Chitosan–Alginate Gels for Sorption of Hazardous Materials: The Effect of Chemical Composition and Physical State

Abstract

:1. Introduction

2. Results and Discussion

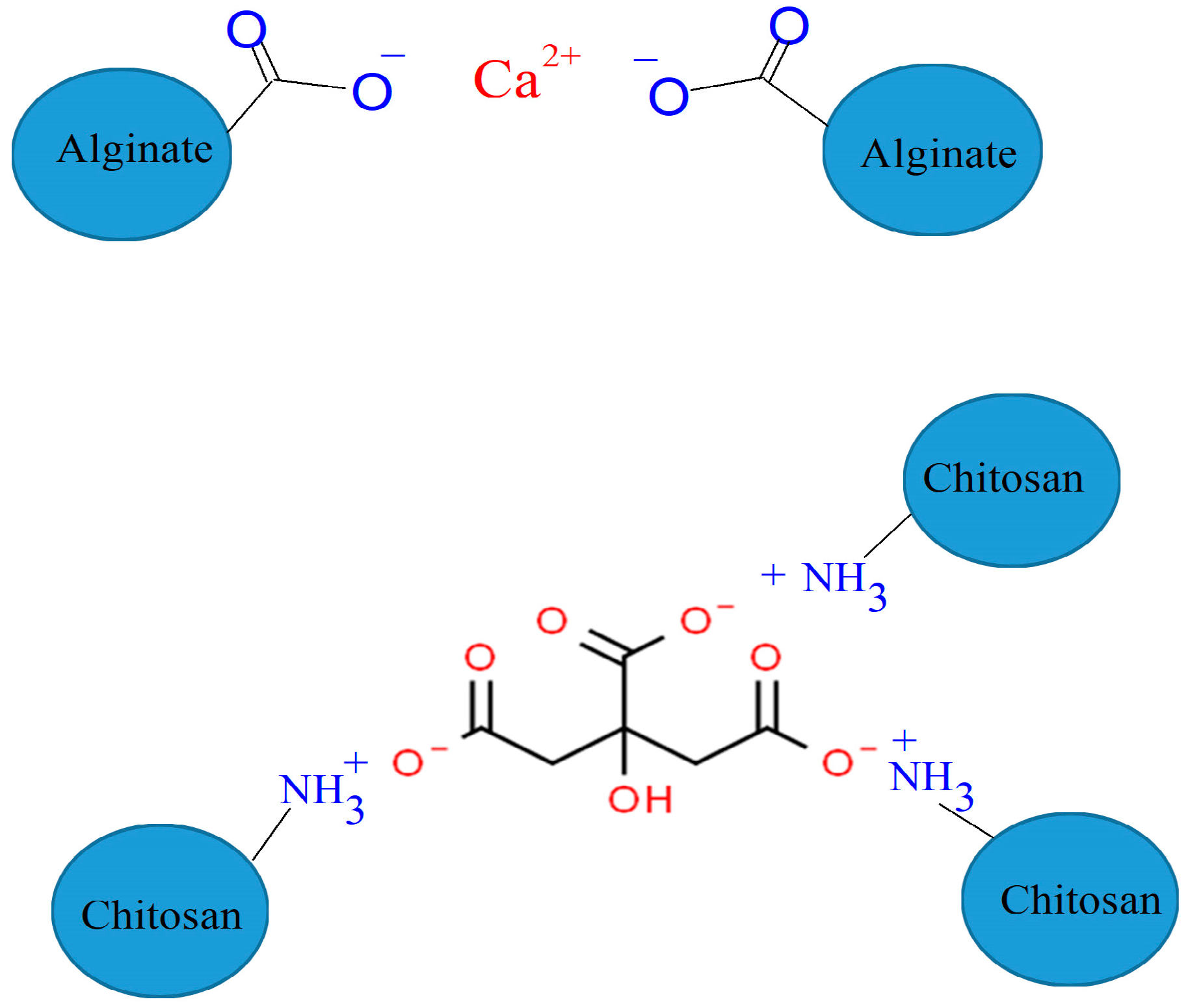

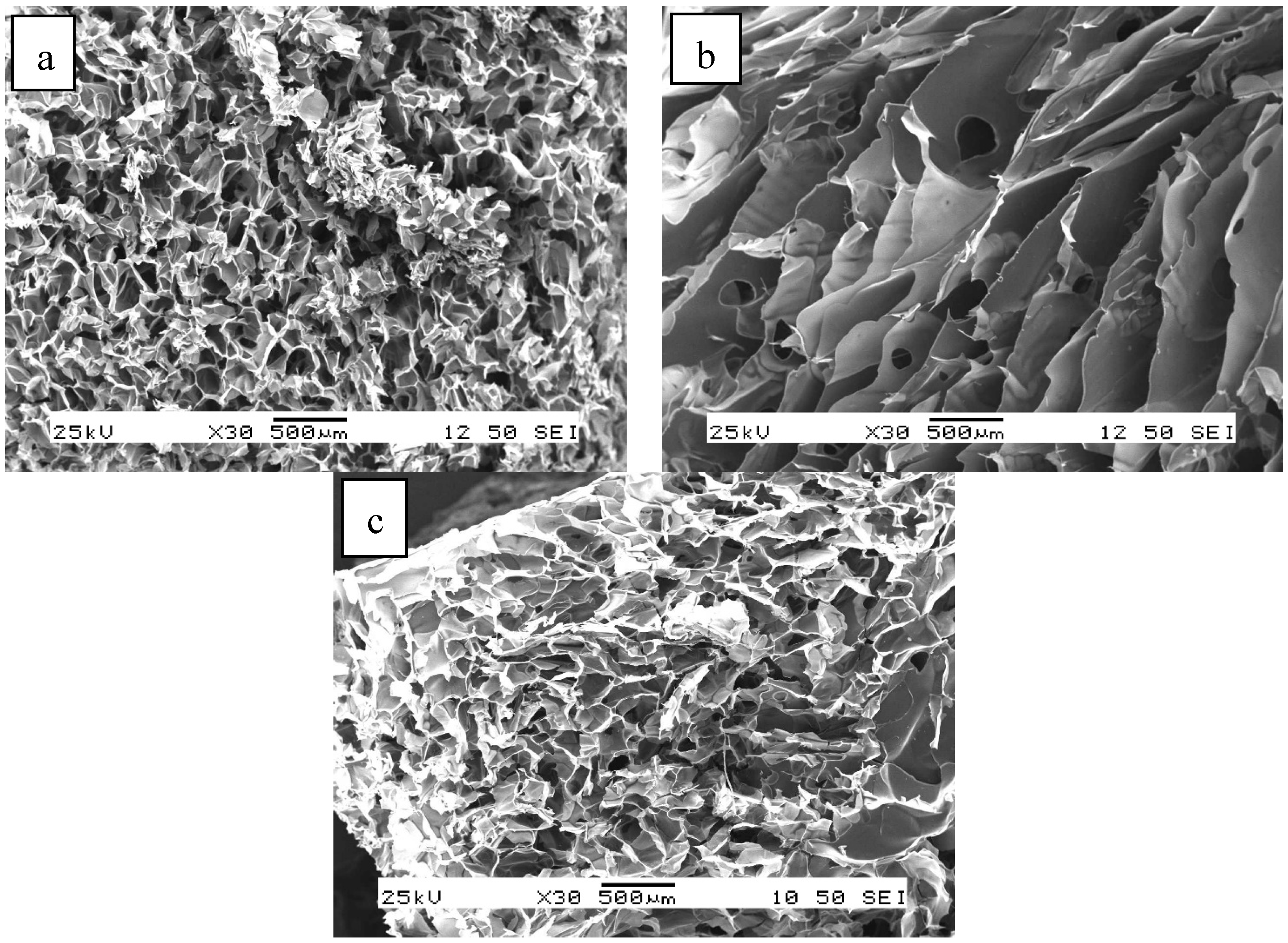

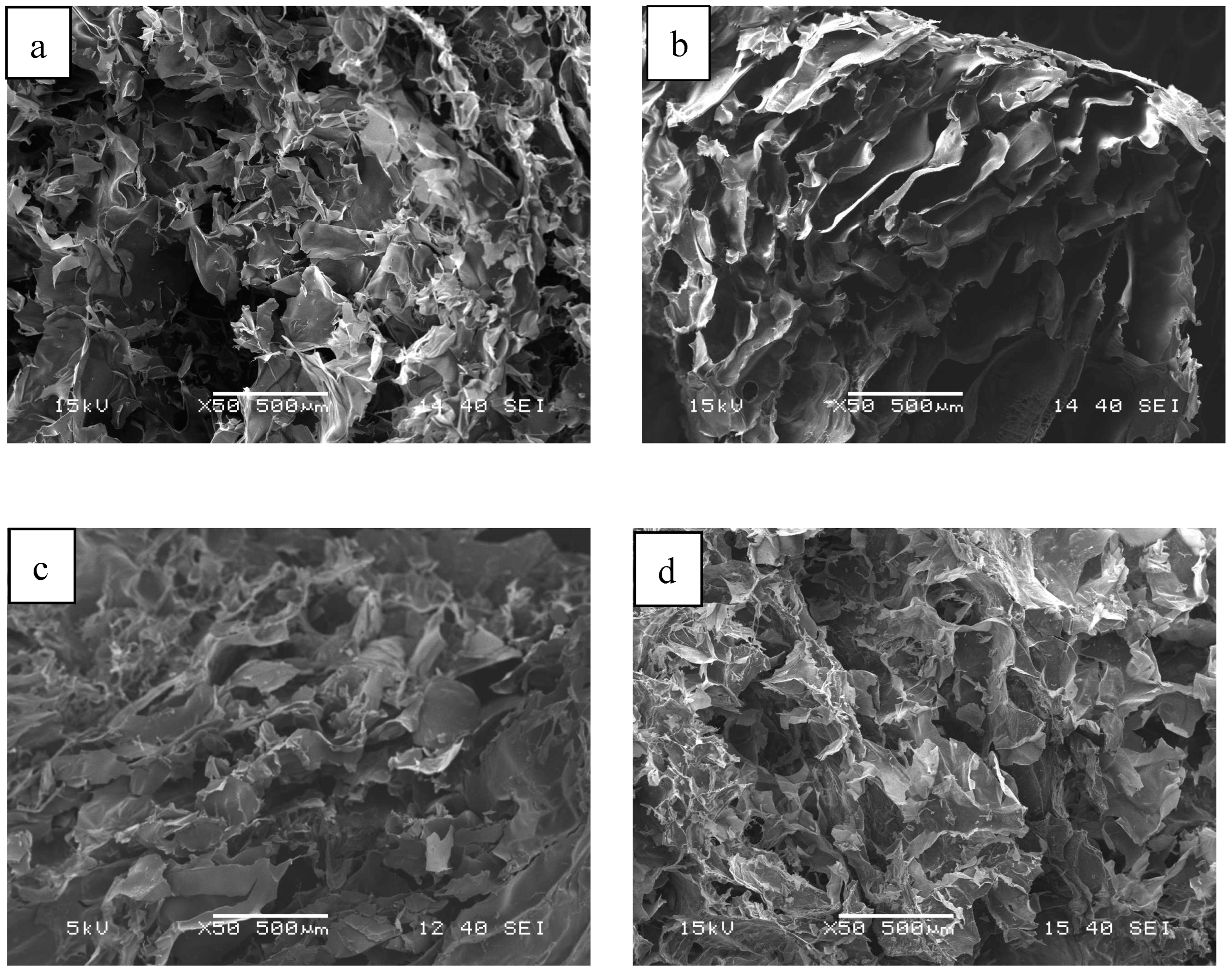

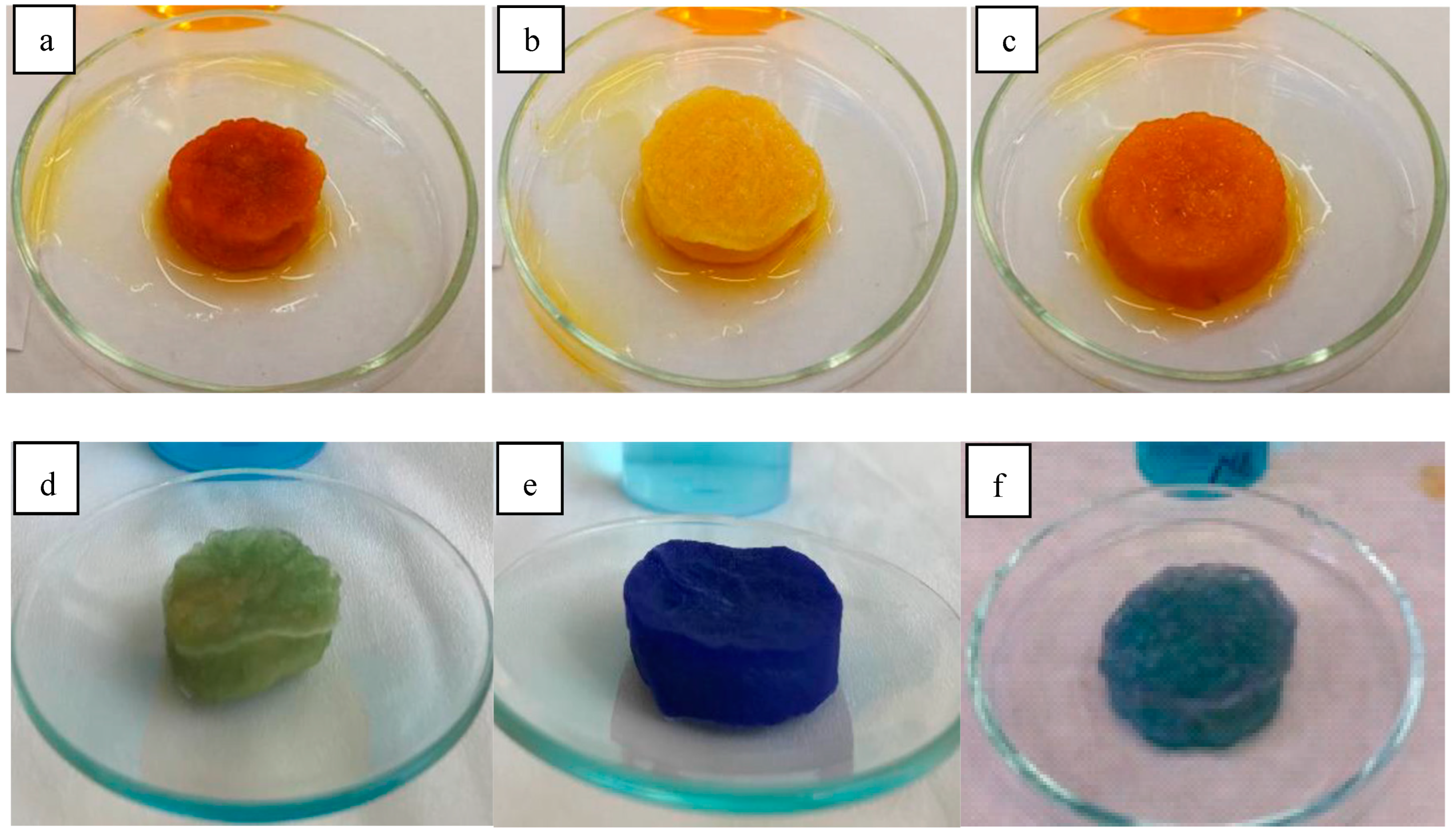

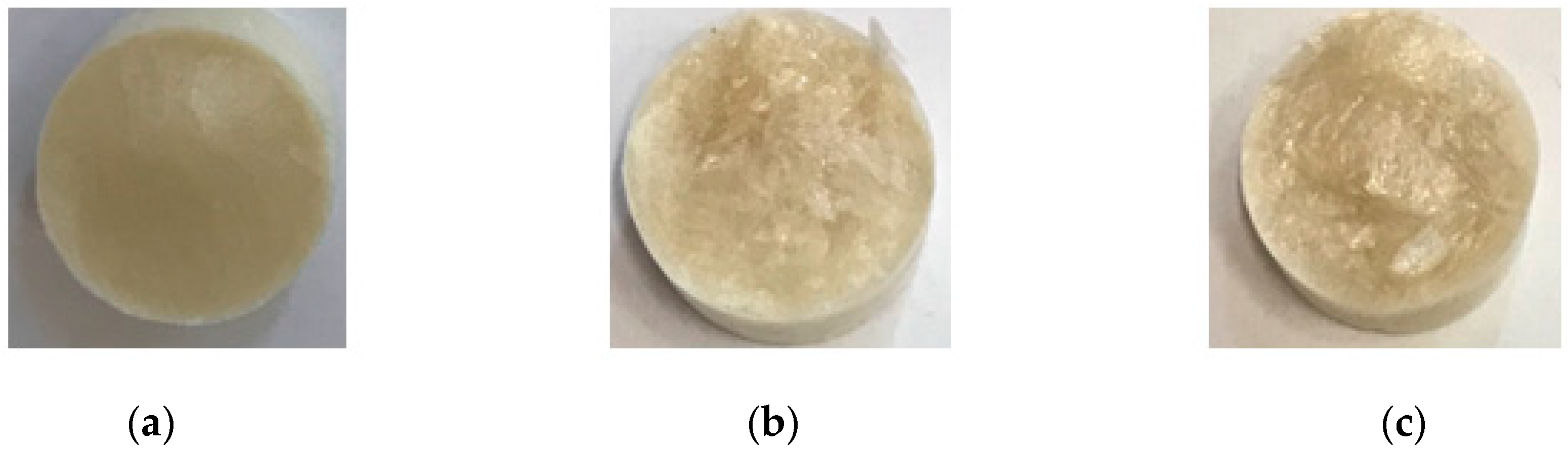

2.1. Morphology of Gels

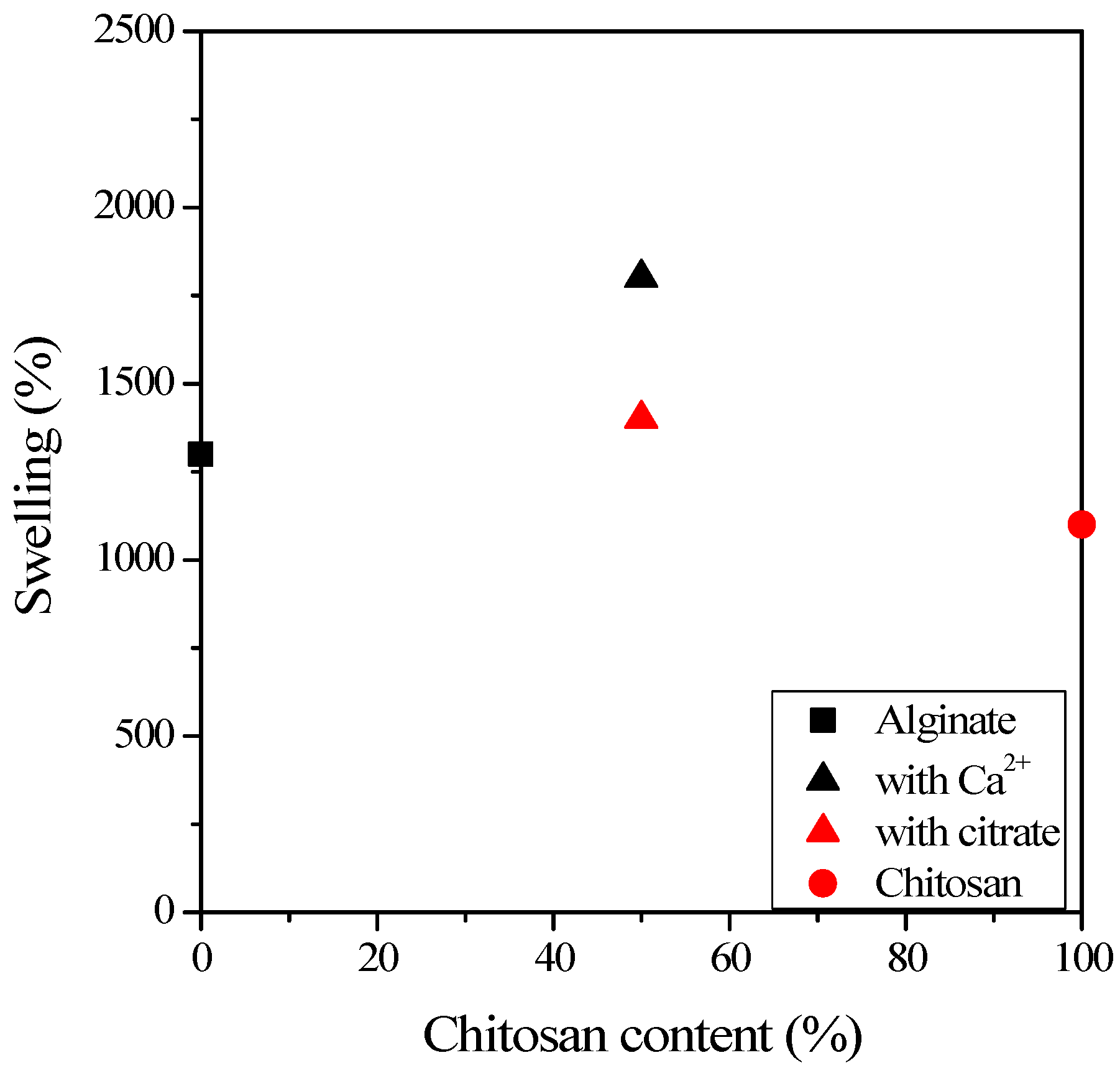

2.2. Swelling of Gels

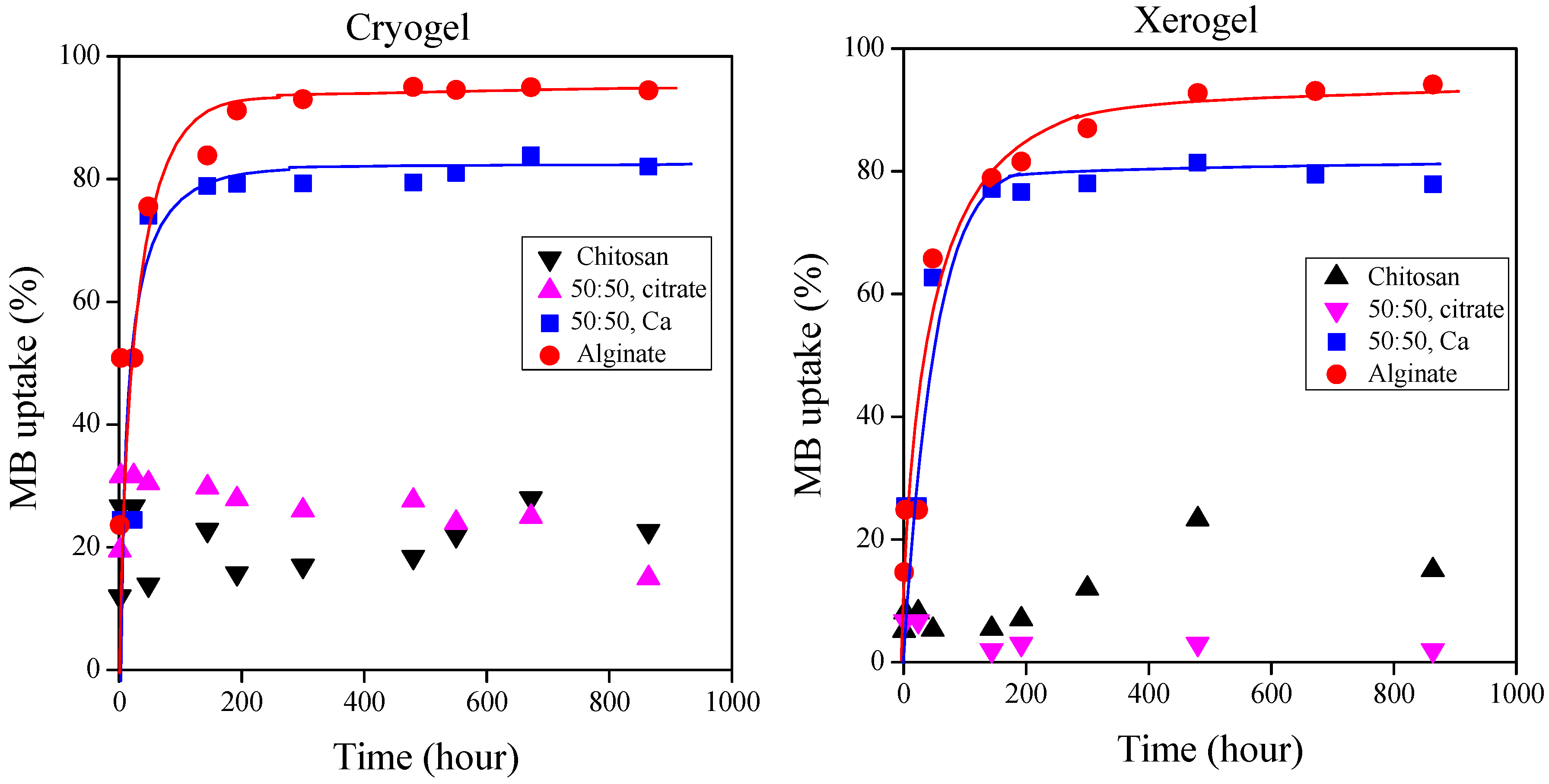

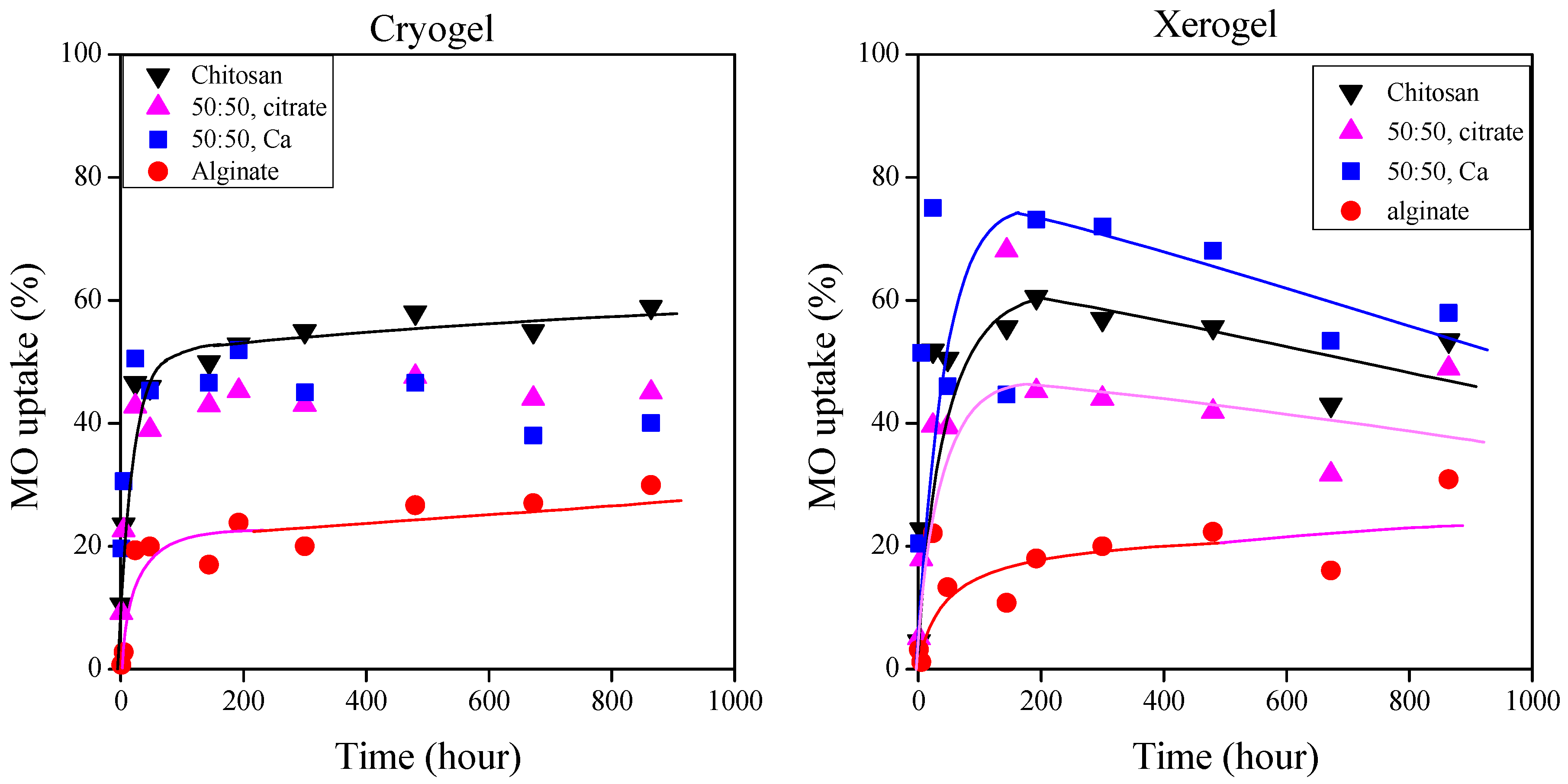

2.3. Dye Sorption of the Gels

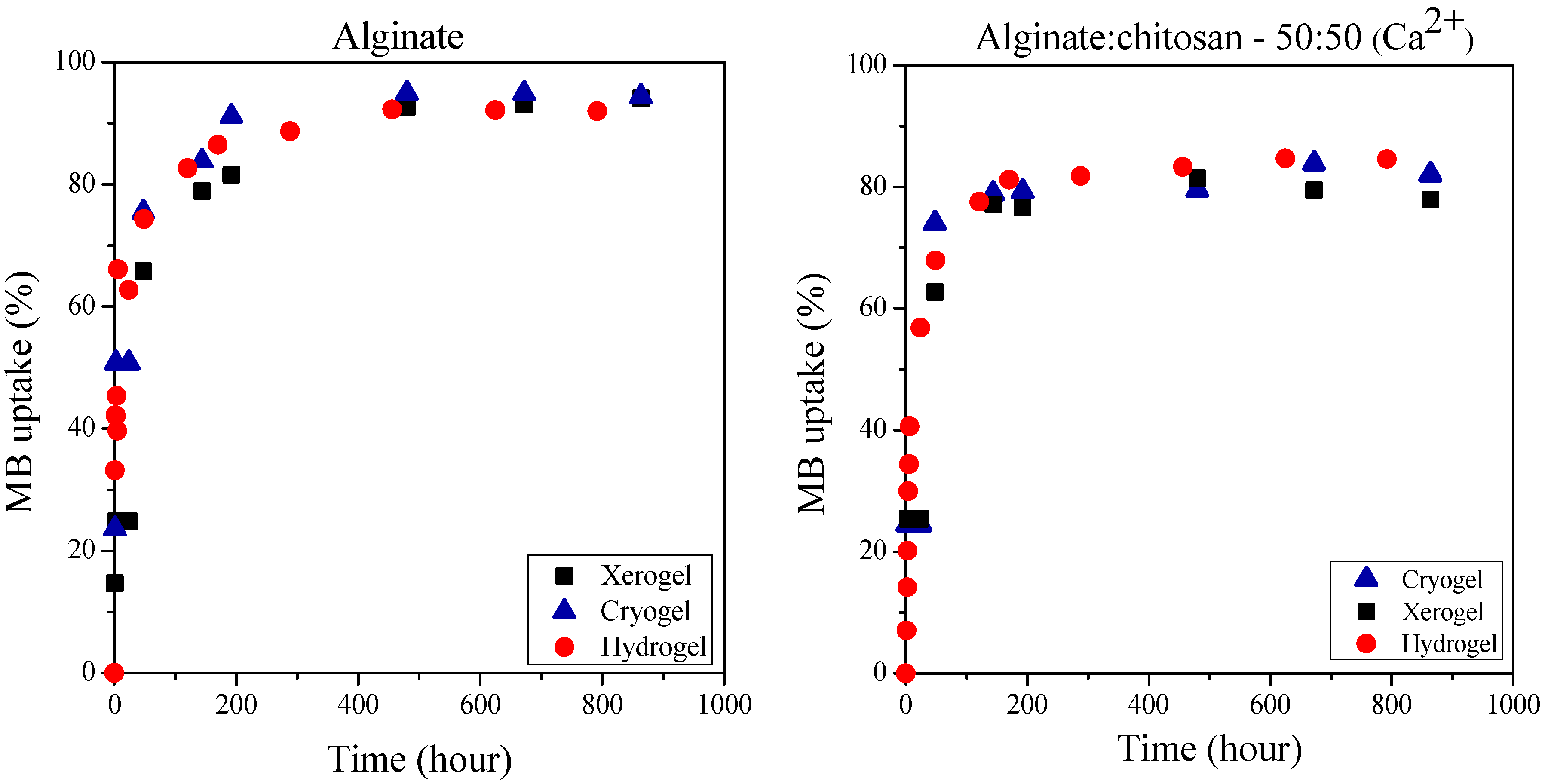

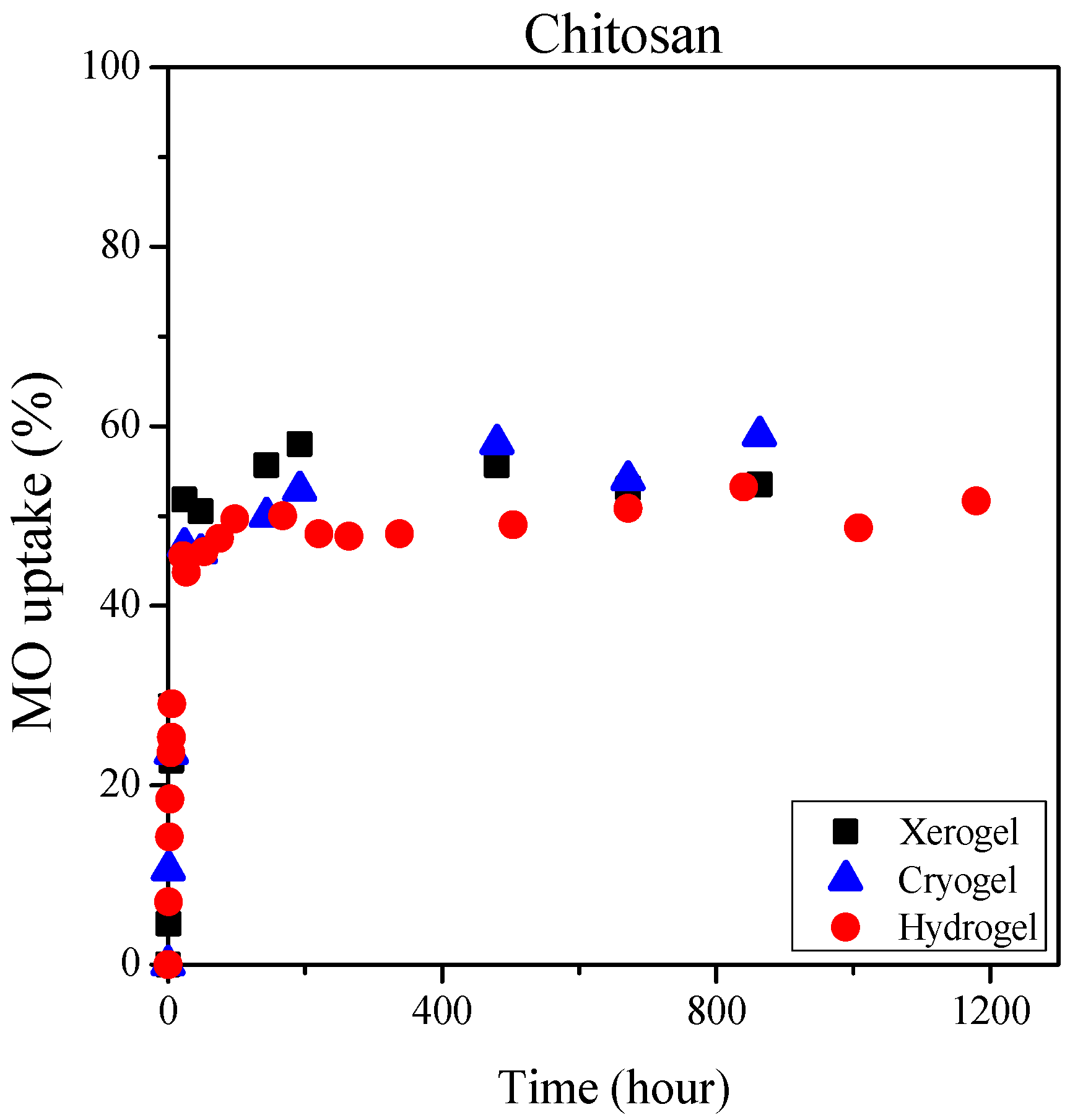

2.4. Effect of the Physical State of Gels on the Dye Sorption

2.5. Comparison of the Present Gel Sorptions with Results of the Literature

3. Materials and Methods

3.1. Materials

3.2. Sample Preparation

3.3. Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guastaferro, M.; Reverchon, E.; Baldino, L. Agarose, Alginate and Chitosan Nanostructured Aerogels for Pharmaceutical Applications: A Short Review. Front. Bioeng. Biotechnol. 2021, 9, 688477. [Google Scholar] [CrossRef] [PubMed]

- Tardy, B.L.; Mattos, B.D.; Otoni, C.G.; Beaumont, M.; Majoinen, J.; Kämäräinen, T.; Rojas, O.J. Deconstruction and Reassembly of Renewable Polymers and Biocolloids into Next Generation Structured Materials. Chem. Rev. 2021, 121, 14088–14188. [Google Scholar] [CrossRef] [PubMed]

- Saqib, M.N.; Khaled, B.M.; Liu, F.; Zhong, F. Hydrogel beads for designing future foods: Structures, mechanisms, applications, and challenges. Food Hydrocoll. Health 2022, 2, 100073. [Google Scholar] [CrossRef]

- Pirsa, S.; Hafezi, K. Hydrocolloids: Structure, preparation method, and application in food industry. Food Chem. 2023, 399, 133967. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Chai, C.; Wu, W.; Qi, P.; Liu, X.; Hao, J. Hydrogels as the plant culture substrates: A review. Carbohydr. Polym. 2023, 305, 120544. [Google Scholar] [CrossRef] [PubMed]

- Guastaferro, M.; Reverchon, E.; Baldino, L. Polysaccharide-based aerogel production for biomedical applications: A comparative review. Materials 2021, 14, 1631. [Google Scholar] [CrossRef] [PubMed]

- Shariatinia, Z.; Jalali, A.M. Chitosan-based hydrogels: Preparation, properties and applications. Int. J. Biol. Macromol. 2018, 115, 194–220. [Google Scholar] [CrossRef] [PubMed]

- Hasnain, M.S.; Jameel, E.; Mohanta, B.; Dhara, A.K.; Alkahtani, S.; Nayak, A.K. Alginates: Sources, structure, and properties. In Alginates in Drug Delivery; Academic Press: Cambridge, MA, USA, 2020; pp. 1–17. [Google Scholar]

- Rodríguez-Dorado, R.; López-Iglesias, C.; García-González, C.A.; Auriemma, G.; Aquino, R.P.; Del Gaudio, P. Design of aerogels, cryogels and xerogels of alginate: Effect of molecular weight, gelation conditions and drying method on particles’ micromeritics. Molecules 2019, 24, 1049. [Google Scholar] [CrossRef] [PubMed]

- Liao, J.; Hou, B.; Huang, H. Preparation, properties and drug controlled release of chitin-based hydrogels: An updated review. Carbohydr. Polym. 2022, 283, 119177. [Google Scholar] [CrossRef]

- Li, S.; Zhang, H.; Chen, K.; Jin, M.; Vu, S.H.; Jung, S.; He, N.; Zheng, Z.; Lee, M.S. Application of chitosan/alginate nanoparticle in oral drug delivery systems: Prospects and challenges. Drug Deliv. 2022, 29, 1142–1149. [Google Scholar] [CrossRef]

- Duceac, I.A.; Coseri, S. Chitosan Schiff-Base Hydrogels—A Critical Perspective Review. Gels 2022, 8, 779. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.Y.; Mooney, D.J. Alginate: Properties and biomedical applications. Prog. Polym. Sci. 2012, 37, 106–126. [Google Scholar] [CrossRef] [PubMed]

- Rassu, G.; Salis, A.; Porcu, E.P.; Giunchedi, P.; Roldo, M.; Gavini, E. Composite chitosan/alginate hydrogel for controlled release of deferoxamine: A system to potentially treat iron dysregulation diseases. Carbohydr. Polym. 2016, 136, 1338–1347. [Google Scholar] [CrossRef] [PubMed]

- Aderibigbe, B.A.; Buyana, B. Alginate in wound dressings. Pharmaceutics 2018, 10, 42. [Google Scholar] [CrossRef] [PubMed]

- Szulc, M.; Lewandowska, K. Biomaterials Based on Chitosan and Its Derivatives and Their Potential in Tissue Engineering and Other Biomedical Applications—A Review. Molecules 2023, 28, 247. [Google Scholar] [CrossRef] [PubMed]

- Al-Manhel, A.J.; Al-Hilphy, A.R.S.; Niamah, A.K. Extraction of chitosan, characterisation and its use for water purification. J. Saudi Soc. Agric. Sci. 2018, 17, 186–190. [Google Scholar] [CrossRef]

- Alsamman, T.M.; Sánchez, J. Chitosan- and Alginate-Based Hydrogels for the Adsorption of Anionic and Cationic Dyes from Water. Polymers 2022, 14, 1498. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Zhao, Y.; Bai, H.; Zhang, T.; Ibarra-Galvan, V.; Song, S. Methylene blue removal from water using the hydrogel beads of poly(vinyl alcohol)-sodium alginate-chitosan-montmorillonite. Carbohydr. Polym. 2018, 198, 518–528. [Google Scholar] [CrossRef]

- Heybet, E.N.; Ugraskan, V.; Isik, B.; Yazici, O. Adsorption of methylene blue dye on sodium alginate/polypyrrole nanotube composites. Int. J. Biol. Macromol. 2021, 193, 88–99. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, M.; Ji, M.; Zhang, L.; Qin, Z.; Zhang, Y.; Gao, L.; Jiao, T. Magnetic graphene oxide-containing chitosan-sodium alginate hydrogel beads for highly efficient and sustainable removal of cationic dyes. Int. J. Biol. Macromol. 2021, 193, 2221–2231. [Google Scholar] [CrossRef]

- Kasbaji, M.; Mennani, M.; Grimi, N.; Oubenali, M.; Mbarki, M.; El Zakhem, H.; Moubarik, A. Adsorption of cationic and anionic dyes onto coffee grounds cellulose/sodium alginate double-network hydrogel beads: Isotherm analysis and recyclability performance. Int. J. Biol. Macromol. 2023, 239, 124288. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Ju, J.; Tan, Y.; Hao, L.; Ma, Y.; Wu, Y.; Zhang, H.; Xia, Y.; Sui, K. Controlled synthesis of sodium alginate electrospun nanofiber membranes for multi-occasion adsorption and separation of methylene blue. Carbohydr. Polym. 2019, 205, 125–134. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Wang, X.; Lou, T. Preparation of fibrous chitosan/sodium alginate composite foams for the adsorption of cationic and anionic dyes. J. Hazard. Mater. 2021, 403, 124054. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Liu, S.J.; Chen, F.M.; Zuo, J.E. High-Strength Apatite/Attapulgite/Alginate Composite Hydrogel for Effective Adsorption of Methylene Blue from Aqueous Solution. J. Chem. Eng. Data 2019, 64, 5469–5477. [Google Scholar] [CrossRef]

- Wong, K.T.; Wong, V.L.; Lim, S.S. Bio-sorptive Removal of Methyl Orange by Micro-Grooved Chitosan (GCS) Beads: Optimization of Process Variables Using Taguchi L9 Orthogonal Array. J. Polym. Environ. 2021, 29, 271–290. [Google Scholar] [CrossRef]

- Snik, A.; Jioui, I.; Larzek, M.; Assabbane, A.; Zahouily, M. Cationic Dye Removal (Methylene Blue) from Aqueous Solution Using the Ecologically Friendly Alginate/Hydroxyapatite/Graphene Oxide Nanocomposite Hydrogel Beads. Water Air Soil Pollut. 2022, 233, 296. [Google Scholar] [CrossRef]

- Vassalini, I.; Ribaudo, G.; Gianoncelli, A.; Casula, M.F.; Alessandri, I. Plasmonic hydrogels for capture, detection and removal of organic pollutants. Environ. Sci. Nano 2020, 7, 3888–3900. [Google Scholar] [CrossRef]

- Balkız, G.; Pingo, E.; Kahya, N.; Kaygusuz, H.; Bedia Erim, F. Graphene Oxide/Alginate Quasi-Cryogels for Removal of Methylene Blue. Water Air Soil Pollut. 2018, 229, 131. [Google Scholar] [CrossRef]

- Li, Q.; Li, Y.; Ma, X.; Du, Q.; Sui, K.; Wang, D.; Wang, C.; Li, H.; Xia, Y. Filtration and adsorption properties of porous calcium alginate membrane for methylene blue removal from water. Chem. Eng. J. 2017, 316, 623–630. [Google Scholar] [CrossRef]

- Tay, S.Y.; Wong, V.L.; Lim, S.S.; Teo, I.L.R. Adsorption equilibrium, kinetics and thermodynamics studies of anionic methyl orange dye adsorption using chitosan-calcium chloride gel beads. Chem. Eng. Commun. 2021, 208, 708–726. [Google Scholar] [CrossRef]

- An, B.; Lee, H.; Lee, S.; Lee, S.H.; Choi, J.W. Determining the selectivity of divalent metal cations for the carboxyl group of alginate hydrogel beads during competitive sorption. J. Hazard. Mater. 2015, 298, 11–18. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Ou, J.; Wang, B.; Wang, H.; He, Q.; Song, J.; Zhang, H.; Tang, M.; Zhou, L.; Gao, Y.; et al. Efficient heavy metal removal from water by alginate-based porous nanocomposite hydrogels: The enhanced removal mechanism and influencing factor insight. J. Hazard. Mater. 2021, 418, 126358. [Google Scholar] [CrossRef] [PubMed]

- Upadhyay, U.; Sreedhar, I.; Singh, S.A.; Patel, C.M.; Anitha, K.L. Recent advances in heavy metal removal by chitosan based adsorbents. Carbohydr. Polym. 2021, 251, 117000. [Google Scholar] [CrossRef] [PubMed]

- Wong, K.T.; Wong, V.L.; Lim, S.S. Methyl orange removal from aqueous solution by sorption onto porous polysaccharide-based adsorbents: Optimization by taguchi design. In IOP Conference Series: Earth and Environmental Science; Noor, N.M., Rahim, N.L., Ting, S.S., Zakarya, I.A., Yusof, S.Y., Izhar, T.N.T., Amat, R.C., Ibrahim, N.M., Eds.; IOP Publishing Ltd.: Bristol, UK, 2020. [Google Scholar]

- Gurikov, P.; Smirnova, I. Non-conventional methods for gelation of alginate. Gels 2018, 4, 14. [Google Scholar] [CrossRef]

- Duceac, I.A.; Stanciu, M.C.; Nechifor, M.; Tanasă, F.; Teacă, C.A. Insights on Some Polysaccharide Gel Type Materialsand Their Structural Peculiarities. Gels 2022, 8, 771. [Google Scholar] [CrossRef]

- Li, Z.; Lin, Z. Recent advances in polysaccharide-based hydrogels for synthesis and applications. Aggregate 2021, 2, e21. [Google Scholar] [CrossRef]

- Grzybek, P.; Jakubski, Ł.; Dudek, G. Neat Chitosan Porous Materials: A Review of Preparation, Structure Characterization and Application. Int. J. Mol. Sci. 2022, 23, 9932. [Google Scholar] [CrossRef]

- Nayak, A.K.; Das, B. Introduction to polymeric gels. In Polymeric Gels: Characterization, Properties and Biomedical Applications; Woodhead Publishing: Cambridge, UK, 2018; pp. 3–27. [Google Scholar]

- Saigl, Z.; Tifouti, O.; Alkhanbashi, B.; Alharbi, G.; Algamdi, H. Chitosan as adsorbent for removal of some organic dyes: A review. Chem. Pap. 2023, 77, 2363–2405. [Google Scholar] [CrossRef]

- Sezen, S.; Thakur, V.K.; Ozmen, M.M. Highly effective covalently crosslinked composite alginate cryogels for cationic dye removal. Gels 2021, 7, 178. [Google Scholar] [CrossRef]

- Qiu, J.; Fan, P.; Feng, Y.; Liu, F.; Ling, C.; Li, A. Comparison of the adsorption behaviors for methylene blue on two renewable gels with different physical state. Environ. Pollut. 2019, 254, 113117. [Google Scholar] [CrossRef]

- Zhang, B.; Tan, Z.; Zhang, Y.; Liu, Q.; Li, Q.; Li, G. Facile Synthesis of Microporous Ferrocenyl Polymers Photocatalyst for Degradation of Cationic Dye. Polymers 2022, 14, 1900. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.-L.; Tsai, I.-L.; Lin, C.; Hang, Y.-H.; Ho, Y.-C.; Tsai, M.-L.; Mi, F.-L. Intelligent films of marine polysaccharides and purple cauliflower extract for food packaging and spoilage monitoring. Carbohydr. Polym. 2023, 299, 120133. [Google Scholar] [CrossRef] [PubMed]

| Composition of Adsorbent | Type of Adsorbent | Dye | Dye Removal Efficiency (%) | Dye Sorption Capacity (mg/g) | Dye Solution Concentration (mg/L) | Volume of Dye Solution (mL) | pH | Sorption Time (min) | Adsorbent Mass (mg) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| SA (SA/Polypyrrol nanotube) | microbeads | MB | ~30 | 230 | 10–50 | 50 | 7 | ~40 | 50–250 | [20] |

| SA/Graphene Oxide /Fe3O4/CS | microbeads | MB | ~90 | 21.3 | - | 100 | 7 | 250–300 | 50 | [21] |

| SA/Fe3O4 | microbeads | MB | ~77 | 18.3 | - | 100 | 7 | 250–300 | 50 | [21] |

| SA/coffee grounds cellulose | microbeads | MB | ~96 | 400.5 | 100 | 250 | 7 | 20–30 | 200 | [22] |

| SA (apatite/attapulgite/alginate) | microbeads | MB | 60 | ~139 | 500 | 100 | 280 | 25 | [25] | |

| SA/Hydroxyapatite/Graphene Oxide | microbeads | MB | ~93 | 311 | 50 | 25 | 7.2 | 350 | 8 | [27] |

| SA (Ag NPs/β-cyclodextrin/alginate) | bubbles | MB | 76 | - | 32 | - | - | 30 | - | [28] |

| SA (SA/Graphene Oxide) | quasi-cryogel beads | MB | ~65 | - | 1–20 | - | - | 150 | - | [29] |

| SA | nanofiber | MB | ~95–100 | 2230 | 200–1500 | 50 | 6 | 50 | 20 | [23] |

| CS:SA 50:50 | foam cryogel | MB | <30 | ~240 | 500 | 100 | 5.8 | ~1500 | 10 | [24] |

| SA covalently cross-linked by cystamine (SA-montmorillonite covalently cross-linked by cystamine) | cryogel | MB | ~85 | ~22 | 25 | 10 | - | 480 | 10 | [42] |

| SA | freeze-dried membrane | MB | ~93 | 300–1000 | 20 | 8 | 550 | 10 | [30] | |

| CS | porous microbeads | MO | 98.7 | 9.4 | 90 | 50 | 3 | >4500 | 500 | [35] |

| CS | grooved microbead | MO | 98 | 9.14 | 90 | 50 | 3 | 4200 | 500 | [26] |

| Cs | microbead | MO | ~22 | 4.04 | 30 | 60 | 3 | 100 | [31] | |

| 0.005 M CS-CaCl2 | microbead | MO | ~74 | 13.86 | 30 | 60 | 3 | 100 | [31] |

| Adsorbent/Dye | pH | Cryogel | Xerogel | Hydrogel | |||

|---|---|---|---|---|---|---|---|

| R (%) | qe (mg/g) | R (%) | qe (mg/g) | R (%) | qe (mg/g) | ||

| Alginate/MB | 8.3 | 95 | 71.3 | 94 | 70.5 | 92 | 68.5 |

| 50:50 (Ca2+)/MB | 8.3 | 83 | 62.2 | 79 | 59.2 | 85 | 63.7 |

| Chitosan/MO | 7.8 | 56 | 42.0 | 54 | 40.5 | 52 | 38.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fekete, E.; Csiszár, E. Chitosan–Alginate Gels for Sorption of Hazardous Materials: The Effect of Chemical Composition and Physical State. Int. J. Mol. Sci. 2024, 25, 8406. https://doi.org/10.3390/ijms25158406

Fekete E, Csiszár E. Chitosan–Alginate Gels for Sorption of Hazardous Materials: The Effect of Chemical Composition and Physical State. International Journal of Molecular Sciences. 2024; 25(15):8406. https://doi.org/10.3390/ijms25158406

Chicago/Turabian StyleFekete, Erika, and Emília Csiszár. 2024. "Chitosan–Alginate Gels for Sorption of Hazardous Materials: The Effect of Chemical Composition and Physical State" International Journal of Molecular Sciences 25, no. 15: 8406. https://doi.org/10.3390/ijms25158406