Growth of Hg0.7Cd0.3Te on Van Der Waals Mica Substrates via Molecular Beam Epitaxy

Abstract

1. Introduction

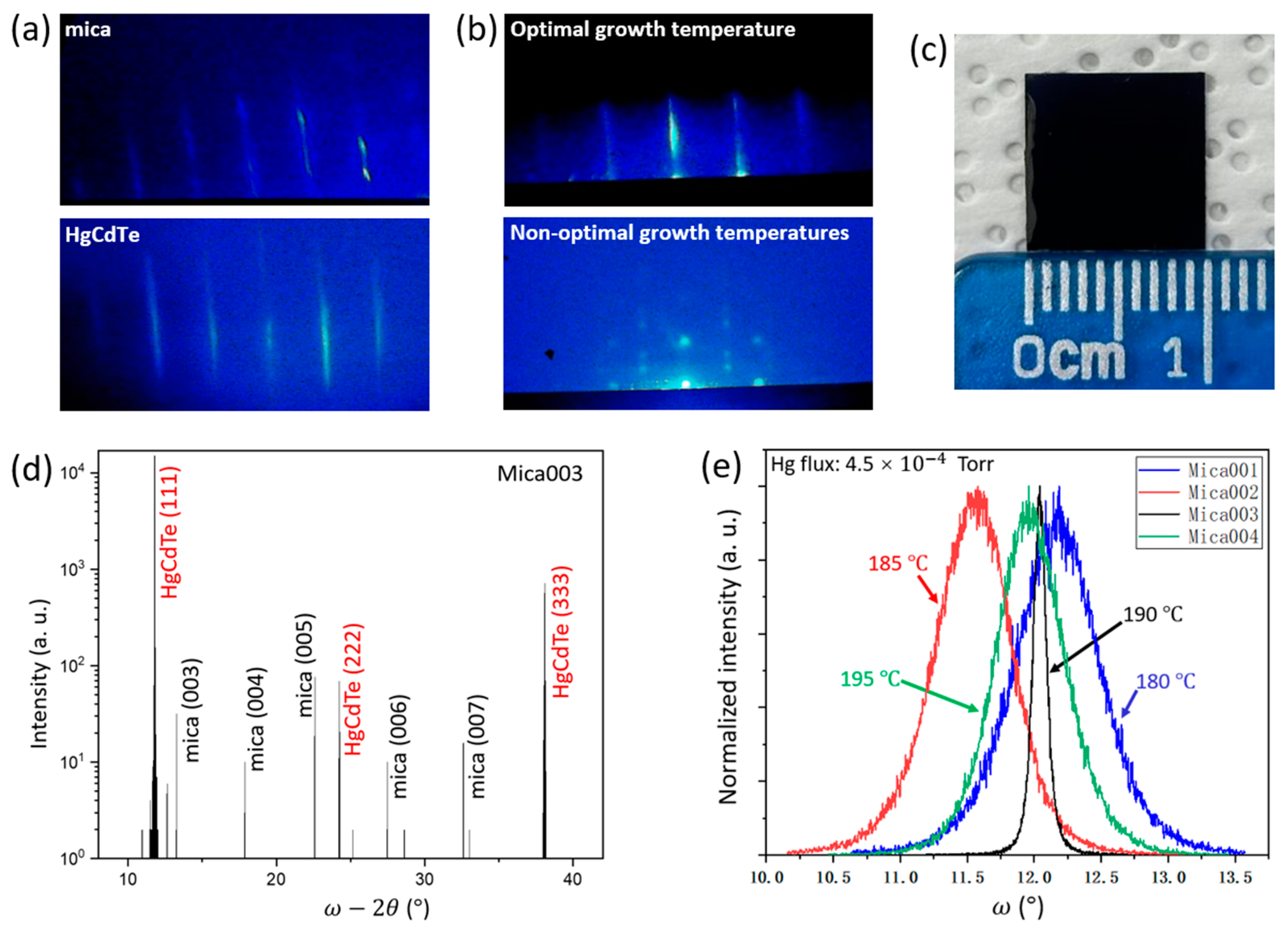

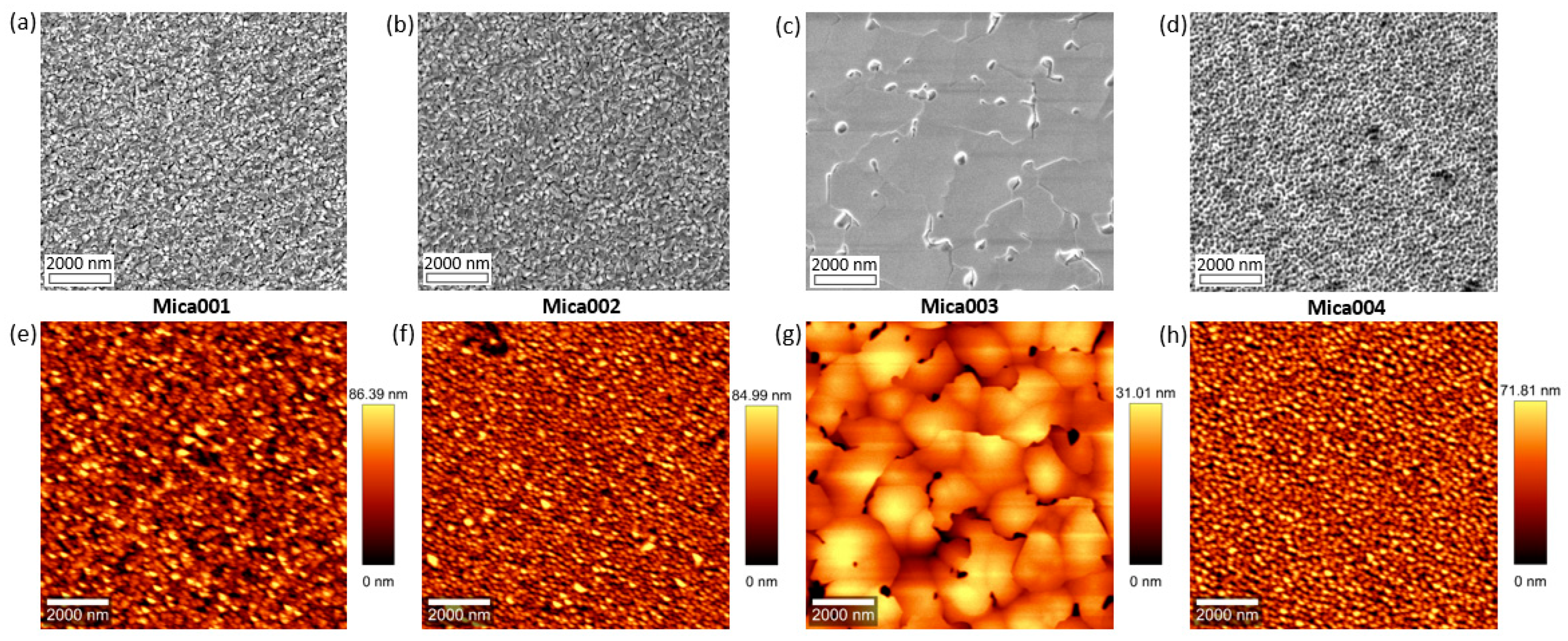

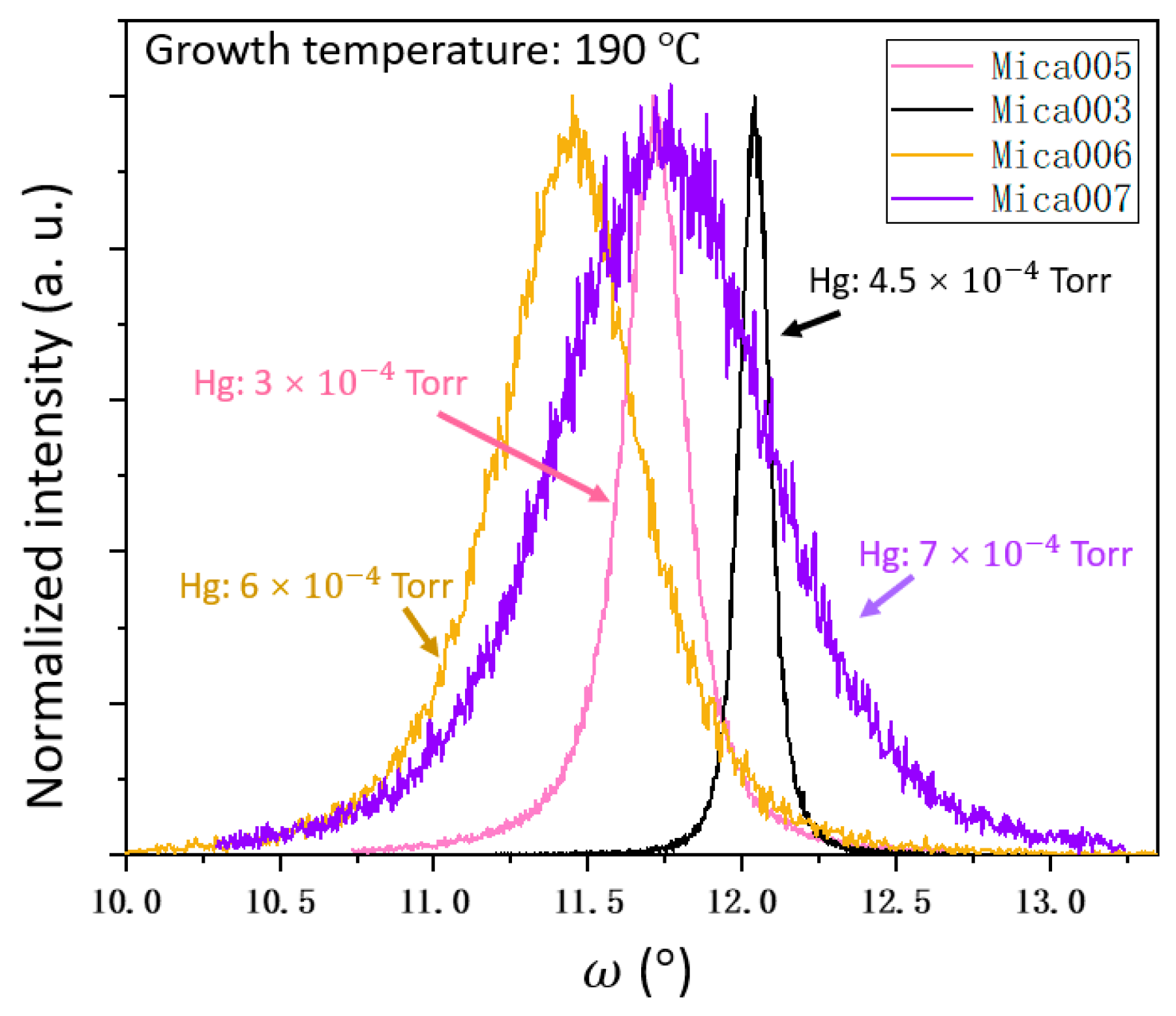

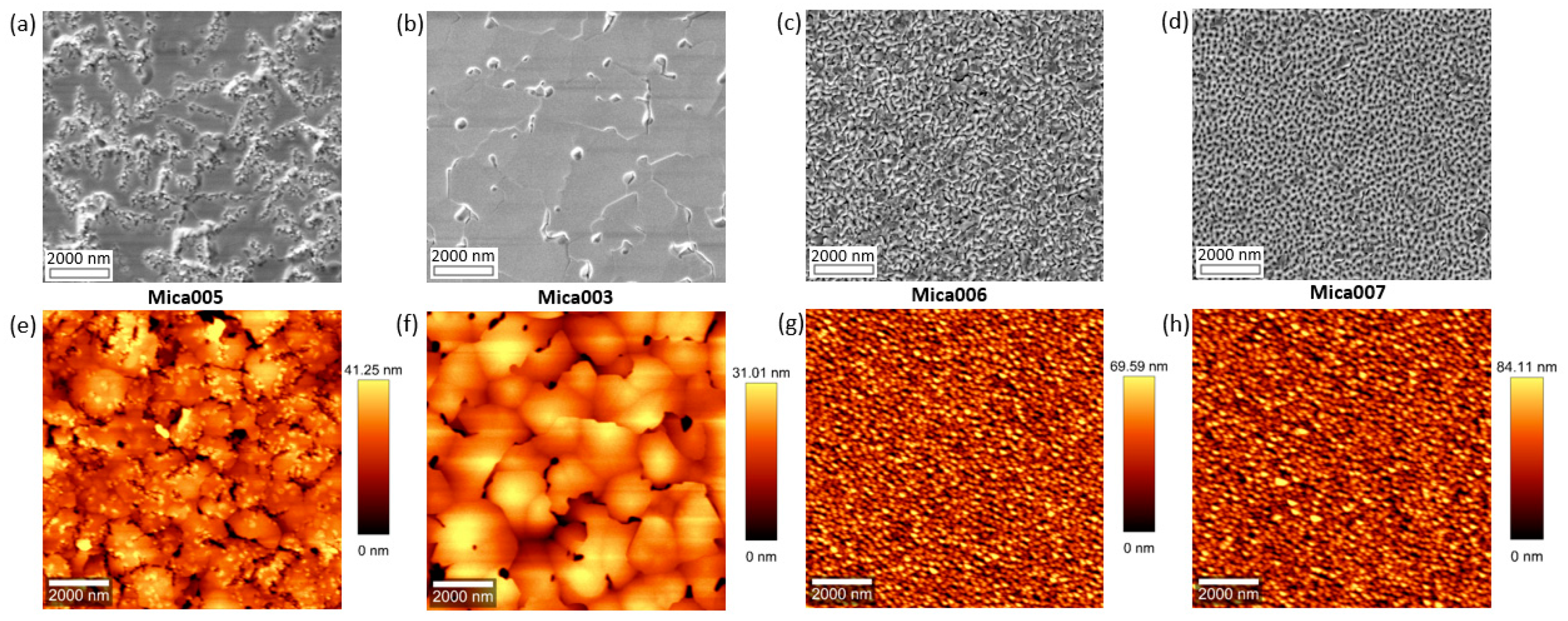

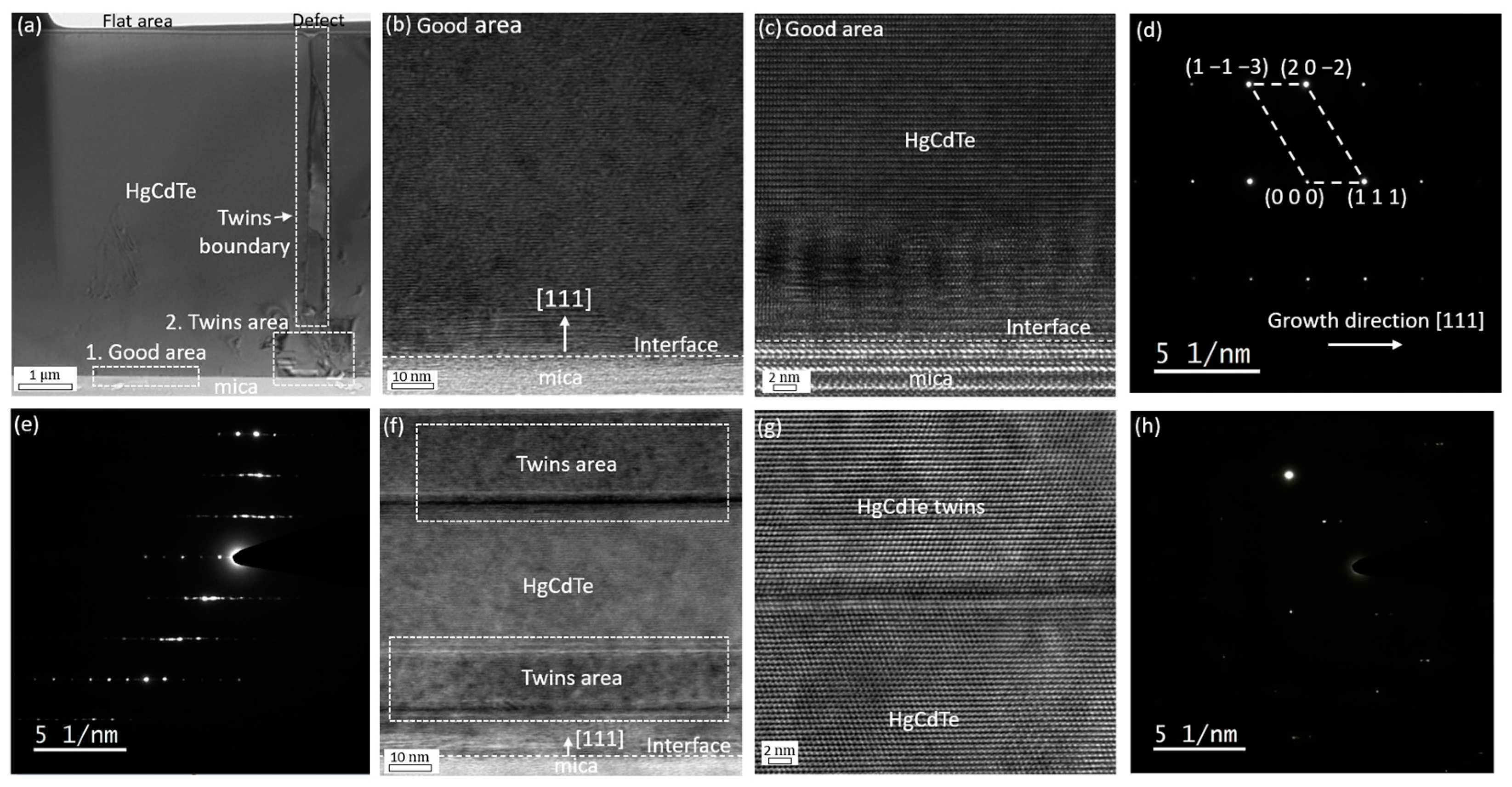

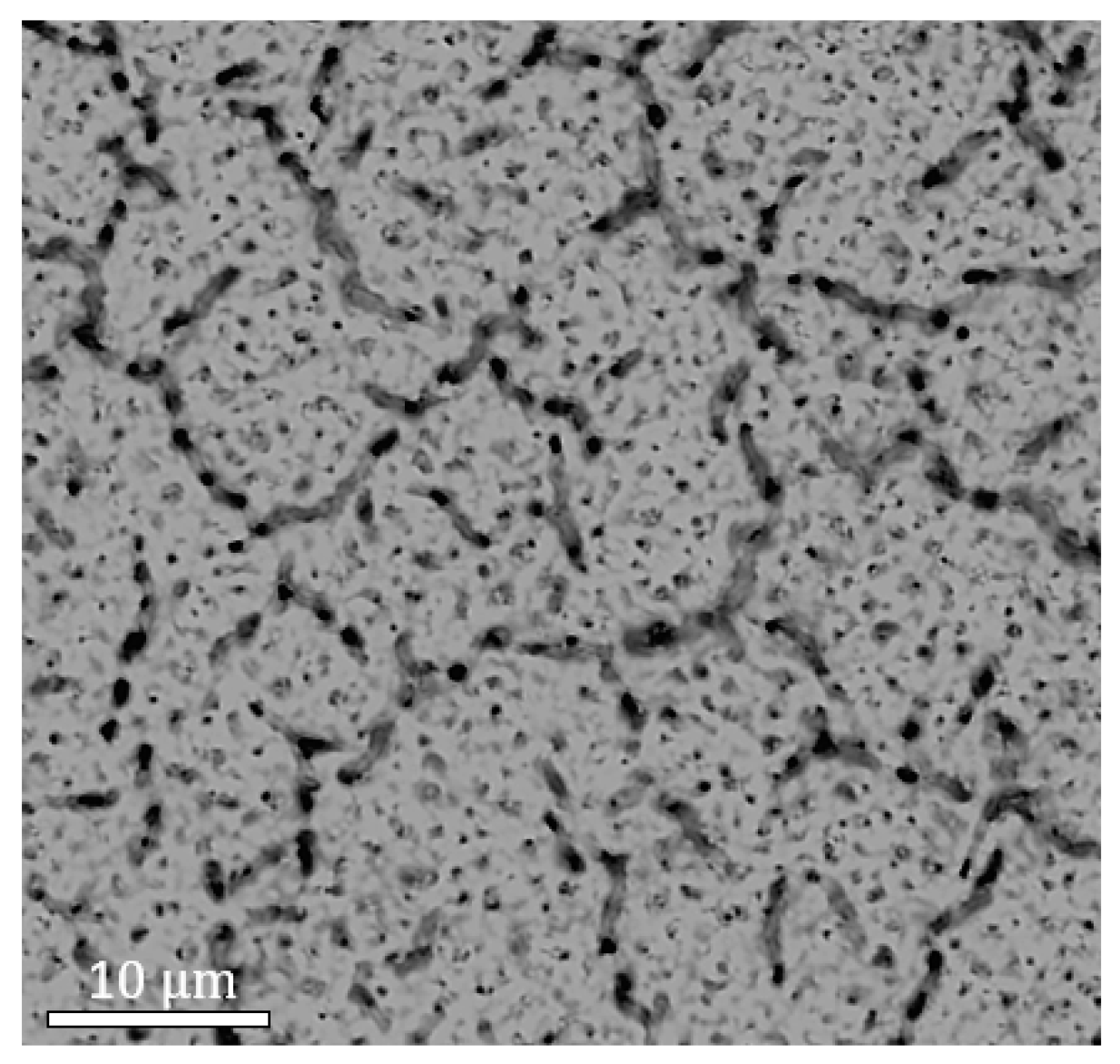

2. Experimental Results

3. Discussion

4. Materials and Methods

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lei, W.; Antoszewski, J.; Faraone, L. Progress, challenges, and opportunities for HgCdTe infrared materials and detectors. Appl. Phys. Rev. 2015, 2, 041303. [Google Scholar] [CrossRef]

- Bhan, R.K.; Dhar, V. Recent infrared detector technologies, applications, trends and development of HgCdTe based cooled infrared focal plane arrays and their characterization. Opto-Electron. Rev. 2019, 27, 174–193. [Google Scholar] [CrossRef]

- Lei, W.; Gu, R.J.; Antoszewski, J.; Dell, J.; Faraone, L. GaSb: A New Alternative Substrate for Epitaxial Growth of HgCdTe. J. Electron. Mater. 2014, 43, 2788–2794. [Google Scholar] [CrossRef]

- Shin, S.H.; Arias, J.M.; Edwall, D.D.; Zandian, M.; Pasko, J.G.; Dewames, R.E. Dislocation Reduction in Hgcdte on Gaas and Si. J. Vac. Sci. Technol. B 1992, 10, 1492–1498. [Google Scholar] [CrossRef]

- Varavin, V.S.; Vasiliev, V.V.; Dvoretsky, S.A.; Mikhailov, N.N.; Ovsyuk, V.N.; Sidorov, Y.G.; Suslyakov, A.O.; Yakushev, M.V.; Aseev, A.L. HgCdTe epilayers on GaAs: Growth and devices. Opto-Electron. Rev. 2003, 11, 99–111. [Google Scholar]

- Zanatta, J.P.; Badano, G.; Ballet, P.; Largeron, C.; Baylet, J.; Gravrand, O.; Rothman, J.; Castelein, P.; Chamonal, J.P.; Million, A.; et al. Molecular beam epitaxy growth of HgCdTe on Ge for third-generation infrared detectors. J. Electron. Mater. 2006, 35, 1231–1236. [Google Scholar] [CrossRef]

- Rim, S.; Catrysse, P.; Dinyari, R.; Huang, K.; Peumans, P. The optical advantages of curved focal plane arrays. Opt. Express 2008, 16, 4965–4971. [Google Scholar] [CrossRef]

- Hu, J.; Bandyopadhyay, S.; Liu, Y.H.; Shao, L.Y. A Review on Metasurface: From Principle to Smart Metadevices. Front. Phys. 2021, 8, 586087. [Google Scholar] [CrossRef]

- Dumas, D.; Fendler, M.; Baier, N.; Primot, J.; le Coarer, E. Curved focal plane detector array for wide field cameras. Appl. Opt. 2012, 51, 5419–5424. [Google Scholar] [CrossRef] [PubMed]

- Floreano, D.; Pericet-Camara, R.; Viollet, S.; Ruffier, F.; Bruckner, A.; Leitel, R.; Buss, W.; Menouni, M.; Expert, F.; Juston, R.; et al. Miniature curved artificial compound eyes. Proc. Natl. Acad. Sci. USA 2013, 110, 9267–9272. [Google Scholar] [CrossRef]

- Jin, H.C.; Abelson, J.R.; Erhardt, M.K.; Nuzzo, R.G. Soft lithographic fabrication of an image sensor array on a curved substrate. J. Vac. Sci. Technol. B 2004, 22, 2548–2551. [Google Scholar] [CrossRef]

- Racicot, I.; Muslimov, E.; Chemla, S.; Blaize, K.; Ferrari, M.; Chavane, F. High resolution, wide field optical imaging of macaque visual cortex with a curved detector. J. Neural Eng. 2022, 19, 066022. [Google Scholar] [CrossRef] [PubMed]

- Itonaga, K.; Arimura, T.; Matsumoto, K.; Kondo, G.; Terahata, K.; Makimoto, S.; Baba, M.; Honda, Y.; Bori, S.; Kai, T.; et al. A novel curved CMOS image sensor integrated with imaging system. In Proceedings of the 2014 Symposium on VLSI Technology (VLSI-Technology): Digest of Technical Papers, Honolulu, HI, USA, 9–12 June 2014; pp. 1–2. [Google Scholar]

- Lombardo, S.; Behaghel, T.; Chambion, B.; Jahn, W.; Hugot, E.; Muslimov, E.; Roulet, M.; Ferrari, M.; Gaschet, C.; Henry, D.; et al. Curved CMOS sensor: Characterization of the first fully-functional prototype. In Optics, Photonics, and Digital Technologies for Imaging Applications V; SPIE: Bellingham, WA, USA, 2018; p. 10679. [Google Scholar]

- Miller, E. Curved Detectors for Future X-ray Astrophysics Missions. arXiv 2024, arXiv:2406.18753. [Google Scholar]

- Tekaya, K.; Fendler, M.; Dumas, D.; Inal, K.; Massoni, E.; Gaeremynck, Y.; Druart, G.; Henry, D. Hemispherical Curved Monolithic Cooled and Uncooled Infrared Focal Plane Arrays for Compact Cameras; SPIE: Bellingham, WA, USA, 2014; Volume 9070. [Google Scholar]

- Koma, A. Van der Waals epitaxy for highly lattice-mismatched systems. J. Cryst. Growth 1999, 201, 236–241. [Google Scholar] [CrossRef]

- Utama, M.I.B.; Zhang, Q.; Zhang, J.; Yuan, Y.W.; Belarre, F.J.; Arbiol, J.; Xiong, Q.H. Recent developments and future directions in the growth of nanostructures by van der Waals epitaxy. Nanoscale 2013, 5, 3570–3588. [Google Scholar] [CrossRef] [PubMed]

- Pan, W.W.; Liu, J.L.; Zhang, Z.K.; Gu, R.J.; Suvorova, A.; Gain, S.; Wang, H.; Li, Z.Y.; Fu, L.; Faraone, L.; et al. Large area van der Waals epitaxy of II-VI CdSe thin films for flexible optoelectronics and full-color imaging. Nano Res. 2021, 15, 368–376. [Google Scholar] [CrossRef]

- Lian, Q.; Zhu, X.T.; Wang, X.D.; Bai, W.; Yang, J.; Zhang, Y.Y.; Qi, R.J.; Huang, R.; Hu, W.D.; Tang, X.D.; et al. Ultrahigh-Detectivity Photodetectors with Van der Waals Epitaxial CdTe Single-Crystalline Films. Small 2019, 15, 1900236. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.B.; Seewald, L.; Mohanty, D.; Wang, Y.; Zhang, L.H.; Kisslinger, K.; Xie, W.Y.; Shi, J.; Bhat, I.; Zhang, S.B.; et al. Surface and interface of epitaxial CdTe film on CdS buffered van der Waals mica substrate. Appl. Surf. Sci. 2017, 413, 219–232. [Google Scholar] [CrossRef]

- Wen, X.; Lu, Z.; Sun, X.; Xiang, Y.; Chen, Z.; Shi, J.; Bhat, I.; Wang, G.-C.; Washington, M.; Lu, T.-M. Epitaxial CdTe Thin Films on Mica by Vapor Transport Deposition for Flexible Solar Cells. ACS Appl. Energy Mater. 2020, 3, 4589–4599. [Google Scholar] [CrossRef]

- Mohanty, D.; Sun, X.; Lu, Z.H.; Washington, M.; Wang, G.C.; Lu, T.M.; Bhat, I.B. Analyses of orientational superlattice domains in epitaxial ZnTe thin films grown on graphene and mica. J. Appl. Phys. 2018, 124, 175301. [Google Scholar] [CrossRef]

- Pan, W.W.; Zhang, Z.K.; Gu, R.J.; Ma, S.; Faraone, L.; Lei, W. Van der Waals Epitaxy of HgCdTe Thin Films for Flexible Infrared Optoelectronics. Adv. Mater. Interfaces 2023, 10, 2201932. [Google Scholar] [CrossRef]

- Yanka, R.W.; Harris, K.A.; Mohnkern, L.M.; Myers, T.H. A novel technique for the MBE growth of twin-free HgCdTe. J. Cryst. Growth 1991, 111, 715–719. [Google Scholar] [CrossRef]

- Sporken, R.; Chen, Y.P.; Sivananthan, S.; Lange, M.D.; Faurie, J.P. Current Status of Direct Growth of Cdte and Hgcdte on Silicon by Molecular-Beam Epitaxy. J. Vac. Sci. Technol. B 1992, 10, 1405–1409. [Google Scholar] [CrossRef]

- Mohanty, D.; Lu, Z.H.; Sun, X.; Xiang, Y.; Wang, Y.P.; Ghoshal, D.; Shi, J.; Gao, L.; Shi, S.S.; Washington, M.; et al. Metalorganic vapor phase epitaxy of large size CdTe grains on mica through chemical and van der Waals interactions. Phys. Rev. Mater. 2018, 2, 113402. [Google Scholar] [CrossRef]

- Faurie, J.-P. Molecular beam epitaxy of Hg1−xCdxTe: Growth and characterization. Prog. Cryst. Growth Charact. Mater. 1994, 29, 85–159. [Google Scholar] [CrossRef]

- Sabinina, I.V.; Gutakovsky, A.K.; Sidorov, Y.G.; Dvoretsky, S.A.; Kuzmin, V.D. Defect Formation during Growth of Cdte(111) and Hgcdte Films by Molecular-Beam Epitaxy. J. Cryst. Growth 1992, 117, 238–243. [Google Scholar] [CrossRef]

- Chang, Y.; Becker, C.R.; Grein, C.H.; Zhao, J.; Fulk, C.; Casselman, T.; Kiran, R.; Wang, X.J.; Robinson, E.; An, S.Y.; et al. Surface morphology and defect formation mechanisms for HgCdTe (211)B grown by molecular beam epitaxy. J. Electron. Mater. 2008, 37, 1171–1183. [Google Scholar] [CrossRef]

- Yang, J.R.; Cao, X.L.; Wei, Y.F.; He, L. Traces of HgCdTe defects as revealed by etch pits. J. Electron. Mater. 2008, 37, 1241–1246. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, J. Rheological behaviors of plasticized polyvinyl chloride thermally conductive composites with oriented flaky fillers: A case study on graphite and mica. J. Appl. Polym. Sci. 2022, 139, 52186. [Google Scholar] [CrossRef]

- Pan, W.W.; Gu, R.J.; Zhang, Z.K.; Liu, J.L.; Lei, W.; Faraone, L. Strained CdZnTe/CdTe Superlattices As Threading Dislocation Filters in Lattice Mismatched MBE Growth of CdTe on GaSb. J. Electron. Mater. 2020, 49, 6983–6989. [Google Scholar] [CrossRef]

- Pan, W.W.; Nath, S.K.; Ma, S.; Gu, R.J.; Zhang, Z.K.; Fu, L.; Faraone, L.; Lei, W. Non-invasive and non-destructive characterization of MBE-grown CdZnTe/CdTe superlattice-based dislocation filtering layers. J. Appl. Phys. 2022, 131, 205304. [Google Scholar] [CrossRef]

| Sample | Growth Temperature () | Hg Flux (Torr) | Flux (Torr) | FWHM (arc sec) | RMS Roughness (nm) |

|---|---|---|---|---|---|

| Mica001 | 180 | 4.5 × | Te: 1.5 × CdTe: 7 × | 2520 | 18.8 |

| Mica002 | 185 | 4.5 × | 2124 | 18 | |

| Mica003 | 190 | 4.5 × | 345.6 | 6 | |

| Mica004 | 195 | 4.5 × | 1692 | 18.8 | |

| Mica005 | 190 | 3 × | 864 | 8.1 | |

| Mica006 | 190 | 6 × | 2340 | 15.2 | |

| Mica007 | 190 | 7 × | 2880 | 18.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, S.; Pan, W.; Sun, X.; Zhang, Z.; Gu, R.; Faraone, L.; Lei, W. Growth of Hg0.7Cd0.3Te on Van Der Waals Mica Substrates via Molecular Beam Epitaxy. Molecules 2024, 29, 3947. https://doi.org/10.3390/molecules29163947

Ma S, Pan W, Sun X, Zhang Z, Gu R, Faraone L, Lei W. Growth of Hg0.7Cd0.3Te on Van Der Waals Mica Substrates via Molecular Beam Epitaxy. Molecules. 2024; 29(16):3947. https://doi.org/10.3390/molecules29163947

Chicago/Turabian StyleMa, Shuo, Wenwu Pan, Xiao Sun, Zekai Zhang, Renjie Gu, Lorenzo Faraone, and Wen Lei. 2024. "Growth of Hg0.7Cd0.3Te on Van Der Waals Mica Substrates via Molecular Beam Epitaxy" Molecules 29, no. 16: 3947. https://doi.org/10.3390/molecules29163947

APA StyleMa, S., Pan, W., Sun, X., Zhang, Z., Gu, R., Faraone, L., & Lei, W. (2024). Growth of Hg0.7Cd0.3Te on Van Der Waals Mica Substrates via Molecular Beam Epitaxy. Molecules, 29(16), 3947. https://doi.org/10.3390/molecules29163947