Regression Analysis of the Dielectric and Morphological Properties for Porous Nanohydroxyapatite/Starch Composites: A Correlative Study

Abstract

:1. Introduction

2. Results and Discussion

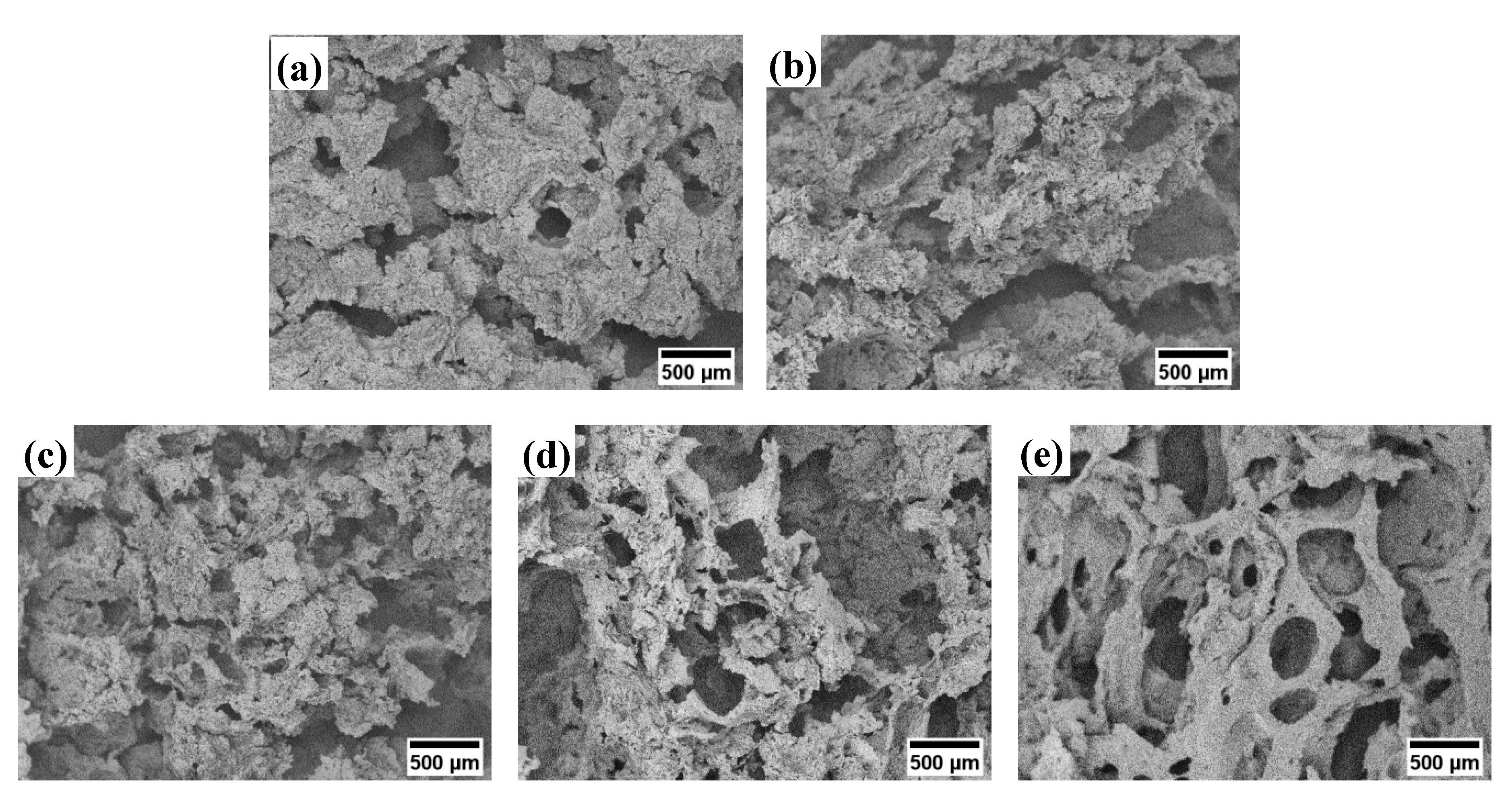

2.1. Morphological Analysis

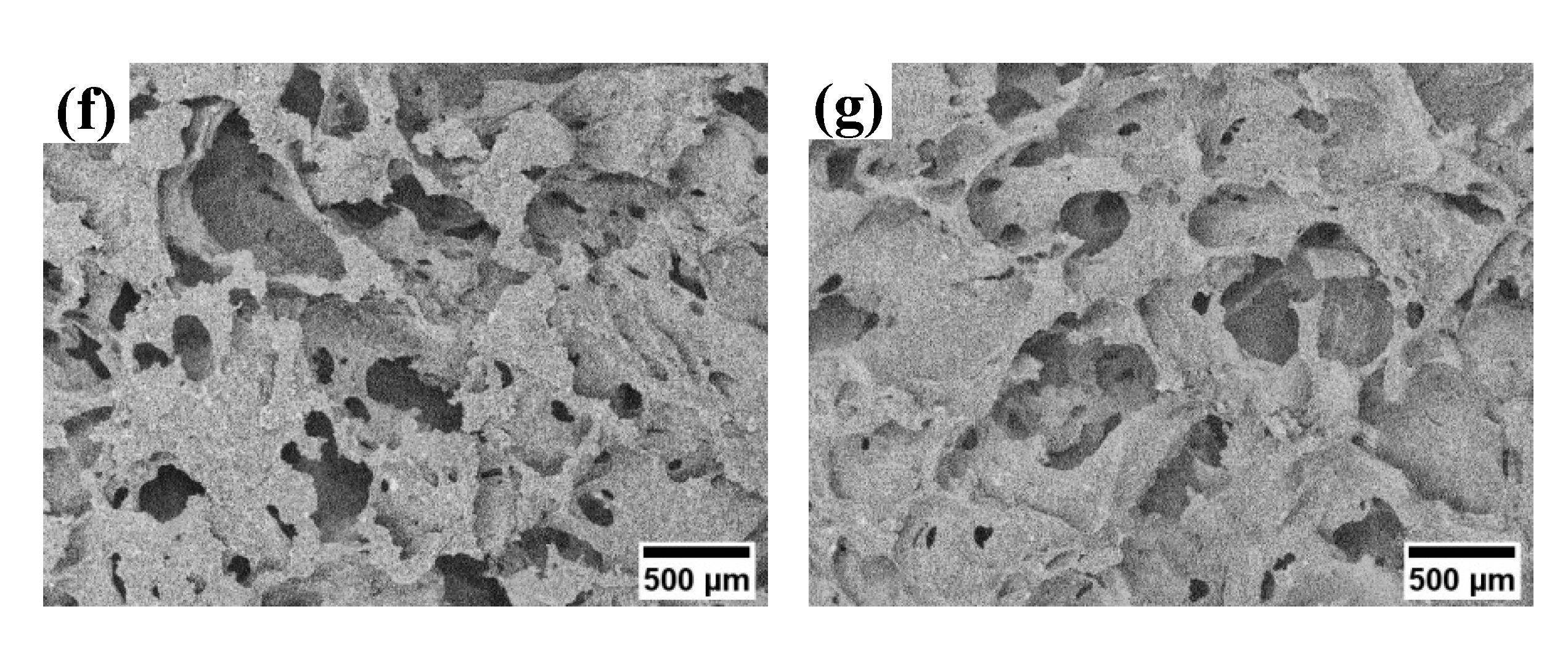

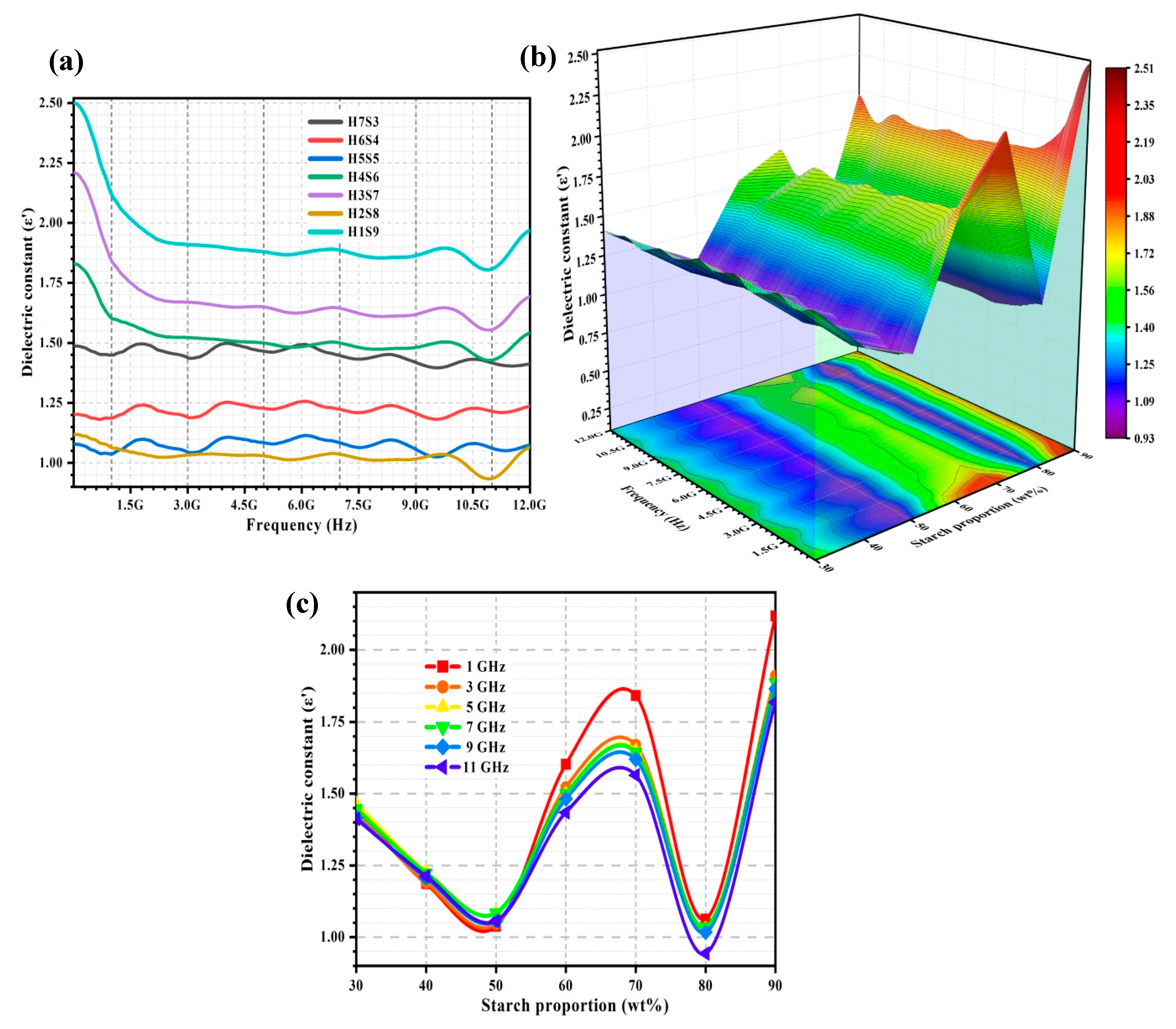

2.2. Dielectric Analysis

2.2.1. Dielectric Constant, ε′

2.2.2. Dielectric Loss Factor, ε′′

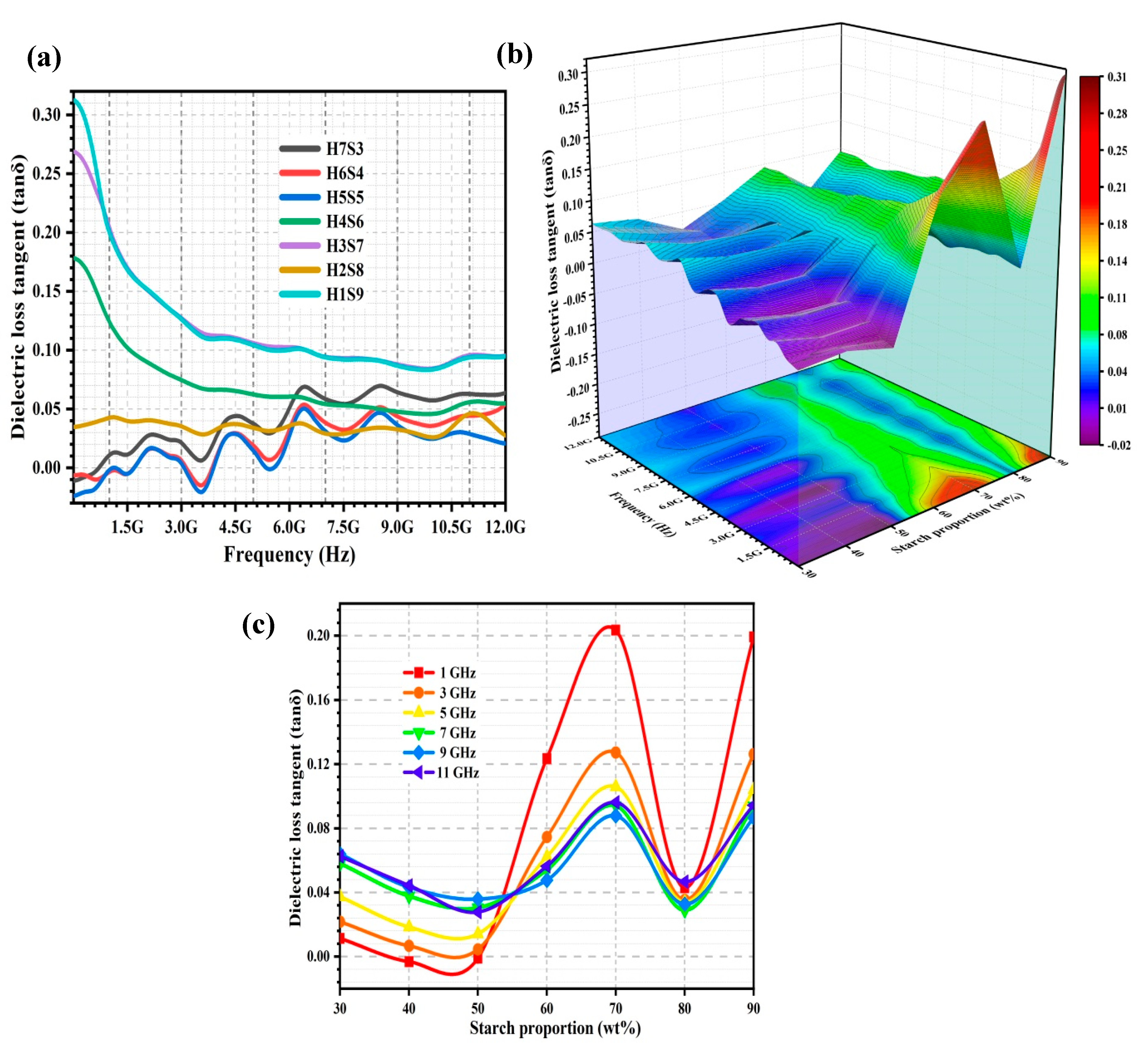

2.2.3. Dielectric Loss Tangent, tan δ

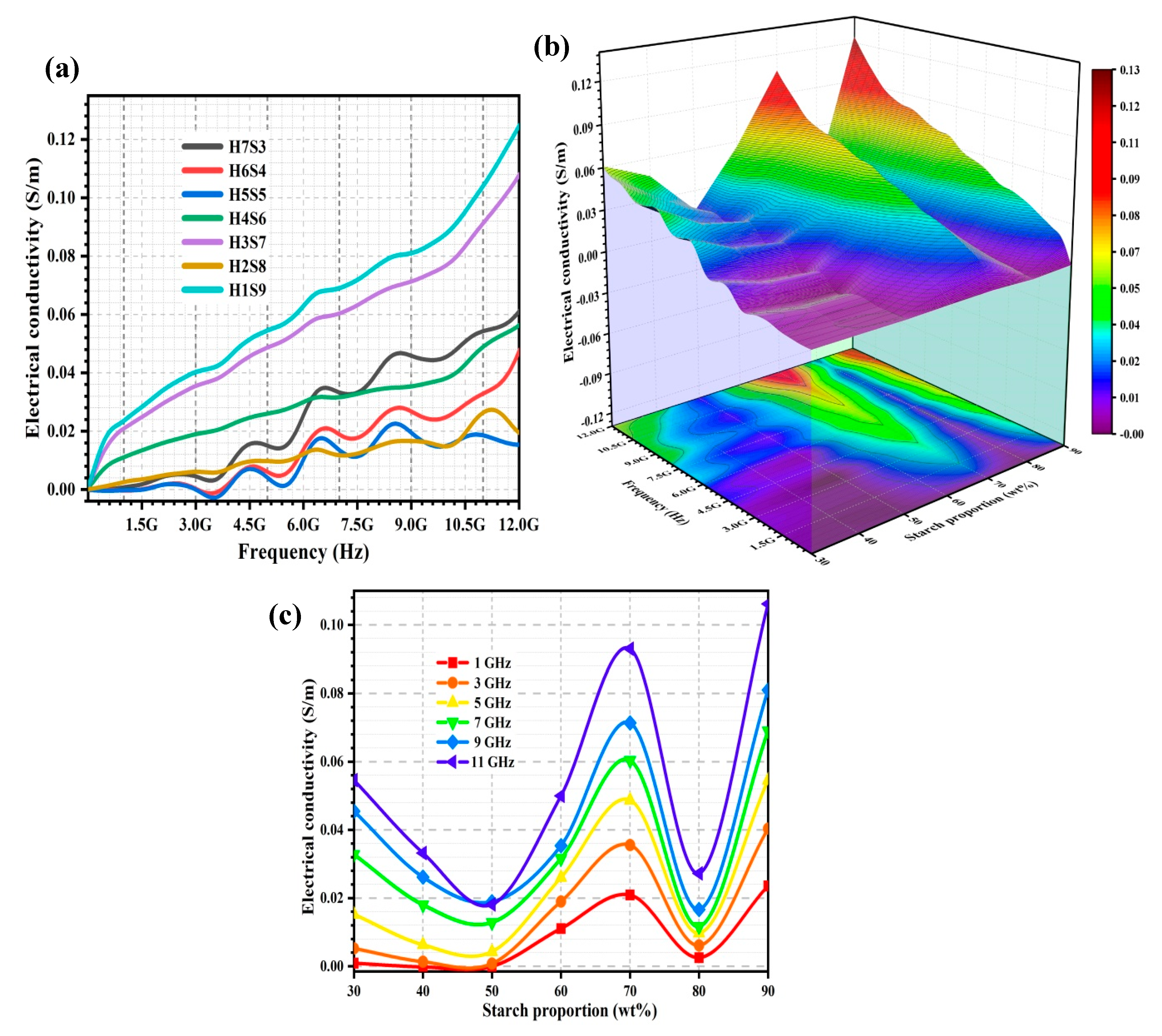

2.2.4. Electrical Conductivity, σ

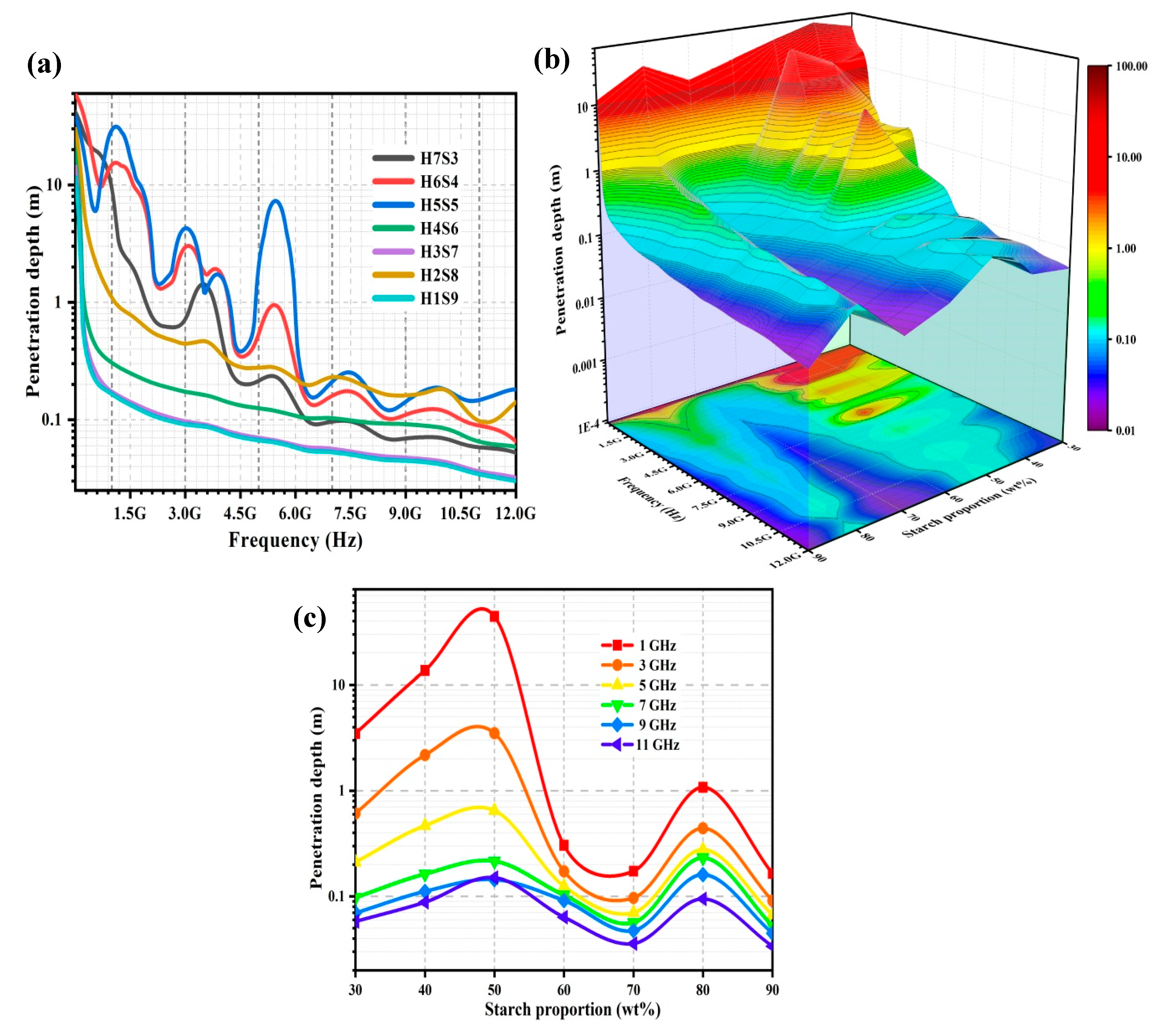

2.2.5. Penetration Depth, Dp

3. Materials and Methods

3.1. Sample Preparations

3.2. Sample Characterizations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pietrucha, K.; Marzec, E.; Kudzin, M. Pore structure and dielectric behaviour of the 3D collagen-DAC scaffolds designed for nerve tissue repair. Int. J. Biol. Macromol. 2016, 92, 1298–1306. [Google Scholar] [CrossRef] [PubMed]

- Mancuso, E.; Shah, L.; Jindal, S.; Serenelli, C.; Michail, Z.; Khanbareh, H.; Tirella, A. Additively manufactured BaTiO3 composite scaffolds: A novel strategy for load bearing bone tissue engineering applications. Mater. Sci. Eng. C 2021, 126, 112192. [Google Scholar] [CrossRef] [PubMed]

- Kim, C.G.; Han, K.S.; Lee, S.; Kim, M.C.; Kim, S.Y.; Nah, J. Fabrication of biocompatible polycaprolactone—Hydroxyapatite composite filaments for the FDM 3D printing of bone scaffolds. Appl. Sci. 2021, 11, 6351. [Google Scholar] [CrossRef]

- Tavangar, M.; Heidari, F.; Hayati, R.; Tabatabaei, F.; Vashaee, D.; Tayebi, L. Manufacturing and characterization of mechanical, biological and dielectric properties of hydroxyapatite-barium titanate nanocomposite scaffolds. Ceram. Int. 2020, 46, 9086–9095. [Google Scholar] [CrossRef]

- Teodori, L.; Crupi, A.; Costa, A.; Diaspro, A.; Melzer, S.; Tarnok, A. Three-dimensional imaging technologies: A priority for the advancement of tissue engineering and a challenge for the imaging community. J. Biophotonics 2017, 10, 24–45. [Google Scholar] [CrossRef] [PubMed]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2019, 53, 1579–1669. [Google Scholar] [CrossRef]

- Nihmath, A.; Ramesan, M.T. Fabrication, characterization and dielectric studies of NBR/hydroxyapatite nanocomposites. J. Inorg. Organomet. Polym. Mater. 2017, 27, 481–489. [Google Scholar] [CrossRef]

- Chaudhuri, B.; Bhadra, D.; Moroni, L.; Pramanik, K. Myoblast differentiation of human mesenchymal stem cells on graphene oxide and electrospun graphene oxide—Polymer composite fi brous meshes: Importance of graphene oxide conductivity and dielectric constant on their biocompatibility. Biofabrication 2015, 7, 015009. [Google Scholar] [CrossRef]

- Sundarabharathi, L.; Ponnamma, D.; Parangusan, H.; Chinnaswamy, M.; Al-Maadeed, M.A.A. Effect of anions on the structural, morphological and dielectric properties of hydrothermally synthesized hydroxyapatite nanoparticles. SN Appl. Sci. 2019, 2, 94. [Google Scholar] [CrossRef] [Green Version]

- Chaudhuri, B.; Mondal, B.; Ray, S.K.; Sarkar, S.C. A novel biocompatible conducting polyvinyl alcohol (PVA)-polyvinylpyrrolidone (PVP)-hydroxyapatite (HAP) composite scaffolds for probable biological application. Colloids Surf. B Biointerfaces 2016, 143, 71–80. [Google Scholar] [CrossRef]

- Tao, Y.; Yan, B.; Fan, D.; Zhang, N.; Ma, S.; Wang, L.; Wu, Y.; Wang, M.; Zhao, J.; Zhang, H.; et al. Structural changes of starch subjected to microwave heating: A review from the perspective of dielectric properties. Trends Food Sci. Technol. 2020, 99, 593–607. [Google Scholar] [CrossRef]

- Sasikala, T.S.; Sebastian, M.T. Mechanical, thermal and microwave dielectric properties of Mg2SiO4 filled polytetera fluoroethylene composites. Ceram. Int. 2016, 42, 7551–7563. [Google Scholar] [CrossRef]

- Beh, C.Y.; Cheng, E.M.; Nasir, N.F.M.; Khor, S.F.; Eng, S.K.; Majid, M.S.A.; Ridzuan, M.J.M.; Lee, K.Y. Low Frequency Dielectric and Optical Behavior on Physicochemical Properties of Hydroxyapatite / Cornstarch Composite. J. Colloid Interface Sci. 2021, 600, 187–198. [Google Scholar] [CrossRef]

- Sanchez, A.G.; Prokhorov, E.; Mora-García, G.L.-B.A.G.; Kovalenko, Y.; Miñoz, E.M.R.; Raucci, M.G.; Buonocore, G. Chitosan-hydroxyapatite nanocomposites: Effect of interfacial layer on mechanical and dielectric properties. Mater. Chem. Phys. 2018, 217, 151–159. [Google Scholar] [CrossRef]

- Peng, H.; Ren, H.; Dang, M.; Zhang, Y.; Yao, X.; Lin, H. Novel high dielectric constant and low loss PTFE/CNT composites. Ceram. Int. 2018, 44, 16556–16560. [Google Scholar] [CrossRef]

- Nunes-pereira, J.; Silva, A.R.; Ribeiro, C.; Carabineiro, S.A.C.; Buijnsters, J.G. Nanodiamonds/poly (vinylidene fluoride) composites for tissue engineering applications. Compos. Part B 2017, 111, 37–44. [Google Scholar] [CrossRef]

- Yew, B.S.; Muhamad, M.; Mohamed, S.B.; Wee, F.H. Coconut shell, coconut shell activated carbon and beta-silicon carbide reinforced polymer composite: An alternative dielectric material for wireless communication application. Bull. Electr. Eng. Inform. 2020, 9, 311–318. [Google Scholar] [CrossRef]

- Ogonna, C.; Li, D.; Lin, M.; Daniel, P.; Katnam, K.B.; Thakur, V.K.; Nezhad, H.Y. Accelerated microwave curing of fibre-reinforced thermoset polymer composites for structural applications: A review of scientific challenges. Compos. Part A 2018, 115, 88–103. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Shi, Z.; Mao, F.; Yang, C.; Yang, J.; Zhu, X.; Zuo, H. Polymer composites with balanced dielectric constant and loss via constructing trilayer architecture. J. Mater. Sci. 2018, 53, 13230–13242. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Mubarak, N.M.; Tiripathi, M.; Jayakumar, N.S.; Sahu, J.N.; Ganesan, P. Chemical, dielectric and structural characterization of optimized hydrochar produced from hydrothermal carbonization of palm shell. Fuel 2016, 163, 88–97. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, X.; Wu, H.; Yan, H.; Qi, S. Impact of morphology and dielectric property on the microwave absorbing performance of MoS2-based materials. J. Alloys Compd. 2018, 751, 34–42. [Google Scholar] [CrossRef]

- Qu, Y.; Du, Y.; Fan, G.; Xin, J.; Liu, Y.; Xie, P.; You, S.; Zhang, Z.; Sun, K.; Fan, R. Low-temperature sintering Graphene/CaCu3Ti4O12 nanocomposites with tunable negative permittivity. J. Alloys Compd. 2019, 771, 699–710. [Google Scholar] [CrossRef]

- Qiu, S.; Lyu, H.; Liu, J.; Liu, Y.; Wu, N.; Liu, W. Facile synthesis of porous nickel/carbon composite microspheres with enhanced electromagnetic wave absorption by magnetic and dielectric losses. ACS Appl. Mater. Interfaces 2016, 8, 20258–20266. [Google Scholar] [CrossRef]

- Wang, L.; Liu, H.; Lv, X.; Cui, G.; Gu, G. Facile synthesis 3D porous MXene Ti3C2Tx@RGO composite aerogel with excellent dielectric loss and electromagnetic wave absorption. J. Alloys Compd. 2020, 828, 154251. [Google Scholar] [CrossRef]

- Amin, B.; Shahzad, A.; Farina, L.; Parle, E.; Mcnamara, L. Dielectric characterization of diseased human trabecular bones at microwave frequency. Med. Eng. Phys. 2020, 78, 21–28. [Google Scholar] [CrossRef]

- Ruggiero, E.; Reboredo, M.M.; Castro, M.S. Structural and dielectric properties of hot-pressed poly (vinylidene fluoride)-based composites. J. Compos. Mater. 2017, 52, 1399–1412. [Google Scholar] [CrossRef]

- Hong, W.; Dong, S.; Hu, P.; Luo, X.; Du, S. In situ growth of one-dimensional nanowires on porous PDC-SiC/Si3N4 ceramics with excellent microwave absorption properties. Ceram. Int. 2017, 43, 14301–14308. [Google Scholar] [CrossRef]

- Zhao, H.; Zhu, J.; Seow, Y.; Cheng, Y.; Xu, Z.J.; Ji, G. Green synthesis of hierarchically porous carbons with tunable dielectric response for microwave absorption. Ceram. Int. 2020, 46, 15447–15455. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, S.; Yan, S.; Shu, X.; Yuan, Y.; Huang, H.; Zhao, J. Overall improvement in dielectric and mechanical properties of porous graphene fluoroxide/polyimide nanocomposite films via bubble-stretching approach. Mater. Des. 2017, 117, 150–156. [Google Scholar] [CrossRef]

- You, Y.; Zhan, C.; Tu, L.; Wang, Y.; Hu, W.; Wei, R.; Liu, X. Polyarylene ether nitrile-based high-k composites for dielectric applications. Int. J. Polym. Sci. 2018, 2018, 5161908. [Google Scholar] [CrossRef] [Green Version]

- Beh, C.Y.; Cheng, E.M.; Nasir, N.F.M.; Eng, S.K.; Majid, M.S.A.; Ridzuan, M.J.M.; Khor, S.F.; Khalid, N.S. Dielectric and material analysis on physicochemical activity of porous hydroxyapatite / cornstarch composites. Int. J. Biol. Macromol. 2021, 166, 1543–1553. [Google Scholar] [CrossRef] [PubMed]

- Qiao, J.; Wen, Y. Mechanical and dielectric properties of porous magnesium aluminate (MgAl2O4) spinel ceramics fabricated by direct foaming-gelcasting. Ceram. Int. 2019, 46, 1442–1447. [Google Scholar] [CrossRef]

- Qiao, J.; Wen, Y. Preparation and characterization of magnesium aluminate (MgAl2O4) spinel ceramic foams via direct foam-gelcasting. Ceram. Int. 2020, 46, 678–684. [Google Scholar] [CrossRef]

- Yang, J.; Zhu, X.; Wang, H.; Wang, X.; Hao, C.; Fan, R.; Dastan, D.; Shi, Z. Achieving excellent dielectric performance in polymer composites with ultralow fi ller loadings via constructing hollow-structured fi ller frameworks. Compos. Part A 2020, 131, 105814. [Google Scholar] [CrossRef]

- Mahani, A.A.; Motahari, S.; Nayyeri, V. Synthesis, characterization and dielectric properties of one-step pyrolyzed / activated resorcinol-formaldehyde based carbon aerogels for electromagnetic interference shielding applications. Mater. Chem. Phys. 2018, 213, 492–501. [Google Scholar] [CrossRef]

- Yang, K.; Young, Y.; Jeong, H.; Kim, D.; Kyun, N.; Choi, S.Q.; Chan, J.; Ho, Y. Porous boron nitride / polyimide composite films with high thermal diffusivity and low dielectric properties via high internal phase Pickering emulsion method. J. Ind. Eng. Chem. 2020, 82, 173–179. [Google Scholar] [CrossRef]

- Chen, C.; Liu, Y.; Yue, W.; Ye, F.; Wang, J.; Zeng, Q. The influence of Si3N4w volume fraction on the microstructure and properties of Si3N4w/Si3N4 composites via CVI technique. Front. Mater. 2020, 7, 390. [Google Scholar] [CrossRef]

- Seok, Y.B.; Nurbazilah, S.; Hoon, W.F.; Bin Mohamed, S.B.; Humaizi, A.; Juhariaan, M.R.M.; Mohamad, W.N.F.W. The investigation on the potential of coconut shell powder composite in term of carbon composition, surface porosity and dielectric properties as a microwave absorbing material. EnvironmentAsia 2016, 9, 9–17. [Google Scholar] [CrossRef]

- Liu, P.; Gao, S.; Wang, Y.; Zhou, F.; Huang, Y.; Luo, J. Metal-organic polymer coordination materials derived Co/N-doped porous carbon composites for frequency-selective microwave absorption. Compos. Part B 2020, 202, 108406. [Google Scholar] [CrossRef]

- Xu, H.; Yin, X.; Zhu, M.; Han, M.; Hou, Z.; Li, X.; Zhang, L.; Cheng, L.; Accepted, J. Carbon hollow microspheres with a designable mesoporous shell for high performance electromagnetic wave absorption. ACS Appl. Mater. Interfaces 2017, 9, 6332–6341. [Google Scholar] [CrossRef]

- Verma, A.S.; Kumar, D.; Dubey, A.K. Dielectric and electrical response of hydroxyapatite—Na0.5K0.5NbO3 bioceramic composite. Ceram. Int. 2019, 45, 3297–3305. [Google Scholar] [CrossRef]

- Saji, J.; Umapathi, A.; Manohara, S.R.; Navya, P.N.; Kumawat, M.; Prakash, D.; Daima, H.K. Polyvinyl alcohol scaffold incorporated with silver nanoparticles and titanium dioxide: Electrical, dielectric, dye degradation, and antibacterial properties. In Advances in Mechanical Engineering; Springer: Singapore, 2021; pp. 367–379. ISBN 978-981-16-0942-8. [Google Scholar]

- Wang, Z.; Myo, N.; Wu, Y.; Liu, X.; Shen, X.; Zheng, Q.; Kim, J. Ultrahigh dielectric constant and low loss of highly-aligned graphene aerogel/poly (vinyl alcohol) composites with insulating barriers. Carbon N. Y. 2017, 123, 385–394. [Google Scholar] [CrossRef]

- Issa, A.A.; Al-maadeed, M.A.; Luyt, A.S.; Ponnamma, D.; Hassan, M.K. Physico-mechanical, dielectric, and piezoelectric properties of PVDF electrospun mats containing silver nanoparticles. C 2017, 3, 30. [Google Scholar] [CrossRef] [Green Version]

- Abdel-baset, T.A.; Hekal, E.A.; Azab, A.A.; Anis, B. Broadband dielectric properties of polyvinyl-formaldehyde/MWCNTs foams. Phys. B Phys. Condens. Matter 2021, 604, 412666. [Google Scholar] [CrossRef]

- Wang, S.; Xiao, N.; Zhou, Y.; Ling, Z.; Li, M.; Qiu, J. Lightweight carbon foam from coal liquefaction residue with broad-band microwave absorbing capability. Carbon N. Y. 2016, 105, 224–226. [Google Scholar] [CrossRef]

- Pan, C.; Kou, K.; Zhang, Y.; Li, Z.; Ji, T.; Wu, G. Investigation of the dielectric and thermal conductive properties of core—Shell structured HGM@hBN/PTFE composites. Mater. Sci. Eng. B 2018, 238–239, 61–70. [Google Scholar] [CrossRef]

- Li, H.; Yang, J.; Dong, S.; Tian, F.; Li, X. Low dielectric constant polyimide obtained by four kinds of irradiation sources. Polymers 2020, 12, 879. [Google Scholar] [CrossRef]

- Wang, B.; Kang, H.; Yang, H.; Xie, J.; Liu, R. Preparation and dielectric properties of porous cyanoethyl cellulose membranes. Cellulose 2018, 26, 1261–1275. [Google Scholar] [CrossRef]

- Huo, W.; Chen, Y.; Zhang, Z.; Liu, J.; Yan, S.; Wu, J.; Zhang, X.; Yang, J. Highly porous barium strontium titanate (BST) ceramic foams with low dielectric constant from particle-stabilized foams. J. Am. Ceram. Soc. 2018, 101, 1737–1746. [Google Scholar] [CrossRef]

- Khan, A.; Savi, P.; Quaranta, S.; Rovere, M.; Giorcelli, M.; Tagliaferro, A.; Rosso, C.; Jia, C.Q. Low-cost carbon fillers to improve mechanical properties and conductivity of epoxy composites. Polymers 2017, 9, 642. [Google Scholar] [CrossRef] [Green Version]

- Zhou, P.; Wang, X.; Wang, L.; Zhang, J.; Song, Z.; Qiu, X.; Yu, M.; Zhang, Q. Walnut shell-derived nanoporous carbon@Fe3O4 composites for outstanding microwave absorption performance. J. Alloys Compd. 2019, 805, 1071–1080. [Google Scholar] [CrossRef]

- Luo, J.; Xu, Y.; Yao, W.; Jiang, C.; Xu, J. Synthesis and microwave absorption properties of reduced graphene oxide-magnetic porous nanospheres-polyaniline composites. Compos. Sci. Technol. 2015, 117, 315–321. [Google Scholar] [CrossRef]

- Nurbazilah, S.; Jabal, A.; Seok, Y.B.; Hoon, W.F. Carbon composition, surface porosities and dielectric properties of coconut shell powder and coconut shell activated carbon composites. ARPN J. Eng. Appl. Sci. 2016, 11, 3832–3837. [Google Scholar]

- Zhang, F.; Cui, W.; Wang, B.; Xu, B.; Liu, X.; Liu, X.; Jia, Z.; Wu, G. Morphology-control synthesis of polyaniline decorative porous carbon with remarkable electromagnetic wave absorption capabilities. Compos. Part B 2021, 204, 108491. [Google Scholar] [CrossRef]

- Pan, F.; Liu, Z.; Deng, B.; Dong, Y.; Zhu, X.; Huang, C. Lotus leaf-derived gradient hierarchical porous C/MoS2 morphology genetic composites with wideband and tunable electromagnetic absorption performance. Nano-Micro Lett. 2021, 13, 1–17. [Google Scholar] [CrossRef]

- Zhu, L. Exploring strategies for high dielectric constant and low loss polymer dielectrics. J. Phys. Chem. Lett. 2014, 5, 3677–3687. [Google Scholar] [CrossRef]

- Hou, Z.; Ye, F.; Liu, L. Effects of pore shape and porosity on the dielectric constant of porous β-SiAlON ceramics. J. Eur. Ceram. Soc. 2015, 35, 4115–4120. [Google Scholar] [CrossRef]

- Sabu, M.; Bementa, E.; Ruban, Y.J.V.; Mon, S.G. A novel analysis of the dielectric properties of hybrid epoxy composites. Adv. Compos. Hybrid Mater. 2020, 3, 325–335. [Google Scholar] [CrossRef]

- Rajeh, A.; Ragab, H.M.; Abutalib, M.M. Co doped ZnO reinforced PEMA/PMMA composite: Structural, thermal, dielectric and electrical properties for electrochemical applications. J. Mol. Struct. 2020, 1217, 128447. [Google Scholar] [CrossRef]

- Choudhary, S.; Sengwa, R.J. Effects of different inorganic nanoparticles on the structural, dielectric and ion transportation properties of polymers blend based nanocomposite solid polymer electrolytes. Electrochim. Acta 2017, 247, 924–941. [Google Scholar] [CrossRef]

- Li, Z.; Haigh, A.; Soutis, C.; Gibson, A. X-band microwave characterisation and analysis of carbon fi bre-reinforced polymer composites. Compos. Struct. 2019, 208, 224–232. [Google Scholar] [CrossRef] [Green Version]

- Galos, J. Microwave processing of carbon fibre polymer composites: A review. Polym. Polym. Compos. 2021, 29, 151–162. [Google Scholar] [CrossRef]

- Song, C.; Wang, Y.; Wang, S.; Cui, Z. Temperature and moisture dependent dielectric properties of chinese steamed bread using mixture equations related to microwave heating. Int. J. Food Prop. 2016, 19, 2522–2535. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Haigh, A.; Soutis, C.; Gibson, A.; Wang, P. A review of microwave testing of glass fibre- reinforced polymer composites. Nondestruct. Test. Eval. 2019, 34, 429–458. [Google Scholar] [CrossRef]

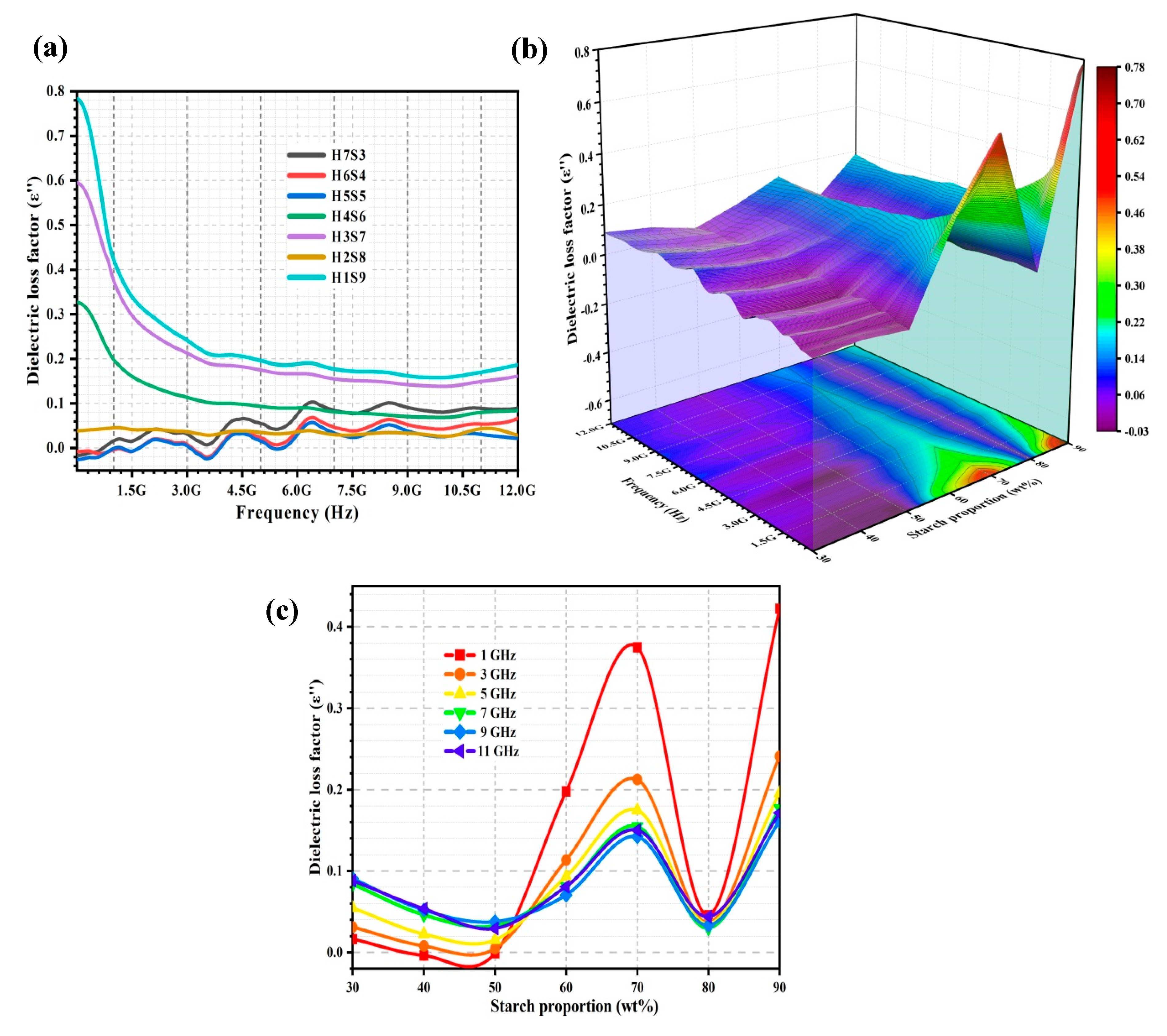

| Dielectric Constant Equation | R2 |

|---|---|

| ε′1GHz = −9.1691 + 0.4058X1 − 0.0211X2 + 0.1937X3 + 0.0671 × 10−2X1X2 − 0.7240 × 10−2X1X3 | 0.997 |

| ε′3GHz = −7.0670 + 0.3330X1 − 0.0180X2 + 0.1571X3 + 0.0550 × 10−2X1X2 − 0.5959 × 10−2X1X3 | 0.994 |

| ε′5GHz = −8.4368 + 0.3432X1 − 0.0188X2 + 0.1800X3 + 0.0552 × 10−2X1X2 − 0.6130 × 10−2X1X3 | 0.992 |

| ε′7GHz = −8.5438 + 0.3424X1 − 0.0182X2 + 0.1804X3 + 0.0536 × 10−2X1X2 − 0.6089 × 10−2X1X3 | 0.993 |

| ε′9GHz = −8.6129 + 0.3422X1 − 0.0197X2 + 0.1830X3 + 0.0556×10−2X1X2 − 0.6108 × 10−2X1X3 | 0.995 |

| ε′11GHz = −11.0086 + 0.3770X1 − 0.0193X2 + 0.2200X3 + 0.0547×10−2X1X2 − 0.6654 × 10−2X1X3 | 0.994 |

| Dielectric Loss Factor Equation | R2 |

|---|---|

| ε″1GHz = −3.2106 + 0.1399X1 + 0.0635 × 10−2X2 + 0.0494X3 + 0.0155 × 10−2X1X2 − 0.2362 × 10−2X1X3 | 0.993 |

| ε″3GHz = −1.8103 + 0.0777X1 − 0.1570 × 10−2X2 + 0.0306X3 + 0.0114 × 10−2X1X2 − 0.1350 × 10−2X1X3 | 0.998 |

| ε″5GHz = −1.6670 + 0.0653X1 − 0.2894 × 10−2X2 + 0.0306X3 + 0.0116 × 10−2X1X2 − 0.1169 × 10−2X1X3 | 0.999 |

| ε″7GHz = −2.3883 + 0.0708X1 − 0.4684 × 10−2X2 + 0.0447X3 + 0.0134 × 10−2X1X2 − 0.1286 × 10−2X1X3 | 0.988 |

| ε″9GHz = −2.4887 + 0.0675X1 − 0.5732 × 10−2X2 + 0.0477X3 + 0.0143 × 10−2X1X2 − 0.1248 × 10−2X1X3 | 0.970 |

| ε″11GHz = −2.2366 + 0.0646X1 − 0.7469 × 10−2X2 + 0.0459X3 + 0.0169 × 10−2X1X2 − 0.1233 × 10−2X1X3 | 0.983 |

| Dielectric Loss Tangent Equation | R2 |

|---|---|

| tanδ1GHz = 0.3317 + 0.0404X1 + 0.2313 × 10−2X2 − 0.7811 × 10−2X3 + 0.0047 × 10−2X1X2 − 0.0681 × 10−2X1X3 | 0.981 |

| tanδ3GHz = −0.6830 × 10−2 + 0.0266X1 − 0.0408 × 10−2X2 + 0.1030 × 10−2X3 + 0.0055 × 10−2X1X2 − 0.0482 × 10−2X1X3 | 0.994 |

| tanδ5GHz = −0.2094 + 0.0238X1 − 0.1327 × 10−2X2 + 0.5644 × 10−2X3 + 0.0059 × 10−2X1X2 − 0.0448 × 10−2X1X3 | 0.999 |

| tanδ7GHz = −0.9280 + 0.0312X1 − 0.2324 × 10−2X2 + 0.0185X3 + 0.0069 × 10−2X1X2 − 0.0583 × 10−2X1X3 | 0.992 |

| tanδ9GHz = −1.0839 + 0.0304X1 − 0.3070 × 10−2X2 + 0.0220X3 + 0.0076 × 10−2X1X2 − 0.0581 × 10−2X1X3 | 0.966 |

| tanδ11GHz = −0.7336 + 0.0252X1 − 0.4971 × 10−2X2 + 0.0189X3 + 0.0103 × 10−2X1X2 − 0.0532 × 10−2X1X3 | 0.985 |

| Electrical Conductivity Equation | R2 |

|---|---|

| σ1GHz = −0.1792 + 0.7807 × 10−2X1 + 0.0035 × 10−2X2 + 0.2754×10−2X3 + 0.0009 × 10−2X1X2 − 0.0132 × 10−2X1X3 | 0.993 |

| σ3GHz = −0.3026 + 0.0130X1 − 0.0262 × 10−2X2 + 0.5122 × 10−2X3 + 0.0019 × 10−2X1X2 − 0.0226 × 10−2X1X3 | 0.998 |

| σ5GHz = −0.4655 + 0.0182X1 − 0.0808 × 10−2X2 + 0.8537 × 10−2X3 + 0.0032 × 10−2X1X2 − 0.0326 × 10−2X1X3 | 0.999 |

| σ7GHz = −0.9318 + 0.0276X1 − 0.1827 × 10−2X2 + 0.0174X3 + 0.0052 × 10−2X1X2 − 0.0502 × 10−2X1X3 | 0.988 |

| σ9GHz = −1.2478 + 0.0339X1 − 0.2873 × 10−2X2 + 0.0239X3 + 0.0072 × 10−2X1X2 − 0.0626 × 10−2X1X3 | 0.970 |

| σ11GHz = −1.3838 + 0.0400X1 − 0.4621 × 10−2X2 + 0.0284X3 + 0.0104 × 10−2X1X2 − 0.0763 × 10−2X1X3 | 0.983 |

| Penetration Depth Equation | R2 |

|---|---|

| Dp1GHz = −500.6451 + 3.4935X1 + 6.0880X2 − 0.0936X3 − 0.0945X1X2 + 0.0708X1X3 | 0.997 |

| Dp3GHz = −70.8607 + 0.6315X1 + 0.2674X2 + 0.7654X3 − 0.4475 × 10−2X1X2 − 0.3925 × 10−2X1X3 | 0.981 |

| Dp5GHz = −8.4976 + 0.0289X1 + 0.0324X2 + 0.0927X3 − 0.0619 × 10−2X1X2 + 0.0385 × 10−2X1X3 | 0.990 |

| Dp7GHz = 1.5279 − 0.0701X1 + 0.6041×10−2X2 − 0.0311X3 − 0.0168 × 10−2X1X2 + 0.1343 × 10−2X1X3 | 0.999 |

| Dp9GHz = 1.7830 − 0.0554X1 + 0.5409×10−2X2 − 0.0343X3 − 0.0133 × 10−2X1X2 + 0.1058 × 10−2X1X3 | 0.992 |

| Dp11GHz = 0.5054 − 0.0270X1 + 0.0124X2 − 0.0233X3 − 0.0217 × 10−2X1X2 + 0.0717 × 10−2X1X3 | 0.995 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beh, C.Y.; Cheng, E.M.; Mohd Nasir, N.F.; Abdul Majid, M.S.; Khor, S.F.; Mohd Jamir, M.R.; Mohd Tarmizi, E.Z.; Lee, K.Y. Regression Analysis of the Dielectric and Morphological Properties for Porous Nanohydroxyapatite/Starch Composites: A Correlative Study. Int. J. Mol. Sci. 2022, 23, 5695. https://doi.org/10.3390/ijms23105695

Beh CY, Cheng EM, Mohd Nasir NF, Abdul Majid MS, Khor SF, Mohd Jamir MR, Mohd Tarmizi EZ, Lee KY. Regression Analysis of the Dielectric and Morphological Properties for Porous Nanohydroxyapatite/Starch Composites: A Correlative Study. International Journal of Molecular Sciences. 2022; 23(10):5695. https://doi.org/10.3390/ijms23105695

Chicago/Turabian StyleBeh, Chong You, Ee Meng Cheng, Nashrul Fazli Mohd Nasir, Mohd Shukry Abdul Majid, Shing Fhan Khor, Mohd Ridzuan Mohd Jamir, Emma Ziezie Mohd Tarmizi, and Kim Yee Lee. 2022. "Regression Analysis of the Dielectric and Morphological Properties for Porous Nanohydroxyapatite/Starch Composites: A Correlative Study" International Journal of Molecular Sciences 23, no. 10: 5695. https://doi.org/10.3390/ijms23105695