Synthesis and Kinetics of CO2-Responsive Gemini Surfactants

Abstract

:1. Introduction

2. Results and Discussions

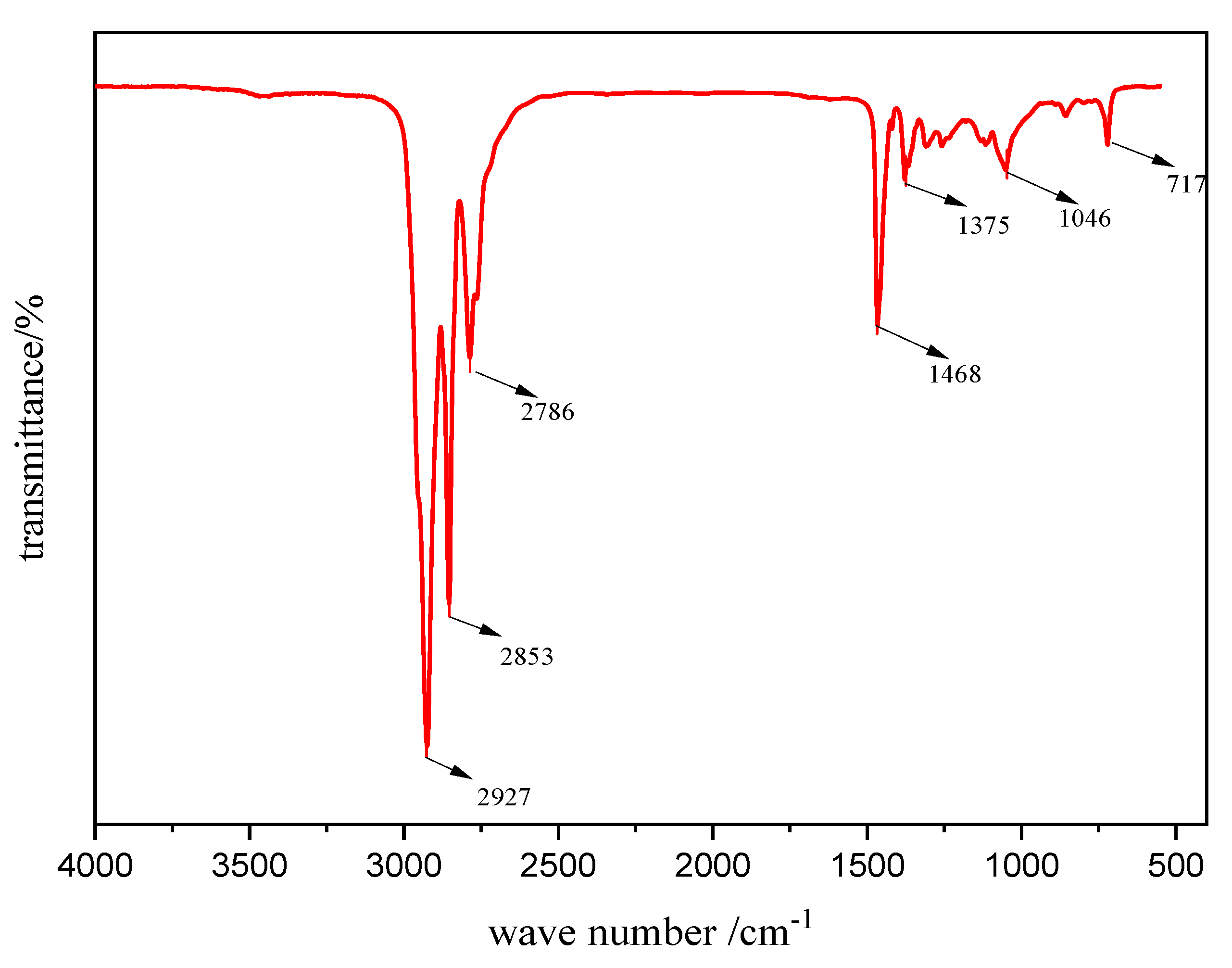

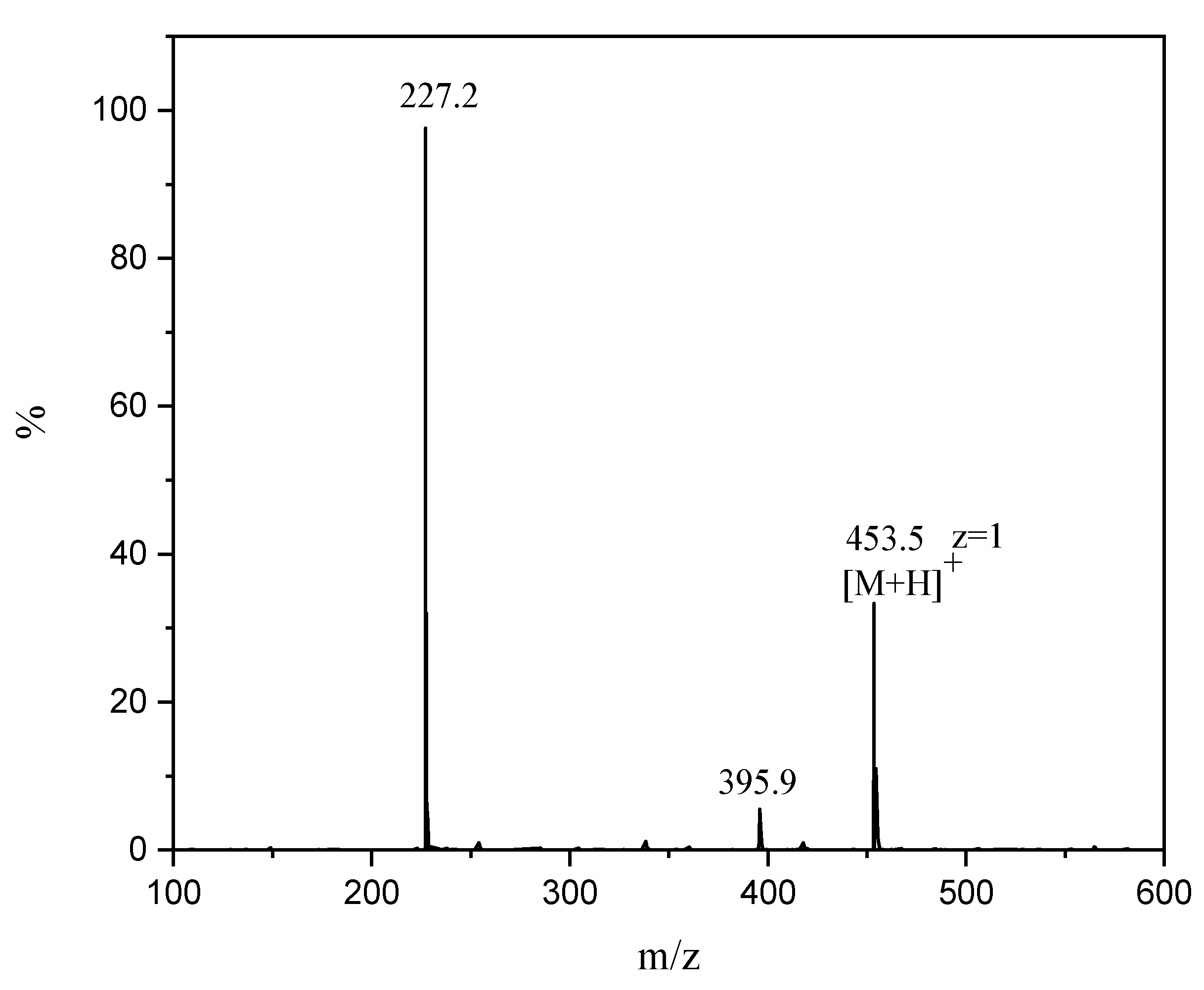

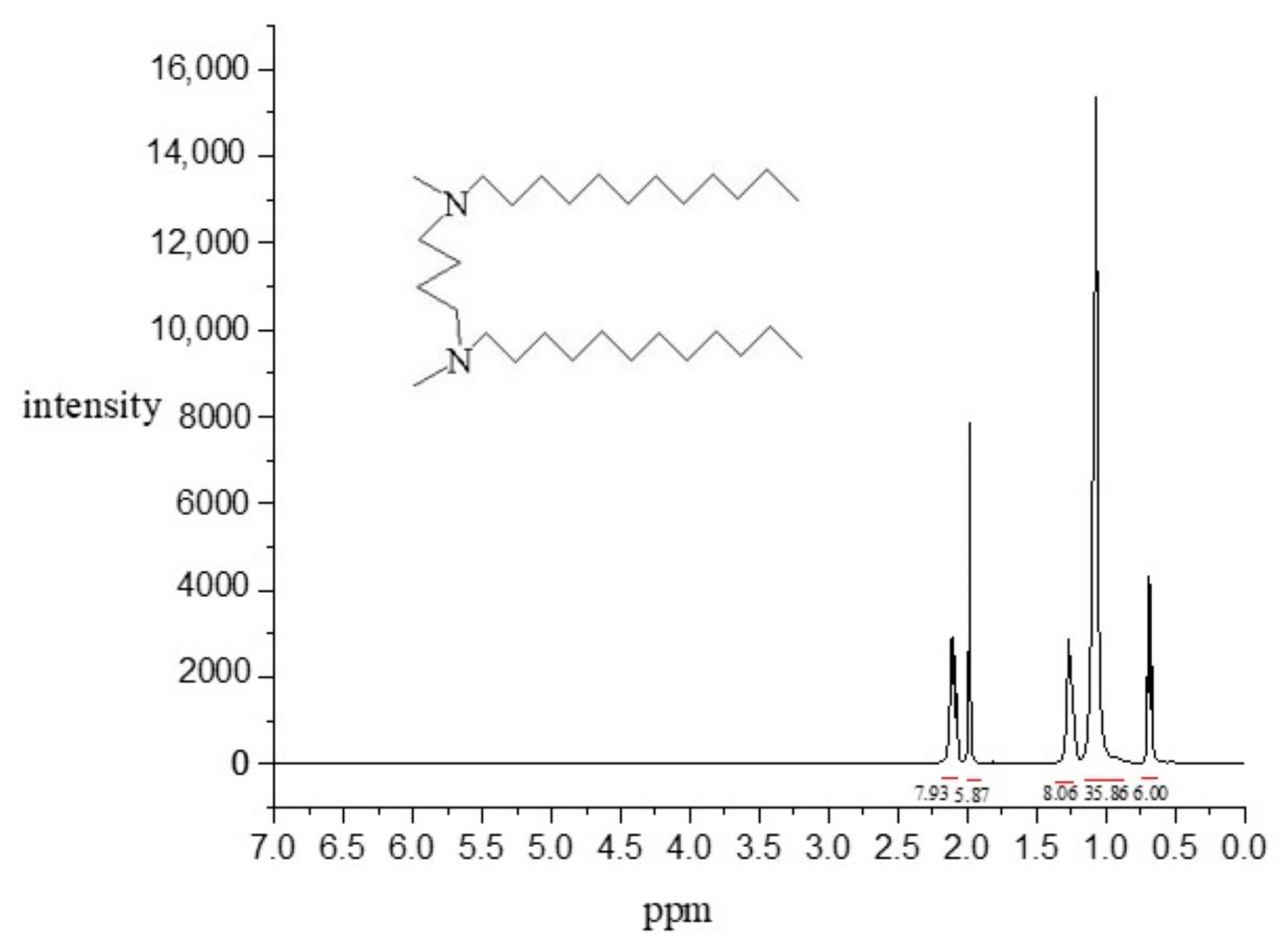

2.1. Structural Characterization of DMDBA

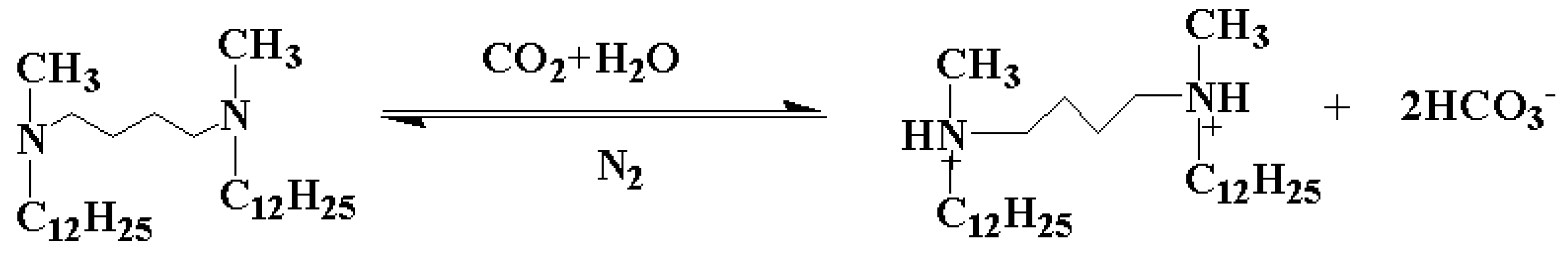

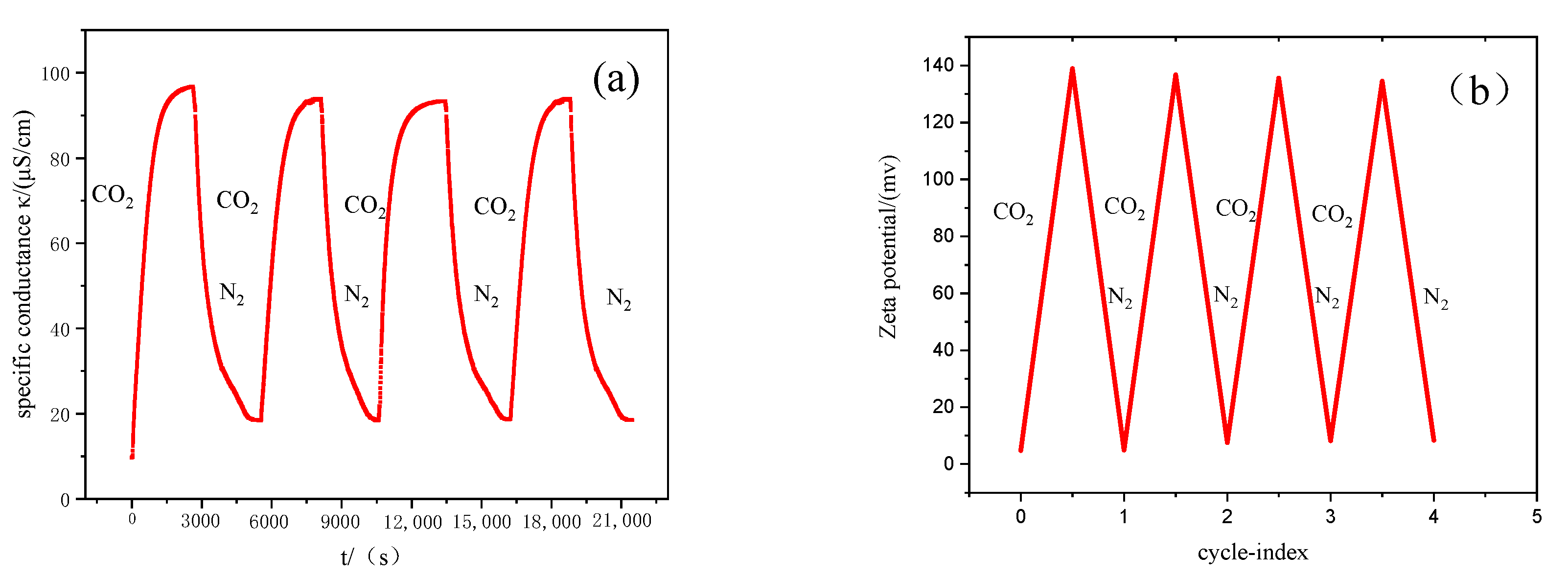

2.2. Switching Property of DMDBAH

2.3. Surface Properties of DMDBAH

2.4. Wettability of DMDBAH

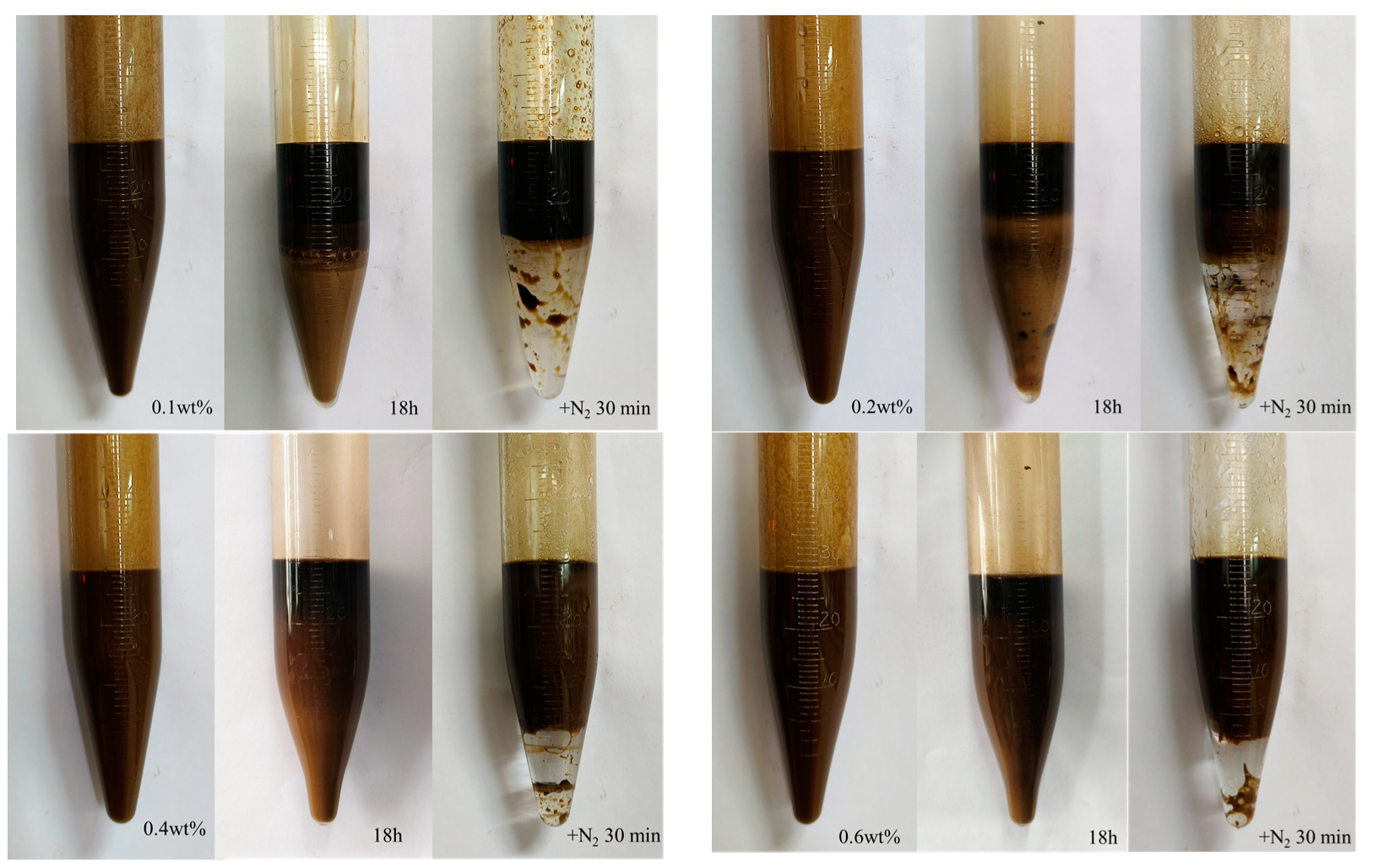

2.5. Emulsification/Demulsification Performance of DMDBAH

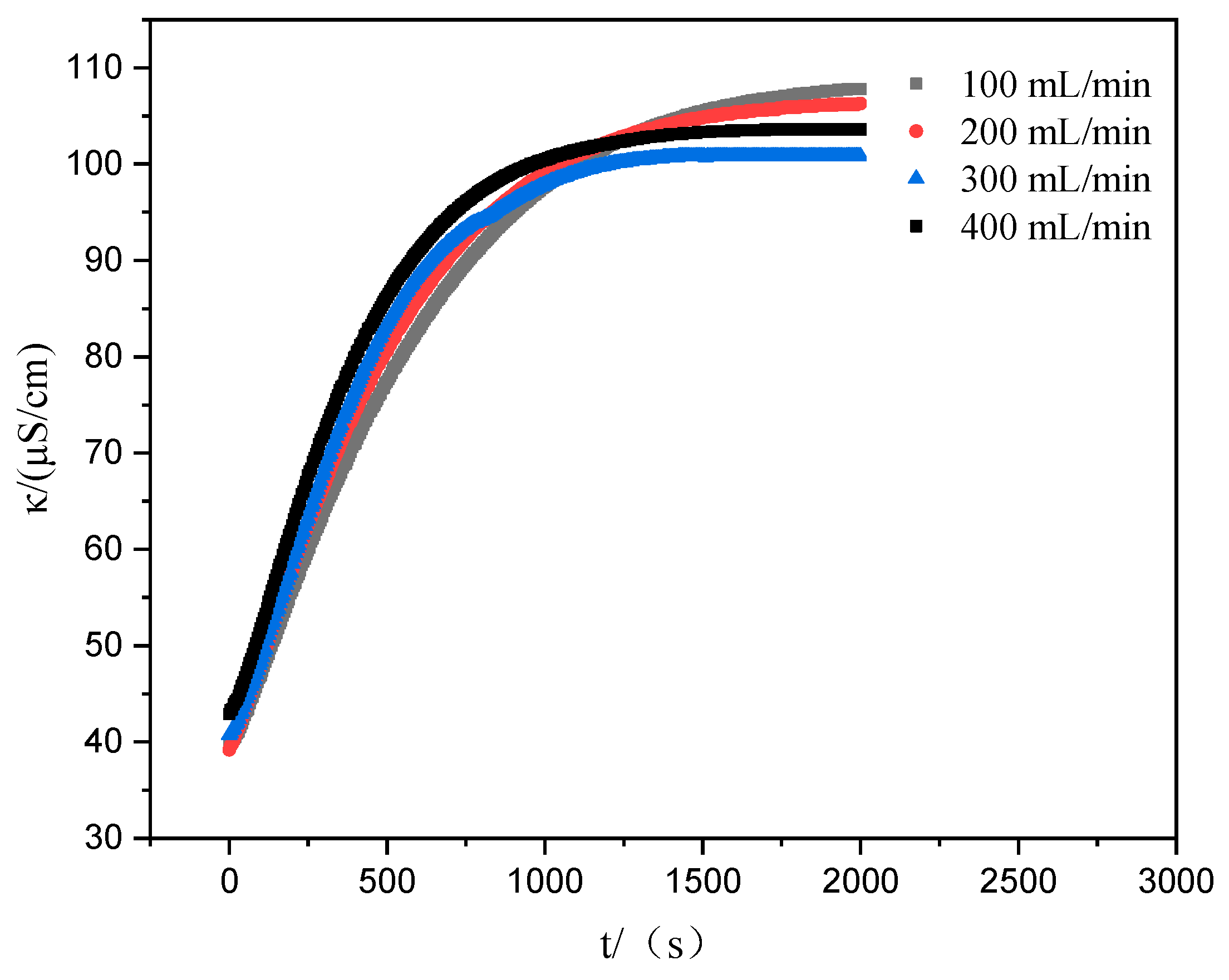

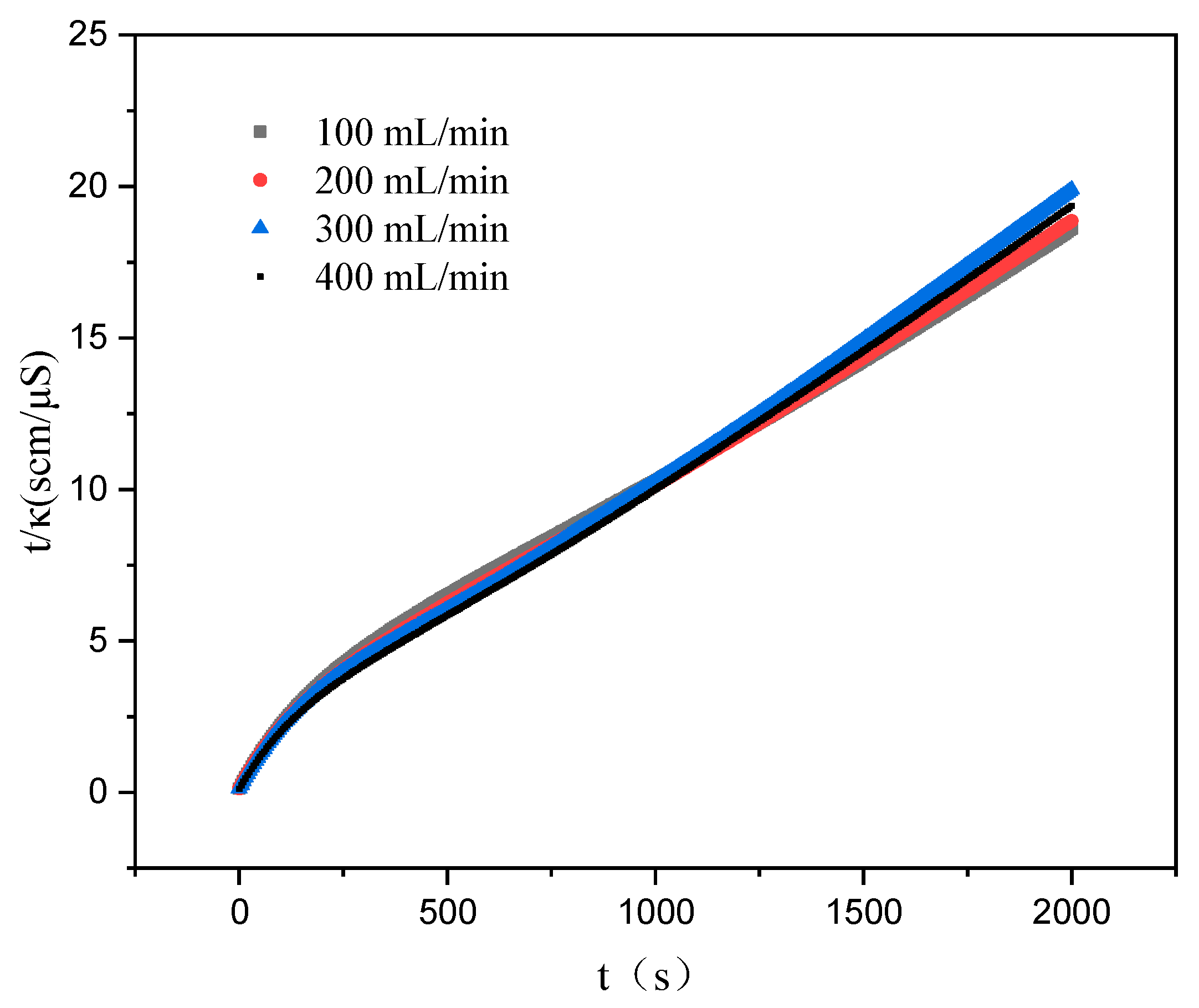

2.6. Reaction Kinetics of DMDBA

3. Materials and Methods

3.1. Reagents and Instruments

3.2. Synthesis

- (1)

- Dodecylamine and 1,4-dibromobutane were added in a substance ratio of 2.5:1 into a three-mouth flask containing ethanol as the solvent, then the mixture was stirred and refluxed for several hours by heating. The reaction equation is shown in Scheme 1. When the reaction is completed, the reaction mixture was cooled to room temperature, and then filtered to obtain the crude product. Afterward, the crude product was washed with ethanol and deionized water multiple times, and then dissolved into an appropriate amount of dichloromethane; when it was dissolved, 20 wt% NaOH solution was added, and then the mixture was transferred into a liquid separation funnel and left for separation, and the lower layer was collected and evaporated in a rotary evaporator before drying in a vacuum. The yield of the first step is 40~50%.

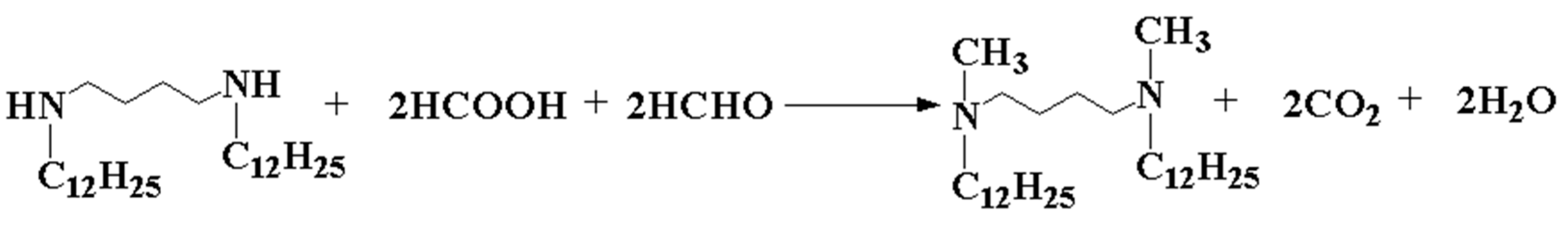

- (2)

- The product of the first step, formic acid and formaldehyde were added in a substance ratio of 1:6:3 into a three-neck flask containing ethanol as the solvent. Then, the mixture was stirred and refluxed for several hours with heating. The reaction equation is shown in Scheme 2. When the reaction was completed, the reaction mixture was cooled to room temperature, and a 20 wt% NaOH solution was added for pH adjustment to pH = 10–12. Then, the mixture was transferred to the separation funnel and left for stratification. The upper layer was collected and evaporated in a rotary evaporator to yield the final product. The second step’s yield is more than 90%.

3.3. Performance Test

3.3.1. Switching Performance

3.3.2. Surface Properties

3.3.3. Wettability

3.3.4. Emulsification/Demulsification Performance

3.4. Reaction Kinetics

4. Conclusions

- (1)

- A kind of CO2-switchable Gemini surfactant, N,N′-dimethyl-N,N′-didodecyl butylene diamine (DMDBA), was synthesized, which enriched the types of switchable Gemini surfactants. Compared with the single-chain surfactant, the CMC of DMDBA surfactant is 1.45 × 10−4 mol/L, which is an order of magnitude lower than that of ordinary surfactants, and the surface tension at the CMC (γCMC) is 33.4 mN·m−1, indicating a more excellent surface activity of the surfactant. Furthermore, the surfactant takes into account the dual effects of emulsion stabilization and simple demulsification. The experimental results show that the introduction of the switchable surfactant during the preparation of an emulsion can save resources and reduce costs. Therefore, the DMDBA surfactant is expected to have promising applications in oil–water separation and other fields.

- (2)

- The process of generating the surfactant by injecting CO2 into tertiary amine follows a second-order kinetic equation, with a correlation coefficient greater than 0.9950. It was found that the reaction rate increased with an increase in the injection speed of CO2; an appropriate increase in temperature was also conducive to accelerating the reaction, although it reduced the degree of protonation; the activation energy was Ea = 91.16 kJ/mol during the formation of the surfactant. This paper provides a theoretical basis for an in-depth understanding of the action mechanism and subsequent applications of switchable tertiary amine surfactants.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mirarefi, P.; Lee, C.T., Jr. Photo-induced unfolding and inactivation of bovine carbonic anhy-drase in the presence of a photoresponsive surfactant. Biochim. Biophys. Acta (BBA)-Proteins Proteom. 2010, 1804, 106–114. [Google Scholar] [CrossRef] [PubMed]

- Alava, C.; Saunders, B.R. Temperature-responsive emulsions: The effect of added surfactant. Colloids Surf. A Physicochem. Eng. Asp. 2005, 270, 18–25. [Google Scholar] [CrossRef]

- Gallardo, B.S.; Hwa, M.J.; Abbott, N.L. In situ and reversible control of the surface activity of ferrocenyl surfactants in aqueous solutions. Langmuir 1995, 11, 4209–4212. [Google Scholar] [CrossRef]

- Lu, Y.; Sun, D.; Ralston, J.; Liu, Q.; Xu, Z. CO2-responsive surfactants with tunable switching pH. Colloid Interface Sci. 2019, 557, 185–195. [Google Scholar] [CrossRef] [PubMed]

- Kong, W.; Guo, S.; Wu, S.; Liu, X.; Zhang, Y. Redox-controllable interfacial properties of zwitterionic surfactant featuring selenium atoms. Langmuir 2016, 32, 9846–9853. [Google Scholar] [CrossRef]

- Zhai, Z.; Ye, S.; Yan, X.; Song, Z.; Shang, S.; Rao, X.; Song, J. pH-responsive wor mLike micelles formed by an anionic surfactant derived from rosin. J. Agric. Food Chem. 2020, 68, 10063–10070. [Google Scholar] [CrossRef]

- Sui, H.; Xu, L.; Li, X.; He, L. Understanding the roles of switchable-hydrophilicity tertiary amines in recovering heavy hydrocarbons from oil sands. Chem. Eng. J. 2016, 290, 312–318. [Google Scholar] [CrossRef]

- Xu, D.; Lu, H.; Liu, D.; Li, X. CO2-switchable surfactant-free microemulsion consisted of N, N-dimethylcyclohexylamine, ethanol and water. Dispers. Sci. Technol. 2020, 41, 117–124. [Google Scholar] [CrossRef]

- Lu, H.S.; He, Y.; Huang, Z.Y. Foaming Properties of CO2-Triggered Surfactants for Switchable Foam Control. Dispers. Sci. Technol. 2014, 35, 832–839. [Google Scholar] [CrossRef]

- Fowler, C.I.; Jessop, P.G.; Cunningham, M.F. Aryl Amidine and Tertiary Amine Switchable Surfactants and Their Application in the Emulsion Polymerization of Methyl Methacrylate. Macromolecules 2012, 45, 2955–2962. [Google Scholar] [CrossRef]

- Liu, J.; Xie, J.C.; Chen, J.F.; Xu, Y.; Sun, J.W. Research progress and application of CO2 switching solvents and surfactants. Environ. Prot. Oil Gas Fields 2019, 29, 9–13+75. [Google Scholar]

- Liu, Y.; Jessop, P.G.; Cunningham, M.; Eckert, C.A.; Liotta, C.L. Switchable surfactants. Science 2006, 313, 958. [Google Scholar] [CrossRef]

- Jiang, J.; Zhu, Y.; Cui, Z.; Binks, B.P. Switchable Pickering Emulsions Stabilized by Silica Nanoparticles Hydrophobized In Situ with a Switchable Surfactant. Angew. Chem. 2013, 125, 12599–12602. [Google Scholar] [CrossRef]

- Qin, Y.; Ji, J.L.; Yao, S.P.; Wang, Y.; Peng, Y.G. Research progress of switching surfactants. Dly. Chem. Ind. 2009, 39, 191–195. [Google Scholar]

- Chen, S.Y.; Zhang, W.; Wang, C.X. Mechanism and properties of alkyl guanidine switch Controlled cyclic coating foam dyeing. J. Text. Sci. 2015, 36, 71–76. [Google Scholar]

- Scott, L.M.; Robert, T.; Harjani, J.R.; Jessop, P.G. Designing the head group of CO2-triggered switchable surfactants. RSC Adv. 2012, 2, 4925–4931. [Google Scholar] [CrossRef]

- Xue, Z.; Zhang, J.; Peng, L.; Li, J.; Mu, T.; Han, B.; Yang, G. Nanosized Poly(ethylene glycol) Domains within Reverse Micelles Formed in CO2. Angew. Chem. Int. Ed. 2012, 51, 12325–12329. [Google Scholar] [CrossRef]

- Cui, Z. Synthesis and Application of Guanidine Switching Surfactants. Master’s Thesis, Jiangnan University, Wuxi, China, 2012. [Google Scholar]

- Zhang, Y.; Chu, Z.; Dreiss, C.A.; Wang, Y.; Fei, C.; Feng, Y. Smart wormLike micelles switched by CO2 and air. Soft Matter 2013, 9, 6217–6221. [Google Scholar] [CrossRef]

- Huang, H.; Huang, X.; Quan, H.; Su, X. Soybean-oil-based CO2-switchable surfactants with multiple heads. Molecules 2021, 26, 4342. [Google Scholar] [CrossRef]

- Yan, X.; Huang, X.; Zhai, Z.; Song, Z.; Shang, S.; Cai, Z. Emulsions stabilized by a CO2 -switchable surfactant based on rigid rosin with or without charged nanoparticles. Mol. Liq. 2022, 352, 118730. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, Y.; Wang, Y.; Li, X. CO2–switchable viscoelastic fluids based on a pseudo gemini surfactant. Langmuir 2013, 29, 4187. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Ren, G.; Yang, J.; Xu, Z.; Sun, D. CO2-responsive aqueous foams stabilized by pseudo gemini surfactants. J. Colloid Interface Sci. 2018, 536, 381–388. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Zhang, M.; Lu, Z.; Jin, Z.; Lu, Y.; Sun, D.; Xu, Z. Molecular structure-tuned stability and switchability of CO2-responsive oil-in-water emulsions. Colloid Interface Sci. 2022, 627, 661–670. [Google Scholar] [CrossRef]

- Mei, P.; Min, H.B.; Lai, L.; Yang, Y.L.; Wu, X.M.; Zheng, Y.C. Research progress on synthesis and application of CO2 switching surfactants. Oilfield Chem. 2016, 33, 564–570. [Google Scholar]

- Suo, Y.X. Effect of Amine Structure on Stability and Demulsification of CO2 Switched Emulsion. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2018. [Google Scholar]

- Zhang, X.G. Determination of critical micelle concentration of surfactant by surface tension Method and conductivity method. Chem. Educ. 2021, 42, 134–136. [Google Scholar]

- Zheng, Z.B. Synthesis of CO2 Switchable Surfactants and Regulation of Emulsions and Vesicles. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2015. [Google Scholar]

- Chen, C.; Luan, H.; Lei, Z.; Li, L.; Feng, Z.; Zhang, D.; Su, X.; Feng, Y. Lauroyl arginate ethyl: A novel bio-based CO2-switchable surfactant. J. Surfactants Deterg. 2023, 26, 761–769. [Google Scholar] [CrossRef]

- Li, C.P.; Li, Z.X.; Zhang, J.H.; Yang, S.C.; Hany, M.A.; Sun, M.Y.; Xia, C. Research progress of highly active amphoteric Gemini surfactants. Appl. Chem. Ind. 2019, 48, 2235–2241. [Google Scholar]

- Yumnam, D.G.; Ajmal, P.K.; Jackson, G. Research Progress on the Synthesis of Different Types of Gemini Surfactants with a Functionalized Hydrophobic Moiety and Spacer. ChemistrySelect 2022, 7, e202203485. [Google Scholar]

- Zhou, M.; Wang, G.; Xu, Y.; Zhang, Z.; Li, S.; Hu, B.; Zhao, Y. Synthesis and Performance Evaluation of CO2/N2 Switchable Tertiary Amine Gemini Surfactant. Surfactants Deterg. 2017, 20, 1483–1489. [Google Scholar] [CrossRef]

- Liu, K. The effect of cationic and zwitterionic surfactants on contact angle at quartz. J. Petrochem. Univ. 2013, 26, 55–59. [Google Scholar]

- Yuan, F.Q.; Liu, D.D.; Guo, L.L.; Zhu, Y.W.; Xu, Z.C.; Huang, J.B.; Zhang, L.; Zhang, L. Effect of branched cationic and betaine surfactants on the wettability of a poly(tetrafluoroethylene) surface. Acta Phys.-Chim. Sin. 2015, 31, 715–721. [Google Scholar]

- Jiang, C.Y. Preparation and Properties of CO2-Triggered Reversible Microemulsion. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2018. [Google Scholar]

- Pawel, W.; Maria, P. Surface properties of cationic-nonionic mixed surfactant systems. Colloids Surf. A Physicochem. Eng. Asp. 2004, 245, 75–79. [Google Scholar]

- Chen, L.; Hu, Z.Y.; Zhu, H.L. Synthesis of Cleavable Aryl Sulfonate anionic surfactants and a study of their surface activity. J. Surfactants Deterg. 2008, 11, 97–102. [Google Scholar] [CrossRef]

- Milton, J.R.o.s.e.n.; Joy, T.K. Surfactants and Interfacial Phenomena, 4th ed.; Wiley: New York, NY, USA, 2012. [Google Scholar]

| Surfactant | CMC/ mol/L | γCMC/ mN·m−1 | Γmax/ μmol·m−2 | Amin/ nm2 | pC20 |

|---|---|---|---|---|---|

| Dodecyl dimethyl tertiary amine bicarbonate (C12A) | 7.41 × 10−3 | 35.6 | 1.34 | 1.24 | 3.21 |

| N,N′-dimethyl-N,N′-didodecyl butylene diamine bicarbonate (DMDBAH) | 1.45 × 10−4 | 33.4 | 1.49 | 1.11 | 4.94 |

| Concentration | 0.1 wt% | 0.2 wt% | 0.4 wt% | 0.6 wt% | |

|---|---|---|---|---|---|

| Time | |||||

| 10 min | 1.0 mL | 0.5 mL | 0.0 mL | 0.0 mL | |

| 30 min | 2.0 mL | 1.0 mL | 0.7 mL | 0.7 mL | |

| 1 h | 4.0 mL | 2.0 mL | 1.8 mL | 1.5 mL | |

| 2 h | 6.0 mL | 3.0 mL | 2.8 mL | 2.5 mL | |

| 3 h | 8.0 mL | 4.5 mL | 3.5 mL | 3.0 mL | |

| 24 h | 14.0 mL | 13.0 mL | 10.5 mL | 10.0 mL | |

| Temperature /°C | Second-Order Reaction | k | Fitting Value of κ0 | Experiment Value of κ0 | Error of κ0 | ||

|---|---|---|---|---|---|---|---|

| Slope | Intercept | R2 | /(μS·cm−1·s−1) | /(μS·cm−1) | /(μS·cm−1) | % | |

| 25 | 0.0085 | 0.8650 | 0.9959 | 8.35 × 10−5 | 117.6 | 106.4 | 9.5 |

| 35 | 0.0116 | 0.6285 | 0.9951 | 2.14 × 10−4 | 86.2 | 79.6 | 7.6 |

| 45 | 0.0156 | 0.5092 | 0.9982 | 4.78 × 10−4 | 64.1 | 61.1 | 3 |

| 55 | 0.0194 | 0.2002 | 0.9998 | 1.88 × 10−3 | 51.54 | 50.3 | 2.4 |

| Gas Velocity /(mL/min) | Second-Order Reaction | k | Fitting Value of κ0 | Experiment Value of κ0 | Error of κ0 | ||

|---|---|---|---|---|---|---|---|

| Slope | Intercept | R2 | /(μS·cm−1·s−1) | /(μS·cm−1) | /(μS·cm−1) | % | |

| 100 | 0.0083 | 1.9022 | 0.9950 | 3.62 × 10−5 | 120.5 | 107.8 | 10.5 |

| 200 | 0.0085 | 1.6117 | 0.9970 | 4.49 × 10−5 | 117.6 | 106.3 | 9.6 |

| 300 | 0.0091 | 1.2484 | 0.9979 | 6.63 × 10−5 | 109.9 | 100.8 | 8.2 |

| 400 | 0.0090 | 1.1357 | 0.9984 | 7.13 × 10−5 | 111.1 | 103.6 | 6.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Tang, X.; Yang, P.; Zhang, Y.; Liu, J. Synthesis and Kinetics of CO2-Responsive Gemini Surfactants. Molecules 2024, 29, 4166. https://doi.org/10.3390/molecules29174166

Li Y, Tang X, Yang P, Zhang Y, Liu J. Synthesis and Kinetics of CO2-Responsive Gemini Surfactants. Molecules. 2024; 29(17):4166. https://doi.org/10.3390/molecules29174166

Chicago/Turabian StyleLi, Yao, Xinyu Tang, Pujiang Yang, Yuhui Zhang, and Jinhe Liu. 2024. "Synthesis and Kinetics of CO2-Responsive Gemini Surfactants" Molecules 29, no. 17: 4166. https://doi.org/10.3390/molecules29174166

APA StyleLi, Y., Tang, X., Yang, P., Zhang, Y., & Liu, J. (2024). Synthesis and Kinetics of CO2-Responsive Gemini Surfactants. Molecules, 29(17), 4166. https://doi.org/10.3390/molecules29174166