Synergistic Integration of Carbon Quantum Dots in Biopolymer Matrices: An Overview of Current Advancements in Antioxidant and Antimicrobial Active Packaging

Abstract

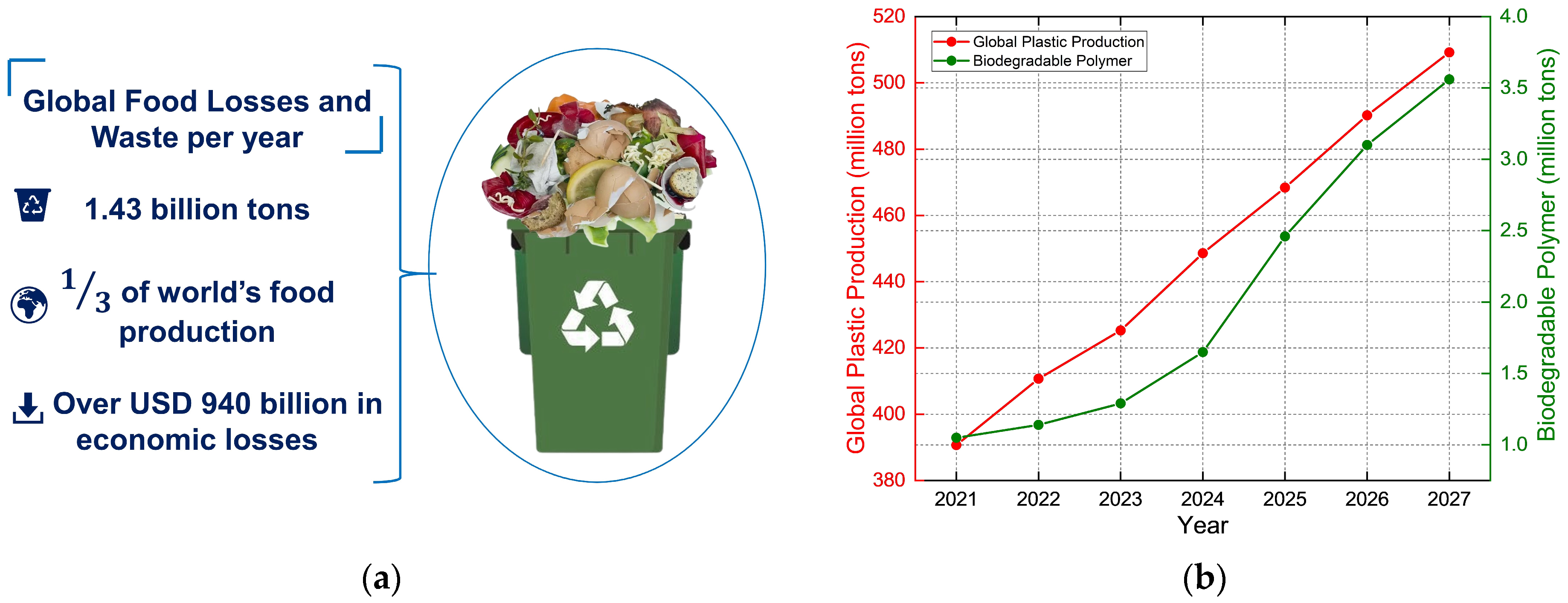

:1. Introduction

2. Carbon Quantum Dots: Overview, Structural Chemistry, and Synthesis Routes

2.1. Overview

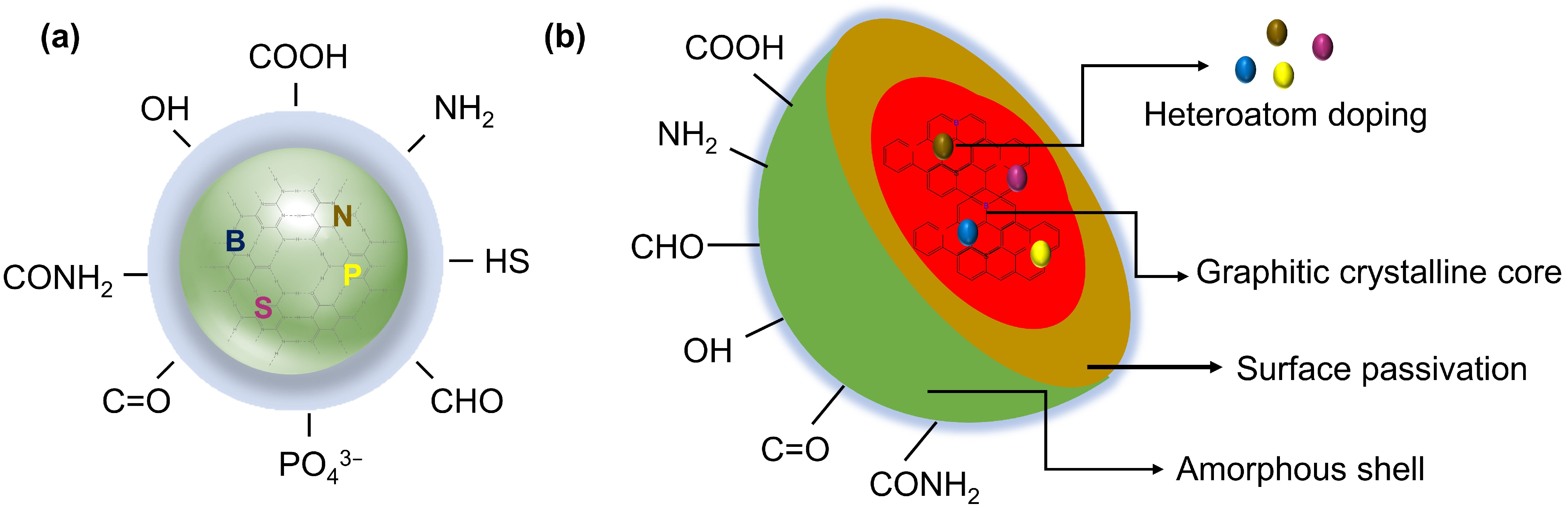

2.2. Structural Chemistry of CQDs

2.3. Synthesis of CQDs

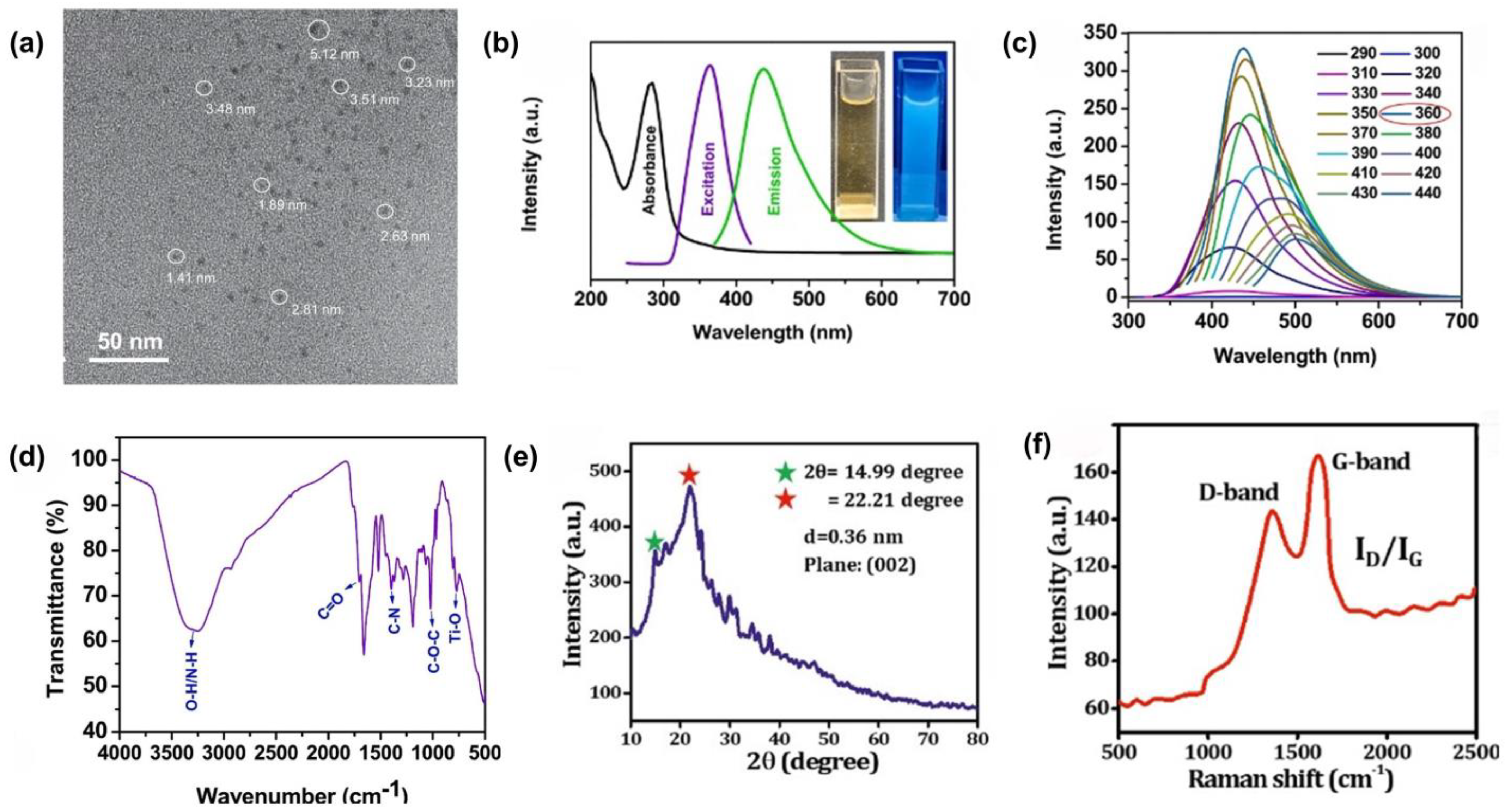

3. Characterization of CQDs

4. Functional Properties of CQDs

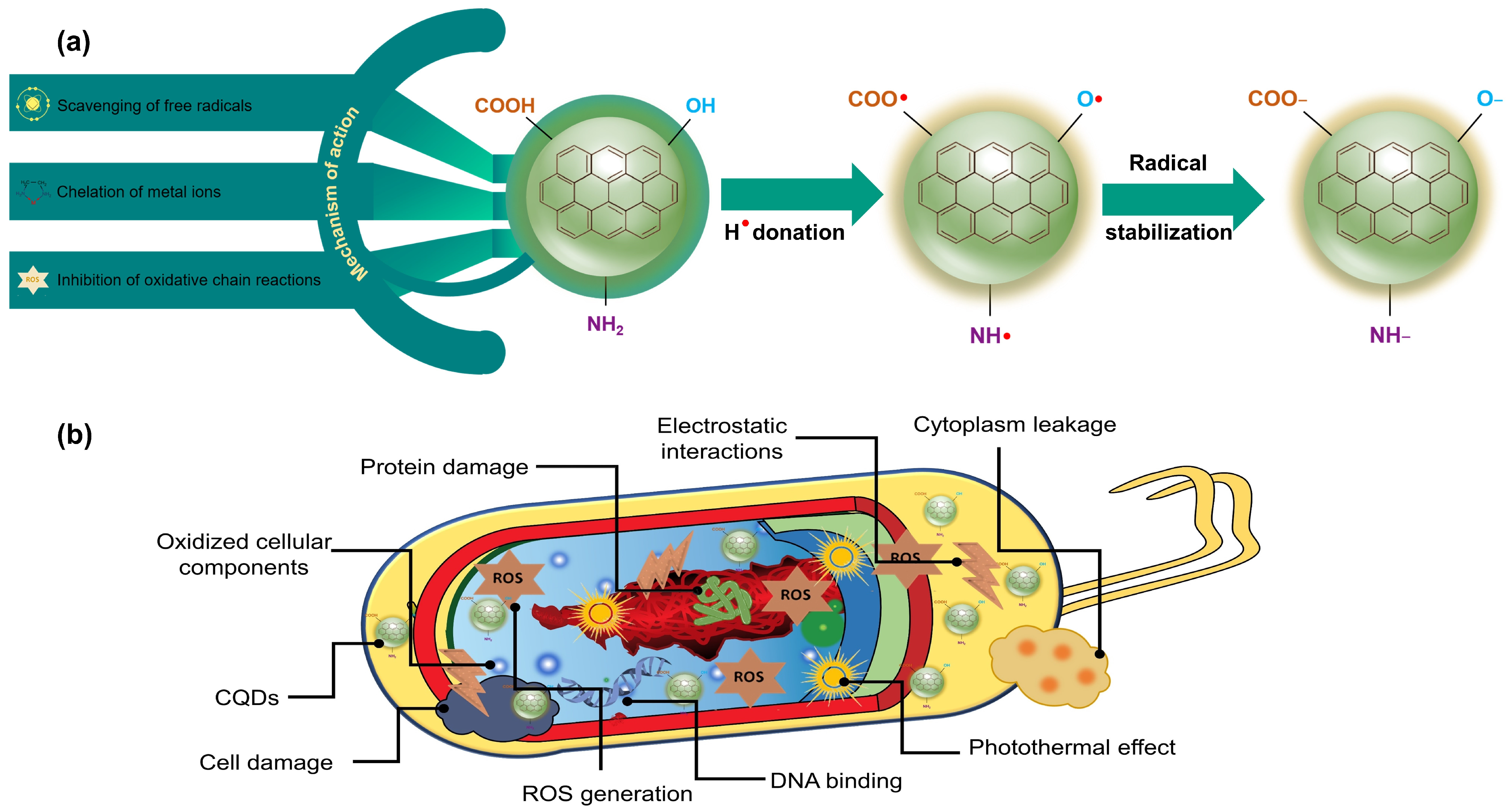

4.1. Antioxidant Properties

4.2. Antimicrobial Activity

5. Application of CQDs in Food Packaging

6. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- FAO. Global Food Losses and Food Waste. Extent, Causes and Prevention; Food and Agriculture Organization of the United Nations: Rome, Italy, 2011; Available online: https://www.fao.org/sustainable-food-value-chains/library/details/en/c/266053/ (accessed on 28 July 2024).

- Manzoor, S.; Fayaz, U.; Dar, A.H.; Dash, K.K.; Shams, R.; Bashir, I.; Pandey, V.K.; Abdi, G. Sustainable Development Goals Through Reducing Food Loss and Food Waste: A Comprehensive Review. Future Foods 2024, 9, 100362. [Google Scholar] [CrossRef]

- Tchonkouang, R.D.; Onyeaka, H.; Miri, T. From Waste to Plate: Exploring the Impact of Food Waste Valorisation on Achieving Zero Hunger. Sustainability 2023, 15, 10571. [Google Scholar] [CrossRef]

- Ruippo, L.; Koivula, H.; Korhonen, J.; Toppinen, A.; Kylkilahti, E. Innovating for sustainability: Attributes, motivations, and responsibilities in the Finnish food packaging ecosystem. Circ. Econ. Sustain. 2023, 3, 919–937. [Google Scholar] [CrossRef] [PubMed]

- Schrobback, P.; Zhang, A.; Loechel, B.; Ricketts, K.; Ingham, A. Food credence attributes: A conceptual framework of supply chain stakeholders, their motives, and mechanisms to address information asymmetry. Foods 2023, 12, 538. [Google Scholar] [CrossRef]

- Jagoda, S.; Gamage, J.; Karunathilake, H. Environmentally sustainable plastic food packaging: A holistic life cycle thinking approach for design decisions. J. Clean. Prod. 2023, 400, 136680. [Google Scholar] [CrossRef]

- Roy, S.; Zhang, W.; Biswas, D.; Ramakrishnan, R.; Rhim, J.-W. Grapefruit seed extract-added functional films and coating for active packaging applications: A review. Molecules 2023, 28, 730. [Google Scholar] [CrossRef]

- Singh, A.K.; Kim, J.Y.; Lee, Y.S. Phenolic compounds in active packaging and edible films/coatings: Natural bioactive molecules and novel packaging ingredients. Molecules 2022, 27, 7513. [Google Scholar] [CrossRef]

- Kuai, L.; Liu, F.; Chiou, B.-S.; Avena-Bustillos, R.J.; McHugh, T.H.; Zhong, F. Controlled release of antioxidants from active food packaging: A review. Food Hydrocoll. 2021, 120, 106992. [Google Scholar] [CrossRef]

- Basavegowda, N.; Baek, K.-H. Synergistic antioxidant and antibacterial advantages of essential oils for food packaging applications. Biomolecules 2021, 11, 1267. [Google Scholar] [CrossRef]

- Bensid, A.; El Abed, N.; Houicher, A.; Regenstein, J.M.; Özogul, F. Antioxidant and antimicrobial preservatives: Properties, mechanism of action and applications in food—A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 2985–3001. [Google Scholar] [CrossRef]

- Castro, F.V.; Andrade, M.A.; Silva, A.S.; Vaz, M.F.; Vilarinho, F. The contribution of a whey protein film incorporated with green tea extract to minimize the lipid oxidation of salmon (Salmo salar L.). Foods 2019, 8, 327. [Google Scholar] [CrossRef] [PubMed]

- Deshmukh, R.K.; Gaikwad, K.K. Natural antimicrobial and antioxidant compounds for active food packaging applications. Biomass Convers. Biorefin. 2024, 14, 4419–4440. [Google Scholar] [CrossRef]

- Yousefi, A.; Hosseini, E.; Sharifan, A.; Pourahmad, R. Application of gelatin-silver nanocomposite film as an active packaging material in toast bread. J. Food Meas. Charact. 2024, 18, 2397–2408. [Google Scholar] [CrossRef]

- Singh, A.K.; Itkor, P.; Lee, Y.S. State-of-the-Art Insights and Potential Applications of Cellulose-Based Hydrogels in Food Packaging: Advances towards Sustainable Trends. Gels 2023, 9, 433. [Google Scholar] [CrossRef] [PubMed]

- Tomić, A.; Šovljanski, O.; Erceg, T. Insight on incorporation of essential oils as antimicrobial substances in biopolymer-based active packaging. Antibiotics 2023, 12, 1473. [Google Scholar] [CrossRef]

- Dıblan, S.; Kaya, S. Shelf life modelling of kaşar cheese packaged with potassium sorbate, nisin, silver substituted zeolite, or chitosan incorporated active multilayer plastic films. Int. Dairy J. 2023, 140, 105596. [Google Scholar] [CrossRef]

- Reyes Méndez, L.M.; Méndez Morales, P.A.; López-Córdoba, A.; Ortega-Toro, R.; Gutiérrez, T.J. Active chitosan/gelatin-based films and coatings containing eugenol and oregano essential oil for fresh cheese preservation. J. Food Process Eng. 2023, 46, e14396. [Google Scholar] [CrossRef]

- Westlake, J.R.; Tran, M.W.; Jiang, Y.; Zhang, X.; Burrows, A.D.; Xie, M. Biodegradable biopolymers for active packaging: Demand, development and directions. Sustain. Food Technol. 2023, 1, 50–72. [Google Scholar] [CrossRef]

- Westlake, J.R.; Tran, M.W.; Jiang, Y.; Zhang, X.; Burrows, A.D.; Xie, M. Biodegradable active packaging with controlled release: Principles, progress, and prospects. ACS Food Sci. Technol. 2022, 2, 1166–1183. [Google Scholar] [CrossRef]

- Singh, A.K.; Lee, M.; Jang, D.; Lee, Y.S. Non-conventional starch nanoparticles: Novel avenues towards improving sustainability of the food packaging sector. Trends Food Sci. Technol. 2023, 143, 104273. [Google Scholar] [CrossRef]

- Kechagias, A.; Lykos, C.; Karabagias, V.K.; Georgopoulos, S.; Sakavitsi, V.; Leontiou, A.; Salmas, C.E.; Giannakas, A.E.; Konstantinou, I. Development and characterization of N/S-carbon quantum dots by valorizing Greek crayfish food waste. Appl. Sci. 2023, 13, 8730. [Google Scholar] [CrossRef]

- Xu, L.; Li, Y.; Gao, S.; Niu, Y.; Liu, H.; Mei, C.; Cai, J.; Xu, C. Preparation and properties of cyanobacteria-based carbon quantum dots/polyvinyl alcohol/nanocellulose composite. Polymers 2020, 12, 1143. [Google Scholar] [CrossRef] [PubMed]

- Ezati, P.; Rhim, J.-W.; Molaei, R.; Rezaei, Z. Carbon quantum dots-based antifungal coating film for active packaging application of avocado. Food Packag. Shelf Life 2022, 33, 100878. [Google Scholar] [CrossRef]

- Khan, A.; Ezati, P.; Rhim, J.-W. Chitosan/starch-based active packaging film with N, P-doped carbon dots for meat packaging. ACS Appl. Bio Mater. 2023, 6, 1294–1305. [Google Scholar] [CrossRef]

- Wen, F.; Li, P.; Zhang, Y.; Zhong, H.; Yan, H.; Su, W. Preparation, characterization of green tea carbon quantum dots/curcumin antioxidant and antibacterial nanocomposites. J. Mol. Struct. 2023, 1273, 134247. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, Y.; Jiang, J.; Chen, J.; Han, W.; Liu, Y.; Kong, L.; Gong, J.; Su, M.; Chen, D. Transfer, transportation, and adsorption of UV-B by Mg-N co doped carbon quantum dots: Response of growth indicators, antioxidant effect and mechanism explanation. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2024, 307, 123618. [Google Scholar] [CrossRef]

- Li, Q.; Shen, X.; Xing, D. Carbon quantum dots as ROS-generator and-scavenger: A comprehensive review. Dye Pigment. 2023, 208, 110784. [Google Scholar] [CrossRef]

- Nejadmansouri, M.; Majdinasab, M.; Nunes, G.S.; Marty, J.L. An overview of optical and electrochemical sensors and biosensors for analysis of antioxidants in food during the last 5 years. Sensors 2021, 21, 1176. [Google Scholar] [CrossRef]

- Das, P.; Ganguly, S.; Ahmed, S.R.; Sherazee, M.; Margel, S.; Gedanken, A.; Srinivasan, S.; Rajabzadeh, A.R. Carbon dot biopolymer-based flexible functional films for antioxidant and food monitoring applications. ACS Appl. Polym. Mater. 2022, 4, 9323–9340. [Google Scholar] [CrossRef]

- Moradi, M.; Molaei, R.; Kousheh, S.A.; Guimarães, J.T.; McClements, D.J. Carbon dots synthesized from microorganisms and food by-products: Active and smart food packaging applications. Crit. Rev. Food Sci. Nutr. 2023, 63, 1943–1959. [Google Scholar] [CrossRef]

- Chen, S.; Zeng, Q.; Tan, X.; Ye, M.; Zhang, Y.; Zou, L.; Liu, S.; Yang, Y.; Liu, A.; He, L. Photodynamic antibacterial chitosan/nitrogen-doped carbon dots composite packaging film for food preservation applications. Carbohydr. Polym. 2023, 314, 120938. [Google Scholar] [CrossRef] [PubMed]

- Ezati, P.; Priyadarshi, R.; Rhim, J.-W. Prospects of sustainable and renewable source-based carbon quantum dots for food packaging applications. Sustain. Mater. Technol. 2022, 33, e00494. [Google Scholar] [CrossRef]

- Bamal, D.; Singh, A.; Chaudhary, G.; Kumar, M.; Singh, M.; Rani, N.; Mundlia, P.; Sehrawat, A.R. Silver nanoparticles biosynthesis, characterization, antimicrobial activities, applications, cytotoxicity and safety issues: An updated review. Nanomaterials 2021, 11, 2086. [Google Scholar] [CrossRef]

- Tripathi, N.; Goshisht, M.K. Recent advances and mechanistic insights into antibacterial activity, antibiofilm activity, and cytotoxicity of silver nanoparticles. ACS Appl. Bio Mater. 2022, 5, 1391–1463. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Zhang, M.; Mujumdar, A.S.; Wang, H. Application of carbon dots in food preservation: A critical review for packaging enhancers and food preservatives. Crit. Rev. Food Sci. Nutr. 2023, 63, 6738–6756. [Google Scholar] [CrossRef] [PubMed]

- Giordano, M.G.; Seganti, G.; Bartoli, M.; Tagliaferro, A. An overview on carbon quantum dots optical and chemical features. Molecules 2023, 28, 2772. [Google Scholar] [CrossRef] [PubMed]

- Dua, S.; Kumar, P.; Pani, B.; Kaur, A.; Khanna, M.; Bhatt, G. Stability of carbon quantum dots: A critical review. RSC Adv. 2023, 13, 13845–13861. [Google Scholar] [CrossRef]

- Khan, A.; Ezati, P.; Kim, J.-T.; Rhim, J.-W. Biocompatible carbon quantum dots for intelligent sensing in food safety applications: Opportunities and sustainability. Mater. Today Sustain. 2023, 21, 100306. [Google Scholar] [CrossRef]

- Xu, X.; Ray, R.; Gu, Y.; Ploehn, H.J.; Gearheart, L.; Raker, K.; Scrivens, W.A. Electrophoretic analysis and purification of fluorescent single-walled carbon nanotube fragments. J. Am. Chem. Soc. 2004, 126, 12736–12737. [Google Scholar] [CrossRef]

- Wang, L.; Liu, X.; Qi, P.; Sun, J.; Jiang, S.; Li, H.; Gu, X.; Zhang, S. Enhancing the thermostability, UV shielding and antimicrobial activity of transparent chitosan film by carbon quantum dots containing N/P. Carbohydr. Polym. 2022, 278, 118957. [Google Scholar] [CrossRef]

- Wen, F.; Li, P.; Yan, H.; Su, W. Turmeric carbon quantum dots enhanced chitosan nanocomposite films based on photodynamic inactivation technology for antibacterial food packaging. Carbohydr. Polym. 2023, 311, 120784. [Google Scholar] [CrossRef] [PubMed]

- Riahi, Z.; Rhim, J.-W.; Bagheri, R.; Pircheraghi, G.; Lotfali, E. Carboxymethyl cellulose-based functional film integrated with chitosan-based carbon quantum dots for active food packaging applications. Prog. Org. Coat. 2022, 166, 106794. [Google Scholar] [CrossRef]

- Janus, Ł.; Radwan-Pragłowska, J.; Piątkowski, M.; Bogdał, D. Facile synthesis of surface-modified carbon quantum dots (CQDs) for biosensing and bioimaging. Materials 2020, 13, 3313. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.E.; Mohammad, A.; Yoon, T. State-of-the-art developments in carbon quantum dots (CQDs): Photo-catalysis, bio-imaging, and bio-sensing applications. Chemosphere 2022, 302, 134815. [Google Scholar] [CrossRef] [PubMed]

- Manikandan, V.; Lee, N.Y. Green synthesis of carbon quantum dots and their environmental applications. Environ. Res. 2022, 212, 113283. [Google Scholar] [CrossRef]

- Samimi, S.; Ardestani, M.S.; Dorkoosh, F.A. Preparation of carbon quantum dots-quinic acid for drug delivery of gemcitabine to breast cancer cells. J. Drug Deliv. Sci. Technol. 2021, 61, 102287. [Google Scholar] [CrossRef]

- Syed, N.; Huang, J.; Feng, Y. CQDs as emerging trends for future prospect in enhancement of photocatalytic activity. Carbon Lett. 2021, 32, 81–97. [Google Scholar] [CrossRef]

- Yuan, T.; Meng, T.; He, P.; Shi, Y.; Li, Y.; Li, X.; Fan, L.; Yang, S. Carbon quantum dots: An emerging material for optoelectronic applications. J. Mater. Chem. C 2019, 7, 6820–6835. [Google Scholar] [CrossRef]

- Tan, T.L.; Nulit, R.; Jusoh, M.; Rashid, S.A. Recent developments, applications and challenges for carbon quantum dots as a photosynthesis enhancer in agriculture. RSC Adv. 2023, 13, 25093–25117. [Google Scholar] [CrossRef]

- Sandeep, D.; Krushna, B.R.; Navya, N.; Santhosh, D.; Sharma, S.; Krithika, C.; Sridhar, C.; Coumare, V.N.; Nagabhushana, H. Sustainable fabrication of fluorescent carbon quantum dots as an optical amplifier in modern agriculture, anti-counterfeiting, food packing and intelligent pH detection. Mater. Today Sustain. 2024, 27, 100855. [Google Scholar] [CrossRef]

- Yang, J.; Li, Y.; Liu, B.; Wang, K.; Li, H.; Peng, L. Carboxymethyl cellulose-based multifunctional film integrated with polyphenol-rich extract and carbon dots from coffee husk waste for active food packaging applications. Food Chem. 2024, 448, 139143. [Google Scholar] [CrossRef] [PubMed]

- Kumar, L.; Gaikwad, K.K. Carbon dots for food packaging applications. Sustain. Food Technol. 2023, 1, 185–199. [Google Scholar] [CrossRef]

- Kumar, P.; Dua, S.; Kaur, R.; Kumar, M.; Bhatt, G. A review on advancements in carbon quantum dots and their application in photovoltaics. RSC Adv. 2022, 12, 4714–4759. [Google Scholar] [CrossRef]

- You, W.; Zou, W.; Jiang, S.; Zhang, J.; Ge, Y.; Lu, G.; Bahnemann, D.W.; Pan, J.H. Fluorescent carbon quantum dots with controllable physicochemical properties fantastic for emerging applications: A review. Carbon Neutralization 2024, 3, 245–284. [Google Scholar] [CrossRef]

- Permatasari, F.A.; Irham, M.A.; Bisri, S.Z.; Iskandar, F. Carbon-based quantum dots for supercapacitors: Recent advances and future challenges. Nanomaterials 2021, 11, 91. [Google Scholar] [CrossRef]

- Jorns, M.; Pappas, D. A review of fluorescent carbon dots, their synthesis, physical and chemical characteristics, and applications. Nanomaterials 2021, 11, 1448. [Google Scholar] [CrossRef]

- Xu, A.; Wang, G.; Li, Y.; Dong, H.; Yang, S.; He, P.; Ding, G. Carbon-based quantum dots with solid-state photoluminescent: Mechanism, implementation, and application. Small 2020, 16, 2004621. [Google Scholar] [CrossRef]

- John, V.L.; Nair, Y.; Vinod, T. Doping and surface modification of carbon quantum dots for enhanced functionalities and related applications. Part. Part. Syst. Charact. 2021, 38, 2100170. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, H.; Cao, W.; Mao, B.; Liu, Y.; Kang, Z. Advances in carbon dots: From the perspective of traditional quantum dots. Mater. Chem. Front. 2020, 4, 1586–1613. [Google Scholar] [CrossRef]

- John, V.L.; Joy, F.; Kollannoor, A.J.; Joseph, K.; Nair, Y.; Vinod, T. Amine functionalized carbon quantum dots from paper precursors for selective binding and fluorescent labelling applications. J. Colloid Interface Sci. 2022, 617, 730–744. [Google Scholar] [CrossRef]

- Hindi, S.S.; Sabir, J.S.; Dawoud, U.M.; Ismail, I.M.; Asiry, K.A.; Mirdad, Z.M.; Abo-Elyousr, K.A.; Shiboob, M.H.; Gabal, M.A.; Albureikan, M.O.I. Nanocellulose-based passivated-carbon quantum dots (P-CQDs) for antimicrobial applications: A practical review. Polymers 2023, 15, 2660. [Google Scholar] [CrossRef] [PubMed]

- Yadav, P.K.; Chandra, S.; Kumar, V.; Kumar, D.; Hasan, S.H. Carbon quantum dots: Synthesis, structure, properties, and catalytic applications for organic synthesis. Catalysts 2023, 13, 422. [Google Scholar] [CrossRef]

- Pang, Y.; Li, X.; Zhang, X.; Yeoh, J.; Wong, C.; Manickam, S.; Yan, Y.; Wu, T.; Pang, C. The synthesis of carbon-based quantum dots: A supercritical fluid approach and perspective. Mater. Today Phys. 2022, 27, 100752. [Google Scholar] [CrossRef]

- Ndlwana, L.; Raleie, N.; Dimpe, K.M.; Ogutu, H.F.; Oseghe, E.O.; Motsa, M.M.; Msagati, T.A.; Mamba, B.B. Sustainable hydrothermal and solvothermal synthesis of advanced carbon materials in multidimensional applications: A review. Materials 2021, 14, 5094. [Google Scholar] [CrossRef] [PubMed]

- Rawat, P.; Nain, P.; Sharma, S.; Sharma, P.K.; Malik, V.; Majumder, S.; Verma, V.P.; Rawat, V.; Rhyee, J.S. An overview of synthetic methods and applications of photoluminescence properties of carbon quantum dots. Luminescence 2023, 38, 845–866. [Google Scholar] [CrossRef] [PubMed]

- Ullal, N.; Mehta, R.; Sunil, D. Separation and purification of fluorescent carbon dots—An unmet challenge. Analyst 2024, 149, 1680–1700. [Google Scholar] [CrossRef]

- Sousa, H.B.; Martins, C.S.; Prior, J.A. You don’t learn that in school: An updated practical guide to carbon quantum dots. Nanomaterials 2021, 11, 611. [Google Scholar] [CrossRef]

- Rasal, A.S.; Yadav, S.; Yadav, A.; Kashale, A.A.; Manjunatha, S.T.; Altaee, A.; Chang, J.-Y. Carbon quantum dots for energy applications: A review. ACS Appl. Nano Mater. 2021, 4, 6515–6541. [Google Scholar] [CrossRef]

- Ezati, P.; Rhim, J.-W. Pectin/carbon quantum dots fluorescent film with ultraviolet blocking property through light conversion. Colloids Surf. B. Biointerfaces 2022, 219, 112804. [Google Scholar] [CrossRef]

- Ran, X.; Qu, Y.; Wang, Y.; Cui, B.; Shen, Y.; Li, Y. Enhanced UV-blocking capabilities of polylactic acid derived from renewable resources for food and drug packaging: A mini-review. J. Compos. Sci. 2023, 7, 410. [Google Scholar] [CrossRef]

- Khan, A.; Ezati, P.; Rhim, J.-W. pH indicator Integrated with carbon quantum dots of glucose to monitor the quality of fish and shrimp. Food Bioprocess Technol. 2024, 17, 554–569. [Google Scholar] [CrossRef]

- Riahi, Z.; Khan, A.; Rhim, J.-W.; Shin, G.H.; Kim, J.T. Carrageenan-based active and intelligent packaging films integrated with anthocyanin and TiO2-doped carbon dots derived from sweet potato peels. Int. J. Biol. Macromol. 2024, 259, 129371. [Google Scholar] [CrossRef] [PubMed]

- Kumar, Y.R.; Deshmukh, K.; Sadasivuni, K.K.; Pasha, S.K. Graphene quantum dot based materials for sensing, bio-imaging and energy storage applications: A review. RSC Adv. 2020, 10, 23861–23898. [Google Scholar] [CrossRef] [PubMed]

- Gan, J.; Chen, L.; Chen, Z.; Zhang, J.; Yu, W.; Huang, C.; Wu, Y.; Zhang, K. Lignocellulosic biomass-based carbon dots: Synthesis processes, properties, and applications. Small 2023, 19, 2304066. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.-L.; Bai, L.-F.; Geng, Z.-R.; Chen, H.; Xu, L.-T.; Xie, Y.-C.; Wang, D.-J.; Gu, H.-W.; Wang, X.-M. Carbon quantum dots: Preparation, optical properties, and biomedical applications. Mater. Today Adv. 2023, 18, 100376. [Google Scholar] [CrossRef]

- Vasile, C.; Baican, M. Progresses in food packaging, food quality, and safety—Controlled-release antioxidant and/or antimicrobial packaging. Molecules 2021, 26, 1263. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Chaudhary, A.; Mathys, A. Nutritional and environmental losses embedded in global food waste. Resour. Conserv. Recycl. 2020, 160, 104912. [Google Scholar] [CrossRef]

- Dey, A.; Neogi, S. Oxygen scavengers for food packaging applications: A review. Trends Food Sci. Technol. 2019, 90, 26–34. [Google Scholar] [CrossRef]

- Xu, M.; Meng, P.; Wang, H.; Liu, J.; Guo, T.; Zhu, Z.; Bi, Y. Synthesis, Characterization and Evaluation of a Novel Tetraphenolic Compound as a Potential Antioxidant. Antioxidants 2023, 12, 1473. [Google Scholar] [CrossRef]

- Li, J.; Zhang, S.; Kuang, Y.; Bi, Y.; Wang, H. A review on losses and transformation mechanisms of common antioxidants. J. Am. Oil Chem. Soc. 2023, 100, 259–285. [Google Scholar] [CrossRef]

- Othón-Díaz, E.D.; Fimbres-García, J.O.; Flores-Sauceda, M.; Silva-Espinoza, B.A.; López-Martínez, L.X.; Bernal-Mercado, A.T.; Ayala-Zavala, J.F. Antioxidants in oak (Quercus sp.): Potential application to reduce oxidative rancidity in foods. Antioxidants 2023, 12, 861. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.K.; Ramakanth, D.; Kumar, A.; Lee, Y.S.; Gaikwad, K.K. Active packaging technologies for clean label food products: A review. J. Food Meas. Charact. 2021, 15, 4314–4324. [Google Scholar] [CrossRef]

- Ji, X.; Liu, J.; Liang, J.; Feng, X.; Liu, X.; Wang, Y.; Chen, X.; Qu, G.; Yan, B.; Liu, R. The hidden diet: Synthetic antioxidants in packaged food and their impact on human exposure and health. Environ. Int. 2024, 186, 108613. [Google Scholar] [CrossRef] [PubMed]

- Janus, Ł.; Radwan-Pragłowska, J.; Piątkowski, M.; Bogdał, D. Smart, tunable CQDs with antioxidant properties for biomedical applications—Ecofriendly synthesis and characterization. Molecules 2020, 25, 736. [Google Scholar] [CrossRef]

- Bijoy, G.; Sangeetha, D. Biomass Derived Carbon Quantum Dots as Potential Tools for Sustainable Environmental Remediation and Eco-friendly Food Packaging. J. Environ. Chem. Eng. 2024, 12, 113727. [Google Scholar] [CrossRef]

- Djiazet, S.; Desmarets, C.; Rinnert, H.; Jasniewski, J.; Medjahdi, G.; Balan, L.; Schneider, R. Photoluminescent carbon quantum dots from Dichrostachys glomerata pods with antioxidant and Cu2+ chelating properties. ChemNanoMat 2024, 10, e202300635. [Google Scholar] [CrossRef]

- Innocenzi, P.; Stagi, L. Carbon dots as oxidant-antioxidant nanomaterials, understanding the structure-properties relationship. A critical review. Nano Today 2023, 50, 101837. [Google Scholar] [CrossRef]

- Jayakumar, A.; Radoor, S.; Shin, G.H.; Kim, J.T. Lemon peel-based fluorescent carbon quantum dots as a functional filler in polyvinyl alcohol-based films for active packaging applications. Ind. Crops Prod. 2024, 209, 117968. [Google Scholar] [CrossRef]

- Li, X.; Liu, X.; Su, Y.; Jiang, T.; Li, D.; Ma, X. Green synthesis of carbon quantum dots from wasted enzymatic hydrolysis lignin catalyzed by organic acids for UV shielding and antioxidant fluorescent flexible film. Ind. Crop. Prod. 2022, 188, 115568. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, L.; Huang, M.; Ma, M.; Zeng, J.; Le, T. Modification of starch-derived graphene quantum dots as multifunctional nanofillers to produce polymer starch/polyvinyl alcohol composite films for active packaging. LWT 2024, 198, 115953. [Google Scholar] [CrossRef]

- Hong, S.J.; Riahi, Z.; Shin, G.H.; Kim, J.T. Pseudomonas aeruginosa-derived carbon dots doped with sulfur as active packaging materials for fresh food preservation. Food Biosci. 2024, 57, 103506. [Google Scholar] [CrossRef]

- Dash, K.K.; Deka, P.; Bangar, S.P.; Chaudhary, V.; Trif, M.; Rusu, A. Applications of inorganic nanoparticles in food packaging: A comprehensive review. Polymers 2022, 14, 521. [Google Scholar] [CrossRef]

- Younis, A.B.; Haddad, Y.; Kosaristanova, L.; Smerkova, K. Titanium dioxide nanoparticles: Recent progress in antimicrobial applications. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnol. 2023, 15, e1860. [Google Scholar] [CrossRef]

- Franco, D.; Calabrese, G.; Guglielmino, S.P.P.; Conoci, S. Metal-based nanoparticles: Antibacterial mechanisms and biomedical application. Microorganisms 2022, 10, 1778. [Google Scholar] [CrossRef] [PubMed]

- Nishimoto-Sauceda, D.; Romero-Robles, L.E.; Antunes-Ricardo, M. Biopolymer nanoparticles: A strategy to enhance stability, bioavailability, and biological effects of phenolic compounds as functional ingredients. J. Sci. Food Agric. 2022, 102, 41–52. [Google Scholar] [CrossRef]

- Chelladurai, D.; Alaguthevar, R.; Murugesan, B.; Subburamu, K.; Khan, A.; Rhim, J.-W. Carbon quantum dots: Progress toward food safety and sustainability. Food Biosci. 2024, 61, 105016. [Google Scholar] [CrossRef]

- Varghese, M.; Balachandran, M. Antibacterial efficiency of carbon dots against Gram-positive and Gram-negative bacteria: A review. J. Environ. Chem. Eng. 2021, 9, 106821. [Google Scholar] [CrossRef]

- Priyadarshi, R.; Pourmoslemi, S.; Khan, A.; Riahi, Z.; Rhim, J.-W. Sulfur quantum dots as sustainable materials for biomedical applications: Current trends and future perspectives. Colloids Surf. B Biointerfaces 2024, 237, 113863. [Google Scholar] [CrossRef]

- Priya, S.; Henry, J.; Aepuru, R.; Arivizhivendhan, K.; Sathish, M. Advancements in Carbon Dot Production and Characterization for Food Packaging: A Comprehensive Review. Braz. J. Phys. 2024, 54, 139. [Google Scholar] [CrossRef]

- Tammina, S.K.; Rhim, J.-W. Carboxymethylcellulose/agar-based functional film incorporated with nitrogen-doped polyethylene glycol-derived carbon dots for active packaging applications. Chemosphere 2023, 313, 137627. [Google Scholar] [CrossRef]

- Ezati, P.; Rhim, J.-W.; Molaei, R.; Priyadarshi, R.; Han, S. Cellulose nanofiber-based coating film integrated with nitrogen-functionalized carbon dots for active packaging applications of fresh fruit. Postharvest Biol. Technol. 2022, 186, 111845. [Google Scholar] [CrossRef]

- Bing, W.; Sun, H.; Yan, Z.; Ren, J.; Qu, X. Programmed Bacteria Death Induced by Carbon Dots with Different Surface Charge. Small 2016, 12, 4713–4718. [Google Scholar] [CrossRef] [PubMed]

- Gedda, G.; Sankaranarayanan, S.A.; Putta, C.L.; Gudimella, K.K.; Rengan, A.K.; Girma, W.M. Green synthesis of multi-functional carbon dots from medicinal plant leaves for antimicrobial, antioxidant, and bioimaging applications. Sci. Rep. 2023, 13, 6371. [Google Scholar] [CrossRef]

- Gupta, D.; Priyadarshi, R.; Tammina, S.K.; Rhim, J.-W.; Agrawal, G. Fruit Processing Wastes as Sustainable Sources to Produce Multifunctional Carbon Quantum Dots for Application in Active Food Packaging. Food Bioprocess Technol. 2024, 1–25. [Google Scholar] [CrossRef]

- Wang, D.; Wang, X.; Zhou, S.; Ren, L.; Meng, Y.; Ma, R.; Wang, S.; Liu, Z.; Alamri, A.S.; Alhomrani, M. Radish residue carbon dots-based novel starch/chitosan film with high antioxidant, biocompatibility, and antibacterial activities for salmon fillets’ active packaging. Int. J. Biol. Macromol. 2024, 273, 133107. [Google Scholar] [CrossRef]

- Nazar, M.; Hasan, M.; Wirjosentono, B.; Gani, B.A. Fabrication and characterization of bio-nanocomposite from sweet potato starch and Moringa oleifera leaf extract loaded with carbon quantum dots from Coffea arabica grounds. Results Eng. 2024, 23, 102448. [Google Scholar] [CrossRef]

- Zhang, L.; Gao, X.; Feng, Y.; Yan, Y.; Zhu, H.; Liu, S.; Yu, Y.; Yu, B. Chitosan-based hydrogel-incorporated Trp-CDs with antibacterial properties and pH-mediated fluorescence response as a smart food preservation material. ACS Appl. Mater. Interfaces 2023, 15, 44097–44108. [Google Scholar] [CrossRef]

- Slewa, L.H. Antifungal films for strawberry packaging using carbon quantum dots derived from lemon and onion juice via green hydrothermal method. Food Biosci. 2024, 61, 104653. [Google Scholar] [CrossRef]

- Sul, Y.; Khan, A.; Rhim, J.-W. Effects of coffee bean types on the characteristics of carbon dots and their use for manufacturing cellulose nanofibers-based films for active packaging of meat. Food Packag. Shelf Life 2024, 43, 101282. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, M.; Mujumdar, A.S.; Adhikari, B.; Wang, H. Preparation of a novel carbon dot/polyvinyl alcohol composite film and its application in food preservation. ACS Appl. Mater. Interfaces 2022, 14, 37528–37539. [Google Scholar] [CrossRef]

- Alzahrani, A. Fluorescent carbon dots in situ polymerized biodegradable semi-interpenetrating tough hydrogel films with antioxidant and antibacterial activity for applications in food industry. Food Chem. 2024, 447, 138905. [Google Scholar] [CrossRef] [PubMed]

- Wagh, R.V.; Ezati, P.; Khan, A.; Priyadarshi, R.; Rhim, J.W. Vaccinium corymbosum–Derived Carbon Dots and Anthocyanin-Infused Gelatin Multifunctional Films for Smart Packaging Applications. Packag. Technol. Sci. 2024, 37. [Google Scholar] [CrossRef]

- Qin, W.; Zou, L.; Hou, Y.; Wu, Z.; Loy, D.A.; Lin, D. Characterization of novel anthocyanins film@ carbon quantum dot nanofiber intelligent active double-layer film, physicochemical properties and fresh-keeping monitoring in Ictalurus punctatus fish. Chem. Eng. J. 2024, 496, 154041. [Google Scholar] [CrossRef]

- Priyadarshi, R.; Uzun, S.; Rhim, J.-W. Edible coating using carbon quantum dots for fresh produce preservation: A review of safety perspectives. Adv. Colloid Interface Sci. 2024, 331, 103211. [Google Scholar] [CrossRef]

| Packaging Type | CQDs Precursor | Antioxidant Activity | Antimicrobial Activity | Applications | References |

|---|---|---|---|---|---|

| Active film | Coffee husk waste | Exhibited more than 95% free radical scavenging efficiency in DPPH and ABTS assays | Demonstrated strong antibacterial action against L. monocytogenes and E. coli | CMC/CQDs composite film delayed the spoilage of fresh-cut apples, extending shelf life to 7 d at 4 °C | [52] |

| Active film | Radish residue | Demonstrated high scavenging efficiencies of 93.8% for DPPH and 99.36% for ABTS | Displayed marked antibacterial efficacy against Aeromonas sobria and Hafnia alvei | Enhanced starch/chitosan film with CQDs for the efficient preservation of salmon fillets | [106] |

| Active film | Pseudomonas aeruginosa and doping with sulfur | Showed significant antioxidant performance of S-doped CQDs with 85.07% DPPH and 94.89% ABTS scavenging | Reported high antibacterial effectiveness against L. monocytogenes | Inhibited microbial spoilage in minced pork and prevented discoloration in fresh-cut apples using PVA/S-CQDs composite films | [92] |

| Active film | Lemon (L-CQDs) and Onion (O-CQDS) | Reported approximately 80% and 90% DPPH free radical scavenging activity for L-CQDs and O-CQDs, respectively | Exhibited strong antifungal activity against Rhizopus sp., Penicillium sp., Candida albicans, Aspergillus sp., and Botrytis cinerea. | Minimized quality degradation and extended the shelf life of strawberries | [109] |

| Active film | Coffee grounds | Achieved high antioxidant performance with 98.2% scavenging of ABTS radicals and 78.8% scavenging of DPPH radicals | Exhibited effective antimicrobial potential, significantly inhibiting the growth of E. coli and L. monocytogenes | Prolonged the freshness of minced pork to 21 d at 4 °C with CQDs-incorporated cellulose nanofiber active packaging | [110] |

| Active film | Green tea | Demonstrated significant antioxidant potential in CQDs-incorporated chitosan/starch film, with 71.4% DPPH and 98% ABTS scavenging efficiencies | Showed substantial antibacterial activity in CQDs-chitosan/starch film, effective against L. monocytogenes, E. coli, and S. aureus | Extended the shelf life and maintained the freshness of minced pork wrapped in CQDs-infused chitosan/starch film | [25] |

| Active film | Banana | Displayed significant antioxidant efficiency in CQDs-infused PVA film, with 72.81% DPPH and 97.08% ABTS radical scavenging | Exhibited strong antibacterial efficacy in CQDs-based PVA film, inhibiting the growth of S. aureus, B. subtilis, and E. coli. | Effective as active packaging for extending the storage life of bananas, jujubes, and fried meatballs | [111] |

| Hydrogel film | Polyethylenimine and l-cysteine | Displayed notable antioxidant properties in CQDs-enhanced hydrogel film, with approximately 50% DPPH and 75% ABTS scavenging rates | Exhibited substantial antimicrobial potential in CQDs-infused hydrogel film, showing strong inhibition of E. coli and L. monocytogenes | Extended the freshness and storage quality of bananas for more than 5 d | [112] |

| Hydrogel film | Glucose and L-tryptophan | Exhibited substantial antioxidant potential in CQDs-integrated chitosan hydrogel, with 95.83% DPPH scavenging rate | Demonstrated strong antimicrobial effects in CQDs-infused chitosan hydrogel, inhibiting E. coli and S. aureus | Enhanced the freshness of strawberries for over 5 d and oranges for 20 d under ambient conditions | [108] |

| Coating | Ascorbic acid and chitosan | Demonstrated high antioxidant performance in CQDs-CMC film, with 88% DPPH and 100% ABTS scavenging efficiencies | Demonstrated a significant bactericidal effect on E. coli and L. monocytogenes | Lemons coated with CMC/CQD film maintained excellent appearance with no mold growth after 21 d of storage | [43] |

| Coating | Glucose | Displayed significant antioxidant performance in CQDs-infused chitosan/gelatin film solution, with more than 95% scavenging efficiency for DPPH and ABTS | Showed potent antimicrobial effects in CQDs-infused chitosan/gelatin films against L. monocytogenes, E. coli, A. flavus, and C. orbiculare | Inhibited mold formation on avocados and extended their storage life by more than 14 d using CQDs-enhanced chitosan/gelatin film | [24] |

| Smart film | Biowaste pomace of blueberries | Demonstrated scavenging activity with 48.7% for DPPH and 54.4% for ABTS | Showed effective antibacterial properties against L. monocytogenes and E. coli | CQDs-based smart film with anthocyanin and gelatin, effectively extending and monitoring the shelf life of minced pork, fish, and shrimp | [113] |

| Smart active double-layer film | Barley bran | Displayed strong antioxidant properties in CQDs-incorporated film, with approximately 80% scavenging for DPPH and 90% for ABTS | Demonstrated potent antibacterial activity targeting S. aureus and E. coli | Implemented as a smart active double-layer film, extending Ictalurus punctatus fish shelf life by 2 d with integrated freshness monitoring | [114] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, A.K.; Itkor, P.; Lee, M.; Saenjaiban, A.; Lee, Y.S. Synergistic Integration of Carbon Quantum Dots in Biopolymer Matrices: An Overview of Current Advancements in Antioxidant and Antimicrobial Active Packaging. Molecules 2024, 29, 5138. https://doi.org/10.3390/molecules29215138

Singh AK, Itkor P, Lee M, Saenjaiban A, Lee YS. Synergistic Integration of Carbon Quantum Dots in Biopolymer Matrices: An Overview of Current Advancements in Antioxidant and Antimicrobial Active Packaging. Molecules. 2024; 29(21):5138. https://doi.org/10.3390/molecules29215138

Chicago/Turabian StyleSingh, Ajit Kumar, Pontree Itkor, Myungho Lee, Aphisit Saenjaiban, and Youn Suk Lee. 2024. "Synergistic Integration of Carbon Quantum Dots in Biopolymer Matrices: An Overview of Current Advancements in Antioxidant and Antimicrobial Active Packaging" Molecules 29, no. 21: 5138. https://doi.org/10.3390/molecules29215138

APA StyleSingh, A. K., Itkor, P., Lee, M., Saenjaiban, A., & Lee, Y. S. (2024). Synergistic Integration of Carbon Quantum Dots in Biopolymer Matrices: An Overview of Current Advancements in Antioxidant and Antimicrobial Active Packaging. Molecules, 29(21), 5138. https://doi.org/10.3390/molecules29215138