Abstract

The practice of combining external stimulation therapy alongside stimuli-responsive bio-scaffolds has shown massive potential for tissue engineering applications. One promising example is the combination of electrical stimulation (ES) and electroactive scaffolds because ES could enhance cell adhesion and proliferation as well as modulating cellular specialization. Even though electroactive scaffolds have the potential to revolutionize the field of tissue engineering due to their ability to distribute ES directly to the target tissues, the development of effective electroactive scaffolds with specific properties remains a major issue in their practical uses. Conductive polymers (CPs) offer ease of modification that allows for tailoring the scaffold’s various properties, making them an attractive option for conductive component in electroactive scaffolds. This review provides an up-to-date narrative of the progress of CPs-based electroactive scaffolds and the challenge of their use in various tissue engineering applications from biomaterials perspectives. The general issues with CP-based scaffolds relevant to its application as electroactive scaffolds were discussed, followed by a more specific discussion in their applications for specific tissues, including bone, nerve, skin, skeletal muscle and cardiac muscle scaffolds. Furthermore, this review also highlighted the importance of the manufacturing process relative to the scaffold’s performance, with particular emphasis on additive manufacturing, and various strategies to overcome the CPs’ limitations in the development of electroactive scaffolds.

1. Introduction

With a strong growth in the field of tissue engineering over the last few decades, the standard for an effective bio-scaffold, which holds an integral role in the process of tissue repair, has also risen over time. The new generation of smart bio-scaffolds are not only able to act as a media or matrix for cellular adhesion, but are also able to control the cellular activities, support cellular proliferation process and promote new tissue specialization [1,2]. In this context, natural-based (e.g., chitosan, gelatin, alginate) and synthetic-based polymers (e.g., polylactide, polycaprolactone, polyvinyl alcohol) are the current dominant class of material for bio-scaffold in tissue engineering due to their processability, biocompatibility, possible biodegradability and similar mechanical properties to most natural tissues [3,4,5,6,7]. Nevertheless, these polymers mostly only act as a passive scaffold to temporarily support the biological structure while waiting for the tissues to naturally recover, without being able to actively provide any support towards cell proliferation and guide cell differentiation.

Bioactivity in a scaffold can be imbued by several approaches. A common approach to accelerate the tissue regenerations rate is by utilization of materials that are widely found in the natural tissue (e.g., collagen, which are commonly found in the extracellular matrix (ECM)) [8]. In specific cases such as bone tissue engineering, hydroxyapatite is a commonly used additive to enhance biomineralization and promote osteogenesis [9]. However, natural polymers have a wide range of natural viability, and their structures are more complex than synthetic polymers, making it difficult to tailor their properties to be used as bio-scaffolds, while the introduction of additives are tissue-specific and may not be an applicable strategy for all tissues. On the other hand, synthetic polymers are much more adjustable in terms of structure and properties. Scaffolds with similar properties (e.g., mechanical, electrical, physiochemical) to the native tissues will result in an enhanced rate of recovery and promote specialization, as the scaffold could provide signals and cues to properly guide new tissue growth [1,2,3,4,5,6,7,8,9,10,11]. These strategies are well-established and are generally regarded as a safe method to imbue some degree of bioactivity to the scaffold. However, the rate of tissue recovery in these ‘passive’ scaffolds are often unsatisfactory, with many studies reporting up to several weeks or even months until the tissues are considered to be fully recovered [12,13].

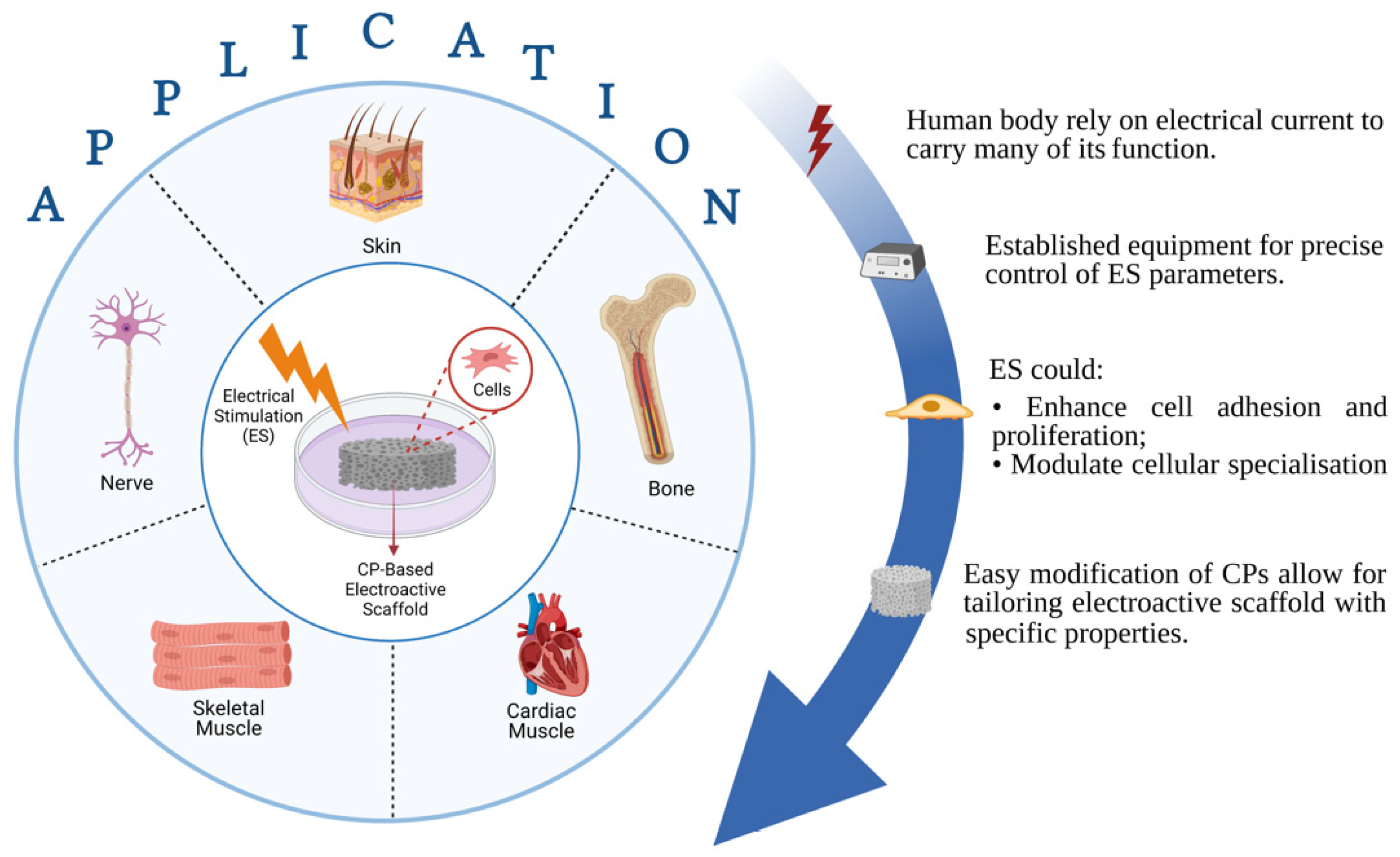

A more ‘aggressive’ approach to further enhance bioactivity may seek to combine the polymeric scaffold with another supporting factor that can enhance the rate of new tissue formation. One commonly used strategy is to incorporate growth factors (e.g., vascular endothelial growth factor (VEGF) [14], bone morphogenetic protein 2 (BMP-2) [15], etc.) into the scaffold ex vivo prior to implantation, which will then be released in a controlled manner in vivo [16,17]. Although phase I trials generally reported promising results, practical application of these approaches are currently obstructed by the strict regulatory approval, as there have been several studies that point to the unwanted formation of dormant tumors when sufficiently large quantities of growth factors were administered [18,19]. Another approach relies on utilizing external stimulation therapy along with stimuli-responsive scaffold as a means of providing cues to guide cellular specialization and promote tissue maturation. These external stimuli may vary from mechanical and biochemical [20,21], magnetic [22], ultrasound [23], and electrical stimulation [24,25], among others. In particular, the usage of electrical stimulation (ES) therapy alongside electroactive scaffolds is regarded as one attractive and promising approach, as it has the established equipment to allow precise control in terms of various therapeutical parameters (e.g., voltage magnitude, duration and interval between pulses), and ES in itself (without accompanied by electroactive scaffold) has been widely used in clinical practices [26,27]. Considering the fact that the human body relies on electrical current to carry many of its functions, the utilization of electroactive scaffolds alone—even without ES—is able to imbue bioactivity, where the conductive scaffold could provide cues to guide tissue formation due to the presence of endogenous electrical fields in the tissue microenvironments [28]. Nevertheless, ES can be used in conjunction with electroactive scaffolds to assist recovery by enhancing cell adhesion and proliferation as well as modulating cellular specialization, and the success has been reported in several tissue engineering applications including bone [29,30], skin [31], neural [32,33], skeletal muscle [34] and cardiac muscle tissues [35,36] (Figure 1). ES are shown to be favorable towards tissue formation, does not negatively affect cell viability in a significant manner, and is considered to be a safe option (potentially as safe as other external stimulation therapies), with no reports regarding harmful long-term effects have been reported so far [37,38,39]. However, the statement is valid only when the ES is operated within the appropriate parameters alongside the scaffold with conductivity in the range of the native tissues, thus extra caution must be made to ensure that all the correct parameters and properties are in place. Overly conductive scaffolds could trigger cell death due to the cell receiving voltage higher than its survival threshold, whereas insufficiently conductive (overly resistive) scaffold may cause the scaffold to be overheated as a result of the applied voltage, which could cause cell death due to protein denaturation [39]. With that in mind, it is imperative that the scaffold’s conductivity must be tailored to be in the range of the native tissues to ensure the biocompatibility of ES.

Figure 1.

Illustration about advantages of conductive polymeric (CP)-based electroactive scaffold and their electrical stimulation for various tissue engineering applications.

In fabricating an electroactive scaffold, electrically conductive materials including carbon-based materials (carbon nanotubes [40,41], graphene [42]), metallic nanostructures [29,43], and conducting polymers (CPs) [44,45] are usually mixed in a composite system alongside the previously mentioned biocompatible polymers. Among these materials, CPs have gained emerging attention particularly due to their easy synthesis and modification that allow for tailoring electroactive scaffold with specific properties (Figure 1) [2]. CPs such as polypyrrole (PPy), polyaniline (PANI), and polythiophene (PTh) derivatives are inherently conductive due to the presence of conjugated chains containing localized carbon-carbon single bonds and less localized carbon-carbon double bonds in their backbone. The electrons are able to move along the polymer chain due to the p-orbitals overlap in the double bonds, thus giving the electron greater mobility between atoms [46]. Their conductivity can be further improved by introducing dopant ions which can disrupt the CP backbone by introducing charge carrier and transfer charge along the polymer, thus a given CP can have a large range of conductivity similar to semiconductors or even metallic conductors [47]. This widely tunable conductivity, alongside the previously listed advantages, have made CPs widely used materials in tissue engineering.

Despite all the promises and potential offered by ES and CP-based scaffolds, its practical application is still largely limited by its unoptimized properties, many of which are caused by the properties of CPs themselves. In this review, the latest (2015–2021) application of CPs-based electroactive scaffolds and their improvement strategies to meet the requirement in biomedical application is thoroughly discussed. This review will start with addressing and discussing the issues that are commonly experienced in CP-based electroactive scaffolds in tissue engineering, including its mechanical properties, biocompatibility, hydrophilicity, and biodegradability. Then, it will be followed by highlighting more specific problems pertinent to each individual tissues including bone, nerve, skin, skeletal and cardiac muscle, each having different and specific requirements. In addition, this review will also highlight the importance of manufacturing process relative to the scaffold’s performance, with particular emphasis on additive manufacturing.

2. General Improvement Strategies for CP-Based Electroactive Scaffolds

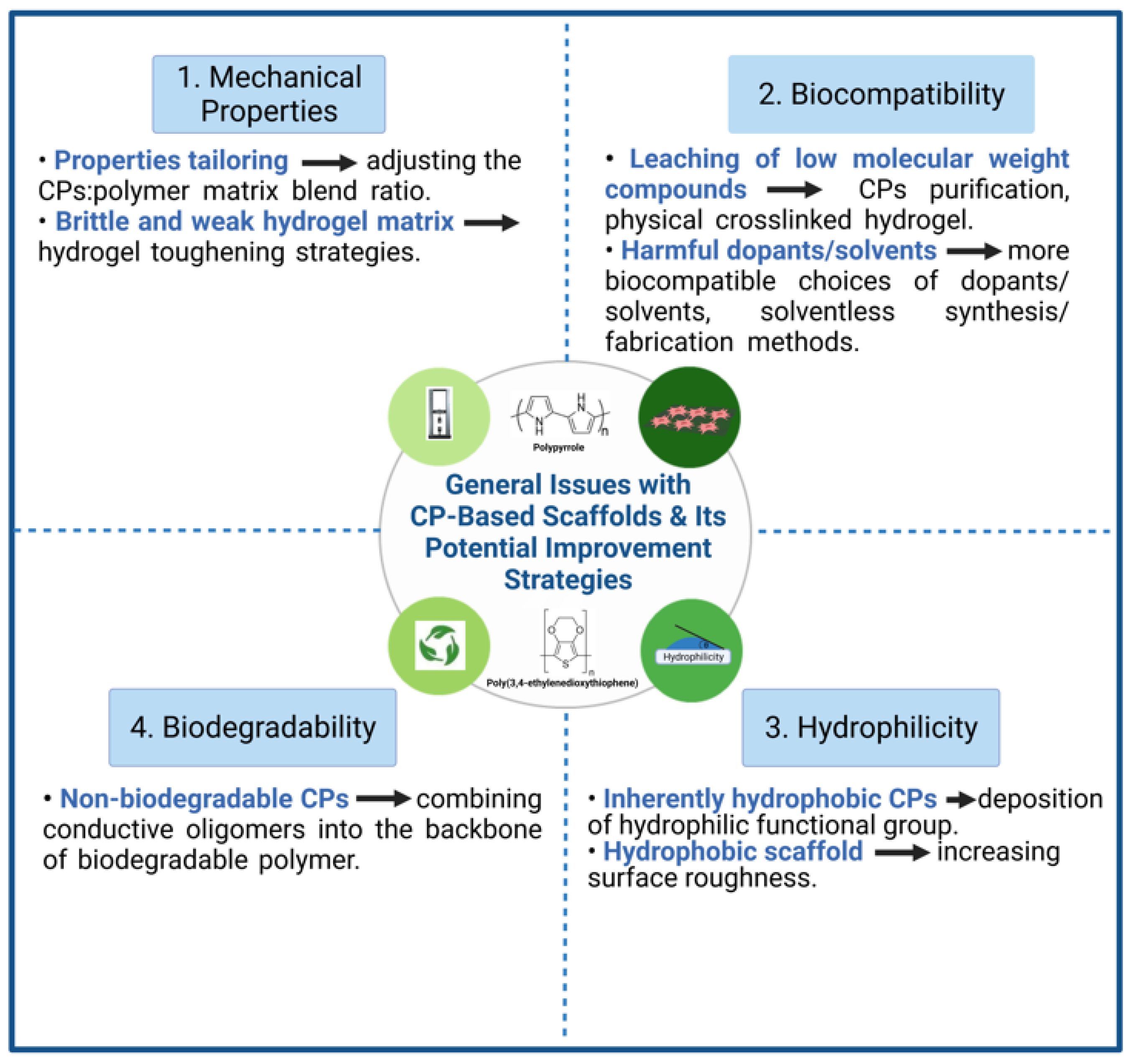

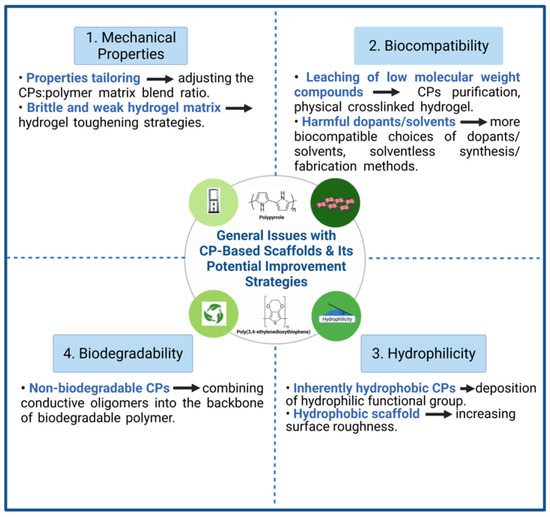

Even though CPs have great potential in tissue engineering applications, CPs are still haunted with several weaknesses and limitations pertinent to their intrinsic properties. Although the main benefit of adding CPs into a scaffold is to imbue electroactive properties, for an in vivo implant, CP-based scaffolds must also be mechanically stable, biocompatible and bioactive. The concept of using pure CPs alongside ES in tissue engineering have been reported and are favorable for cell maturation. Nevertheless, they are restricted in the form of thin films with no data regarding its mechanical performances and biocompatibility, thus making pure CPs not applicable as in vivo implant [48,49]. Discussions within this review will be aimed at CP-polymer composite, as it is by far the most common class of CP-based electroactive scaffold. This section will discuss the inherent weaknesses of CP-based scaffolds that may hinder its application in tissue engineering and electroactive scaffolds in general, as well as highlighting some strategies that have been, or could have the potential to be employed to resolve these issues (summarized in Figure 2).

Figure 2.

General issues with CP-based scaffolds and its potential improvement strategies.

2.1. Mechanical Properties

CPs in themselves are known to be very brittle, therefore making it difficult to fabricate a conductive scaffold using high concentration of CPs [2]. The common strategy to overcome its inherent brittleness is to blend together small but adequate quantity of CPs—just enough to mimic the natural tissue’s conductivity—alongside non-conductive polymers (e.g., PLA, PCL, chitosan, etc.) or hydrogels that are less brittle than the CPs as matrix, creating a composite. In turn, the introduction of CPs can help to improve the modest mechanical strength and Young’s modulus of the non-conductive polymer, which are often too low for practical use as bio-scaffolds. In this sense, the CPs can be seen as filler particles (i.e., load-carrying medium) in a composite that will help strengthen the non-conductive polymer matrix (i.e., load-transporting medium), provided that there are sufficient interaction forces between the CP’s and the polymer matrix’s interface.

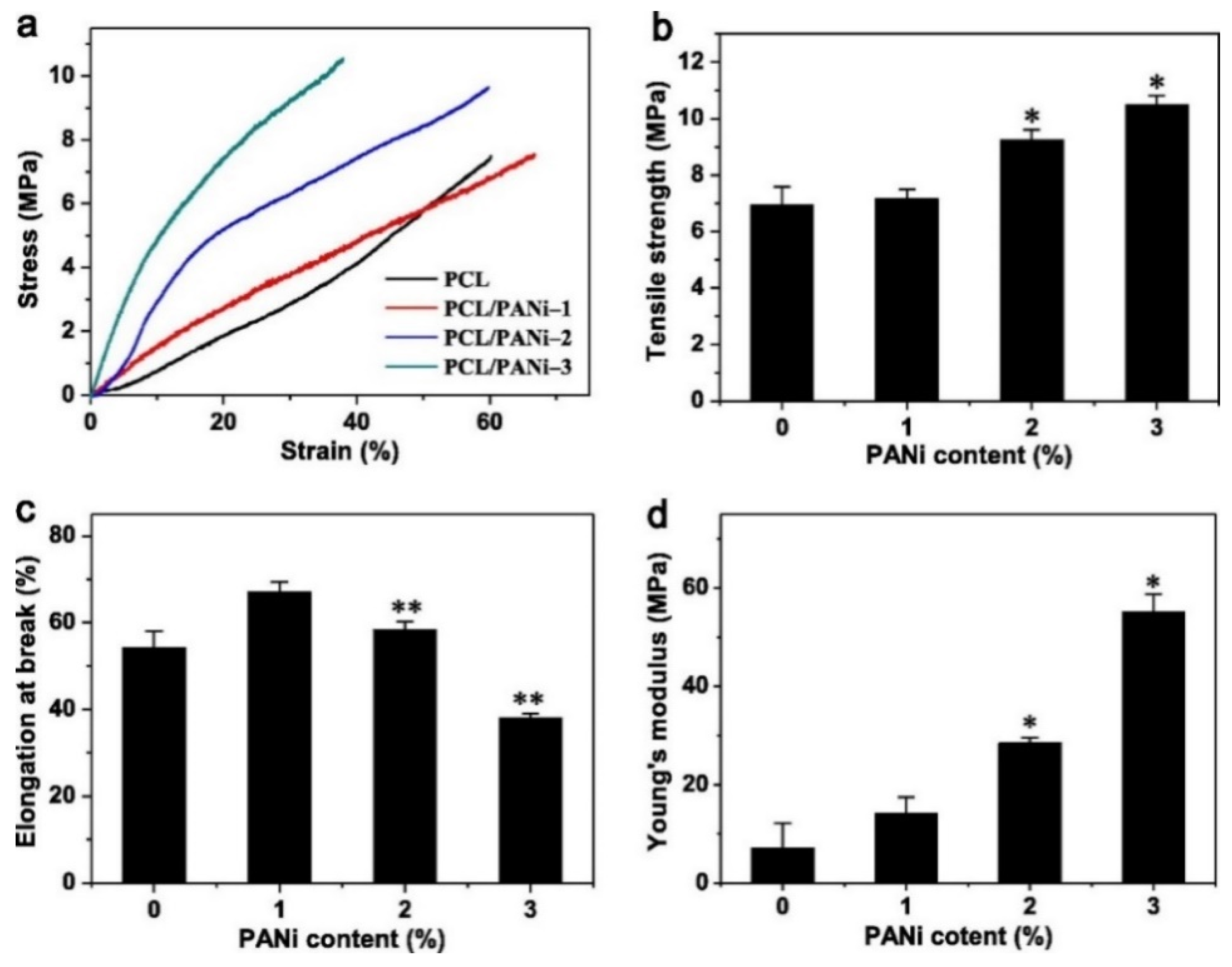

In film and fiber-based composite scaffolds, the main challenge often comes in the form of tailoring the right mechanical properties for specific tissues. Sometimes, an increase in stiffness is needed, while other times it needs to be decreased. This issue can be addressed by adjusting the ratio between CPs and its polymer matrix. For instance, blending of PEDOT:PSS with chitosan and polyvinyl alcohol (PVA) via solution electrospinning was able to tune both the stiffness and tensile strength of the nanofibrous scaffold to better match the mechanical properties of cardiac muscle tissues [50]. When used as the matrix, the chitosan/PVA blend used in this study is able to significantly reduce the overly high stiffness and increase the elongation at break of the PEDOT:PSS. An increase in Young’s modulus, strength and toughness is directly proportional to the PEDOT:PSS content ratio (up to 1 wt%). This was mainly attributed to the reduction in fiber diameter caused by the addition of PEDOT:PSS, which in turn will result in higher crystallinity and more aligned molecular orientation. Hydrogen bond was also introduced as a result of the interaction between the OH groups in PVA and chitosan with the SO3− groups in PSS, which may also contribute to the enhanced mechanical properties. A similar trend was also observed in PCL/PANI nanofiber scaffold, reporting increasing tensile strength and significantly increased Young’s modulus (almost 8-fold at 3% wt PANI) as the content of PANI goes up, although elongation at break may be compromised (Figure 3) [51]. This phenomenon is also observed in 3D architecture, as is seen in our previous work which indicated that increasing the weight percentage of PANI in PCL/PANI bone scaffold can help increase the Young’s modulus and compressive strength of the scaffold [44]. At 2 wt% PANI, the scaffold was 28% stiffer than pure PCL scaffold from 64.43 MPa to 82.61 MPa, making it mechanically more suitable for application as a cancellous bone scaffold. It should be noted that not every addition of CPs into non-conductive polymer matrix resulted in increased mechanical properties, as was demonstrated in silk fibroin scaffold [52] or in chitosan/collagen scaffold [53] which experienced reduction in Young’s modulus and tensile strength when PPy was added. Some plausible explanations are attributed to the fragility of PPy, non-homogeneous CP distribution, or the lack of strong interfacial interaction between PPy and the matrix (thus the CP particles are viewed as holes/porosities rather than strengthening filler particles), but these claims are rarely backed up by experimental results, and the exact reasons thus far are still inconclusive.

Figure 3.

Effect of incorporating PANI into PCL nanofibrous scaffold to its mechanical properties. (a) Stress-strain curve, (b) Tensile strength, (c) Elongation at break, and (d) Young’s modulus. * Significantly different from pure PCL (p < 0.05, n = 5); ** Significantly different from PCL-PANI-1 (p < 0.05, n = 5). Reproduced with permission from [51]. Copyright (2013) Elsevier.

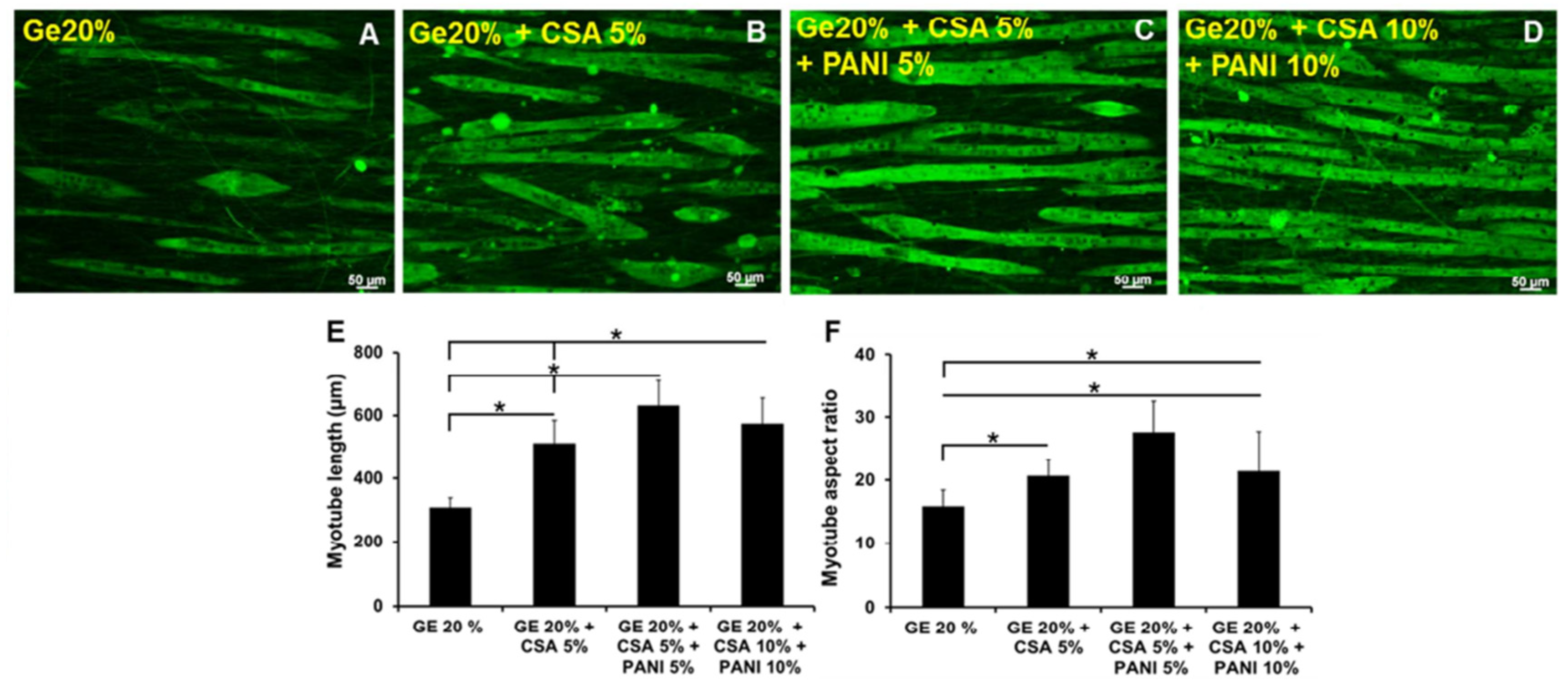

On the other hand, the problems with hydrogel-based conductive scaffolds in terms of mechanical properties is more one-directional compared to films and fiber-scaffolds. While CP-based films and nanofibers scaffolds can possess both overly high or overly low stiffness as previously discussed, CP-based hydrogels are almost always on the weaker side in terms of the mechanical properties due to its highly porous structure and hydrated nature. This often becomes a hindrance for in vivo applications that experiences substantial mechanical loading (e.g., cartilage, skeletal and cardiac muscle). This issue is both experienced in conductive hydrogel composite, as well as in films grown on top of hydrogel substrate (i.e., layered structure). For instance, PANI/gelatin gum hydrogel as shown in the work of Shrisuk et al. exhibits a compressive modulus of ~30 kPa and relatively poor elastic recovery capability, which may limit its practical application as in vivo muscle implant despite its excellent ability in promoting differentiation of myoblasts into myotubes [54]. Simply adding higher concentration of CPs may not solve the whole problem, as there is a certain limit of how high the concentration can go before excessive CP loading may cause a decrease in mechanical properties due to heterogeneous composite formation, as well as other issues such as diminished biocompatibility [55]. Therefore, in this case, the mechanical properties of the matrix itself may be improved.

To improve the hydrogel’s mechanical properties (and thus the overall scaffold), tough structures such as double network (DN) or triple network may be employed [56,57]. For layered architecture, PEDOT/polyurethane elastic electrode was electropolymerized on top of DN gel substrate, where the DN gel possess extremely high mechanical integrity when compared to conventional single network hydrogels [58]. The DN gel, which in this case consists of poly(2-acrylamido-2-methylpropanesulfonic acid) and poly(acrylamide) (PAMPS-PAAm), has been used in various biomedical applications that requires exceptional mechanical properties [59,60,61]. Without compromising conductivity and biocompatibility, the utilization of double network structure managed to significantly improve the scaffold’s durability, which remains electrically stable after 100 repeated cycles of bending and stretching. DN gel can also be fabricated in the form of CP-hydrogel composite [62,63]. Darabi et al. fabricated PPy-grafted chitosan as its first network, and poly(acrylic acid) (PAA) as its second network [62]. Reversible ionic interaction between carboxylic group in PAA and NH group in PPy allows the scaffold to possess self-healing property. At its highest crosslinking density, the DN gel possess very high compressive modulus (up to 800 kPa). However, addition of PPy can actually lower the modulus since the hydrogen and ionic bonding between PPy and the gel is weaker than the covalent bonds present in the DN gel, and the crosslinking density can be reduced and tailored to better match the modulus of the replaced tissue.

2.2. Biocompatibility

Currently, there are conflicting reports regarding the biocompatibility of CPs. For example, although reported to be generally safe and biocompatible in low concentration, the usage of PANI in high concentration are reported to be cytotoxic and even promote chronic inflammation when implanted in vivo [44,64,65]. Contrary to popular beliefs, PPy which is often viewed as a CP with more favorable biocompatibility than PANI does not fare much better in terms of biocompatibility, showing mild to moderate toxicity against common fibroblasts NIH/3T3 cells at a solution concentration of 10%, which is similar in performance with PANI when compared side-by-side [66]. However, since most of these CPs are fully insoluble in aqueous condition, it is likely that the one causing biocompatibility issues are not the materials of the CPs themselves. Further supporting this hypothesis is the fact that even though PEDOT:PSS is dispersible in water and can be formulated as water-soluble molecule, it also reported excellent biocompatibility [67]. Therefore, cytotoxicity has been related to the leaching of low molecular weight compounds found in the CPs, which can be in the form of its leftover/unpolymerized oligomers, or leftover acids that helps form the CPs during the synthesis process [68]. Size and shapes of the CPs in the composite may also plays a part in determining the overall scaffold’s cytotoxicity [66]. The insolubility and hydrophobicity of CPs can also trigger an immune response and subsequently cause inflammation, but discussion in improving the CP’s hydrophilicity will be split into the next part, whereas this part will focus on solving the issues around preventing the low molecular weight compounds to cause further unwanted cytotoxicity.

To remove the unwanted impurities from the CPs, several methods of purifications can be used. Since the transition between PANI base (non-conductive form) and PANI salt (conductive form) is reversible, Humpolicek et al. used a purification method involving cycles of deprotonation of PANI salt and reprotonation of PANI base in order to remove the low molecular weight impurities from the samples as much as possible [69]. The sample which underwent deprotonation and reprotonation reported significantly higher biocompatibility, being able to support cell viability of HaCaT at a value of 0.67 (mild cytotoxicity) compared to untreated samples of the same concentration at 0.40 (severe cytotoxicity), supporting the hypothesis that removal of low molecular weight impurities play a huge part in improving the overall CP-based scaffold’s biocompatibility. Another method of post-synthesis purification in the form of reprecipitation was also used for the removal of residual monomers [70]. In this procedure, the CP is dissolved in a suitable solvent (for PANI, N-methyl pyrrolidone can be used, even though the solubility is not complete), and then added dropwise to a non-solvent, allowing the CP to precipitate while the monomers stay dissolved. The purified sample also shows much higher cell viability, reporting 0.89 (no cytotoxicity) compared to 0.56 (moderate toxicity) of untreated PANI at the concentration of 5%. In this study, the group reported relatively comparable cytotoxicity between globular and nanotubular morphology of PANI. However, another study reported that the size of PPy nanoparticles have a significant effect on the cell viability of human lung fibroblast, where larger particle size will generally result in lower cytotoxicity [71].

Acid doping is a commonly used strategy to oxidize CPs such as PPy and PANI, converting them from its non-conductive form to its conductive form. In this case, dopants are proton donors (p-doping) and are usually strong acids such as hydrochloric acid (HCl) and sulfuric acid (H2SO4). However, these acids may cause cytotoxicity issues in the cellular environment, especially when not removed properly after synthesis [72]. Thus, biocompatibility of the resulting PANI can be increased by substituting the acids with a more biocompatible acid, as was shown in the work of Daraeinejad and Shabani, who replaced camphorsulfonic acid (CSA) with taurine [73]. Aside from being less toxic than CSA, some studies have also shown that taurine can promote cell proliferation and differentiation in neural tissues, thus making it bioactive [74]. The cellular viability of 3T3 cell is significantly higher in the PANI/poly(ether sulfonate) scaffold treated with taurine (more than 0.80 value after 7 days which indicates no cytotoxicity) compared to the CSA-treated scaffold (below 0.60 value after 7 days, indicating moderate cytotoxicity). Nevertheless, conductivity was compromised as a result of taurine’s shorter molecular chains which leads to better PANI solubility in the composite (0.5 × 10−5 S/cm in taurine-treated scaffold compared to 3.7 × 10−5 S/cm in CSA-treated scaffold).

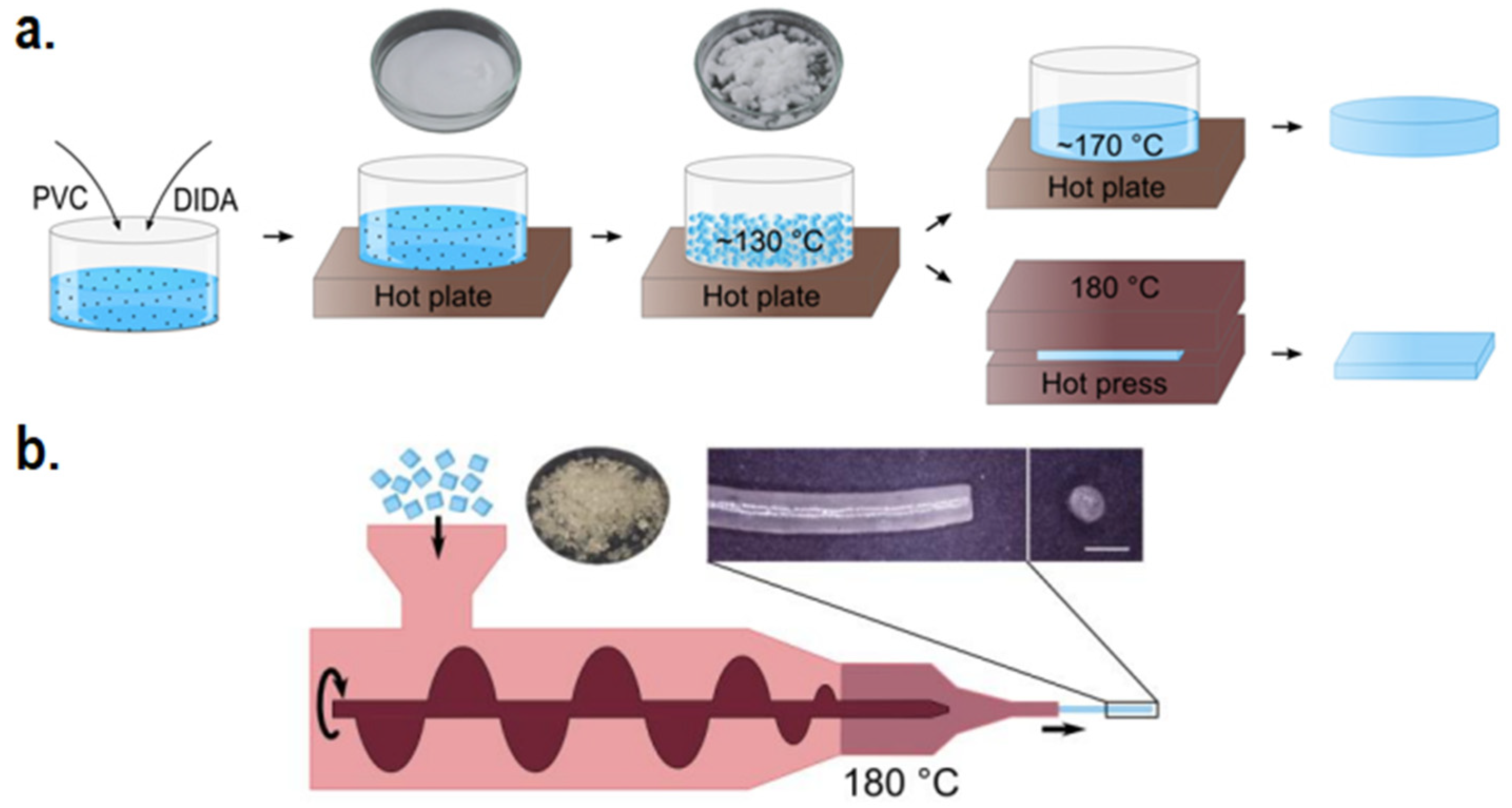

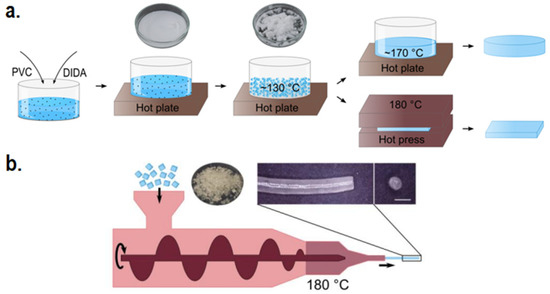

Blending CPs with non-conductive biocompatible polymers also serves as a means to enhance the scaffold’s biocompatibility. In fact, biocompatibility is often not an issue when the weight percentage of the CPs is sufficiently low compared to the biocompatible polymer matrix, while adequate conductivity and mechanical properties can usually be achieved even with low CP concentration [44,75]. Nevertheless, mishandling during blending or with the blended materials themselves may possess threat to biocompatibility. As previously stated, leaching of solvents involved during synthesis can impart negative effect on biocompatibility, as the organic solvents used during solvent-based synthesis such as solution electrospinning may potentially be unsafe for biomedical uses (e.g., chloroform, dimethylformamide, etc.) [76,77,78]. Thus, solvent-less methods of blending such as melt electrospinning or melt extrusion additive manufacturing may be employed instead [79]. And although the usage of hydrogel-based scaffolds generally leads to better biocompatibility due to the similarity in the nature of hydrogel and ECM, leaching of unreacted crosslinker monomers may possess unwanted cytotoxic issues. To resolve this, physically crosslinked hydrogels which relies on ionic crosslinking or hydrogen bonding can be chosen as a safer alternative rather than conventional chemically crosslinked hydrogels with covalent bonds [80]. Bi et al. constructed a physically crosslinked chitosan/PVA hydrogel with the aforementioned double network structure to strengthen the gel, since physical hydrogels are known to be mechanically weaker compared to chemical hydrogels [81]. The obtained hydrogel shows excellent biocompatibility in vitro, and were able to host hydroxyapatite nanoparticles on its surface to enhance bone regeneration, hinting the possibility for similarly constructed hydrogel to be used as a hydrogel matrix for CP-based composite hydrogel scaffold.

2.3. Hydrophilicity

Natural tissues and ECM are hydrophilic in nature, and therefore are more likely to attach to a hydrophilic surface. However, commonly utilized CPs are inherently hydrophobic in nature, thus leading to unfavorable cell-substrate interaction. This may negatively affect the process of cell adhesion and attachment of other necessary biological molecules to the scaffold’s surface, subsequently causing major issues in biocompatibility and may cause inflammation [18]. Furthermore, the immune system in the human body detects hydrophobic substances as foreign objects due to their significantly different properties from natural hydrophilic tissues, thus the introduction of hydrophobic pure CPs may trigger an unwanted foreign body response from the immune system [82]. This has become one of the reasons why blending CPs with biocompatible and hydrophilic non-conductive polymer has become the norm for electroactive scaffolds (aside from mechanical properties), with hydrophilic polymers such as chitosan [83] and alginate [84] being some of the attractive choices. As mentioned, this part is closely linked with the previous sub-section as both are discussing about the ability for the scaffold to facilitate cell attachment and growth. That being said, the following section will focus more on the surface properties of the scaffold to achieve favorable biocompatibility and bioactivity.

To promote hydrophilicity, there are two general approaches that can be used. The first approach is to deposit hydrophilic functional groups to the CP, which can be done either by grafting and creating a copolymer [85] or surface coating which can be achieved by substrate growing or by surface treatments such as plasma treatment [86]. Dopamine (DA)—which contains various functional groups including amine, imine, and catechol—can be used as universal anchor for surface modification, as was demonstrated by Tan et al. in their study for the development of DA-modified PANI [85]. The DA-modified PANI are shown to be dispersable in water due to the hydrophilic catechol group found in DA, whereas the hydrophobic unmodified PANI was completely destabilized and formed precipitate. Biocompatibility is greatly enhanced relative to pure PANI as a result of increased hydrophilicity, demonstrated by the high HeLa cell viability of 0.88 compared to 0.75 of pure PANI in the same concentration. Due to the non-conductive nature of DA, creation of DA-modified PANI results in compromised conductivity with an increased ratio of DA, although this can be resolved by adjusting the ratio between DA and PANI to the necessary level. Even though hydrophilicity is necessary to some extent in order to prevent inflammatory responses, some studies seem to suggest that excessive hydrophilicity may lead to hindered protein and cell adhesion, in a way so that there is an optimum range of how hydrophilic a substrate should be to prevent macrophage from attaching, while at the same time allowing specific protein pertinent to cell adhesion to be adsorbed [87,88]. For example, doping of PPy with hyaluronic acid (HA) is known to increase its hydrophilicity, and the hydrophilicity will increase with higher molecular weight (Mw) of HA (40° water contact angle at 35 × 103 Da of HA, down to 19.4° at 30 × 105 Da of HA) [88]. Even though hydrophilicity is increased, in vitro cell viability of NIH3T3 fibroblast and SH-SY5Y neuroblastoma were severely reduced in samples with higher Mw of HA, possibly because the specific protein that facilitates the cell adhesion cannot be efficiently adsorbed by the overly hydrophilic surface.

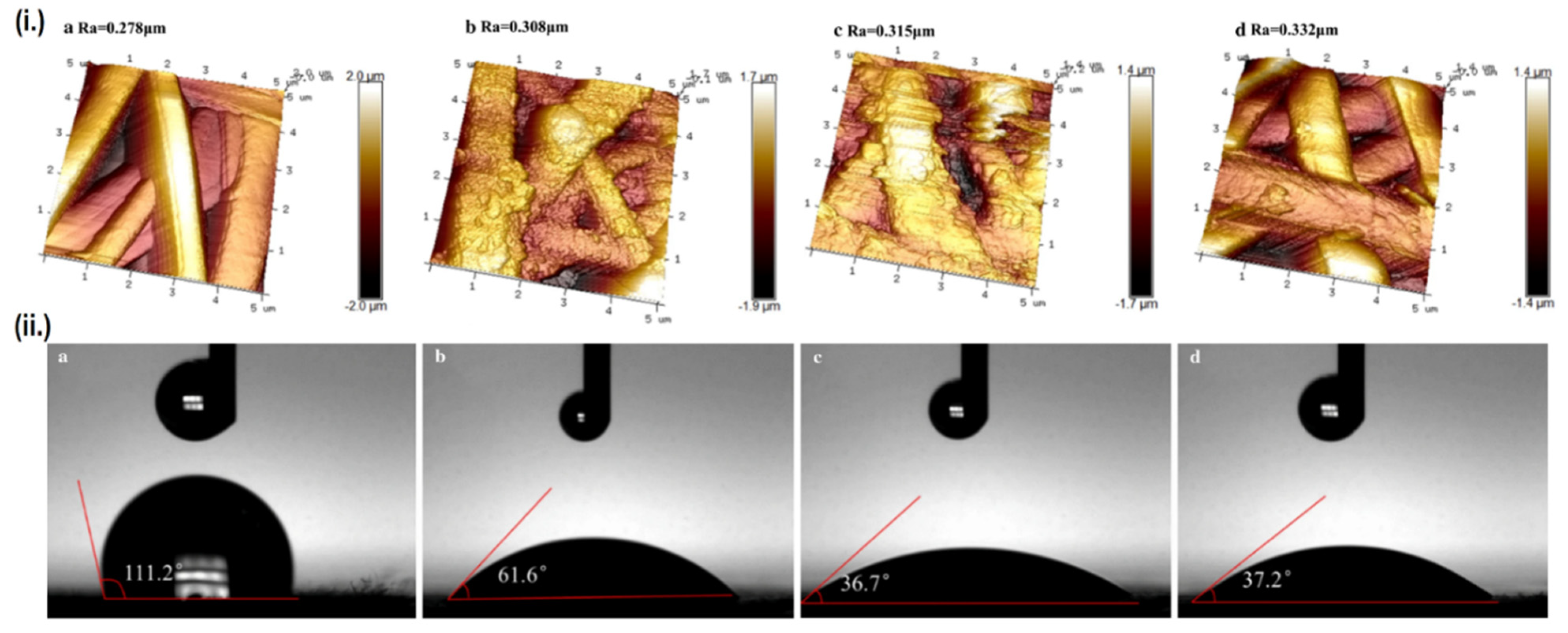

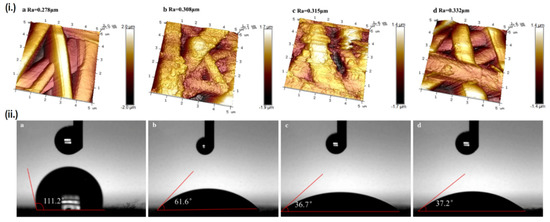

The other approach is by modifying the scaffold’s surface roughness, as higher surface roughness is known to promote hydrophilicity [89]. The creation of a CP-polymer composite may enhance the scaffold’s hydrophilicity even though the CPs themselves are hydrophobic, as the dispersed CPs particle will increase the scaffold’s surface roughness, although the effect is often minor due to the counteraction by CP’s innate hydrophobicity [90]. Another means of enhancing surface roughness is by using post-fabrication surface finishing, such as mechanical finishing, acid etching, or the previously mentioned plasma treatment. Interestingly, these two approaches can be simultaneously employed to impart greater effect on hydrophilicity. Aside from converting CPs from its non-conductive to conductive form, doping of acids can also be used to increase the scaffold’s surface roughness as a result of etching [91]. Liu et al. doped various inorganic acids (HCl, H2SO4 and HClO4) into PANI/PLA nanofibers to alter their surface roughness, while plasma treatment was also used in conjunction to imbue oxygen-containing groups (OH and COOH) onto the surface of PLA [92]. Ultimately, the combination of these two factors managed to significantly reduce the contact angle of PLA from 111.2° down to 37.2° when doped with perchloric acid, subsequently enhancing the biocompatibility as well. The perchloric acid-doped PANI/PLA nanofibers displays the highest cell viability and degradation rate, although the mechanical properties were severely compromised due to extreme surface roughness. On the other hand, samples doped with HCl and H2SO4 which presents less extreme surface roughness, displays much better mechanical properties, along with comparable biocompatibility and hydrophilicity as the HClO4 doped sample (Figure 4). It should be noted that not all acid doping will yield positive result, as another study by the same group reported decreased cellular attachment and proliferation when PANI is doped by PAMPS, possibly caused by a dramatic decrease in total surface energy, creating a huge gap between the total surface energy of the scaffold’s and the cell’s [93].

Figure 4.

Relationship between surface roughness and hydrophilicity. (i.) AFM images and surface roughness value (Ra) of the scaffolds, and (ii.) Contact angle of each scaffold. Each alphabet corresponds to different samples, namely: (a) PLA, (b) PANI/PLA-HCl, (c) PANI/PLA-H2SO4, and (d) PANI/PLA-HClO4. Adapted with permission from [92]. Copyright (2021) Springer.

2.4. Biodegradability

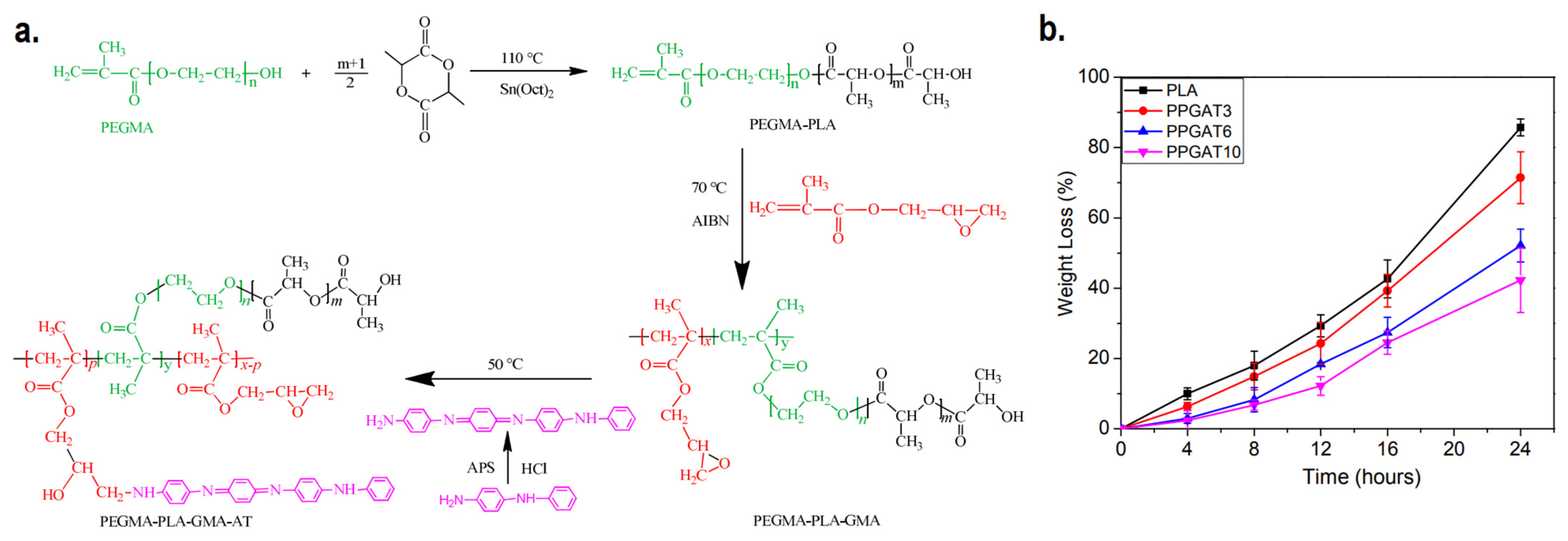

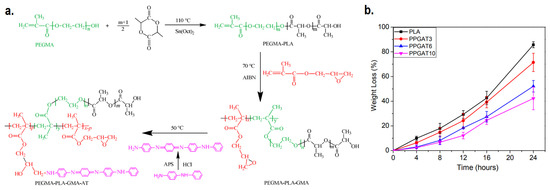

Biodegradable scaffolds which have the ability to undergo controlled degradation when implanted in vivo are desirable, as it makes the process of post-recovery implant detachment unnecessary. CPs homopolymers are not inherently biodegradable, and biodegradability itself is not something that is commonly expected in the current generation of CP-based electroactive scaffolds. Even though blending CPs with biodegradable polymers (e.g., chitosan, gelatin, alginate, etc.) will result in mostly biodegradable scaffolds, the CPs are expected to remain inside the body after the matrix has been degraded, potentially causing harmful effects afterwards due to its potential cytotoxicity [26]. For the development of biodegradable and intrinsically conductive polymers, a new class of materials must be developed, branching from the conventional CPs homopolymers. One promising example is the development of degradable electroactive polymers by combining oligomers of CPs along with biodegradable polymers, creating copolymers. Li et al. synthesized an inherently electroactive biodegradable polymer based on polylactide and aniline tetramer as a base material for electroactive scaffold [94]. The synthesis first began by adding poly(ethylene glycol) methacrylate (PEGMA) as initiator to PLA synthesis by ring-opening polymerization. The resulting PEGMA-PLA copolymer is then further copolymerized with glycidyl methacrylate (GMA) via free radical polymerization. This allows the aniline tetramer to be introduced to the copolymer to imbue electroactivity to the biodegradable copolymer, as a result of the interaction between the amine group of aniline tetramer and epoxy group from GMA. The synthesized film demonstrated up to 71% of degradation in NaOH solution within 24 h, although the increase in aniline tetramer percentage will decrease its degradation capability (Figure 5). Later, the same group utilized similar concept to create tetraaniline-b-PCL-b-tetraaniline block copolymer, and demonstrated its printability in additive manufacturing to fabricate electroactive biodegradable cartilage scaffold [95]. A similar approach can be used to fabricate biodegradable electroactive hydrogel. Tetraaniline-graft-oxidized alginate (OA) nanoparticles alongside OA can be used as crosslinkers to gelatin hydrogel, where the conductive nanoparticles would reinforce the hydrogel while simultaneously imparting electroconductivity, and the gels were able to mostly degrade (~65%) after 5 weeks of in vitro incubation in phosphate-buffered saline (PBS) solution [96].

Figure 5.

(a) Synthesis route of PEGMA-PLA-GMA-AT biodegradable conductive polymer. (b) Biodegradability of the copolymer with various ratio of PLA:aniline tetramer. Adapted with permission from [94]. Copyright (2016) Royal Society of Chemistry.

3. Specific Improvement Strategies for Specific Body Parts

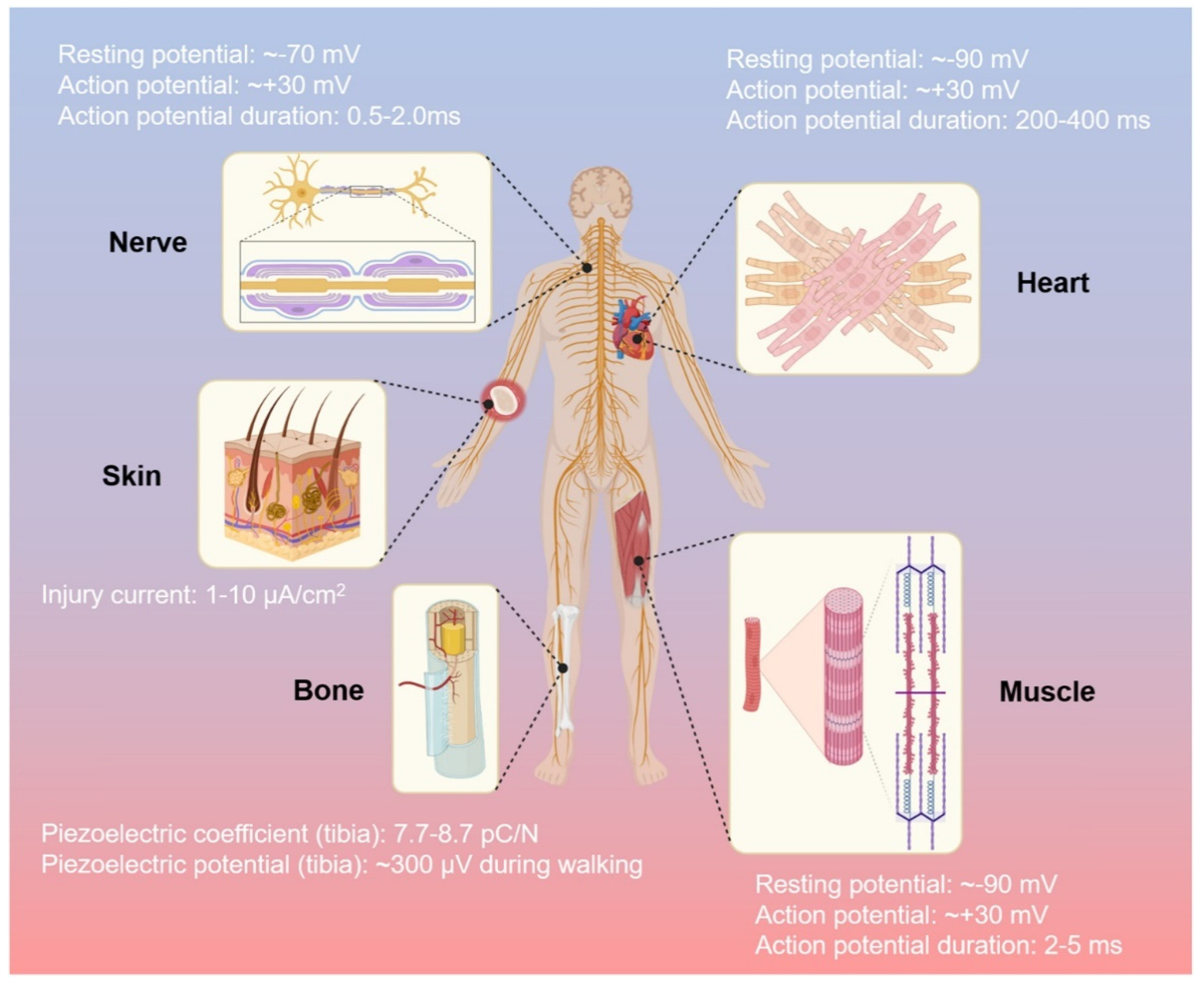

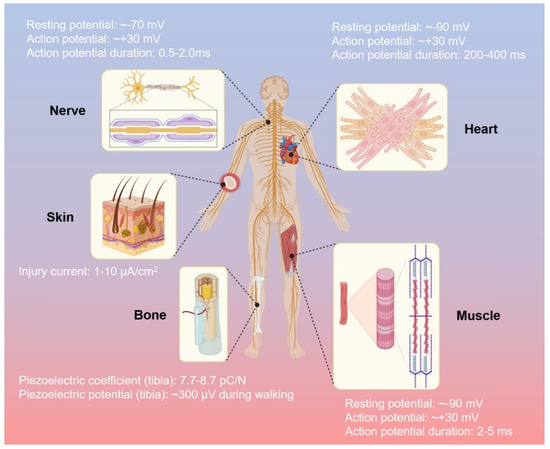

Various types of tissues are regulated by electrical signals in the human body, such as activities of neural communication, heartbeat activities, bone regeneration, muscle contractions, and wound healing, respectively [97]. The important role of the electric biological field leads to tissues repair due to direct current and stable electric potential, causing cells to migrate to the wound site [98]. CPs allow fine-tuning of chemical, electrical, and physical properties to suit the needs of the tissue part in which they are used [99]. To obtain greater impact of electroactive scaffolds, their implementation should fulfill not only general characteristics of biomaterials (that were already described in Section 2), but also specific needs of each tissue that might vary with other tissue due to the difference of extracellular matrices and function. Various electrical activities of each tissue in the human body as the guideline of specific requirements for implementation of electroactive scaffold in each tissue are described in Figure 6 [97]. Beside electrical conductivity, certain mechanical properties that specific to each tissue should also be considered, such as high compression strength and modulus for bone tissue and typical elasticity for skin tissue. Thus, this section will focus on the improvement of (i) required electrical properties of CP-based electroactive scaffolds that are suitable with designated tissue and their electrical stimulation phenomena, and (ii) certain mechanical properties of CP-based electroactive scaffolds that correlated with the target tissues (summarized at the end of this section in Table 1).

Figure 6.

The human body and its electrical activity. Reproduced with permission from [97]. Copyright (2021) Elsevier.

3.1. Bone Tissue Engineering

3.1.1. Conductivity of Bone Scaffold

Bone has conductivity values around 1.6–2.0 × 10−3 S/cm and 5.8–6.3 × 10−4 S/cm for cancellous bone and cortical bone, respectively [100]. One of the common strategies to mimics the electrical properties of bone tissue is incorporating conductive fillers such as CPs to improve the conductivity value of the scaffold [101]. For example, our previous study showed that the conductivity of the pure PCL scaffold (1.1 × 10−11 S/cm) could be enhanced significantly by the addition of 0.1% wt PANI (2.46 ± 0.85 × 10−4 S/cm), which is within the region observed in cancellous and cortical bone [44]. Conductivity of CP-based electroactive scaffold could be improved by increasing the CPs concentration in the scaffold. However, it should be noted that the higher amount of CPs concentration in scaffold could also enhance their toxicity in biological environment [102]. Thus, finding the optimum CPs concentration in the scaffold that provide a sufficient conductivity for bone tissue with less toxicity is crucial for the application of CPs-based electroactive scaffold on bone tissue engineering. The optimum PANI concentration of 3D printed PCL/PANI scaffold was 0.1% wt, because increasing PANI concentration on the scaffold by 1% wt and 2% wt led to elevating their cytotoxicity with only slight improvement of the scaffold’s conductivity [44]. It is noteworthy that they used melt blending method to prepare pre-mixed of PCL and PANI, which is a facile mixing method and suitable for scaffold manufacturing through 3D printed method without utilization of any toxic organic solvents.

The same tendency was also observed in electroactive scaffold based on other CPs, such as PPy as observed by Zarei et al. [53]. They prepared conductive polypyrrole/chitosan/collagen electrospun nanofiber scaffold with varied PPy concentration (0, 5, 10, 15, 20 and 25% wt) and crosslinked by glutaraldehyde vapor (denoted as PPCC, PPCC5, PPCC10, PPCC15, PPCC20 and PPCC25 respectively). They found that the conductivity of PPCC, PPCC5, PPCC10 and PPCC15 were 0.8, 1.2, 1.5 and 1.6 × 10−3 S/cm respectively. The scaffold conductivity enhanced as PPy concentration increased might be the result of more contact between the conductive polymer particles, both on the surface of the fiber and within it. Interestingly, all scaffolds showed low cell toxicity regardless of their PPy concentration due to the presence of bioactive ingredients such as chitosan and collagen that able to stimulate cell proliferation, although the maximum performance was owned by the scaffold with 10% wt of PPy [53].

Beside increasing CPs concentration, utilization of different CPs morphology might be an attractive strategy to improve electrical properties of electroactive scaffold [11]. An example of this approach is the application of tubular and spherical morphology of PPy in PLLA/PPy electroactive scaffold [103]. It is known that the conductivity of the tubular PPy (4.8 × 10−1 S/cm) is higher than the spherical PPy (0.6 × 10−4 S/cm). As the result, employing the tubular PPy in composite scaffold (~7.0 × 10−4 S/cm) gave a conductivity value that almost four times higher than the spherical PPy (~1.8 × 10−4 S/cm), while maintaining their low cytotoxicity with cell viability is higher than 80% [103]. The possible reason for this phenomenon is that the tubular PPy could intertwine and contact between adjacent tubular PPy easier than the spherical PPy, so that the tubular PPy could produce higher conductivity than the spherical PPy at lower concentrations.

The other strategy to increase the conductivity of the electroactive scaffold is by adding organic solvents to the CPs solution during the synthesis process. Ruzaidi et al. prepared chitosan–gelatin–agar-PEDOT:PSS electroactive scaffold and PEDOT:PSS were synthesized through the chemical oxidative polymerization method [104]. They found that adding 3.0 vol.% organic solvent dimethyl sulfoxide (DMSO) into PEDOT:PSS solution during their synthesis could significantly increase their conductivity from 1.71 ± 0.01 × 10−5 S/cm to 3.75 ± 0.06 × 10−1 S/cm [104]. Even though DMSO is considered as non-toxic solvent at a concentration below 10% (v/v), its utilization on biomedical application should be avoided as much as possible because DMSO could induce alterations in miRNA and epigenetic landscape in the 3D maturing cardiac model at 0.1% DMSO [105] and induce retinal apoptosis at DMSO concentration above 1% [106].

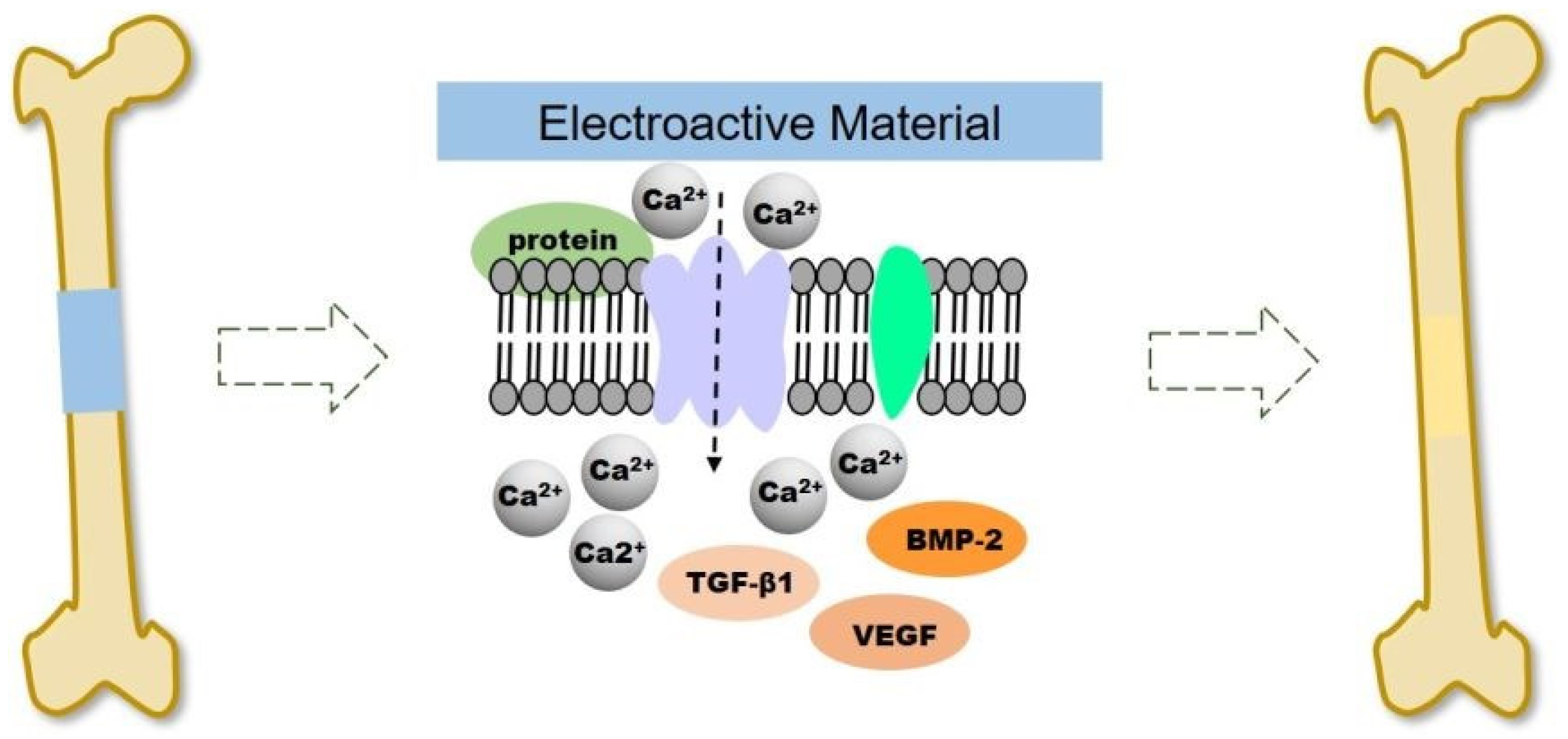

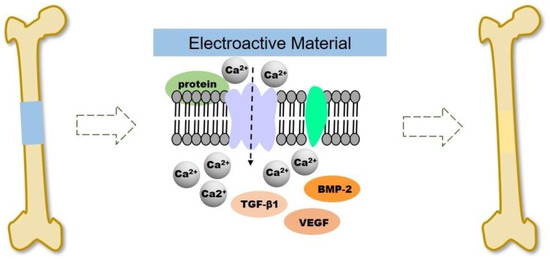

To optimize the utilization of the electrical properties of CPs at the injury site, improvements to the performance of the scaffold can be enhanced through exogenous electrical stimulation. The methods of providing electrical stimulation used in clinical practice are direct current and capacitive coupling [107,108]. Electrical stimulation (ES) can significantly promote the proliferation and differentiation of osteoblasts at the cellular and tissue level in a small amount of currents between 5 and 100 μA [108,109]. A representative example was carried out by He et al. by using a continuous micro constant current electrical stimulation signal (10 µA) on the surface of different substrates (PPy NWs and PPy/PDA NWs) via an electrochemical workstation for 12 h after cells inoculation and for 2 h per day for 14 days [110]. It was noticeable that continuous ES increase the adhesion and proliferation of MC3T3-E1 cell in PPy/PDA NWs, significantly. Also, the result showed ES addition could accelerate the cells entering the mature stage of osteogenic differentiation of osteogenesis differentiation. Electrical signals regulate cell proliferation and differentiation by controlling ion channels and altering the structure of the cytoskeleton in bone tissue [111]. As illustrated in Figure 7, ES causes the voltage gate Ca2+ channels on the cell membrane to open, allowing Ca2+ to enter the cells, resulting in intracellular Ca2+ concentration increased, and activates the expression of various growth factors such as transcriptional transforming growth factor (TGF). -β) and bone morphogenetic protein (BMP) [112,113].

Figure 7.

Schematic illustration of electroactive scaffold to induce bone regeneration. Reproduced with permission from [113]. Copyright (2020) Royal Society of Chemistry.

In capacitive coupling, bone stimulation has been shown to be efficient by using a potential of 1 to 10 V at frequencies between 20 and 200 kHz, which creates an electric field of 1 to 100 mV/cm [108]. In another way, Maharjan et al. applied modified DC pulse stimulation (200 mV/cm) at a frequency of 100 Hz at 50% duty cycle for 1 h every day on PCL/PPy scaffold, which improved alkaline phosphatase (ALP) activity and alizarin red S (ARS) staining that significant for osteogenic differentiation [114]. Applied a potential at bone tissue, will increase electrical potential at the fracture site. Hereinafter, electroactive materials can increase local ES and assist in rebuilding the electrophysiological microenvironment to promote bone regeneration. Cells are recruited from the surrounding tissue to or into the electroactive material due to the galvanotaxis effect [115]. The mechanism of this effect is that protein adsorption will increase due to the ability to attract ions possessed by the surface charge of the electroactive material, which can bind to cells through ionic or charge interactions. As a result, cell migration, adhesion, proliferation, and osteogenic differentiation via activation of growth factor expression (eg., BMP, TGF-β) with locally generated ES will be enhanced by electroactive material [113,116].

3.1.2. Mechanical Properties of Bone Scaffold

The common issue is CPs are very brittle, as we mentioned in the previous section. This property is opposite with the requirement of bone scaffold that needs strength and ductility to avoid brittle fracture. CPs like PPy, PANI, and PEDOT:PSS have Young’s modulus value of 180 MPa, 1.3 GPa, and 2.7 GPa, respectively which is very low compared to Young’s modulus of bone, especially cortical bone [117,118].

To overcome this problem, the mechanical properties of CPs can be optimized by doping or combining the CPs with metals, ceramics, or other polymers that have higher mechanical properties than CPs. For instead, fabrication electroactive bone scaffold mesoporous silica PPy-based through solvent casting method improved the young’s modulus (0.11 GPa) and compressive strength (7 MPa) of scaffold to have similar properties with cancellous bone [119]. Created a mesoporous silica PPy-based scaffold made the scaffold more porous and less dense, which decreased the young’s modulus (0.125 GPa) and compressive strength (8 MPa) of pure mesoporous silica but still within the allowable range.

An interesting approach to improve the poor mechanical properties of CPs-based scaffold was conducted by Ghorbani et.al. They decorated the electroactive scaffold with PU-PANI/PVA/PDA through the electrospinning method [120]. It was known that polyurethane (PU) has high mechanical properties that will resolve the brittle issue of PANI. The result showed that scaffold has 34.06 ± 1.16 MPa tensile strength showed higher similarity to the bone and 24.75 ± 2.32 MPa young’s modulus, which is in the range of cancellous bone. Another polymer that is used as an alternative to obtain good mechanical properties from CPs-based scaffold is polyethersulfone (PES) which is a biocompatible material. Pournaqi et al. used the electrospinning method to fabricate the PES/PANI scaffold to mimic the physiochemical structure of native bone tissue ECM [121]. PES/PANI nanofibers showed tensile strength of 1.85 ± 0.365 MPa, which was in the cancellous bone region.

Apart from that, incorporating CPs with metals would be the best strategy to obtain the higher mechanical properties due to high mechanical properties of metals. This strategy has been carried out by Jie et al. who fabricated bone scaffold using rGO/PPy through electrostatic LBL assembly strategy, followed by an electrochemical deposition process results in better mechanical properties and can be processed into the desired configuration [122]. The 3D rGO/PPY scaffold has a hardness value (92.27 ± 4.03 MPa) and Young’s modulus (185.94 ± 10.76 MPa) almost twice as high as the hardness value (48.59 ± 4.96 MPa) and Young’s modulus (91.0 ± 4.19 MPa) of 3D rGO met the requirements of clinical surgery for trabecular defect repair [122].

3.2. Nerve Tissue Engineering

3.2.1. Conductivity of Nerve Scaffold

The neural network within the human body plays a distinct and important role in all physiological processes, including cell recognition, sensory and motor functions. The application of electroactive scaffold is attractive and promising to further promote the growth and differentiation of neurons and the formation of neural networks. Wang et al. showed that scaffolds can be considered as suitable candidates for electrical stimulation of cells if they have a conductivity around 1.0 × 10−3 S/cm [123]. To meet the conductivity requirement of neural tissue, the CPs can be coating, doping, or blending to a scaffold as a strategy to improve electrical properties.

Incorporation of the conductive polymer PEDOT:PSS to produce a scaffold with the required conductivity was applied to a silk fibroin (SF) scaffold [124]. The SF scaffold was fabricated using the electrospun method and then submerged into PEDOT:PSS and DMSO-treated PEDOT:PSS solutions. It is known that the isoelectric point of PSS and SF is at pH 1.2–1.5 and pH 4–5, so that the optimal submerged process can be carried out in an acidic environment (positively charged polypeptide fiber) [125,126]. An acidic environment conditioning (~pH = 2) was carried out to ensure that the silk and PEDOT:PSS were at a high level of electrostatic attraction during the process. Measurement of the conductivity value showed that neat silk has a very low conductivity (~10−6 S/cm), while the conductivity value is higher and tends to increase with the addition of PEDOT:PSS concentration (range ×10−5 to 10−1 S/cm). Moreover, the conductivity values of the DMSO-treated scaffold were much higher than that of the other samples (range ×10−5 to 4 S/cm), which tended to increase with the addition of PPy concentration (solvent concentration of PPy ranging from 0.5 to 13 mg/mL). Treatment with DMSO which is a polar solvent leads to optimization of the conductivity value of PEDOT:PSS. Polar solvents cause the anionic shell of PSS to be partially washed away, causing a shift in the PEDOT:PSS structure which decomposes from the coil conformation (benzoid) to linear extended coil conformation (quinoid), so that the undissolved PEDOT:PSS results in efficiency in changes in orbital overlap and packing between chain. Then a better pathway for charge transport is available which leads to an increase in conductivity [127]. DMSO is an example of a solvent treatment that is often used, but other types of solvent treatment commonly used are methanol, dimethylformamide, tetrahydrofuran, or ethylene glycol. Improvements made to SF/PEDOT:PSS and SF/DMSO-treated PEDOT:PSS scaffolds did not show major cytotoxic effects and were able to modulate growth and differentiation of NG108−15 cells in vitro better than pure SF scaffolds. SF/DMSO-treated PEDOT:PSS scaffold with 3 mg/mL PEDOT:PSS showed the most optimal results compared to other concentration variations in testing metabolic activity, cell proliferation, and neuron differentiation.

Improvement of the conductivity of the scaffold with an increase in the concentration of CPs when blended with other materials was also observed in the PCL/PPy scaffold. Sanjairaj et al. varied the concentration of PPy (0.5%, 1%, and 2% v/v) when fabricating a porous 3D scaffold from block copolymer PPy and Polycaprolactone (PPy-b-PCL) which can be decomposed through a novel electrohydrodynamic 3D jet printing process [128]. Significant improvement occurred due to the addition of PPy to the scaffold, where the measured conductivity of pure PCL was 0.09 S/cm, much lower than PCL/PPy 0.5% (28 mS/cm), 1% PCL/PPy (1.02 mS/cm) and PCL/PPy 2% (1.15 mS/cm). Very low conductivity values in PCL scaffolds are undesirable in neural network scaffold applications, as conductivity is a desirable property of ideal neural guiding channels (NGC) such as peripheral nerve regeneration. As was the case with the previous use of PEDOT:PSS, an increase in the concentration of CPs which results in higher conductivity is not always in line with optimal biological activity. The 1% PCL/PPy scaffold showed optimal results in biological activity characterized by strengthening the differentiation and maturation of hESC-20 NCSCs to peripheral neurons.

Eftekhari et al. did the fabrication of the scaffold using a different conductive polymer of PANI [129]. PANI was blended with CS to produce a conductive scaffold in the form of cell-imprinted hydrogel on the differentiation of mouse adipose-derived stem cells (rADSCs) into neuron-like cells. It is known that chitosan is a non-conductive material with a conductivity value of 7.5 × 10−8 S/cm so that blending with PANI will improve the conductivity value of the scaffold which is also in line with increasing PANI concentration. PANI with high -conjugated system, affected the electrical conductivity of the blend materials, strongly [130]. Increasing the amount of PANI from 0% to 2.5 wt% increased the conductivity value of the scaffold from 7.5 × 10−8 to 10−4 S/cm, which is sufficient for applications in neural tissue engineering [131]. However, PANI at certain concentrations can be toxic to cells, so PANI must be used at optimal concentrations to be compatible with cells. The results of the MTT test showed that the scaffold at all concentrations of PANI had low toxicity to ADSCs.

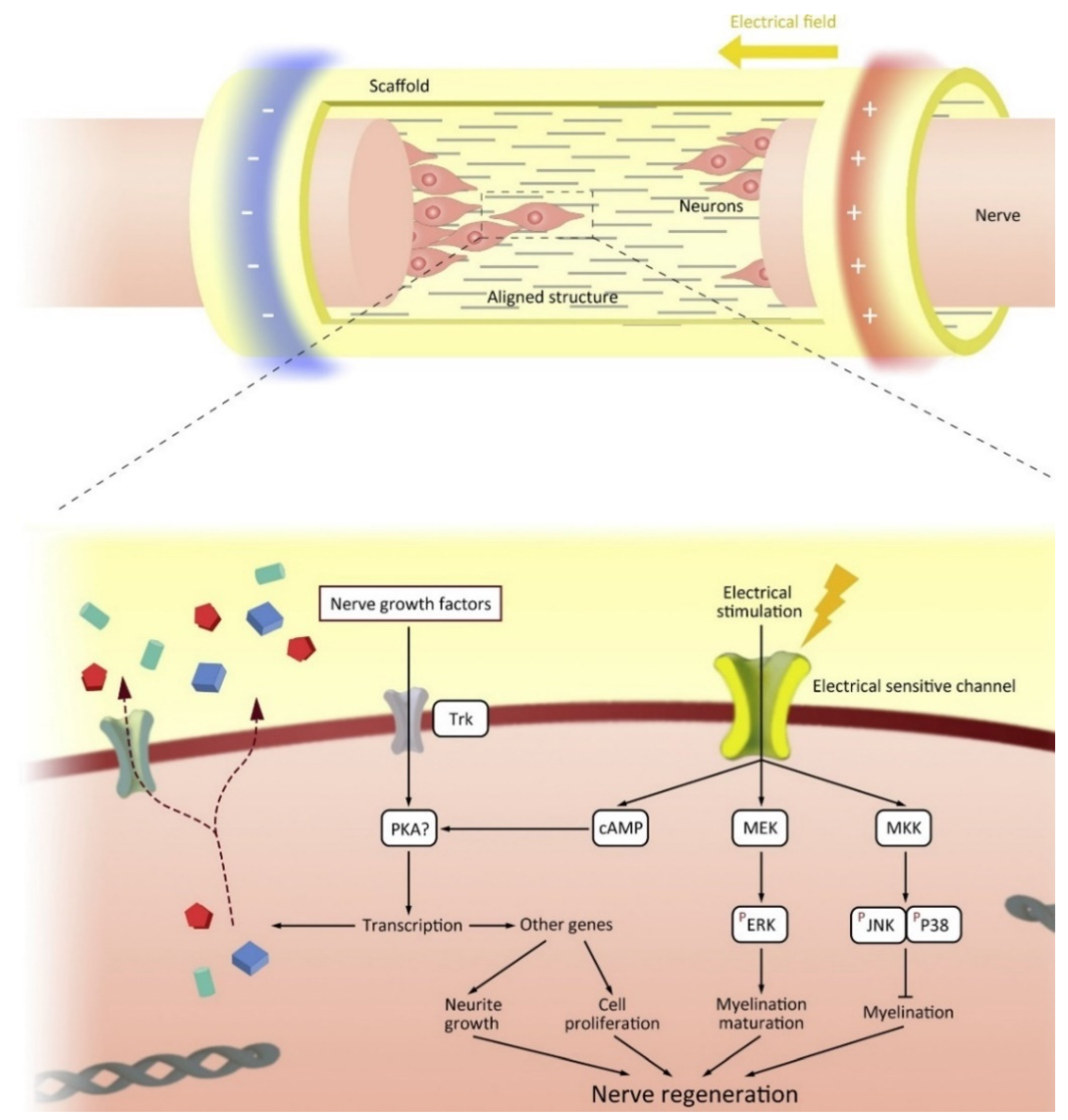

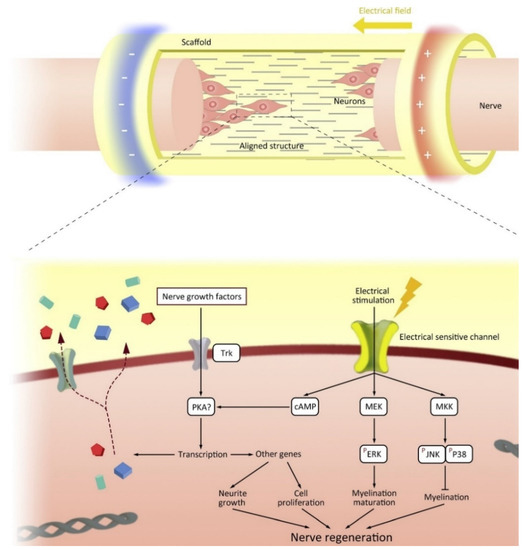

The conductive properties of conductive scaffolds can be utilized through electrical stimulation. When an injury occurs, neural cells will migrate to the site of damage to regenerate the damaged area. However, the microenvironment does not support the neural cells due to the damage that occurs resulting in the loss of cells and ECM. Electroactive scaffold will guide neural cells to the site of damage by mimicking the ECM required for the path to the site of damage [132]. Interestingly, neurons transmit information via synaptic and electrical junctions whereby neuronal signaling occurs both within and between nerve cells via the entry and exit of ions (sodium (Na+), potassium (K+), and calcium (Ca2+) along the axon [133]. Intercellular electrical signaling pathways are formed by differentiation of neural stem cells to form axons and dendrites, and proliferation of Schwann cells (SCs) aids neuronal development by growing myelin sheaths [134]. Synaptic processes are a combination of electrical and chemical events, the growth and differentiation of neurons can be regulated as a result of electrical stimulation [135]. The interaction between the nerve cell and the electroactive material is shown in Figure 8. Thus, the application of electroactive scaffold and electrical stimulation can increase the growth and differentiation of neurons and the formation of neural networks [132].

Figure 8.

The mechanism of how electroconductive materials trigger the nerve regeneration through intracellular signalling. Reproduced with permission from [136]. Copyright (2020) Elsevier.

Zhao et al. applied ES to a PPy/SF conductive composite scaffold fabricated by 3D bioprinting and electrospinning, then compared it with a conductive scaffold not applied to ES to observe various cell behaviors under the influence of ES [136]. ES is done by providing a direct current of 100 mV/mm at different times. Cell viability observed in Schwann cells after 8 h of ES administration increased apoptotic cells and necrotic cells significantly and showed better cell proliferation than scaffold without ES. In the absence of ES, the PPy, SF, PPy/SF and blank groups showed SCs extension lengths of 28 ± 5 μm, 56 ± 3 μm, 65 ± 4 μm, and 22 ± 2 μm after 6 h. The long existence of SCs belongs to the PPy/SF scaffold. In addition, an increase of 140–170% occurs when ES is applied. These results demonstrate the important role of PPy in admixture with SF as a conductive scaffold and the impact exerted by ES application on the scaffold. The application of ES to the electroactive PPY/SF scaffold aligned the SC arrangement and its proliferation on the scaffold (marked by the finding of S100 and EdU positive cells). The administered ES also facilitates SC migration so as to provide contact guiding cues for anchorage and elongation and regeneration of axons [137]. The application of SF/PPy and ES scaffolds was able to increase neurotrophic factor, BDNF, and NT-4/5, as well as activate protein kinases of the MAPK signaling pathway. These substances play a role in accelerating neuronal regeneration and controlling important cytological activity in response to stimulation and cell types [138].

Significant differences in cell length due to ES administration were also observed in the PANI/ITO scaffold [139]. On the surface of the PANI/ITO scaffold without ES, the neurite length of 15.57 ± 5.65 μm was quantified. After ES administration for 4 h with 100 A amplitude, 0.8 ms pulse width and 1s with a repeat interval stimulating biphasic rectangular current pulse gave optimal results with an increase to 35.87 ± 7.74 m on the PANI/ITO scaffold [140]. An increase in the number of PC 12 cells also occurred after applying ES to the scaffold. Differences in the optimization of scaffold properties with conductive polymers were also observed in electrical stimulation for PANI/ITO and ITO (without PANI) surfaces. The increase in DMEM protein adsorption of about 54% occurred in the PANI/ITO scaffold compared to the ITO scaffold under ES for 3 h. The high protein absorption is associated with the electric field formed between the two sides of the scaffold surface which causes the protein interaction with the scaffold to be stronger than without ES. In addition, ES may change the conformation of the protein lead to more protein attachment to the surface of the scaffold which further enhances cellular adhesion (increases neurite extension).

3.2.2. Mechanical Properties of Nerve Scaffold

The mechanical properties of the scaffolds used for neural tissue engineering should mimic the mechanical properties of the ECM to promote the neural differentiation of cells. Physical cues are an important factor in designing an artificial ECM to guide cells because according to the mechanical properties of stem cells, niches can regulate cell behaviour such as attachment, migration, and differentiation [129]. The use of conductive polymers in electroactive scaffolds can decrease and increase the mechanical properties of the scaffold. Therefore, it is necessary to determine the optimal composition of the conductive polymer in the electroactive scaffold to obtain an improvement in the mechanical properties. A recent example of this was demonstrated by Tavakoli et al. [84]. The group revealed that scaffolds containing concentrations higher than 2 mL PPy were brittle, so they broke into pieces during the drying process and in their surface evaluation with a four-point probe. These results indicate that higher PPy concentration causes brittleness of the scaffold [141,142]. As a result, this group uses a composite ratio of 2:10 for PPy:alginate which produces suitable and optimal mechanical properties [84]. Therefore, considering the optimal concentration of conductive polymer will be the first approach to achieve improvement in mechanical properties. The increase in mechanical properties must meet the target mechanical properties so that the increase and decrease in the value of mechanical properties such as Young’s modulus, compressive strength, tensile strength, etc. is not a problem, as long as the values are similar to or close to the target mechanical properties. For example native human peripheral nerve strength is ~6.5 MPa [128], spinal cord ~1.02–1.37 MPa [143], and the Young modulus of brain tissue is 7.11–9.21 KPa [45].

Other conductive polymers such as PEDOT also show lower mechanical properties (tensile strength) than PVA materials in PVA/PEDOT:PSS electroactive scaffolds. Babaie et al. added 0.1% by weight of PEDOT to the pure PVA scaffold which caused a decrease in tensile strength from 14.2 MPa to 7.2 MPa [144]. PEDOT is known as a brittle polymer with high young modulus and low mechanical strength due to its chemical structure and the presence of a thiophene ring [145]. However, the improvement of the mechanical properties of the scaffold by increasing the PEDOT content could be the result of increased crystallinity, decreased structural defects and decreased fiber diameter [50,146]. In fact, structural defects can form and spread more easily in thicker fibers than in thinner fibers [50]. Therefore, conductive polymers in electroactive scaffolds have a unique role in the improvement of mechanical properties in neural tissue application. Most importantly, the scaffold has the necessary mechanical properties, which allow it to maintain its bulk architectural morphology without collapsing before the tissue can regenerate.

Huang et al. also fabricated a PEDOT scaffold combined with chitosan in the form of a hydrogel through electrostatic interactions between partially deacetylated chitin (degree of acetylation = 80%, DA80%) [147]. In chitosan, a decrease in the value of DA causes a decrease in the value of Young’s modulus. Young’s modulus is an important property in providing a stable microenvironment for cell proliferation and tissue regeneration during recovery, so a high modulus will be advantageous for a long-term healing process. Huang et al. used 80% chitin with Young’s modulus of 4.1 MPa and (1–3%) PEDOT to fabricate ChT-1% PEDOT, ChT-2% PEDOT, and ChT-3% PEDOT scaffold. PEDOT mixing decreased Young’s modulus insignificantly due to an increase in sacrificial bonds (electrostatic interaction). Measurement of tensile strength increased with increasing PEDOT ratio, with values of 1.93, 2.14, and 2.49 MPa. Moreover, in in vitro and in vivo activity, the scaffolds exhibited cytocompatibility that promotes neuronal cell attachment and proliferation.

Blended conductive polymer with graphene can be an alternative solution to improve the mechanical properties of the scaffold. Chen et al. added carboxylic graphene oxide to polypyrrole/poly-l-lactic acid via electrochemical deposition method to obtain C-GO/PPy/PLLA-composite for neural network applications [148]. Measurements of the average tensile strength showed a value of ~32.7 MPa for C-GO/PPy/PLLA which was higher than ~21.1 MPa for PPy/PLLA. This increase indicates the polarity interaction between the imino group of PPy and the carboxyl group of C-GO. The tensile strength value of ~26.4 MPa of C-GO/PPy/PLLA was also significantly higher than that of PPy/PLLA. This value satisfies the need for application to the rabbit sciatic nerve and human peripheral nerve having ultimate tensile values of ~11.7 and ~15.87 MPa, respectively [149], whereas C-GO/PPy/PLLA can induce functional recovery from in vivo testing of SD rat sciatic nerve repair.

3.3. Skin Tissue Engineering

3.3.1. Conductivity of Skin Scaffold

Skin wounds are one of the most common wounds caused by burns, diabetes, trauma, surgery, wound bed, and aging problems [150]. Scaffold applications can expand the ECM, presenting potential opportunities for cell attachment, proliferation, and migration, ultimately leading to the development of new skin tissues regeneration (e.g., keratinocytes and fibroblasts) [151,152]. The development of electroactive scaffolds in skin wound management has a beneficial effect on enhancing innate wound repair processes such as local inflammation, cell infiltration, and neovascularization [153]. Skin is a sensitive tissue to electrical signals and has a conductivity from 2.6 to 1 × 10−7 S/cm, depending on the component [154]. Numerous studies have been in order to improve electrical properties of skin scaffold to meet the requirement of skin conductivity.

On the other hand, the deposited CPs have formed a coating at the surface of the scaffold improved conductivity as constituted a relatively homogenous and continuous path. Silk fiber (SF) coated with PPy and PANI resulted in a significant improvement in the electrical properties of the scaffold. Measurement of conductivity of pristine silk fibroin fibers is 1 × 10−11 S/cm, the bulk conductivity of pure PPY is 1.3 ± 0.1 × 10−5 S/cm, and the pure PANI conductivity is 0.8 ± 0.1 × 10−4 S/cm [155]. In contrast, PPY/SF and PANI/SF-coated exhibited conductivities of 2.2 ± 0.1 × 10−5 S cm−1 and 1.6 ± 0.1 × 10−4 S cm−1, respectively. Coated fibers show higher compatibility properties than pristine SF making them more suitable for tissue engineering. Tests on HaCaT cells showed that the cells adhered to the PPY-coated SF surface and were more effective at PANI. In addition, good cytocompatibility was also shown by PPY/SF and PANI/SF coated [155]. Another coating using nanometer-scale PPy was applied via in situ chemical polymerization method on the surface of electrospun polycaprolactone-gelatin (PCL-Gel) nanofibers [156]. The conductivity of PPy-coated PCL-Gel scaffold nanofibers with various PCL-Gel concentrations ranged from 4.6 to 5.8 S/cm in a reaction time of 7 min in the in-situ chemical polymerization process. The increase in conductivity reached a maximum value (11.3 ± 2 S/cm) when the polymerization reaction time was increased to 55 min. Meanwhile, a two-fold increase in oxidant in the reaction led to a slight decrease in the conductivity value (4.81 ± 0.5 S/cm) compared to a two-fold increased in pyrrole (3.6 ± 0.07 S/cm) [156]. Low oxidant-to-monomer ratio could reduce the conductivity value of PPy [157]. Apart from that, the application of PPy coating on the PCL-Gel has improved the conductivity of the scaffold because the conductivity measurements of the uncoated PCL-Gel fibers showed insulating properties [156].

Crosslinking of conductive polymer (PPy) to poly(glycerol-amino acid) (PGA) was carried out by Zhou et al. to produce controlled electrical conductivity, skin adhesive behavior, and photothermo-chemo scaffold tumor therapy [158]. The cross-linking between branched poly(glycerol-amino acid), polypyrrole@polydopamine (PPy@PDA) nanoparticles and aldehyde F127 (PGFP scaffold) resulted in a multifunctional scaffold with higher conductivity properties. The PGFP scaffold showed an increase in the conductivity value due to the presence of PPy from (1.9 ± 0.009) × 10−3 S/cm (without PPy) to (6.7 ± 0.008) × 10−3 S/cm (incorporated PPy) [158]. Blending PANI with chitosan (CS) also gives satisfactory results in the application of wound healing to skin tissue. Blended PANI/CS is done through electrospinning method. CS is a non-conductive material, which when combined with PANI provides the conductivity values required for wound healing applications. The highest conductivity values were obtained by mixing CS with a higher concentration of PANI, as expected. In this study, Moutsatsou et al. used a 1:1 ratio (CS:PANI) as the highest PANI concentration, which gave conductivity values of ~2.75 × 10−5 S/cm and ~0.5 × 10−5 S/cm for before and after neutralization, respectively. Cytocompatibility evaluation on CS/PANI performed by human osteoblast cells showed that CS/PANI at all concentrations was not toxic, even supporting better osteoblast attachment than chitosan control [158].

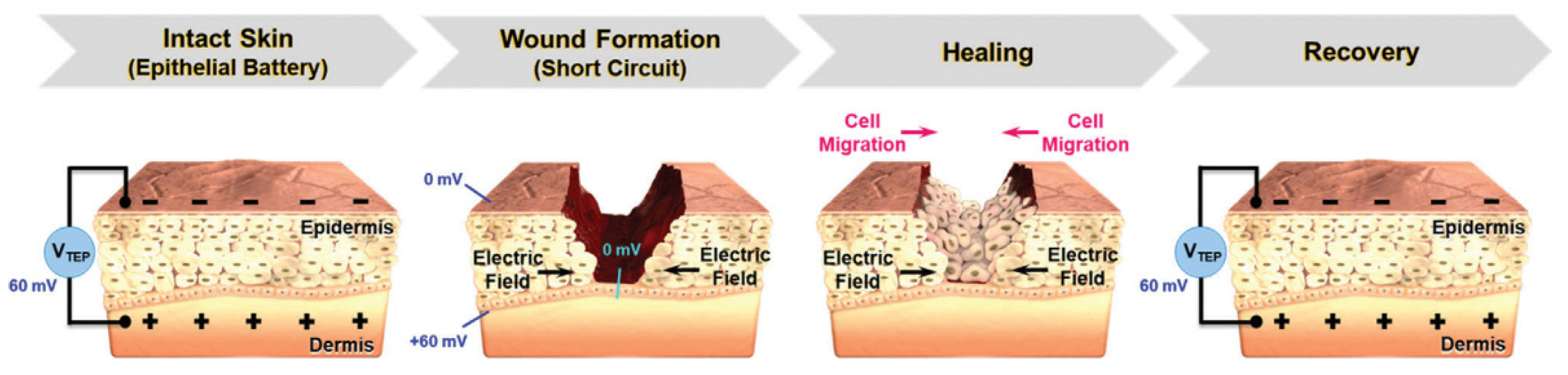

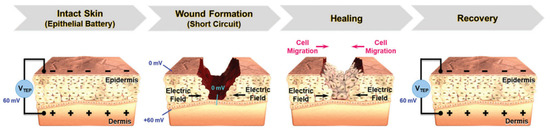

Electrical stimulation (ES) in wound care leads to the application of external electrical stimulation to tissues adjacent to, or directly within, the wound [159]. ES will accelerate the wound healing process due to it provides greater control over cellular differentiation and proliferation [159]. The mechanism that explains this function is that, in human skin, there is epithelial tissue that transports ions across the epidermis of the skin, forming a transepithelial potential (TEP) which is usually analogous to the ‘endogenous battery’ (Figure 9). When the wound penetrates the epithelial barrier, the TEP will drop because the epidermal battery is short-circuited. The internal electric current or TEP will decrease due to increased resistance during the skin healing process. ES operate by applying a small electrical field to the skin to mimic the TEP that occur during the granulation phase of wound healing [160]. ES that will promote wound regeneration and the conductive materials will support to distribute ES more effectively to the tissues in the wound [161].

Figure 9.

TEP and electric field at wound site before and after healing process. Reproduced with permission from [154]. Copyright (2021) John Wiley and Sons.

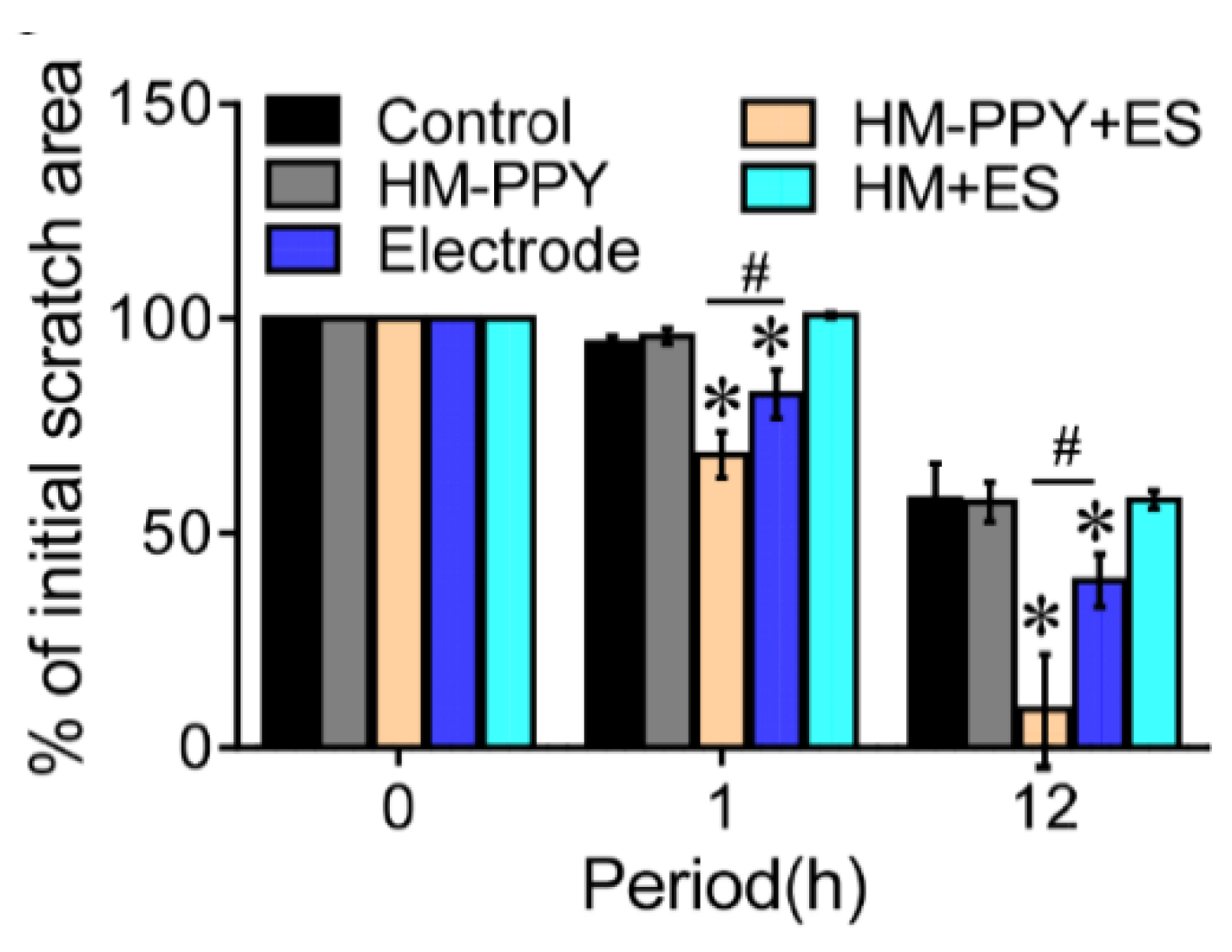

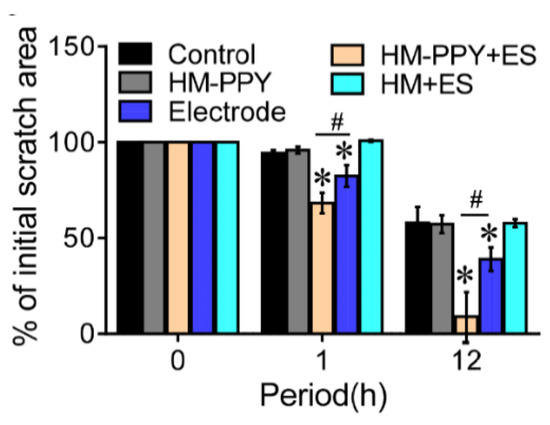

Lu et al. have proven that applying ES to conductive materials accelerates the wound healing process through applied ES in the form of AC current with varying voltage and frequency to the fibroblast culture [37]. The optimization results show that the AC current with 5V, 40Hz for 1 h supports cellular metabolic activity significantly. ES was administered to HM-PPy for 1 h to 12 h and showed the remaining scratch area was reduced by 17% (1 h) and 77% (12 h) compared to the Electrode group. Another result showed that HM-PPy not treated with ES did not accelerate wound closure, indicated by a much slower scratch closure rate than HM-PPY+ES and confirmed the important role of ES in the wound healing process. The important role of PPy can be shown in Figure 10, where HM-PPY+ES showed a significant reduction in scratch area compared to HM+ES, where the application of ES requires sufficient conductivity [37]. The current intensity through PPY is estimated to be 10 times higher than HM based on its conductivity value. Therefore, the large electric current through the PPY component in the hydrogel could contribute to the initial closing process for the HM-PPY+ES group.

Figure 10.

Quantification of % of initial scratch area for the different groups. * Significant difference with the control group (p = 0.05); # Significant difference between the designated groups (p < 0.05). Reproduced with permission from [37]. Copyright (2019) Elsevier.

The electrical response activity of the scaffold was also investigated by Niu et al. on human skin fibroblasts through the PLLA/PEDOT scaffold through a two-step approach (melt spinning and melt spun) followed by an oxidative polymerization process [162]. ES was applied to the scaffold through a constant DC potential gradient of 40 mV/mm for 48 h. After that, the culture medium was changed and ES at 50 mV/mm for 6 h was applied to the cells. After the ES had ended, the cells were cultured for another 48 h and evaluated. The MTT assay showed a less significant increase in cellular activity, but still demonstrated the feasibility of using ES to mediate cells cultured on the scaffold. In addition, the scaffold did not indicate cytotoxicity and also able to maintain its electrical conductivity in culture media [162].

3.3.2. Mechanical Properties of Skin Scaffold

The design of mechanical properties on skin scaffold engineering must be considered carefully because the development of skin substitutes is a functional performance that is closely related to mechanical strength. Cellular behaviours such as cell viability, cell-matrix interactions, cellular phenotype, differentiation, and focal adhesion size are highly dependent on the mechanical properties of the scaffold. In addition, the mechanical integrity of the skin tissue in vitro and in vivo to integration and remodelling of the ECM is also affected the scaffold [163,164]. Therefore, fabricating a scaffold with mechanical properties similar to natural ECM is essential to ensure no mechanical failures that limit cell growth and behaviour. On the fabrication method side, there is no such method that produces a functional scaffold with strength and rigidity that is very similar to that of genuine leather ECM, whereas tensile strength and Young’s modulus of skin tissue are 5–32 MPa and 25 kPa–140 MPa, respectively [165,166]. Therefore, other alternatives are used for the improvement of scaffold mechanics such as chemical cross-linking, mixing, and copolymerization [167].

Wang et al. fabricated bacterial hydrogel cellulose/polypyrrole/carbon nanotubes (rBC/PPy/CNT) by dissolving the polymerized BC/PPy in aqueous NaOH/urea solution, then the CNTs were impregnated, and physical and chemical crosslinking was performed [168]. CNT mixing is expected to improve the mechanical properties of the materials. In addition, the good properties of PPy and CNT can be used as reinforcement of hydrogel so that it can increase cellular activity with ES to improve the wound healing process. The mechanical properties test showed that the addition of PPy and CNT greatly affected the mechanical performance of the hydrogel, where the highest value of the compressive modulus was achieved (38.7 KPa). This value is almost three times higher than rBC (13.75 KPa). The stress at fracture and fracture strain was 17.79 KPa and 75.15% also higher than rBC (6.96 KPa; 72.5%). The addition of PPy also increased the compressive modulus from 13.75 KPa to 33.3 KPa. The test results showed an increase in the 3D rBC hydrogel network due to PPy and CNT, where there was a strong hydrogen bond between the OH group of BC nanofibers with CNT and PPy. This reduces the space between nanofibers and then increases the hardness of the hydrogel [169]. In addition, at the stress of 2.5 KPa which is much higher than rBC (1.6 KPa), rBC/PPy/CNT is able to withstand repeated loads (100 cycles) [168]. The compact structure of the rBC/PPy/CNT hydrogel can support a uniform response to continuously applied forces. Overall, the highest and stable mechanical strength can be obtained by the rBC/PPy/CNT hydrogels through this strategy. Improvements in mechanical properties by PPy and CNTs are also in line with in vitro biological evaluations showing that electroactive rBC/PPy/CNT hydrogels have good biocompatibility for NIH3T3 cell proliferation. In addition, cell proliferation in rBC/PPy/CNT hydrogels after application of ES was significantly increased compared to rBC hydrogels.

Another strategic approach was carried out by Razak et al. through the solvent-freeze extraction method where the conductive PANI was mixed to PLA [170]. The mechanical properties of PANI were improved by mixing it with PLA, wherein the increase in the PANI concentration on the PLA/PANI scaffold was directly proportional to the decrease in the tensile strength of the scaffold. The increase in PANI concentration on the PLA/PANI scaffold up to 4 wt% caused a decrease in the tensile strength value which was not too significant. Test results showed that PLA/0.5PANI has a tensile strength of 3.37 ± 2.2 MPa and PLA/4PANI has a tensile strength of 3. 08 ± 1.3 MPa, then increasing the concentration of PANI in PLA/5PANI reduces the tensile strength value a half to 1.58 ± 4.7 MPa. The decrease was due to PANI being brittle and the PANI chain conjugate acting as a non-reinforcing filler [171]. The PLA/5PANI samples showed a significant decrease in mechanical strength due to the larger PANI network. Hence, it is necessary to calculate the optimal number of PANI in tissue engineering applications in order to obtain proper mechanical properties. Optimization carried out by Razak et al. showed that the PLA/4PANI scaffold is a suitable scaffold based on its biological properties which is able to facilitate cell growth and good DC conductivity level, despite a significant reduction in its mechanical strength [170].

Chemical oxidation polymerization approach is one of the strategies used in scaffold fabrication. Massoumi et al. used this method to produce PEGs-b-(PPy)4 from PyPEGs macromonomers obtained from Steglich esterification of PEGs(OH)4 using pyrrole-2-carboxylic acid [172]. Solution of the electrospun-synthesized PEGs-b-(PPy)4 copolymer and PCL to produce nanofibrous scaffolds. This method produces a scaffold that has linear elastic properties before failure. Scaffolds were fabricated in two types based on differences in PEG molecular weight, where PEG (electrospun nanofiber PEG6000-b-(PPy)4/PCL) with higher molecular weight showed Young’s modulus (115 ± 4.1 MPa), tensile strength (9.2 ± 0.57 MPa), and higher elongation at break (46.6 ± 3.4 MPa) than PEG with lower molecular weight (electrospun nanofiber PEG2000-b-(PPy)4/PCL) with Young’s modulus value (108 ± 3.2 MPa), tensile strength (7.4 ± 0.46 MPa), and elongation at break (40.1 ± 2.7 MPa). The two fabricated electrospun nanofibers showed no significant toxicity and had excellent biocompatibility, as well as in vitro biodegradability, electroactivity, and proper conductivity in the presence of PPy [172,173].

3.4. Skeletal Muscle Tissue Engineering

3.4.1. Conductivity of Skeletal Muscle Scaffold

Comprising about 45% of the total body mass in humans, skeletal muscle tissues are responsible for generating forces for various biological motoric functions. Muscles can be seen as electromechanical actuators, which converts electrical energy delivered from the nervous systems into mechanical energy. It is no surprise that electrical conductivity is a necessary factor to consider when attempting to mimic the functions and behaviors of muscle tissue. Skeletal muscles have a high capability of regenerating itself from minor injuries. Nevertheless, severe injuries resulting from major traumas, or medical causes such as myopathy or prolonged denervation, often results in irreversible loss of muscle functions [10]. Due to its ability to mimic the muscle tissues function as electromechanical actuators, CPs have gained attention in the development of electroactive muscle scaffolds. These actuators are noted to even exceed the performance of natural muscle tissues in terms of work density, making them desirable for replicating many muscle-like actions both inside and outside the body [174].

The mechanism in which CPs can act as actuators are due to the dimensional change produced as a result of insertion and de-insertion of electrochemical ions. When positive voltage is applied to the CP electrode, electrons will leave the CP, creating an imbalance in charge. This attracts the mobile anions found in the matrix to be inserted to the polymer to balance the charge, leading to expansion in the dimension of one electrode. In the case of antagonistic asymmetric architecture (i.e., two layers of CPs, each corresponds to a different electrode), the opposite process can occur in the counter-electrode, where the expulsion of ions will cause contraction of the electrode. Together, the expansion and contraction on the opposite side will cause the structure to bend, serving as the basic mechanism for electromechanical actuation based on the Faradaic principle. Skeletal muscle scaffolds can be divided into three categories based on its architecture: (1) monolith, (2) bilayer and (3) trilayer. A monolith structure consists of CP mixed with other polymers made into a singular structure, with CP-hydrogel composite being one such example [34,175]. Comparatively, this architecture has relatively low conductivity and unreliable mechanical stability, although the introduction of cations into the scaffold has been demonstrated to increase the conductivity of this approach [176]. Another approach is by creating a laminate structure, consisting of two or more layers of different materials bonded together into a single-layered architecture. These layers may constitute of two active CP components, or a CP component bonded with another passive layer of material [26]. Generally, scaffolds produced by this approach has significantly higher conductivity, as the electron mobility in the CP is not affected by the presence of other non-conductive polymer chains. A recent example of bilayer structure with passive layer was reported by Wang et al., who deposited PPy nano-/microstructured film on top of PET film [177]. Au was sputtered as coating to further reduce the resistance to allow lower driving voltage, and the bilayer shows bending angle of >480° when exposed to 4.5 V DC. As a continuation of bilayer structure, creation of trilayer structure may be beneficial in increasing the degree of actuation. In a trilayer structure, the middle passive layer is sandwiched between two CP layers, allowing for one side to contract while the other expand, resulting in improved performance over equivalent bilayer device. For instance, a trilayer architecture arranged as PPy-silk-PPy was fabricated, and was reported to demonstrate a larger magnitude of movement relative to its analogous PPy-silk bilayer devices with the same applied voltage [178].