | Stearic acid | 18:0–C18H36O2 | 284.48 | 2.8 | 5.3 | 5.2 | 6 |

| 3 | Oleic acid | 18:1–C18H34O2 | 282.46 | 35.8 | 38.1 | 36.4 | 38.7 |

| 4 | Linoleic acid | 18:2–C18H32O2 | 280.45 | 50.9 | 43.1 | 46.8 | 45 |

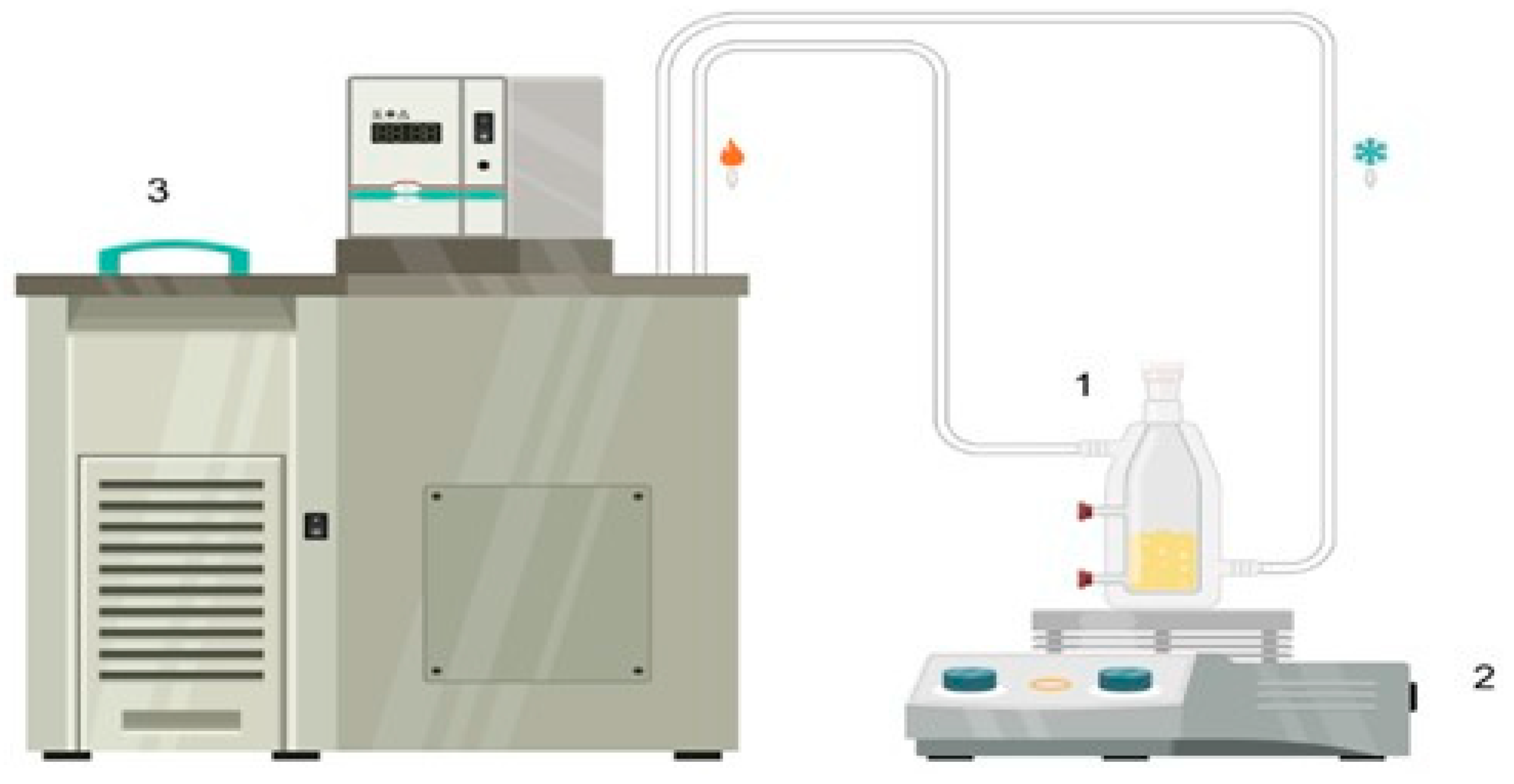

2.3. Apparatus and Procedures for Equilibrium Liquid–Liquid

Liquid–Liquid Equilibrium Data

2.4. Quality Test of the Experimental Data

2.5. Distribution Coefficient and Selectivity

3. Thermodynamic Modeling

4. Results and Discussions

4.1. Experimental Data

4.2. Quality Test of the LLE Data

4.3. Separation Factor and Distribution Coefficient

4.4. Thermodynamic Modeling

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rinaldi, R.; Garcia, C.; Marciniuk, L.L.; Rossi, A.V.; Schuchardt, U. Síntese de Biodiesel: Uma Proposta Contextualizada de Experimento Para Laboratório de Química Geral. Química Nova 2007, 30, 1374–1380. [Google Scholar] [CrossRef]

- Jones, J.C. On the Processing of Biodiesel Fuels. Fuel 2009, 88, 583. [Google Scholar] [CrossRef]

- Lotero, E.; Liu, Y.; Lopez, D.E.; Suwannakarn, K.; Bruce, D.A.; Goodwin, J.G. Synthesis of Biodiesel via Acid Catalysis. Ind. Eng. Chem. Res. 2005, 44, 5353–5363. [Google Scholar] [CrossRef]

- Knothe, G. Biodiesel and Renewable Diesel: A Comparison. Prog. Energy Combust. Sci. 2010, 36, 364–373. [Google Scholar] [CrossRef]

- Moradi, G.R.; Dehghani, S.; Khosravian, F.; Arjmandzadeh, A. The Optimized Operational Conditions for Biodiesel Production from Soybean Oil and Application of Artificial Neural Networks for Estimation of the Biodiesel Yield. Renew. Energy 2013, 50, 915–920. [Google Scholar] [CrossRef]

- Cagirgan, I.; Selçuk, Ö.; Özbaş, M.O. Agronomic Trait Assessment and Selection for Number Ofcapsules in Determinate x Indeterminate Crosses of Sesame. Turk. J. Agric. For. 2009, 33, 231–241. [Google Scholar] [CrossRef]

- Weiss, E.A. Oilseed Crops, 2nd ed.; Blackwell Science Ltd.: Chichester, UK, 2000. [Google Scholar]

- Zhao, Y.; Yang, M.; Wu, K.; Liu, H.; Wu, J.; Liu, K. Characterization and Genetic Mapping of a Novel Recessive Genic Male Sterile Gene in Sesame (Sesamum indicum L.). Mol. Breed. 2013, 32, 901–908. [Google Scholar] [CrossRef]

- Queiroga, V.D.P.; Gondim, T.M.S.; Vale, D.G.; Gereon, H.G.M.; Moura, J.A.; Silva, P.J.; Souza Filho, J.F. Produção de Gergelim Orgânico Nas Comunidades de Produtores Familiares de São Francisco de Assis do Piauí; EMBRAPA-CNP: Campina Grande, Brazil, 2008. [Google Scholar]

- Boureima, S.; Oukarroum, A.; Diouf, M.; Cisse, N.; Van Damme, P. Screening for Drought Tolerance in Mutant Germplasm of Sesame (Sesamum indicum) Probing by Chlorophyll a Fluorescence. Environ. Exp. Bot. 2012, 81, 37–43. [Google Scholar] [CrossRef]

- Botelho, J.R.S.; Medeiros, N.G.; Rodrigues, A.M.C.; Araújo, M.E.; Machado, N.T.; Guimarães Santos, A.; Santos, I.R.; Gomes-Leal, W.; Carvalho, R.N. Black Sesame (Sesamum indicum L.) Seeds Extracts by CO2 Supercritical Fluid Extraction: Isotherms of Global Yield, Kinetics Data, Total Fatty Acids, Phytosterols and Neuroprotective Effects. J. Supercrit. Fluids 2014, 93, 49–55. [Google Scholar] [CrossRef]

- Egbekun, M.K.; Ehieze, M.U. Proximate Composition and Functional Properties of Fullfat and Defatted Beniseed (Sesamum indicum L.) Flour. Plant Foods Hum. Nutr. 1997, 51, 35–41. [Google Scholar] [CrossRef]

- Antoniassi, R.; Arriel, N.H.C.; Gonçalves, E.B.; de Freitas, S.C.; Zanotto, D.L.; Bizzo, H.R. Effect of cultivation conditions on the composition of sesame seed and oil. Rev. Ceres 2013, 60, 301–310. [Google Scholar] [CrossRef]

- Arslan, Ç.; Uzun, B.; Ülger, S.; İlhan Çağırgan, M. Determination of Oil Content and Fatty Acid Composition of Sesame Mutants Suited for Intensive Management Conditions. J. Am. Oil Chem. Soc. 2007, 84, 917–920. [Google Scholar] [CrossRef]

- Euba Neto, M.; Pereira, W.E.; Souto, J.S.; Arriel, N.H.C. Crescimento e Produtividade de Gergelim Em Neossolo Flúvico Em Função de Adubação Orgânica e Mineral. Rev. Ceres 2016, 63, 568–575. [Google Scholar] [CrossRef][Green Version]

- Csernica, S.N.; Hsu, J.T. Reverse-Phase Ternary Phase Diagram, Tie Lines, and Plait Point for Commercial Biodiesel−Glycerol−Methanol. Ind. Eng. Chem. Res. 2011, 50, 1012–1016. [Google Scholar] [CrossRef]

- Toledo, I.E.P.; Ferreira-Pinto, L.; Voll, F.A.P.; Cardozo-Filho, L.; Meili, L.; de Gusmão Coêlho, D.; de Carvalho, S.H.V.; Soletti, J.I. Liquid–Liquid Equilibrium of the System {Peanut Biodiesel + Glycerol + Ethanol} at Atmospheric Pressure. J. Chem. Eng. Data 2019, 64, 2207–2212. [Google Scholar] [CrossRef]

- Gomes Filho, J.C.; Peiter, A.S.; Pimentel, W.R.O.; Soletti, J.I.; Carvalho, S.H.V.; Meili, L. Biodiesel Production from Sterculia striata Oil by Ethyl Transesterification Method. Ind. Crops Prod. 2015, 74, 767–772. [Google Scholar] [CrossRef]

- Batista, E.; Monnerat, S.; Kato, K.; Stragevitch, L.; Meirelles, A.J.A. Liquid−Liquid Equilibrium for Systems of Canola Oil, Oleic Acid, and Short-Chain Alcohols. J. Chem. Eng. Data 1999, 44, 1360–1364. [Google Scholar] [CrossRef]

- EN 14103; Fat and Oil Derivatives—Fatty Acid Methyl Esters (FAME)—Determination of Ester and Linolenic acid Methyl Ester Contents. European Committee for Standardization: Brussels, Belgium, 2003.

- Halvorsen, J.D.; Mammel, W.C.; Clements, L.D. Density Estimation for Fatty Acids and Vegetable Oils Based on Their Fatty Acid Composition. J. Am. Oil Chem. Soc. 1993, 70, 875–880. [Google Scholar] [CrossRef]

- Carvalho, R.H.R.; Galvão, E.L.; Barros, J.Â.C.; Conceição, M.M.; Sousa, E.M.B.D. Extraction, Fatty Acid Profile and Antioxidant Activity of Sesame Extract (Sesamum indicum L.). Braz. J. Chem. Eng. 2012, 29, 409–420. [Google Scholar] [CrossRef]

- Corso, M.P.; Fagundes-Klen, M.R.; Silva, E.A.; Cardozo Filho, L.; Santos, J.N.; Freitas, L.S.; Dariva, C. Extraction of Sesame Seed (Sesamun indicum L.) Oil Using Compressed Propane and Supercritical Carbon Dioxide. J. Supercrit. Fluids 2010, 52, 56–61. [Google Scholar] [CrossRef]

- Feihrmann, A.C.; Giufrida, W.M.; Saldaña, M.D.A.; de Carvalho Lima, J.; Ferreira-Pinto, L.; Botelho, J.R.S.; Cabral, V.F.; de Carvalho Junior, R.N.; Corazza, M.L.; Cardozo-Filho, L. Phase Behaviour of Sesame (Sesamum indicum L.) Seed Oil Using Supercritical CO2. Can. J. Chem. Eng. 2016, 94, 310–314. [Google Scholar] [CrossRef]

- Machado, A.B.; Ardila, Y.C.; de Oliveira, L.H.; Aznar, M.; Wolf Maciel, M.R. Liquid–Liquid Equilibria in Ternary and Quaternary Systems Present in Biodiesel Production from Soybean Oil at (298.2 and 333.2) K. J. Chem. Eng. Data 2012, 57, 1417–1422. [Google Scholar] [CrossRef]

- Marcilla, A.; Ruiz, F.; García, A.N. Liquid-Liquid-Solid Equilibria of the Quaternary System Water-Ethanol-Acetone-Sodium Chloride at 25 °C. Fluid Phase Equilibria 1995, 112, 273–289. [Google Scholar] [CrossRef]

- Gallo-García, L.A.; Marciano, C.H.; Freire, N.V.; Melo, L.F.; Biaggio, F.C.; Sousa, M.N.; Guimarães, D.H.P.; Arce, P.F. Liquid-Liquid Phase of Imidazolium-Based Ionic Liquids in n-Butyl Acetate + n-Butanol Mixtures: Experimental Measurements, Quality Testing, Phase Stability, Thermodynamic Modeling. J. Ind. Eng. Chem. 2024, 134, 260–270. [Google Scholar] [CrossRef]

- Ferrari, J.C.; Nagatani, G.; Corazza, F.C.; Oliveira, J.V.; Corazza, M.L. Application of Stochastic Algorithms for Parameter Estimation in the Liquid–Liquid Phase Equilibrium Modeling. Fluid Phase Equilibria 2009, 280, 110–119. [Google Scholar] [CrossRef]

- Renon, H.; Prausnitz, J.M. Local Compositions in Thermodynamic Excess Functions for Liquid Mixtures. AIChE J. 1968, 14, 135–144. [Google Scholar] [CrossRef]

- Press, W.H.; Teukolsky, S.A.; Vetterling, W.T.; Flannery, B.P. Numerical Recipes in FORTRAN 77, 2nd ed.; Cambridge University Press: New York, NY, USA, 1992; ISBN 052143064X. [Google Scholar]

- Taylor, B.N.; Kuyatt, C.E. Guidelines for the Evaluation and Expression of Uncertainty in NIST Measurement Results; NIST Technical Note 1297; NIST: Gaithersburg, MD, USA, 1994.

- Zhang, M.; Wu, H. Phase Behavior and Fuel Properties of Bio-Oil/Glycerol/Methanol Blends. Energy Fuels 2014, 28, 4650–4656. [Google Scholar] [CrossRef]

, 323.15 K).

, 323.15 K).

, 323.15 K).

, 323.15 K).

, 323.15 K).

, 323.15 K).

, 323.15 K).

, 323.15 K).

, overall composition;

, overall composition;  , tie line; and

, tie line; and  , binodal points) and NRTL model (△

, binodal points) and NRTL model (△ △, tie line; and

△, tie line; and  , binodal line).

, binodal line).

, overall composition;

, overall composition;  , tie line; and

, tie line; and  , binodal points) and NRTL model (△

, binodal points) and NRTL model (△ △, tie line; and

△, tie line; and  , binodal line).

, binodal line).

, overall composition;

, overall composition;  , tie line; and

, tie line; and  , binodal points) and NRTL model (△

, binodal points) and NRTL model (△ △, tie line; and

△, tie line; and  , binodal line).

, binodal line).

, overall composition;

, overall composition;  , tie line; and

, tie line; and  , binodal points) and NRTL model (△

, binodal points) and NRTL model (△ △, tie line; and

△, tie line; and  , binodal line).

, binodal line).

| T = 313.15 K | T = 323.15 K | ||||

|---|---|---|---|---|---|

| 100.w1 | 100.w2 | 100.w3 | 100.w1 | 100.w2 | 100.w3 |

| 90.91 | 2.35 | 6.74 | 85.20 | 5.20 | 9.60 |

| 85.66 | 2.60 | 11.74 | 74.90 | 5.70 | 19.40 |

| 77.99 | 3.12 | 18.89 | 63.00 | 7.70 | 29.30 |

| 64.60 | 4.52 | 30.88 | 54.70 | 9.40 | 35.90 |

| 53.86 | 6.20 | 39.94 | 43.10 | 12.30 | 44.60 |

| 43.21 | 8.96 | 47.83 | 34.60 | 15.50 | 49.90 |

| 33.97 | 11.97 | 54.06 | 24.90 | 19.40 | 55.70 |

| 24.07 | 16.54 | 59.39 | 15.40 | 24.30 | 60.30 |

| 14.83 | 22.1 | 63.07 | 7.40 | 31.50 | 61.10 |

| 8.00 | 28.90 | 63.10 | 4.80 | 38.40 | 56.80 |

| 3.50 | 40.00 | 56.50 | 3.00 | 49.50 | 47.50 |

| 3.10 | 47.16 | 49.74 | 2.40 | 59.70 | 37.90 |

| 2.82 | 55.67 | 41.51 | 2.20 | 67.9 | 29.90 |

| 2.52 | 67.75 | 29.73 | 1.40 | 79.00 | 19.60 |

| 2.48 | 75.62 | 21.90 | 1.20 | 88.50 | 10.30 |

| T (K) | Overall Composition (Sol) | Experimental (Tie Lines) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Biodiesel Rich-Phase (FAEE) | Glycerol Rich-Phase (Gly) | ||||||||

| 100.w1 | 100.w2 | 100.w3 | 100.w1 | 100.w2 | 100.w3 | 100.w1 | 100.w2 | 100.w3 | |

| 313.15 | 44.39 | 44.29 | 11.32 | 93.52 | 2.49 | 3.99 | 2.05 | 80.72 | 17.23 |

| 41.24 | 42.02 | 16.74 | 89.61 | 2.90 | 7.49 | 2.64 | 73.28 | 24.08 | |

| 37.78 | 39.18 | 23.04 | 85.70 | 3.42 | 10.93 | 3.21 | 65.97 | 30.82 | |

| 33.78 | 35.48 | 30.74 | 80.93 | 3.79 | 15.28 | 2.99 | 56.48 | 40.53 | |

| 29.49 | 31.11 | 39.41 | 76.20 | 4.02 | 19.78 | 2.96 | 46.91 | 50.14 | |

| 25.72 | 24.86 | 49.42 | 65.59 | 4.03 | 30.38 | 4.92 | 35.19 | 59.89 | |

| 22.74 | 20.43 | 56.83 | 56.29 | 5.47 | 38.24 | 12.33 | 25.08 | 62.59 | |

| 323.15 | 43.84 | 42.89 | 13.27 | 85.91 | 4.61 | 9.48 | 1.16 | 81.63 | 17.21 |

| 40.65 | 40.05 | 19.32 | 81.65 | 5.06 | 13.35 | 1.73 | 73.91 | 24.39 | |

| 37.62 | 37.02 | 25.36 | 77.37 | 5.29 | 17.34 | 2.15 | 66.29 | 31.56 | |

| 35.26 | 34.63 | 30.11 | 73.06 | 5.72 | 21.24 | 2.82 | 58.62 | 38.61 | |

| 32.21 | 32.31 | 35.48 | 67.81 | 6.71 | 25.48 | 3.01 | 53.21 | 43.78 | |

| 29.87 | 30.08 | 40.05 | 62.52 | 7.88 | 29.61 | 3.22 | 47.94 | 48.84 | |

| 27.11 | 27.63 | 45.27 | 56.91 | 9.31 | 33.79 | 4.27 | 41.72 | 54.01 | |

| 24.97 | 25.02 | 50.03 | 51.52 | 10.61 | 37.87 | 5.31 | 35.38 | 59.31 | |

| T = 313.15 K | T = 323.15 K | ||||

|---|---|---|---|---|---|

| 100.w1 | 100.w2 | 100.w3 | 100.w1 | 100.w2 | 100.w3 |

| 0.92 | 83.25 | 15.83 | 1.87 | 83.90 | 14.23 |

| 1.11 | 79.02 | 19.30 | 2.46 | 77.54 | 20.00 |

| 1.43 | 58.96 | 39.61 | 2.68 | 58.62 | 38.70 |

| 1.49 | 68.42 | 30.09 | 4.12 | 47.53 | 48.35 |

| 2.15 | 48.67 | 49.18 | 4.42 | 28.64 | 66.94 |

| 3.79 | 38.37 | 57.84 | 6.48 | 18.40 | 75.13 |

| 4.75 | 27.95 | 67.31 | 18.68 | 8.63 | 72.69 |

| 5.72 | 18.33 | 75.96 | 28.70 | 4.07 | 67.24 |

| 12.22 | 8.08 | 79.71 | 39.10 | 3.53 | 57.37 |

| 18.60 | 4.77 | 76.63 | 48.48 | 2.64 | 48.89 |

| 35.35 | 1.45 | 63.20 | 59.06 | 1.62 | 39.32 |

| 49.89 | 1.20 | 48.91 | 68.67 | 1.44 | 29.89 |

| 59.17 | 0.92 | 39.91 | 79.02 | 0.69 | 20.29 |

| 69.20 | 0.73 | 30.07 | 84.27 | 0.42 | 15.31 |

| 79.54 | 0.54 | 19.92 | |||

| 85.24 | 0.31 | 14.54 | |||

| T (K) | Overall Composition (Sol) | Experimental (Tie Lines) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Biodiesel Rich-Phase (FAME) | Glycerol Rich-Phase (Gly) | ||||||||

| 100.w1 | 100.w2 | 100.w3 | 100.w1 | 100.w2 | 100.w3 | 100.w1 | 100.w2 | 100.w3 | |

| 313.15 | 45.98 | 47.18 | 6.84 | 98.99 | 0.08 | 0.93 | 1.28 | 85.61 | 13.11 |

| 44.15 | 44.91 | 10.94 | 98.33 | 0.08 | 1.59 | 1.31 | 79.25 | 19.45 | |

| 42.02 | 42.34 | 15.64 | 97.59 | 0.08 | 2.33 | 1.51 | 72.87 | 25.62 | |

| 39.46 | 40.59 | 19.95 | 96.92 | 0.09 | 3.03 | 1.69 | 66.37 | 31.95 | |

| 36.89 | 37.24 | 25.87 | 95.92 | 0.09 | 3.99 | 1.94 | 59.58 | 38.48 | |

| 34.65 | 34.82 | 30.55 | 95.01 | 0.09 | 4.91 | 2.25 | 52.66 | 45.10 | |

| 29.30 | 30.45 | 40.25 | 93.24 | 0.09 | 6.67 | 2.80 | 42.58 | 54.63 | |

| 24.61 | 24.98 | 50.42 | 91.38 | 0.08 | 8.54 | 3.42 | 33.71 | 62.87 | |

| 20.01 | 19.76 | 60.23 | 89.44 | 0.08 | 10.48 | 3.92 | 24.89 | 71.19 | |

| 323.15 | 45.36 | 46.78 | 7.86 | 99.26 | 0.02 | 0.72 | 2.03 | 83.69 | 14.31 |

| 43.37 | 44.78 | 11.85 | 98.81 | 0.01 | 1.18 | 2.25 | 77.55 | 20.20 | |

| 41.39 | 42.88 | 15.73 | 98.39 | 0.01 | 1.61 | 2.46 | 71.53 | 26.01 | |

| 39.63 | 40.49 | 19.88 | 97.78 | 0.01 | 2.21 | 2.72 | 65.38 | 31.92 | |

| 37.47 | 37.32 | 25.21 | 96.99 | 0.02 | 2.99 | 3.01 | 59.63 | 37.37 | |

| 34.94 | 34.94 | 30.12 | 96.39 | 0.01 | 3.62 | 3.27 | 53.76 | 42.96 | |

| 30.81 | 29.33 | 39.86 | 94.14 | 0.01 | 5.84 | 4.04 | 41.73 | 54.23 | |

| 25.82 | 24.64 | 49.54 | 91.41 | 0.01 | 8.58 | 4.88 | 32.54 | 62.58 | |

| 21.64 | 18.63 | 59.73 | 88.59 | 0.02 | 11.39 | 5.59 | 23.42 | 70.99 | |

| T (K) | WSol kg | Overall Composition | WBio kg | WGly kg | WSol calc kg | δ (%) | ||

|---|---|---|---|---|---|---|---|---|

| 100.w1 | 100.w2 | 100.w3 | ||||||

| 313.15 | 0.1543 | 0.4439 | 0.4429 | 0.1132 | 0.0709 | 0.0833 | 0.1542 | 0.0648 |

| 0.1658 | 0.4124 | 0.4202 | 0.1674 | 0.0736 | 0.0922 | 0.1658 | 0.0000 | |

| 0.1342 | 0.3778 | 0.3918 | 0.2304 | 0.0564 | 0.0774 | 0.1338 | 0.2981 | |

| 0.1739 | 0.3378 | 0.3548 | 0.3074 | 0.0688 | 0.1051 | 0.1739 | 0.0000 | |

| 0.1673 | 0.2949 | 0.3110 | 0.3941 | 0.0607 | 0.1067 | 0.1674 | 0.0598 | |

| 0.1276 | 0.2572 | 0.2486 | 0.4942 | 0.0436 | 0.0837 | 0.1273 | 0.2351 | |

| 0.1428 | 0.2274 | 0.2043 | 0.5683 | 0.0338 | 0.1090 | 0.1428 | 0.0000 | |

| 323.15 | 0.1963 | 0.4384 | 0.4289 | 0.1327 | 0.0988 | 0.0975 | 0.1963 | 0.0000 |

| 0.1874 | 0.4065 | 0.4005 | 0.1930 | 0.0914 | 0.0956 | 0.1870 | 0.2134 | |

| 0.1953 | 0.3762 | 0.3702 | 0.2536 | 0.0924 | 0.1025 | 0.1949 | 0.2048 | |

| 0.1746 | 0.3526 | 0.3463 | 0.3011 | 0.0803 | 0.0944 | 0.1747 | 0.0573 | |

| 0.1849 | 0.3221 | 0.3231 | 0.3548 | 0.0833 | 0.1016 | 0.1849 | 0.0000 | |

| 0.1841 | 0.2987 | 0.3008 | 0.4005 | 0.0809 | 0.1031 | 0.1840 | 0.0543 | |

| 0.1948 | 0.2710 | 0.2763 | 0.4527 | 0.0845 | 0.1103 | 0.1948 | 0.0000 | |

| 0.1563 | 0.2497 | 0.2500 | 0.5003 | 0.0664 | 0.0898 | 0.1562 | 0.0640 | |

| δ average: | 0.0848 | |||||||

| T (K) | WSol kg | Overall Composition | WBio kg | WGly kg | WSol calc kg | δ (%) | ||

|---|---|---|---|---|---|---|---|---|

| 100.w1 | 100.w2 | 100.w3 | ||||||

| 313.15 | 0.1758 | 0.4598 | 0.4718 | 0.0684 | 0.0804 | 0.0958 | 0.1762 | 0.2275 |

| 0.1684 | 0.4415 | 0.4491 | 0.1094 | 0.0751 | 0.0935 | 0.1686 | 0.1188 | |

| 0.1815 | 0.4202 | 0.4234 | 0.1564 | 0.0765 | 0.1052 | 0.1817 | 0.1102 | |

| 0.1871 | 0.3946 | 0.4059 | 0.1995 | 0.0742 | 0.1135 | 0.1877 | 0.3207 | |

| 0.1963 | 0.3689 | 0.3724 | 0.2587 | 0.0730 | 0.1231 | 0.1961 | 0.1019 | |

| 0.1569 | 0.3465 | 0.3480 | 0.3055 | 0.0547 | 0.1022 | 0.1569 | 0.0000 | |

| 0.1758 | 0.2930 | 0.3045 | 0.4025 | 0.0515 | 0.1241 | 0.1756 | 0.1138 | |

| 0.1637 | 0.2460 | 0.2498 | 0.5042 | 0.0395 | 0.1249 | 0.1644 | 0.4276 | |

| 0.1642 | 0.2001 | 0.1976 | 0.6023 | 0.0309 | 0.1339 | 0.1648 | 0.3654 | |

| 323.15 | 0.1926 | 0.4536 | 0.4678 | 0.0786 | 0.0858 | 0.1075 | 0.1933 | 0.3634 |

| 0.2041 | 0.4337 | 0.4478 | 0.1185 | 0.0871 | 0.1178 | 0.2049 | 0.3920 | |

| 0.2008 | 0.4139 | 0.4288 | 0.1573 | 0.0815 | 0.1199 | 0.2014 | 0.2988 | |

| 0.1956 | 0.3963 | 0.4049 | 0.1988 | 0.0759 | 0.1203 | 0.1962 | 0.3067 | |

| 0.1839 | 0.3747 | 0.3732 | 0.2521 | 0.0675 | 0.1161 | 0.1836 | 0.1631 | |

| 0.1874 | 0.3494 | 0.3494 | 0.3012 | 0.0638 | 0.1234 | 0.1872 | 0.1067 | |

| 0.1931 | 0.3081 | 0.2933 | 0.3986 | 0.0574 | 0.1357 | 0.1931 | 0.0000 | |

| 0.1868 | 0.2582 | 0.2464 | 0.4954 | 0.0422 | 0.1442 | 0.1864 | 0.2141 | |

| 0.1988 | 0.2164 | 0.1863 | 0.5973 | 0.0384 | 0.1608 | 0.1992 | 0.2012 | |

| δ average: | 0.1910 | |||||||

| T (K) | S | D1 | D2 |

|---|---|---|---|

| 313.15 | 196.9985 | 0.0219 | 4.3183 |

| 109.1209 | 0.0295 | 3.2150 | |

| 75.4887 | 0.0375 | 2.8275 | |

| 71.7946 | 0.0369 | 2.6525 | |

| 65.2561 | 0.0388 | 2.5349 | |

| 26.2808 | 0.0750 | 1.9714 | |

| 7.4723 | 0.2190 | 1.6368 | |

| 323.15 | 134.4492 | 0.0135 | 1.8154 |

| 87.7481 | 0.0208 | 1.8270 | |

| 65.4971 | 0.0278 | 1.8201 | |

| 47.4192 | 0.0383 | 1.8173 | |

| 38.7083 | 0.0444 | 1.7182 | |

| 32.0366 | 0.0515 | 1.6500 | |

| 21.2995 | 0.0750 | 1.5984 | |

| 15.1955 | 0.1031 | 1.5661 |

| T (K) | S | D1 | D2 |

|---|---|---|---|

| 313.15 | 1090.2093 | 0.0129 | 14.0968 |

| 925.2629 | 0.0132 | 12.2327 | |

| 710.6286 | 0.0155 | 10.9957 | |

| 610.7680 | 0.0174 | 10.6500 | |

| 476.8366 | 0.0202 | 9.6441 | |

| 387.8661 | 0.0237 | 9.1853 | |

| 272.7405 | 0.0300 | 8.1904 | |

| 196.7028 | 0.0374 | 7.3618 | |

| 154.9951 | 0.0438 | 6.7929 | |

| 323.15 | 986.4360 | 0.0201 | 19.8750 |

| 751.7748 | 0.0228 | 17.1186 | |

| 646.1455 | 0.0250 | 16.1553 | |

| 518.8951 | 0.0278 | 14.4344 | |

| 404.0793 | 0.0309 | 12.4983 | |

| 351.7596 | 0.0339 | 11.9333 | |

| 216.3812 | 0.0429 | 9.2860 | |

| 136.6225 | 0.0534 | 7.2937 | |

| 98.7771 | 0.0631 | 6.2327 |

| System: FAEE (1) + Glycerol (2) + Ethanol (3) | |||||

|---|---|---|---|---|---|

| Temperature (K) | Pair i-j | ∆gij (K) a | ∆gji (K) a | rmsd × 100 | |

| Phase FAEE | Phase Glyc | ||||

| 313.15–323.15 | 1–2 | 11.57 | 2061.04 | 3.01 | 1.51 |

| 1–3 | −841.28 | 1845.96 | |||

| 2–3 | −874.07 | 2036.37 | |||

| System: FAME (1) + glycerol (2) + methanol (3) | |||||

| Temperature (K) | Pair i-j | ∆gij (K) a | ∆gji (K) a | rmsd × 100 | |

| Phase FAME | Phase Glyc | ||||

| 313.15–323.23 | 1–2 | 2210.27 | 2357.81 | 0.93 | 1.04 |

| 1–3 | −648.67 | 1521.47 | |||

| 2–3 | −1348.47 | −2604.06 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, A.; Lopes, G.; Corazza, M.; Arce, P.; Coêlho, D.; Meili, L.; Carvalho, S.; Ferreira-Pinto, L.; Soletti, J. Liquid–Liquid Equilibrium of Sesame Fatty Acid (Ethyl and Methyl) Ester + Glycerol + Ethanol/Methanol Mixtures at Different Temperatures. Molecules 2024, 29, 3167. https://doi.org/10.3390/molecules29133167

Silva A, Lopes G, Corazza M, Arce P, Coêlho D, Meili L, Carvalho S, Ferreira-Pinto L, Soletti J. Liquid–Liquid Equilibrium of Sesame Fatty Acid (Ethyl and Methyl) Ester + Glycerol + Ethanol/Methanol Mixtures at Different Temperatures. Molecules. 2024; 29(13):3167. https://doi.org/10.3390/molecules29133167

Chicago/Turabian StyleSilva, Anderson, Guilherme Lopes, Marcos Corazza, Pedro Arce, Dayana Coêlho, Lucas Meili, Sandra Carvalho, Leandro Ferreira-Pinto, and João Soletti. 2024. "Liquid–Liquid Equilibrium of Sesame Fatty Acid (Ethyl and Methyl) Ester + Glycerol + Ethanol/Methanol Mixtures at Different Temperatures" Molecules 29, no. 13: 3167. https://doi.org/10.3390/molecules29133167

APA StyleSilva, A., Lopes, G., Corazza, M., Arce, P., Coêlho, D., Meili, L., Carvalho, S., Ferreira-Pinto, L., & Soletti, J. (2024). Liquid–Liquid Equilibrium of Sesame Fatty Acid (Ethyl and Methyl) Ester + Glycerol + Ethanol/Methanol Mixtures at Different Temperatures. Molecules, 29(13), 3167. https://doi.org/10.3390/molecules29133167