Effect of Different Cooking Methods on the Aroma and Taste of Chicken Broth

Abstract

1. Introduction

2. Results and Discussion

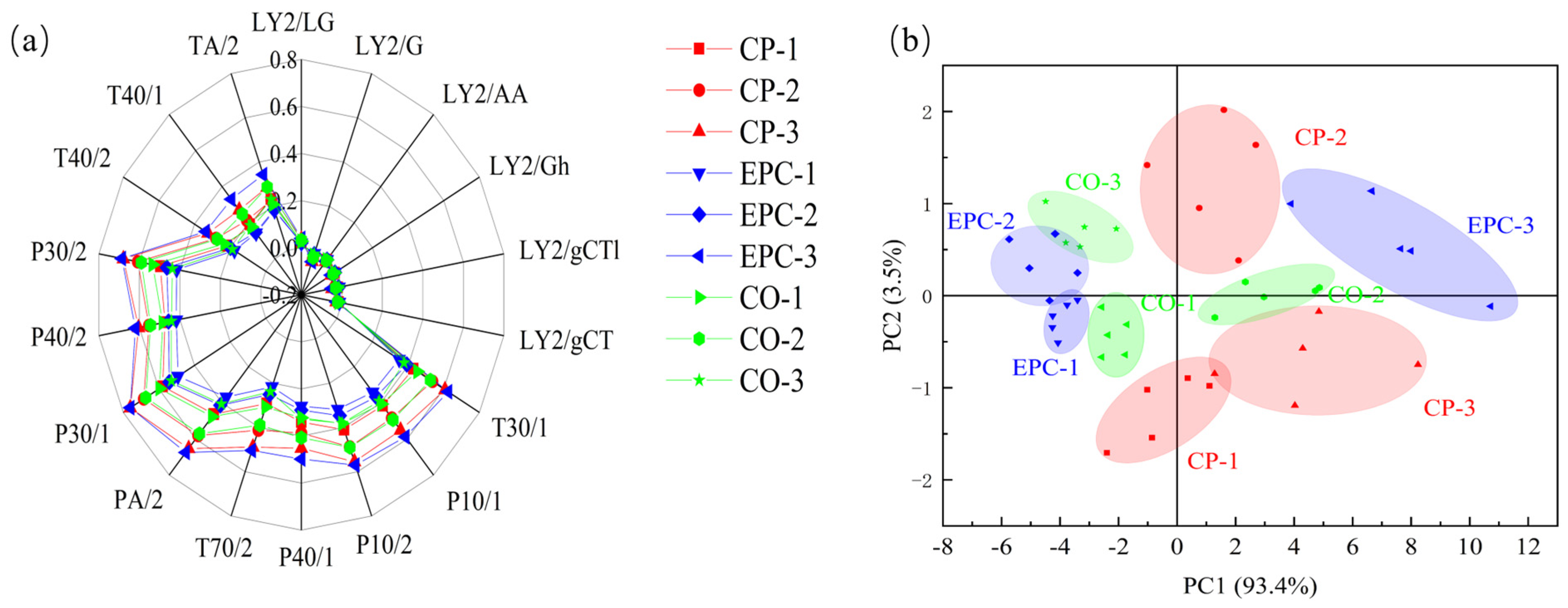

2.1. E-Nose Analysis

2.2. E-Tongue Analysis

2.3. FAA Analysis

2.4. GC–IMS Analysis

2.5. Key Volatile Aroma Compounds

2.6. Correlation Analysis

3. Materials and Methods

3.1. Materials

3.2. Instruments and Equipment

3.3. Cooking of Chicken Soup and Sample Preparation

3.4. Physicochemical Measurements

3.4.1. E-Nose Analysis

3.4.2. E-Tongue Analysis

3.4.3. Free Amino Acid (FAA) Compositional Analysis

3.4.4. GC–IMS

3.4.5. Identification of Key Volatile Aroma Compounds

3.5. Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, L.L.; Hao, Z.L.; Zhao, C.; Zhang, Y.Y.; Li, J.; Sun, B.G.; Tang, Y.Z. Taste compounds, affecting factors, and methods used to evaluate chicken soup: A review. Food Sci. Nutr. 2021, 9, 5833–5853. [Google Scholar] [CrossRef] [PubMed]

- Liang, L.; Zhang, J.C.; Huang, Y.; Zhang, Y.Y.; Sun, B.Q. Characterization and molecular docking study of taste peptides from chicken soup by sensory analysis combined with nano-LC-Q-TOF-MS/MS. Food Chem. 2022, 383, 132455. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.L.; Liang, L.; Qiao, K.N.; Pu, D.D.; Sun, B.G.; Zhou, X.W. Decoding the effect of age on the taste perception of chicken breast soup based on LC-QTOF-MS/MS combined with a chemometric approach. Foods 2023, 12, 674. [Google Scholar] [CrossRef] [PubMed]

- Lai, J.; Wu, R.Y.; Wang, J. Effect of cooking modes on quality and flavor characteristic in Clitocybe squamulose chicken soup. Front. Nutr. 2022, 9, 1048352. [Google Scholar] [CrossRef] [PubMed]

- Guan, H.N.; Yang, C.; Tian, Y.L.; Feng, C.M.; Gai, S.M.; Liu, D.Y.; Diao, X.Q. Changes in stability and volatile flavor compounds of self-emulsifying chicken soup formed during the stewing process. LWT—Food Sci. Technol. 2022, 175, 114520. [Google Scholar] [CrossRef]

- Wang, S.C.; Zhang, S.K.; Adhikari, K. Influence of monosodium glutamate and its substitutes on sensory characteristics and consumer perceptions of chicken soup. Foods 2019, 8, 71. [Google Scholar] [CrossRef] [PubMed]

- Nishimura, T.; Goto, S.; Miura, K.; Takakura, Y.; Egusa, A.S.; Wakabayashi, H. Umami compounds enhance the intensity of retronasal sensation of aromas from model chicken soups. Food Chem. 2016, 196, 577–583. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Palacios, T.; Eusebio, J.; Palma, S.F.; Carvalho, M.J.; Mir-Bel, J.; Antequera, T. Taste compounds and consumer acceptance of chicken soups as affected by cooking conditions. Inter. J. Food Prop. 2017, 20, 5154–5165. [Google Scholar] [CrossRef]

- Qi, J.; Liu, D.Y.; Zhou, G.H.; Xu, X.L. Characteristic flavor of traditional soup made by stewing chinese yellow-feather chickens. J. Food Sci. 2017, 82, 2031–2035. [Google Scholar] [CrossRef] [PubMed]

- Zeng, X.F.; Liu, J.L.; Dong, H.; Bai, W.D.; Yu, L.M.; Li, X.M. Variations of volatile flavour compounds in Cordyceps militaris chicken soup after enzymolysis pretreatment by SPME combined with GC-MS, GC × GC-TOF MS and GC-IMS. Inter. J. Food Sci. Technol. 2020, 55, 509–516. [Google Scholar] [CrossRef]

- Kong, Y.; Yang, X.; Ding, Q.; Zhang, Y.Y.; Sun, B.G.; Chen, H.T.; Sun, Y. Comparison of non-volatile umami components in chicken soup and chicken enzymatic hydrolysate. Food Res. Inter. 2017, 102, 559–566. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.; Li, Z.J.; Chao, Y.Z.; Wu, Z.Q.; Zhou, M.X.; Xiao, S.T.; Zeng, J.; Zhe, J. Evaluation by electronic tongue and headspace-GC-IMS analyses of the flavor compounds in dry-cured pork with different salt content. Food Res. Inter. 2020, 137, 109456. [Google Scholar] [CrossRef] [PubMed]

- Barido, F.H.; Utama, D.T.; Kim, Y.J.; Lee, S.K. Fatty acid profiles and flavour-related compounds of retorted Korean ginseng chicken soup (Samgyetang) affected by pre-treated black garlic extract. Anim. Biosci. 2022, 35, 1080–1090. [Google Scholar] [CrossRef] [PubMed]

- Li, D.Y.; Yuan, Z.; Liu, Z.Q.; Yu, M.M.; Guo, Y.; Liu, X.Y. Effect of oxidation and Maillard reaction on color deterioration of ready-to eat shrimps during storage. LWT—Food Sci. Technol. 2020, 131, 109696. [Google Scholar] [CrossRef]

- Liu, J.B.; Liu, M.Y.; He, C.C.; Song, H.L.; Chen, F. Effect of thermal treatment on the flavor generation from Maillard reaction of xylose and chicken peptide. LWT—Food Sci. Technol 2015, 64, 316–325. [Google Scholar] [CrossRef]

- Qi, J.; Du, C.; Yao, X.N.; Yang, C.; Zhang, Q.Y.; Liu, D.Y. Enrichment of taste and aroma compounds in braised soup during repeated stewing of chicken meat. LWT—Food Sci. Technol. 2022, 168, 113926. [Google Scholar] [CrossRef]

- Chen, Y.; Li, P.; Liao, L.Y.; Qin, Y.Y.; Jiang, L.W.; Liu, Y. Characteristic fingerprints and volatile flavor compound variations in Liuyang Douchi during fermentation via HS-GC-IMS and HS-SPME- GC-MS. Food Chem. 2021, 361, 130055. [Google Scholar] [CrossRef] [PubMed]

- Yao, W.S.; Cai, Y.X.; Liu, D.Y.; Chen, Y.; Li, J.R.; Zhang, M.C.; Chen, N.; Zhang, H. Analysis of flavor formation during production of Dezhou braised chicken using headspace-gas chromatography-ion mobility spectrometry (HS-GC-IMS). Food Chem. 2022, 370, 130989. [Google Scholar] [CrossRef] [PubMed]

- Zou, J.; Xu, M.J.; Zou, Y.F.; Yang, B. Chemical compositions and sensory characteristics of pork rib and Silkie chicken soups prepared by various cooking techniques. Food Chem. 2020, 345, 128755. [Google Scholar] [CrossRef] [PubMed]

- Czarnowska-Kujawska, M.; Draszanowska, A.; Starowicz, M. Effect of different cooking methods on the folate content, organoleptic and functional properties of broccoli and spinach. LWT—Food Sci. Technol. 2022, 167, 113825. [Google Scholar] [CrossRef]

- Danowska-Oziewicz, M.; Narwojsz, A.; Draszanowska, A.; Marat, N. The effects of cooking method on selected quality traits of broccoli and green asparagus. Inter. J. Food Sci. Technol. 2020, 55, 127–135. [Google Scholar] [CrossRef]

- Zhuang, H.; Savage, E.M. Validation of a Combi Oven Cooking Method for Preparation of Chicken Breast Meat for Quality Assessment. J. Food Sci. 2008, 73, 425–430. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Yuan, L.; Liu, H.J.; Liu, H.Y.; Zhou, Y.; Li, M.N.; Gao, R.C. Analysis of the changes of volatile flavor compounds in a traditional Chinese shrimp paste during fermentation based on electronic nose, SPME-GC-MS and HS-GC-IMS. Food Sci. Hum. Well. 2023, 12, 173182. [Google Scholar] [CrossRef]

- Rosa, A.R.D.; Francesco, L.; Cheli, F.; Vincenzo, C. Fusion of electronic nose, electronic tongue and computer vision for animal source food authentication and quality assessment -A review. J. Food Eng. 2017, 210, 62–75. [Google Scholar] [CrossRef]

- Lan, Y.L.; Wu, J.; Wang, X.J.; Sun, X.C.; Hackman, R.M.; Li, Z.X.; Feng, X.C. Evaluation of antioxidant capacity and flavor profile change of pomegranate wine during fermentation and aging process. Food Chem. 2017, 232, 767–787. [Google Scholar] [CrossRef]

- Castura, J.C.; Varela, P.; Næs, T. Investigating paired comparisons after principal component analysis. Food Qual. Prefer. 2023, 106, 104814. [Google Scholar] [CrossRef]

- Matsuoa, Y.; Miuraa, L.A.; Araki, T.; Yoshie-Starka, Y. Proximate composition and profiles of free amino acids, fatty acids, mineralsand aroma compounds in Citrus natsudaidai peel. Food Chem. 2019, 279, 356–363. [Google Scholar] [CrossRef] [PubMed]

- Moerdijk-Poortvliet, T.C.W.; Jong, D.L.C.; Fremouw, R.; Reu, S.D.; Winter, J.M.D.; Timmermans, K. Extraction and analysis of free amino acids and 5’-nucleotides, the key contributors to the umamo taste of seaweed. Food Chem. 2022, 370, 131352. [Google Scholar] [CrossRef] [PubMed]

- Zhao, D.; Li, H.; Huang, M.X.; Wang, T.L.; Hu, Y.; Wang, L.P.; Xu, D.N.; Mao, S.Y.; Li, C.B.; Zhou, G.H. Influence of proteolytic enzyme treatment on the changes in volatile compounds and odors of beef longissimus dorsi. Food Chem. 2020, 333, 127549. [Google Scholar] [CrossRef]

- Pérez-Palacios, T.; Melo, A.; Cunha, S.C.; Ferreira, I.M.P.L.V.O. Determination of Free Amino Acids in Coated Foods by GC–MS: Optimization of the Extraction Procedure by Using Statistical Design. Food Anal. Meth. 2014, 7, 172–180. [Google Scholar] [CrossRef]

- Wan, P.; Liu, J.; Chen, D.W. Analysis of aroma-active compounds in bighead carp head soup and their influence on umami of a model soup. Microchem. J. 2021, 168, 1064236. [Google Scholar] [CrossRef]

- Ogasawara, Y.; Mochimaru, S.; Ueda, R.; Ban, M.; Kabuto, S.; Abe, K. Preparation of an aroma fraction from dried bonito by steam distillation and its effect on modification of salty and umami taste qualities. J. Food Sci. 2016, 8, 308–310. [Google Scholar] [CrossRef] [PubMed]

- Du, C.; Qi, J.; Yang, C.; Zhang, Q.Y.; Liu, D.Y. Enrichment of taste and aroma perceptions in chicken meat stewed in braised soup used repeatedly. J. Food Sci. 2022, 87, 2563–2577. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.C.; Cui, H.P.; Yang, N.; Ayed, C.; Zhang, X.M.; Fisk, I.D. Enhancement of coffee brew aroma through control of the aroma staling pathway of 2-furfurylthiol. Food Chem. 2020, 322, 126754. [Google Scholar] [CrossRef] [PubMed]

- Fu, H.X.; Feng, Q.H.; Qin, D.; Shen, X.R.; Li, C.; He, Y.F.; Shang, W.T. Improving the flavor of tilapia fish head soup by adding lipid oxidation products and cysteine. Food Chem. 2023, 429, 136976. [Google Scholar] [CrossRef] [PubMed]

- Zou, T.T.; Kang, L.; Yang, C.; Song, H.L.; Liu, Y. Flavour precursor peptide from an enzymatic beef hydrolysate Maillard reaction-II: Mechanism of the synthesis of flavour compounds from a sulphur-containing peptide through a Maillard reaction. LWT—Food Sci. Technol. 2020, 110, 8–18. [Google Scholar] [CrossRef]

- Wang, L.; Li, C.; Al-Dalali, S.; Liu, Y.Y.; Zhou, H.; Chen, C.G.; Xu, B.C.; Wang, Y. Characterization of key aroma compounds in traditional beef soup. J. Food Compos. Anal. 2022, 114, 104839. [Google Scholar] [CrossRef]

- Jin, L.; Lian, X.Y.; Chen, L.; Lei, Y.; Li, J.Y.; Yang, Z.Y.; Li, D. Characteristic aroma analysis and interaction study of key aroma compounds of Chuanhong congou black tea. Eur. Food Res. Technol. 2023, 23, 4398. [Google Scholar] [CrossRef]

- Azcarate, S.M.; de Araújo Gomes, A.; Alcaraz, M.R.; Ugulino de Araújo, M.C.; Camiña, J.M.; Goicoechea, H.C. Modeling excitation–emission fluorescence matrices with pattern recognition algorithms for classification of Argentine white wines according grape variety. Food Chem. 2015, 184, 214–219. [Google Scholar] [CrossRef] [PubMed]

| Taste | Name | Threshold Value mg/10 g | Free Amino Acid Content (mg/10 g) | TAV | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CP-1 | CP-2 | CP-3 | EPC-1 | EPC-2 | EPC-3 | CO-1 | CO-2 | CO-3 | CP-1 | CP-2 | CP-3 | EPC-1 | EPC-2 | EPC-3 | CO-1 | CO-2 | CO-3 | |||

| umami | Asp | 10.00 | 8.68 ± 0.32 a | 8.99 ± 0.32 a | 9.87 ± 0.42 a | 6.81 ± 0.28 b | 7.20 ± 0.31 b | 7.14 ± 0.28 b | 7.34 ± 0.23 b | 7.66 ± 0.34 b | 9.42 ± 0.43 a | 0.77 | 0.90 | 0.99 | 0.68 | 0.72 | 0.71 | 0.73 | 0.77 | 0.94 |

| Glu | 3.00 | 6.32 ± 0.14 c | 7.39 ± 0.36 b | 9.22 ± 0.32 a | 6.21 ± 0.31 c | 5.77 ± 0.23 c | 6.03 ± 0.19 c | 5.88 ± 0.32 c | 7.35 ± 0.25 b | 8.82 ± 0.36 a | 2.11 | 2.46 | 3.07 | 2.07 | 1.92 | 2.01 | 1.96 | 2.45 | 2.94 | |

| Total | 14.00 | 16.38 | 19.09 | 13.02 | 12.97 | 13.17 | 13.22 | 15.01 | 18.24 | |||||||||||

| Sweet | Thr | 26.00 | 1.23 ± 0.07 c | 2.10 ± 0.11 a | 2.04 ± 0.06 a | 1.48 ± 0.08 b | 1.53 ± 0.05 b | 1.63 ± 0.12 b | 1.61 ± 0.09 b | 1.73 ± 0.12 b | 2.12 ± 0.10 a | 0.05 | 0.08 | 0.08 | 0.06 | 0.06 | 0.06 | 0.06 | 0.07 | 0.08 |

| Ser | 15.00 | 0.92 ± 0.06 a | 0.81 ± 0.05 a | 0.86 ± 0.11 a | 0.53 ± 0.03 b | 0.59 ± 0.06 b | 0.60 ± 0.04 b | 0.68 ± 0.03 b | 0.72 ± 0.03 b | 0.86 ± 0.04 a | 0.06 | 0.05 | 0.06 | 0.04 | 0.04 | 0.04 | 0.05 | 0.05 | 0.06 | |

| Gly | 13.00 | 3.12 ± 0.15 a | 3.29 ± 0.13 a | 3.29 ± 0.14 a | 2.60 ± 0.12 b | 2.39 ± 0.17 b | 0 | 2.59 ± 0.21 b | 2.72 ± 0.14 b | 3.21 ± 0.12 a | 0.24 | 0.25 | 0.25 | 0.20 | 0.18 | -- | 0.20 | 0.21 | 0.25 | |

| Ala | 6.00 | 5.55 ± 0.23 a | 5.42 ± 0.21 a | 5.50 ± 0.19 a | 4.41 ± 0.22 b | 3.78 ± 0.17 c | 3.90 ± 0.16 c | 3.90 ± 0.17 c | 4.18 ± 0.35 b | 5.40 ± 0.21 a | 0.92 | 0.90 | 0.92 | 0.76 | 0.63 | 0.65 | 0.65 | 0.70 | 0.9 | |

| Total | 10.82 | 11.62 | 11.69 | 9.02 | 8.29 | 6.13 | 8.78 | 9.35 | 11.58 | |||||||||||

| bitter | Val | 4.00 | 0 | 0 | 1.81 ± 0.09 a | 0 | 0 | 1.16 ± 0.06 b | 1.08 ± 0.04 b | 1.23 ± 0.06 b | 1.64 ± 0.08 a | 0 | 0 | 0.45 | 0 | 0 | 0.29 | 0.27 | 0.31 | 0.41 |

| Ile | 9.00 | 1.36 ± 0.06 a | 1.33 ± 0.06 a | 1.29 ± 0.05 a | 0.71 ± 0.03 b | 0.81 ± 0.05 b | 0.94 ± 0.03 b | 0.91 ± 0.07 b | 0.91 ± 0.05 b | 1.18 ± 0.06 a | 0.15 | 0.15 | 0.14 | 0.08 | 0.09 | 0.10 | 0.10 | 0.10 | 0.13 | |

| Leu | 19.00 | 2.28 ± 0.14 a | 2.45 ± 0.12 a | 2.39 ± 0.13 a | 0 | 1.46 ± 0.07 b | 1.61 ± 0.07 b | 1.80 ± 0.13 b | 1.59 ± 0.08 b | 2.05 ± 0.09 a | 0.12 | 0.13 | 0.13 | 0 | 0.08 | 0.08 | 0.09 | 0.08 | 0.11 | |

| Tyr | 26.00 | 1.35 ± 0.08 a | 1.43 ± 0.08 a | 1.49 ± 0.06 a | 0.93 ± 0.04 b | 1.00 ± 0.06 b | 1.06 ± 0.05 b | 1.06 ± 0.05 b | 1.05 ± 0.04 b | 1.50 ± 0.06 a | 0.05 | 0.06 | 0 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.0 | |

| Phe | 9.00 | 1.05 ± 0.06 a | 1.18 ± 0.11 a | 1.22 ± 0.09 a | 0.78 ± 0.03 b | 0.90 ± 0.03 b | 0.83 ± 0.03 b | 0.81 ± 0.03 b | 0.91 ± 0.05 b | 1.34 ± 0.05 a | 0.12 | 0.13 | 0.14 | 0.09 | 0.10 | 0.09 | 0.09 | 0.10 | 0.15 | |

| His | 2.00 | 1.17 ± 0.04 a | 1.26 ± 0.02 a | 1.44 ± 0.07 a | 0.95 ± 0.06 b | 1.14 ± 0.05 a | 1.19 ± 0.11 a | 1.03 ± 0.06 b | 0.93 ± 0.08 b | 1.29 ± 0.06 a | 0.59 | 0.63 | 0.72 | 0.48 | 0.57 | 0.60 | 0.52 | 0.47 | 0.65 | |

| Lys | 5.00 | 0.00 | 4.69 ± 0.23 a | 0.30 ± 0.04 e | 0.13 ± 0.02 f | 2.30 ± 0.13 b | 0.92 ± 0.04 c | 0.16 ± 0.02 f | 0.61 ± 0.02 d | 0.11 ± 0.02 f | 0.00 | 0.94 | 0.06 | 0.03 | 0.46 | 0.18 | 0.03 | 0.12 | 0.02 | |

| Arg | 5.00 | 1.36 ± 0.12 d | 1.72 ± 0.08 c | 2.03 ± 0.13 b | 3.02 ± 0.19 a | 2.05 ± 0.11 b | 1.16 ± 0.13 e | 1.52 ± 0.11 c | 0.00 | 2.15 ± 0.13 b | 0.27 | 0.34 | 0.41 | 0.60 | 0.41 | 0.23 | 0.30 | 0 | 0.43 | |

| Total | 8.57 | 14.06 | 11.97 | 6.52 | 9.66 | 8.87 | 8.37 | 7.23 | 11.26 | |||||||||||

| Free amino acid content (TFAA) | 33.39 | 42.06 | 42.75 | 28.56 | 30.92 | 28.17 | 30.37 | 31.59 | 41.08 | |||||||||||

| Number | Equipment | Stewing Time/h | Sample Number |

|---|---|---|---|

| 1 | Ceramic pot (CP) | 2 | CP-1 |

| 2 | 3 | CP-2 | |

| 3 | 4 | CP-3 | |

| 4 | Electric pressure cooker (EPC) | 2 | EPC-1 |

| 5 | 3 | EPC-2 | |

| 6 | 4 | EPC-3 | |

| 7 | Combi oven (CO) | 2 | CO-1 |

| 8 | 3 | CO-2 | |

| 9 | 4 | CO-3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, C.; Xu, C.; Chen, L.; Yang, J.; Qiao, M.; Wu, Z. Effect of Different Cooking Methods on the Aroma and Taste of Chicken Broth. Molecules 2024, 29, 1532. https://doi.org/10.3390/molecules29071532

Yuan C, Xu C, Chen L, Yang J, Qiao M, Wu Z. Effect of Different Cooking Methods on the Aroma and Taste of Chicken Broth. Molecules. 2024; 29(7):1532. https://doi.org/10.3390/molecules29071532

Chicago/Turabian StyleYuan, Can, Chengjian Xu, Lilan Chen, Jun Yang, Mingfeng Qiao, and Zhoulin Wu. 2024. "Effect of Different Cooking Methods on the Aroma and Taste of Chicken Broth" Molecules 29, no. 7: 1532. https://doi.org/10.3390/molecules29071532

APA StyleYuan, C., Xu, C., Chen, L., Yang, J., Qiao, M., & Wu, Z. (2024). Effect of Different Cooking Methods on the Aroma and Taste of Chicken Broth. Molecules, 29(7), 1532. https://doi.org/10.3390/molecules29071532