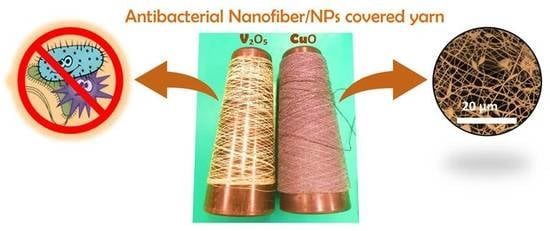

Polyvinyl Butyral (PVB) Nanofiber/Nanoparticle-Covered Yarns for Antibacterial Textile Surfaces

Abstract

1. Introduction

2. Results and Discussion

2.1. Surface Morphology

2.2. Antibacterial Test Result

3. Materials and Methods

3.1. Yarn Preparation

3.2. Antibacterial Test

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| NPs | Nanoparticles |

| CuO | Copper oxide |

| V2O5 | vanadium oxide |

| PVB | Polyvinyl butyral |

| E. coli | Escherichia coli |

| CFU | Colony forming unit |

| LB | Lysogeny broth |

| ROS | reactive oxygen species |

References

- Yalcinkaya, F.; Yalcinkaya, B.; Hruza, J.; Hrabak, P. Effect of nanofibrous membrane structures on the treatment of wastewater microfiltration. Sci. Adv. Mater. 2016, 9, 747–757. [Google Scholar] [CrossRef]

- Ma, Z.; Kotaki, M.; Ramakrishna, S. Electrospun cellulose nanofiber as affinity membrane. J. Memb. Sci. 2005, 265, 115–123. [Google Scholar]

- Fan, Y.; Chen, S.; Zhao, H.; Liu, Y. Distillation membrane constructed by TiO2nanofiber followed by fluorination for excellent water desalination performance. Desalination 2017, 405, 51–58. [Google Scholar] [CrossRef]

- Yalcinkaya, F. A review on advanced nanofiber technology for membrane distillation. J. Eng. Fiber. Fabr. 2019, 14. [Google Scholar] [CrossRef]

- Yalcinkaya, B.; Yalcinkaya, F.; Chaloupek, J. Optimisation of thin film composite nanofiltration membranes based on laminated nanofibrous and nonwoven supporting material. Desalin. Water Treat. 2017, 59, 19–30. [Google Scholar] [CrossRef]

- Yalcinkaya, B.; Yalcinkaya, F.; Chaloupek, J. Thin Film Nanofibrous composite membrane for dead-end seawater desalination. J. Nanomater. 2016, 2016, 1–12. [Google Scholar]

- Kadam, V.V.; Wang, L.; Padhye, R. Electrospun nanofibre materials to filter air pollutants—A review. J. Ind. Text. 2018, 47, 2253–2280. [Google Scholar]

- Roche, R.; Yalcinkaya, F. Incorporation of PVDF nanofibre multilayers into functional structure for filtration applications. Nanomaterials 2018, 8, 771. [Google Scholar] [CrossRef]

- Yusof, M.R.; Shamsudin, R.; Abdullah, Y.; Yalcinkaya, F.; Yaacob, N. Electrospinning of carboxymethyl starch/poly(L-lactide acid) composite nanofiber. Polym. Advan. Technol. 2018, 29, 1843–1851. [Google Scholar]

- Yalcin Enis, I.; Gok Sadikoglu, T. Design parameters for electrospun biodegradable vascular grafts. J. Ind. Text. 2016. [Google Scholar] [CrossRef]

- Macagnano, A.; Perri, V.; Zampetti, E.; Bearzotti, A.; De Cesare, F.; Sprovieri, F.; Pirrone, N. A smart nanofibrous material for adsorbing and detecting elemental mercury in air. Atmos. Chem. Phys. 2017, 17, 6883–6893. [Google Scholar] [CrossRef]

- Liu, P.; Wu, S.; Zhang, Y.; Zhang, H.; Qin, X. A Fast Response ammonia sensor based on coaxial PPy–PAN nanofiber yarn. Nanomaterials 2016, 6, 121. [Google Scholar]

- Gopalan, A.I.; Santhosh, P.; Manesh, K.M.; Nho, J.H.; Kim, S.H.; Hwang, C.G.; Lee, K.P. Development of electrospun PVdF-PAN membrane-based polymer electrolytes for lithium batteries. J. Memb. Sci. 2008, 325, 683–690. [Google Scholar]

- Aydın, H.; Çelik, S.Ü.; Bozkurt, A. Electrolyte loaded hexagonal boron nitride/polyacrylonitrile nanofibers for lithium ion battery application. Solid State Ionics 2017, 309, 71–76. [Google Scholar] [CrossRef]

- Döpke, C.; Grothe, T.; Steblinski, P.; Klöcker, M.; Sabantina, L.; Kosmalska, D.; Blachowicz, T.; Ehrmann, A. Magnetic nanofiber mats for data storage and transfer. Nanomaterials 2019, 9, 92. [Google Scholar] [CrossRef]

- Juhász Junger, I.; Wehlage, D.; Böttjer, R.; Grothe, T.; Juhász, L.; Grassmann, C.; Blachowicz, T.; Ehrmann, A. Dye-sensitized solar cells with electrospun nanofiber mat-based counter electrodes. Materials 2018, 11, 1604. [Google Scholar] [CrossRef]

- Grothe, T.; Sabantina, L.; Klöcker, M.; Junger, I.; Döpke, C.; Ehrmann, A. Wet relaxation of electrospun nanofiber mats. Technologies 2019, 7, 23. [Google Scholar]

- Yalcinkaya, F. Preparation of various nanofiber layers using wire electrospinning system. Arab. J. Chem. 2016. [Google Scholar] [CrossRef]

- Turky, A.O.; Barhoum, A.; MohamedRashad, M.; Bechlany, M. Enhanced the structure and optical properties for ZnO/PVP nanofibers fabricated via electrospinning technique. J. Mater. Sci. Mater. Electron. 2017, 28, 17526–17532. [Google Scholar] [CrossRef]

- Jahanbaani, A.R.; Behzad, T.; Borhani, S.; Darvanjooghi, M.H.K. Electrospinning of cellulose nanofibers mat for laminated epoxy composite production. Fiber. Polym. 2016, 17, 1438–1448. [Google Scholar]

- Yalcinkaya, F.; Hruza, J. Effect of Laminating pressure on polymeric multilayer nanofibrous membranes for liquid filtration. Nanomaterials 2018, 8, 272. [Google Scholar]

- Charles, L.F.; Shaw, M.T.; Olson, J.R.; Wei, M. Fabrication and mechanical properties of PLLA/PCL/HA composites via a biomimetic, dip coating, and hot compression procedure. J. Mater. Sci. Mater. Med. 2010, 21, 1845–1854. [Google Scholar] [CrossRef] [PubMed]

- Wirth, E.; Sabantina, L.; Weber, M.; Finsterbusch, K.; Ehrmann, A. Preliminary study of ultrasonic welding as a joining process for electrospun nanofiber mats. Nanomaterials 2018, 8, 746. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhang, K.; Zhu, M.; Yu, H.; Zhou, Z.; Chen, Y.; Hsiao, B.S. Continuous polymer nanofiber yarns prepared by self-bundling electrospinning method. Polymer 2008, 49, 2755–2761. [Google Scholar]

- Khil, M.S.; Bhattarai, S.R.; Kim, H.Y.; Kim, S.Z.; Lee, K.H. Novel fabricated matrix via electrospinning for tissue engineering. J. Biomed. Mater. Res. B 2005, 72, 117–124. [Google Scholar] [CrossRef] [PubMed]

- Smit, E.; Buttner, U.; Sanderson, R.D. Continuous yarns from electrospun fibers. Polymer 2005, 46, 2419–2423. [Google Scholar] [CrossRef]

- Teo, W.E.; Gopal, R.; Ramaseshan, R.; Fujihara, K.; Ramakrishna, S. A dynamic liquid support system for continuous electrospun yarn fabrication. Polymer 2007, 48, 3400–3405. [Google Scholar]

- Jin, S.; Xin, B.; Zheng, Y.; Liu, S. Effect of electric field on the directly electrospun nanofiber yarns: Simulation and experimental study. Fiber. Polym. 2018, 19, 116–124. [Google Scholar] [CrossRef]

- Levitt, A.S.; Vallett, R.; Dion, G.; Schauer, C.L. Effect of electrospinning processing variables on polyacrylonitrile nanoyarns. J. Appl. Polym. Sci. 2018, 135, 46404. [Google Scholar] [CrossRef]

- Shuakat, M.N.; Lin, T. Highly-twisted, continuous nanofibre yarns prepared by a hybrid needle-needleless electrospinning technique. RSC Adv. 2015, 5, 33930–33937. [Google Scholar]

- Pokorny, P.; Kostakova, E.; Sanetrnik, F.; Mikes, P.; Chvojka, J.; Kalous, T.; Bilek, M.; Pejchar, K.; Valtera, J.; Lukas, D. Effective AC needleless and collectorless electrospinning for yarn production. Phys. Chem. Chem. Phys. 2014, 16, 26816–26822. [Google Scholar] [CrossRef] [PubMed]

- Yener, F.; Jirsak, O.; Gemci, R. Using a range of PVB spinning solution to acquire diverse morphology for electrospun nanofibres. Iran. J. Chem. Chem. Eng. 2012, 31, 49–58. [Google Scholar]

- Yener, F.; Yalcinkaya, B. Electrospinning of polyvinyl butyral in different solvents. E-Polymers 2013, 13, 229–242. [Google Scholar] [CrossRef]

- Xu, X.; Shen, J.; Qin, J.; Duan, H.; He, G.; Chen, H. Cytotoxicity of bacteriostatic reduced graphene oxide-based copper oxide nanocomposites. JOM 2019, 71, 294–301. [Google Scholar]

- Khatoon, U.T.; Mohan Mantravadi, K.; Nageswara Rao, G.V.S. Strategies to synthesise copper oxide nanoparticles and their bio applications–a review. Mater. Sci. Technol. 2018, 34, 2214–2222. [Google Scholar] [CrossRef]

- Dhayal Raj, A.; Pazhanivel, T.; Suresh Kumar, P.; Mangalaraj, D.; Nataraj, D.; Ponpandian, N. Self assembled V2O5 nanorods for gas sensors. Curr. Appl. Phys. 2010, 10, 531–537. [Google Scholar]

- Pan, A.; Zhang, J.G.; Nie, Z.; Cao, G.; Arey, B.W.; Li, G.; Liang, S.Q.; Liu, J. Facile synthesized nanorod structured vanadium pentoxide for high-rate lithium batteries. J. Mater. Chem. 2010, 20, 9193–9199. [Google Scholar] [CrossRef]

- Elbohy, H.; Thapa, A.; Poudel, P.; Adhikary, N.; Venkatesan, S.; Qiao, Q. Vanadium oxide as new charge recombination blocking layer for high efficiency dye-sensitized solar cells. Nano Energy 2015, 13, 368–375. [Google Scholar] [CrossRef]

- Ottaviano, L.; Pennisi, A.; Simone, F.; Salvi, A.M. RF sputtered electrochromic V2O5 films. Opt. Mater. 2004, 27, 307–313. [Google Scholar] [CrossRef]

- Pan, K.-Y.; Wei, D.-H. Optoelectronic and electrochemical properties of vanadium pentoxide nanowires synthesized by vapor-solid process. Nanomaterials 2016, 6, 140. [Google Scholar] [CrossRef]

- Raj, S.; Kumar, S.; Chatterjee, K. Facile synthesis of vanadia nanoparticles and assessment of antibacterial activity and cytotoxicity. Mater. Technol. 2016, 31, 562–573. [Google Scholar] [CrossRef]

- Coliform Bacteria in Drinking Water Supplies. Available online: https://www.health.ny.gov/environmental/water/drinking/coliform_bacteria.htm (accessed on 29 July 2019).

- Kaper, J.B. Pathogenic Escherichia coli. Int. J. Med. Microbiol. 2005, 295, 355–356. [Google Scholar] [CrossRef] [PubMed]

- Yener, F.; Jirsak, O. Comparison between the needle and roller electrospinning of polyvinylbutyral. J. Nanomater. 2012, 2012, 1–6. [Google Scholar] [CrossRef]

- Demir, D.; Güreş, D.; Tecim, T.; Genç, R.; Bölgen, N. Magnetic nanoparticle-loaded electrospun poly(ε-caprolactone) nanofibers for drug delivery applications. Appl. Nanosci. 2018, 8, 1461–1469. [Google Scholar] [CrossRef]

- Seil, J.T.; Webster, T.J. Antimicrobial applications of nanotechnology: Methods and literature. Int. J. Nanomed. 2012, 7, 2767–2781. [Google Scholar]

- Padmavathy, N.; Vijayaraghavan, R. Enhanced bioactivity of ZnO nanoparticles—An antimicrobial study. Sci. Technol. Adv. Mater. 2008, 9, 035004. [Google Scholar] [CrossRef] [PubMed]

- Meghana, S.; Kabra, P.; Chakraborty, S.; Padmavathy, N. Understanding the pathway of antibacterial activity of copper oxide nanoparticles. RSC Adv. 2015, 5, 12293–12299. [Google Scholar] [CrossRef]

- Crans, D.C.; Smee, J.J.; Gaidamauskas, E.; Yang, L. The chemistry and biochemistry of vanadium and the biological activities exerted by vanadium compounds. Chem. Rev. 2004, 104, 849–902. [Google Scholar] [CrossRef] [PubMed]

- Jayaraj, S.K.; Sadishkumar, V.; Arun, T.; Thangadurai, P. Enhanced photocatalytic activity of V2O5 nanorods for the photodegradation of organic dyes: A detailed understanding of the mechanism and their antibacterial activity. Mater. Sci. Semicond. Process. 2018, 85, 122–133. [Google Scholar] [CrossRef]

- Yalcinkaya, F.; Komarek, M.; Lubasova, D.; Sanetrnik, F.; Maryska, J. Preparation of Antibacterial nanofibre/nanoparticle covered composite yarns. J. Nanomater. 2016, 2016, 1–7. [Google Scholar] [CrossRef]

- Yalcinkaya, F.; Komarek, M.; Lubasova, D.; Sanetrnik, F.; Maryska, J. Producing antibacterial textile material by weaving PVB/CuO nanocomposite fiber covered yarn. Nanocon 2014, 6th International Conference 2015. Available online: http://nanocon2014.tanger.cz/en/view-list-of-papers/3255-producing-antibacterial-textile-material-by-weaving-pvb-cuo-nanocomposite-fiber-covered-yarn/ (accessed on 1 May 2019).

- Ungur, G.; Hrůza, J. Modified polyurethane nanofibers as antibacterial filters for air and water purification. RSC Adv. 2017, 7, 49177–49187. [Google Scholar] [CrossRef]

- Yalcinkaya, F.; Lubasova, D. Quantitative evaluation of antibacterial activities of nanoparticles (ZnO, TiO2, ZnO/TiO2, SnO2, CuO, ZrO2, and AgNO3) incorporated into polyvinyl butyral nanofibers. Polym. Adv. Technol. 2017, 28, 137–140. [Google Scholar] [CrossRef]

- Homaeigohar, S.; Zillohu, A.U.; Abdelaziz, R.; Hedayati, M.K.; Elbahri, M. A Novel nanohybrid nanofibrous adsorbent for water purification from dye pollutants. Materials (Basel) 2016, 9, 848. [Google Scholar] [CrossRef]

| Sample | %Reduction of E. coli in Time | |||||

|---|---|---|---|---|---|---|

| 0 Contact Time | 1 h | 2 h | 3 h | 4 h | 24 h | |

| P0 | 0% | 6.66% | 23.52% | 29.01% | 23.33% | 17.19% |

| PC_5_100 | 74.67% | 90.67% | 95.56% | 99.21% | 96.58% | 100.00% |

| PV_5_100 | 72.00% | 14.67% | 25.93% | 52.63% | 55.26% | 97.37% |

| PC_10_100 | 89.00% | 100.00% | 100.00% | 100.00% | 100.00% | 100.00% |

| PC_5_150 | 44.67% | 1.33% | 3.70% | 5.26% | 42.11% | 94.21% |

| PV_5_150 | 66.67% | 20.00% | 12.96% | 53.95% | 65.79% | 95.53% |

| PC_10_150 | 81.33% | 100.00% | 100.00% | 100.00% | 100.00% | 100.00% |

| PV_5_200 | 40.00% | 53.33% | 37.04% | 52.63% | 44.74% | 91.84% |

| PC_10_200 | 84.67% | 100.00% | 100.00% | 100.00% | 100.00% | 100.00% |

| Solution | Nanoparticles (wt.%) | Speed of Core Yarn (m/min) | Abbreviation |

|---|---|---|---|

| 11% PVB dissolved in acetic acid | 5% CuO | 100 ± 15 | PC_5_100 |

| 5% V2O5 | PV_5_100 | ||

| 10% CuO | PC_10_100 | ||

| 5% CuO | 150 ± 15 | PC_5_150 | |

| 5% V2O5 | PV_5_150 | ||

| 10% CuO | PC_10_150 | ||

| 5% V2O5 | 200 ± 15 | PV_5_200 | |

| 10% CuO | PC_10_200 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yalcinkaya, F.; Komarek, M. Polyvinyl Butyral (PVB) Nanofiber/Nanoparticle-Covered Yarns for Antibacterial Textile Surfaces. Int. J. Mol. Sci. 2019, 20, 4317. https://doi.org/10.3390/ijms20174317

Yalcinkaya F, Komarek M. Polyvinyl Butyral (PVB) Nanofiber/Nanoparticle-Covered Yarns for Antibacterial Textile Surfaces. International Journal of Molecular Sciences. 2019; 20(17):4317. https://doi.org/10.3390/ijms20174317

Chicago/Turabian StyleYalcinkaya, Fatma, and Michal Komarek. 2019. "Polyvinyl Butyral (PVB) Nanofiber/Nanoparticle-Covered Yarns for Antibacterial Textile Surfaces" International Journal of Molecular Sciences 20, no. 17: 4317. https://doi.org/10.3390/ijms20174317

APA StyleYalcinkaya, F., & Komarek, M. (2019). Polyvinyl Butyral (PVB) Nanofiber/Nanoparticle-Covered Yarns for Antibacterial Textile Surfaces. International Journal of Molecular Sciences, 20(17), 4317. https://doi.org/10.3390/ijms20174317