Multifunctional Hydrogel with 3D Printability, Fluorescence, Biodegradability, and Biocompatibility for Biomedical Microrobots

Abstract

1. Introduction

2. Results and Discussion

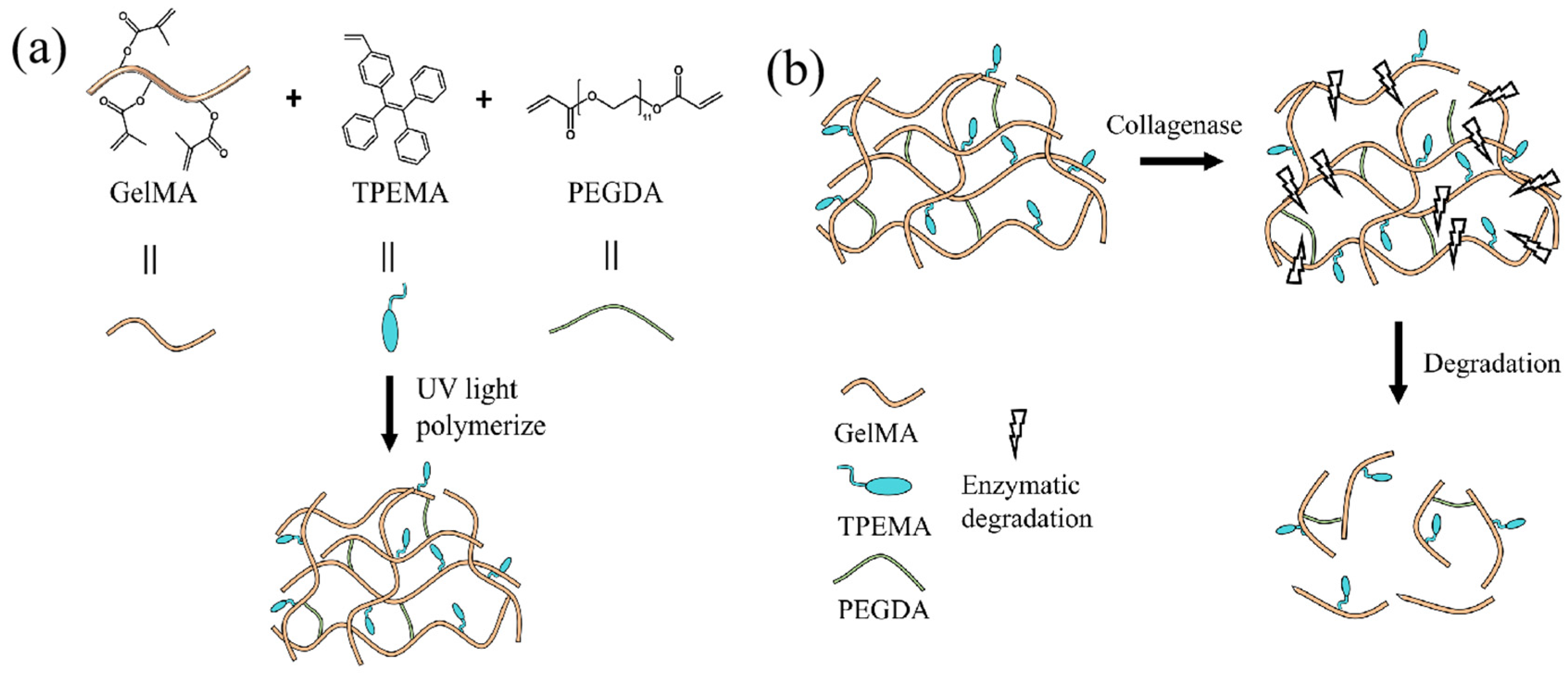

2.1. Synthesis of Multifunctional Hydrogel

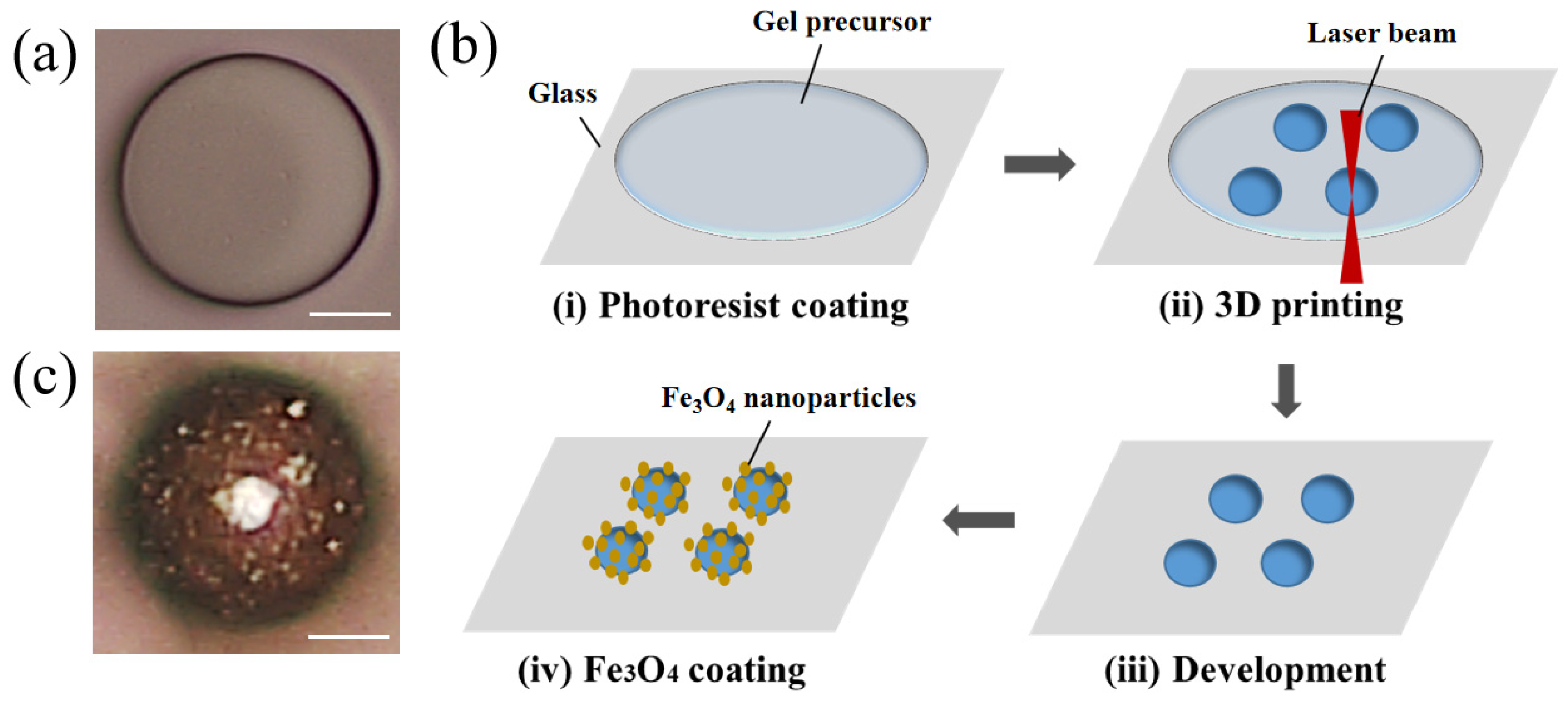

2.2. Three-Dimensional-Printability and Microrobot Design

2.3. Swelling Properties

2.4. Drug Loading and Release Capacity

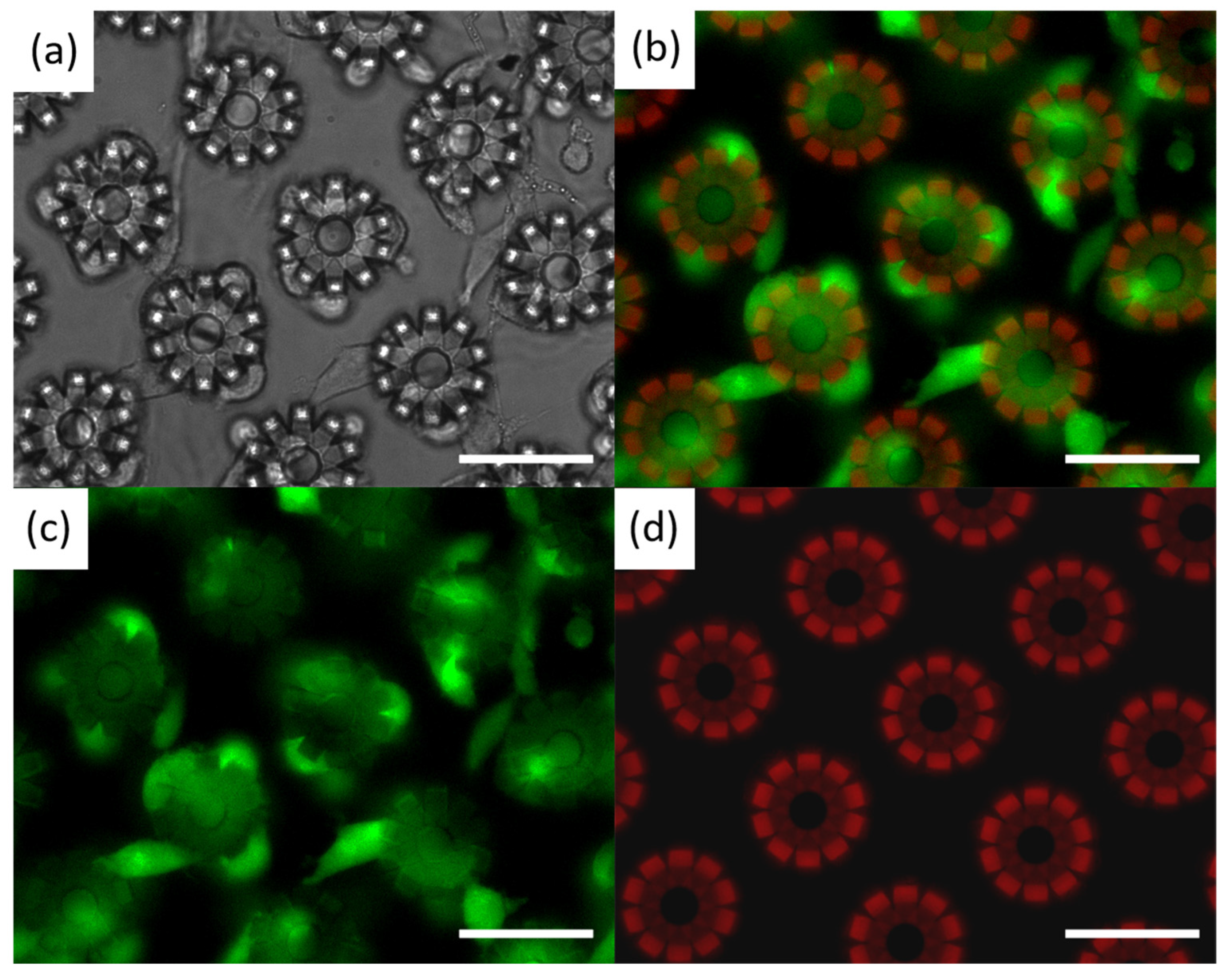

2.5. Movement Performance of Microspheres

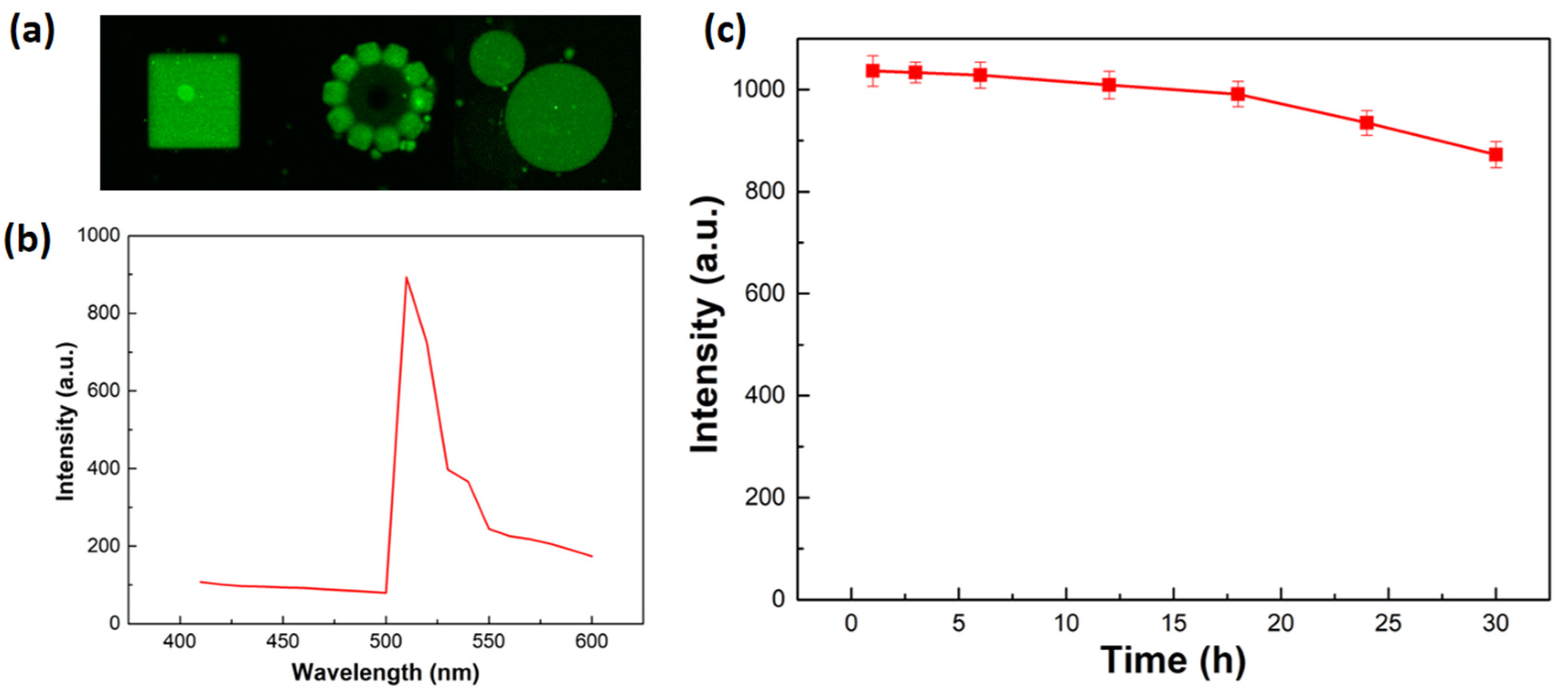

2.6. Fluorescence Properties

2.7. Biodegradability

2.8. Biocompatibility

3. Materials and Methods

3.1. Materials

3.2. Synthesis of the Hydrogel Precursor

3.3. Mechanical Property Measurements

3.4. Fabrication of Fe3O4-Coated Microspheres

3.5. Manipulation on the Movement of Microspheres in Magnetic Actuation System

3.6. Drug Loading and Release

3.7. Degradation of GelMA-Based Hydrogel Microstructures

3.8. Fluorescence of Hydrogels

3.9. Cytotoxicity Assay

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, B.; Kostarelos, K.; Nelson, B.J.; Zhang, L. Trends in micro-/nanorobotics: Materials development, actuation, localization, and system integration for biomedical applications. Adv. Mater. 2021, 33, 2002047. [Google Scholar] [CrossRef]

- Nelson, B.J.; Kaliakatsos, I.K.; Abbott, J.J. Microrobots for minimally invasive medicine. Annu. Rev. Biomed. Eng. 2010, 12, 55–85. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.-Z.; Marcus, H.; Naveen, S.; Tianyun, H.; Berna, Ö.; Qian, L.; Erdem, S.; Fajer, M.; Luca, D.T.; Bradley, J.N.; et al. Hybrid magnetoelectric nanowires for nanorobotic applications: Fabrication, magnetoelectric coupling, and magnetically assisted in vitro targeted drug delivery. Adv. Mater. 2017, 29, 1605458. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Mooney, D.J. Designing hydrogels for controlled drug delivery. Nat. Rev. Mater. 2016, 1, 16071. [Google Scholar] [CrossRef]

- Shao, J.; Xuan, M.; Zhang, H.; Lin, X.; Wu, Z.; He, Q. Chemotaxis-guided hybrid neutrophil micromotor for actively targeted drug ttransport. Angew. Chem. Int. Ed. 2017, 56, 12935–12939. [Google Scholar] [CrossRef]

- Srivastava, S.K.; Medina-Sánchez, M.; Koch, B.; Schmidt, O.G. Medibots: Dual-Action Biogenic Microdaggers for Single-Cell Surgery and Drug Release. Adv. Mater. 2016, 28, 832–837. [Google Scholar] [CrossRef]

- Xi, W.; Solovev, A.A.; Ananth, A.N.; Gracias, D.H.; Sanchez, S.; Schmidt, O.G. Rolled-Up Magnetic Microdrillers: Towards Remotely Controlled Minimally Invasive Surgery. Nanoscale 2013, 5, 1294–1297. [Google Scholar] [CrossRef]

- Vyskocil, J.; Mayorga-Martinez, C.C.; Jablonská, E.; Novotny, F.; Ruml, T.; Pumera, M. Cancer Cells Microsurgery via Asymmetric Bent Surface Au/Ag/Ni Microrobotic Scalpels through a Transversal Rotating Magnetic Field. ACS Nano 2020, 14, 8247–8256. [Google Scholar] [PubMed]

- Wang, J.; Dong, R.; Wu, H.; Cai, Y.; Ren, B. A review on artificial micro/nanomotors for cancer-targeted delivery, diagnosis, and therapy. Nano-Micro Lett. 2020, 12, 11. [Google Scholar] [CrossRef]

- Khezri, B.; Moo, J.G.S.; Song, P.; Fisher, A.C.; Pumera, M. Detecting the Complex Motion of Self-Propelled Micromotors in Microchannels by Electrochemistry. RSC Adv. 2016, 6, 99977–99982. [Google Scholar] [CrossRef]

- Esteban-Fernaández de Aávila, B.; Lopez-Ramirez, M.A.; Baáez, D.F.; Jodra, A.; Singh, V.V.; Kaufmann, K.; Wang, J. Aptamer-Modified Graphene-Based Catalytic Micromotors: Off–On Fluorescent Detection of Ricin. ACS Sens. 2016, 1, 217–221. [Google Scholar] [CrossRef]

- Lee, Y.-W.; Kim, J.-K.; Bozuyuk, U.; Dogan, N.O.; Khan, M.T.A.; Shiva, A.; Wild, A.-M.; Sitti, M. Multifunctional 3D-printed pollen grain-inspired hydrogel microrobots for on-demand anchoring and cargo delivery. Adv. Mater. 2023, 35, 2209812. [Google Scholar] [CrossRef]

- Lee, J.G.; Raj, R.R.; Day, N.B.; Shields, C.W., IV. Microrobots for biomedicine: Unsolved challenges and opportunities for translation. ACS Nano 2023, 17, 14196–14204. [Google Scholar] [CrossRef]

- Zhang, L.; Abbott, J.J.; Dong, L.; Kratochvil, B.E.; Bell, D.; Nelson, B.J. Artificial bacterial flagella: Fabrication and magnetic control. Appl. Phys. Lett. 2009, 94, 064107. [Google Scholar] [CrossRef]

- Ghosh, A.; Fischer, P. Controlled propulsion of artificial magnetic nanostructured propellers. Nano Lett. 2009, 9, 2243–2245. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Yoo, S.H.; Lee, S.A.; Park, S. Wet-chemical synthesis of palladium nanosprings. Nano Lett. 2011, 11, 3979–3982. [Google Scholar] [CrossRef]

- Li, J.; Sattayasamitsathit, S.; Dong, R.; Gao, W.; Tam, R.; Feng, X.; Ai, S.; Wang, J. Template electrosynthesis of tailored-made helical nanoswimmers. Nanoscale 2014, 6, 9415–9420. [Google Scholar] [CrossRef]

- Tottori, S.; Zhang, L.; Qiu, F.; Krawczyk, K.K.; Franco-Obregón, A.; Nelson, B.J. Magnetic helical micromachines: Fabrication, controlled swimming, and cargo transport. Adv. Mater. 2012, 24, 811–816. [Google Scholar] [CrossRef] [PubMed]

- Huang, T.; Sakar, M.S.; Mao, A.; Petruska, A.J.; Qiu, F.; Chen, X.; Kennedy, S.; Mooney, D.; Nelson, B.J. 3D printed microtransporters: Compound micromachines for spatiotemporally controlled delivery of therapeutic agents. Adv. Mater. 2015, 27, 6644–6650. [Google Scholar] [CrossRef]

- Jin, D.; Chen, Q.; Huang, T.-Y.; Huang, J.; Zhang, L.; Duan, H. Four-dimensional direct laser writing of reconfigurable compound micromachines. Mater. Today 2020, 32, 19–25. [Google Scholar] [CrossRef]

- Alapan, Y.; Bozuyuk, U.; Erkoc, P.; Karacakol, A.C.; Sitti, M. Multifunctional surface microrollers for targeted cargo delivery in physiological blood flow. Sci. Robot. 2020, 5, eaba5726. [Google Scholar] [CrossRef] [PubMed]

- Alapan, Y.; Yigit, B.; Beker, O.; Demirörs, A.F.; Sitti, M. Shape-encoded dynamic assembly of mobile micromachines. Nat. Mater. 2019, 18, 1244–1251. [Google Scholar] [CrossRef] [PubMed]

- Bozuyuk, U.; Suadiye, E.; Aghakhani, A.; Dogan, N.O.; Lazovic, J.; Tiryaki, M.E.; Schneider, M.; Karacakol, A.C.; Demir, S.O.; Richter, G.; et al. High-performance magnetic FePt (L10) surface microrollers towards medical imaging-guided endovascular delivery applications. Adv. Funct. Mater. 2022, 32, 2109741. [Google Scholar] [CrossRef]

- Giltinan, J.; Sridhar, V.; Bozuyuk, U.; Sheehan, D.; Sitti, M. 3D microprinting of iron platinum nanoparticle-based magnetic mobile microrobots. Adv. Intell. Syst. 2021, 3, 2000204. [Google Scholar] [CrossRef] [PubMed]

- Wrede, P.; Degtyaruk, O.; Kalva, S.K.; Deán-Ben, X.L.; Bozuyuk, U.; Aghakhani, A.; Akolpoglu, B.; Sitti, M.; Razansky, D. Real-time 3D optoacoustic tracking of cell-sized magnetic microrobots circulating in the mouse brain vasculature. Sci. Adv. 2022, 8, eabm9132. [Google Scholar] [CrossRef] [PubMed]

- Kellaris, N.; Venkata, V.G.; Smith, G.M.; Mitchell, S.K.; Keplinger, C. Peano-HASEL actuators: Muscle-mimetic, electrohydraulic transducers that linearly contract on activation. Sci. Robot. 2018, 3, eaar3276. [Google Scholar] [CrossRef]

- Acome, E.; Mitchell, S.K.; Morrissey, T.G.; Emmett, M.B.; Benjamin, C.; King, M.; Radakovitz, M.; Keplinge, C. Hydraulically amplified self-healing electrostatic actuators with muscle-like performance. Science 2018, 359, 61–65. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Hortelão, A.C.; Patiño, T.; Sánchez, S. Enzyme catalysis to power micro/nanomachines. ACS Nano 2016, 10, 9111–9122. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Gentile, K.; Mohajerani, F.; Sen, A. Powering motion with enzymes. Acc. Chem. Res. 2018, 51, 2373–2381. [Google Scholar] [CrossRef]

- Palagi, S.; Mark, A.G.; Reigh, S.Y.; Melde, K.; Qiu, T.; Zeng, H.; Parmeggiani, C.; Martella, D.; Sanchez-Castillo, A.; Kapernaum, N.; et al. Structured light enables biomimetic swimming and versatile locomotion of photoresponsive soft microrobots. Nat. Mater. 2016, 15, 647–653. [Google Scholar] [CrossRef]

- Pena-Francesch, A.; Giltinan, J.; Sitti, M. Multifunctional and biodegradable self-propelled protein motors. Nat. Commun. 2019, 10, 3188. [Google Scholar] [CrossRef]

- Sridhar, V.; Podjaski, F.; Alapan, Y.; Kröger, J.; Grunenberg, L.; Kishore, V.; Lotsch, B.V.; Sitti, M. Light-driven carbon nitride microswimmers with propulsion in biological and ionic media and responsive on-demand drug delivery. Sci. Robot. 2022, 7, eabm1421. [Google Scholar] [CrossRef] [PubMed]

- Aghakhani, A.; Yasa, O.; Wrede, P.; Sitti, M. Acoustically powered surface-slip mobile microrobots. Proc. Natl. Acad. Sci. USA 2020, 117, 3469–3477. [Google Scholar] [CrossRef] [PubMed]

- Louf, J.; Bertin, N.; Dollet, B.; Stephan, O.; Marmottant, P. Hovering microswimmers exhibit ultrafast motion to navigate under acoustic forces. Adv. Mater. Interfaces 2018, 5, 1800425. [Google Scholar] [CrossRef]

- Kim, Y.; Zhao, X. Magnetic soft materials and robots. Chem. Rev. 2022, 122, 5317–5364. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, L. Magnetic actuation systems for miniature robots: A review. Adv. Intell. Syst. 2020, 2, 2000082. [Google Scholar] [CrossRef]

- Servant, A.; Qiu, F.; Mazza, M.; Kostarelos, K.; Nelson, B.J. Controlled in vivo swimming of a swarm of bacteria-like microrobotic flagella. Adv. Mater. 2015, 27, 2981–2988. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, L.; Yang, L.; Vong, C.I.; Chan, K.F.; Wu, W.K.; Zhang, L. Real-time tracking of fluorescent magnetic spore-based microrobots for remote detection of C. diff toxins. Sci. Adv. 2019, 5, eaau9650. [Google Scholar] [CrossRef]

- Yan, X.; Zhou, Q.; Vincent, M.; Deng, Y.; Yu, J.; Xu, J.; Xu, T.; Tang, T.; Bian, L.; Wang, Y.-X.J.; et al. Multifunctional biohybrid magnetite microrobots for imaging-guided therapy. Sci. Robot. 2017, 2, eaaq1155. [Google Scholar] [CrossRef]

- Martel, S.; Felfoul, O.; Mathieu, J.-B.; Chanu, A.; Tamaz, S.; Mohammadi, M.; Mankiewicz, M.; Tabatabaei, N. MRI-based medical nanorobotic platform for the control of magnetic nanoparticles and flagellated bacteria for target interventions in human capillaries. Int. J. Robot. Res. 2009, 28, 1169–1182. [Google Scholar] [CrossRef]

- Kósa, G.; Jakab, P.; Székely, G.; Hata, N. MRI driven magnetic microswimmers. Biomed. Microdevices 2012, 14, 165–178. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Li, L.; Yang, Y.; Hu, P.; Li, Y.; Yang, S.-Y.; Wang, L.V.; Gao, W. A microrobotic system guided by photoacoustic computed tomography for targeted navigation in intestines in vivo. Sci. Robot. 2019, 4, eaax0613. [Google Scholar] [CrossRef] [PubMed]

- Aziz, A.; Pane, S.; Iacovacci, V.; Koukourakis, N.; Czarske, J.; Menciassi, A.; Medina-Sánchez, M.; Schmidt, O.G. Medical imaging of microrobots: Toward in vivo applications. ACS Nano 2020, 14, 10865–10893. [Google Scholar] [CrossRef] [PubMed]

- Medina-Sánchez, M.; Schwarz, L.; Meyer, A.K.; Hebenstreit, F.; Schmidt, O.G. Cellular cargo delivery: Toward assisted fertilization by sperm-carrying micromotors. Nano Lett. 2015, 16, 555–561. [Google Scholar] [CrossRef] [PubMed]

- Bhuyan, M.M.; Jeong, J.H. Synthesis and Characterization of Gamma Radiation Induced Diallyldimethylammonium Chloride-Acrylic Acid-(3-Acrylamidopropyl) Trimethylammonium Chloride Superabsorbent Hydrogel. Gels 2023, 9, 159. [Google Scholar] [CrossRef] [PubMed]

- Bhuyan, M.M.; Jeong, J.H. Gamma Radiation-Induced Advanced 2, 3-Dimethylacrylic Acid-(2-Acrylamido-2-methyl-1-propanesulfonic Acid) Superabsorbent Hydrogel: Synthesis and Characterization. Gels 2023, 9, 426. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Qin, X.H.; Hu, C.; Terzopoulou, A.; Chen, X.Z.; Huang, T.Y.; Nelson, B.J. 3D printed enzymatically biodegradable soft helical microswimmers. Adv. Funct. Mater. 2018, 28, 1804107. [Google Scholar] [CrossRef]

- Wei, T.; Liu, J.; Li, D.; Chen, S.; Zhang, Y.; Li, J.; Fan, L.; Guan, Z.; Lo, C.; Wang, L.; et al. Development of magnet-driven and image-guided degradable microrobots for the precise delivery of engineered stem cells for cancer therapy. Small 2020, 16, 1906908. [Google Scholar] [CrossRef] [PubMed]

- Peters, C.; Hoop, M.; Pané, S.; Nelson, B.J.; Hierold, C. Degradable magnetic composites for minimally invasive interventions: Device fabrication, targeted drug delivery, and cytotoxicity tests. Adv. Mater. 2016, 28, 533–538. [Google Scholar] [CrossRef]

- Ceylan, H.; Yasa, I.C.; Yasa, O.; Tabak, A.F.; Giltinan, J.; Sitti, M. 3D-Printed biodegradable microswimmer for theranostic cargo delivery and release. ACS Nano 2019, 13, 3353–3362. [Google Scholar] [CrossRef]

- Kim, D.-I.; Lee, H.; Kwon, S.-H.; Choi, H.; Park, S. Magnetic nanoparticles retrievable biodegradable hydrogel microrobot. Sens. Actuators B Chem. 2019, 289, 65–77. [Google Scholar] [CrossRef]

- Dong, M.; Wang, X.; Chen, X.; Mushtaq, F.; Deng, S.; Zhu, C.; Torlakcik, H.; Terzopoulou, A.; Qin, X.; Xiao, X.; et al. 3D-printed soft magnetoelectric microswimmers for delivery and differentiation of neuron-like cells. Adv. Funct. Mater. 2020, 30, 1910323. [Google Scholar] [CrossRef]

- Kim, D.I.; Lee, H.; Kwon, S.H.; Sung, Y.J.; Song, W.K.; Park, S. Bilayer hydrogel sheet-type intraocular microrobot for drug delivery and magnetic nanoparticles retrieval. Adv. Healthc. Mater. 2020, 9, 2000118. [Google Scholar] [CrossRef]

- Sanchis-Gual, R.; Ye, H.; Ueno, T.; Landers, F.C.; Hertle, L.; Deng, S.; Pané, S. 3D Printed Template-Assisted Casting of Biocompatible Polyvinyl Alcohol-Based Soft Microswimmers with Tunable Stability. Adv. Funct. Mater. 2023, 33, 2212952. [Google Scholar] [CrossRef]

- Lin, X.; Xu, B.; Zhu, H.; Liu, J.; Solovev, A.; Mei, Y. Requirement and development of hydrogel micromotors towards biomedical applications. Research 2020, 2020, 7659749. [Google Scholar] [CrossRef]

- Lu, P.; Takai, K.; Weaver, V.M.; Werb, Z. Extracellular matrix degradation and remodeling in development and disease. Cold Spring Harb. Perspect. Biol. 2011, 3, a005058. [Google Scholar] [CrossRef]

- Loessner, D.; Meinert, C.; Kaemmerer, E.; Martine, L.C.; Yue, K.; Levett, P.A.; Hutmacher, D.W. Functionalization, preparation and use of cell-laden gelatin methacryloyl-based hydrogels as modular tissue culture platforms. Nat. Protoc. 2016, 11, 727–746. [Google Scholar] [CrossRef]

- Yue, K.; Trujillo-de Santiago, G.; Alvarez, M.M.; Tamayol, A.; Annabi, N.; Khademhosseini, A. Synthesis, properties, and biomedical applications of gelatin methacryloyl (GelMA) hydrogels. Biomaterials 2015, 73, 254–271. [Google Scholar] [CrossRef]

- Zhang, D.; Fan, Y.; Chen, H.; Trépout, S.; Li, M.H. CO2-Activated Reversible Transition between Polymersomes and Micelles with AIE Fluorescence. Angew. Chem. Int. Ed. 2019, 58, 10260–10265. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Zhang, X.; Zhang, X.; Fu, C.; Wang, K.; Yuan, J.; Wei, Y. Amphiphilic fluorescent copolymers via one-pot combination of chemoenzymatic transesterification and RAFT polymerization: Synthesis, self-assembly and cell imaging. Polym. Chem. 2015, 6, 607–612. [Google Scholar] [CrossRef]

- Wu, X.; Wang, R.; Kwon, N.; Ma, H.; Yoon, J. Activatable fluorescent probes for in situ imaging of enzymes. Chem. Soc. Rev. 2022, 51, 450–463. [Google Scholar] [CrossRef]

- McKenzie, M.; Betts, D.; Suh, A.; Bui, K.; Kim, L.D.; Cho, H. Hydrogel-based drug delivery systems for poorly water-soluble drugs. Molecules 2015, 20, 20397–20408. [Google Scholar] [CrossRef]

- Jin, X.; Wei, C.-X.; Wu, C.-W.; Zhang, W. Customized Hydrogel for Sustained Release of Highly Water-Soluble Drugs. ACS Omega 2022, 7, 8493–8497. [Google Scholar] [CrossRef]

- Xue, B.; Kozlovskaya, V.; Liu, F.; Chen, J.; Williams, J.F.; Campos-Gomez, J.; Saeed, M.; Kharlampieva, E. Intracellular degradable hydrogel cubes and spheres for anti-cancer drug delivery. ACS Appl. Mater. Interfaces 2015, 7, 13633–13644. [Google Scholar] [CrossRef]

- Kozlovskaya, V.; Chen, J.; Tedjo, C.; Liang, X.; Campos-Gomez, J.; Oh, J.; Kharlampieva, E. pH-responsive hydrogel cubes for release of doxorubicin in cancer cells. J. Mater. Chem. B 2014, 2, 2494–2507. [Google Scholar] [CrossRef]

- Xue, B.; Kozlovskaya, V.; Sherwani, M.A.; Ratnayaka, S.; Habib, S.; Anderson, T.; Manuvakhova, M.; Klampfer, L.; Yusuf, N.; Kharlampieva, E. Peptide-functionalized hydrogel cubes for active tumor cell targeting. Biomacromolecules 2018, 19, 4084–4097. [Google Scholar] [CrossRef]

- Goldman, A.J.; Cox, R.G.; Brenner, H. Slow viscous motion of a sphere parallel to a plane wall—I Motion through a quiescent fluid. Chem. Eng. Sci. 1967, 22, 637–651. [Google Scholar] [CrossRef]

- Wang, G.; Li, X.; Tan, X.; Ji, S.; Huang, J.; Duan, H.; Lv, P. Motion enhancement of spherical surface walkers with microstructures. Adv. Intell. Syst. 2021, 3, 2000226. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Wang, S.; Hu, T.; Shi, F. Multifunctional Hydrogel with 3D Printability, Fluorescence, Biodegradability, and Biocompatibility for Biomedical Microrobots. Molecules 2024, 29, 3351. https://doi.org/10.3390/molecules29143351

Wang G, Wang S, Hu T, Shi F. Multifunctional Hydrogel with 3D Printability, Fluorescence, Biodegradability, and Biocompatibility for Biomedical Microrobots. Molecules. 2024; 29(14):3351. https://doi.org/10.3390/molecules29143351

Chicago/Turabian StyleWang, Gang, Sisi Wang, Tao Hu, and Famin Shi. 2024. "Multifunctional Hydrogel with 3D Printability, Fluorescence, Biodegradability, and Biocompatibility for Biomedical Microrobots" Molecules 29, no. 14: 3351. https://doi.org/10.3390/molecules29143351

APA StyleWang, G., Wang, S., Hu, T., & Shi, F. (2024). Multifunctional Hydrogel with 3D Printability, Fluorescence, Biodegradability, and Biocompatibility for Biomedical Microrobots. Molecules, 29(14), 3351. https://doi.org/10.3390/molecules29143351