High-Density Capacitive Energy Storage in Low-Dielectric-Constant Polymer PMMA/2D Mica Nanofillers Heterostructure Composite

Abstract

:1. Introduction

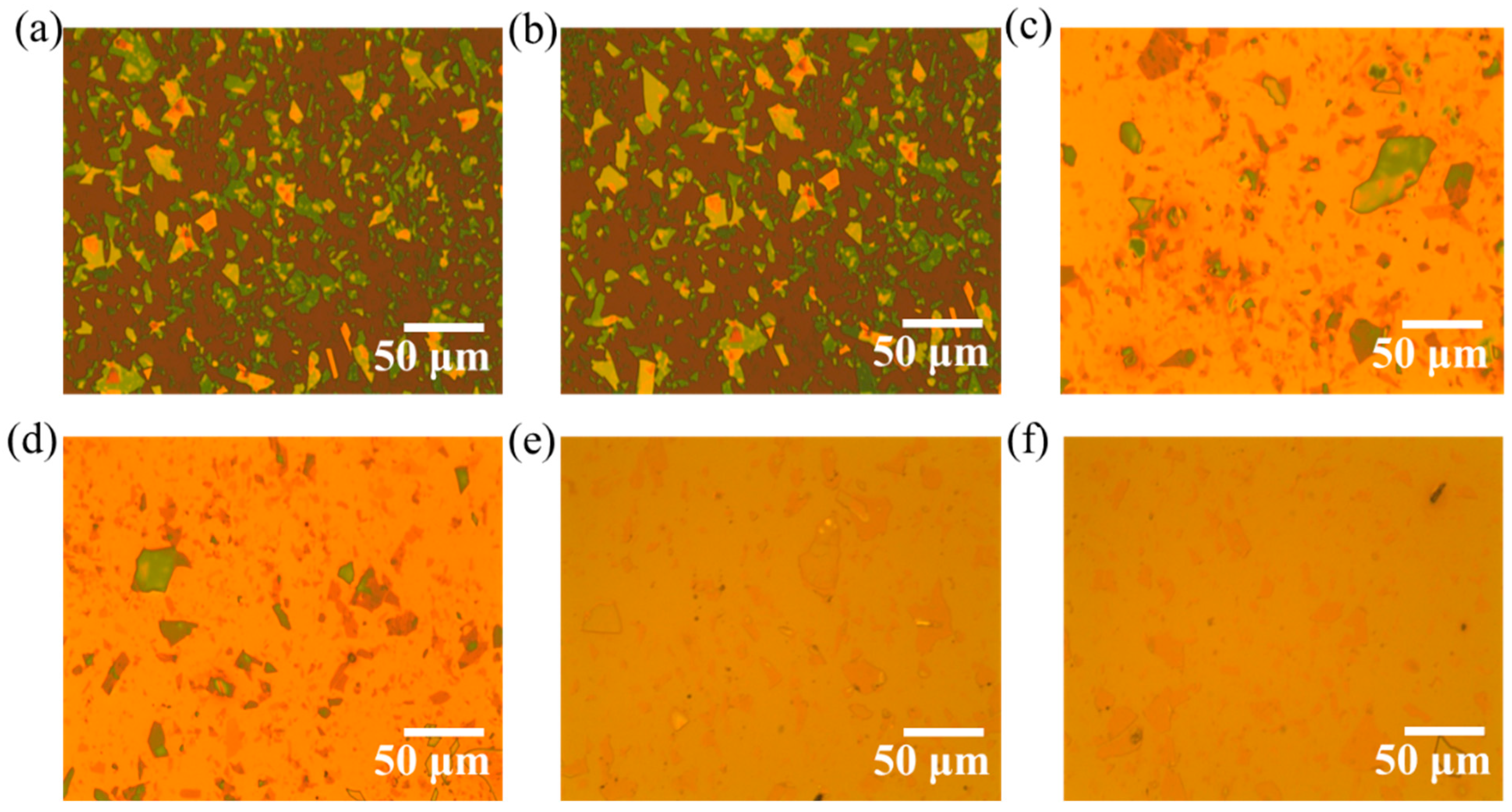

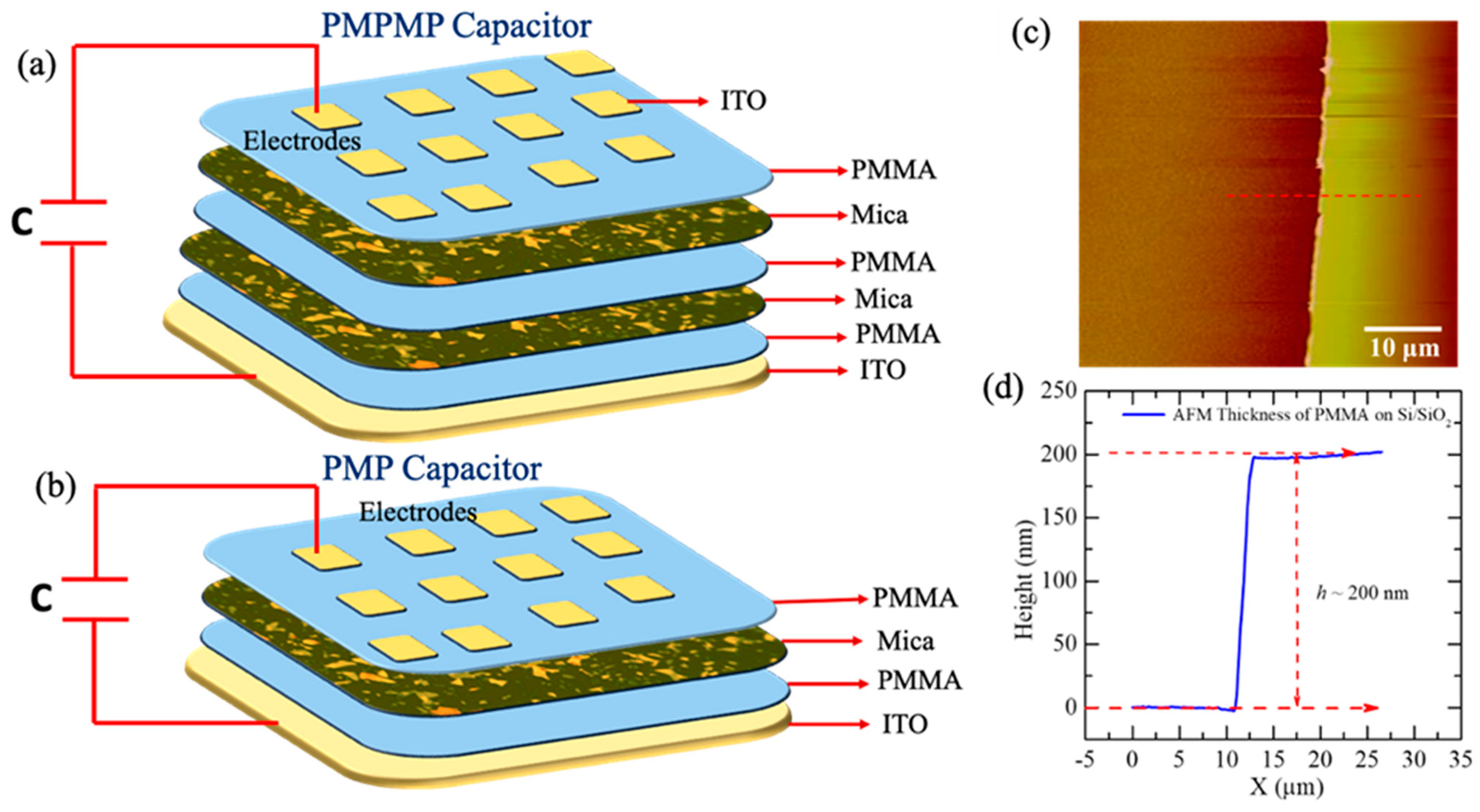

2. Results and Discussion

3. Materials and Methods

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kebede, A.A.; Kalogiannis, T.; Van Mierlo, J.; Berecibar, M. A comprehensive review of stationary energy storage devices for large scale renewable energy sources grid integration. Renew. Sustain. Energy Rev. 2022, 159, 112213. [Google Scholar] [CrossRef]

- Kadam, S.A.; Kadam, K.P.; Pradhan, N.R. Pradhan, Advancements in 2D MXene-based supercapacitor electrodes: Synthesis, mechanisms, electronic structure engineering, flexible wearable energy storage for real-world applications, and future prospects. J. Mater. Chem. A 2024, 12, 17992–18046. [Google Scholar] [CrossRef]

- Kadam, S.A.; Ma, Y.-R.; Chen, Y.-R.; Navale, Y.H.; Salunkhe, A.S.; Patil, V.B.; Ralegankar, S.D.; More, P.D. Mn-Incorporated α-Fe2O3 Nanostructured Thin Films: Facile Synthesis and Application as a High-Performance Supercapacitor. J. Electron. Mater. 2023, 52, 500–513. [Google Scholar] [CrossRef]

- Zhang, M.; Du, H.; Wei, Z.; Zhang, X.; Wang, R. Ultrafast Microwave Synthesis of Nickel-Cobalt Sulfide/Graphene Hybrid Electrodes for High-Performance Asymmetrical Supercapacitors. ACS Appl. Energy Mater. 2021, 4, 8262–8274. [Google Scholar] [CrossRef]

- Zhang, M.; Nautiyal, A.; Du, H.; Wei, Z.; Zhang, X.; Wang, R. Electropolymerization of polyaniline as high-performance binder free electrodes for flexible supercapacitor. Electrochim. Acta 2021, 376, 138037. [Google Scholar] [CrossRef]

- Feng, Q.-K.; Zhong, S.-L.; Pei, J.-Y.; Zhao, Y.; Zhang, D.-L.; Liu, D.-F.; Zhang, Y.-X.; Dang, Z.-M. Recent Progress and Future Prospects on All-Organic Polymer Dielectrics for Energy Storage Capacitors. Chem. Rev. 2022, 122, 3820–3878. [Google Scholar] [CrossRef]

- Yang, C.; Wei, H.; Guan, L.; Guo, J.; Wang, Y.; Yan, X.; Zhang, X.; Wei, S.; Guo, Z. Polymer nanocomposites for energy storage, energy saving, and anticorrosion. J. Mater. Chem. A 2015, 3, 14929–14941. [Google Scholar] [CrossRef]

- Arunachalam, P. 6-Polymer-based nanocomposites for energy and environmental applications, In Polymer-Based Nanocomposites for Energy and Environmental Applications; Jawaid, M., Khan, M.M., Eds.; Woodhead Publishing: Sawston, UK, 2018; pp. 185–203. [Google Scholar]

- Bera, S.; Singh, M.; Thantirige, R.; Tiwary, S.K.; Shook, B.T.; Nieves, E.; Raghavan, D.; Karim, A.; Pradhan, N.R. 2D-Nanofiller-Based Polymer Nanocomposites for Capacitive Energy Storage Applications. Small Sci. 2023, 3, 2300016. [Google Scholar] [CrossRef]

- Singh, M.; Das, P.; Samanta, P.N.; Bera, S.; Thantirige, R.; Shook, B.; Nejat, R.; Behera, B.; Zhang, Q.; Dai, Q.; et al. Ultrahigh Capacitive Energy Density in Stratified 2D Nanofiller-Based Polymer Dielectric Films. ACS Nano 2023, 17, 20262–20272. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhu, Y.; Huang, X.; Chen, J.; Li, Q.; He, J.; Jiang, P. High Energy Density Polymer Dielectrics Interlayered by Assembled Boron Nitride Nanosheets. Adv. Energy Mater. 2019, 9, 1901826. [Google Scholar] [CrossRef]

- Li, H.; Ren, L.; Zhou, Y.; Yao, B.; Wang, Q. Recent progress in polymer dielectrics containing boron nitride nanosheets for high energy density capacitors. High Volt. 2020, 5, 365–376. [Google Scholar] [CrossRef]

- Liu, F.; Li, Q.; Li, Z.; Dong, L.; Xiong, C.; Wang, Q. Ternary PVDF-based terpolymer nanocomposites with enhanced energy density and high power density. Compos. Part A Appl. Sci. Manuf. 2018, 109, 597–603. [Google Scholar] [CrossRef]

- Likhi, F.H.; Singh, M.; Chavan, S.V.; Cao, T.; Shanbedi, M.; Karim, A. Effects of Film Confinement on Dielectric and Electrical Properties of Graphene Oxide and Reduced Graphene Oxide-Based Polymer Nanocomposites: Implications for Energy Storage. ACS Appl. Nano Mater. 2023, 6, 11699–11714. [Google Scholar] [CrossRef]

- Ji, M.; Min, D.; Li, Y.; Yang, L.; Wu, Q.; Liu, W.; Li, S. Improved energy storage performance of polyimide nanocomposites by constructing the meso- and macroscopic interfaces. Mater. Today Energy 2023, 31, 101200. [Google Scholar] [CrossRef]

- Xie, B.; Wang, Q.; Zhang, Q.; Liu, Z.; Lu, J.; Zhang, H.; Jiang, S. High Energy Storage Performance of PMMA Nanocomposites Utilizing Hierarchically Structured Nanowires Based on Interface Engineering. ACS Appl. Mater. Interfaces 2021, 13, 27382–27391. [Google Scholar] [CrossRef] [PubMed]

- Yao, L.; Pan, Z.; Liu, S.; Zhai, J.; Chen, H.H.D. Significantly Enhanced Energy Density in Nanocomposite Capacitors Combining the TiO2 Nanorod Array with Poly(vinylidene fluoride). ACS Appl. Mater. Interfaces 2016, 8, 26343–26351. [Google Scholar] [CrossRef]

- Pan, Z.; Yao, L.; Zhai, J.; Shen, B.; Liu, S.; Wang, H.; Liu, J. Excellent energy density of polymer nanocomposites containing BaTiO3@Al2O3 nanofibers induced by moderate interfacial area. J. Mater. Chem. A 2016, 4, 13259–13264. [Google Scholar] [CrossRef]

- Jia, Q.; Huang, X.; Wang, G.; Diao, J.; Jiang, P. MoS2 Nanosheet Superstructures Based Polymer Composites for High-Dielectric and Electrical Energy Storage Applications. J. Phys. Chem. C 2016, 120, 10206–10214. [Google Scholar] [CrossRef]

- McPherson, J.; Kim, J.; Shanware, A.; Mogul, H.; Rodriguez, J. Proposed universal relationship between dielectric breakdown and dielectric constant. In Digest. International Electron Devices Meeting; IEEE: San Francisco, CA, USA, 2002; pp. 633–636. [Google Scholar]

- Peng, S.; Du, X.; Liang, Z.; Ma, M.; Guo, Y.; Xiong, L. Multilayer polymer nanocomposites based on interface engineering for high-performance capacitors. J. Energy Storage 2023, 60, 106636. [Google Scholar] [CrossRef]

- Chen, X.; Tseng, J.-K.; Treufeld, I.; Mackey, M.; Schuele, D.E.; Li, R.; Fukuto, M.; Baer, E.; Zhu, L. Enhanced dielectric properties due to space charge-induced interfacial polarization in multilayer polymer films. J. Mater. Chem. C 2017, 5, 10417–10426. [Google Scholar] [CrossRef]

- Rahimabady, M.; Lu, L.; Yao, K. Nanocomposite multilayer capacitors comprising BaTiO3@TiO2 and poly(vinylidene fluoride-hexafluoropropylene) for dielectric-based energy storage. J. Adv. Dielectr. 2014, 4, 1450009. [Google Scholar] [CrossRef]

- Li, W.; Song, Z.; Zhong, J.; Qian, J.; Tan, Z.; Wu, X.; Chu, H.; Nie, W.; Ran, X. Multilayer-structured transparent MXene/PVDF film with excellent dielectric and energy storage performance. J. Mater. Chem. C 2019, 7, 10371–10378. [Google Scholar] [CrossRef]

- Zulkifli, A. Polymer Dielectric Materials. In Dielectric Material; Marius Alexandru, S., Ed.; IntechOpen: Rijeka, Croatia, 2012; p. 314. [Google Scholar]

- Bera, S.; Thantirige, R.M.; Wu, J.; Davidson, E.C.; Kadam, S.A.; Sumant, A.V.; Shook, B.T.; Rao, R.; Selhorst, R.; Singh, M.; et al. Enhanced Energy Density in a Heterostructure Capacitor of Multilayered PVDF and 2D Mica Nanocomposites. ACS Appl. Electron. Mater. 2024, 6, 6582–6590. [Google Scholar] [CrossRef]

- Weeks, J.J.R. The Dielectric Constant of Mica. Phys. Rev. 1922, 19, 319–322. [Google Scholar] [CrossRef]

- Pei, J.; Yin, L.; Zhong, S.; Dang, Z. Suppressing the Loss of Polymer-Based Dielectrics for High Power Energy Storage. Adv. Mater 2022, 35, 2203623. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.; Yuan, Q.; Xu, X.; Niu, Y.; Wang, Q.; Wang, H. Multilayered ferroelectric polymer films incorporating low-dielectric-constant components for concurrent enhancement of energy density and charge–discharge efficiency. Nano Energy 2018, 54, 288–296. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, J.; Li, Y.; Niu, Y.; Wang, Q.; Wang, H. Multilayered hierarchical polymer composites for high energy density capacitors. J. Mater. Chem. A 2019, 7, 2965–2980. [Google Scholar] [CrossRef]

- Bai, H.; Zhu, K.; Wang, Z.; Shen, B.; Zhai, J. 2D Fillers Highly Boost the Discharge Energy Density of Polymer-Based Nanocomposites with Trilayered Architecture. Adv. Funct. Mater. 2021, 31, 2102646. [Google Scholar] [CrossRef]

- Liu, Y.; Luo, H.; Xie, H.; Xiao, Z.; Wang, F.; Jiang, X.; Zhou, X.; Zhang, D. Trilayer PVDF nanocomposites with significantly enhanced energy density and energy efficiency using 0.55Bi0.5Na0.5TiO3-0.45(Sr0.7Bi0.2) TiO3 nanofibers. Microstructures 2023, 3, 2023008. [Google Scholar]

- Li, Z.; Shen, Z.; Yang, X.; Zhu, X.; Zhou, Y.; Dong, L.; Xiong, C.; Wang, Q. Ultrahigh charge-discharge efficiency and enhanced energy density of the sandwiched polymer nanocomposites with poly(methyl methacrylate) layer. Compos. Sci. Technol. 2020, 202, 108591. [Google Scholar] [CrossRef]

- More, P.; Kadam, S.A.; Ma, Y.; Chen, Y.; Tarwal, N.; Navale, Y.; Salunkhe, A.; Patil, V. Spray Synthesized Mn-doped CuO Electrodes for High Performance Supercapacitor. ChemistrySelect 2022, 7, e202202504. [Google Scholar] [CrossRef]

- Hingangavkar, G.M.; Kadam, S.A.; Ma, Y.-R.; Sartale, S.D.; Mulik, R.N.; Patil, V.B. Intercalation of two-dimensional graphene oxide in WO3 nanoflowers for NO2 sensing. Nano-Struct. Nano-Objects 2023, 34, 100964. [Google Scholar] [CrossRef]

- Hingangavkar, G.M.; Kadam, S.A.; Ma, Y.-R.; Bandgar, S.S.; Mulik, R.N.; Patil, V.B. Tailored formation of WO3-rGO nanohybrids for dependable low temperature NO2 sensing. Ceram. Int. 2023, 49, 38866–38876. [Google Scholar] [CrossRef]

- Zhang, T.; Dan, Z.; Shen, Z.; Jiang, J.; Guo, M.; Chen, B.; Lin, Y.; Nan, C.-W.; Shen, Y. An alternating multilayer architecture boosts ultrahigh energy density and high discharge efficiency in polymer composites. RSC Adv. 2020, 10, 5886–5893. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Tong, X.; Liu, Z.; Zhang, Y.; Zhang, T.; Tang, C.; Liu, X.; Chi, Q. Enhancement of Energy Storage Performance of PMMA/PVDF Composites by Changing the Crystalline Phase through Heat Treatment. Polymers 2023, 15, 2486. [Google Scholar] [CrossRef] [PubMed]

- Wen, F.; Zhu, C.; Lv, W.; Wang, P.; Zhang, L.; Li, L.; Wang, G.; Wu, W.; Ying, Z.; Zheng, X.; et al. Improving the Energy Density and Efficiency of the Linear Polymer PMMA with a Double-Bond Fluoropolymer at Elevated Temperatures. ACS Omega 2021, 6, 35014–35022. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Z.; Gao, J.; Wu, M.; Lou, X.; Hu, Y.; Li, Y.; Zhong, L. High Energy Density and Temperature Stability in PVDF/PMMA via In Situ Polymerization Blending. Front. Chem. 2022, 10, 902487. [Google Scholar] [CrossRef]

- Wu, Q.; Feng, Z.; Cai, Z.; Lan, C.; Xu, J.; Bi, K.; Hao, Y. Poly(methyl methacrylate)-based ferroelectric/dielectric laminated films with enhanced energy storage performances. Adv. Compos. Hybrid Mater. 2022, 5, 1137–1144. [Google Scholar] [CrossRef]

- Baer, E.; Zhu, L. 50th Anniversary Perspective: Dielectric Phenomena in Polymers and Multilayered Dielectric Films. Macromolecules 2017, 50, 2239–2256. [Google Scholar] [CrossRef]

- Mackey, M.; Hiltner, A.; Baer, E.; Flandin, L.; Wolak, A.; Shirk, M.; Shirk, J.S. Enhanced breakdown strength of multilayered films fabricated by forced assembly microlayer coextrusion. J. Phys. D Appl. Phys. 2009, 42, 175304. [Google Scholar] [CrossRef]

- Jiang, J.; Shen, Z.; Qian, J.; Dan, Z.; Guo, M.; He, Y.; Lin, Y.; Nan, C.-W.; Chen, L.; Shen, Y. Synergy of micro-/mesoscopic interfaces in multilayered polymer nanocomposites induces ultrahigh energy density for capacitive energy storage. Nano Energy 2019, 62, 220–229. [Google Scholar] [CrossRef]

- Xie, B.; Zhang, Q.; Zhang, L.; Zhu, Y.; Guo, X.; Fan, P.; Zhang, H. Ultrahigh discharged energy density in polymer nanocomposites by designing linear/ferroelectric bilayer heterostructure. Nano Energy 2018, 54, 437–446. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, H.; Dang, Z.; Zhan, S.; Sun, C.; Hu, G.; Lin, Y.; Yuan, Q. Multilayer Structured Poly(vinylidene fluoride)-Based Composite Film with Ultrahigh Breakdown Strength and Discharged Energy Density. ACS Appl. Mater. Interfaces 2020, 12, 22137–22145. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Liu, L.; Zhang, T.; Zhang, C.; Chen, Q.; Wang, X.; Lei, Q. PVDF-Based Dielectric Composite Films with Excellent Energy Storage Performances by Design of Nanofibers Composition Gradient Structure. ACS Appl. Energy Mater. 2018, 1, 6320–6329. [Google Scholar] [CrossRef]

- Yang, X.; Zhu, X.; Ji, L.; Hu, P.; Li, Z. Largely enhanced energy storage performance in multilayered ferroelectric polymer nanocomposites with optimized spatial arrangement of ceramic nanofillers. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106111. [Google Scholar] [CrossRef]

- Zhou, L.; Zhao, S.; Xie, P.; Miao, X.; Liu, S.; Sun, N.; Guo, M.; Xu, Z.; Zhong, T.; Shen, Y. Research progress and prospect of polymer dielectrics. Appl. Phys. Rev. 2023, 10, 031310. [Google Scholar] [CrossRef]

- Shen, Z.-H.; Wang, J.-J.; Lin, Y.; Nan, C.-W.; Chen, L.-Q.; Shen, Y. High-Throughput Phase-Field Design of High-Energy-Density Polymer Nanocomposites. Adv. Mater. 2018, 30, 1704380. [Google Scholar] [CrossRef]

- Luo, H.; Zhou, X.; Ellingford, C.; Zhang, Y.; Chen, S.; Zhou, K.; Zhang, D.; Bowen, C.R.; Wan, C. Interface design for high energy density polymer nanocomposites. Chem. Soc. Rev. 2019, 48, 4424–4465. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bera, S.; Thantirige, R.; Kadam, S.A.; Sumant, A.V.; Pradhan, N.R. High-Density Capacitive Energy Storage in Low-Dielectric-Constant Polymer PMMA/2D Mica Nanofillers Heterostructure Composite. Molecules 2024, 29, 4671. https://doi.org/10.3390/molecules29194671

Bera S, Thantirige R, Kadam SA, Sumant AV, Pradhan NR. High-Density Capacitive Energy Storage in Low-Dielectric-Constant Polymer PMMA/2D Mica Nanofillers Heterostructure Composite. Molecules. 2024; 29(19):4671. https://doi.org/10.3390/molecules29194671

Chicago/Turabian StyleBera, Sumit, Rukshan Thantirige, Sujit A. Kadam, Anirudha V. Sumant, and Nihar R. Pradhan. 2024. "High-Density Capacitive Energy Storage in Low-Dielectric-Constant Polymer PMMA/2D Mica Nanofillers Heterostructure Composite" Molecules 29, no. 19: 4671. https://doi.org/10.3390/molecules29194671