Investigation of Far Infrared Emission and UV Protection Properties of Polypropylene Composites Embedded with Candlenut-Derived Biochar for Health Textiles

Abstract

1. Introduction

2. Results and Discussion

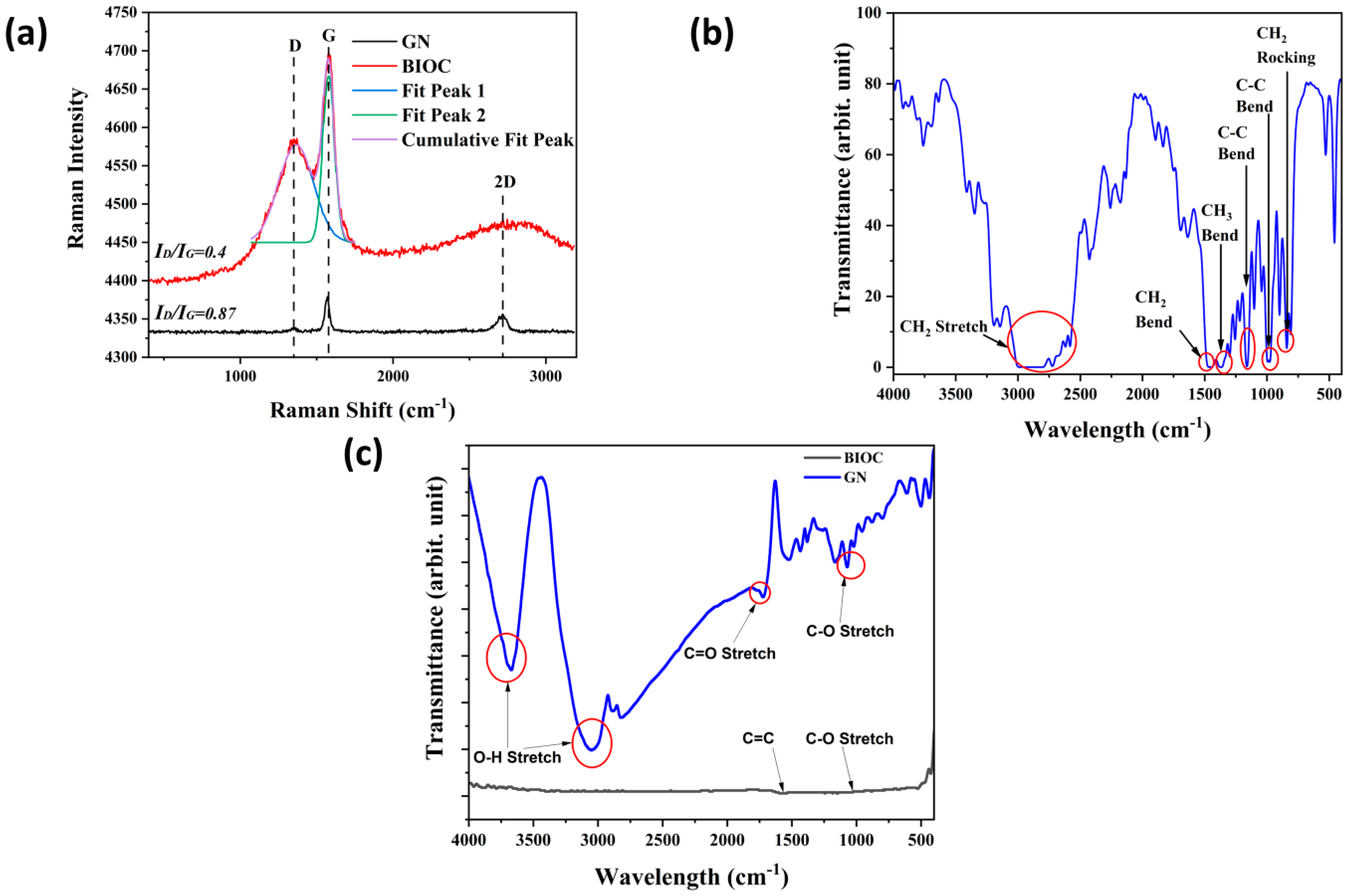

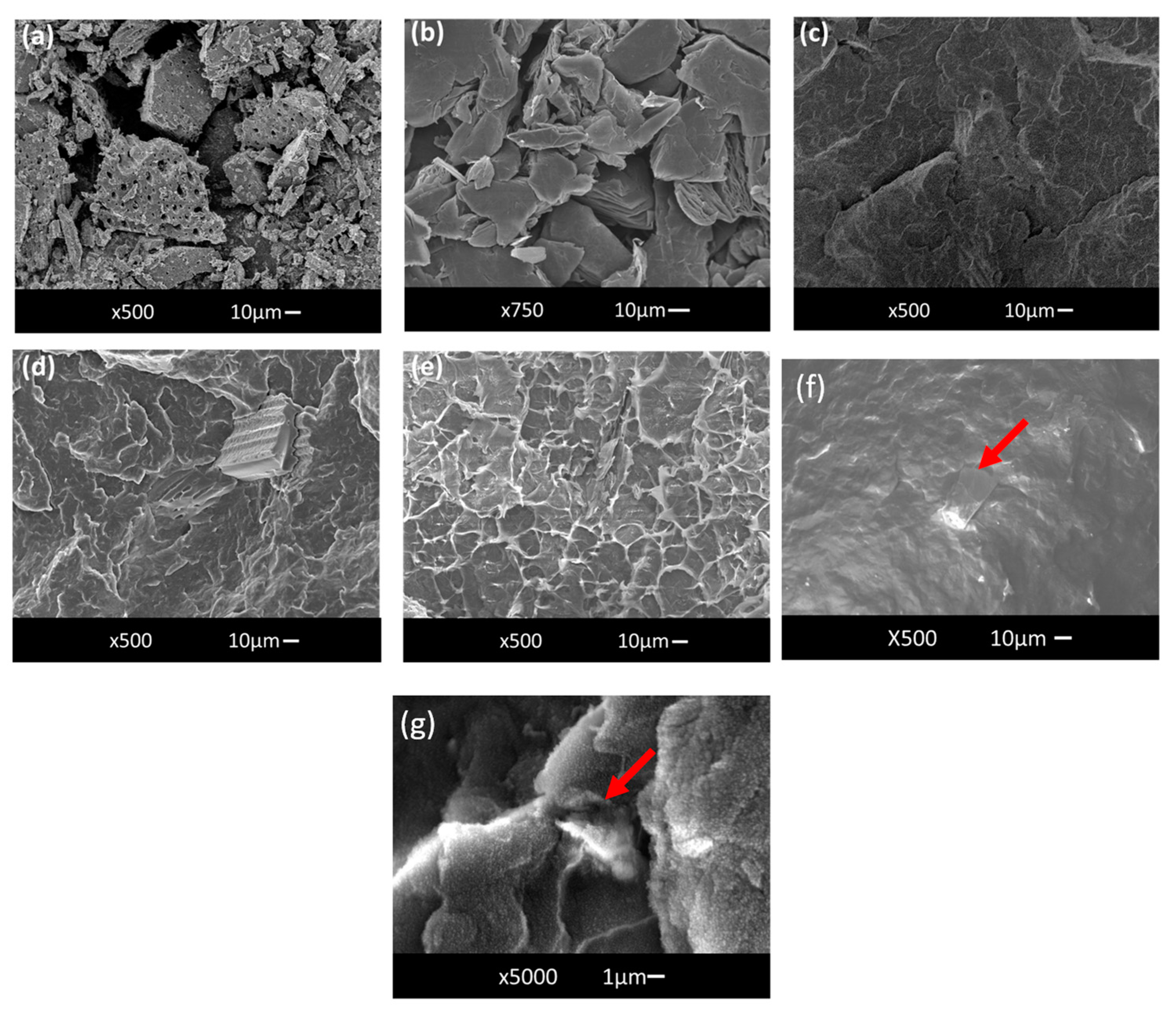

2.1. Raman and FTIR Spectra of Graphene and Biochar Composites

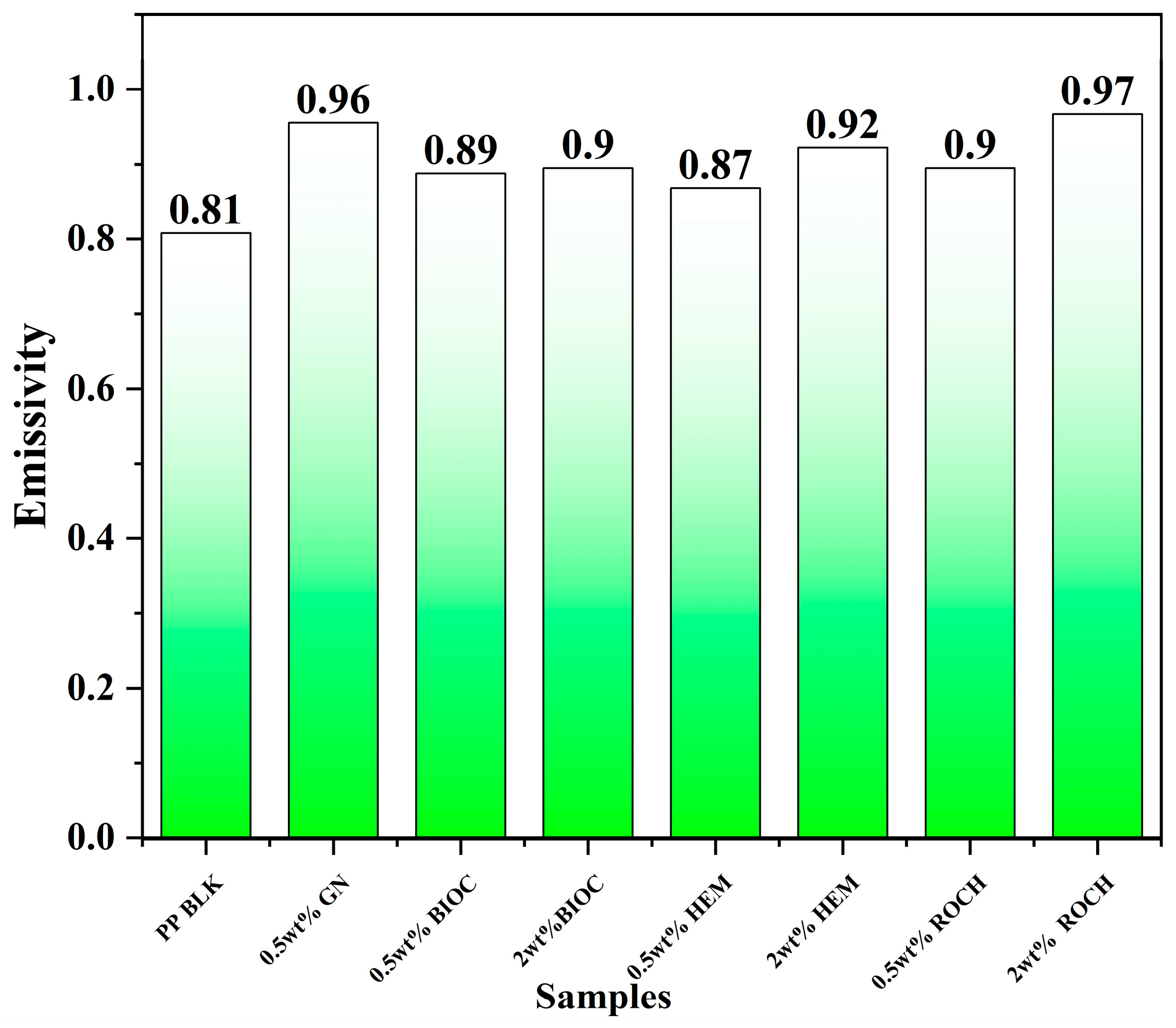

2.2. Far Infrared Emissivity of PP Films with Functional Additives

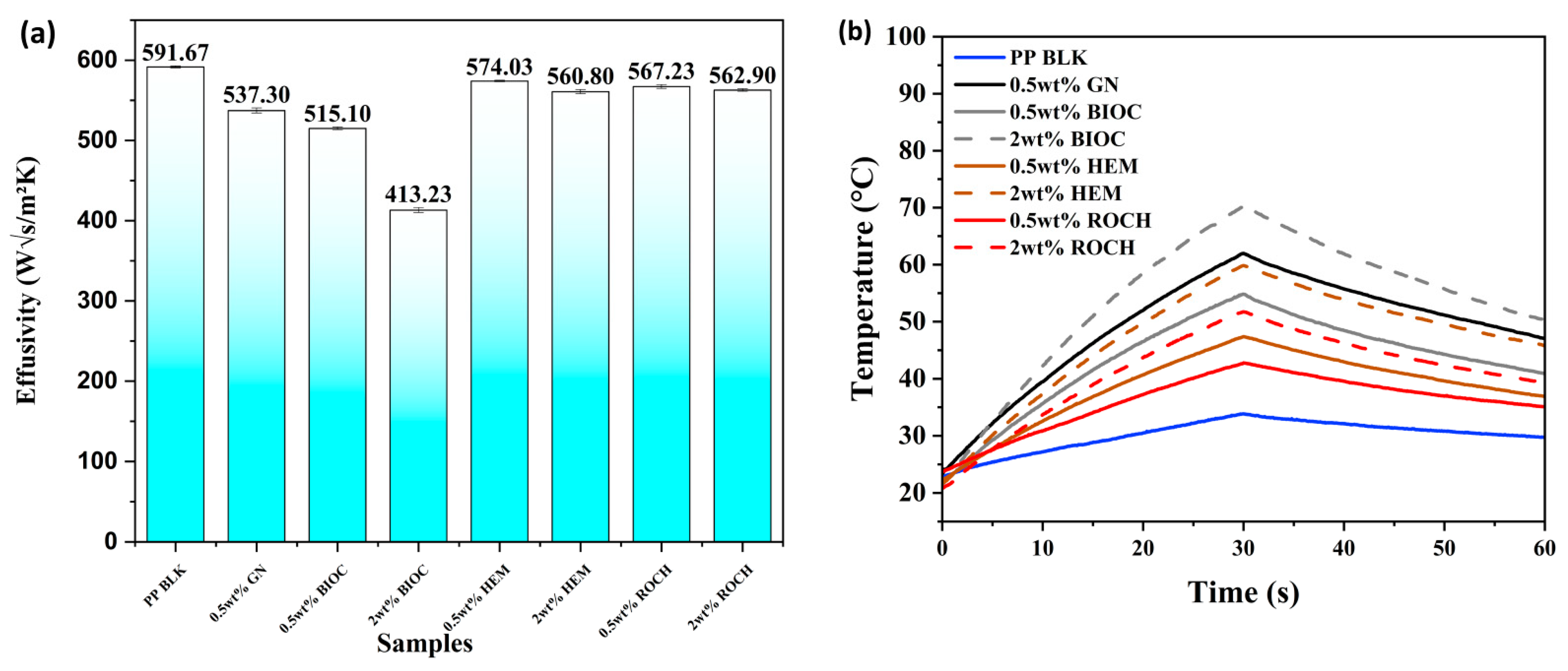

2.3. Thermal Effusivity and Heat Retention Properties of PP Films with Functional Additives

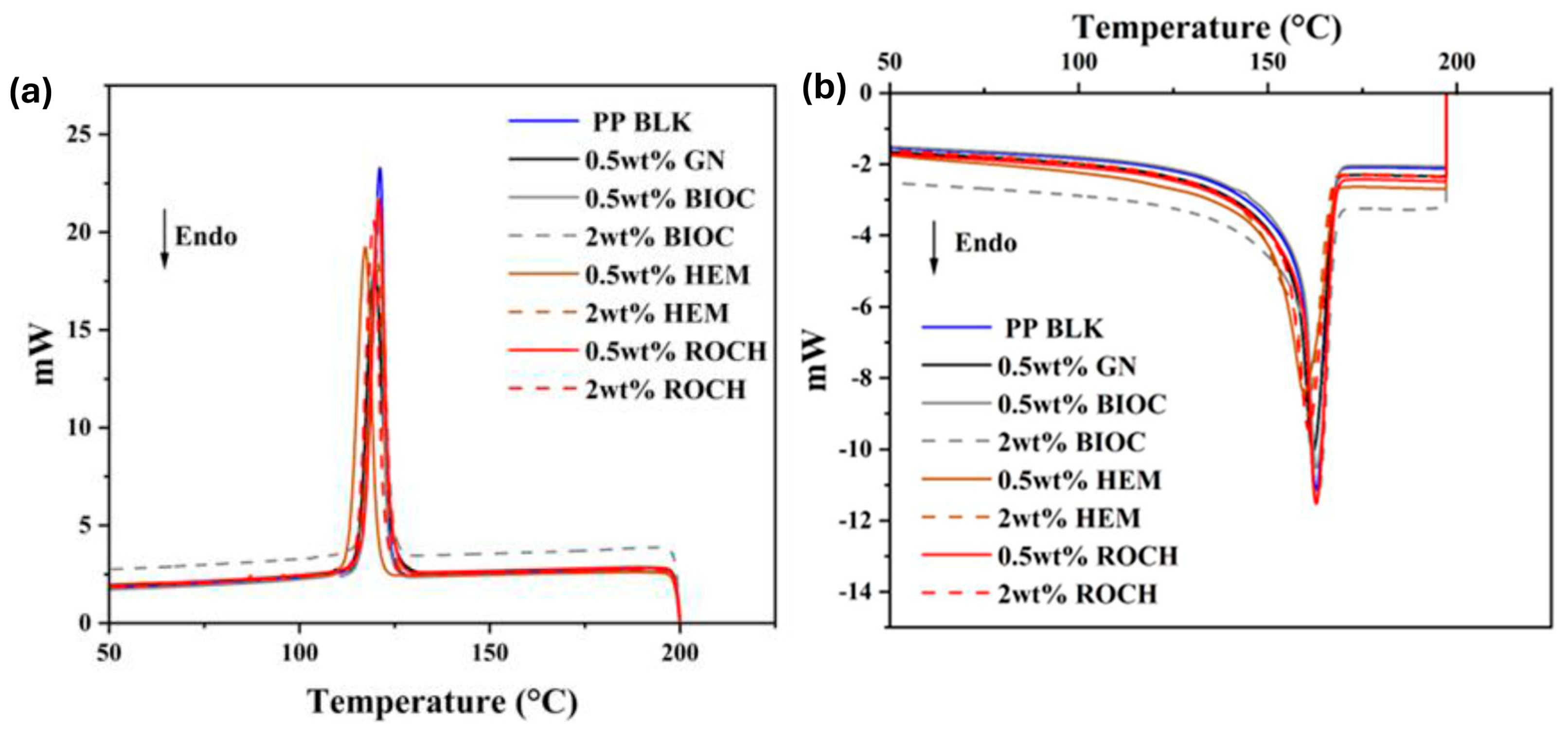

2.4. Thermal Properties by DSC Analysis

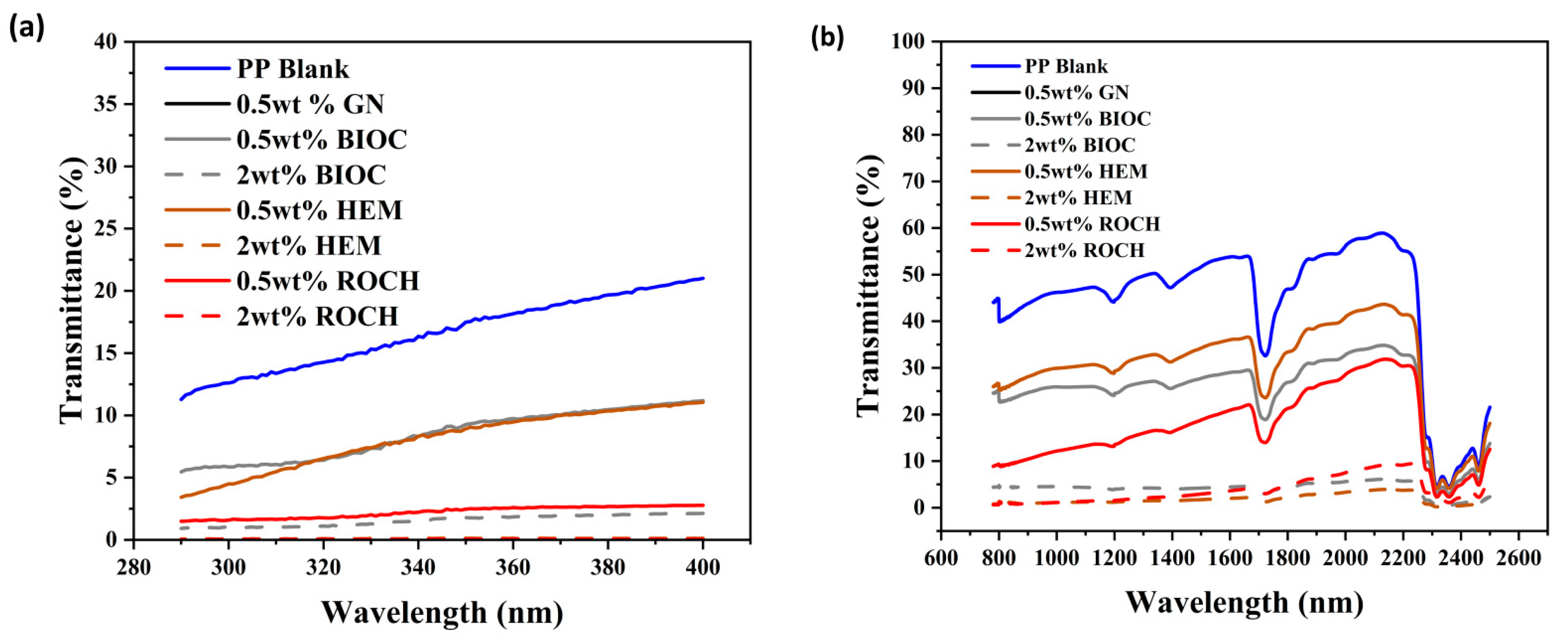

2.5. UV and NIR Shielding Properties of PP Films with Functional Additives

2.6. Mechanical Properties of PP Films with Functional Additives

3. Materials and Methods

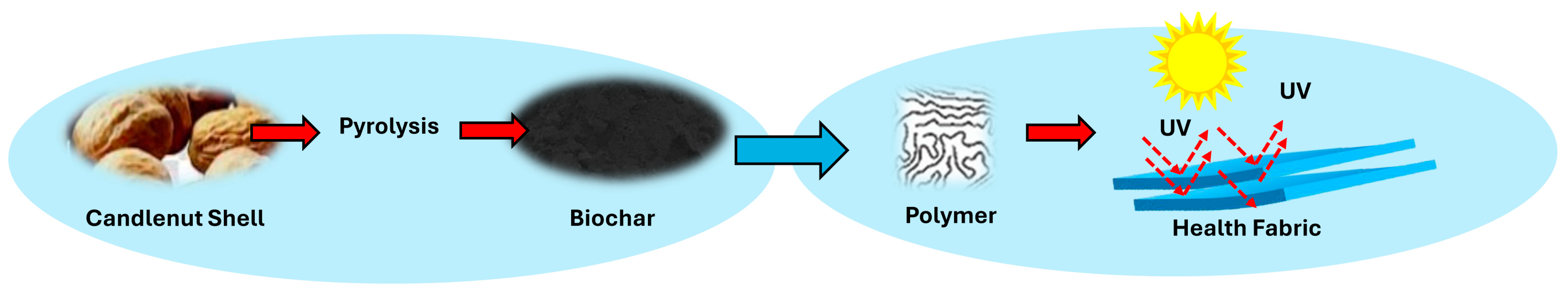

3.1. Preparation of Biochar and Functional Additives

3.2. Preparation of PP Composite Films

3.3. UV and NIR Protection Properties

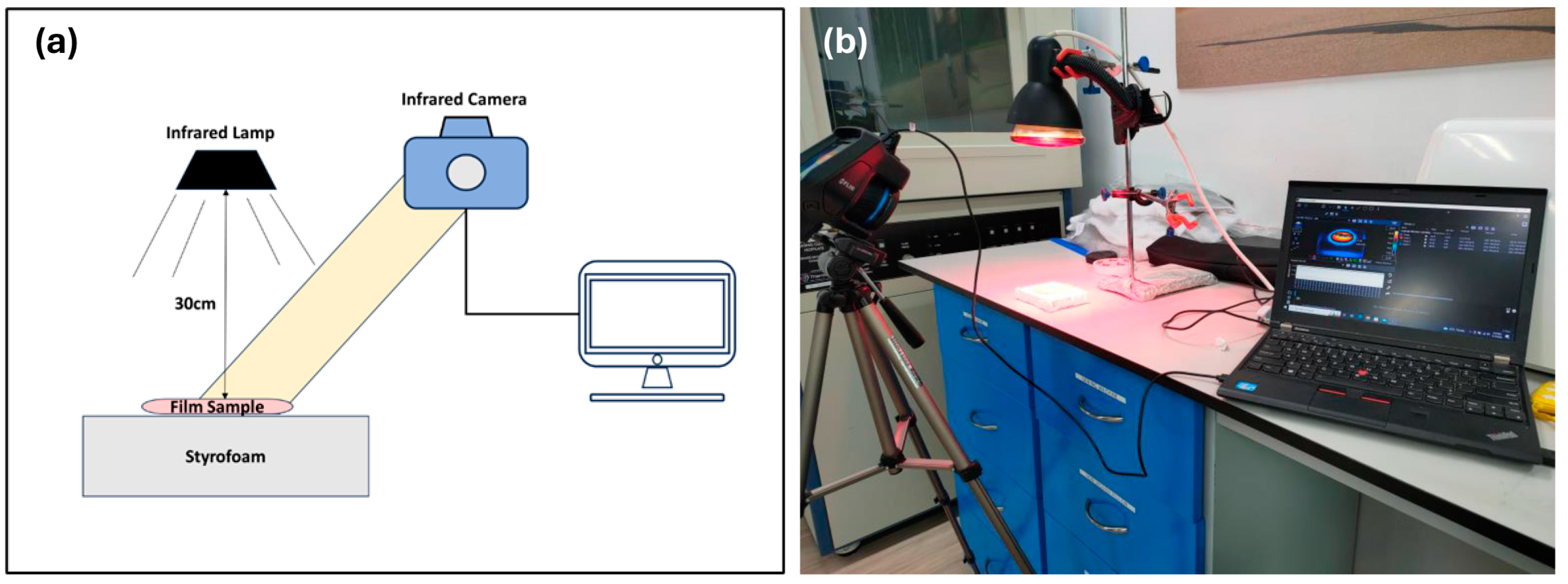

3.4. Thermal Analysis and Heat Storage

3.5. Other Characterisations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bontemps, B.; Gruet, M.; Vercruyssen, F.; Louis, J. Utilisation of far infrared-emitting garments for optimising performance and recovery in sport: Real potential or new fad? A systematic review. PLoS ONE 2021, 16, e0251282. [Google Scholar] [CrossRef] [PubMed]

- Hamada, Y.; Teraoka, F.; Matsumoto, T.; Madachi, A.; Toki, F.; Uda, E.; Hase, R.; Takahashi, J.; Matsuura, N. Effect of Far Infrared ray on Jela Cells and WI-38 Cells. Int. Congr. Ser. 2003, 1255, 339–341. [Google Scholar] [CrossRef]

- Dyer, J. Infrared functional textiles. In Functional Textiles for Improved Performance, Protection and Health; Elsevier: Amsterdam, The Netherlands, 2011; pp. 184–197. [Google Scholar] [CrossRef]

- Chang, J.-C.; Wu, S.-L.; Hoel, F.; Cheng, Y.-S.; Liu, K.-H.; Hsieh, M.; Hoel, A.; Tronstad, K.J.; Yan, K.-C.; Hsieh, C.-L.; et al. Far-infrared radiation protects viability in a cell model of Spinocerebellar Ataxia by preventing polyQ protein accumulation and improving mitochondrial function. Sci. Rep. 2016, 6, 30436. [Google Scholar] [CrossRef]

- McCall, W.V.; Letton, A.; Lundeen, J.; Case, D.; Cidral-Filho, F.J. The effect of far-infrared emitting sheets on sleep. Res. J. Text. Appar. 2018, 22, 247–259. [Google Scholar] [CrossRef]

- Worobets, J.T.; Skolnik, E.R.; Stefanyshyn, D.J. Apparel with Far Infrared Radiation for Decreasing an Athlete’s Oxygen Consumption during Submaximal Exercise. Res. J. Text. Appar. 2015, 19, 52–57. [Google Scholar] [CrossRef]

- Liu, J.; Meng, J.; Liang, J.; Huo, X. Effect of far infrared radiation ceramics containing rare earth additives on surface tension of water. J. Rare Earths 2014, 32, 890–894. [Google Scholar] [CrossRef]

- Gao, Z.; Liang, J.; Zhang, H.; Meng, J. Strengthening mechanism of far-infrared radiation of tourmaline in iron-tailing ceramics. Ceram. Int. 2021, 47, 25214–25220. [Google Scholar]

- He, P.; Low, R.J.Y.; Burns, S.F.; Lipik, V.; Tok, A.I.Y. Enhanced far infrared emissivity, UV protection and near-infrared shielding of polypropylene composites via incorporation of natural mineral for functional fabric development. Sci. Rep. 2023, 13, 22329. [Google Scholar] [CrossRef]

- Matsumoto, T.; Koizumi, T.; Kawakami, Y.; Okamoto, K.; Tomita, M. Perfect blackbody radiation from a graphene nanostructure with application to high-temperature spectral emissivity measurements. Opt. Express 2013, 21, 30964. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, Y.; Xu, J.; Chen, D.; Chen, G. The synergistic effects study between metal oxides and graphene on far-infrared emission performance. SN Appl. Sci. 2020, 2, 610. [Google Scholar] [CrossRef]

- Hoang-Minh, T.; Le, T.L.; Kasbohm, J.; Gieré, R. UV-protection characteristics of some clays. Appl. Clay Sci. 2010, 48, 349–357. [Google Scholar] [CrossRef]

- Ouadil, B.; Cherkaoui, O.; Safi, M.; Zahouily, M. Surface modification of knit polyester fabric for mechanical, electrical and UV protection properties by coating with graphene oxide, graphene and graphene/silver nanocomposites. Appl. Surf. Sci. 2017, 414, 292–302. [Google Scholar] [CrossRef]

- Kim, H.S.; Bae, H.S.; Yu, J.; Kim, S.Y. Thermal conductivity of polymer composites with the geometrical characteristics of graphene nanoplatelets. Sci. Rep. 2016, 6, 26825. [Google Scholar] [CrossRef] [PubMed]

- Rufus, A.; Sreeju, N.; Philip, D. Synthesis of biogenic hematite (α-Fe2O3) nanoparticles for antibacterial and nanofluid applications. RSC Adv. 2016, 6, 94206–94217. [Google Scholar] [CrossRef]

- Shahrousvand, M.; Hoseinian, M.S.; Ghollasi, M.; Karbalaeimahdi, A.; Salimi, A.; Tabar, F.A. Flexible magnetic polyurethane/Fe2O3 nanoparticles as organic-inorganic nanocomposites for biomedical applications: Properties and cell behavior. Mater. Sci. Eng. C 2017, 74, 556–567. [Google Scholar] [CrossRef]

- Chaharmahali, M.; Hamzeh, Y.; Ebrahimi, G.; Ashori, A.; Ghasemi, I. Effects of nano-graphene on the physico-mechanical properties of bagasse/polypropylene composites. Polym. Bull. 2014, 71, 337–349. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Chen, R.; Yu, R.; Pei, X.; Wang, W.; Li, D.; Xu, Z.; Luo, S.; Tang, Y.; Deng, H. Interface design of carbon filler/polymer composites for electromagnetic interference shielding. New J. Chem. 2021, 45, 8370–8385. [Google Scholar] [CrossRef]

- Tang, L.-C.; ZhaoLi, Z.; Qiang, F.; Wu, Q.; Gong, L.-X.; Peng, J.-P. Carbon-Based Nanofillers and Their Rubber Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Sae-oui, P.; Sirisinha, C.; Thepsuwan, U.; Hatthapanit, K. Roles of silane coupling agents on properties of silica-filled polychloroprene. Eur. Polym. J. 2006, 42, 479–486. [Google Scholar] [CrossRef]

- Yoo, T.W.; Yoon, H.G.; Choi, S.J.; Kim, M.S.; Kim, Y.H.; Kim, W.N. Effects of compatibilizers on the mechanical properties and interfacial tension of polypropylene and poly(lactic acid) blends. Macromol. Res. 2010, 18, 583–588. [Google Scholar] [CrossRef]

- Kambo, H.S.; Dutta, A. A comparative review of biochar and hydrochar in terms of production, physico-chemical properties and applications. Renew. Sustain. Energy Rev. 2015, 45, 359–378. [Google Scholar] [CrossRef]

- Chang, B.P.; Gupta, A.; Muthuraj, R.; Mekonnen, T.H. Bioresourced fillers for rubber composite sustainability: Current development and future opportunities. Green Chem. 2021, 23, 5337–5378. [Google Scholar] [CrossRef]

- De Gortari, M.G.; Rodriguez-Uribe, A.; Misra, M.; Mohanty, A.K. Insights on the structure-performance relationship of polyphthalamide (PPA) composites reinforced with high-temperature produced biocarbon. RSC Adv. 2020, 10, 26917–26927. [Google Scholar] [CrossRef] [PubMed]

- Watt, E.; Abdelwahab, M.A.; Mohanty, A.K.; Misra, M. Biocomposites from biobased polyamide 4,10 and waste corn cob based biocarbon. Compos. Part Appl. Sci. Manuf. 2021, 145, 106340. [Google Scholar] [CrossRef]

- Chang, B.P.; Rodriguez-Uribe, A.; Mohanty, A.K.; Misra, M. A comprehensive review of renewable and sustainable biosourced carbon through pyrolysis in biocomposites uses: Current development and future opportunity. Renew. Sustain. Energy Rev. 2021, 152, 111666. [Google Scholar] [CrossRef]

- Mohamed, M.E.; Adel, O.; Khamis, E. Fabrication of biochar-based superhydrophobic coating on steel substrate and its UV resistance, anti-scaling, and corrosion resistance performance. Sci. Rep. 2023, 13, 9453. [Google Scholar] [CrossRef]

- Pusceddu, E.; Montanaro, A.; Fioravanti, G.; Santilli, S.F.; Foscolo, P.U.; Criscuoli, I.; Raschi, A.; Miglietta, F. Comparison between Ancient and Fresh Biochar Samples, A Study on The Recalcitrance of Carbonaceous Structures During Soil Incubation. Int. J. New Technol. Res. 2017, 3, 39–46. [Google Scholar]

- González-Hourcade, M.; dos Reis, G.S.; Grimm, A.; Dinh, V.M.; Lima, E.C.; Larsson, S.H.; Gentili, F.G. Microalgae biomass as a sustainable precursor to produce nitrogen-doped biochar for efficient removal of emerging pollutants from aqueous media. J. Clean. Prod. 2022, 348, 131280. [Google Scholar] [CrossRef]

- Seto, C.; Chang, B.P.; Tzoganakis, C.; Mekonnen, T.H. Lignin derived nano-biocarbon and its deposition on polyurethane foam for wastewater dye adsorption. Int. J. Biol. Macromol. 2021, 185, 629–643. [Google Scholar] [CrossRef]

- Yan, Y.; Manickam, S.; Lester, E.; Wu, T.; Pang, C.H. Synthesis of graphene oxide and graphene quantum dots from miscanthus via ultrasound-assisted mechano-chemical cracking method. Ultrason. Sonochem. 2021, 73, 105519. [Google Scholar] [CrossRef]

- Brzozowska-Stanuch, A.; Rabiej, S.; Fabia, J.; Nowak, J. Changes in thermal properties of isotactic polypropyene with different additives during aging process. Polymery 2014, 59, 302–307. [Google Scholar] [CrossRef]

- Ji, R.; Wu, Y.; Bian, Y.; Song, Y.; Sun, Q.; Jiang, X.; Zhang, L.; Han, J.; Cheng, H. Nitrogen-doped porous biochar derived from marine algae for efficient solid-phase microextraction of chlorobenzenes from aqueous solution. J. Hazard. Mater. 2021, 407, 124785. [Google Scholar] [CrossRef] [PubMed]

- Gopanna, A.; Mandapati, R.N.; Thomas, S.P.; Rajan, K.; Chavali, M. Fourier transform infrared spectroscopy (FTIR), Raman spectroscopy and wide-angle X-ray scattering (WAXS) of polypropylene (PP)/cyclic olefin copolymer (COC) blends for qualitative and quantitative analysis. Polym. Bull. 2019, 76, 4259–4274. [Google Scholar] [CrossRef]

- Prabowo, I.; Pratama, J.N.; Chalid, M. The effect of modified ijuk fibers to crystallinity of polypropylene composite. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 223, p. 012020. [Google Scholar] [CrossRef]

- Caban, R. FTIR-ATR spectroscopic, thermal and microstructural studies on polypropylene-glass fiber composites. J. Mol. Struct. 2022, 1264, 133181. [Google Scholar] [CrossRef]

- Chaiyakun, S.; Witit-Anun, N.; Nuntawong, N.; Chindaudom, P.; Oaew, S.; Kedkeaw, C.; Limsuwan, P. Preparation and characterization of graphene oxide nanosheets. Procedia Eng. 2012, 32, 759–764. [Google Scholar] [CrossRef]

- Marrot, L.; Zouari, M.; Schwarzkopf, M.; DeVallance, D.B. Sustainable biocarbon/tung oil coatings with hydrophobic and UV-shielding properties for outdoor wood substrates. Prog. Org. Coat. 2023, 177, 107428. [Google Scholar] [CrossRef]

- Mishra, R.K.; Misra, M.; Mohanty, A.K. Value-added biocarbon production through slow pyrolysis of mixed bio-oil wastes: Studies on their physicochemical characteristics and structure–property–processing co-relation. Biomass Conv. Biorefin. 2022, 14, 7887–7901. [Google Scholar] [CrossRef]

- Chamritski, I.; Burns, G. Infrared- and Raman-Active Phonons of Magnetite, Maghemite, and Hematite: A Computer Simulation and Spectroscopic Study. J. Phys. Chem. B 2005, 109, 4965–4968. [Google Scholar] [CrossRef]

- Hu, X.; Tian, M.; Qu, L.; Zhu, S.; Han, G. Multifunctional cotton fabrics with graphene/polyurethane coatings with far-infrared emission, electrical conductivity, and ultraviolet-blocking properties. Carbon 2015, 95, 625–633. [Google Scholar] [CrossRef]

- Huang, J.; Li, Y.; Song, G.; Zhang, X.; Sun, Y.; He, X.; Du, S. Highly enhanced infrared spectral emissivity of porous CeO2 coating. Mater. Lett. 2012, 85, 57–60. [Google Scholar] [CrossRef]

- Xiong, Y.; Huang, S.; Wang, W.; Liu, X.; Li, H. Properties and Applications of High Emissivity Composite Films Based on Far-Infrared Ceramic Powder. Materials 2017, 10, 1370. [Google Scholar] [CrossRef] [PubMed]

- Cottrill, A.L.; Liu, A.T.; Kunai, Y.; Koman, V.B.; Kaplan, A.; Mahajan, S.G.; Liu, P.; Toland, A.R.; Strano, M.S. Ultra-high thermal effusivity materials for resonant ambient thermal energy harvesting. Nat. Commun. 2018, 9, 664. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Shen, Y.; Yang, P. Building efficient thermal transport at graphene/polypropylene interfaces by non-covalent functionalized graphene. Phys. Lett. A 2023, 469, 128766. [Google Scholar] [CrossRef]

- Chi, Q.; Ma, T.; Dong, J.; Cui, Y.; Zhang, Y.; Zhang, C.; Xu, S.; Wang, X.; Lei, Q. Enhanced Thermal Conductivity and Dielectric Properties of Iron Oxide/Polyethylene Nanocomposites Induced by a Magnetic Field. Sci. Rep. 2017, 7, 3072. [Google Scholar] [CrossRef]

- Bordoloi, U.; Das, D.; Kashyap, D.; Patwa, D.; Bora, P.; Muigai, H.H.; Kalita, P. Synthesis and comparative analysis of biochar based form-stable phase change materials for thermal management of buildings. J. Energy Storage 2022, 55, 105801. [Google Scholar] [CrossRef]

- Sankauskaitė, A.; Rubežienė, V.; Kubilienė, D.; Abraitienė, A.; Baltušnikaitė-Guzaitienė, J.; Dubinskaitė, K. Investigation of Thermal Behavior of 3D PET Knits with Different Bioceramic Additives. Polymers 2020, 12, 1319. [Google Scholar] [CrossRef]

- Mak, K.F.; Ju, L.; Wang, F.; Heinz, T.F. Optical spectroscopy of graphene: From the far infrared to the ultraviolet. Solid State Commun. 2012, 152, 1341–1349. [Google Scholar] [CrossRef]

- Jeon, J.; Park, J.H.; Wi, S.; Yang, S.; Ok, Y.S.; Kim, S. Characterization of biocomposite using coconut oil impregnated biochar as latent heat storage insulation. Chemosphere 2019, 236, 124269. [Google Scholar] [CrossRef]

- Das, O.; Bhattacharyya, D.; Hui, D.; Lau, K.-T. Mechanical and flammability characterisations of biochar/polypropylene biocomposites. Compos. Part B Eng. 2016, 106, 120–128. [Google Scholar] [CrossRef]

- Piffer, V.S.; Soares, K.; Galdino, A.G.S. Evaluation of mechanical and thermal properties of PP/iron ore tailing composites. Compos. Part B Eng. 2021, 221, 109001. [Google Scholar] [CrossRef]

- Doumeng, M.; Berthet, F.; Delbé, K.; Marsan, O.; Denape, J.; Chabert, F. Effect of size, concentration, and nature of fillers on crystallinity, thermal, and mechanical properties of polyetheretherketone composites. J. Appl. Polym. Sci. 2022, 139, 51574. [Google Scholar] [CrossRef]

- Qu, L.; Tian, M.; Hu, X.; Wang, Y.; Zhu, S.; Guo, X.; Han, G.; Zhang, X.; Sun, K.; Tang, X. Functionalization of cotton fabric at low graphene nanoplate content for ultrastrong ultraviolet blocking. Carbon 2014, 80, 565–574. [Google Scholar] [CrossRef]

- Bramhecha, I.; Sheikh, J. Antibacterial and waterproof breathable waterborne polyurethane functionalised by graphene to develop UV and NIR-protective cotton fabric. Carbon Trends 2021, 4, 100067. [Google Scholar] [CrossRef]

- Bond, T.C.; Bergstrom, R.W. Light Absorption by Carbonaceous Particles: An Investigative Review. Aerosol Sci. Technol. 2006, 40, 27–67. [Google Scholar] [CrossRef]

- Kibria, G.; Repon, R.; Hossain, F.; Islam, T.; Jalil, M.A.; Aljabri, M.D.; Rahman, M.M. UV-blocking cotton fabric design for comfortable summer wears: Factors, durability and nanomaterials. Cellulose 2022, 29, 7555–7585. [Google Scholar] [CrossRef]

- Beasley, D.G.; Meyer, T.A. Characterization of the UVA Protection Provided by Avobenzone, Zinc Oxide, and Titanium Dioxide in Broad-Spectrum Sunscreen Products. Am. J. Clin. Dermatol. 2010, 11, 413–421. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Y.; Li, T.; Wu, J.; Huang, J.; Jiang, J.; Chen, M.; Dong, W. Mussel-inspired anti-permeation hybrid sunscreen with reinforced UV-blocking and safety performance. Colloids Surf. Physicochem. Eng. Asp. 2023, 676, 132140. [Google Scholar] [CrossRef]

- Schroeder, P.; Haendeler, J.; Krutmann, J. The role of near infrared radiation in photoaging of the skin. Exp. Gerontol. 2008, 43, 629–632. [Google Scholar] [CrossRef]

- Okuno, T.; Kojima, M.; Yamaguchi-Sekino, S.; Ishiba, Y.; Suzuki, Y.; Sliney, D.H. Cataract Formation by Near-infrared Radiation in Rabbits. Photochem. Photobiol. 2021, 97, 372–376. [Google Scholar] [CrossRef]

- Sable, S.; Ahuja, S.; Bhunia, H. Preparation and Characterization of Oxo-degradable Polypropylene Composites Containing a Modified Pro-oxidant. J. Polym. Environ. 2021, 29, 721–733. [Google Scholar] [CrossRef]

- Guo, Z.; Lei, K.; Li, Y.; Ng, H.W.; Prikhodko, S.; Hahn, H.T. Fabrication and characterization of iron oxide nanoparticles reinforced vinyl-ester resin nanocomposites. Compos. Sci. Technol. 2008, 68, 1513–1520. [Google Scholar] [CrossRef]

- Nurdina, A.K.; Mariatti, M.; Samayamutthirian, P. Effect of single-mineral filler and hybrid-mineral filler additives on the properties of polypropylene composites. J. Vinyl Addit. Technol. 2009, 15, 20–28. [Google Scholar] [CrossRef]

- Drupitha, M.P.; Misra, M.; Mohanty, A.K. Recent advances on value-added biocarbon preparation by the pyrolysis of renewable and waste biomass, their structure and properties: A move toward an ecofriendly alternative to carbon black. Environ. Sci. Adv. 2023, 2, 1282–1301. [Google Scholar] [CrossRef]

- Watt, E.; Abdelwahab, M.A.; Snowdon, M.R.; Mohanty, A.K.; Khalil, H.; Misra, M. Hybrid biocomposites from polypropylene, sustainable biocarbon and graphene nanoplatelets. Sci. Rep. 2020, 10, 10714. [Google Scholar] [CrossRef]

- Behazin, E.; Misra, M.; Mohanty, A.K. Sustainable biocarbon from pyrolyzed perennial grasses and their effects on impact modified polypropylene biocomposites. Compos. Part B Eng. 2017, 118, 116–124. [Google Scholar] [CrossRef]

- AS/NZS 4399:1996; Sun Protective Clothing: Evaluation and Classification. Council of Standards Australia: Homebush, NSW, Australia; Council of Standards New Zealand: Wellington, New Zealand, 1996.

- Plastics—Differential Scanning Calorimetry (DSC)—Part 1: General Principles. Available online: https://www.iso.org/obp/ui/#iso:std:iso:11357:-1:ed-4:v1:en (accessed on 15 April 2023).

- Standard Test Method for Tensile Properties of Thin Plastic Sheeting. Available online: https://www.astm.org/standards/d882 (accessed on 15 April 2023).

| Films | Tm (°C) | Tc (°C) | ΔHm (J/g) | Xc (%) |

|---|---|---|---|---|

| PP BLK | 162.79 ± 0.01 | 120.85 ± 0.25 | 77.88 ± 0.33 | 37.26 ± 0.16 |

| 0.5 wt% GN | 161.76 ± 0.17 | 119.77 ± 0.02 | 88.89 ± 1.30 | 44.77 ± 0.65 |

| 0.5 wt% BIOC | 162.92 ± 0.11 | 120.79 ± 0.09 | 87.51 ± 0.48 | 42.08 ± 0.23 |

| 2 wt BIOC | 163.29 ± 0.16 | 120.87 ± 0.18 | 88.88 ± 0.58 | 43.39 ± 0.29 |

| 0.5 wt% HEM | 159.69 ± 0.08 | 117.64 ± 0.35 | 86.58 ± 1.92 | 41.63 ± 0.92 |

| 2 wt% HEM | 160.87 ± 0.30 | 120.46 ± 0.23 | 95.25 ± 0.75 | 46.50 ± 0.37 |

| 0.5 wt% ROCH | 160.48 ± 1.54 | 121.12 ± 0.15 | 76.14 ± 0.85 | 36.61 ± 0.41 |

| 2 wt% ROCH | 160.72 ± 0.11 | 119.36 ± 0.04 | 81.46 ± 2.02 | 39.77 ± 0.99 |

| Films | UPF | UPF Protection Category | UVA AV, (%) | UVB AV, (%) | UVR AV, % | NIR Shielding, % |

|---|---|---|---|---|---|---|

| PP BLK | 7.31 | No protection | 17.71 | 12.74 | 16.58 | 56.02 |

| 0.5 wt% GN | 58.05 | Excellent protection | 2.40 | 1.61 | 2.22 | 82.58 |

| 0.5 wt% BIOC | 15.79 | Good protection | 9.14 | 5.89 | 8.42 | 75.09 |

| 2 wt% BIOC | 91.41 | Excellent protection | 1.72 | 1.00 | 1.56 | 95.85 |

| 0.5 wt% HEM | 8.03 | No protection | 9.03 | 4.72 | 17.73 | 69.59 |

| 2 wt% HEM | 1142.38 | Excellent protection | 0.11 | 0.08 | 0.11 | 98.19 |

| 0.5 wt% ROCH | 58.05 | Excellent protection | 2.40 | 1.61 | 2.22 | 82.58 |

| 2 wt% ROCH | 2529.36 | Excellent protection | 0.06 | 0.04 | 0.05 | 96.31 |

| Films | Ultimate Tensile Strength, (MPa) | Elongation at Break, (%) | Young’s Modulus (GPa) |

|---|---|---|---|

| PP BLK | 29.36 ± 0.47 | 4.20 ± 0.08 | 1.71 ± 0.07 |

| 0.5 wt% GN | 18.20 ± 1.13 | 1.37 ± 0.19 | 1.83 ± 0.16 |

| 0.5 wt% BIOC | 29.94 ± 0.83 | 3.70 ± 0.42 | 1.87 ± 0.04 |

| 2 wt% BIOC | 31.45 ± 0.50 | 3.47 ± 0.29 | 2.20 ± 0.10 |

| 0.5 wt% HEM | 16.24 ± 2.88 | 1.40 ± 0.00 | 1.78 ± 0.09 |

| 2 wt% HEM | 11.91 ± 1.60 | 0.73 ± 0.21 | 2.12 ± 0.05 |

| 0.5 wt% ROCH | 8.00 ± 3.30 | 0.40 ± 0.08 | 1.91 ± 0.21 |

| 2 wt% ROCH | 6.00 ± 2.62 | 0.40 ± 0.16 | 1.85 ± 0.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Low, R.J.Y.; He, P.; Junianto; Qiu, N.; Ong, A.J.; Choo, H.H.; Manik, Y.G.O.; Siburian, R.; Goei, R.; Burns, S.F.; et al. Investigation of Far Infrared Emission and UV Protection Properties of Polypropylene Composites Embedded with Candlenut-Derived Biochar for Health Textiles. Molecules 2024, 29, 4798. https://doi.org/10.3390/molecules29204798

Low RJY, He P, Junianto, Qiu N, Ong AJ, Choo HH, Manik YGO, Siburian R, Goei R, Burns SF, et al. Investigation of Far Infrared Emission and UV Protection Properties of Polypropylene Composites Embedded with Candlenut-Derived Biochar for Health Textiles. Molecules. 2024; 29(20):4798. https://doi.org/10.3390/molecules29204798

Chicago/Turabian StyleLow, Rayland Jun Yan, Pengfei He, Junianto, Ningyu Qiu, Amanda Jiamin Ong, Hong Han Choo, Yosia Gopas Oetama Manik, Rikson Siburian, Ronn Goei, Stephen F. Burns, and et al. 2024. "Investigation of Far Infrared Emission and UV Protection Properties of Polypropylene Composites Embedded with Candlenut-Derived Biochar for Health Textiles" Molecules 29, no. 20: 4798. https://doi.org/10.3390/molecules29204798

APA StyleLow, R. J. Y., He, P., Junianto, Qiu, N., Ong, A. J., Choo, H. H., Manik, Y. G. O., Siburian, R., Goei, R., Burns, S. F., Tok, A. I. Y., Lipik, V., & Chang, B. P. (2024). Investigation of Far Infrared Emission and UV Protection Properties of Polypropylene Composites Embedded with Candlenut-Derived Biochar for Health Textiles. Molecules, 29(20), 4798. https://doi.org/10.3390/molecules29204798