Synthesis, Optimization and Molecular Self-Assembly Behavior of Alginate-g-Oleylamine Derivatives Based on Ugi Reaction for Hydrophobic Drug Delivery

Abstract

:1. Introduction

2. Results and Discussion

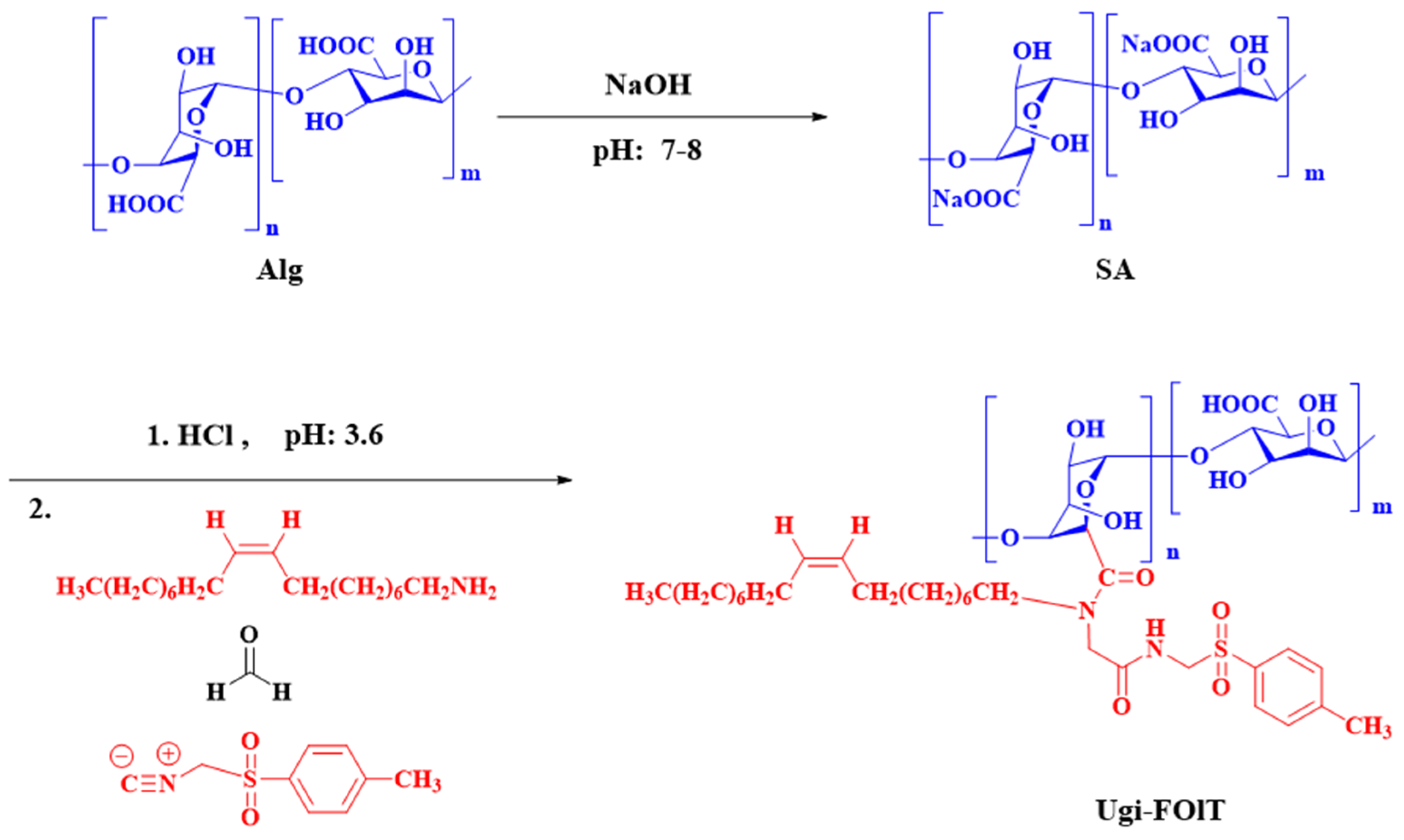

2.1. Optimization of Process Parameters for the Synthesis of Ugi-FOlT

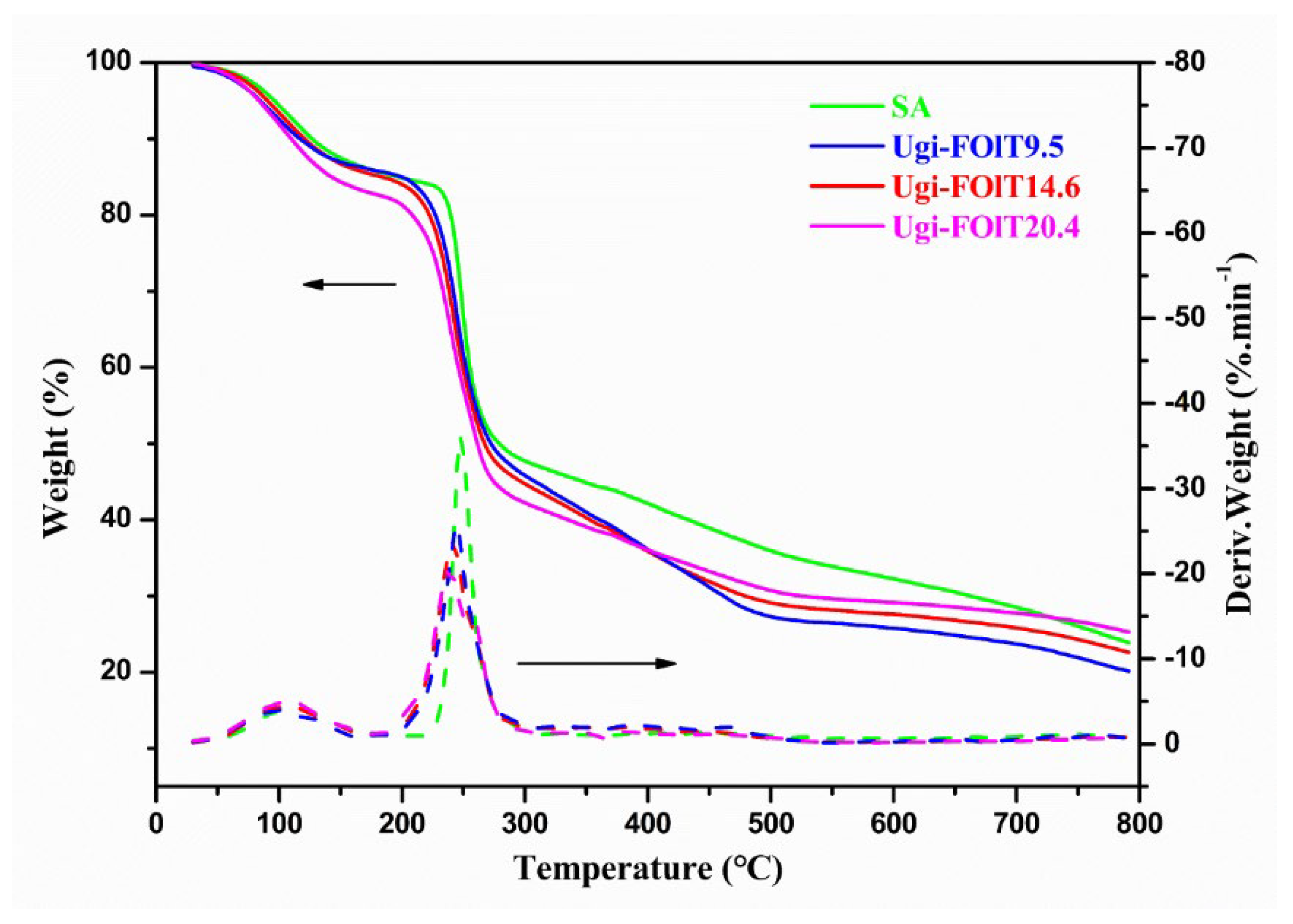

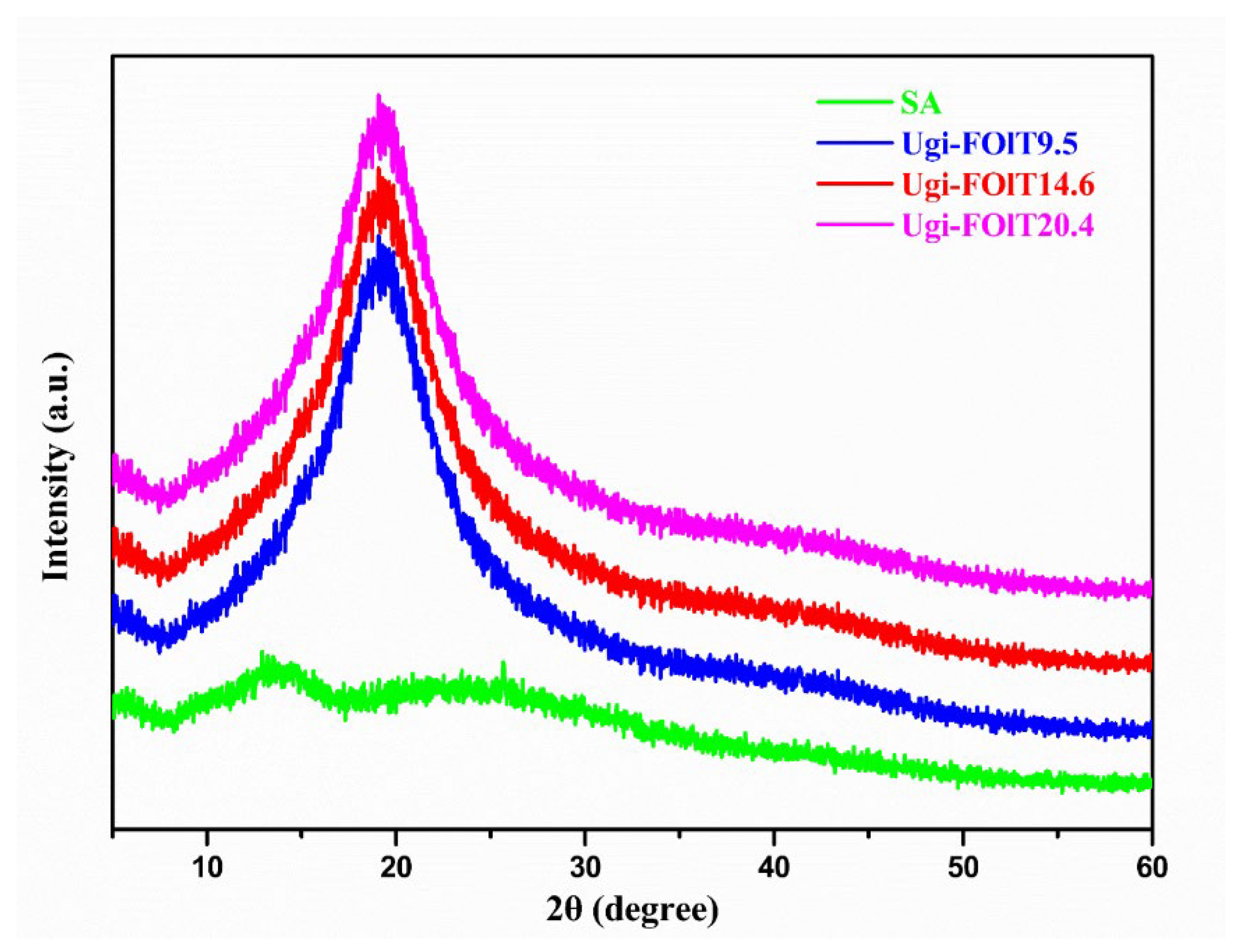

2.2. Structural Characteristics of Ugi-FOlT

2.3. Self-Assembly Behavior of Ugi-FOlT

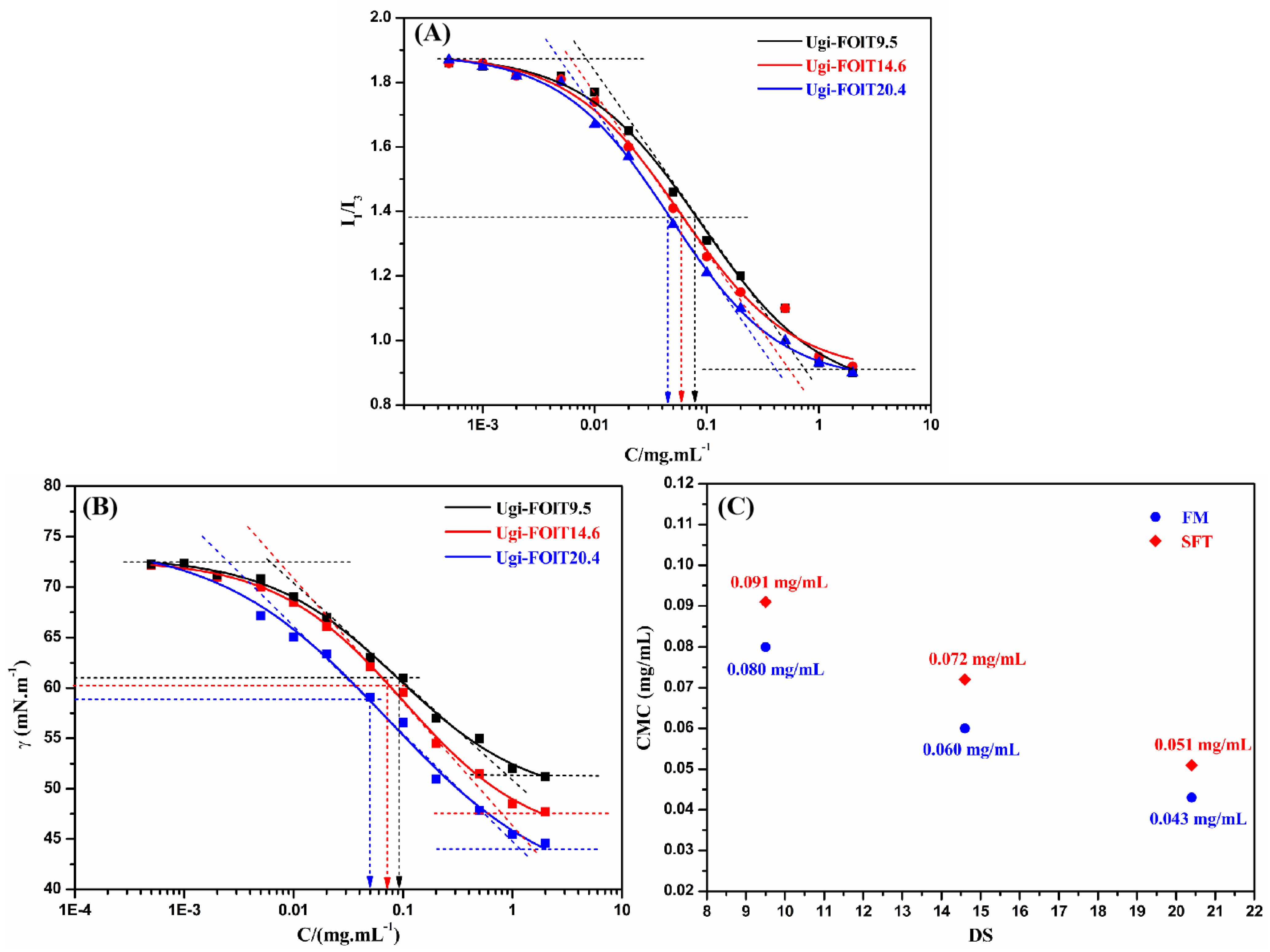

2.3.1. Amphiphilic Ugi-FOlT’s CMC Value

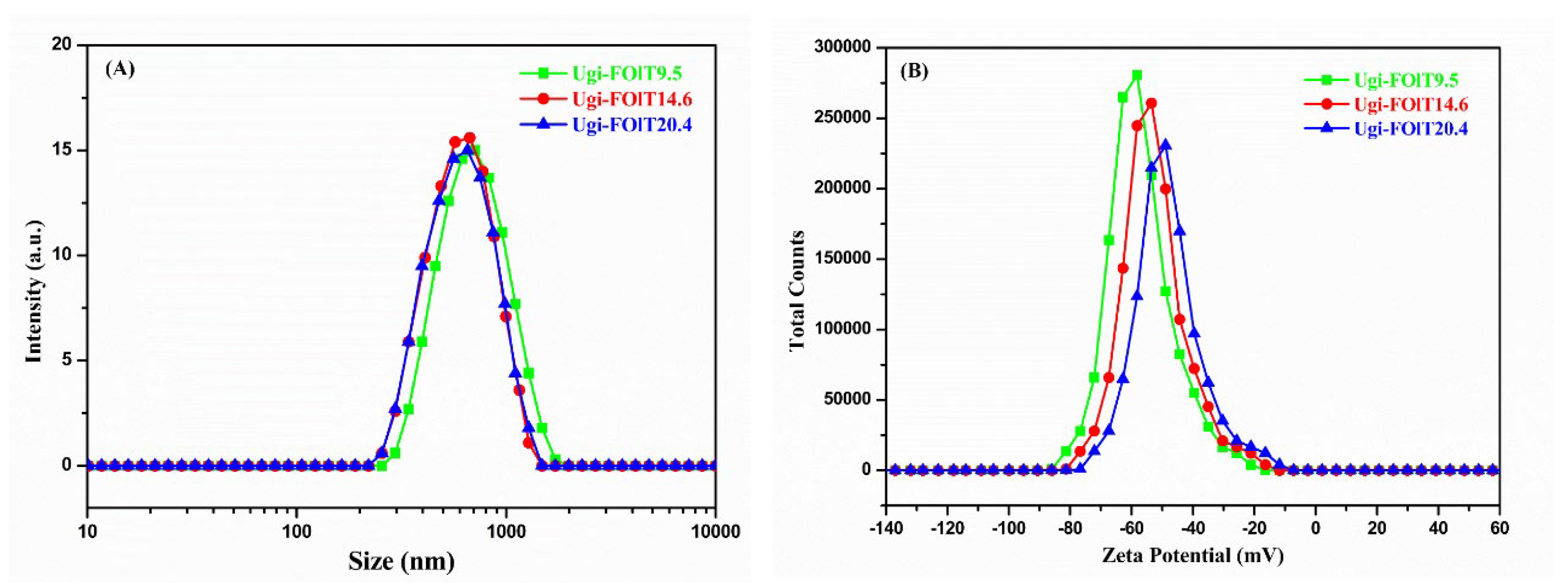

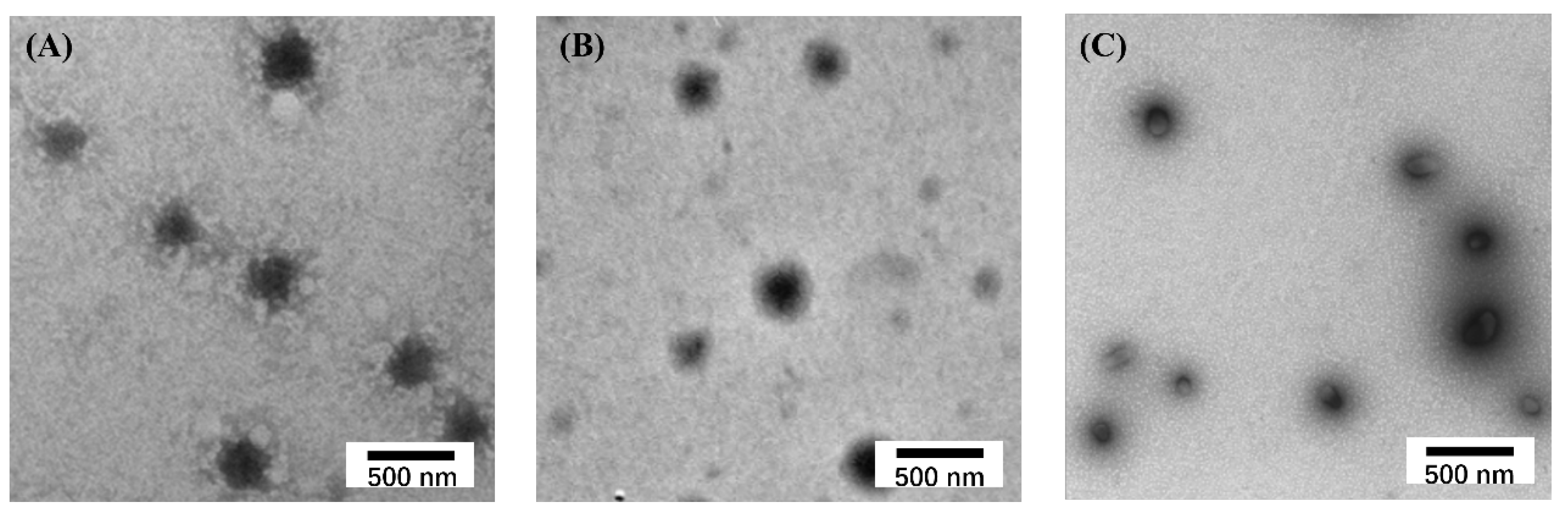

2.3.2. Colloidal Properties of Ugi-FOlT Self-Assembled Micelles

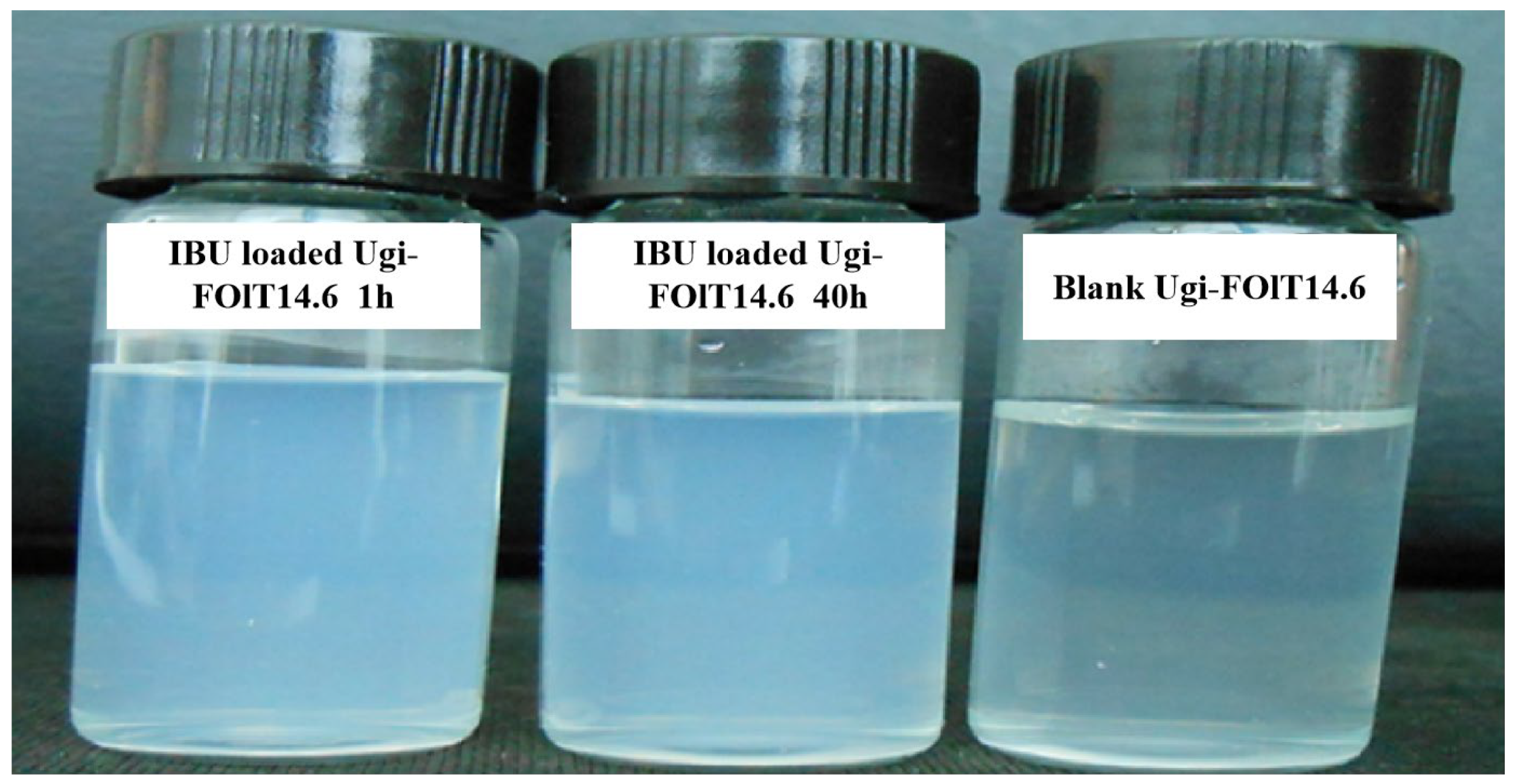

2.4. In Vitro Release Behavior of IBU for Ugi-FOlT Micelles

2.5. In Vitro Cytotoxicity of Ugi-FOlT

3. Materials and Methods

3.1. Materials

3.2. Synthesis and Optimization of Process Conditions of Ugi-FOlT

3.3. Structural Characterization of Ugi-FOlT

3.4. Determination of the Critical Micelle Concentration Value of Ugi-FOlT

3.5. Preparation and Colloidal Properties of Ugi-FOlT Micelles

3.6. Loading and In Vitro Release of Ibuprofen

3.7. Cytotoxicity of Ugi-FOlT

3.8. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kubiak, T. Polymeric capsules and micelles as promising carriers of anticancer drugs. Polym. Med. 2022, 52, 37–50. [Google Scholar] [CrossRef] [PubMed]

- Hu, S.; Yan, J.; Yang, G.; Ma, C.; Yin, J. Self-Assembled Polymeric Materials: Design, Morphology, and Functional-Oriented Applications. Macromol. Rapid Commun. 2022, 43, 2100791. [Google Scholar] [CrossRef] [PubMed]

- Foroughi-Nia, B.; Barar, J.; Memar, M.Y.; Aghanejad, A.; Davaran, S. Progresses in polymeric nanoparticles for delivery of tyrosine kinase inhibitors. Life Sci. 2021, 278, 119642. [Google Scholar] [CrossRef] [PubMed]

- Bhia, M.; Motallebi, M.; Abadi, B.; Zarepour, A.; Pereira-Silva, M.; Saremnejad, F.; Santos, A.C.; Zarrabi, A.; Melero, A.; Jafari, S.M.; et al. Naringenin Nano-Delivery Systems and Their Therapeutic Applications. Pharmaceutics 2021, 13, 291. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Liu, Y.; Wu, Y.; Dai, F.; Yuan, M.; Wang, F.; Bai, Y.; Deng, H. Natural polysaccharides based self-assembled nanoparticles for biomedical applications—A review. Int. J. Biol. Macromol. 2021, 192, 1240–1255. [Google Scholar] [CrossRef] [PubMed]

- Mizrahy, S.; Peer, D. Polysaccharides as building blocks for nanotherapeutics. Chem. Soc. Rev. 2012, 41, 2623–2640. [Google Scholar] [CrossRef] [PubMed]

- Manivasagan, P.; Oh, J. Marine polysaccharide-based nanomaterials as a novel source of nanobiotechnological applications. Int. J. Biol. Macromol. 2016, 82, 315–327. [Google Scholar] [CrossRef] [PubMed]

- Prajapati, S.K.; Jain, A.; Jain, A.; Jain, S. Biodegradable polymers and constructs: A novel approach in drug delivery. Eur. Polym. J. 2019, 120, 109191. [Google Scholar] [CrossRef]

- Lee, K.Y.; Mooney, D.J. Alginate: Properties and biomedical applications. Prog. Polym. Sci. 2012, 37, 106–126. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.Q.; Zhang, B.F.; Wen, L.Q.; Liang, Q.Y.; Zhang, L.-M. Amphiphilic cholesteryl grafted sodium alginate derivative: Synthesis and self-assembly in aqueous solution. Carbohydr. Polym. 2007, 68, 218–225. [Google Scholar] [CrossRef]

- Emami, Z.; Ehsani, M.; Zandi, M.; Foudazi, R. Controlling alginate oxidation conditions for making alginate-gelatin hydrogels. Carbohydr. Polym. 2018, 198, 509–517. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Tan, H. Alginate-Based Biomaterials for Regenerative Medicine Applications. Materials 2013, 6, 1285–1309. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.T.; Cheng, J.Q.; Ao, Q. Preparation of alginate-based biomaterials and their applications in biomedicine. Mar. Drugs 2021, 19, 264. [Google Scholar] [CrossRef] [PubMed]

- Gheorghita Puscaselu, R.; Lobiuc, A.; Dimian, M.; Covasa, M. Alginate: From Food Industry to Biomedical Applications and Management of Metabolic Disorders. Polymers 2020, 12, 2417. [Google Scholar] [CrossRef] [PubMed]

- Ugi, I. The α-addition of immonium ions and anions to isonitriles accompanied by secondary reactions. Angew. Chem. Int. Ed. Engl. 1962, 1, 8–21. [Google Scholar] [CrossRef]

- Xu, M.H. Asymmetric Ugi four-component reaction catalyzed by chiral phosphoric acid. Chin. Sci. Bull. 2018, 63, 3159–3160. [Google Scholar]

- Sehlinger, A.; Ochsenreither, K.; Bartnick, N.; Meier, M.A.R. Potentially biocompatible polyacrylamides derived by the Ugi four-component reaction. Eur. Polym. J. 2015, 65, 313–324. [Google Scholar] [CrossRef]

- Wang, S.; Fu, C.; Wei, Y.; Tao, L. Facile One-Pot Synthesis of New Functional Polymers through Multicomponent Systems. Macromol. Chem. Phys. 2014, 215, 486–492. [Google Scholar] [CrossRef]

- Bu, H.; Kjøniksen, A.L.; Knudsen, K.D.; Nyström, B. Rheological and Structural Properties of Aqueous Alginate during Gelation via the Ugi Multicomponent Condensation Reaction. Biomacromolecules 2004, 5, 1470–1479. [Google Scholar] [CrossRef] [PubMed]

- Patil, P.; Ahmadian-Moghaddam, M.; Dömling, A. Isocyanide 2.0. Green Chem. 2020, 22, 6902–6911. [Google Scholar] [CrossRef]

- Wen, Y.; Chen, X.; Liu, Z.; Zhu, Q.; Li, Z.; He, G.; Yan, H.; Lin, Q. Hydrophobically Modified Alginate Derivatives via the Ugi Multicomponent Reaction for the Development of Hydrophobic Pharmaceutical Formulations. ChemistrySelect 2021, 6, 10965–10973. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, X.; Wen, Y.; Bao, C.; Liu, C.; Cao, S.; Yan, H.; Lin, Q. Chemical modification of alginate with tosylmethyl isocyanide, propionaldehyde and octylamine via the Ugi reaction for hydrophobic drug delivery. Polym. Bull. 2021, 79, 7809–7826. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, X.; Huang, Z.; Wang, H.; Cao, S.; Liu, C.; Yan, H.; Lin, Q. One-Pot Synthesis of Amphiphilic Biopolymers from Oxidized Alginate and Self-Assembly as a Carrier for Sustained Release of Hydrophobic Drugs. Polymers 2022, 14, 694. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Chen, X.; Huang, Z.; Shi, J.; Liu, C.; Cao, S.; Yan, H.; Lin, Q. Self-assembled oleylamine grafted alginate aggregates for hydrophobic drugs loading and controlled release. Int. J. Polym. Mater. Polym. Biomater. 2021, 72, 212–223. [Google Scholar] [CrossRef]

- Lin, W.J.; Juang, L.W.; Lin, C.C. Stability and release performance of a series of pegylated copolymeric micelles. Pharm. Res. 2003, 20, 668–673. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.S.; Ren, H.B.; Xie, Y.J. Synthesis of Amidic Alginate Derivatives and Their Application in Microencapsulation of λ-Cyhalothrin. Biomacromolecules 2011, 12, 2982–2987. [Google Scholar] [CrossRef] [PubMed]

- Mourdikoudis, S.; Liz-Marzán, L.M. Oleylamine in Nanoparticle Synthesis. Chem. Mater. 2013, 25, 1465–1476. [Google Scholar] [CrossRef]

- Galant, C.; Kjøniksen, A.L.; Nguyen, G.T.M.; Knudsen, K.D.; Nyström, B. Altering Associations in Aqueous Solutions of a Hydrophobically Modified Alginate in the Presence of β-Cyclodextrin Monomers. J. Phys. Chem. B 2005, 110, 190–195. [Google Scholar] [CrossRef] [PubMed]

- Singh, B.; Sharma, D.K.; Kumar, R.; Gupta, A. Controlled release of the fungicide thiram from starch-alginate-clay based formulation. Appl. Clay Sci. 2009, 45, 76–82. [Google Scholar] [CrossRef]

- Walvekar, P.; Gannimani, R.; Salih, M.; Makhathini, S.; Mocktar, C.; Govender, T. Self-assembled oleylamine grafted hyaluronic acid polymersomes for delivery of vancomycin against methicillin resistant Staphylococcus aureus (MRSA). Colloids Surf. B Biointerfaces 2019, 182, 110388. [Google Scholar] [CrossRef] [PubMed]

- Yan, H.; Chen, X.; Feng, M.; Shi, Z.; Zhang, W.; Wang, Y.; Ke, C.; Lin, Q. Entrapment of bacterial cellulose nanocrystals stabilized Pickering emulsions droplets in alginate beads for hydrophobic drug delivery. Colloids Surf. B Biointerfaces 2019, 177, 112–120. [Google Scholar] [CrossRef] [PubMed]

- Kang, H.; Shu, Y.; Li, Z.; Guan, B.; Peng, S.; Huang, Y.; Liu, R. An effect of alginate on the stability of LDH nanosheets in aqueous solution and preparation of alginate/LDH nanocomposites. Carbohydr. Polym. 2014, 100, 158–165. [Google Scholar] [CrossRef]

- Yang, X.D.; Zhang, C.G.; Qiao, C.D.; Mu, X.L.; Li, T.D.; Xu, J.K.; Shi, L.; Zhang, D.J. A simple and convenient method to synthesize N-[(2-hydroxyl)-propyl-3-trimethylammonium] chitosan chloride in an ionic liquid. Carbohydr. Polym. 2015, 130, 325–332. [Google Scholar] [CrossRef] [PubMed]

- Samanta, H.S.; Ray, S.K. Synthesis, characterization, swelling and drug release behavior of semi-interpenetrating network hydrogels of sodium alginate and polyacrylamide. Carbohydr. Polym. 2014, 99, 666–678. [Google Scholar] [CrossRef] [PubMed]

- Ionita, M.; Pandele, M.A.; Iovu, H. Sodium alginate/graphene oxide composite films with enhanced thermal and mechanical properties. Carbohydr. Polym. 2013, 94, 339–344. [Google Scholar] [CrossRef] [PubMed]

- Xue, Y.N.; Huang, Z.Z.; Zhang, J.T.; Liu, M.; Zhang, M.; Huang, S.W.; Zhuo, R.X. Synthesis and self-assembly of amphiphilic poly(acrylic acid-b-dl-lactide) to form micelles for pH-responsive drug delivery. Polymer 2009, 50, 3706–3713. [Google Scholar] [CrossRef]

- Gaucher, G.; Dufresne, M.H.; Sant, V.P.; Kang, N.; Maysinger, D.; Leroux, J.C. Block copolymer micelles: Preparation, characterization and application in drug delivery. J. Control. Release 2005, 109, 169–188. [Google Scholar] [CrossRef] [PubMed]

- Mai, Y.; Eisenberg, A. Self-assembly of block copolymers. Chem. Soc. Rev. 2012, 41, 5969–5985. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Liu, M.; Yang, X.; Zhai, G. The role of glycyrrhetinic acid modification on preparation and evaluation of quercetin-loaded chitosan-based self-aggregates. J. Colloid Interface Sci. 2015, 460, 87–96. [Google Scholar] [CrossRef]

- Jiang, C.; Wang, X.; Sun, P.; Yang, C. Synthesis and solution behavior of poly(ε-caprolactone) grafted hydroxyethyl cellulose copolymers. Int. J. Biol. Macromol. 2011, 48, 210–214. [Google Scholar] [CrossRef]

- Chen, X.; Zhu, Q.; Liu, Z.; Zhang, T.; Gong, C.; Li, J.; Yan, H.; Lin, Q. Self-aggregate performance of hexyl alginate ester derivative synthesized via SN2 reaction for controlled release of λ-cyhalothrin. Polym. Bull. 2023, 80, 495–514. [Google Scholar] [CrossRef]

- Li, Q.; Liu, C.G.; Huang, Z.H.; Xue, F.F. Preparation and characterization of nanoparticles based on hydrophobic alginate derivative as carriers for sustained release of vitamin D3. J. Agric. Food Chem. 2011, 59, 1962–1967. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, N.; Ramsch, R.; Llinàs, M.; Solans, C.; Hashim, R.; Tajuddin, H.A. Influence of nonionic branched-chain alkyl glycosides on a model nano-emulsion for drug delivery systems. Colloids Surf. B Biointerfaces 2014, 115, 267–274. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Luo, G.F.; Liu, Y.; Li, C.; Cheng, S.X.; Zhuo, R.X.; Zhang, X.Z. Redox-sensitive shell cross-linked PEG–polypeptide hybrid micelles for controlled drug release. Polym. Chem. 2012, 3, 1084. [Google Scholar] [CrossRef]

- Fang, X.; Zhao, X.; Yu, G.; Zhang, L.; Feng, Y.; Zhou, Y.; Liu, Y.; Li, J. Effect of molecular weight and pH on the self-assembly microstructural and emulsification of amphiphilic sodium alginate colloid particles. Food Hydrocoll. 2020, 103, 105593. [Google Scholar] [CrossRef]

- He, C.; Hu, Y.; Yin, L.; Tang, C.; Yin, C. Effects of particle size and surface charge on cellular uptake and biodistribution of polymeric nanoparticles. Biomaterials 2010, 31, 3657–3666. [Google Scholar] [CrossRef] [PubMed]

- Astete, C.E.; Sabliov, C.M.; Watanabe, F.; Biris, A. Ca2+ cross-linked alginic acid nanoparticles for solubilization of lipophilic natural colorants. J. Agric. Food Chem. 2009, 57, 7505–7512. [Google Scholar] [CrossRef]

- Kulkarni, S.A.; Feng, S.S. Effects of particle size and surface modification on cellular uptake and biodistribution of polymeric nanoparticles for drug delivery. Pharm. Res. 2013, 30, 2512–2522. [Google Scholar] [CrossRef] [PubMed]

- Sukamporn, P.; Baek, S.J.; Gritsanapan, W.; Chirachanchai, S.; Nualsanit, T.; Rojanapanthu, P. Self-assembled nanomicelles of damnacanthal-loaded amphiphilic modified chitosan: Preparation, characterization and cytotoxicity study. Mater. Sci. Eng. C 2017, 77, 1068–1077. [Google Scholar] [CrossRef] [PubMed]

- Ritsema, J.; Herschberg, E.; Borgos, S.; Løvmo, C.; Schmid, R.; Te Welscher, Y.; Storm, G.; van Nostrum, C.F. Relationship between polarities of antibiotic and polymer matrix on nanoparticle formulations based on aliphatic polyesters. Int. J. Pharm. 2018, 548, 730–739. [Google Scholar] [CrossRef] [PubMed]

- Kietzmann, D.; Béduneau, A.; Pellequer, Y.; Lamprecht, A. pH-sensitive microparticles prepared by an oil/water emulsification method using n-butanol. Int. J. Pharm. 2009, 375, 61–66. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Tai, G.X.; Liu, H.Y.; Ge, J.Y.; Feng, Y.; Chen, F.F.; Yu, F.; Liu, Z.H. Activin A down-regulates the phagocytosis of lipopolysaccharide-activated mouse peritoneal macrophages in vitro and in vivo. Cell. Immunol 2009, 255, 69–75. [Google Scholar] [CrossRef] [PubMed]

- Cao, X.L.; Cheng, C.; Ma, Y.L.; Zhao, C.S. Preparation of silver nanoparticles with antimicrobial activities and the researches of their biocompatibilities. J. Mater. Sci. Mater. Med. 2010, 21, 2861–2868. [Google Scholar] [CrossRef] [PubMed]

- Opanasopit, P.; Ngawhirunpat, T.; Chaidedgumjorn, A.; Rojanarata, T.; Apirakaramwong, A.; Phongying, S.; Choochottiros, C.; Chirachanchai, S. Incorporation of camptothecin into N-phthaloyl chitosan-g-mPEG self-assembly micellar system. Eur. J. Pharm. Biopharm. 2006, 64, 269–276. [Google Scholar] [CrossRef] [PubMed]

- Naksuriya, O.; Shi, Y.; van Nostrum, C.F.; Anuchapreeda, S.; Hennink, W.E.; Okonogi, S. HPMA-based polymeric micelles for curcumin solubilization and inhibition of cancer cell growth. Eur. J. Pharm. Biopharm. 2015, 94, 501–512. [Google Scholar] [CrossRef] [PubMed]

- Malarvizhi, G.L.; Retnakumari, A.P.; Nair, S.; Koyakutty, M. Transferrin targeted core-shell nanomedicine for combinatorial delivery of doxorubicin and sorafenib against hepatocellular carcinoma. Nanomed. Nanotechnol. Biol. Med. 2014, 10, 1649–1659. [Google Scholar] [CrossRef] [PubMed]

| NSA:NOLA:NFA:Np-TI | Time (h) | Temp (°C) | pH | DS (%) | Yield (%) |

|---|---|---|---|---|---|

| 1:0.4:0.4:0.5 | 24 | 25 | 3.6 | 9.5 | 61.8 |

| 1:0.8:0.8:1.0 | 24 | 25 | 3.6 | 14.6 | 62.7 |

| 1:1.2:1.2:1.4 | 24 | 25 | 3.6 | 20.4 | 74.0 |

| 1:1.4:1.4:1.6 | 24 | 25 | 3.6 | 20.5 | 78.5 |

| 1:1.2:1.2:1.4 | 24 | 37 | 3.6 | 19.1 | 76.4 |

| 1:1.2:1.2:1.4 | 24 | 25 | 4.8 | 16.4 | 68.2 |

| 1:1.2:1.2:1.4 | 24 | 25 | 6.0 | 13.1 | 51.5 |

| Sample | C (%) | H (%) | N (%) | DS (%) |

|---|---|---|---|---|

| SA | 30.60 | 5.96 | 0.005 | - |

| Ugi-FOlT9.5 | 33.78 | 7.26 | 0.87 | 9.5 |

| Ugi-FOlT14.6 | 35.45 | 7.14 | 1.20 | 14.6 |

| Ugi-FOlT20.4 | 38.34 | 6.97 | 1.57 | 20.4 |

| Sample | Size (nm) | PDI | Zeta Potential (mV) |

|---|---|---|---|

| Ugi-FOlT9.5 | 710 ± 40 | 0.38 ± 0.03 | −58.2 ± 1.9 |

| Ugi-FOlT14.6 | 670 ± 35 | 0.35 ± 0.05 | −53.5 ± 2.1 |

| Ugi-FOlT20.4 | 653 ± 25 | 0.31 ± 0.04 | −48.9 ± 2.8 |

| Solution | λmax (nm) | Standard Curve Equation | R2 |

|---|---|---|---|

| PBS (pH 7.4) | 222 | A = 0.04909C + 0.02814 | 0.99928 |

| PBS (pH 5.0) | 222 | A = 0.01520C + 0.06280 | 0.99683 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bu, Y.; Chen, X.; Wu, T.; Zhang, R.; Yan, H.; Lin, Q. Synthesis, Optimization and Molecular Self-Assembly Behavior of Alginate-g-Oleylamine Derivatives Based on Ugi Reaction for Hydrophobic Drug Delivery. Int. J. Mol. Sci. 2024, 25, 8551. https://doi.org/10.3390/ijms25158551

Bu Y, Chen X, Wu T, Zhang R, Yan H, Lin Q. Synthesis, Optimization and Molecular Self-Assembly Behavior of Alginate-g-Oleylamine Derivatives Based on Ugi Reaction for Hydrophobic Drug Delivery. International Journal of Molecular Sciences. 2024; 25(15):8551. https://doi.org/10.3390/ijms25158551

Chicago/Turabian StyleBu, Yanan, Xiuqiong Chen, Ting Wu, Ruolin Zhang, Huiqiong Yan, and Qiang Lin. 2024. "Synthesis, Optimization and Molecular Self-Assembly Behavior of Alginate-g-Oleylamine Derivatives Based on Ugi Reaction for Hydrophobic Drug Delivery" International Journal of Molecular Sciences 25, no. 15: 8551. https://doi.org/10.3390/ijms25158551