Abstract

Nitrophenols can be obtained in moderate to high yields using a combination of Mg(HSO4)2 or NaHSO4.H2O, NaNO3 and wet SiO2 in dichloromethane at room temperature.

Introduction

The nitration of aromatic compounds may be achieved with many nitrating reagents and is a very useful method in organic synthesis [1]. Also, nitro compounds find use in many industrial applications [2,3,4]. Nitration of phenol as a special case has been studied using various nitrating agents under different conditions [4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22]. Recently, in this connection we have reported the use and reaction mechanisms of some hydrated metal nitrates (containing covalent nitrato groups) and their dinitrogen tetroxide complex analogues for the nitration of phenols under various conditions [23]. Our goal, in undertaking this line of work, is two-fold: (a) to overcome the limitations and drawbacks of the reported methods such as tedious work-up [9,10,11], strongly acidic media (Ho~ -8) [4b], oxidation ability of the reagents and safety problems (storage, handling, use and also the presence of poisonous transition metal cations such as Cr+3, Hg+2, Cu+2, etc. within the molecular structures of the reagents ) [24,25]; (b) moreover, constraining a reagent to the surface of a solid usually allows the use of milder conditions and increases its reactivity [26]. Very recently, we and others have demonstrated that heterogeneous reagent systems have many advantages such as simple experimental procedures, mild reaction conditions and minimization of chemical wastes as compared to their liquid phase counterparts [27]. Consequently, we decided to seek a heterogeneous system for the nitration of phenol, and we have investigated a number of different reaction conditions based upon the in situ generation of HNO3 by solid inorganic acidic salts [NaHSO4·H2O, Mg(HSO4)2, pka~2 ] with sodium nitrate. We report here a one-pot heterogeneous procedure for nitration of phenols.

Results and Discussion

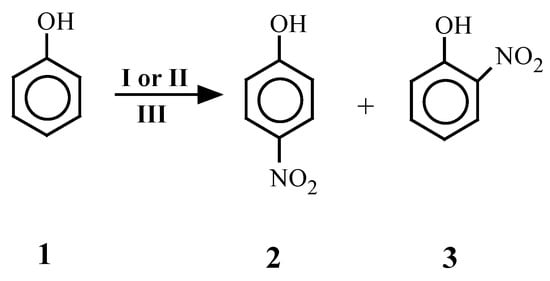

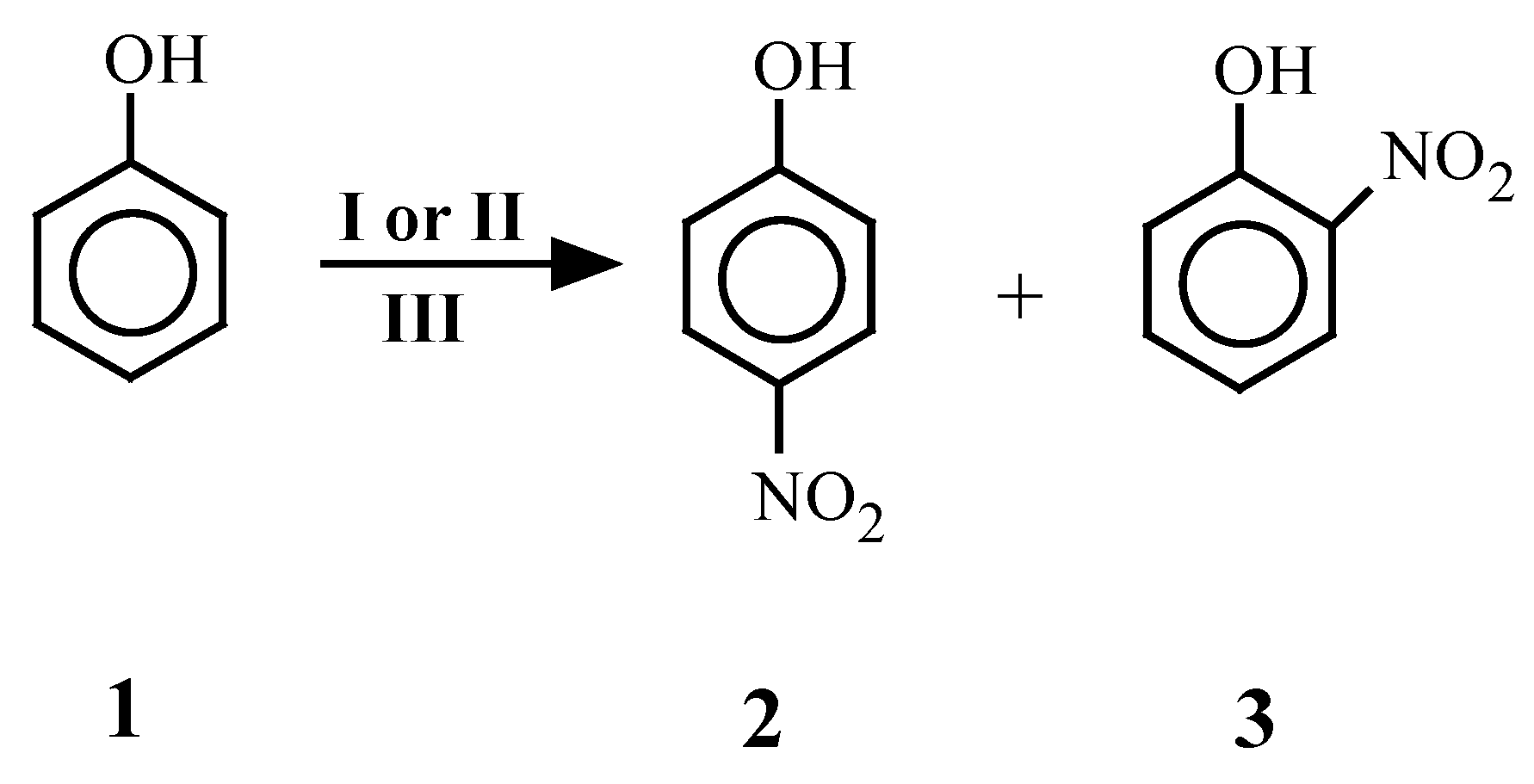

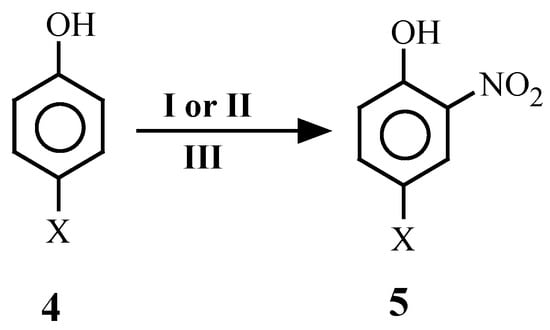

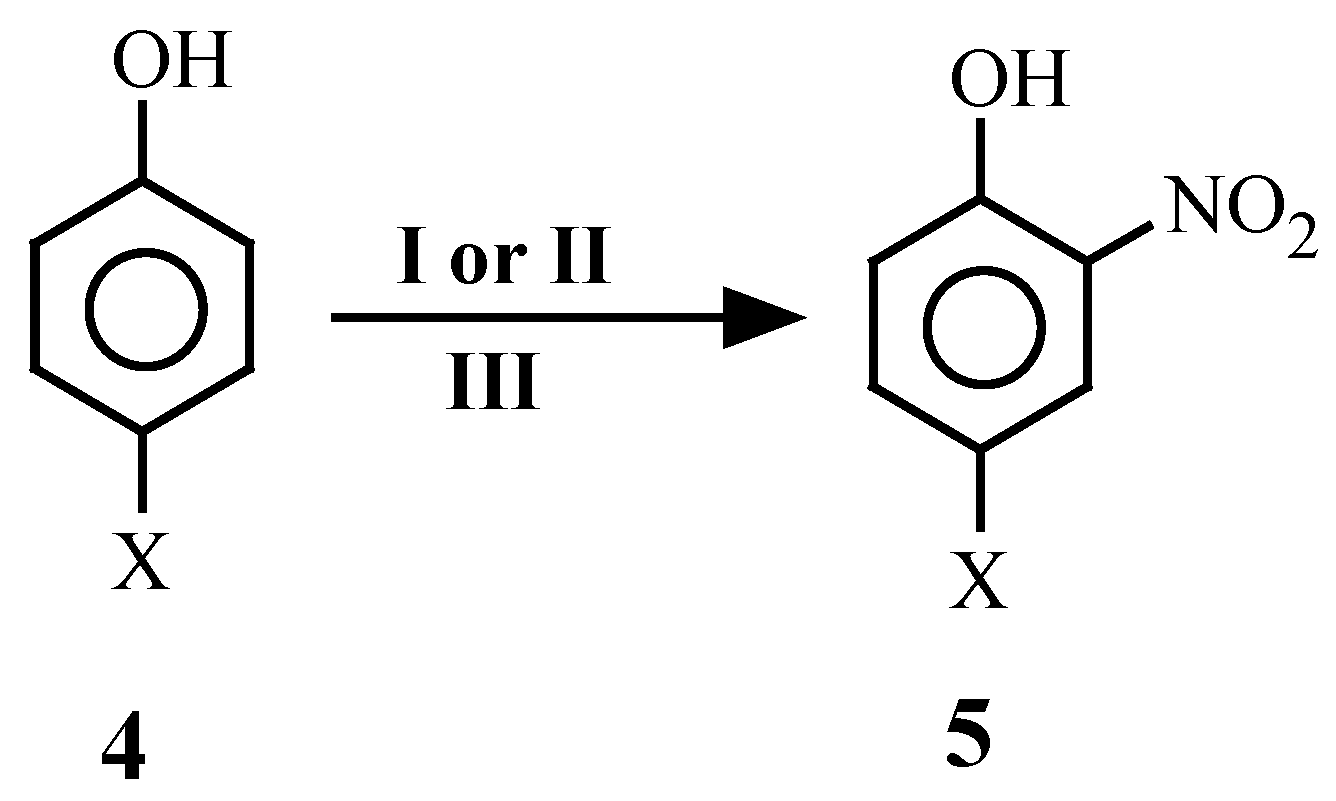

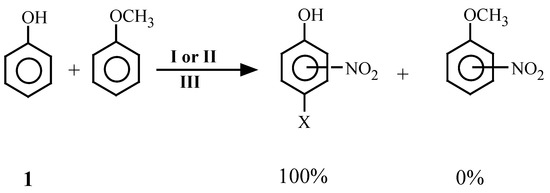

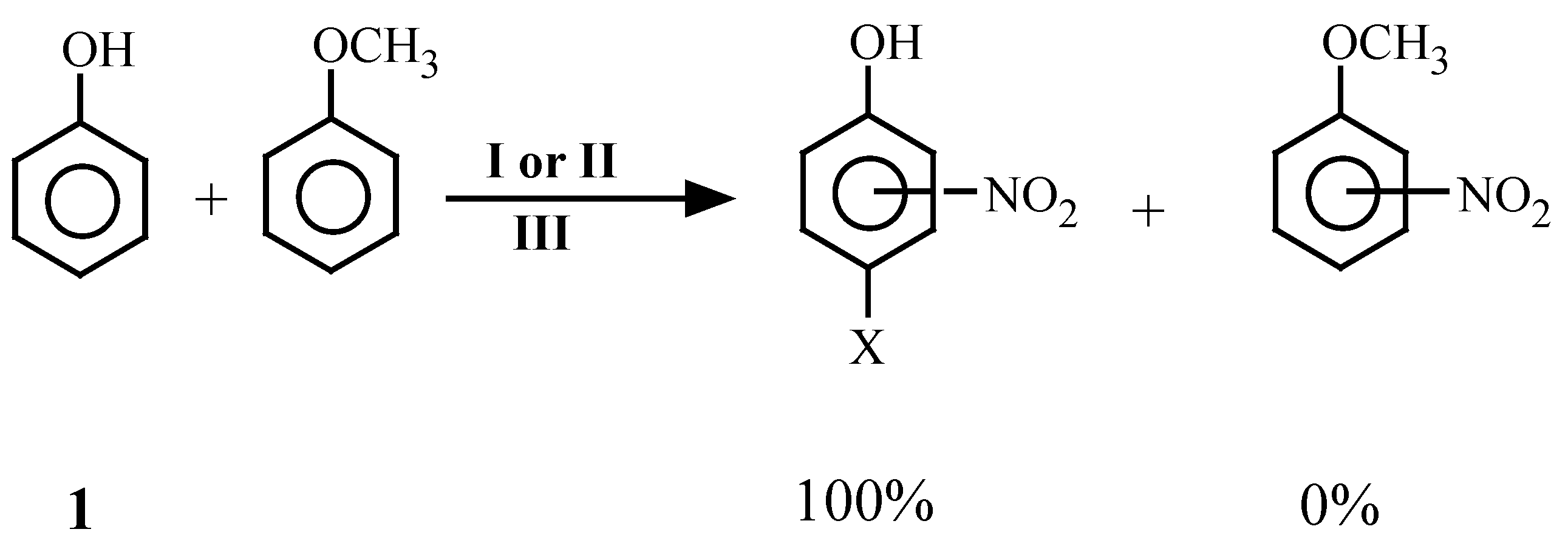

Phenol (1) and different types of 4-substituted phenols (4) were subjected to a nitration reaction in the presence of inorganic acidic salts [e.g. Mg(HSO4)2 (I) or NaHSO4·H2O (II)], NaNO3 (III), and wet SiO2 (50% w/w) in dichloromethane (Scheme 1 and Scheme 2). The nitration reactions were performed under mild and heterogeneous conditions at room temperature to give the products in moderate to excellent yields (Table 1).

Scheme 1.

Scheme 1.

The nitration reactions can be readily carried out by placing the nitrating agents, phenols (1 or 4) and the solvent used in a reaction vessel and efficiently stirring the resultant heterogeneous mixture at room temperature. The resulting mononitrophenols can be obtained by simple filtration and evaporation of the solvent. This alternative method thus provides nitrated phenols directly, in short reaction times and good yields.

Scheme 2.

Scheme 2.

| 4 | X | 4 | X | 4 | X |

|---|---|---|---|---|---|

| a | F | e | Ph | i | COOH |

| b | Cl | f | CH3 | j | CH2Ph |

| c | Br | g | OCH3 | k | NHOAc |

| d | CN | h | COCH3 | l | 4-HOC6H4- |

In fact, a combination of sodium nitrate and inorganic acidic salts (I or II) can act as a solid HNO3 equivalent which can be readily handled and used for different purposes in the presence of wet SiO2 [28].

A competitive reaction between phenols and anisole was also performed. It was observed that exclusive phenol nitration proceeded, whereas anisole is remained intact in the reaction mixtures after 24 hours (Scheme 3).

Scheme 3.

Scheme 3.

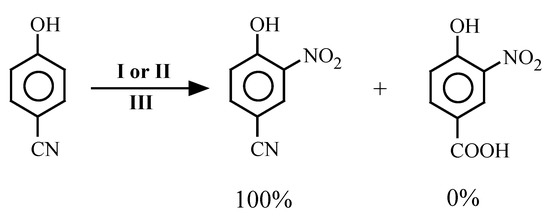

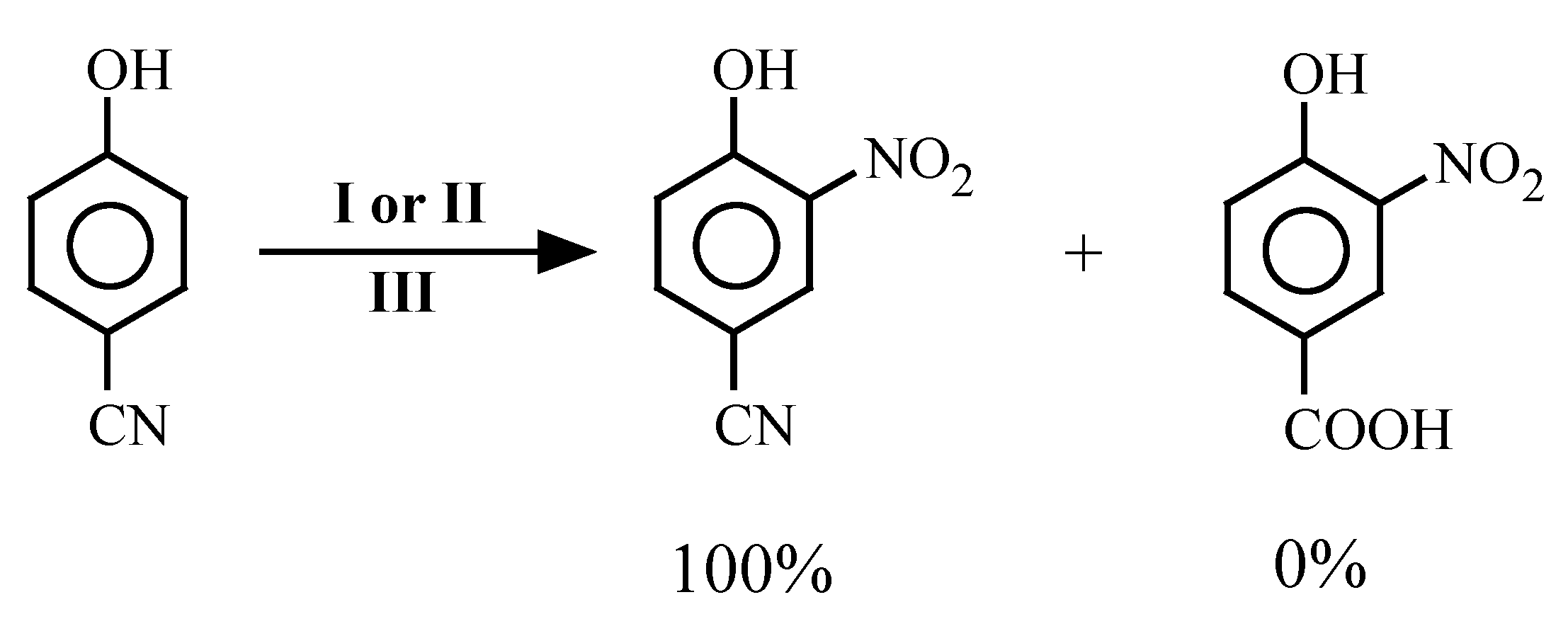

This method is also very mild as indicated by the fact that the hydrolysis product of 4-cyano-phenol was not observed (Scheme 4, Table 1, entries 9 and 10). Selective mononitration of 4,4’-dihydroxydiphenyl (4l) was also achieved by controlling the stoichiometry of the reagents (Table 1, entries 25 and 26).

Scheme 4.

Scheme 4.

Table 1.

Substrates and Products

| Entry | Substrate | Productsa | Reag. /Subst. (mmol)b | Time (Min) | Yieldsc % | ||

|---|---|---|---|---|---|---|---|

| I | II | III | |||||

| 1 | 1 | 2[7] | 1 | -- | 1 | 30 | 26 |

| 3[7] | 36 | ||||||

| 2 | 1 | 2[7] 3[7] | -- | 1 | 1 | 30 | 20 50 |

| 3 | 4a | 5a[4]c | 1 | -- | 1 | 90 | 54 |

| 4 | 4a | 5a[4c] | -- | 1 | 1 | 90 | 60 |

| 5 | 4b | 5b[11, 18] | 1 | -- | 1 | 90 | 70 |

| 6 | 4b | 5b[11, 18] | -- | 1 | 1 | 90 | 72 |

| 7 | 4c | 5c[11, 18] | 1 | -- | 1 | 130 | 78 |

| 8 | 4c | 5c[11, 18] | -- | 1 | 1 | 130 | 70 |

| 9 | 4d | 5d[11, 18] | 1 | -- | 1 | 180 | 88 |

| 10 | 4d | 5d[11, 18] | -- | 1 | 1 | 180 | 92 |

| 11 | 4e | 5e[11, 18] | 1 | -- | 1 | 180 | 90 |

| 12 | 4e | 5e[11, 18] | -- | 1 | 1 | 180 | 92 |

| 13 | 4f | 5f[11, 18] | 1 | -- | 1 | 180 | 72 |

| 14 | 4f | 5f[11, 18] | -- | 1 | 1 | 180 | 78 |

| 15 | 4g | 5g[18] | 1 | -- | 1 | 45 | 84 |

| 16 | 4g | 5g[18] | -- | 1 | 1 | 45 | 79 |

| 17 | 4h | 5h[11, 18] | 2 | -- | 2 | 120 | 74 |

| 18 | 4h | 5h[11, 18] | -- | 2 | 2 | 120 | 79 |

| 19 | 4i | 5i[18] | 2 | -- | 2 | 90 | 80 |

| 20 | 4i | 5i[18] | -- | 2 | 2 | 90 | 83 |

| 21 | 4j | 5j[18] | 2 | -- | 2 | 180 | 91 |

| 22 | 4j | 5j[18] | -- | 2 | 2 | 180 | 91 |

| 23 | 4k | 5k[22] | -- | 1 | 1 | 180 | 55 |

| 24 | 4k | 5k[22] | 1 | -- | 1 | 180 | 74 |

| 25 | 4l | 5l[21] | -- | 1 | 1 | 90 | 56 |

| 26 | 4l | 5l[21] | 1 | -- | 1 | 90 | 63 |

| 27 | 1 | 2, 3 | -- | -- | 1 | No Reactiond | |

a All of the isolated products are known compounds and their spectra and physical data have been reported in the literature; b Wet SiO2 : substrate (1) (0.2 g : 1 mmol); cIsolated pure Yields; d Nitration did not occur in the absence of inorganic acidic salts.

Although the nitration reaction also occurs in the absence of wet SiO2, the reaction times are very long and the reactions only go to completion after several days. Therefore, we think that the wet SiO2 acts as a reaction medium providing a heterogeneous effective surface area for in situ generation of HNO3 in low concentrations. It also makes work-up easy. On the other hand, nitration did not occur in the absence of the inorganic acidic salts (Table 1, entry 27).

Conclusions

In conclusion, the low cost and the availability of the reagents, easy and clean work-up, and high yields make this an attractive method for Organic Synthesis. This simple procedure is highly selective and contamination by oxidation side-products is avoided. Moreover, a key new feature is the heterogeneous nature of the reaction, which could be worthwhile in an industrial setting [26].

Acknowledgments

The authors gratefully acknowledge partial support of this work by the Research Affairs Office of Bu-Ali Sina University, Hamadan, I.R Iran.

Experimental section

General

Chemicals were purchased from the Fluka, Merck and Aldrich chemical companies. Melting points were taken on a Gallenkamp melting point apparatus and are uncorrected. Proton and carbon nuclear magnetic resonance spectra were recorded on a JEOL NMR-Spectrometer FX 90Q. IR spectra were recorded on a Shimadzu 435 IR spectrophotometer. Thin layer chromatography (TLC) on commercial aluminium-backed plates of silica gel 60 F254 was used to monitor the progress of the reactions. Yields refer to isolated pure products. The nitration products were characterized by comparison of their spectral (IR, 1H-NMR, 13C-NMR), TLC and physical data with authentic samples.

Typical Procedure for Mononitration of Phenol (1) with Mg(HSO4)2 (I), NaNO3 (III) and wet SiO2

A suspension of compound 1 (1.88 g, 0.02 mol), I (4.40 g, 0.02 mol), III (1.7 g, 0.02 mol) and wet SiO2 (50% w/w, 4 g) in CH2Cl2 (20 mL) was stirred magnetically at room temperature. The reaction was complete after 30 min. and the reaction mixture was then filtered. The residue was washed with CH2Cl2 (2x10 mL). Anhydrous Na2SO4 (10 g) was added to the combined filtrate and washings. After 15 minutes the mixture was filtered. The solvent was removed by distillation using a water bath (35-40°C). The residue is a mixture of 2- and 4-nitrophenol, which may be purified by addition of n-pentane as the latter is insoluble in this solvent. Yield of 4-nitrophenol (2): 1.44 g, 26%, mp 112-113 °C {lit [7] mp 114 °C}. The n-pentane was evaporated on a water bath (35-40 °C) to give the 2-nitrophenol (3): 2 g, 36%, mp 43-45 °C {lit. [7] mp 44 °C}.

Typical Procedure for Mononitration of 4-Cyanophenol (4d) with Mg(HSO4)2 (I), NaNO3 (III) and wet SiO2

A suspension of compound 4d (0.238 g, 2 mmol), I (0.44 g 2 mmol), wet SiO2 (50% w/w, 0.4 g) and III (0.17 g, 2 mmol) in dichloromethane (4 mL) was stirred at room temperature for 3 hours (the progress of the reaction was monitored by TLC) and then filtered. Anhydrous Na2SO4 (5 g) was added to the filtrate. After 15 minutes the resulting mixture was also filtered. Dichloromethane was removed by simple distillation using a water bath (35-40 °C). The yield was 0.288 g, (88%) of crystalline pale yellow solid (5d), mp 143-144 °C,{Lit. [4c] mp 145 °C}. 1H-NMR (FT-90 MHz, CDCl3, TMS): δ 7.34 (d, 1H), 7.77 (dd, 1H), 8.48 (d, 1H), 10.87 (b, 1H). 1H-NMR spectra were identical with reference spectra [4c].

References and Notes

- Gu, S.; Jing, H.; Wu, J.; Liang, y. Synth. Commun. 1997, 27, 2793.

- Smith, K.; Musson, A.; DeBoos, G. A. Chem. Commun. 1996, 469.

- Waller, F. G.; Barrett, A. G. M.; Braddock, D. C.; Ramprasad, D. Chem. Commun. 1997, 613, and references cited therein.

- (a) Delaude, L.; Laszlo, P.; Smith, K. Acc. Chem. Res. 1993, 26, 607. (b) Laszlo, P. Acc. Chem. Res. 1986, 19, 121. (c) Cornelis, A.; Laszlo, P.; Pennetreau, P. Bull. Soc. Chim. Belg. 1984, 93, 961.

- Zeegers, P. J. J. Chem. Ed. 1993, 70, 1036.

- Pervas, H.; Onysiuka, S. O.; Rees, L.; Rooney, J. R.; Sukling, G. J. Tetrahedron 1988, 44, 4555.

- Furniss, B. S.; Smith, P. W. G.; Hannaford, A. J.; Tatchell, A. R. "Vogel’s Textbook of Practical Organic Chemistry", 4th Ed ed; Longman: London and New York, 1986. [Google Scholar]

- Bruice, T. C.; Gregor, M. G.; Walters, S. L. J. Am. Chem. Soc. 1986, 90, 1612.

- Crivello, J. V. J. Org. Chem. 1981, 46, 3056.

- Oueartani, M.; Girard, P.; Kagan, H. B. Tetrahedron Lett 1982, 23, 4315.

- Poirier, J. M.; Vottero, C. Tetrahedron 1989, 45, 1415.

- Thompson, M. J.; Zeegers, P. J. Tetrahedron 1989, 45, 191.

- Tapia, R.; Torres, G.; Valderrama, J. A. Synth. Commun. 1986, 16, 681.

- Gaude, D.; Goallar, R. L.; Pierre, J. L. Synth. Commun. 1986, 16, 63.

- Gigante, B.; Prazeres, A. O.; Marcelo-Curto, M. J. J. Org. Chem. 1995, 60, 3445.

- Rodrigues, J. A. R.; Filho, A. P. O.; Moran, P. J. S. Tetrahedron 1999, 55, 6733.

- Suboch, G. A.; Belyaev, E. Y. Russ. Org. Chem. 1998, 34, 288.

- Nonoyama, N.; Chiba, K.; Hisatome, K.; Suzuki, H.; Shintani, F. Tetrahedron Lett. 1999, 40, 6923.

- Lehnig, M. Tetrahedron Lett. 1999, 40, 2299.

- “Dictionary of Organic Compounds”, 3th Ed ed; Eyre & Spottiswoode: London, 1965; Volume 2, p. 620.

- Raiford, L. C.; Colbert, J. C. J. Am. Chem. Soc. 1925, 47, 1454.

- Hancock, C. K.; Clagvex, A. D. J. Am. Chem. Soc. 1964, 86, 4942.

- (a) Zolfigol, M. A.; Iranpoor, N.; Firouzabadi, H. Orient. J. Chem. 1998, 14, 369. (b) Firouzabadi, H.; Iranpoor, N.; Zolfigol, M. A. Iran. J. Chem. & Chem. Eng. 1997, 16, 48. (c) Firouzabadi, H.; Iranpoor, N.; Zolfigol, M. A. Synth. Commun. 1997, 27, 3301. (d) Iranpoor, N.; Firouzabadi, H.; Zolfigol, M. A. Synth. Commun. 1998, 28, 2773.

- (a) Firouzabadi, H.; Iranpoor, N.; Zolfigol, M. A. Synth. Commun. 1998, 28, 377. (b) Firouzabadi, H.; Iranpoor, N.; Zolfigol, M. A. Synth. Commun. 1998, 28, 1179. (c) Iranpoor, N.; Firouzabadi, H.; Zolfigol, M. A. Synth. Commun. 1998, 28, 367. (d) Firouzabadi, H.; Iranpoor, N.; Zolfigol, M. A. Bull. Chem. Soc. Jpn. 1998, 71, 2169. (e) Iranpoor, N.; Firouzabadi, H.; Zolfigol, M. A. Bull. Chem. Soc. Jpn. 1998, 71, 905.

- (a) Laszlo, P.; Cornelis, A. Aldrichimica Acta 1988, 21, 97. (b) Cornelis, A.; Laszlo, P. Synthesis 1985, 909. (c) Laszlo, P.; Cornelis, A. Synthesis 1994, 155.

- Riego, J. M.; Sedin, Z.; Zaldivar, J. M.; Marziano, N. C.; Tortato, C. Tetrahedron Lett. 1996, 37, 513.

- (a) Zolfigol, M. A.; Kiany-Borazjani, M.; Sadeghi, M. M.; Mohammadpoor-Baltork, I.; Memarian, H. R. Synth. Commun. 2000, 30, 551. (b) Zolfigol, M. A.; Kiany-Borazjani, M.; Sadeghi, M. M.; Memarian, H. R.; Mohammadpoor-Baltork, I. Synth. Commun. 2000, 30, 2954. (c) Zolfigol, M. A. Synth. Commun. 1999, 29, 905. (d) Zolfigol, M. A.; Nematollahi, D.; Mallakpour, S. E. Synth. Commun. 1999, 29, 2277. (e) Zolfigol, M. A.; Mallakpour, S. E. Synth. Commun. 1999, 29, 4061. (f) Zolfigol, M. A. Synth. Commun. 2000, 30, 1593. (g) Zolfigol, M. A.; Ghaemi, E.; Madrakian, E.; Kiany-Borazjani, M. Synth. Commun. 2000, 30, 2057. (h) Zolfigol, M. A.; Kiany-Borazjani, M.; Mallakpour, S. E.; Nassr-Isfahani, H. Synth. Commun. 2000, 30, 2573. (i) Zolfigol, M. A.; Madrakian, E.; Ghaemi, E. Indian J. Chem. 2000, 39B, 308. (j) Zolfigol, M. A.; Ghaemi, E.; Madrakian, E. Synth. Commun. 2000, 30, 1689. (k) Zolfigol, M. A.; Kiany-Borazjani, M.; Sadeghi, M. M.; Mohammadpoor-Baltork, I.; Memarian, H. R. Synth. Commun. 2000, 30, 3919. (l) Zolfigol, M. A.; Shirini, F.; Ghorbani Choghamarani, A.; Taqian-nasab, A.; Keypour, H.; Salehzadeh, S. J. Chem. Research (S). 2000, 420.

- For the application of this system to the oxidation of 1,4-dihydropyridines: Zolfigol, M. A.; Kiany-Borazjani, M.; Sadeghi, M. M.; Memarian, H. R.; Mohammadpoor-Baltork, I. J. Chem. Research (S) 2000, 167.

- Anderson, R. A.; Dalgleish, D. T.; Nonhebel, D. C.; Pauson, P. L. J. Chem. Research (S) 1977, 12.

- Sample Availability: All products reported in this paper are available from the authors.

© 2001 by MDPI (http://www.mdpi.org). Reproduction is permitted for noncommercial purposes.