Multi-Functional Repair and Long-Term Preservation of Paper Relics by Nano-MgO with Aminosilaned Bacterial Cellulose

Abstract

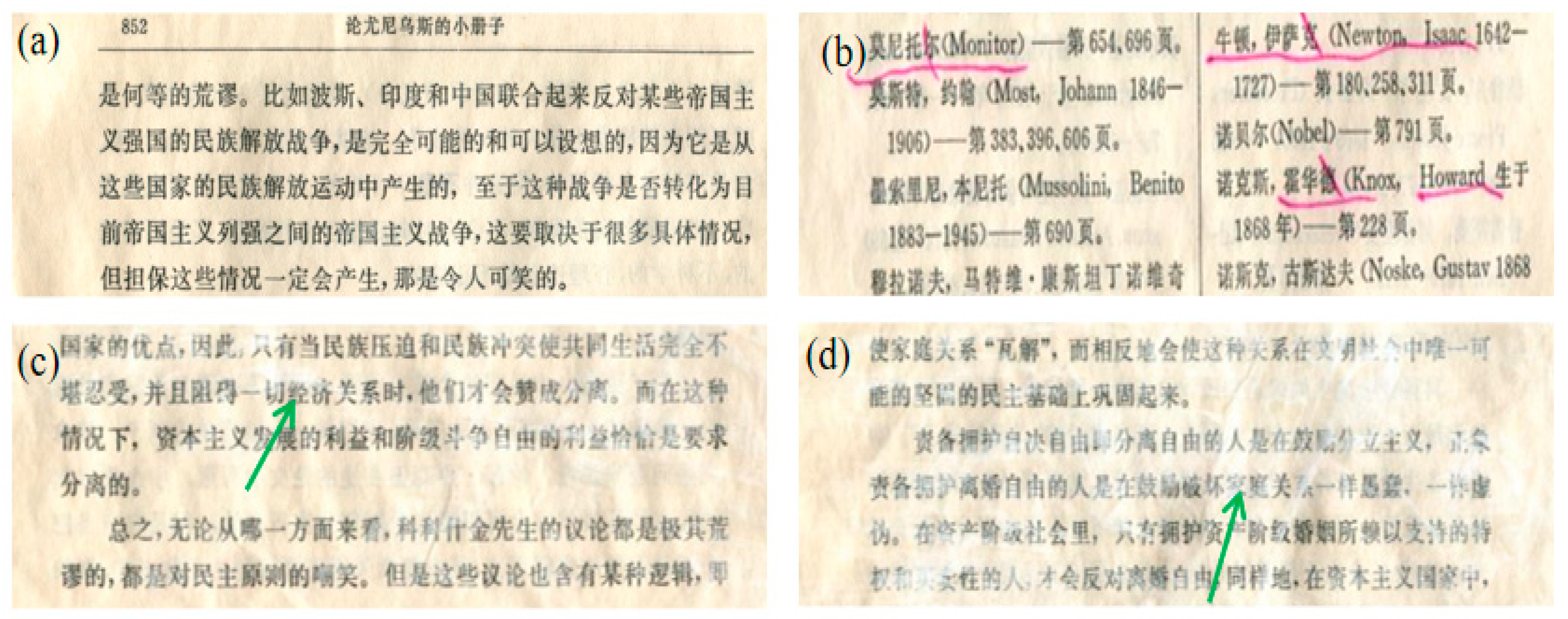

1. Introduction

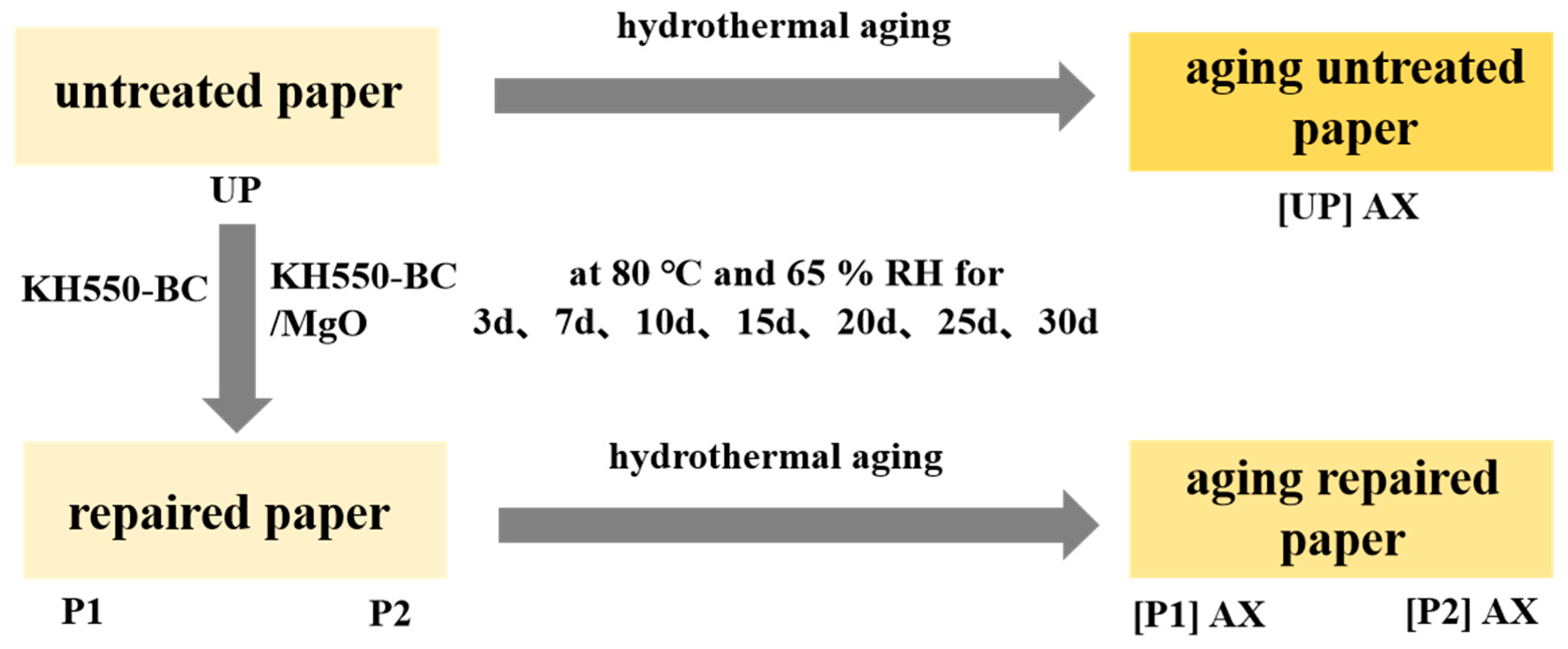

2. Results and Discussion

2.1. Effect of Loading Nano-MgO in KH550-BC on Deacidification

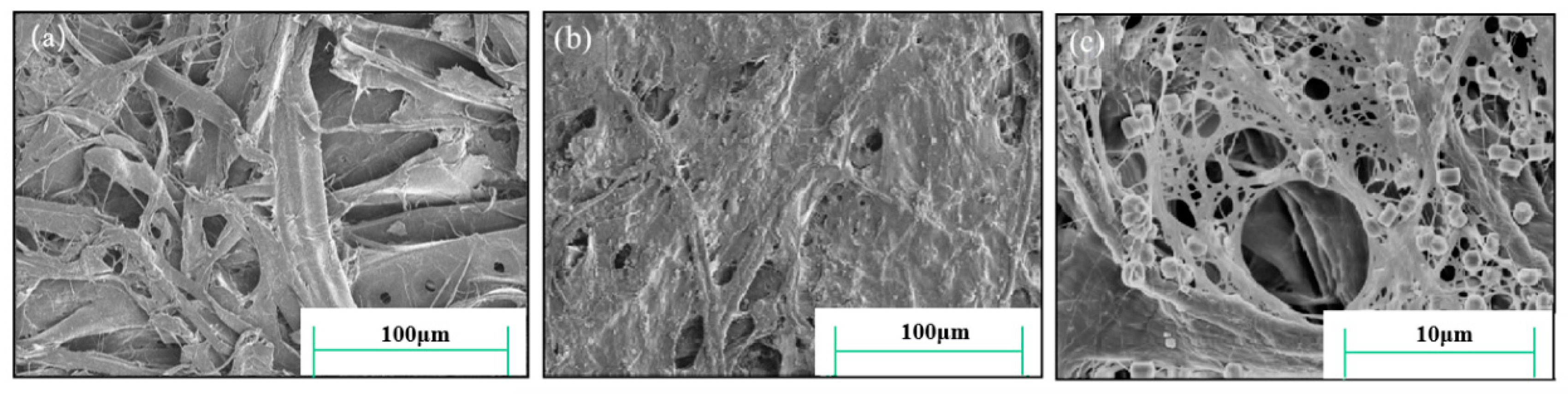

2.2. Strengthening Effect of KH550-BC/MgO on Aged Paper

2.3. Wettability Analysis of Repaired Paper

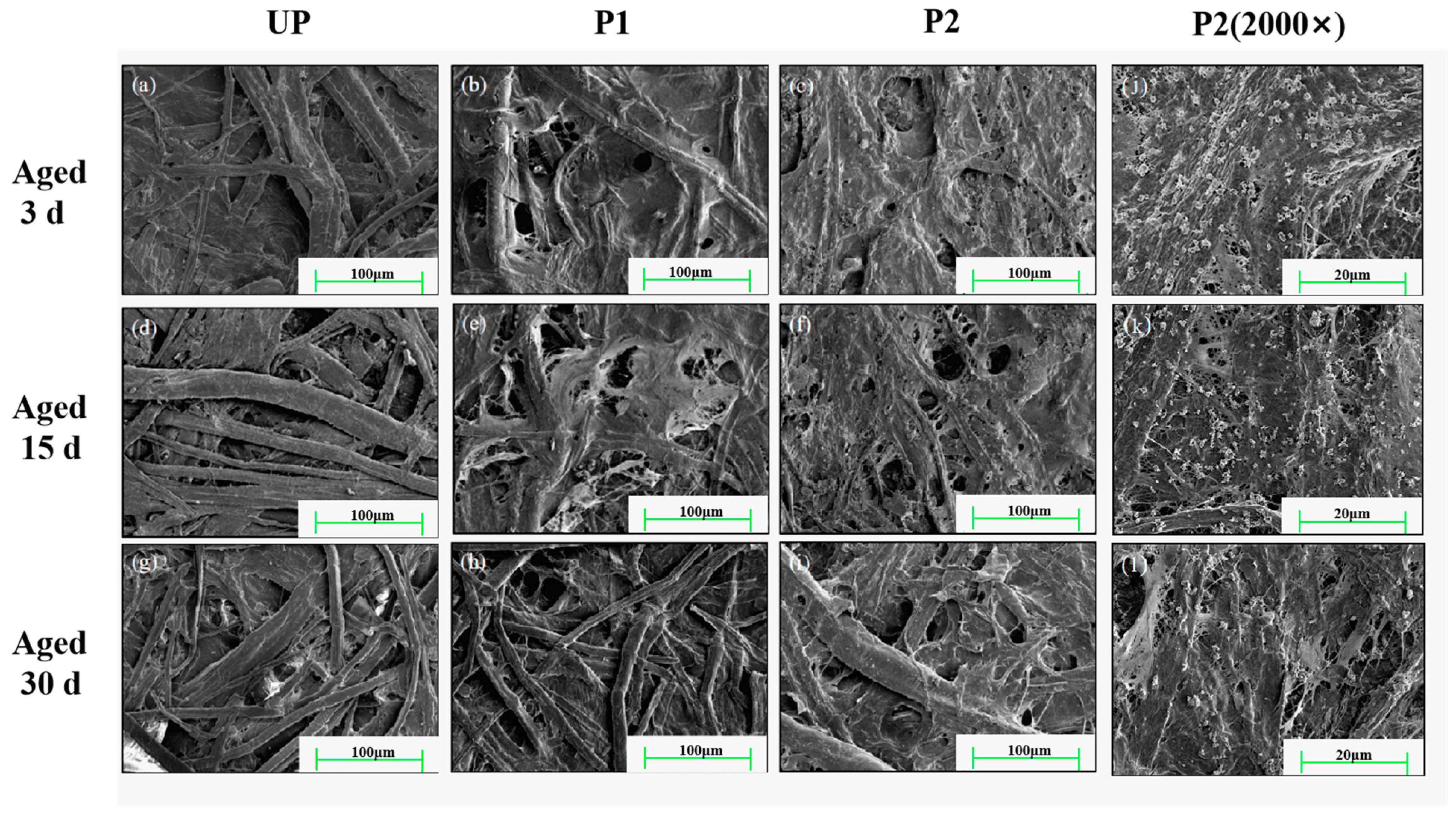

2.4. Aging Resistance and Stability Studies of Repaired Paper

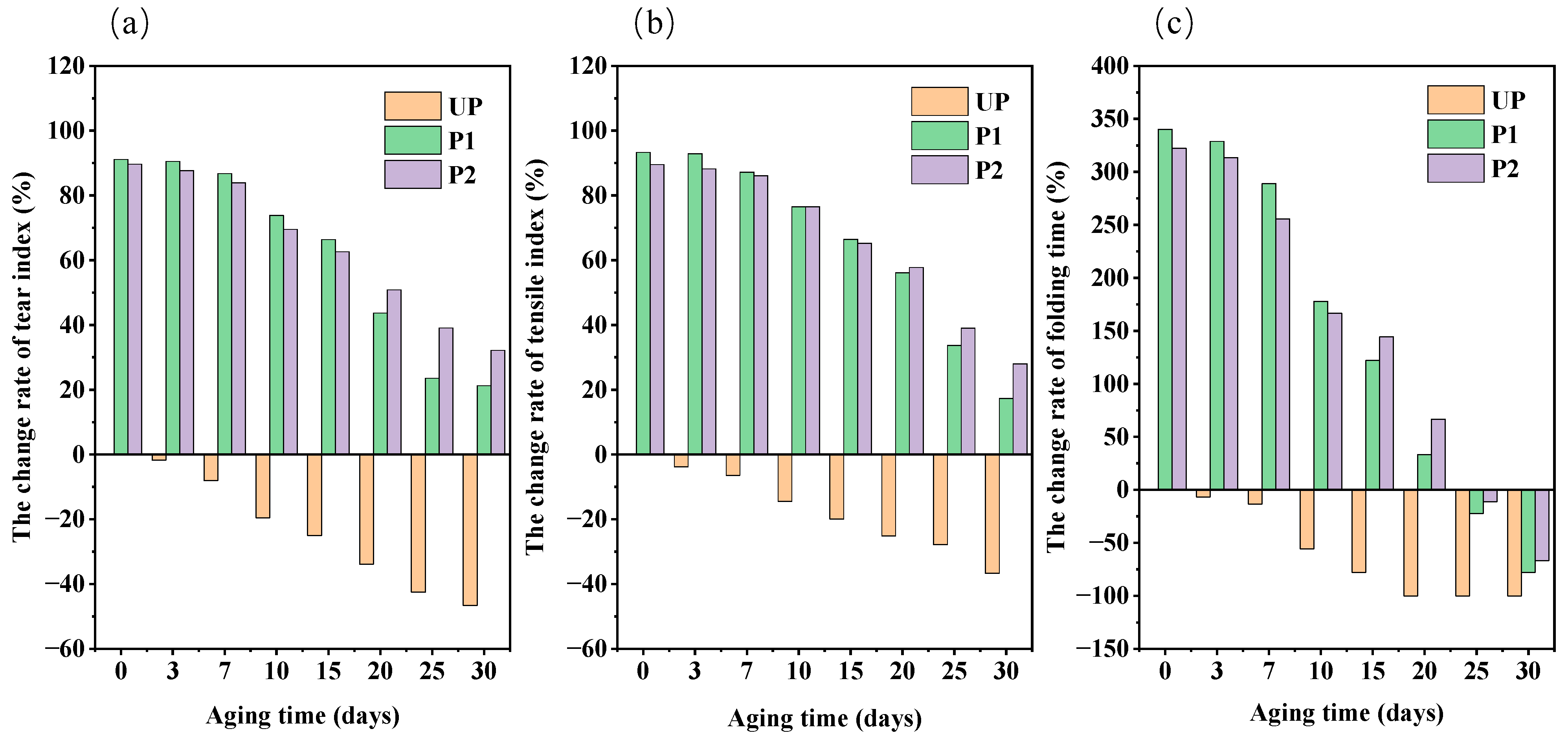

2.4.1. Mechanical Properties Change in Repaired Paper during Aging

2.4.2. Resistance to Acidification of Repaired Paper

2.4.3. Whiteness and Chromatic Aberration Change during Aging

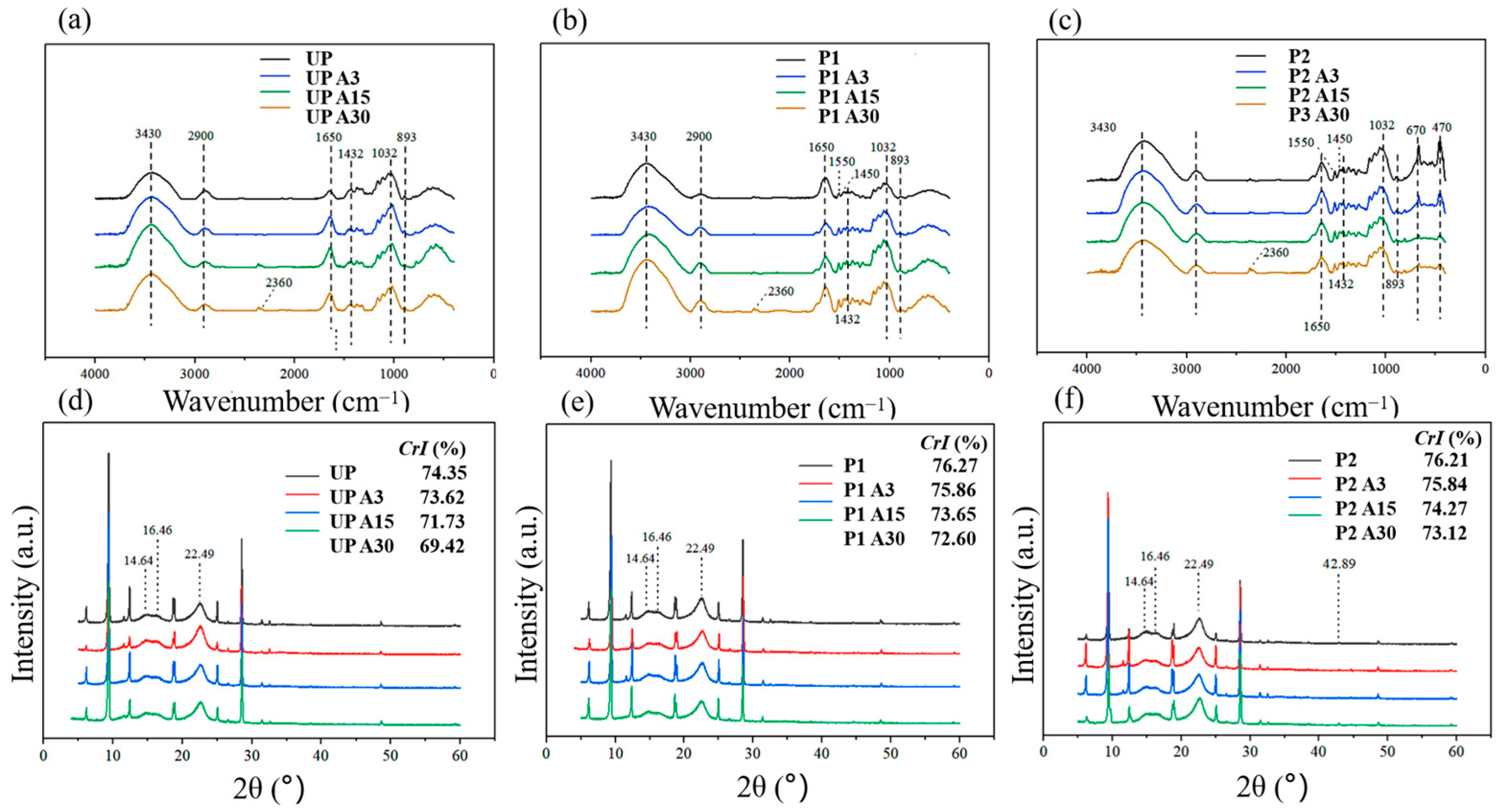

2.5. Anti-Aging Mechanism Analysis

3. Material and Methods

3.1. Material

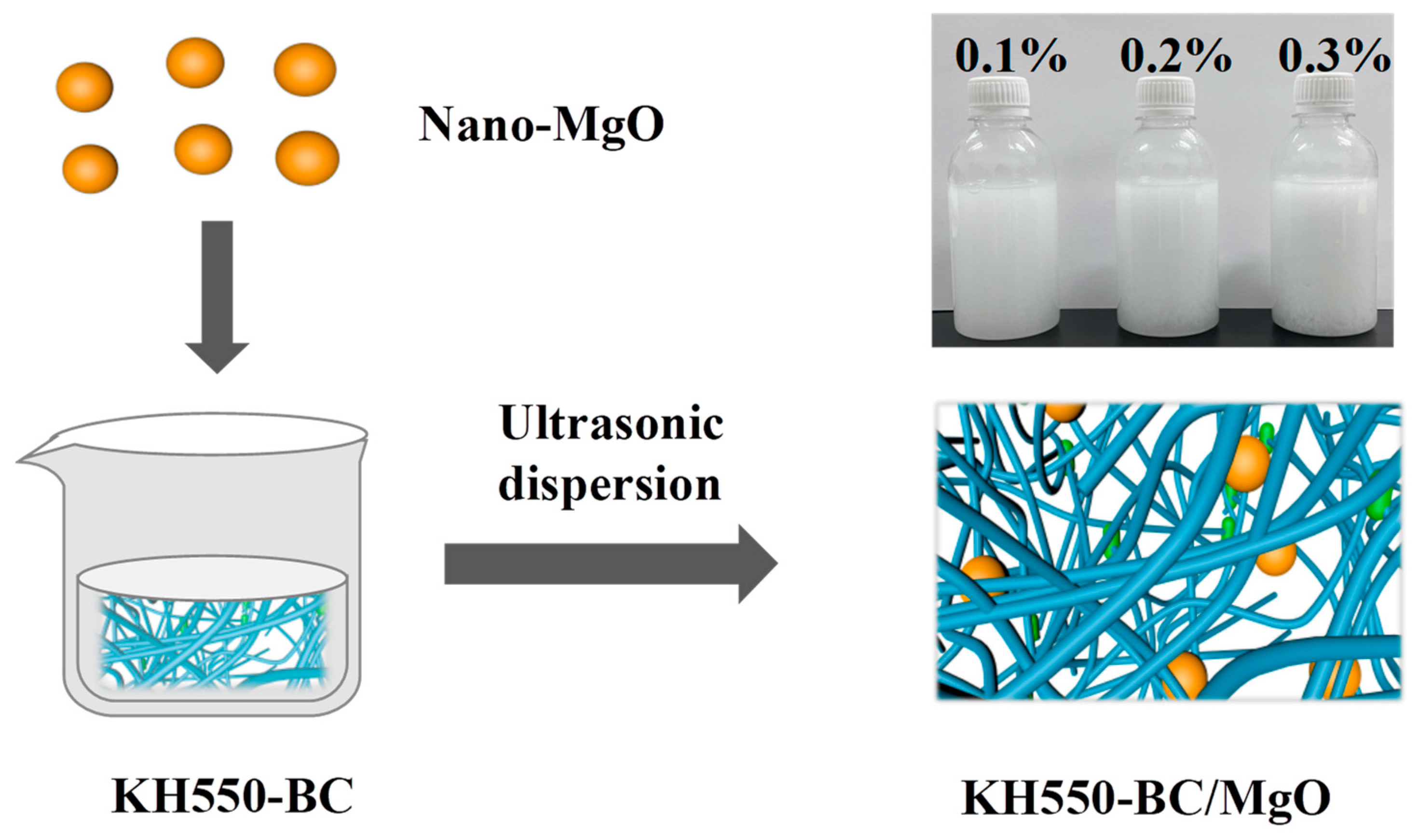

3.2. Preparation of KH550-BC/MgO Dispersion

3.3. Artificial Accelerated Aging of Paper Samples

3.4. Characterization of Paper Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zervos, S.; Moropoulou, A. Methodology and Criteria for the Evaluation of Paper Conservation Interventions: A Literature Review. Restaur.-Int. J. Preserv. Libr. Arch. Mater. 2006, 27, 219–274. [Google Scholar] [CrossRef]

- Fan, L.-t.; Gharpuray, M.M.; Lee, Y.-H. Acid Hydrolysis of Cellulose. In Cellulose Hydrolysis; Fan, L.-T., Gharpuray, M.M., Lee, Y.-H., Eds.; Springer: Berlin/Heidelberg, Germany, 1987; pp. 121–148. [Google Scholar]

- Strlič, M.; Kolar, J.; Pihlar, B. Methodology and analytical techniques in paper stability studies. In Aging and Stabilisation of Paper; Strlič, M., Kolar, J., Eds.; University of Ljubljana: Ljubljana, Slovenia, 2005; pp. 27–47. [Google Scholar]

- Strlič, M.; Menart, E.; Cigić, I.K.; Kolar, J.; de Bruin, G.; Cassar, M. Emission of reactive oxygen species during degradation of iron gall ink. Polym. Degrad. Stab. 2010, 95, 66–71. [Google Scholar] [CrossRef][Green Version]

- Croitoru, C.; Roata, I.C. Ionic Liquids as Reconditioning Agents for Paper Artifacts. Molecules 2024, 29, 963. [Google Scholar] [CrossRef]

- Santos, A.; Cerrada, A.; García, S.; San Andrés, M.; Abrusci, C.; Marquina, D. Application of Molecular Techniques to the Elucidation of the Microbial Community Structure of Antique Paintings. Microb. Ecol. 2009, 58, 692–702. [Google Scholar] [CrossRef]

- Magaudda, G. The recovery of biodeteriorated books and archive documents through gamma radiation: Some considerations on the results achieved. J. Cult. Herit. 2004, 5, 113–118. [Google Scholar] [CrossRef]

- Liang, X.; Zheng, L.; Li, S.; Fan, X.; Shen, S.; Hu, D. Electrochemical removal of stains from paper cultural relics based on the electrode system of conductive composite hydrogel and PbO2. Sci. Rep. 2017, 7, 8865. [Google Scholar] [CrossRef]

- Jiang, F.; Yang, Y.; Weng, J.; Zhang, X. Layer-by-Layer Self-Assembly for Reinforcement of Aged Papers. Ind. Eng. Chem. Res. 2016, 55, 10544. [Google Scholar] [CrossRef]

- Jia, Z.; Yang, C.; Zhao, F.; Chao, X.; Li, Y.; Xing, H. One-Step Reinforcement and Deacidification of Paper Documents: Application of Lewis Base—Chitosan Nanoparticle Coatings and Analytical Characterization. Coatings 2020, 10, 1226. [Google Scholar] [CrossRef]

- Li, S.; Tang, J.; Jiang, L.; Jiao, L. Conservation of aged paper using reduced cellulose nanofibrils/aminopropyltriethoxysilane modified CaCO3 particles coating. Int. J. Biol. Macromol. 2023, 255, 128254. [Google Scholar] [CrossRef]

- Xiang, Z.; Liu, Q.; Chen, Y.; Lu, F. Effects of physical and chemical structures of bacterial cellulose on its enhancement to paper physical properties. Cellulose 2017, 24, 3513–3523. [Google Scholar] [CrossRef]

- Wang, Y.; Luo, W.; Tu, Y.; Zhao, Y. Gelatin-Based Nanocomposite Film with Bacterial Cellulose–MgO Nanoparticles and Its Application in Packaging of Preserved Eggs. Coatings 2021, 11, 39. [Google Scholar] [CrossRef]

- Santos, S.M.; Carbajo, J.M.; Gómez, N.; Quintana, E.; Ladero, M.; Sánchez, A.; Chinga-Carrasco, G.; Villar, J.C. Use of bacterial cellulose in degraded paper restoration. Part I: Application on model papers. J. Mater. Sci. 2016, 51, 1541–1552. [Google Scholar] [CrossRef]

- Gómez, N.; Santos, S.; Carbajo, J.; Villar, J. Use of bacterial cellulose in degraded paper restoration: Effect on visual appearance of printed paper. Bioresources 2017, 12, 9130–9142. [Google Scholar] [CrossRef]

- Chen, X.; Ding, L.; Ma, G.; Yu, H.; Wang, X.; Zhang, N.; Zhong, J. Use of bacterial cellulose in the restoration of creased Chinese Xuan paper. J. Cult. Herit. 2023, 59, 23–29. [Google Scholar] [CrossRef]

- Wu, X.; Mou, H.Y.; Fan, H.; Yin, J.; Liu, Y.; Liu, J. Improving the Flexibility and Durability of Aged Paper with Bacterial Cellulose. Mater. Today Commun. 2022, 32, 103827. [Google Scholar] [CrossRef]

- Nakayama, A.; Kakugo, A.; Gong, J.P.; Osada, Y.; Takai, M.; Erata, T.; Kawano, S. High Mechanical Strength Double-Network Hydrogel with Bacterial Cellulose. Adv. Funct. Mater. 2004, 14, 1124–1128. [Google Scholar] [CrossRef]

- He, H.; Teng, H.; An, F.; Wang, Y.-W.; Qiu, R.; Chen, L.; Song, H. Nanocelluloses review: Preparation, biological properties, safety, and applications in the food field. Food Front. 2023, 4, 85–99. [Google Scholar] [CrossRef]

- Zhang, X.; Yao, J.; Yan, Y.; Huang, X.; Zhang, Y.; Tang, Y.; Yang, Y. Reversible Deacidification and Preventive Conservation of Paper-Based Cultural Relics by Mineralized Bacterial Cellulose. ACS Appl. Mater. Interfaces 2024, 16, 13091–13102. [Google Scholar] [CrossRef] [PubMed]

- Choo, K.W.; Dhital, R.; Mao, L.; Lin, M.; Mustapha, A. Development of polyvinyl alcohol/chitosan/modified bacterial nanocellulose films incorporated with 4-hexylresorcinol for food packaging applications. Food Packag. Shelf Life 2021, 30, 100769. [Google Scholar] [CrossRef]

- Shao, W.; Wu, J.; Liu, H.; Ye, S.; Jiang, L.; Liu, X. Novel bioactive surface functionalization of bacterial cellulose membrane. Carbohydr. Polym. 2017, 178, 270–276. [Google Scholar] [CrossRef]

- Fernandes, S.C.; Sadocco, P.; Alonso-Varona, A.; Palomares, T.; Eceiza, A.; Silvestre, A.J.; Mondragon, I.; Freire, C.S. Bioinspired antimicrobial and biocompatible bacterial cellulose membranes obtained by surface functionalization with aminoalkyl groups. ACS Appl. Mater. Interfaces 2013, 5, 3290–3297. [Google Scholar] [CrossRef] [PubMed]

- Mou, H.; Wu, T.; Wu, X.; Zhang, H.; Ji, X.; Fan, H.; Song, H. Improvement of interface bonding of bacterial cellulose reinforced aged paper by amino-silanization. Int. J. Biol. Macromol. 2024, 275, 133130. [Google Scholar] [CrossRef]

- Ahn, K.; Banik, G.; Potthast, A. Sustainability of Mass-Deacidification. Part II: Evaluation of Alkaline Reserve. Restaur. Int. J. Preserv. Libr. Arch. Mater. 2012, 33, 48–75. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Jia, Z.; Zhou, Y.; Chao, X.; Terigele; Li, J.; Li, Y.; Xing, H. Deacidification and consolidation of brittle book paper using bacterial cellulose composite with zinc oxide nanoparticles. J. Cult. Herit. 2023, 64, 83–91. [Google Scholar] [CrossRef]

- Jablonsky, M.; Holubkova, S.; Kazikova, J.; Botkova, M.; Haz, A.; Bajzikova, M. The treatment of acid newsprint paper: Evaluation of treatment bymgo or by a mixture of MgO and methyl methoxy magnesium carbonate. Wood Res. 2013, 58, 151–164. [Google Scholar]

- Huang, J.; Liang, G.; Lu, G.; Zhang, J. Conservation of acidic papers using a dispersion of oleic acid-modified MgO nanoparticles in a non-polar solvent. J. Cult. Herit. 2018, 34, 61–68. [Google Scholar] [CrossRef]

- He, B.; Ai, J.; Qi, S.; Ren, J.; Zhao, L.; Liu, C.; Fan, H. Highly stable nano magnesium oxide organic coatings for nondestructive protection of acidic paper documents. Prog. Org. Coat. 2022, 167, 106833. [Google Scholar] [CrossRef]

- Amornkitbamrung, L.; Bračič, D.; Bračič, M.; Hribernik, S.; Malešič, J.; Hirn, U.; Vesel, A.; Stana-Kleinschek, K.; Kargl, R.; Mohan, T. Comparison of Trimethylsilyl Cellulose-Stabilized Carbonate and Hydroxide Nanoparticles for Deacidification and Strengthening of Cellulose-Based Cultural Heritage. ACS Omega 2020, 5, 29243–29256. [Google Scholar] [CrossRef]

- Wu, X.; Xiang, Z.; Song, T.; Qi, H. Wet-strength agent improves recyclability of dip-catalyst fabricated from gold nanoparticle-embedded bacterial cellulose and plant fibers. Cellulose 2019, 26, 3375–3386. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, Y.; Yao, J.; Jin, S.; Tang, Y. Chemistry directs the conservation of paper cultural relics. Polym. Degrad. Stab. 2023, 207, 110228. [Google Scholar] [CrossRef]

- Kumar, S.; Chauhan, V.S.; Chakrabarti, S.K. Separation and analysis techniques for bound and unbound alkyl ketene dimer (AKD) in paper: A review. Arab. J. Chem. 2016, 9, S1636–S1642. [Google Scholar] [CrossRef]

- Basta, A.; El-Saied, H.; Mohamed, S.; El-sherbiny, S. The Role of Neutral Rosin-Alum Size in the Production of Permanent Paper. Restaur.-Int. J. Preserv. Libr. Arch. Mater. 2006, 27, 67–80. [Google Scholar] [CrossRef]

- Wu, C.; Liu, Y.; Hu, Y.; Ding, M.; Cui, X.; Liu, Y.; Liu, P.; Zhang, H.; Yang, Y.; Zhang, H. An Investigation into the Performance and Mechanisms of Soymilk-Sized Handmade Xuan Paper at Different Concentrations of Soymilk. Molecules 2023, 28, 6791. [Google Scholar] [CrossRef]

- Kono, H.; Uno, T.; Tsujisaki, H.; Anai, H.; Kishimoto, R.; Matsushima, T.; Tajima, K. Nanofibrillated Bacterial Cellulose Surface Modified with Methyltrimethoxysilane for Fiber-Reinforced Composites. ACS Appl. Nano Mater. 2020, 3, 8232–8241. [Google Scholar] [CrossRef]

- Zervos, S. Natural and Accelerated Ageing of Cellulose and Paper: A Literature Review. In Cellulose Structure and Properties, Derivatives and Industrial Uses; Lejeune, A., Deprez, T., Eds.; Nova Science Publishers: Happauge, NY, USA, 2010; pp. 155–203. [Google Scholar]

- Wong, K.K.Y.; Richardson, J.D.; Mansfield, S.D. Enzymatic Treatment of Mechanical Pulp Fibers for Improving Papermaking Properties. Biotechnol. Prog. 2000, 16, 1025–1029. [Google Scholar] [CrossRef]

- Liu, J.; Gao, S.; Wang, Y.; Li, X.; Xuan, C. Effect of ambient humidity on water content and mechanical properties of paper. J. Beijing Inst. Print. 2013, 21, 5–8. [Google Scholar]

- He, B.; Lin, Q.; Chang, M.; Liu, C.; Fan, H.; Ren, J. A New and Highly Efficient Conservation Treatment for Deacidification and Strengthening of Aging Paper by In-situ Quaternization. Carbohydr. Polym. 2019, 209, 250–257. [Google Scholar] [CrossRef]

- Zou, X.; Uesaka, T.; Gurnagul, N. Prediction of paper permanence by accelerated aging I. Kinetic analysis of the aging process. Cellulose 1996, 3, 243–267. [Google Scholar] [CrossRef]

- Łojewski, T.; Miśkowiec, P.; Molenda, M.; Lubańska, A.; Łojewska, J. Artificial versus natural ageing of paper. Water role in degradation mechanisms. Appl. Phys. A 2010, 100, 625–633. [Google Scholar] [CrossRef]

- Safaei, M.; Taran, M. Preparation of Bacterial Cellulose Fungicide Nanocomposite Incorporated with MgO Nanoparticles. J. Polym. Environ. 2022, 30, 2066–2076. [Google Scholar] [CrossRef]

- Liang, G.; Lu, G.; Zhang, J.; Zhen, D. Study on the application of nano-magnesium oxide to the deacidification of paper cultural relics. New Chem. Mater. 2017, 45, 244–246. [Google Scholar]

- Hajji, L.; Boukir, A.; Assouik, J.; Pessanha, S.; Figueirinhas, J.L.; Carvalho, M.L. Artificial aging paper to assess long-term effects of conservative treatment. Monitoring by infrared spectroscopy (ATR-FTIR), X-ray diffraction (XRD), and energy dispersive X-ray fluorescence (EDXRF). Microchem. J. 2016, 124, 646–656. [Google Scholar] [CrossRef]

- Wang, Y.J.; Zhang, X.N.; Song, Y.; Zhao, Y.; Chen, L.; Su, F.; Li, L.; Wu, Z.L.; Zheng, Q. Ultrastiff and Tough Supramolecular Hydrogels with a Dense and Robust Hydrogen Bond Network. Chem. Mater. 2019, 31, 1430–1440. [Google Scholar] [CrossRef]

- Jinquan, W.; Yongwen, M.; Yan, W.; Chen, Y. The Content of Different Hydrogen Bond Models and Crystal Structure of Eucalyptus Fibers during Beating. BioResources 2013, 8, 717–734. [Google Scholar]

- Wu, C.; Jin, C.; Zhu, Z.; Liu, P.; Zhang, H. Discussion on the method of detecting the crystalline structure of cellulose in paper. Fudan J. (Nat. Sci. Ed.) 2022, 61, 589–597. [Google Scholar]

- Ju, X.; Bowden, M.; Brown, E.E.; Zhang, X. An improved X-ray diffraction method for cellulose crystallinity measurement. Carbohydr. Polym. 2015, 123, 476–481. [Google Scholar] [CrossRef]

- Hassan, R. Thermal degradation of paper: The structural changes of fibres. Egypt. J. Archaeol. Restor. Stud. 2016, 6, 71–84. [Google Scholar]

- Ma, X.; Tian, S.; Li, X.; Fan, H.; Fu, S. Combined Polyhexamethylene Quanidine and Nanocellulose for the Conservation and Enhancement of Ancient Paper. Cellulose 2021, 28, 8027–8042. [Google Scholar] [CrossRef]

- ISO 187:1990; Paper, Board and Pulps—Standard Atmosphere for Conditioning and Testing and Procedure for Monitoring the Atmosphere and Conditioning of Samples. ISO: Geneva, Switzerland, 1990. Available online: https://www.iso.org/standard/4037.html (accessed on 16 August 2024).

- ISO 5630-3:1996; Paper and Board—Accelerated Ageing Part 3: Moist Heat Treatment at 80 Degrees C and 65% Relative Humidity. ISO: Geneva, Switzerland, 1996. Available online: https://www.iso.org/standard/23402.html (accessed on 16 August 2024).

- ISO 6588–1:2021; Paper, Board and Pulps—Determination of pH of Aqueous Extracts—Part 1: Cold Extraction. ISO: Geneva, Switzerland, 2021. Available online: https://www.iso.org/standard/83250.html (accessed on 16 August 2024).

- ISO 10716-1994; Paper and Board—Determination of Alkali Reserve. ISO: Geneva, Switzerland, 1994. Available online: https://www.iso.org/standard/18809.html (accessed on 16 August 2024).

- ISO 11476:2010; Paper and Board—Determination of CIE Whiteness, C/2 Degrees (Indoor Illumination Conditions). ISO: Geneva, Switzerland, 2010. Available online: https://www.iso.org/standard/44136.html (accessed on 16 August 2024).

| Samples | Mass Fraction of MgO/% | pH | Alkali Reserve/mol kg−1 |

|---|---|---|---|

| 1 | 0 | 7.96 | 0.26 |

| 2 | 0.1 | 9.42 | 0.36 |

| 3 | 0.2 | 9.98 | 0.53 |

| 4 | 0.3 | 10.21 | 0.82 |

| Sample | pH | Alkali Reserve (mol/kg) | Tear Index (mN·m2/g) | Tensile Index (N·m/g) | Folding Endurance (Times) | Zero-Span Tensile Strength (kN/m) | Tensile Stress (MPa) |

|---|---|---|---|---|---|---|---|

| UP | 6.45 | 0 | 3.48 | 18.70 | 4.50 | 68.30 | 14.27 |

| P1 | 7.96 | 0.26 | 6.65 | 36.15 | 19.80 | 78.60 | 28.02 |

| The increased ratio (%) | 23.41 | — | 91.09 | 93.32 | 340 | 15.08 | 96.36 |

| P2 | 9.42 | 0.36 | 6.60 | 35.44 | 19 | 77.80 | 27.29 |

| The Increased ratio (%) | 46.05 | — | 89.66 | 89.52 | 322.20 | 13.91 | 88.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mou, H.; Wu, T.; Ji, X.; Zhang, H.; Wu, X.; Fan, H. Multi-Functional Repair and Long-Term Preservation of Paper Relics by Nano-MgO with Aminosilaned Bacterial Cellulose. Molecules 2024, 29, 3959. https://doi.org/10.3390/molecules29163959

Mou H, Wu T, Ji X, Zhang H, Wu X, Fan H. Multi-Functional Repair and Long-Term Preservation of Paper Relics by Nano-MgO with Aminosilaned Bacterial Cellulose. Molecules. 2024; 29(16):3959. https://doi.org/10.3390/molecules29163959

Chicago/Turabian StyleMou, Hongyan, Ting Wu, Xingxiang Ji, Hongjie Zhang, Xiao Wu, and Huiming Fan. 2024. "Multi-Functional Repair and Long-Term Preservation of Paper Relics by Nano-MgO with Aminosilaned Bacterial Cellulose" Molecules 29, no. 16: 3959. https://doi.org/10.3390/molecules29163959

APA StyleMou, H., Wu, T., Ji, X., Zhang, H., Wu, X., & Fan, H. (2024). Multi-Functional Repair and Long-Term Preservation of Paper Relics by Nano-MgO with Aminosilaned Bacterial Cellulose. Molecules, 29(16), 3959. https://doi.org/10.3390/molecules29163959