Core–Shell CoS2@MoS2 with Hollow Heterostructure as an Efficient Electrocatalyst for Boosting Oxygen Evolution Reaction

Abstract

1. Introduction

2. Results and Discussion

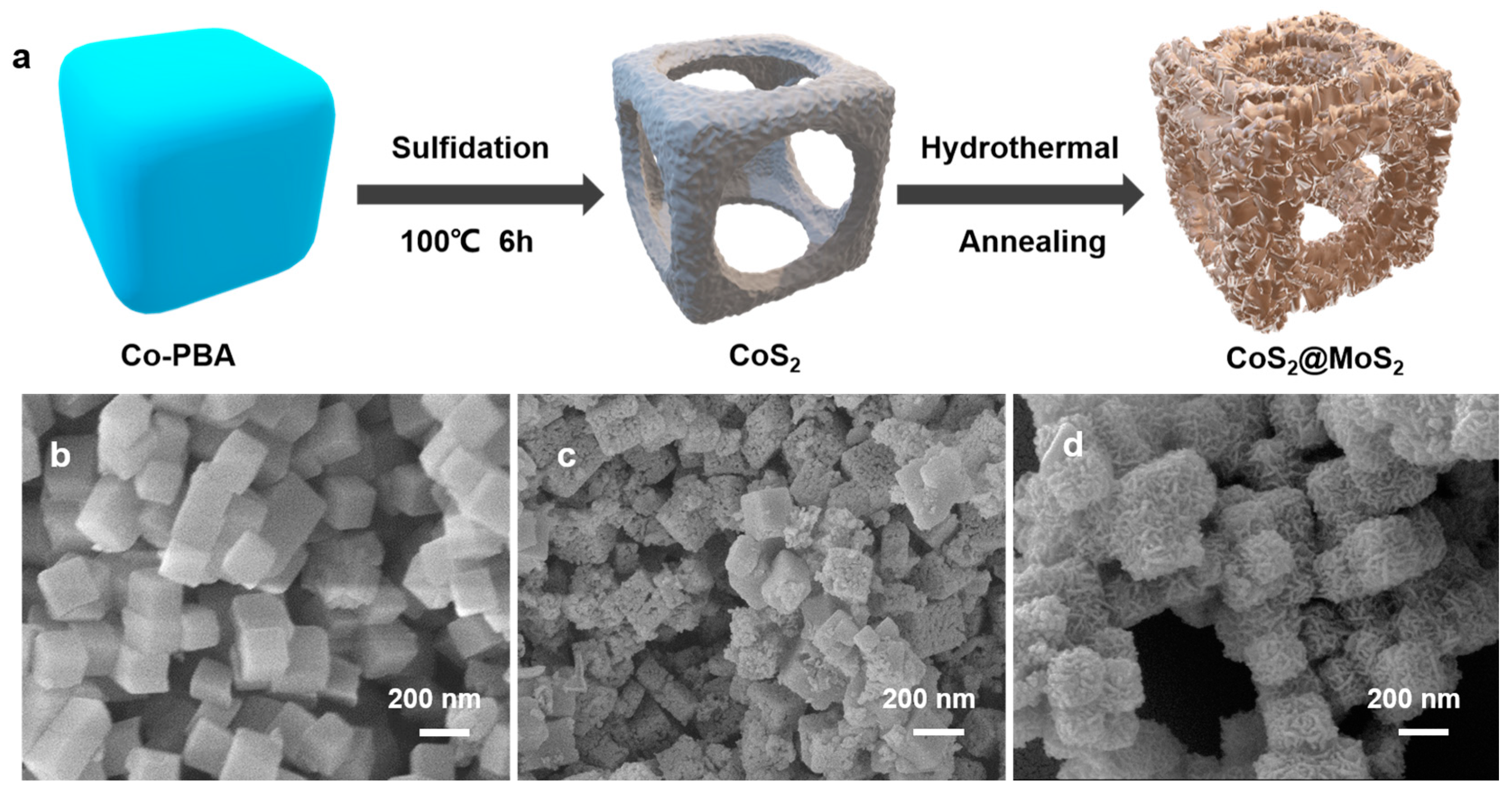

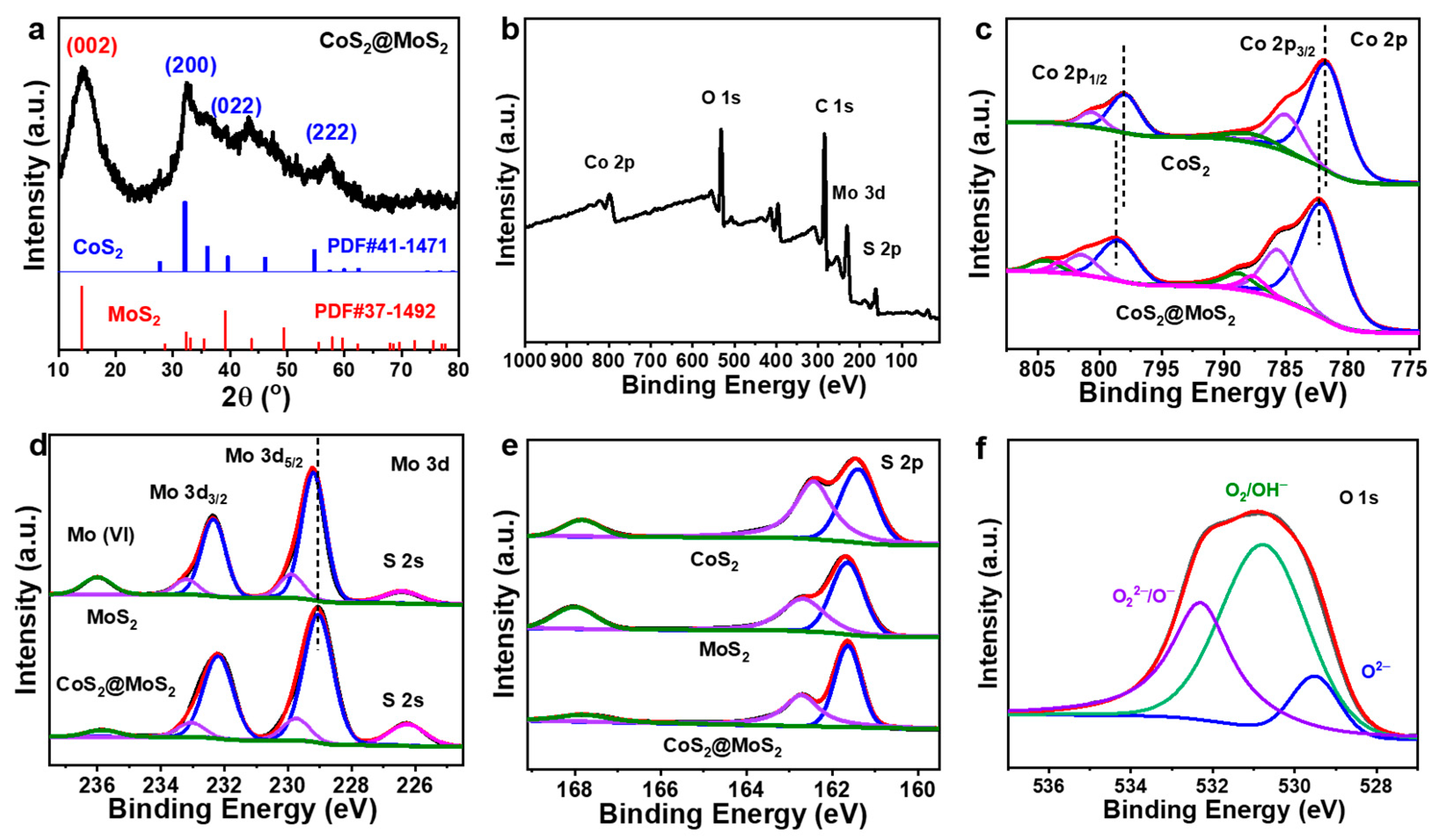

2.1. Synthesis and Characterization of CoS2@MoS2

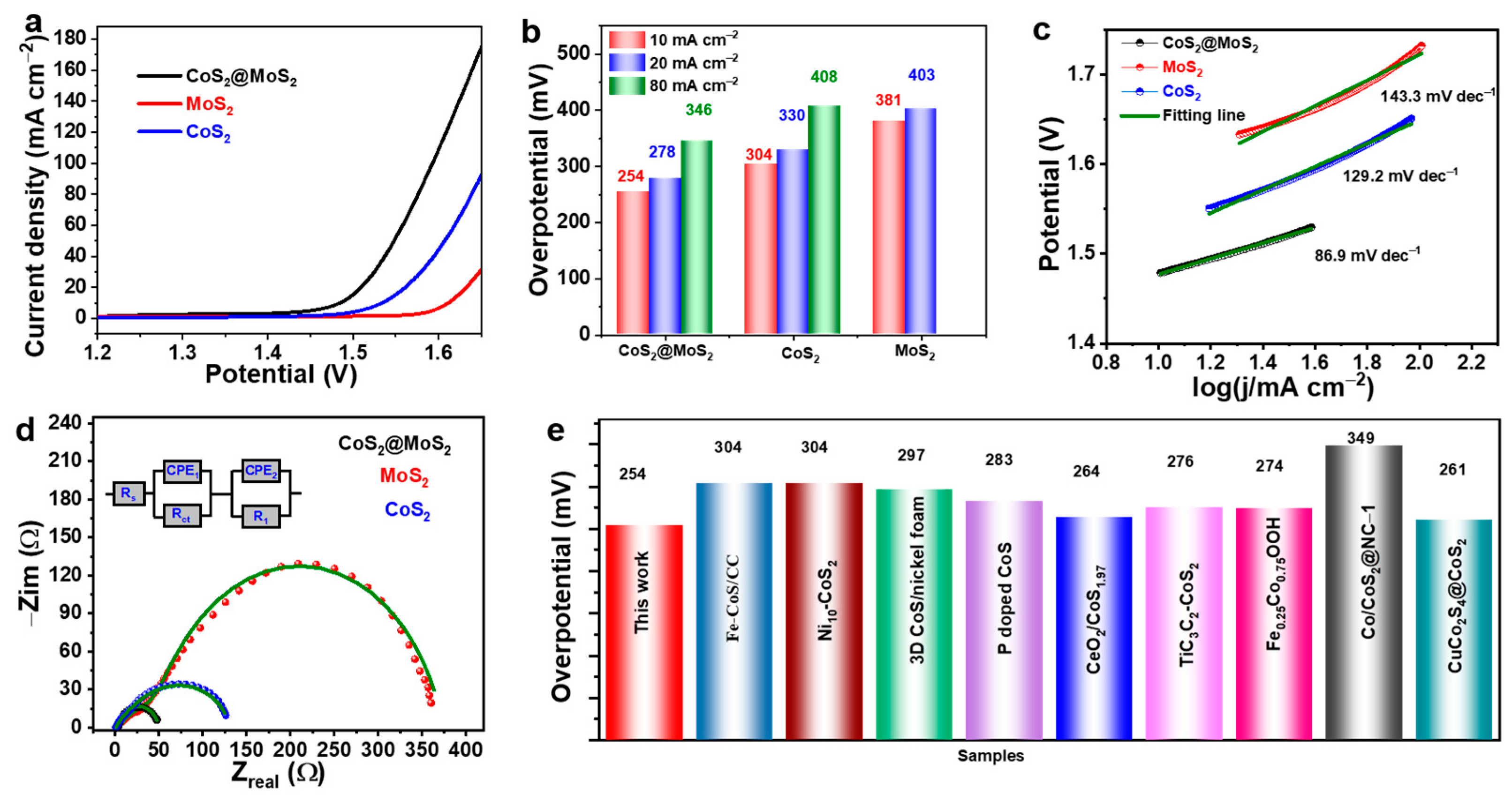

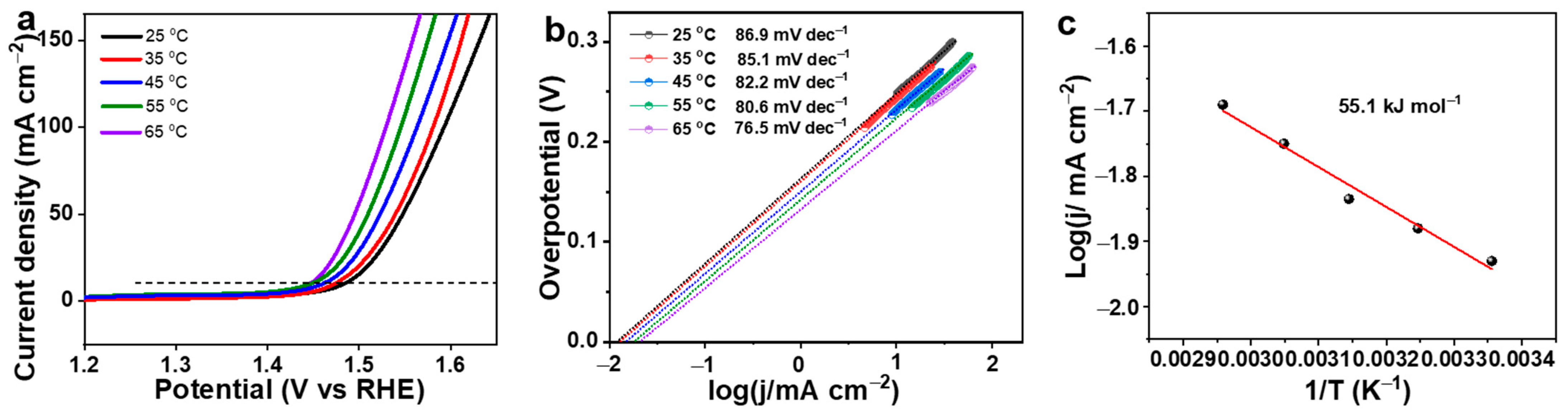

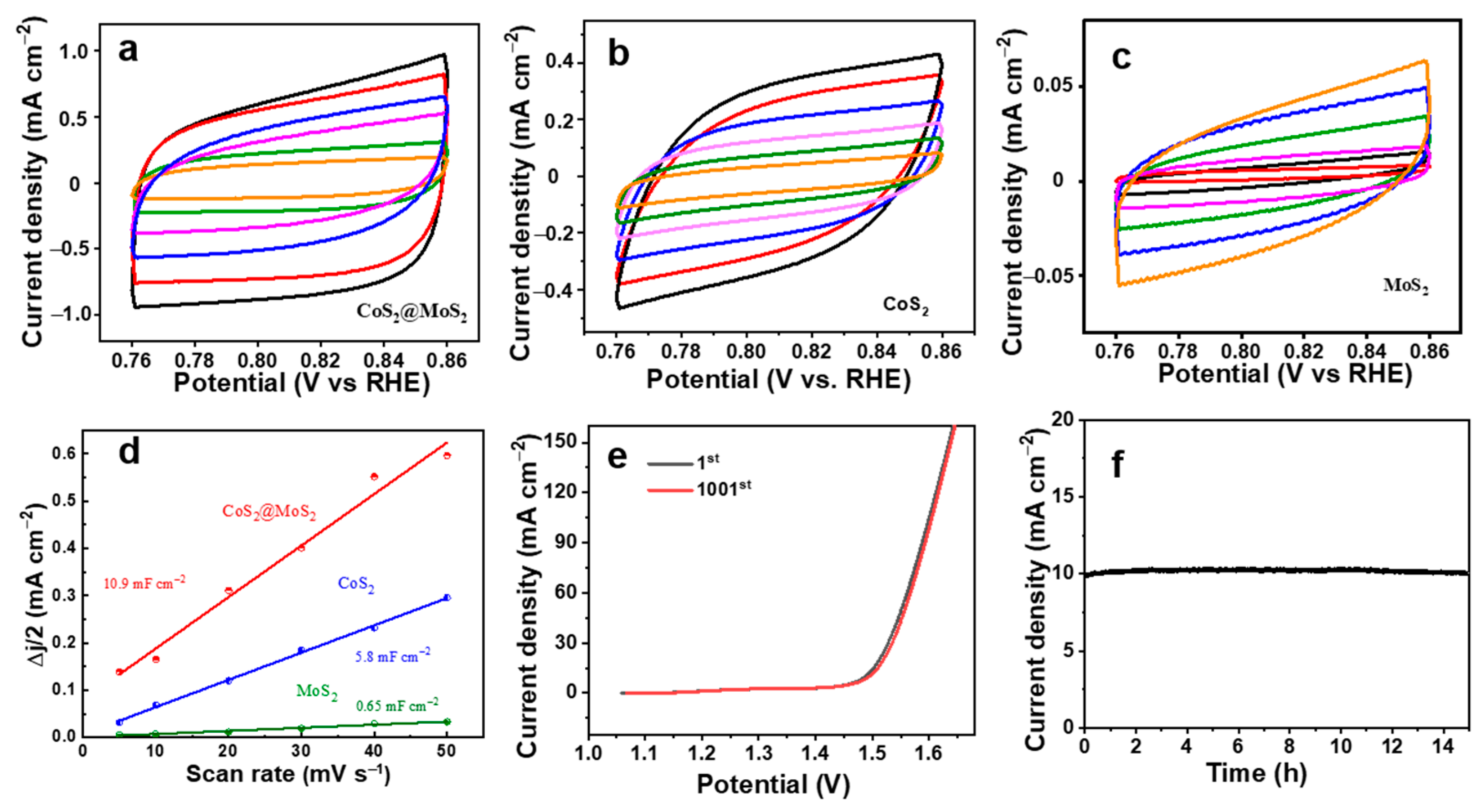

2.2. Electrocatalytic Performance

3. Materials and Methods

3.1. Synthesis of Co-PBA

3.2. Synthesis of CoS2

3.3. Synthesis of Pure MoS2

3.4. Synthesis of Hollow CoS2@MoS2

3.5. Characterization

3.6. Electrochemical Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, C.; Bai, Y.; Li, W.; Yang, F.; Zhang, G.; Pang, H. In Situ Growth of Three-Dimensional MXene/Metal-Organic Framework Composites for High-Performance Supercapacitors. Angew. Chem. Int. Ed. Engl. 2022, 61, e202116282. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Liu, C.; Chen, T.; Li, W.; Zheng, S.; Pi, Y.; Luo, Y.; Pang, H. MXene-Copper/Cobalt Hybrids via Lewis Acidic Molten Salts Etching for High Performance Symmetric Supercapacitors. Angew. Chem. Int. Ed. 2021, 60, 25318–25322. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Li, W.-P.; Cao, Y.; Portniagin, A.; Tang, B.; Wang, S.; Liu, Q.; Yu, D.Y.W.; Zhong, X.; Zheng, X.; et al. Dual-Atom Co/Ni Electrocatalyst Anchored at the Surface-Modified Ti3C2Tx MXene Enables Efficient Hydrogen and Oxygen Evolution Reactions. ACS Nano 2024, 18, 4256–4268. [Google Scholar] [CrossRef]

- Hanan, A.; Nazim Lakhan, M.; Walvekar, R.; Khalid, M.; Prakash, C. Heteroatom-doped MXenes as Electrocatalysts for Hydrogen Evolution Reaction: A Review on the Recent Advances, Mechanisms and Prospects. Chem. Eng. J. 2024, 483, 149107. [Google Scholar] [CrossRef]

- Ren, X.; Wu, T.; Sun, Y.; Li, Y.; Xian, G.; Liu, X.; Shen, C.; Gracia, J.; Gao, H.-J.; Yang, H.; et al. Spin-Polarized Oxygen Evolution Reaction Under Magnetic Field. Nat. Commun. 2021, 12, 2608. [Google Scholar] [CrossRef] [PubMed]

- Kuang, Y.; Qiao, W.; Yang, F.; Feng, L. Electrochemical Hydrogen Evolution Efficiently Boosted by Interfacial Charge Redistribution in Ru/MoSe2 Embedded Mesoporous Hollow Carbon Spheres. J. Energy Chem. 2023, 85, 447–454. [Google Scholar] [CrossRef]

- Yu, X.; Lin, L.; Pei, C.; Ji, S.; Sun, Y.; Wang, Y.; Kim, J.K.; Park, H.S.; Pang, H. Immobilizing Bimetallic RuCo Nanoalloys on Few-layered MXene as a Robust Bifunctional Electrocatalyst for Overall Water Splitting. Chem. Eur. J. 2023, 30, e202303524. [Google Scholar] [CrossRef] [PubMed]

- Pan, Y.; Gao, J.; Lv, E.; Li, T.; Xu, H.; Sun, L.; Nairan, A.; Zhang, Q. Integration of Alloy Segregation and Surface Co-O Hybridization in Carbon-Encapsulated CoNiPt Alloy Catalyst for Superior Alkaline Hydrogen Evolution. Adv. Funct. Mater. 2023, 33, 2303833. [Google Scholar] [CrossRef]

- Li, T.-T.; Cui, J.-Y.; Xu, M.; Song, K.; Yin, Z.-H.; Meng, C.; Liu, H.; Wang, J.-J. Efficient Acidic Photoelectrochemical Water Splitting Enabled by Ru Single Atoms Anchored on Hematite Photoanodes. Nano Lett. 2024, 24, 958–965. [Google Scholar] [CrossRef]

- Tu, W.; Chen, K.; Zhu, L.; Zai, H.E.B.; Ke, X.; Chen, C.; Sui, M.; Chen, Q.; Li, Y. Tungsten-Doping-Induced Surface Reconstruction of Porous Ternary Pt-Based Alloy Electrocatalyst for Oxygen Reduction. Adv. Funct. Mater. 2019, 29, 1807070. [Google Scholar] [CrossRef]

- He, R.; Wang, C.; Feng, L. Amorphous FeCoNi-S as Efficient Bifunctional Electrocatalysts for Overall Water Splitting Reaction. Chin. Chem. Lett. 2023, 34, 107241. [Google Scholar] [CrossRef]

- Lin, J.; Zhou, H.; Amin, R.S.; Fetohi, A.E.; El-Khatib, K.M.; Wang, C.; Guo, L.; Wang, Y. In situ Formation of Nickel Sulfide Quantum Dots Embedded into a Two-Dimensional Metal–Organic Framework for Water Splitting. Inorg. Chem. Front. 2023, 10, 1294–1304. [Google Scholar] [CrossRef]

- Zhang, T.; Sun, J.; Guan, J. Self-Supported Transition Metal Chalcogenides for Oxygen Evolution. Nano Res. 2023, 16, 8684–8711. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, T.; Han, J.; Qi, H.; Jiao, S.; Hou, C.; Guan, J. Interface Engineering of Fe-Sn-Co Sulfide/Oxyhydroxide Heterostructural Electrocatalyst for Synergistic Water Splitting. Nano Res. Energy 2024, 3, e9120106. [Google Scholar] [CrossRef]

- Huang, Y.; Jiang, L.-W.; Liu, H.; Wang, J.-J. Electronic Structure Regulation and Polysulfide Bonding of Co-doped (Ni, Fe)1+xS Enable Highly Efficient and Stable Electrocatalytic Overall Water Splitting. Chem. Eng. J 2022, 441, 136121. [Google Scholar] [CrossRef]

- Hu, X.; Wang, R.; Feng, W.; Xu, C.; Wei, Z. Electrocatalytic Oxygen Evolution Activities of Metal Chalcogenides and Phosphides: Fundamentals, Origins, and Future Strategies. J. Energy Chem. 2023, 81, 167–191. [Google Scholar] [CrossRef]

- Mijowska, E.; Pietrusewicz, K.; Maślana, K. Highly Porous Carbon Flakes Derived from Cellulose and Nickel Phosphide Heterostructure towards Efficient Electrocatalysis of Oxygen Evolution Reaction. Molecules 2024, 29, 352. [Google Scholar] [CrossRef]

- Yuan, S.; Peng, J.; Cai, B.; Huang, Z.; Garcia-Esparza, A.T.; Sokaras, D.; Zhang, Y.; Giordano, L.; Akkiraju, K.; Zhu, Y.G.; et al. Tunable Metal Hydroxide–Organic Frameworks for Catalysing Oxygen Evolution. Nat. Mater. 2022, 21, 673–680. [Google Scholar] [CrossRef] [PubMed]

- Fu, K.; Chen, W.; Jiang, F.; Chen, X.; Liu, J. Research Progress of Perovskite-Based Bifunctional Oxygen Electrocatalyst in Alkaline Conditions. Molecules 2023, 28, 7114. [Google Scholar] [CrossRef]

- Yin, Z.-H.; Huang, Y.; Song, K.; Li, T.-T.; Cui, J.-Y.; Meng, C.; Zhang, H.; Wang, J.-J. Ir Single Atoms Boost Metal–Oxygen Covalency on Selenide-Derived NiOOH for Direct Intramolecular Oxygen Coupling. J. Am. Chem. Soc. 2024, 146, 6846–6855. [Google Scholar] [CrossRef]

- Yu, J.; Qian, Y.; Seo, S.; Liu, Y.; Bui, H.T.D.; Tran, N.Q.; Lee, J.; Kumar, A.; Wang, H.; Luo, Y.; et al. Exploring Catalytic Behaviors of CoS2-ReS2 Heterojunction by Interfacial Engineering. J. Energy Chem. 2023, 85, 11–18. [Google Scholar] [CrossRef]

- Kong, W.; Luan, X.; Du, H.; Xia, L.; Qu, F. Enhanced Electrocatalytic Activity of Water Oxidation in an Alkaline Medium via Fe Doping in CoS2 Nanosheets. Chem. Commun. 2019, 55, 2469–2472. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Pan, Z.; Pei, C.; Lin, L.; Lu, Y.; Park, H.S.; Pang, H. Core-shell Heterostructure by Coupling Layered ReS2 with Co9S8 Nanocubes for Boosted Oxygen Evolution Reaction. Chin. Chem. Lett. 2024, 35, 108484. [Google Scholar] [CrossRef]

- Yang, G.; Pei, C.; Xu, F.; Park, H.S.; Yu, X.; Pang, H. Prussian Blue Analogue Derived NiCoSe4 Coupling with Nitrogen-Doped Carbon Nanofibers for Pseudocapacitive Electrodes. Chin. Chem. Lett. 2023, 34, 108152. [Google Scholar] [CrossRef]

- Lee, J.H.; Kattel, S.; Wang, Y.; Tackett, B.M.; Xie, Z.; Hwang, S.; Denny, S.R.; Xu, W.; Chen, J.G. Prussian Blue Analogues as Platform Materials for Understanding and Developing Oxygen Evolution Reaction Electrocatalysts. J. Catal. 2021, 393, 390–398. [Google Scholar] [CrossRef]

- Chang, J.; Hu, Z.; Wu, D.; Xu, F.; Chen, C.; Jiang, K.; Gao, Z. Prussian Blue Analog-Derived Nickel Iron Phosphide-Reduced Graphene Oxide Hybrid as an Efficient Catalyst for Overall Water Electrolysis. J. Colloid Interf. Sci. 2023, 638, 801–812. [Google Scholar] [CrossRef]

- Wang, L.; Wang, J.; Yan, L.; Ding, Y.; Wang, X.; Liu, X.; Li, L.; Ju, J.; Zhan, T. Prussian Blue Analogue-Derived Iron Sulfide–Cobalt Sulfide Nanoparticle-Decorated Hollow Nitrogen-Doped Carbon Nanocubes for the Selective Electrochemical Detection of Dopamine. ACS Sustain. Chem. Eng. 2022, 10, 17230–17240. [Google Scholar] [CrossRef]

- Guo, Y.; Jia, K.; Dai, F.; Liu, Y.; Zhang, C.; Su, J.; Wang, K. Hierarchical Porous Tri-Metallic NiCoFe-Se/CFP Derived from Ni-Co-Fe Prussian Blue Analogues as Efficient Electrocatalyst for Oxygen Evolution Reaction. J. Colloid Interf. Sci. 2023, 642, 638–647. [Google Scholar] [CrossRef]

- Pei, C.; Chen, H.; Dong, B.; Yu, X.; Feng, L. Electrochemical Oxygen Evolution Reaction Efficiently Catalyzed by a Novel Porous Iron-Cobalt-Fluoride Nanocube Easily Derived from 3-Dimensional Prussian Blue Analogue. J. Power Sources 2019, 424, 131–137. [Google Scholar] [CrossRef]

- Sun, P.; Zhou, Y.; Li, H.; Zhang, H.; Feng, L.; Cao, Q.; Liu, S.; Wågberg, T.; Hu, G. Round-the-clock Bifunctional Honeycomb-like Nitrogen-Doped Carbon-Decorated Co2P/Mo2C-Heterojunction Electrocatalyst for Direct Water Splitting with 18.1% STH Efficiency. Appl. Catal. B Environ. 2022, 310, 121354. [Google Scholar] [CrossRef]

- Ma, Y.; Leng, D.; Zhang, X.; Fu, J.; Pi, C.; Zheng, Y.; Gao, B.; Li, X.; Li, N.; Chu, P.K.; et al. Enhanced Activities in Alkaline Hydrogen and Oxygen Evolution Reactions on MoS2 Electrocatalysts by In-Plane Sulfur Defects Coupled with Transition Metal Doping. Small 2022, 18, 2203173. [Google Scholar] [CrossRef]

- Wu, K.; Li, X.; Wang, W.; Huang, Y.; Jiang, Q.; Li, W.; Chen, Y.; Yang, Y.; Li, C. Creating Edge Sites within the Basal Plane of a MoS2 Catalyst for Substantially Enhanced Hydrodeoxygenation Activity. ACS Catal. 2021, 12, 8–17. [Google Scholar] [CrossRef]

- Ran, N.; Song, E.; Wang, Y.; Zhou, Y.; Liu, J. Dynamic Coordination Transformation of Active Sites in Single-Atom MoS2 Catalysts for Boosted Oxygen Evolution Catalysis. Energy Environ. Sci. 2022, 15, 2071–2083. [Google Scholar] [CrossRef]

- Chen, B.; Hu, P.; Yang, F.; Hua, X.; Yang, F.F.; Zhu, F.; Sun, R.; Hao, K.; Wang, K.; Yin, Z. In Situ Porousized MoS2 Nano Islands Enhance HER/OER Bifunctional Electrocatalysis. Small 2023, 19, 2207177. [Google Scholar] [CrossRef]

- Rong, M.; Mo, Y.; Zhou, S.; Ma, X.; Wang, S.; Cao, Z.; Zhong, H. Ce and MoS2 Dual-Doped Cobalt Aluminum Layered Double Hydroxides for Enhanced Oxygen Evolution Reaction. Int. J. Hydrogen Energy 2022, 47, 1644–1655. [Google Scholar] [CrossRef]

- Mu, X.; Zhu, Y.; Gu, X.; Dai, S.; Mao, Q.; Bao, L.; Li, W.; Liu, S.; Bao, J.; Mu, S. Awakening the Oxygen Evolution Activity of MoS2 by Oxophilic-Metal Induced Surface Reorganization Engineering. J. Energy Chem. 2021, 62, 546–551. [Google Scholar] [CrossRef]

- Chakraborty, S.; Marappa, S.; Agarwal, S.; Bagchi, D.; Rao, A.; Vinod, C.P.; Peter, S.C.; Singh, A.; Eswaramoorthy, M. Improvement in Oxygen Evolution Performance of NiFe Layered Double Hydroxide Grown in the Presence of 1T-Rich MoS2. ACS Appl. Mater. Interfaces 2022, 14, 31951–31961. [Google Scholar] [CrossRef] [PubMed]

- Lu, G.; Huang, X.; Li, Y.; Zhao, G.; Pang, G.; Wang, G. Covalently Integrated Core-Shell MOF@COF Hybrids as Efficient Visible-Light-Driven Photocatalysts for Selective Oxidation of Alcohols. J. Energy Chem. 2020, 43, 8–15. [Google Scholar] [CrossRef]

- Huang, X.; Yu, L.; Wang, X.; Feng, L. Insights into Fe-Doping Effect-Induced Heterostructure Formation for the Oxygen Evolution Reaction. Chem. Commun. 2023, 59, 12294–12297. [Google Scholar] [CrossRef]

- Hu, J.; Li, Z.; Zhao, D.; Han, Z.; Wu, X.; Zhai, J.; Liu, Z.; Tang, Y.; Fu, G. l-Lysine-Induced Green Synthesis of CoS/Co3O4 Nanoframes for Efficient Electrocatalytic Oxygen Evolution. Green Chem. 2023, 25, 7309–7317. [Google Scholar] [CrossRef]

- Jiang, J.; Sun, R.; Huang, X.; Xu, W.; Zhou, S.; Wei, Y.; Han, S.; Li, Y. In-situ Derived Mo-doped NiCoP and MXene to Form Mott-Schottky Heterojunction with Tunable Surface Electron Density to Promote Overall Water Splitting. Compos. Part B Eng. 2023, 263, 110834. [Google Scholar] [CrossRef]

- Yin, C.; Yang, F.; Wang, S.; Feng, L. Heterostructured NiSe2/MoSe2 Electronic Modulation for Efficient Electrocatalysis in Urea Assisted Water Splitting Reaction. Chin. J. Catal. 2023, 51, 225–236. [Google Scholar] [CrossRef]

- Guo, Y.; Tang, J.; Henzie, J.; Jiang, B.; Xia, W.; Chen, T.; Bando, Y.; Kang, Y.-M.; Hossain, M.S.A.; Sugahara, Y.; et al. Mesoporous Iron-doped MoS2/CoMo2S4 Heterostructures through Organic–Metal Cooperative Interactions on Spherical Micelles for Electrochemical Water Splitting. ACS Nano 2020, 14, 4141–4152. [Google Scholar] [CrossRef] [PubMed]

- Frost, D.C.; McDowell, C.A.; Woolsey, I.S. Evidence for Multiplet Splitting of 2p Photoelectron Lines of Transition Metal Complexes. Chem. Phys. Lett. 1972, 17, 320–323. [Google Scholar] [CrossRef]

- Mahmood, Q.; Park, S.K.; Kwon, K.D.; Chang, S.-J.; Hong, J.-Y.; Shen, G.; Jung, Y.M.; Park, T.J.; Khang, S.W.; Kim, W.S.; et al. Transition from Diffusion-Controlled Intercalation into Extrinsically Pseudocapacitive Charge Storage of MoS2 by Nanoscale Heterostructuring. Adv. Energy Mater. 2015, 6, 1501115. [Google Scholar] [CrossRef]

- Yang, F.; Hu, P.; Yang, F.F.; Chen, B.; Yin, F.; Hao, K.; Sun, R.; Gao, L.; Sun, Z.; Wang, K.; et al. CNTs Bridged Basal-Plane-Active 2H-MoS2 Nanosheets for Efficient Robust Electrocatalysis. Small 2023, 19, 2301468. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, G.; Ke, X.; Chen, X.; Chen, X.; Wang, Y.; Huang, G.; Dong, J.; Chu, S.; Sui, M. Direct Synthesis of Stable 1T-MoS2 Doped with Ni Single Atoms for Water Splitting in Alkaline Media. Small 2022, 18, 2107238. [Google Scholar] [CrossRef] [PubMed]

- Pei, C.; Kim, M.-C.; Li, Y.; Xia, C.; Kim, J.; So, W.; Yu, X.; Park, H.S.; Kim, J.K. Electron Transfer-Induced Metal Spin-Crossover at NiCo2S4/ReS2 2D–2D Interfaces for Promoting pH-universal Hydrogen Evolution Reaction. Adv. Funct. Mater. 2023, 33, 2210072. [Google Scholar] [CrossRef]

- Zhang, H.; Guan, D.; Gu, Y.; Xu, H.; Wang, C.; Shao, Z.; Guo, Y. Tuning Synergy Between Nickel and Iron in Ruddlesden–Popper Perovskites through Controllable Crystal Dimensionalities towards Enhanced Oxygen-Evolving Activity and Stability. Carbon Energy 2024, e465. [Google Scholar] [CrossRef]

- Anantharaj, S.; Noda, S.; Driess, M.; Menezes, P.W. The Pitfalls of Using Potentiodynamic Polarization Curves for Tafel Analysis in Electrocatalytic Water Splitting. ACS Energy Lett. 2021, 6, 1607–1611. [Google Scholar] [CrossRef]

- Guo, P.; Wu, Y.-X.; Lau, W.-M.; Liu, H.; Liu, L.-M. CoS Nanosheet Arrays Grown on Nickel Foam as an Excellent OER Catalyst. J. Alloys Compd. 2017, 723, 772–778. [Google Scholar] [CrossRef]

- Mathankumar, M.; Karthick, K.; Nanda kumar, A.K.; Kundu, S.; Balasubramanian, S. In Situ Decorated Ni Metallic Layer with CoS2-Layered Thin Films via a Layer-by-Layer Strategy Using Pulsed Laser Deposition for Enhanced Electrocatalytic OER. Inorg. Chem. 2021, 60, 8946–8957. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Li, C.; Huang, J.; Sun, W.; Cheng, W.; He, C.; Tian, L. Structure Engineering of Amorphous P–CoS Hollow Electrocatalysts for Promoted Oxygen Evolution Reaction. Int. J. Hydrogen Energy 2022, 47, 15189–15197. [Google Scholar] [CrossRef]

- Dai, T.; Zhang, X.; Sun, M.; Huang, B.; Zhang, N.; Da, P.; Yang, R.; He, Z.; Wang, W.; Xi, P.; et al. Uncovering the Promotion of CeO2/CoS1.97 Heterostructure with Specific Spatial Architectures on Oxygen Evolution Reaction. Adv. Mater. 2021, 33, 2102593. [Google Scholar] [CrossRef] [PubMed]

- Devi, S.B.; Navamathavan, R. One-Pot Hydrothermal Synthesis of Ti3C2 (MXene)-CoS2 Nanocomposite as a Bifunctional Electrocatalyst (HER/OER) for a Clean Environment. J. Electrochem. Soc. 2023, 170, 096503. [Google Scholar] [CrossRef]

- Qian, L.-H.; Dong, W.-W.; Cao, Y.-B.; Ma, R.; Ding, Y.; Wang, X. ZIF-67-Derived CuCo2S4@CoS2 as an Efficient Bifunctional Electrocatalyst for Overall Water Splitting. New J. Chem. 2023, 47, 20574–20582. [Google Scholar] [CrossRef]

- Li, W.; Feng, X.; Zeng, X.; Gong, C.; Chen, X.; Li, D.; Zeng, Y.; Wang, X.; Pan, X.; Shi, Z.; et al. ZIF-8@ZIF-67 Derived Fe–CoS2/CNT Carbon Polyhedron for Enhanced Electrocatalytic Oxygen Evolution Reaction. Int. J. Hydrogen Energy 2024, 51, 20–29. [Google Scholar] [CrossRef]

- Gao, G.; Fang, B.; Ding, Z.; Dong, W.; Li, Y.-X.; Wang, X.L.; Yao, Y.-F. Co/CoS2 Heterojunction Embedded in Nitrogen-Doped Carbon Framework as bifunctional Electrocatalysts for Hydrogen and Oxygen Evolution. Int. J. Hydrogen Energy 2023, 48, 1831–1841. [Google Scholar] [CrossRef]

- Niu, H.-J.; Yan, Y.; Jiang, S.; Liu, T.; Sun, T.; Zhou, W.; Guo, L.; Li, J. Interfaces Decrease the Alkaline Hydrogen-Evolution Kinetics Energy Barrier on NiCoP/Ti3C2Tx MXene. ACS Nano 2022, 16, 11049–11058. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, D.; Xu, J.; Liu, G.; Yu, X. Core–Shell CoS2@MoS2 with Hollow Heterostructure as an Efficient Electrocatalyst for Boosting Oxygen Evolution Reaction. Molecules 2024, 29, 1695. https://doi.org/10.3390/molecules29081695

Guo D, Xu J, Liu G, Yu X. Core–Shell CoS2@MoS2 with Hollow Heterostructure as an Efficient Electrocatalyst for Boosting Oxygen Evolution Reaction. Molecules. 2024; 29(8):1695. https://doi.org/10.3390/molecules29081695

Chicago/Turabian StyleGuo, Donglei, Jiaqi Xu, Guilong Liu, and Xu Yu. 2024. "Core–Shell CoS2@MoS2 with Hollow Heterostructure as an Efficient Electrocatalyst for Boosting Oxygen Evolution Reaction" Molecules 29, no. 8: 1695. https://doi.org/10.3390/molecules29081695

APA StyleGuo, D., Xu, J., Liu, G., & Yu, X. (2024). Core–Shell CoS2@MoS2 with Hollow Heterostructure as an Efficient Electrocatalyst for Boosting Oxygen Evolution Reaction. Molecules, 29(8), 1695. https://doi.org/10.3390/molecules29081695