Structural Features, Chemical Diversity, and Physical Properties of Microporous Sodalite-Type Materials: A Review

Abstract

1. Introduction

2. Synthesis

2.1. Synthesis of Sodalite and Basic Sodalite

2.2. Synthesis of Other Sodalite-Related Materials

3. Crystallography, Crystal Chemistry, and Intra-Cage Chemical Conversions of Sodalite-Type Compounds

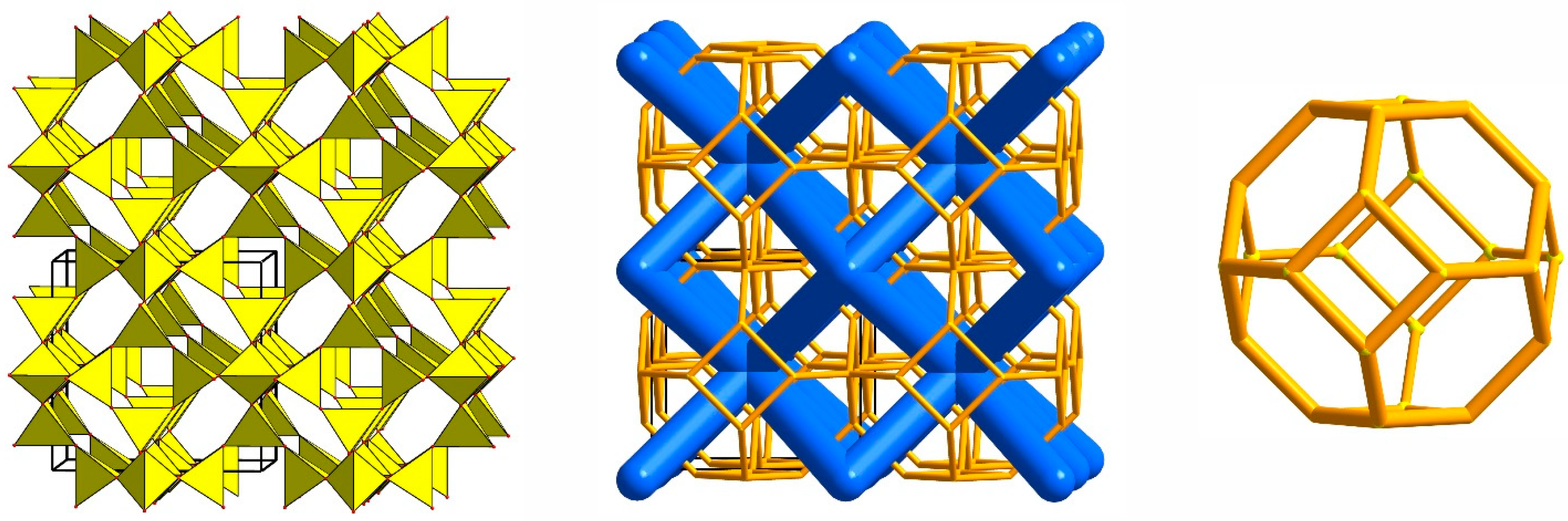

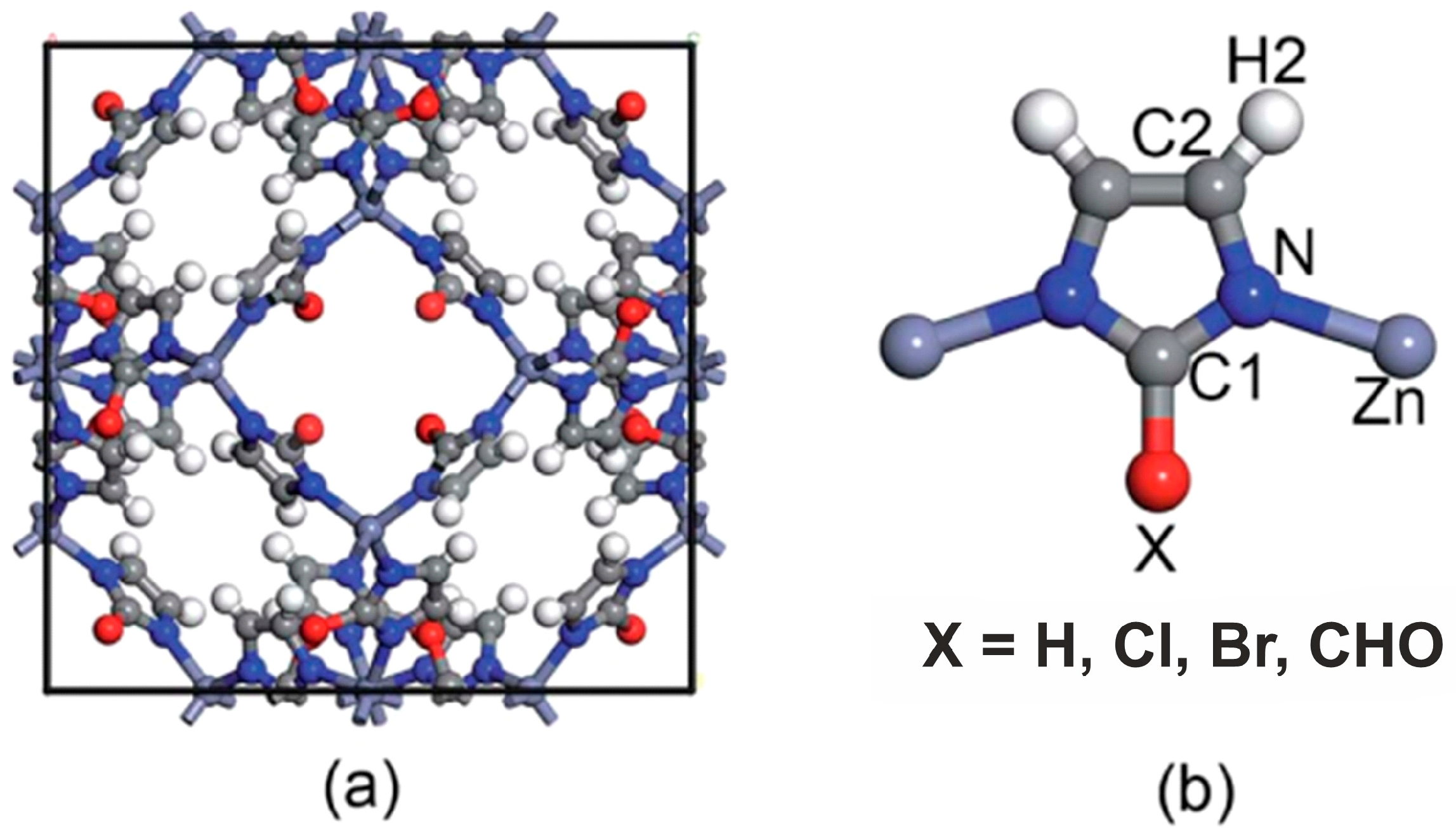

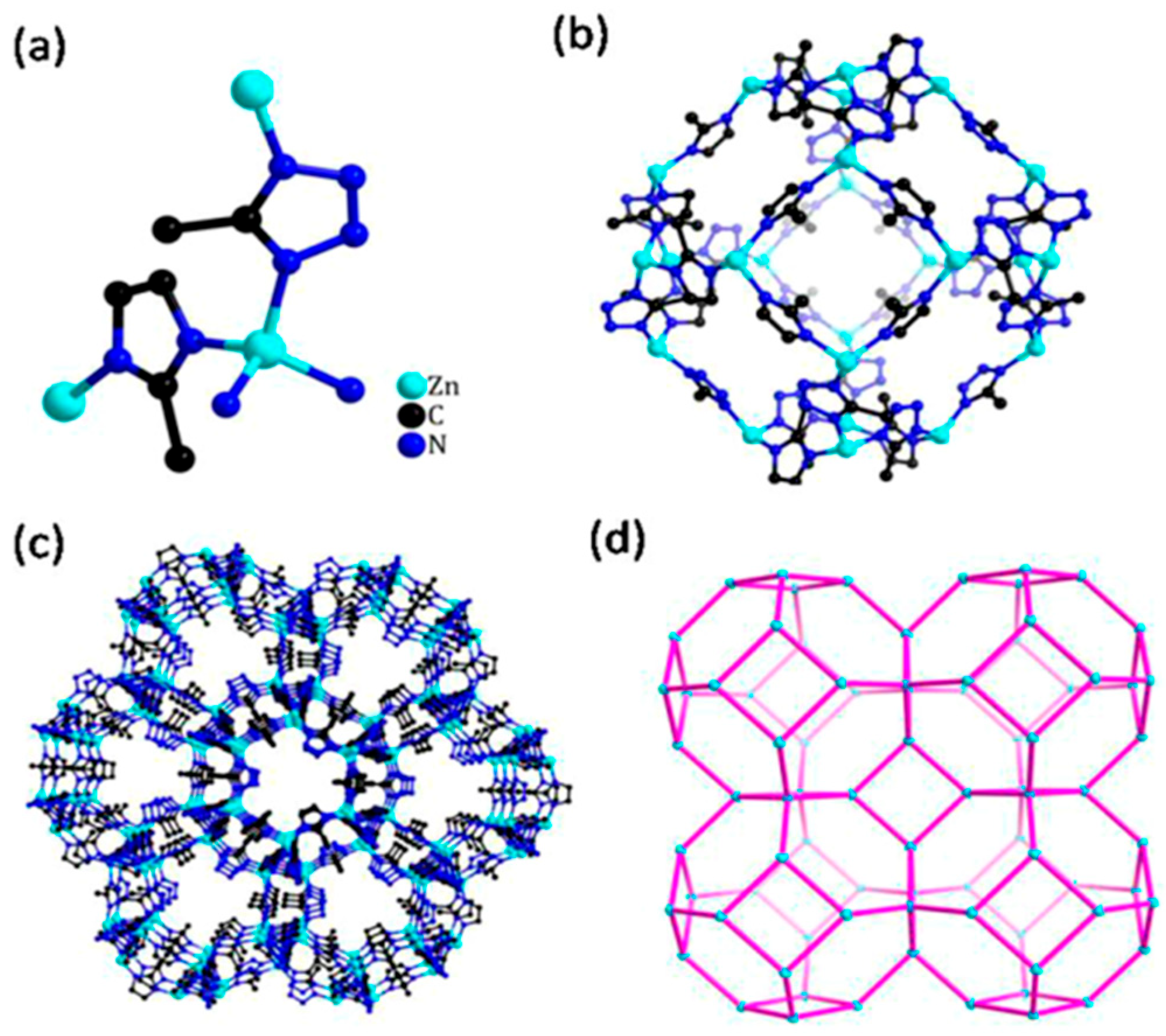

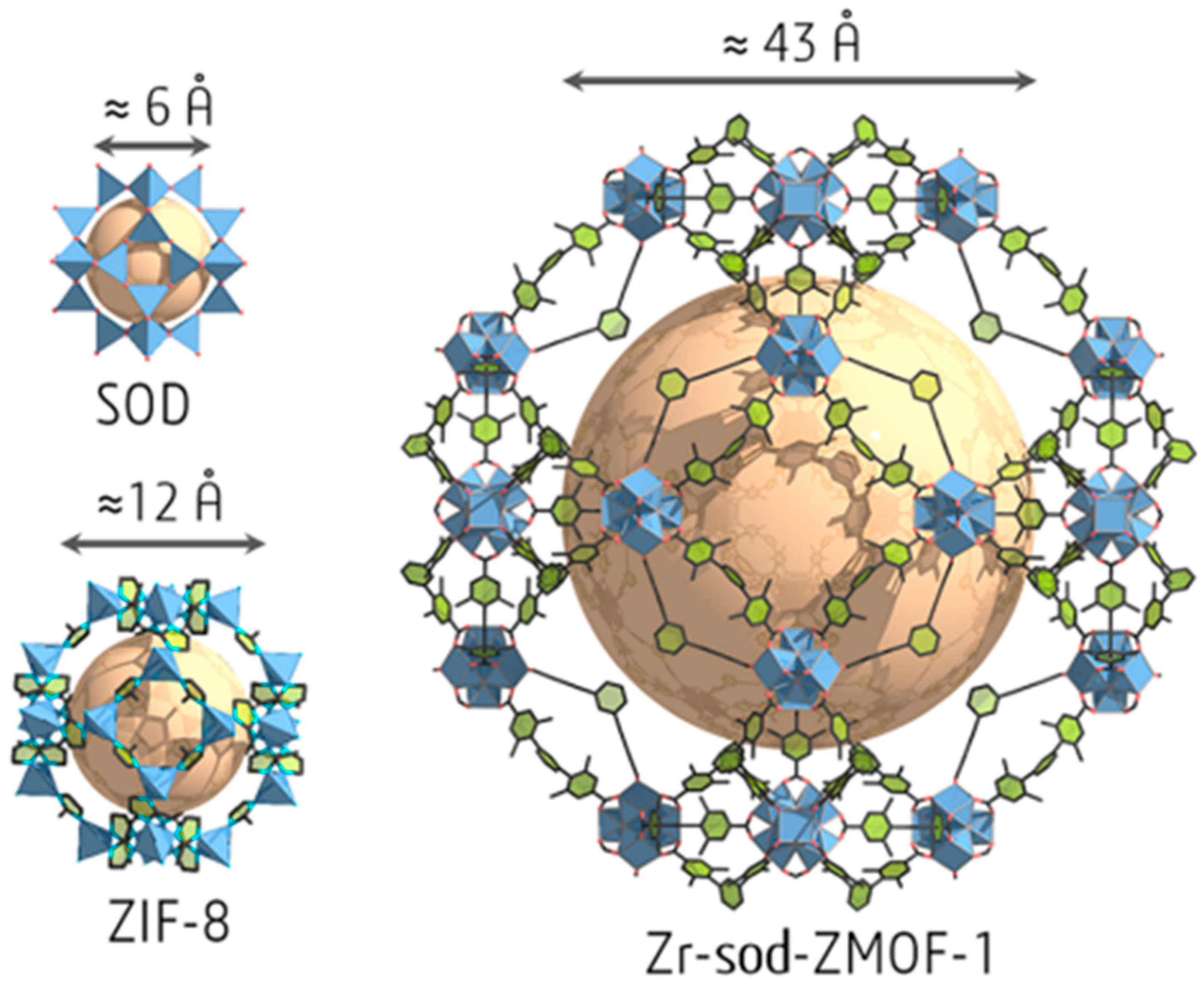

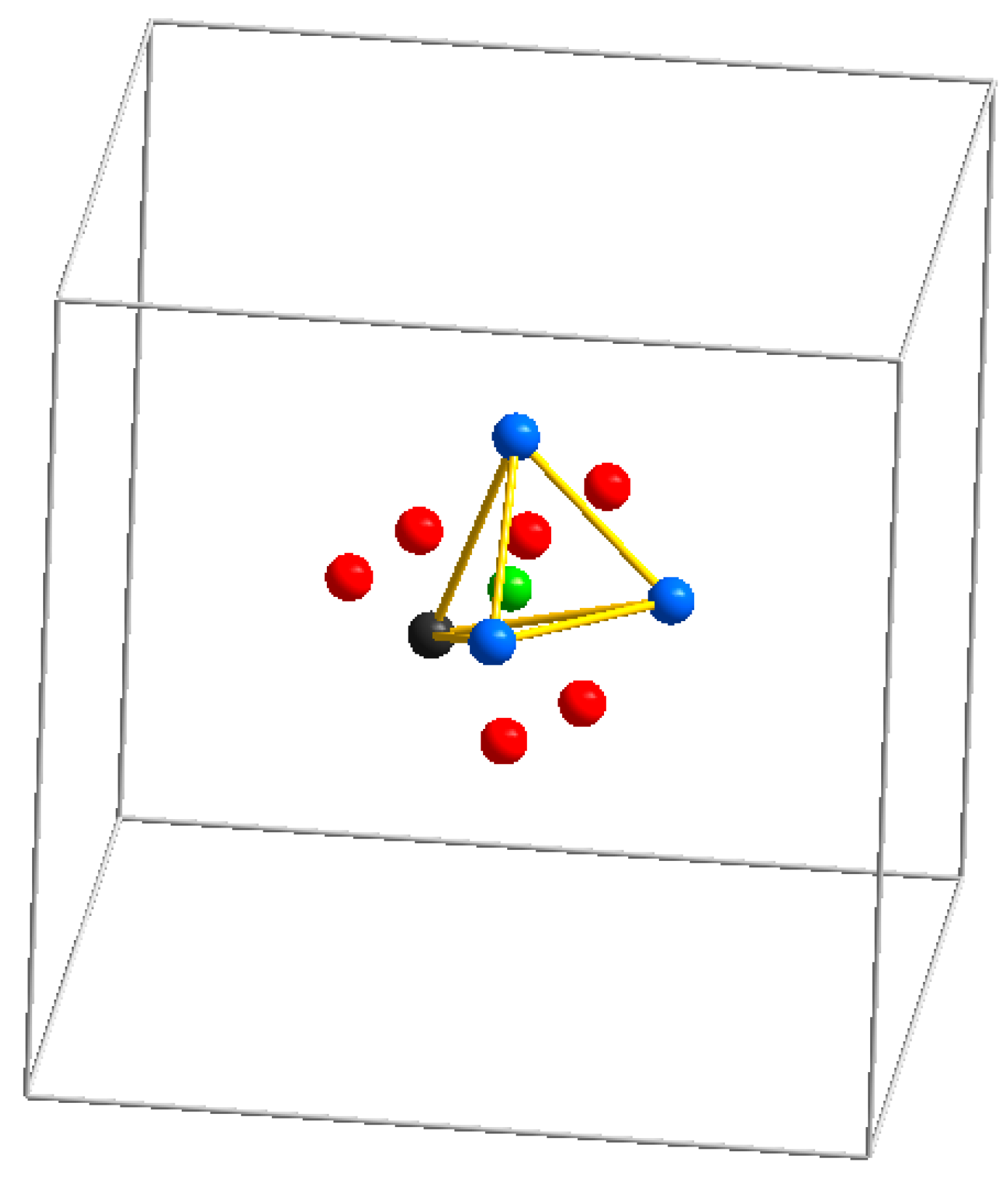

3.1. SOD-Type Topology of Zeolites and Related Materials

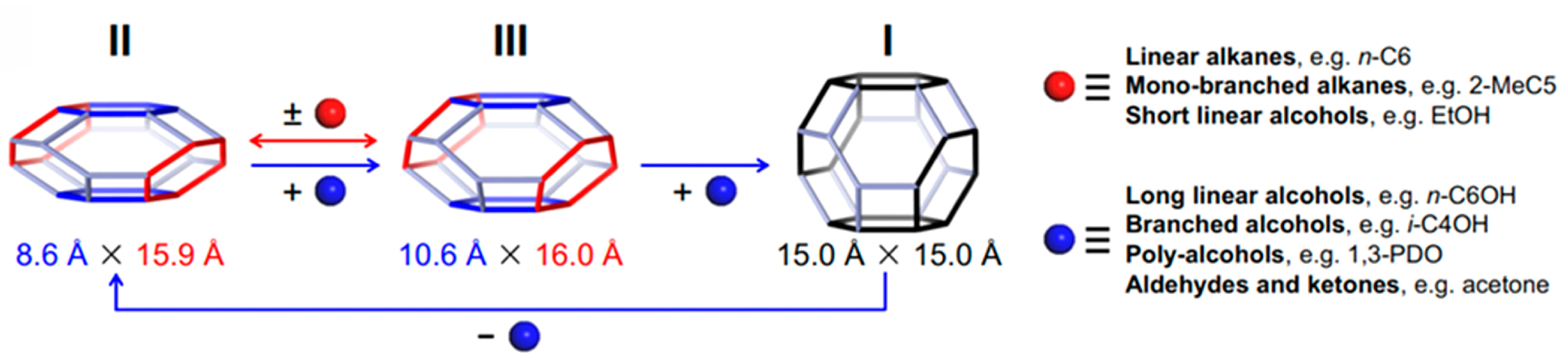

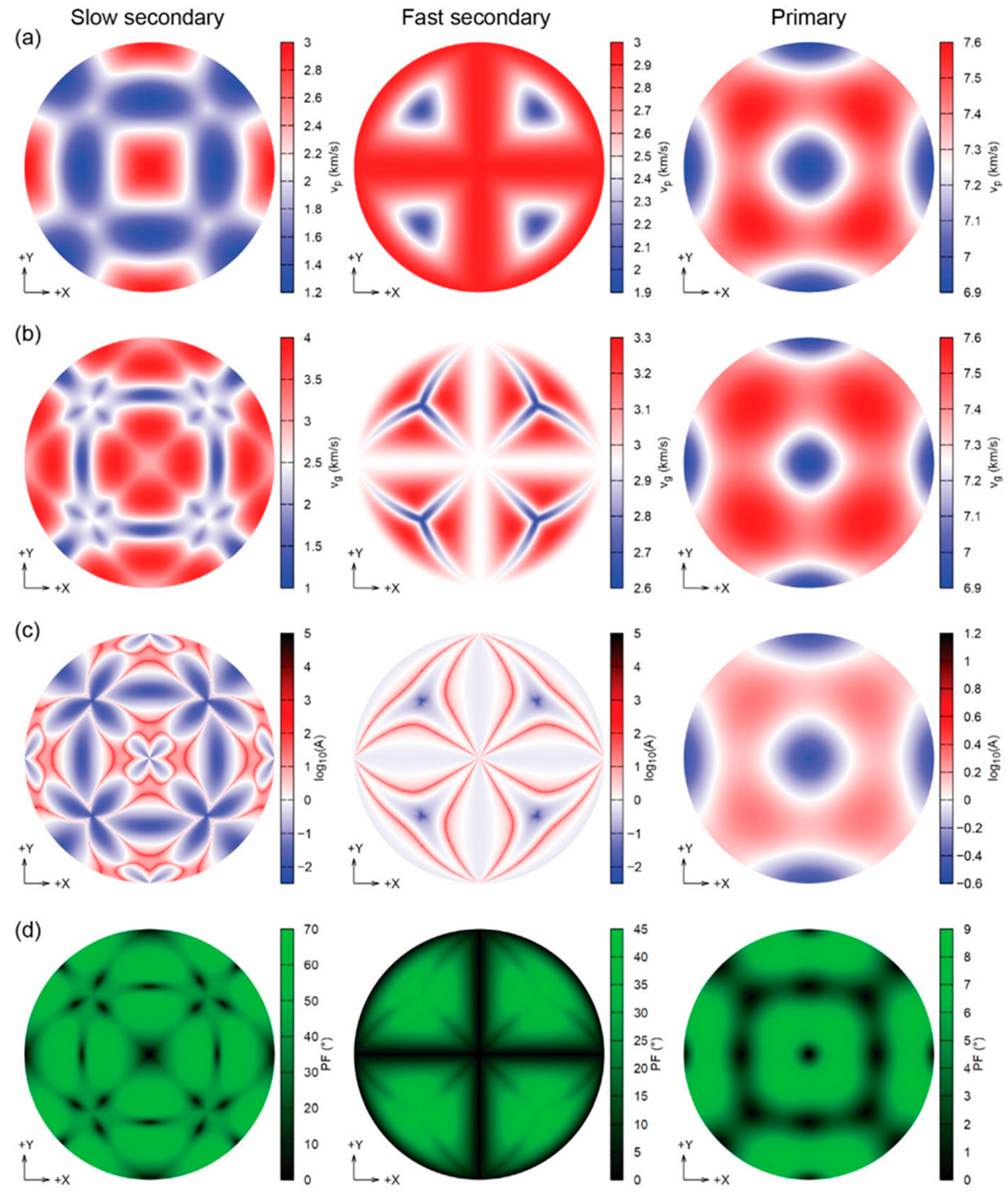

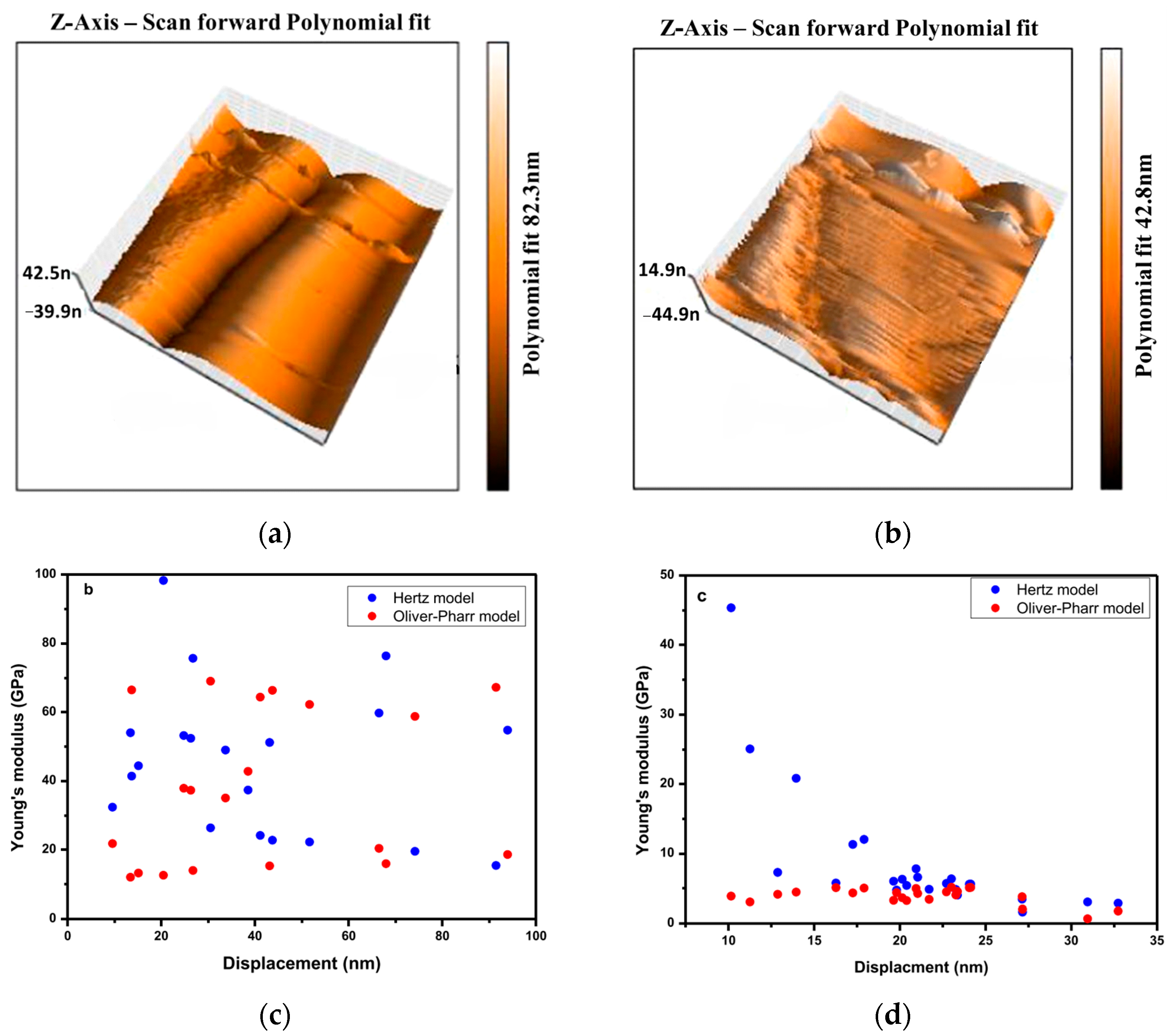

3.2. Framework Composition, Elasticity and Porosity

3.3. Inorganic and Organic Guest Species in the Sodalite Cages

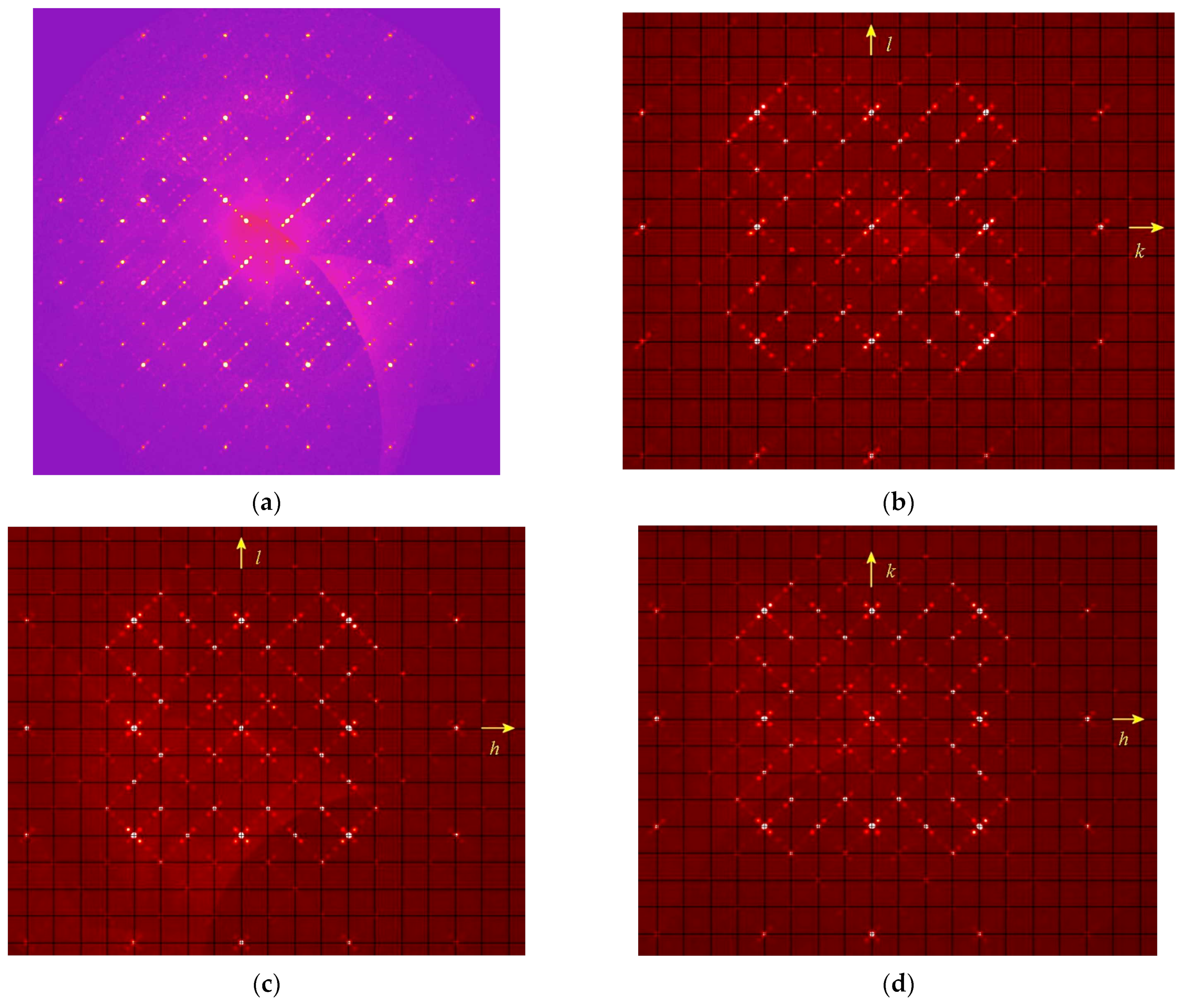

3.4. Symmetry, Structure Modulations, and Twinning

3.5. Intracage Reactions Involving H, S, C, N, B, Cl, and Mn in Sodalite-Type Compounds

4. Properties and Application of Sodalite-Related Materials

4.1. Ion Exchange; Immobilization of Heavy Metals and Redionuclides

4.2. Hydrogen and Methane Storage

4.3. Gas Sorption; Sodalite-Related Membranes

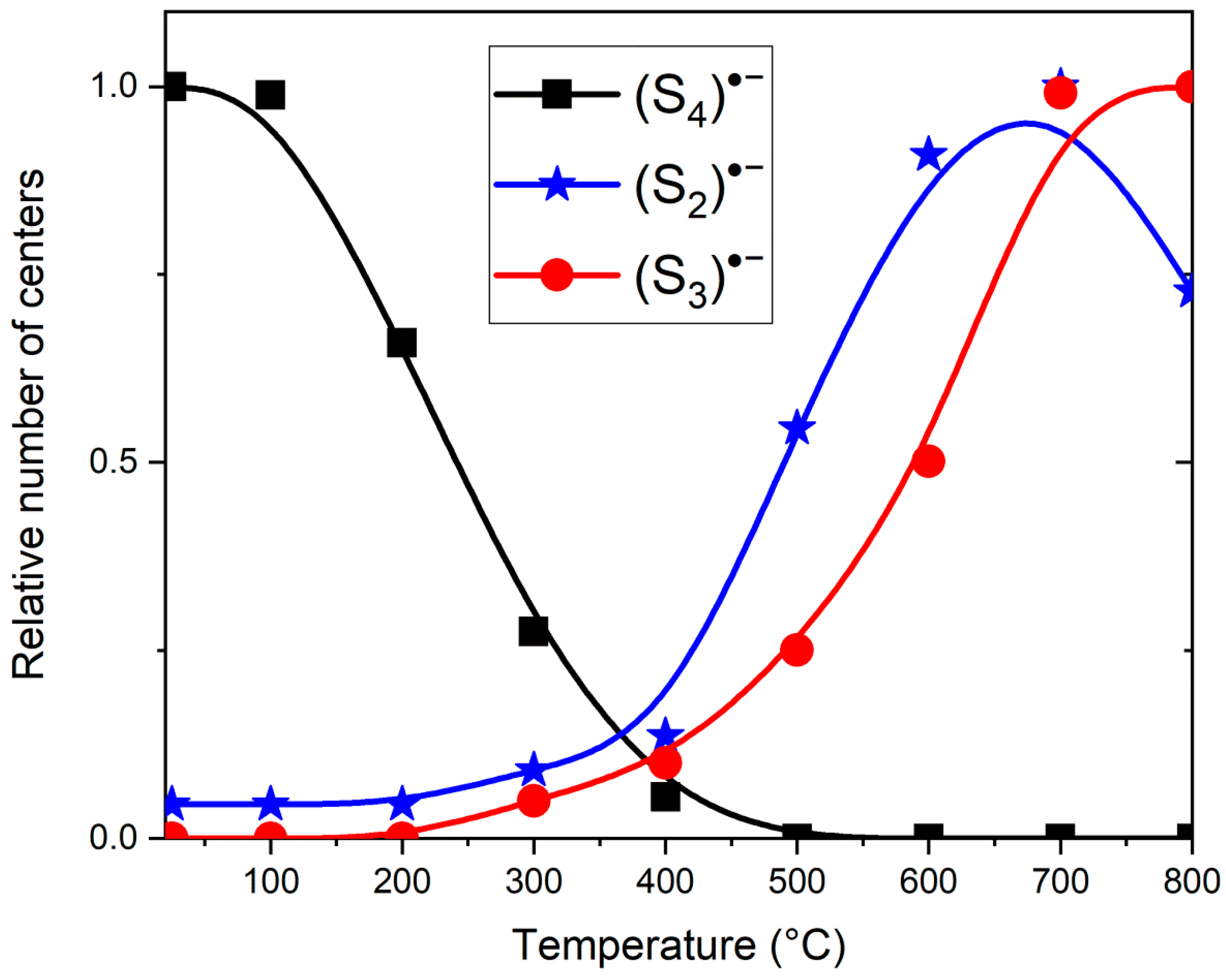

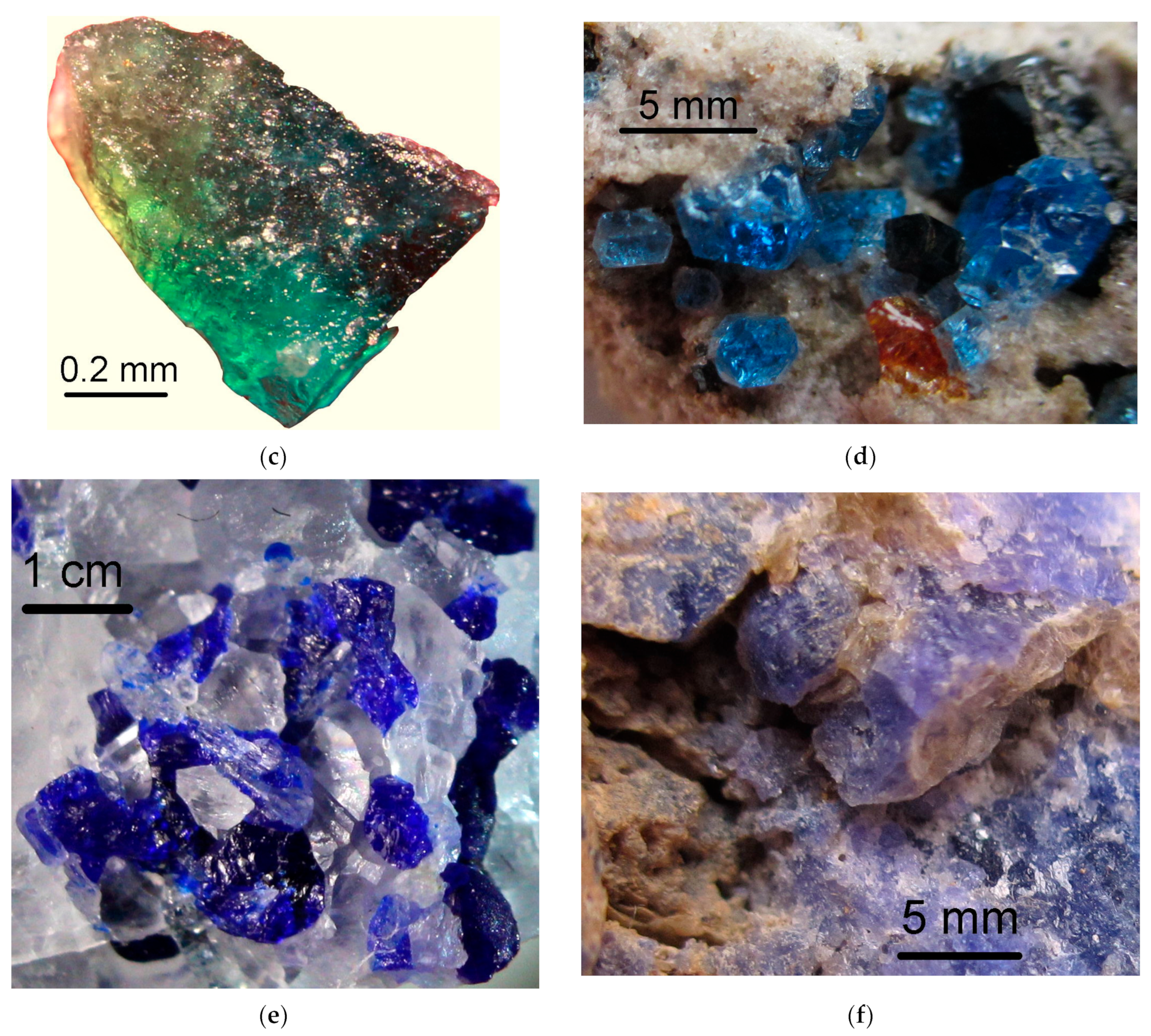

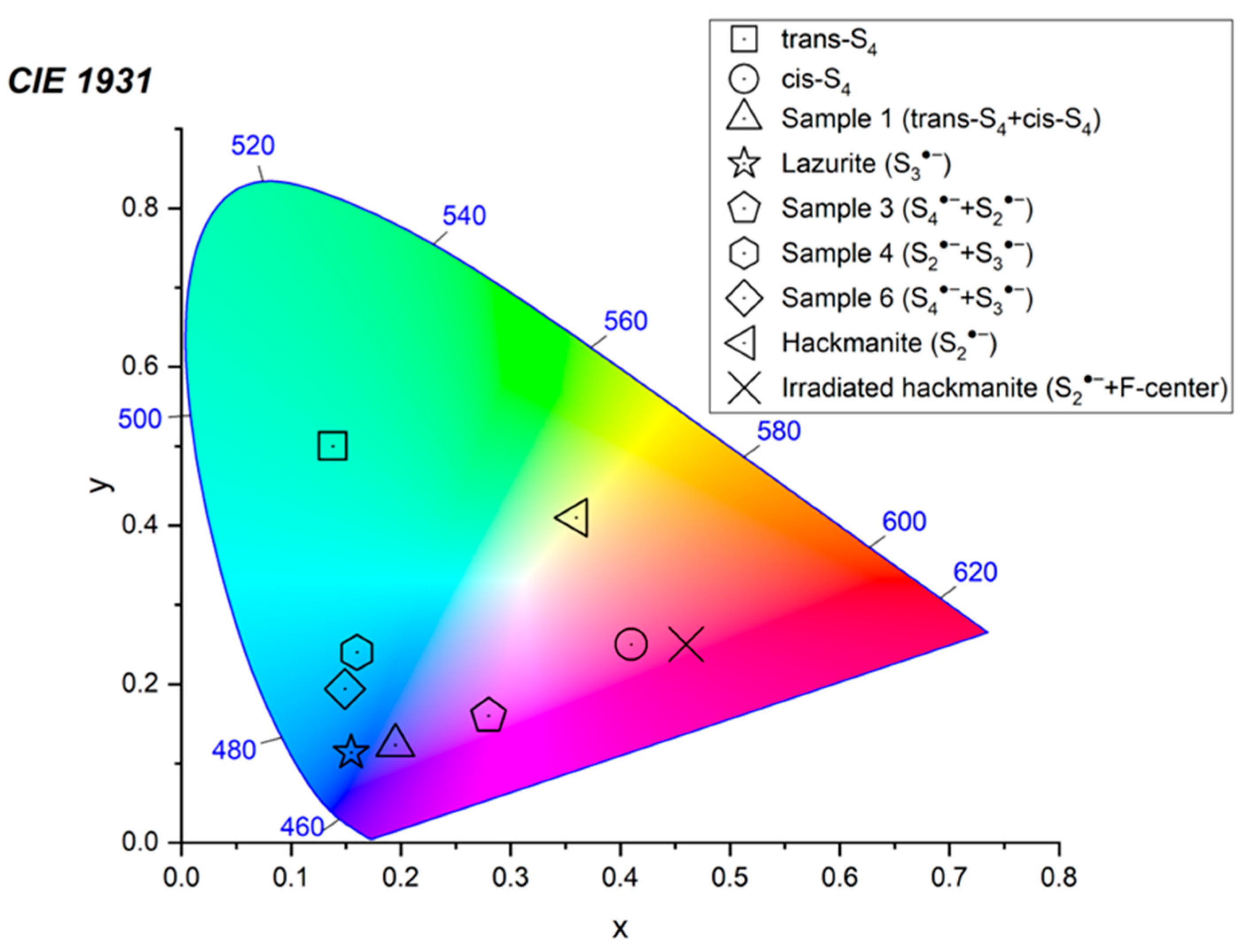

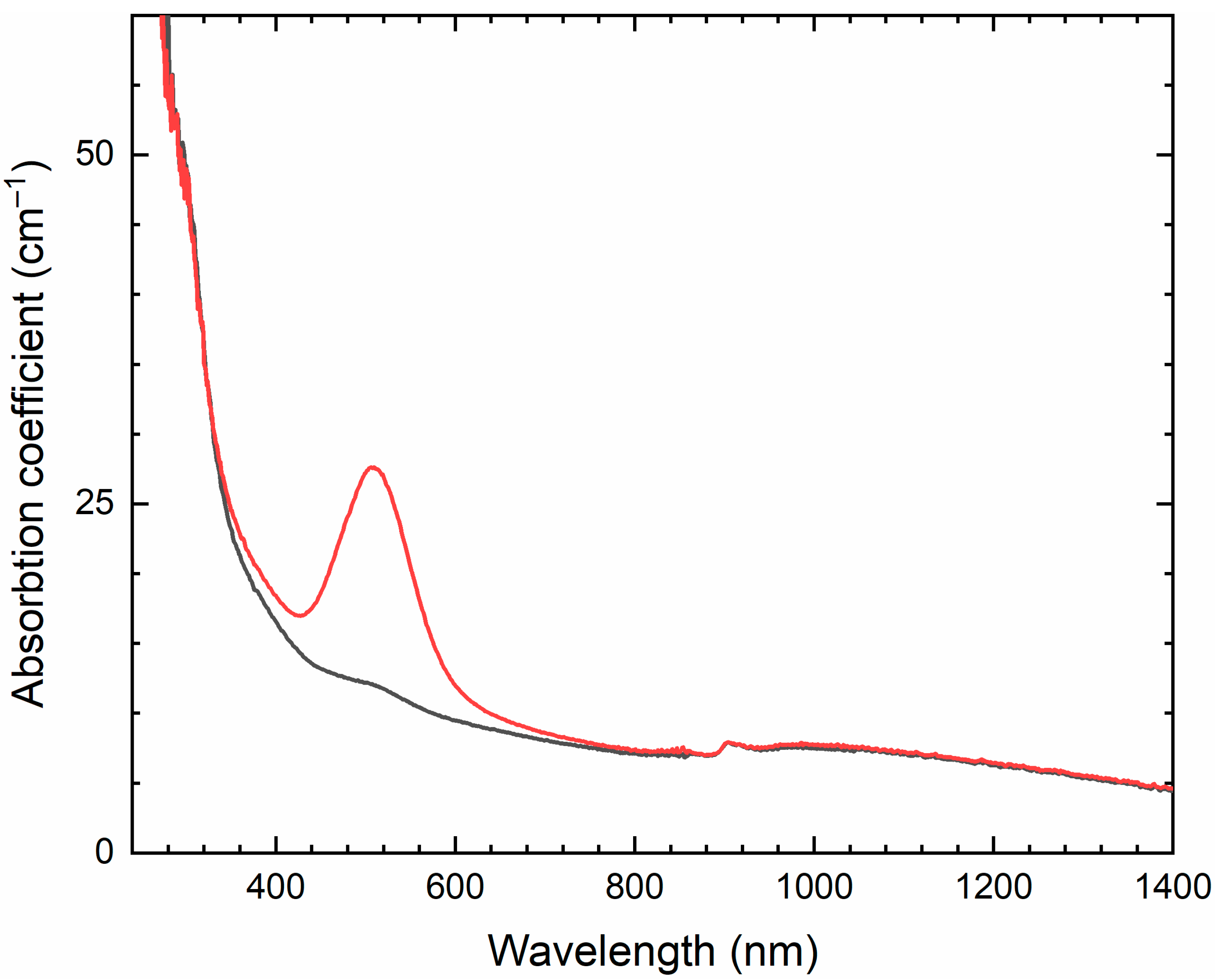

4.4. Color Centers, Optical Properties, and Luminescence; Sodalite-Based Pigments

4.5. Application of Sodalite-Related Materials for Organic Synthesis

4.6. Electroconductivity

4.7. Magnetic Properties

4.8. Thermal Properties and Thermal Conversions

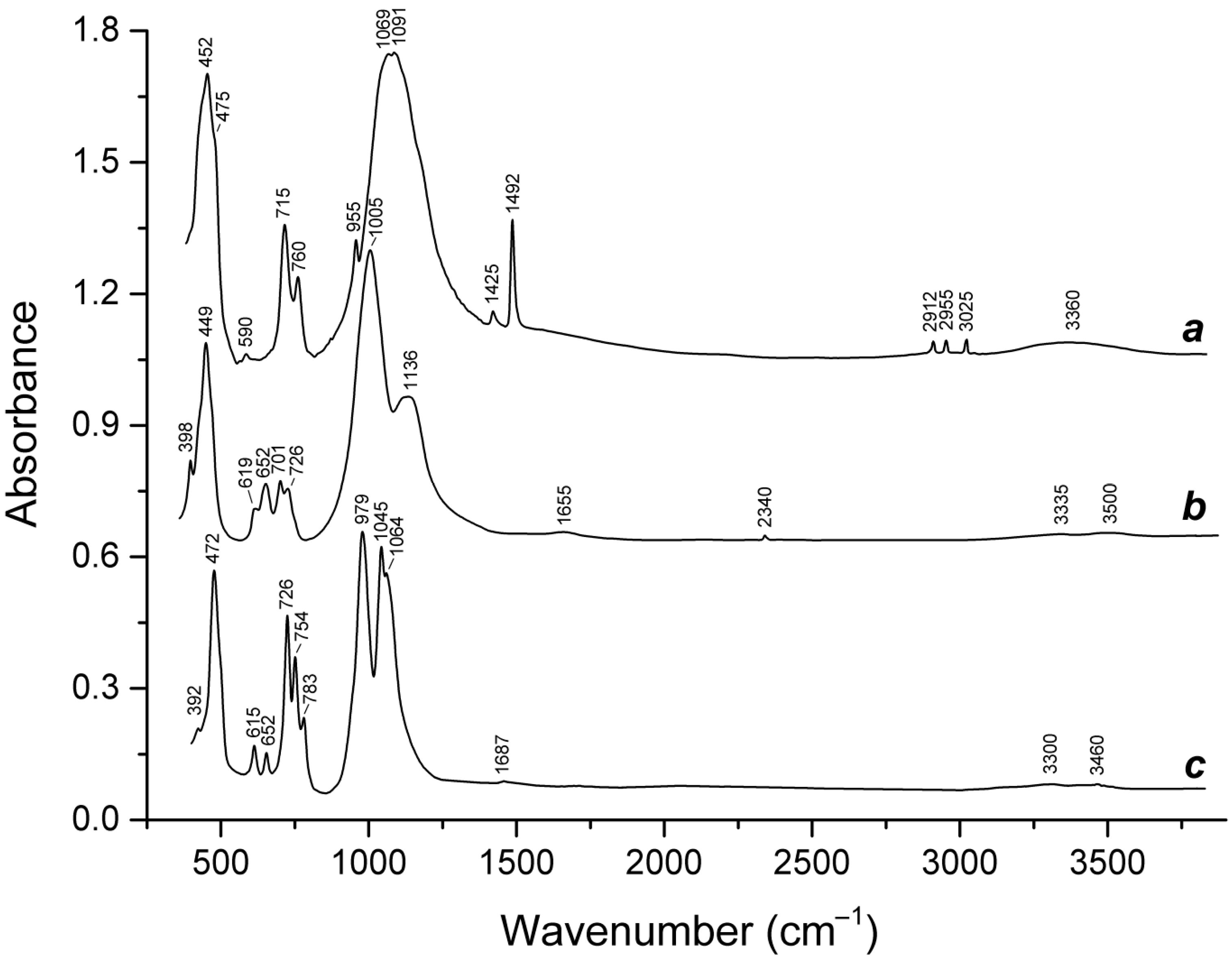

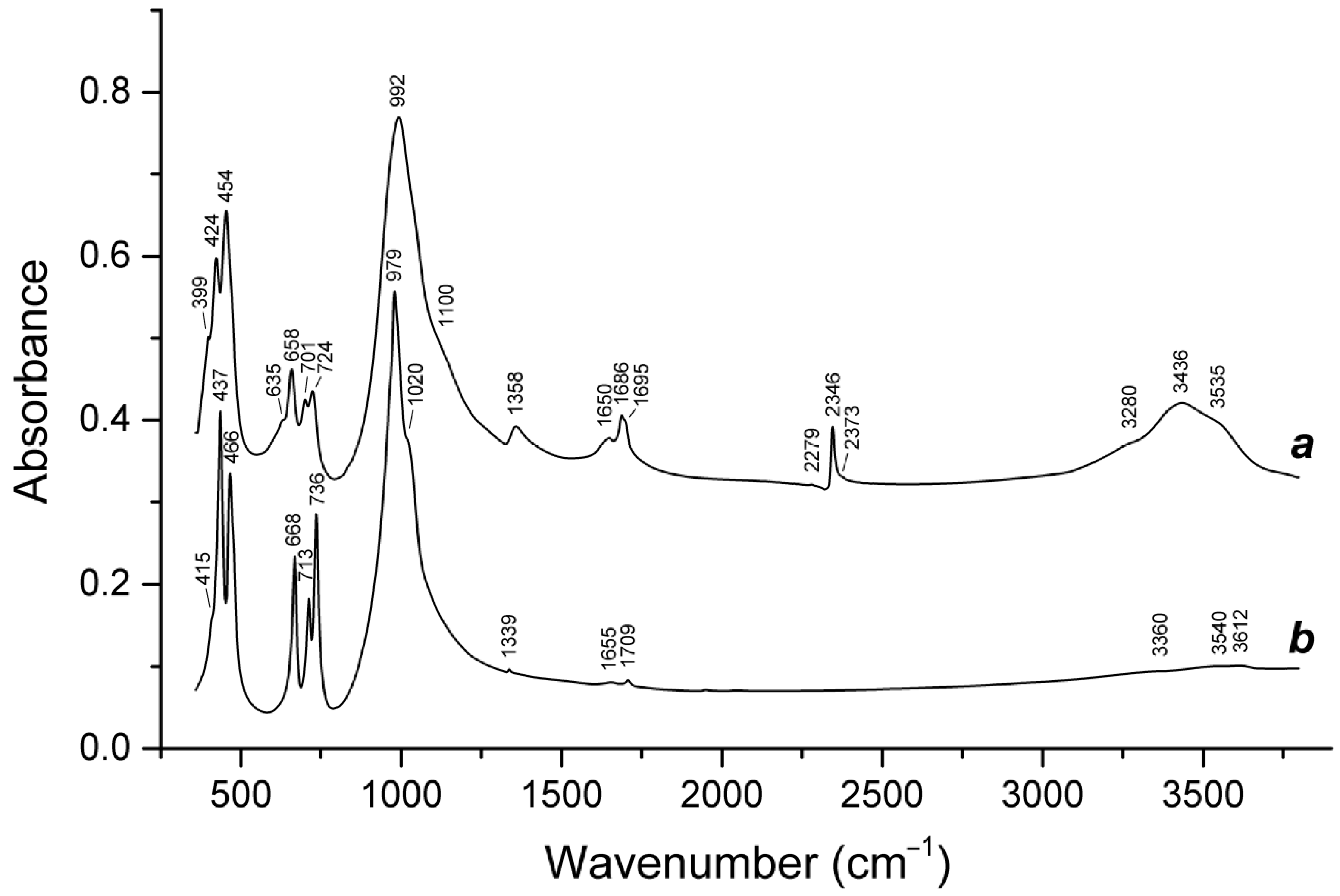

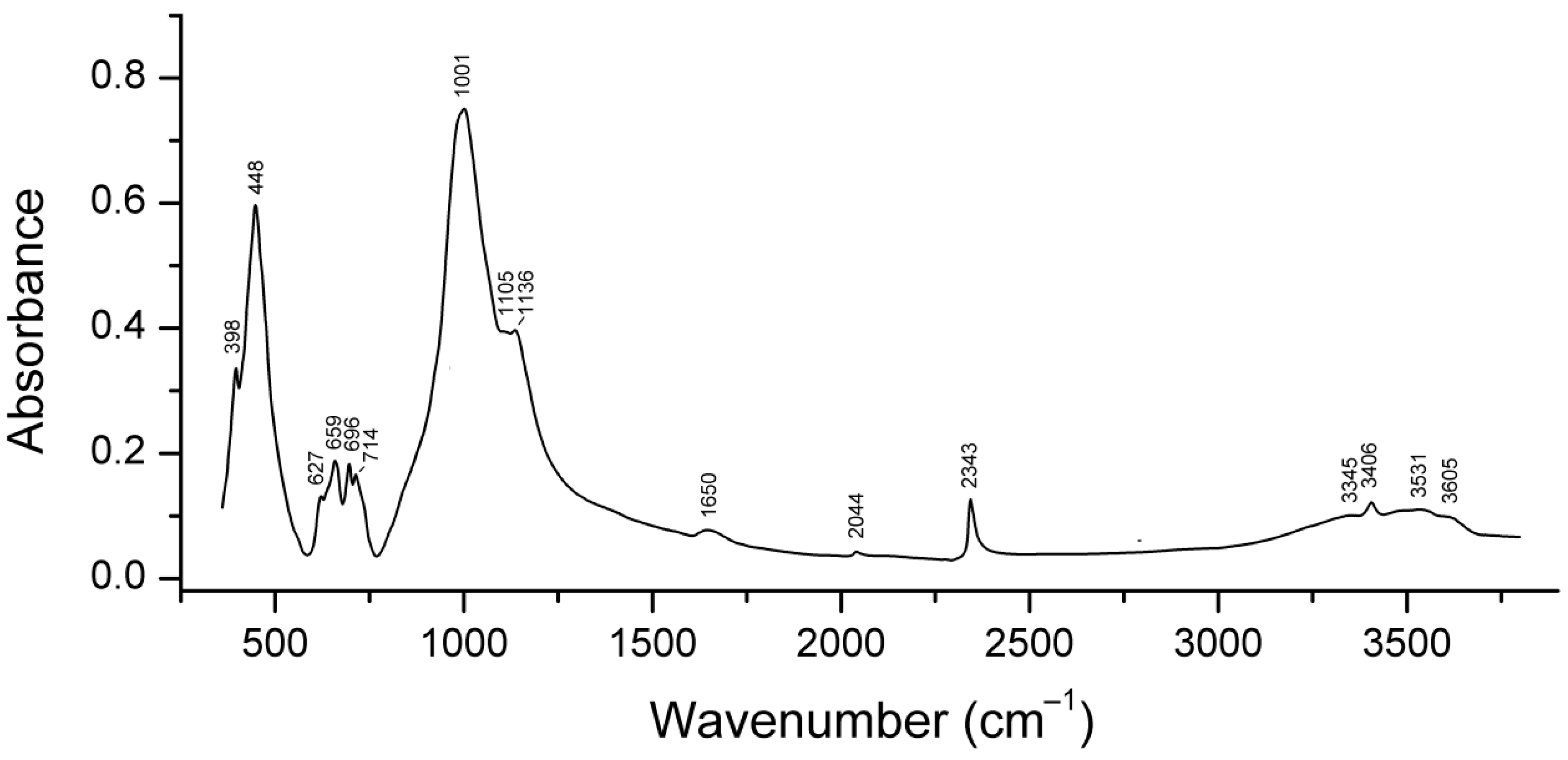

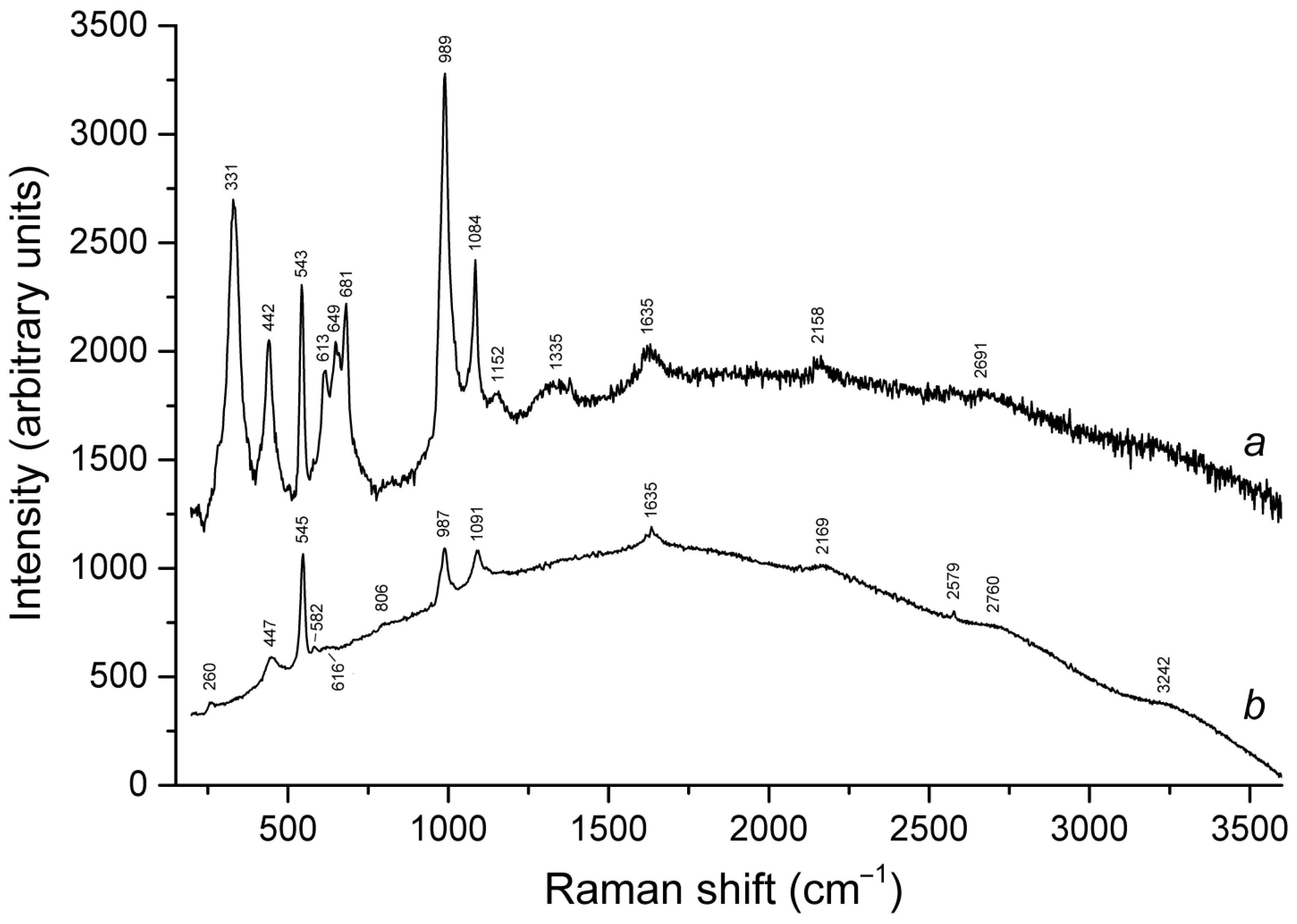

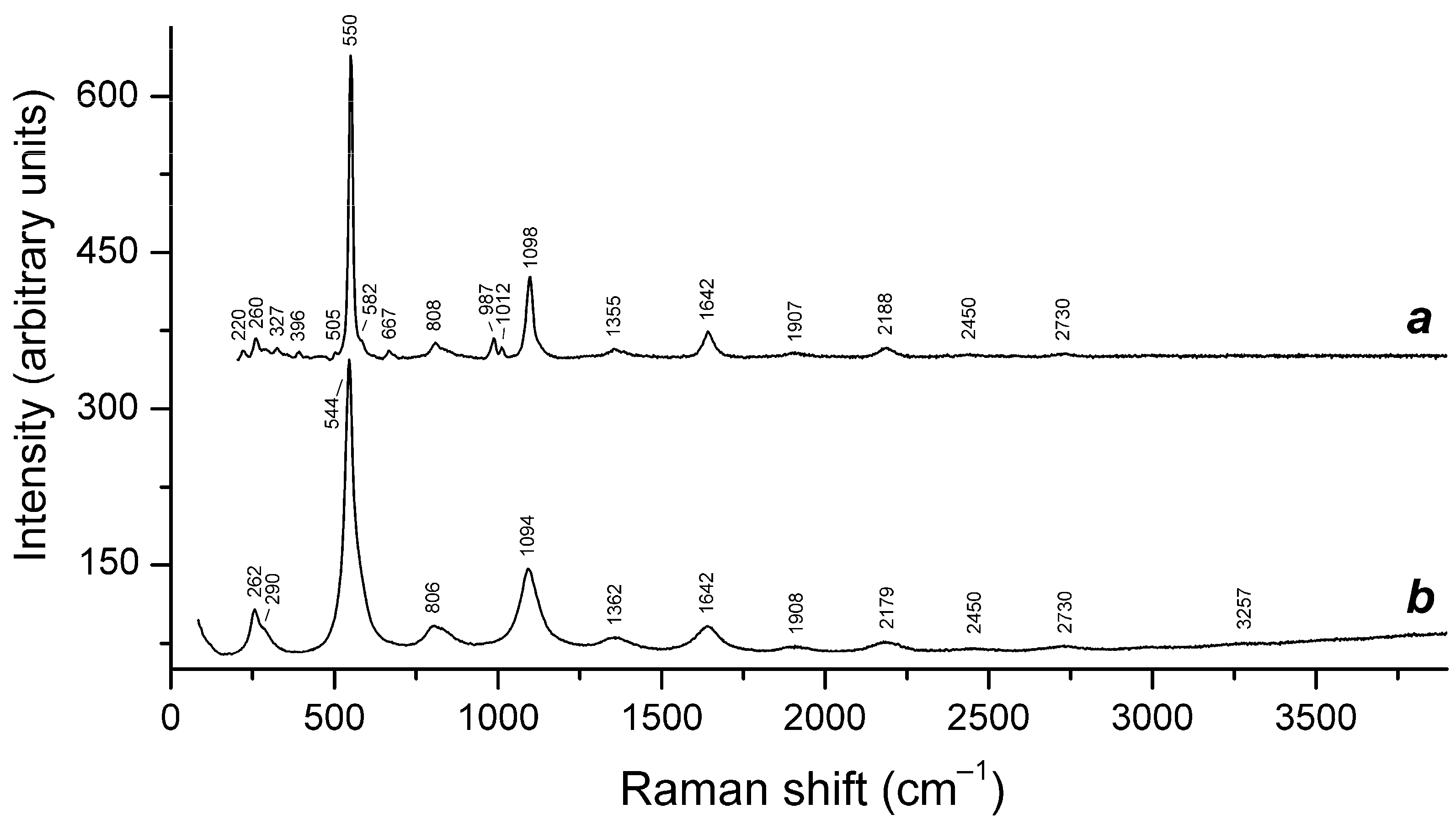

4.9. Vibrational Spectroscopy of Sodalite-Group Minerals

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Kind of the Framework | Formula | Synthesis Conditions (If Available) | References |

|---|---|---|---|

| [Al–Si–O] | Na8(Al6Si6O24)(HS)2 | Synthesized hydrothermally from kaolin, Na2S·10H2O, and NaOH at 180 °C to 230 °C for 16–24 h. | [26] |

| Na8(Al6Si6O24)(NO3)2 | First, dry gel was prepared by the addition of a solution of aluminum nitrate ethanol solution to a solution of tetraethylorthosilicate. The mixture was held at 70 °C for 17 h, then dried in air at 120 °C for 2 h. The final product was synthesized hydrothermally from the dry gel, at 90 °C for 3 h in the presence of NaOH. | [387] | |

| Na8(Al6Si6O24)(OH)(CO3)0.5·3H2O | Synthesized in the Na2O-SiO2-Al2O3-Na2CO3-H2O system in the presence of 8M NaOH solution, under hydrothermal conditions, at 80 °C. | [372] | |

| Na8(Al6Si6O24)(CO3) | Synthesized in a two-step anion exchange reaction at 700–800 °C in a CO2 atmosphere using basic nitrite sodalite as a starting material. | [372] | |

| Na8(Al6Si6O24)Cl2−xIx | Prepared hydrothermally using zeolite A as a starting material with different proportions of NaCl and NaI, along with appropriate amount of NaOH, at 100 °C for one week. The products obtained were then heated at 300 °C to evaporate adsorbed water. | [388] | |

| Na8(Al6Si6O24)I2 | Prepared hydrothermally from AgI and Zeolite 13 X at 150 °C for 48 h. | [186] | |

| Rb2K6(Al6Si6O24)(OH)2 | Ion exchange of the Na analogue with K and Rb nitrate solutions. | [339] | |

| Na8(Al6Si6O24)(WO4)2 | Synthesized by heating a mixture of zeolite X and WO3 at 660 °C to 800 °C in air for 12 h. | [389] | |

| Na5.12Ca1.92[Al6Si6O24] (MoO4)1.52 | Prepared using a mixture of nepheline gel, anorthite gel, and Na2MoO4·2H2O; first reacted at 1200 °C and 4 kbar during 5–6 h and then at 750 °C and p = 3 kbar during 10 days. | [129] | |

| Na7.68[(Al,Si)12O24] [(Mo0.65W0.35)O4]0.78·H2O | Prepared using a mixture of nepheline gel, Na2MoO4·2H2O, and Na2WO4∙ 2H2O at 750 °C and 3 kbar. | [129] | |

| Na8(Al6Si6O24)(ReO4)2 | Synthesized in equilibrium with Na–Fe-rich aluminosilicate melt and Re metal at 1100 °C and 500 MPa. | [179] | |

| Na8−x(Al6Si6O24)(ReO4, CO3,SO4,MnO4,WO4,Cl)2−y | Synthesized from zeolite 4A in binary solutions containing ReO4 and a corresponding competing anion in the presence of NaOH, at 90 °C for 96 h. | [185] | |

| Na8[Al6Si6O24](ReO4,TcO4)2 | Synthesized using hydrothermal methods by treating zeolite 4A with 8 M NaOH in the presence different amounts of sodium perrhenate and/or sodium pertechnetate at 225 °C for 7 days. | [178] | |

| Na8[Al6Si6O24](ReO4)2 | Synthesized hydrothermally from NaAlO2, Na2SiO3·9H2O, and NaReO4, in the presence of NaOH at 175 °C for 24 h. | [130] | |

| Na8[Al6Si6O24](ReO4,NO3)2 | Synthesized hydrothermally from zeolite A in sodium hydroxide, nitrate, and perrhenate solutions at 90 °C for 24 h. | [181,182] | |

| Na8[Al6Si6O24](SO4)·nH2O | Obtained by precipitation of the desilication product, LTA zeolite, in synthetic Bayer liquor prepared from gibbsite, at 90 °C, in the presence of Na2SO4. | [390] | |

| Ca8(Al12O24)(SO4)2 | Synthesized in a solid-state reaction at 1300 °C using calcite, Al2O3, and gypsum as the starting materials. | [116] | |

| Na7+x[Si5+2xAl7–2xO24](AlF6)x(H2O)4–4x·4H2O (x = 0–1). | Synthesized hydrothermally in the Si–Al–Na–H–O–F system at temperatures of 400–800 °C and H2O pressures of 1–2 kbar. The crystal structure is solved. | [131] | |

| Na7.38[Si6.74Al5.26O24] (AlF6)0.70(H2O)4–4x·4.88H2O | Synthesized hydrothermally from a mixture of nepheline gel and NaF, in the presence of natural sodalite added as a seed, at 650 °C and H2O pressure of 2 kbar. The crystal structure is solved. | [132] | |

| Ag8[Al6Si6O24]I2 | Iodine was captured from the vapour phase using a silver exchanged zrolite and converted to sodalite in hot-isostatic pressing canisters. | [190] | |

| Na8(Al6Si6O24)(NO2)2 | Prepared hydrothermally from kaolin, sodium nitrite, and NaOH at 570 K and 0.1 GPa. | [174] | |

| Na7.7(Al6Si6O24)6(MnO4)1.7 ·0.8H2O | Synthesized hydrothermally from Na2SiO3, NaAlO2, and NaMnO4·H2O in a molar ratio of 1:1:2.6, in the presence of NaOH, at 80 °C, for 48 h. | [156] | |

| Na6Mn2[Al6Si6O24](SO4)2 | Prepared by reacting zeolite A, Na6(Al6Si6O24), with MnSO4 as a compacted mixed-powder monolith at 650 °C under air. | [391] | |

| Na6Zn2[Al6Si6O24](SO4)2 | Prepared in a solid-state reaction of a charge containing appropriate amounts of ZnSO4·H2O and zeolite A at 700 °C for 8 h. | [369] | |

| Li8[Al6Si6O24]Cl2 | No data. | [392] | |

| Li7.4Na0.6[Al6Si6O24](ClO4)2 | Prepared by ion exchange of the sodium perchlorate sodalite (synthesized hydrothermally from the sodium silicate glass, NaClO4 and NaOH at 120 °C under reflux, for 24 h) with LiCl solution at 110 °C for 48 h. | [393] | |

| Na8(Al6Si6O24)Br2 | Synthesized hydrothermally from fly ash and NaBr at 500–550 °C for 2 h. | [394] | |

| (Na,Ag)8[Al6Si6O24]X2 (X = Cl, Br, I) | Aqueous exchanges were used to replace Na+ by Ag+ in hydrothermally synthesized Na8[Al6Si6O24]X2 sodalites (X = Cl, Br, I). | [395,396] | |

| Na8[Si6Al6O24]6·(ClO4)2 | Synthesized by addition of sodium aluminate solution to a concentrated solution of sodium perchlorate and sodium silicate. | [377] | |

| Na8[Si6Al6O24]6·(ClO4)2 | Synthesized by addition of sodium aluminate solution to a concentrated solution of sodium perchlorate and sodium silicate. | [152] | |

| K7.7Na0.3[Al6Si6O24](ClO4)2 | Prepared by ion exchange of the sodium perchlorate sodalite (synthesized hydrothermally from the sodium silicate glass, NaClO4 and NaOH at 120 °C under reflux, for 24 h) with KCl solution at 110 °C for 48 h. | [393] | |

| Na8[Al6Si6O24](XO4)2 (X = Cl, Mn, Re) | Partly prepared hydrothermally from NaAlO2, Na2SiO3 and corresponding Na salts (perchlorate, permanganate, and perrhenate), at 230 °C for perrhenate. | [183,397] | |

| Na8[Al6Si6O24](XO4)2 (X = Cl, Mn) | Synthesized hydrothermally from the sodium silicate glass and NaClO4 or NaMnO4 in the presence of NaOH at 120 °C under reflux, for 24 h. | [393] | |

| Na8−xLix[Al6Si6O24](ClO3)2−y(OH)y | Obtained by aqueous cation exchange of a pure sodium analogue. | [398] | |

| K8−xNax[Al6Si6O24](XO3)2−y(OH)y (X = Cl, Br) | Obtained by aqueous cation exchange of a pure sodium analogue. | [398] | |

| Na8[Al6Si6O24](XO3)2−y(OH)y (X = Cl, Br) | Synthesized by a low-temprtature hydrothermal method. | [398] | |

| Li8−xNax[Al6Si6O24](BrO3)2−y(OH)y | Obtained by aqueous cation exchange of a pure sodium analogue. | [398] | |

| Na8[Si6Al6O24]6·(IO3)2 | Synthesized by hydrothermal treatment from coal fly ash, NaIO3, and NaOH at 100 °C | [197] | |

| Na8[AlxGa6−xSi6O24](NO2)2 0 ≤ x ≤ 6) | Prepared hydrothermally from stoichiometric quantities of Na2SiO3, NaAlO2, NaGaO2, and NaNO2, in the presence of NaOH, at 200 °C for 48 h. | [399] | |

| K8[Al6Si6O24]Cl2 | No data. | [392] | |

| Ag6[Al6Si6O24] | Prepared by ion exchange of hydrous hydroxysodalite, Na8[AlSiO4]6(OH)2·2H2O, with 0.7 M aqueous AgNO3 solution in two 24 h cycles, at 70 °C. | [400] | |

| Tl6[Al6Si6O24] | Prepared by ion exchange of hydrous hydroxysodalite, Na8[AlSiO4]6(OH)2·2H2O, with 1 M aqueous TlNO3 solution at 100 °C. | [400] | |

| (C4H12N)[Al2Si10O24] | Synthesized under hydrothermal conditions in the absence of metal cations. | [401] | |

| Na8[Si6Al6O24]6·(MnO4)2 | Synthesized by addition of sodium aluminate solution to a concentrated solution of sodium permanganate and sodium silicate. | [156] | |

| Na8(Al6Si6O24)(BH4)2 | Synthesized hydrothermally from NaAlO2, Na2SiO3, and NaBH4 at 60 °C for 12 h. | [217] | |

| ~K4Na4(Al6Si6O24)(BH4)2 | Produced by cation exchange between the Na8(Al6Si6O24)(BH4)2 sodalite-type compound and 1 mol/l aqueous solution of KNO3 at 200 °C for 48 h. | [175] | |

| Na8[AlSiO4]6(BH4)2 | Synthesized hydrothermally from kaolinite, NaOH, and NaBH4, at 100 °C, for 24 h. | [219] | |

| Na8[AlSiO4]6(N3)2 | Synthesized hydrothermally from zeolite A and NaN3, at 160 °C, for two weeks. | [162] | |

| Na8[Al6Si6O24]I2 | Prepared hydrothermally from zeolite 4A, kaolinite, and meta-kaolin, as well as colloidal silica and NaAlO2 at 140–180 °C. Decreasing the Al/Si ratio by half increased the crystallization of basic cancrinite. | [402] | |

| [Al–Fe3+–Si–O] | (Na,Fe2+)8−x[(Si,Al,Fe3+)12O24] (OH,Cl)2·nH2O? | Synthesized from Fe- and Al-containing gels, prepared from Fe(NO3)3·9H2O and AlCl3·6H2O in hydrochloric acid solution, and Aldrich type waterglass at 88 °C for 2–2.5 h. | [403] |

| [Al–P–O] | (C3H7NO)2[Al6P6O24]·nH2O | Synthesized hydrothermally. | [153,404,405,406,407] |

| [Mg–Al–P–O] | (C4H12N)2[Mg2Al4P6O24] | Prepared hydrothermally from a gel based on tetramethylammonium hydroxide, MgO, Al2O3, and P2O5. | [408] |

| [Al–O] | Ca8[Al12O24]S2 | Obtained by reduction of the corresponding sulfate material, Ca4[Al96O192]·(SO4)16 via an intra-cage reaction. | [409,410] |

| Ca8[Al12O24]X2 (X = O, Te) | Prepared by solid-state reaction of a stoichiometric mixture of CaO, Al2O3, and CaTe (for X = Te) at 1100 °C for 48. | [411] | |

| Cd8[Al12O24]O2 | Prepared by solid-state reaction of a stoichiometric mixture of CdO and Al2O3 at 1100 °C for 48. | [411] | |

| Ca8[Al12O24](XO4)2 (X = S, Mo, W, Cr) | Synthesized in solid-state reactions. | [154,363,412,413,414,415] | |

| Sr8[Al12O24]X2 (X = S, Te) | Prepared by reduction of the corresponding sulfate and tellurite materials via intra-cage reactions. | [409] | |

| Sr8[Al12O24](TeO3)2 | Prepared using solid-state synthesis from the stoichiometric mixture of oxides at 1200 °C for 48 h. | [416] | |

| Sr8[Al12O24]Te2 | Prepared by the reduction of Sr8[Al12O24](TeO3)2 in a stream of hydrogen at 850 °C for 8 h. | [416] | |

| Sr8[Al12O24](XO4)2 (X = Mo, W, Cr) | Crystals partly grown from the B2O3 flux. | [417,418,419,420] | |

| Cd8[Al12O24]Te2 | Prepared by solid-state reaction of a stoichiometric mixture of CdO, Al2O3 and CdTe at 1100 °C for 48. | [411] | |

| Pb8REE4[Al12O24]O8 (REE = Ho, Lu) | Crystals grown from the melts prepared from corresponding oxides and PbF2 at 850 °C for 7 days. | [421] | |

| [Si–O] | SiO2 | Prepared by thermal treatment of ethylene glycol silica sodalite at 680 °C. | [422] |

| SiO2 | Obtained by heating the AcOH-treated double four-ring lamellar 8TMA(Si8O20)·xH2O precursor (TMA = tetramethylammonium) at 800 °C for one week. | [423] | |

| SiO2 | Silica sodalite formed as a result of the interlayer condensation of the layered silicate RUB-15 during a heat treatment at 800 °C in an inert atmosphere. | [424] | |

| (C2H4(OH)2)2[Si12O24] | Partly synthesized from essentially nonaqueous medium in which ethylene glycol is acting both as a solvent and as a structure-directing agent. | [425,426,427,428] | |

| (C3H6O3)2[Si12O24] | Synthesized from essentially nonaqueous medium in which 1,3,5-trioxane is acting both as a solvent and as a structure-directing agent. | [117,354] | |

| □2−x(C3H6O3)x[Si12O24] | Synthesized from essentially nonaqueous medium in which 1,3,5-trioxane is acting both as a solvent and as a structure-directing agent. | [354] | |

| [Al–Ga–Si–O] | Na6[Al1–yGaySiO4]6(H2O)8 (0 ≤ y ≤ 1) | Prepared from Na6[Al1–yGaySiO4]6(OH·H2O)x(H2O)8–4x sodalites by NaOH/H2O exchange methods carried out in acidic aqueous media at pH = 5.5–6.6. | [429] |

| [Ga–Si–O] | Na6[GaSiO4]6(H2O)8 | Obtained from Na8[GaSiO4]6I2 by a hydrothermal transformation process in the excess of water, at 200 °C for 24 h. | [429] |

| Na8[Ga6Si6O24]X2 (X = Cl, Br, I) | Prepared under hydrothermal conditions by heating aqueous solutions of NaOH, Ga2O3, Na2SiO3, and NaX for at 160 °C for 100 h. | [352] | |

| Li8[Ga6Si6O24]X2 (X = Cl, Br, I) | Obtained by replacement of Na+ by Li+ in sodalite of composition Na8[GaSiO4]6×2, where X is a halide, in nitrate melt at 240 °C. | [430] | |

| Na6[Ga6Si6O24]·8H2O | Synthesized hydrothermally from corresponding sodium salts. | [364,377,378,379,380] | |

| Na8[Ga6Si6O24]X2 (X = OH, Cl, Br, I) | Synthesized hydrothermally from corresponding sodium salts. | [352,377,431] | |

| Na8[Ga6Si6O24](XO4)2 (X = Cl, Mn) | Synthesized hydrothermally from corresponding sodium salts. | [162,432] | |

| Na8[Ga6Si6O24](XO3)2 (X = Cl, N, C) | Synthesized hydrothermally from corresponding sodium salts. | [377] | |

| Na8[Ga6Si6O24](NO2)2 | Synthesized hydrothermally from corresponding sodium salts. | [353,377,433] | |

| Na8[Ga6Si6O24](BH4)2 | Synthesized under mild hydrothermal conditions from NaAlGeO4 and NaBH4 at 80–120 °C for 12–48 h. Increasing temperatures above 120 °C favor the decomposition of the tetrahydroborate anions before encapsulation within the sodalite framework cavities. | [434] | |

| Na8[Ga6Si6O24](SCN)2 | Synthesized hydrothermally from corresponding sodium salts. | [377] | |

| Na8[Ga6Si6O24](HCO2)2 | Synthesized hydrothermally from corresponding sodium salts. | [377] | |

| K4.88Na3.12[Ga6Si6O24](NO2)2 | Obtained by cation exchange of a pure sodium analogue at 100 °C. | [435] | |

| Ag5.98Na2.02[Ga6Si6O24](NO2)2 | Obtained by cation exchange of a pure sodium analogue at 100 °C. | [435] | |

| [Be–Si–O] | Na8[Be3Si9O24]Cl2 | Prepared by a solid-state synthesis method from a sodium silicate glass, Na6Si9O21, stoichiometric quantity of BeO, and a four-fold excess of NaCl at 800 °C for 48 h. | [436] |

| Mn8[Be6Si6O24]X2 (X = S, Se, Te) | Synthesized by solid state reactions of the constituent oxides and MnX at 1000−1100 °C. | [118] | |

| Cd8[Be6Si6O24]X2 (X = S, Se, Te) | Synthesized by hydrothermal reaction of CdO, BeO, SiO2, and X at 750 °C and 2 kbar. | [437] | |

| [Be–Si–O] | Na6[Zn6As6O24]·8H2O | Synthesized hydrothermally from Na2HSO4·7H2O, NaOH, and Zn(NO3)2 at 70 °C for 12 h. | [378,438] |

| [Zn–P–O] | Na6[Zn6P6O24]·Br2? (No data on the chemical composition are provided) | Synthesized from a solution containing Zn(NO3)2, (H3PO4), NaBr, and NaOH at pH 7. | [439] |

| [Ga–As–O] | BaGe8As14 | Synthesized via solid-state reactions. No details provided. | [151] |

| [Zn–P–O] | Na6[Zn6P6O24]·8H2O | Synthesized hydrothermally from ZnO, H3PO4, and NaOH at 50 °C for 12 h. | [438] |

| [Be–P–O] | Li8[Be6P6O24]X2 (X = Cl, Br) | Synthesized at 550 °C and 0.3447 GPa. | [119,440] |

| [Al–Ge–O] | Na8(Al6Ge6O24)X2 (X = Cl, Br, I) | Crystallyzed by solvothermal method at 120 °C, using 50% ethanol + 50% water as a solvent, and NaAlO2, GeO2, NaX, and NaOH as rectants. | [128] |

| Na8(Al6Ge6O24)(ClO3)2 | Synthesized hydrothermally from NaAlO2, GeO2, NaClO3, and NaOH at 120 °C for 120 h. | [158] | |

| Na8(Al6Ge6O24)6(SCN)2 | Synthesized hydrothermally from GeO2 and NaAlO2 in the presence of NaOH, at 150 °C for three days. | [161] | |

| Na8(Al6Ge6O24)Br2 | Synthesized from NaAlO2, GeO2, SiO2, and NaOH under hydrothermal conditions at 320–450°. | [150] | |

| Li8[Al6Ge6O24]X2 (X = Cl, Br, I) | Obtained by replacement of Na+ by Li+ in sodalite of composition Na8[AlGeO4]6×2, where X is a halide, in nitrate melt at 240 °C. | [430] | |

| Na6[Al6Ge6O24]·8H2O | Synthesized hydrothermally from corresponding sodium salts. | [377,378] | |

| Na6+x[Al6Ge6O24](OH)x·3H2O | Synthesized by reacting Al2O3, GeO2, and NaOH solution under mild hydrothermal conditions. | [441] | |

| Na8[Al6Ge6O24]X2 (X = OH, Cl, Br, I) | Synthesized hydrothermally from sodium aluminate, GeO2 and corresponding sodium salts. | [120,377,442,443] | |

| Na8[Al6Ge6O24](S2/S3)2 | Synthesized hydrothermally from corresponding sodium salts. | [377] | |

| Na8[Al6Ge6O24](Se2)2 | Synthesized hydrothermally from corresponding sodium salts. | [377] | |

| Na8[Al6Ge6O24](XO4)2 (X = Cl, S, Mn) | Synthesized hydrothermally from sodium aluminate, GeO2, and corresponding sodium salts. | [377,444] | |

| Na8[Al6Ge6O24](NO2)2 | Synthesized hydrothermally in the system Na2O–GeO2–Al2O3–NaNO2–H2O at 200 °C. | [445] | |

| Na8[Al6Ge6O24](XO3)2 (X = Cl, Br, N, C, Se) | Synthesized hydrothermally from corresponding sodium salts. | [377] | |

| Na8[Al6Ge6O24](SCN)2 | Synthesized hydrothermally from corresponding sodium salts. | [377] | |

| Na8[Al6Ge6O24](HCO2)2 | Synthesized hydrothermally from corresponding sodium salts. | [377] | |

| Na8[Al6Ge6O24](H3C2O2)2 | Synthesized hydrothermally from corresponding sodium salts. | [377] | |

| K8−xNax[Al6Ge6O24](ClO4)2 | Obtained by cation exchange of corresponding pure Na analogue. | [444] | |

| [Zn–Si–O] | (C4H12N)2−xNax[Zn1.6Si10.4O24] | Obtained from a silicate gel with included Zn2+. | [446] |

| [Ga–Co–Si–O] | (C4H10N2)2[Ga2Co4P6O24] | Synthesized hydrothermally from C4H10N2, Ga2O3, and Co phosphate. | [447,448] |

| [Be–Ge–O] | Mn8[Be6Ge6O24]X2 (X = S, Se) | Synthesized by solid state reactions of the constituent oxides and MnX at 1000−1100 °C in sealed quartz ampoules. | [118] |

| [Al–Co–P–O] | (C4H10N2)2[Al2Co4P6O24] | Synthesized either hydrothermally from C4H10N2, Al2O3, and Co phosphate or by an ionothermal method (an ionic liquid as both solvent and structure-directing agent has been used). | [447,449] |

| [Zn–Ga–P–O] | (C4H12N)2[Zn2Ga4P6O24] | Synthesized hydrothermally from C4H12N, Ga2O3, and Zn phosphate. | [448] |

| [Zn–Ga–As–O] | (C4H12N)2[Zn2Ga4As6O24] | Synthesized hydrothermally from C4H12N, Ga2O3, and Zn arsenate. | [448,450] |

| (C4H10N2)2[Zn4Ga2As6O24] | Synthesized hydrothermally from C4H10N2, Ga2O3, and Zn arsenate. | [450] | |

| [Zn–Al–As–O] | (C4H12N)2[Zn2Al4As6O24] | Obtained by successive adding of As2O5 + C4H12N, Al nitrate, Zn arsenate, and HNO3 to a mixed water–ethylene glycol solvent to pH of 5.25 and heating at 150 °C for 4 days. | [450] |

| [Ga–Ge–O] | Na8−x(Ga6Ge6O24) [B(OH)4]2−x(H2O)x (?) | Synthesized hydrothermally, using NaGaGeO4 and Na[B(OH)4] as the starting materials, at 120 °C for 24 h. | [451] |

| (Am)2[Ga2Ge10O24] (Am = ammonium cation) | Synthesized hydrothermally from GeO2, Ga(NO3)3·nH2O, and corresponding amine at 180 °C for 8 days. | [452] | |

| Na6[Ga6Ge6O24]·xH2O | Prepared from sodium germanate and sodium gallate in aqueous sodium tetramethylammonium hydroxide solution, in the presence of Na2SO4, at 100 °C. | [377,453] | |

| Na8[Ga6Ge6O24](OH)2·6H2O | Prepared from sodium germanate and sodium gallate in aqueous sodium tetramethylammonium hydroxide solution, in the presence of Na2SO4, at 100–150 °C. | [453] | |

| Na8[Ga6Ge6O24]X2 (X = Cl, Br, I) | Synthesized hydrothermally from corresponding sodium salts. | [377] | |

| Na8[Ga6Ge6O24](ClO4)2 | Synthesized hydrothermally from corresponding sodium salts. | [377] | |

| Na8[Ga6Ge6O24](NO2)2 | Synthesized starting with the formation of gallogermanate basic-hydro-sodalite under hydrothermal conditions, at 100 °C, followed by hydrothermal treatment in concentrated NaNO2 solution. | [454] | |

| Na8[Ga6Ge6O24](BH4)2 | Separate suspensions of NaGaGeO4 and NaBH4 in sodium hydroxide solutions were combined before the hydrothermal treatment in the presence of NaOH at 150 °C for 4 h. | [370] | |

| [Al–Be–Si–O] | Na8[Al2Be2Si8O24]Cl2 | Prepared by a solid-state synthesis method from a sodium silicate glass, Na6Si8O19, stoichiometric quantities of BeO and Al2O3, and a four-fold excess of NaCl at 800 °C for 48 h. | [436] |

| Na8[Al4BeSi7O24]X2 (X = Cl, Br) | Prepared by a solid-state synthesis method from a sodium silicate glass, Na6Si7O17, stoichiometric quantities of BeO and Al2O3, and a four-fold excess of NaCl or NaBr at 800 °C for 48 h. | [436] | |

| [Be–As–O] | Li8[Be6As6O24]Cl2 | No data. | [119] |

| [B–O] | (Zn,Ga)8(B12O24)(Se,P)2 | Prepared by a solid-state synthesis method from a mixture of ZnB4O7, ZnO, ZnSe, and GaP at 900–950 °C for 12–36 h. | [121] |

| Co[B12O24]S2 | Synthesized from a stoichiometric mixture of B2O3, CoO, and CoS at 920 °C. | [455] | |

| Zn[B12O24]S2 | Synthesized from a stoichiometric mixture of B2O3, ZnO, and ZnS at 920 °C. | [455] | |

| (Zn,Mn)4[B6O12]O | Synthesized via solid-state reaction from ZnO, H3BO3 and MnCO3, first at 500 °C for 5 h in air atmosphere, then at 700 and 900 °C for 7 h in a reduced carbon atmosphere. | [304] | |

| [B–Ge–O] | Cs2[B2Ge10O24] | Obtained by the solvothermal reaction of H3BO3, GeO2, CsCl, HF, pyridine, and H2O at 200 °C for 7 days. | [456] |

| Organic and metal–organic | [(CH3)2NH2]4[In6(BTC)12]2[(M3OH)4(H2O)36][(In2MO)4(BTC)4(H2O)12]·(solvent)x (M = Mg, Mn, Co, Ni, and Cd). | Synthesized by a single-step low-temperature method of simultaneous formation of sodalite-type frameworks and covalent attachment of transition- and non-transition-metal clusters in a solution containing 1,3,5-benzenetricarboxylate (BTC). | [457,458] |

| Zn(im)2 (zinc imidazolate) | Synthesized mechanochemically at room temperature. | [459,460] | |

| Zn(im)2·nC60 (im = imidazolate, n = 0.15–1) | Fullerene C60 was entrapped in the cages of the sodalite-type imidazolate framework by mechanochemical processing. | [460] | |

| Zn(im)2 (zinc imidazilate) | Synthesized via solvent-assisted linker exchange of ZIF-8 (Zn(Me-im)2). | [461] | |

| Zn(5-mtz)(2-eim) | Obtained by heating a mixture of Zn(CH3CO2)2·2H2O, 5-methyltetrazole (5-mtz) and 2-ethylimidazole (2-eim) in dimethylformamide and ethanol to 120 °C. | [329,330,331] | |

| Zn(Me-im)2 | Synthesized from methyl imidazol (Me-im) and a Zn salt at room temperature under aqueous conditions for 10 min. | [462] | |

| Co(Me-im)2 | Synthesized from methyl imidazol (Me-im) and a Co salt at room temperature under aqueous conditions for 10 min. | [462] | |

| [(Cu4Cl)3(H0.5BTT)8(H2O)12]·3MeOH·9DMF | Prepared from CuCl2, 5,5′-(1,4-phenylene) bis(1H-tetrazole) (H3BTT), methanol, and dimethyl formamide (DMF). | [316] | |

| Cu3[(Cu4Cl)3(TPB-3tz)8]2·11CuCl2·8H2O·120DMF | Obtained in the reactions of 2,4,6-tri-p-(tetrazol-5-yl)-phenyl-s-triazine (H3TPB-3tz) with CuCl2in the presence of dimethyl formamide (DMF). | [205] | |

| Mn3[(Mn4Cl)3(TPT-3tz)8]2 ·25H2O·15CH3OH·95DMF | Obtained in the reactions of 2,4,6-tri-p-(tetrazol-5-yl)-phenyl-s-triazine (H3TPB-3tz) with MnCl2 in the presence of dimethyl formamide (DMF). | [205] | |

| Cu3[(Cu4Cl)3(TPT-3tz)8]2·x(solvent) | Obtained in the reactions of 2,4,6-tri-p-(tetrazol-5-yl)- phenyl-s-triazine (H3TPB-3tz) with CuCl2 in different solvents. | [205] | |

| ML2 (M = PdII or CuII, L = 2-hydroxypyrimidine or 4-hydroxypyrimidine) | Prepared by a solid–liquid sorption method. | [233] | |

| (Et2NH2)3[(Cu4Cl)3(TTCA)8] ·26DEF | Synthesized in the solvothermal reaction of triphenylene-2,6,10-tricarboxylic acid (H3TTCA)9 with CuCl2·2H2O in N,N-diethylformamide (DEF) at 110 °C for 48 h. | [214] | |

| Li3[(Cu4Cl)3(TTCA)8]·26DEF | Ion exchange of (Et2NH2)3[(Cu4Cl)3(TTCA)8]·26DEF with Li+. | [214] | |

| Fe3[(Fe4Cl)3(BTT)8]2·22DMF ·32DMSO·11H2O | Synthesized in the reaction between FeCl2 and H3BTT·2HCl (BTT3− = 1,3,5-benzenetristetrazolate) in a mixture of dimethylformamide (DMF) and dimethylsulfoxide (DMSO). | [215] | |

| [Zn(HL)]·DMA | Solvothermally synthesized based on an N-rich aromatic ligand L = 4,5-di(1H-tetrazol-5-yl)-2H-1,2,3-triazole in dimethyl acetate (DMA) | [230] |

References

- Peterson, R.C. The structure of hackmanite, a variety of sodalite, from Mont St-Hilaire, Quebec. Can. Mineral. 1983, 21, 549–552. [Google Scholar]

- Hassan, I.; Grundy, H.D. The crystal structures of sodalite-group minerals. Acta Crystallogr. Sect. B Struct. Sci. 1984, 40, 6–13. [Google Scholar] [CrossRef]

- Löhn, J.; Schulz, H. Strukturverfeinerung am gestörten Haüyn, (Na5K1Ca2)Al6Si6O24(SO4)1.5. Neues Jahrb. Mineral. Abh. 1968, 109, 201–210. (In German) [Google Scholar]

- Hassan, I.; Grundy, H.D. The crystal structure of haüyne at 273 and 153 K. Can. Mineral. 1991, 29, 123–130. [Google Scholar]

- Hassan, I.; Peterson, R.C.; Grundy, H.D. The structure of lazurite, ideally Na6Ca2(Al6Si6O24)S2, a member of the sodalite group. Acta Crystallogr. Sect. C Cryst. Struct. Commun. 1985, 41, 827–832. [Google Scholar] [CrossRef]

- IMA, List of Mineral Species. 2020. Available online: http://cnmnc.main.jp/ (accessed on 21 August 2024).

- Sapozhnikov, A.N.; Tauson, V.L.; Lipko, S.V.; Shendrik, R.Y.; Levitskii, V.I.; Suvorova, L.F.; Chukanov, N.V.; Vigasina, M.F. On the crystal chemistry of sulfur-rich lazurite, ideally Na7Ca(Al6Si6O24)(SO4)(S3)–·nH2O. Am. Mineral. 2020, 106, 226–234. [Google Scholar] [CrossRef]

- Hassan, I.; Grundy, H.D. The structure of nosean, ideally Na8[Al6Si6O24]SO4∙H2O. Can. Mineral. 1989, 27, 165–172. [Google Scholar]

- Sahl, K. Refinement of the crystal structure of bicchulite, Ca2[Al2SiO6](OH)2. Z. Krist. Cryst. Mater. 1980, 152, 13–22. [Google Scholar] [CrossRef]

- Uchida, E.; Iiyama, J.T. On kamaishilite, Ca2Al2SiO6(OH)2, a new mineral dimorphous (tetragonal) with bicchulite from the Kamaishi mine, Japan. Proc. Jpn. Acad. Ser. B Phys. Biol. Sci. 1981, 57, 239–243. [Google Scholar] [CrossRef][Green Version]

- Lee, S.; Xu, H.; Xu, H.; Jacobs, R.; Morgan, D. Valleyite: A new magnetic mineral with the sodalite-type structure. Am. Mineral. 2019, 104, 1238–1245. [Google Scholar] [CrossRef]

- Sapozhnikov, A.N.; Kaneva, E.V.; Cherepanov, D.I.; Suvorova, L.F.; Levitsky, V.I.; Ivanova, L.A.; Reznitsky, L.Z. Vladimirivanovite, Na6Ca2[Al6Si6O24](SO4,S3,S2,Cl)2·H2O, a new mineral of sodalite group. Geol. Ore Depos. 2012, 54, 557–564. [Google Scholar] [CrossRef]

- Sokolova, E.V.; Rybakov, V.B.; Pautov, L.A. Crystal structure of a new natural tetramethyammonium aluminosilicate [N(CH3)4][Si2(Si0.5Al0.5)O6]2. Proc. USSR Acad. Sci. 1991, 317, 884–887. (In Russian) [Google Scholar]

- Pautov, L.A.; Karpenko, V.Y.; Sokolova, E.V.; Ignatenko, K.I. Tsaregorodtsevite N(CH3)4[Si2(Si0.5Al0.5)O6]2—A new mineral. Zap. Vses. Miner. Obsh. 1993, 121, 128–135. (In Russian) [Google Scholar]

- Hassan, I.; Grundy, H.D. The crystal structure and thermal expansion of tugtupite, Na8[Al2Be2Si8O24]Cl2. Can. Mineral. 1991, 29, 385–390. [Google Scholar]

- Hassan, I.; Grundy, H.D. The crystal structures of helvite group minerals, (Mn,Fe,Zn)8(Be6Si6O24)S2. Am. Mineral. 1985, 70, 186–192. [Google Scholar]

- Chukanov, N.V.; Zubkova, N.V.; Pekov, I.V.; Shendrik, R.Y.; Varlamov, D.A.; Vigasina, M.F.; Belakovskiy, D.I.; Britvin, S.N.; Yapaskurt, V.O.; Pushcharovsky, D.Y. Sapozhnikovite, Na8(Al6Si6O24)(HS)2, a new sodalite-group mineral from the Lovozero alkaline massif, Kola Peninsula. Mineral. Mag. 2022, 86, 49–59. [Google Scholar] [CrossRef]

- Sapozhnikov, A.N.; Bolotina, N.B.; Chukanov, N.V.; Shendrik, R.Y.; Kaneva, E.V.; Vigasina, M.F.; Ivanova, L.A.; Tauson, V.L.; Lipko, S.V. Slyudyankaite, Na28Ca4(Si24Al24O96)(SO4)6(S6)1/3(CO2)·2H2O, a new sodalite group mineral from the Malo-Bystrinskoe lazurite deposit, Baikal Lake area, Russia. Am. Mineral. 2023, 108, 1805–1817. [Google Scholar] [CrossRef]

- Dunn, P.E. Genthelvite and the helvine group. Mineral. Mag. 1976, 40, 627–636. [Google Scholar] [CrossRef]

- Sapozhnikov, A.N.; Chukanov, N.V.; Shendrik, R.Y.; Vigasina, M.F.; Tauson, V.L.; Lipko, S.V.; Belakovskiy, D.I.; Levitskii, V.I.; Suvorova, L.G.; Ivanova, L.A. Lazurite: Validation as a mineral species with the formula Na7Ca(Al6Si6O24)(SO4)S3•–·H2O and new data. Geol. Ore Depos. 2022, 64, 470–475. [Google Scholar] [CrossRef]

- Chukanov, N.V.; Zubkova, N.V.; Schäfer, C.; Pekov, I.V.; Shendrik, R.Y.; Vigasina, M.F.; Belakovskiy, D.I.; Britvin, S.N.; Yapaskurt, V.O.; Pushcharovsky, D.Y. Bolotinaite, (Na6K−)(Al6Si6O24)F·4H2O, a new sodalite-group mineral from the Eifel paleovolcanic region, Germany. Mineral. Mag. 2022, 86, 920–928. [Google Scholar] [CrossRef]

- Chukanov, N.V.; Aksenov, S.M.; Rastsvetaeva, R.K. Structural chemistry, IR spectroscopy, properties, and genesis of natural and synthetic microporous cancrinite- and sodalite-related materials: A review. Microporous Mesoporous Mater. 2021, 323, 111098. [Google Scholar] [CrossRef]

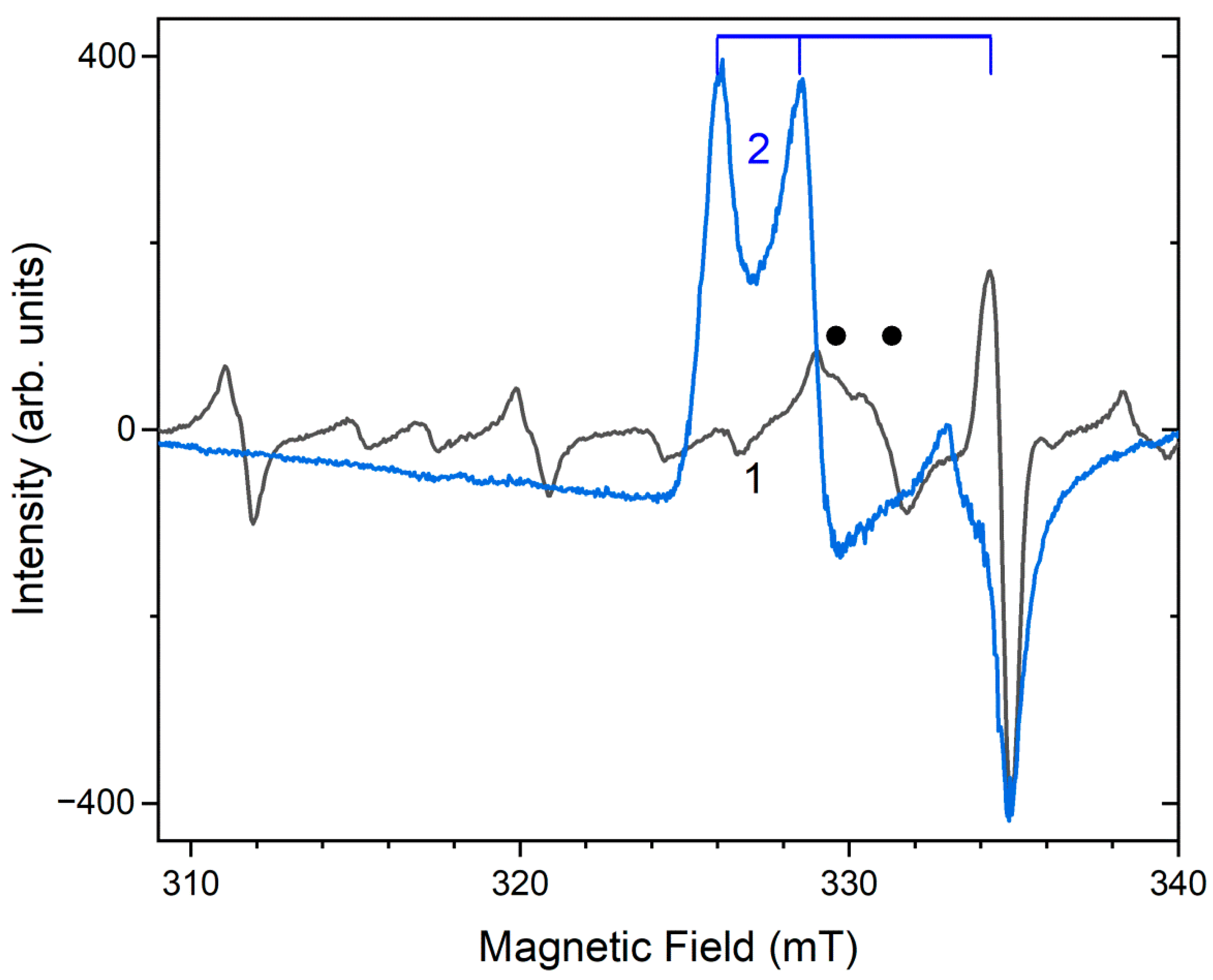

- Chukanov, N.V.; Vigasina, M.F.; Zubkova, N.V.; Pekov, I.V.; Schäfer, C.; Kasatkin, A.V.; Yapaskurt, V.O.; Pushcharovsky, D.Y. Extra-framework content in sodalite-group minerals: Complexity and new aspects of its study using infrared and Raman spectroscopy. Minerals 2020, 10, 363. [Google Scholar] [CrossRef]

- Chukanov, N.V.; Shendrik, R.Y.; Vigasina, M.F.; Pekov, I.V.; Sapozhnikov, A.N.; Shcherbakov, V.D.; Varlamov, D.A. Crystal chemistry, isomorphism, and thermal conversions of extra-framework components in sodalite-group minerals. Minerals 2022, 12, 887. [Google Scholar] [CrossRef]

- Chukanov, N.V.; Vigasina, M.F.; Shendrik, R.Y.; Varlamov, D.A.; Pekov, I.V.; Zubkova, N.V. Nature and isomorphism of extra-framework components in cancrinite- and sodalite-related minerals: New data. Minerals 2022, 12, 729. [Google Scholar] [CrossRef]

- Chukanov, N.V.; Shchipalkina, N.V.; Shendrik, R.Y.; Vigasina, M.F.; Tauson, V.L.; Lipko, S.V.; Varlamov, D.A.; Shcherbakov, V.D.; Sapozhnikov, A.N.; Kasatkin, A.V.; et al. Isomorphism and mutual transformations of S-bearing components in feldspathoids with microporous structures. Minerals 2022, 12, 1456. [Google Scholar] [CrossRef]

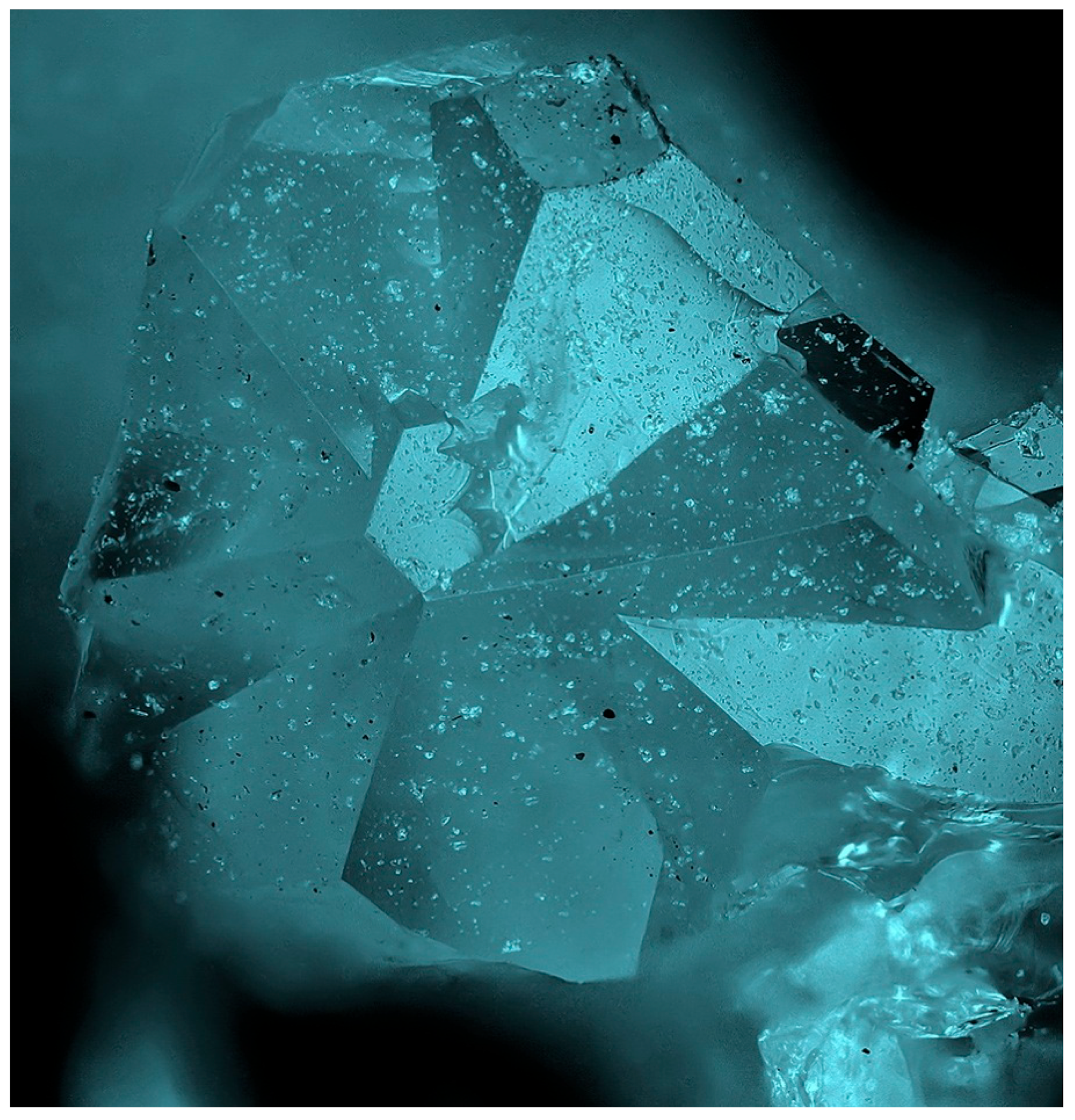

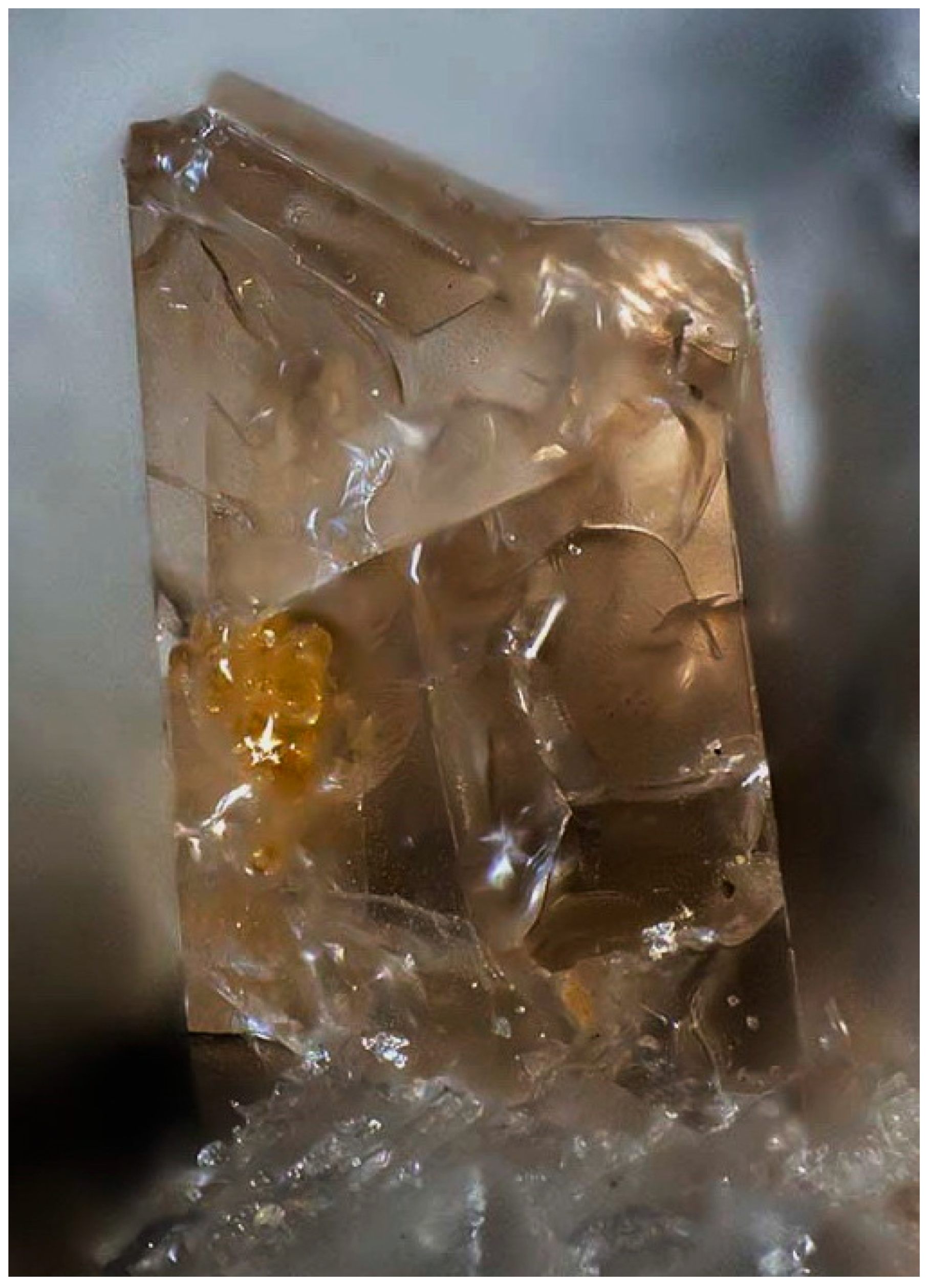

- NChukanov, V.; Sapozhnikov, A.N.; Shendrik, R.Y.; Vigasina, M.F.; Steudel, R. Spectroscopic and crystal-chemical features of sodalite-group minerals from gem lazurite deposits. Minerals 2020, 10, 1042. [Google Scholar] [CrossRef]

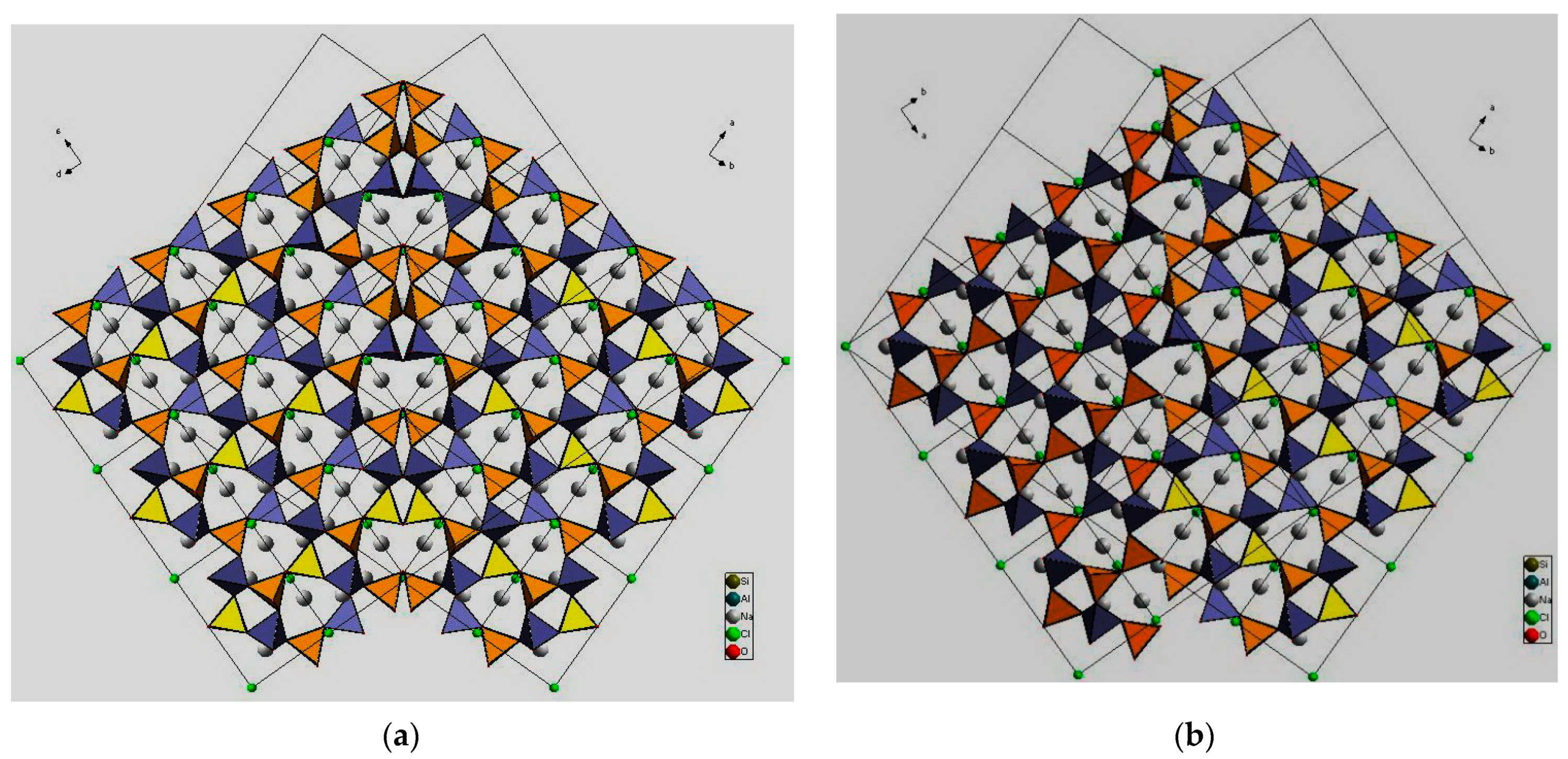

- NBolotina, B.; Sapozhnikov, A.N.; Chukanov, N.V.; Vigasina, M.F. Structure modulations and symmetry of lazurite-related sodalite-group minerals. Crystals 2023, 13, 768. [Google Scholar] [CrossRef]

- Dumańska-Słowik, M.; Heflik, W.; Pieczka, A.; Sikorska, M.; Dąbrowa, Ł. The transformation of nepheline and albite into sodalite in pegmatitic mariupolite of the Oktiabrski Massif (SE Ukraine). Spectrochim. Acta A Mol. Biomol. Spectrosc. 2015, 150, 837–845. [Google Scholar] [CrossRef]

- Schneider, J.B.; Jenkins, D.M. Stability of sodalite relative to nepheline in NaCl–H2O brines at 750 °C: Implications for hydrothermal formation of sodalite. Can. Mineral. 2020, 58, 3–18. [Google Scholar] [CrossRef]

- Hassan, I.; Grundy, H.D. Structure of basic sodalite, Na8Al6Si6O24(OH)2·2H2O. Acta Crystallogr. Sect. C Cryst. Struct. Commun. 1983, 39, 3–5. [Google Scholar] [CrossRef]

- Felsche, J.; Luger, S.; Baerlocher, C. Crystal structures of the hydro-sodalite Na6[AlSiO4]6·8H2O and of the anhydrous sodalite Na6[AlSiO4]6. Zeolites 1986, 6, 367–372. [Google Scholar] [CrossRef]

- Fazal, T. High Temperature Studies of Sodalites. Master’s Thesis, University of Birmingham, Birmingham, UK, 2011. [Google Scholar]

- Felsche, J.; Luger, S. Phases and thermal decomposition characteristics of hydro-sodalites Na6+x[AISiO4]6(OH)x·nH2O. Thermochim. Acta 1987, 118, 35–55. [Google Scholar] [CrossRef]

- Sari, M.E.F.; Suprapto, S.; Prasetyoko, D. Direct synthesis of sodalite from kaolin: The influence of alkalinity. Indones. J. Chem. 2018, 18, 607–613. [Google Scholar] [CrossRef]

- Khalifah, S.N.; Cahyawati, M.; Cahyani, D.K.D.; Arifah, A.; Prasetyo, A. Synthesis of sodalite from indonesian kaolin with conventional and alkali fusion method. IOP Conf. Ser. Mater. Sci. Eng. 2019, 578, 012006. [Google Scholar] [CrossRef]

- Reyes, C.A.R.; Williams, C.; Mauricio, O.; Alarcón, C. Nucleation and growth process of sodalite and cancrinite from kaolinite-rich clay under low-temperature hydrothermal conditions. Mater. Res. 2013, 16, 424–438. [Google Scholar] [CrossRef]

- Li, J.; Zeng, X.; Yang, X.; Wang, C.; Luo, X. Synthesis of pure sodalite with wool ball morphology from alkali fusion kaolin. Mater. Lett. 2015, 161, 157–159. [Google Scholar] [CrossRef]

- Maia, A.Á.B.; Neves, R.F.; Angélica, R.S.; Pöllmann, H. Synthesis of sodalite from Brazilian kaolin wastes. Clay Miner. 2015, 50, 663–675. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, Q.; Liu, Y. Ionothermal synthesis of sodalite from metakaolin. Adv. Mater. Res. 2012, 487, 789–792. [Google Scholar] [CrossRef]

- Wahyuni, T.; Prasetyoko, D.; Suprapto, S.; Qoniah, I.; Bahruji, H.; Dawam, A.; Triwahyono, S.; Jalil, A.A. Direct synthesis of sodalite from indonesian kaolin for adsorption of Pb2+ solution, kinetics, and isotherm approach. Bull. Chem. React. Eng. Catal. 2019, 14, 502–512. [Google Scholar] [CrossRef]

- Esaifan, M.; Warr, L.N.; Grathoff, G.; Meyer, T.; Schafmeister, M.-T.; Kruth, A.; Testrich, H. Synthesis of hydroxy-sodalite/cancrinite zeolites from calcite-bearing kaolin for the removal of heavy metal ions in aqueous media. Minerals 2019, 9, 484. [Google Scholar] [CrossRef]

- Yanga, J.; Li, T.; Bao, X.; Yue, Y.; Liua, H. Mesoporogen-free synthesis of hierarchical sodalite as a solid basecatalyst from sub-molten salt-activated aluminosilicate. Particuology 2020, 48, 48–54. [Google Scholar] [CrossRef]

- Passos, F.A.C.M.; Castro, D.C.; Ferreira, K.K.; Simoes, K.M.A.; Bertolino, L.C.; Barbato, C.N.; Garrido, F.M.S.; Felix, A.A.S.; Silva, F. Synthesis and Characterization of Sodalite and Cancrinite from Kaolin; Ikhmayies, S., Li, B., Carpenter, J.S., Li, J., Hwang, J.Y., Monteiro, S.N., Firrao, D., Zhang, M., Peng, Z., Escobedo Diaz, J.P., et al., Eds.; Characterization of Minerals, Metals, and Materials; Springer: Cham, Switzerland, 2017; pp. 279–288. [Google Scholar] [CrossRef]

- Golbad, S.; Khoshnoud, P.; Abu-Zahra, N. Hydrothermal synthesis of hydroxy sodalite from fly ash for the removal of lead ions from water. Int. J. Environ. Sci. Technol. 2017, 14, 135–142. [Google Scholar] [CrossRef]

- Zong, Y.-B.; Zhao, C.-Y.; Chen, W.-H.; Liu, Z.-B.; Cang, D.-Q. Preparation of hydro-sodalite from fly ash using a hydrothermal method with a submolten salt system and study of the phase transition process. Int. J. Miner. Metall. Mater. 2020, 27, 55–62. [Google Scholar] [CrossRef]

- Shabani, J.M.; Babajide, O.; Oyekola, O.; Petrik, L. Synthesis of hydroxy sodalite from coal fly ash for biodiesel production from waste-derived maggot oil. Catalysts 2019, 9, 1052. [Google Scholar] [CrossRef]

- Luo, J.; Zhangb, H.; Yang, J. Hydrothermal synthesis of sodalite on alkali-activated coal fly ash for removal of lead ions. Procedia Environ. Sci. 2016, 31, 605–614. [Google Scholar] [CrossRef]

- Oh, J.E.; Moon, J.; Mancio, M.; Clark, S.M.; Monteiro, P.J.M. Bulk modulus of basic sodalite, Na8[AlSiO4]6(OH)2·2H2O, a possible zeolitic precursor in coal-fly-ash-based geopolymers. Cem. Concr. Res. 2011, 41, 107–112. [Google Scholar] [CrossRef]

- Musyoka, N.M.; Petrik, L.F.; Gitari, W.M.; Balfour, G.; Hums, E. Optimization of hydrothermal synthesis of pure phase zeolite Na-P1 from South African coal fly ashes. J. Environ. Sci. Health A 2012, 47, 337–350. [Google Scholar] [CrossRef]

- Sun, L.; Wu, J.; Wang, J.; Yu, G.; Liu, J.; Du, Y.; Li, Y.; Li, H. Controlled synthesis of Zeolite adsorbent from lowgrade diatomite: A case study of self-assembled sodalite microspheres. J. Environ. Sci. 2020, 91, 92–104. [Google Scholar] [CrossRef]

- Kamyab, S.M.; Williams, C.D.; Badiei, A. Synthesis of sodalite from sepiolite by alkali fusion method and its application to remove Fe3+, Cr3+, and Cd2+ from aqueous solutions. Environ. Eng. Sci. 2020, 37, 689–701. [Google Scholar] [CrossRef]

- Xie, L.; Wang, P.; Li, Z.; Peng, H.; Li, X.; Zhou, Y. Preparation and performance study on sodalite/magnetite from tourmaline. Mater. Sci. Eng. 2018, 381, 012109. [Google Scholar] [CrossRef]

- Esaifan, M.; Hourani, M.; Khoury, H.; Rahier, H.; Wastiels, J. Synthesis of hydroxysodalite zeolite by alkali-activation of basalt powder rich in calc-plagioclase. Adv. Powder Technol. 2017, 28, 473–480. [Google Scholar] [CrossRef]

- Jiang, J.; Gu, X.; Feng, L.; Duanmu, C.; Jin, Y.; Hu, T.; Wu, J. Controllable synthesis of sodalite submicron crystals and microspheres from palygorskite clay using a two-step approach. Powder Technol. 2012, 217, 298–303. [Google Scholar] [CrossRef]

- Li, Y.; Peng, T.; Man, W.; Ju, L.; Zheng, F.; Zhang, M.; Guo, M. Hydrothermal synthesis of mixtures of NaA zeolite and sodalite from Ti-bearing electric arc furnace slag. R. Soc. Chem. Adv. 2016, 6, 8358–8366. [Google Scholar] [CrossRef]

- Kim, J.-C.; Choi, M.; Kim, D.-S.; Song, H.J.; Kim, D.-W. Windshield-waste-driven synthesis of hydroxy sodalite. J. Ceram. Soc. Jpn. 2015, 123, 2022–2026. [Google Scholar] [CrossRef]

- Naskar, M.K.; Kundu, D.; Chatterjee, M. Coral-like hydroxy sodalite particles from rice husk ash as silica source. Mater. Lett. 2011, 65, 3408–3410. [Google Scholar] [CrossRef]

- Choy, H.; Lee, S.-R.; Han, Y.-S.; Park, M.; Park, G.-S. Solid–solid transformation mechanism for nanocrystalline sodalite from pillared clay. Chem. Commun. 2003, 15, 1922–1923. [Google Scholar] [CrossRef]

- Belviso, C.; Cavalcante, F.; Niceforo, G.; Lettino, A. Sodalite, faujasite and A-type zeolite from 2:1dioctahedral and 2:1:1 trioctahedral clay minerals. A singular review of synthesis methods through laboratory trials at a low incubation temperature. Powder Technol. 2017, 320, 483–497. [Google Scholar] [CrossRef]

- Mundus, C.; Müller-Warmuth, W.; Buhl, J.-C. Crystallization of a basic sodalite under hydrothermal conditions studied by MAS-NMR, XRD and DTA/DTG. Eur. J. Mineral. 1996, 8, 231–240. [Google Scholar] [CrossRef]

- Fan, W.; Morozumi, K.; Kimura, R.; Yokoi, T.; Okubo, T. Synthesis of nanometer-sized sodalite without adding organic additives. Langmuir 2008, 24, 6952–6958. [Google Scholar] [CrossRef]

- You, S.; Zhang, Y.; Chen, F.; Cao, S.; Zhang, Y. Transformation of NaCaHSiO4 to sodalite and katoite in sodium aluminate solution. Hydrometallurgy 2014, 141, 43–48. [Google Scholar] [CrossRef]

- Naskar, M.K.; Kundu, D.; Chatterjee, M.I. An aqueous-based synthesis of flower-like hydroxy sodalite particles in the presence of cetyltrimethylammonium bromide. Am. Ceram. Soc. 2011, 94, 1643–1646. [Google Scholar] [CrossRef]

- Lapari, S.S.; Ramli, Z.; Triwahyono, S. Effect of different templates on the synthesis of mesoporous sodalite. J. Chem. 2015, 2015, 272613. [Google Scholar] [CrossRef]

- Cui, L.; Han, R.; Yang, L.; Wu, Y.; Pei, R.; Li, F. Synthesis and characterization of mesoporous sodalite and investigation of the effects of inorganic salts on its structure and properties. Microporous Mesoporous Mater. 2020, 306, 110385. [Google Scholar] [CrossRef]

- Huang, Y.; Yao, J.; Zhang, X.; Kong, C.; Chen, H.; Liu, D.; Tsapatsis, M.; Hill, M.R.; Hill, A.J.; Wang, H. Role of ethanol in sodalite crystallization in an ethanol–Na2O–Al2O3–SiO2–H2O system. CrystEngComm 2011, 13, 4714–4722. [Google Scholar] [CrossRef]

- Naskar, M.K.; Kundu, D.; Chatterjee, M. Effect of process parameters on surfactant-based synthesis of hydroxyl sodalite particles. Mater. Lett. 2011, 65, 436–438. [Google Scholar] [CrossRef]

- Barnes, M.C.; Addai-Mensah, J.; Gerson, A.R. The mechanism of the sodalite-to-cancrinite phase transformation in synthetic spent Bayer liquor. Microporous Mesoporous Mater. 1999, 31, 287–302. [Google Scholar] [CrossRef]

- Xu, B.; Smith, P.; Wingate, C.; De Silva, L. The effect of calcium and temperature on the transformation of sodalite to cancrinite in Bayer digestion. Hydrometallurgy 2010, 105, 75–81. [Google Scholar] [CrossRef]

- Buhl, J.-C. Enhanced methods of crystallization: The crossover synthesis from gel to melt flow—A case study on sodalites. Microporous Mesoporous Mater. 2016, 236, 13–20. [Google Scholar] [CrossRef]

- Zeng, S.; Wang, R.; Zhang, Z.; Qiu, S. Solventless green synthesis of sodalite zeolite using diatomite as silica source by a microwave heating technique. Inorg. Chem. Commun. 2016, 70, 168–171. [Google Scholar] [CrossRef]

- Zeng, S.; Wang, R.; Li, A.; Huang, W.; Zhang, Z.; Qiu, S. Solvent-free synthesis of nanosized hierarchical sodalite zeolite with a multi-hollow polycrystalline structure. CrystEngComm 2016, 18, 6779–6783. [Google Scholar] [CrossRef]

- Novembre, D.; Gimeno, D.; Pasculli, A.; Di Sabatino, B. Synthesis and characterization of sodalite using natural kaolinite: An analytical and mathematical to simulate the loss in weight of chlorine during the synthesis process. Fresenius Environ. Bull. 2010, 19, 1109–1117. [Google Scholar]

- Pascull, A.; Novembre, D. Phenomenological–mathematical approach in simulating the loss in weight of chlorine during sodalite synthesis. Comput. Geosci. 2012, 42, 110–117. [Google Scholar] [CrossRef]

- Song, Q.; Shen, J.; Yang, Y.; Wang, J.; Yang, Y.; Sun, J.; Jiang, B.; Liao, Z. Effect of temperature on the synthesis of sodalite by crystal transition process. Microporous Mesoporous Mater. 2020, 292, 109755. [Google Scholar] [CrossRef]

- Hayashi, T.; Shiga, H.; Sadakata, M.; Okuboa, T. Hydrothermal growth of millimeter-sized aluminosilicate sodalite single crystals in noble metal capsules. J. Mater. Res. 1998, 13, 891–895. [Google Scholar] [CrossRef]

- Klunk, M.; Dasgupta, S.; Das, M.; Cunha, M.G.; Wander, P.R. Synthesis of sodalite zeolite and adsorption study of crystal violet dye. ECS J. Solid State Sci. Technol. 2019, 8, N144–N150. [Google Scholar] [CrossRef]

- Ding, L.; Yang, H.; Rahimi, P.; Omotoso, O.; Friesen, W.; Fairbridge, C.; Shi, Y.; Ng, S. Solid transformation of zeolite NaA to sodalite. Microporous Mesoporous Mater. 2010, 130, 303–308. [Google Scholar] [CrossRef]

- Greer, H.; Wheatley, P.S.; Ashbrook, S.E.; Morris, R.E.; Zhou, W. Early stage reversed crystal growth of zeolite A and its phase transformation to sodalite. J. Am. Chem. Soc. 2009, 131, 17986–17992. [Google Scholar] [CrossRef]

- Depmeier, W. The sodalite family—A simple but versatile framework structure. Rev. Mineral. Geochem. 2005, 57, 203–240. [Google Scholar] [CrossRef]

- Baur, W.H.; Fischer, R.X. ZeoBase, a Databank for Zeolitetype Crystal Structures; Northwestern University, Evanston and Universitat Bremen: Evanston, IL, USA, 2008. [Google Scholar]

- Fischer, R.X.; Baur, W.H. Symmetry relationships of sodalite (SOD)-type crystal structures. Z. Krist. 2009, 224, 185–197. [Google Scholar] [CrossRef]

- Baerlocher, C.; McCusker, L.B. Atlas of Zeolite Framework Types; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar] [CrossRef]

- Furukawa, H.; Cordova, K.E.; O’Keeffe, M.; Yaghi, O.M. The chemistry and Applications of Metal-Organic Frameworks. Science 2013, 341, 6149. [Google Scholar] [CrossRef]

- Park, K.S.; Ni, Z.; Côté, A.P.; Choi, J.Y.; Huang, R.; Uribe-Romo, F.J.; Chae, H.K.; O’Keeffe, M.; Yaghi, O.M. Exceptional chemical and thermal stability of zeolitic imidazolate frameworks. Proc. Natl. Acad. Sci. USA 2006, 103, 10186–10191. [Google Scholar] [CrossRef] [PubMed]

- Khay, I.; Chaplais, G.; Nouali, H.; Ortiz, G.; Marichal, C.; Patarin, J. Assessment of the energetic performances of various ZIFs with SOD or RHO topology using high pressure water intrusion–extrusion experiments. Dalton Trans. 2016, 45, 4392–4400. [Google Scholar] [CrossRef] [PubMed]

- Zheng, B.; Zhu, Y.; Fu, F.; Wang, L.L.; Wang, J.; Du, H. Theoretical prediction of the mechanical properties of zeolitic imidazolate frameworks (ZIFs). RSC Adv. 2017, 7, 41499–41503. [Google Scholar] [CrossRef]

- Andres-Garcia, E.; López-Cabrelles, J.; Oar-Arteta, L.; Roldan-Martinez, B.; Cano-Padilla, M.; Gascon, J.; Espallargas, G.M.; Kapteijn, F. Cation influence in adsorptive propane/propylene separation in ZIF-8 (SOD) topology. Chem. Eng. J. 2019, 371, 848–856. [Google Scholar] [CrossRef]

- Bose, R.; Ethiraj, J.; Sridhar, P.; Varghese, J.J.; Kaisare, N.S.; Selvam, P. Adsorption of hydrogen and carbon dioxide in zeolitic imidazolate framework structure with SOD topology: Experimental and modelling studies. Adsorption 2020, 26, 1027–1038. [Google Scholar] [CrossRef]

- Chen, C.; Kim, J.; Yang, D.-A.; Ahn, W.-S. Carbon dioxide adsorption over zeolite-like metal organic frameworks (ZMOFs) having a sod topology: Structure and ion-exchange effect. Chem. Eng. J. 2011, 168, 1134–1139. [Google Scholar] [CrossRef]

- Li, M.-Y.; Wang, F.; Zhang, J. Zeolitic Tetrazolate–Imidazolate Frameworks with SOD Topology for Room Temperature Fixation of CO 2 to Cyclic Carbonates. Cryst. Growth Des. 2020, 20, 2866–2870. [Google Scholar] [CrossRef]

- Huh, S.; Kwon, T.-H.; Park, N.; Kim, S.-J.; Kim, Y. Nanoporous In-MOF with multiple one-dimensional pores. Chem. Commun. 2009, 33, 4953–4955. [Google Scholar] [CrossRef]

- Sun, L.; Xing, H.; Liang, Z.; Yu, J.; Xu, R. A 4 + 4 strategy for synthesis of zeolitic metal–organic frameworks: An indium-MOF with SOD topology as a light-harvesting antenna. Chem. Commun. 2013, 49, 11155. [Google Scholar] [CrossRef]

- Alsadun, N.; Mouchaham, G.; Guillerm, V.; Czaban-Jóźwiak, J.; Shkurenko, A.; Jiang, H.; Bhatt, P.M.; Parvatkar, P.; Eddaoudi, M. Introducing a Cantellation Strategy for the Design of Mesoporous Zeolite-like Metal–Organic Frameworks: Zr-sod-ZMOFs as a Case Study. J. Am. Chem. Soc. 2020, 142, 20547–20553. [Google Scholar] [CrossRef]

- Lee, J.H.; Jeoung, S.; Chung, Y.G.; Moon, H.R. Elucidation of flexible metal-organic frameworks: Research progresses and recent developments. Coord. Chem. Rev. 2019, 389, 161–188. [Google Scholar] [CrossRef]

- Gao, M.; Huang, R.-K.; Zheng, B.; Wang, P.; Shi, Q.; Zhang, W.-X.; Dong, J. Large breathing effect in ZIF-65(Zn) with expansion and contraction of the SOD cage. Nat. Commun. 2022, 13, 4569. [Google Scholar] [CrossRef] [PubMed]

- Trojan, I.A.; Semenok, D.V.; Ivanova, A.G.; Kvashnin, A.G.; Zhou, D.; Sadakov, A.V.; Sobolevsky, O.A.; Pudalov, V.M.; Lyubutin, I.S.; Oganov, A.R. High-temperature superconductivity in hydrides. Usp. Fiz. Nauk. 2022, 192, 799–813. [Google Scholar] [CrossRef]

- Semenok, D.V.; Kvashnin, A.G.; Ivanova, A.G.; Svitlyk, V.; Fominski, V.Y.; Sadakov, A.V.; Sobolevskiy, O.A.; Pudalov, V.M.; Troyan, I.A.; Oganov, A.R. Superconductivity at 161 K in thorium hydride ThH10: Synthesis and properties. Mater. Today 2020, 33, 36–44. [Google Scholar] [CrossRef]

- Semenok, D.V.; Kruglov, I.A.; Savkin, I.A.; Kvashnin, A.G.; Oganov, A.R. On Distribution of Superconductivity in Metal Hydrides. Curr. Opin. Solid State Mater. Sci. 2020, 24, 100808. [Google Scholar] [CrossRef]

- Liu, H.; Naumov, I.I.; Hoffmann, R.; Ashcroft, N.W.; Hemley, R.J. Potential high- T c superconducting lanthanum and yttrium hydrides at high pressure. Proc. Natl. Acad. Sci. USA 2017, 114, 6990–6995. [Google Scholar] [CrossRef]

- Heil, C.; di Cataldo, S.; Bachelet, G.B.; Boeri, L. Superconductivity in sodalite-like yttrium hydride clathrates. Phys. Rev. B 2019, 99, 220502. [Google Scholar] [CrossRef]

- Semenok, D.V.; Troyan, I.A.; Ivanova, A.G.; Kvashnin, A.G.; Kruglov, I.A.; Hanfland, M.; Sadakov, A.V.; Sobolevskiy, O.A.; Pervakov, K.S.; Lyubutin, I.S.; et al. Superconductivity at 253 K in lanthanum–yttrium ternary hydrides. Mater. Today 2021, 48, 18–28. [Google Scholar] [CrossRef]

- Du, M.; Song, H.; Zhang, Z.; Duan, D.; Cui, T. Room-Temperature Superconductivity in Yb/Lu Substituted Clathrate Hexahydrides under Moderate Pressure. Research 2022, 2022, 9784309. [Google Scholar] [CrossRef]

- Tsuppayakorn-aek, P.; Phaisangittisakul, N.; Ahuja, R.; Bovornratanaraks, T. High-temperature superconductor of sodalite-like clathrate hafnium hexahydride. Sci. Rep. 2021, 11, 16403. [Google Scholar] [CrossRef]

- Ma, L.; Wang, K.; Xie, Y.; Yang, X.; Wang, Y.; Zhou, M.; Liu, H.; Yu, X.; Zhao, Y.; Wang, H.; et al. High-temperature superconducting phase in clathrate calcium hydride CaH6 up to 215 K at a pressure of 172 GPa. Phys. Rev. Lett. 2022, 128, 167001. [Google Scholar] [CrossRef] [PubMed]

- Karttunen, A.J.; Fässler, T.F.; Linnolahti, M.; Pakkanen, T.A. Structural Principles of Semiconducting Group 14 Clathrate Frameworks. Inorg. Chem. 2011, 50, 1733–1742. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Borstad, G.M.; Liu, H.; Guńka, P.A.; Guerette, M.; Dolyniuk, J.-A.; Meng, Y.; Greenberg, E.; Prakapenka, V.B.; Chaloux, B.L.; et al. Carbon-boron clathrates as a new class of sp 3 -bonded framework materials. Sci. Adv. 2020, 6, eaay8361. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.; Xie, T.; Zhang, L.; Wang, P.; Fang, Z. Si2Ge: A New VII-Type Clathrate with Ultralow Thermal Conductivity and High Thermoelectric Property. Sci. Rep. 2020, 10, 3068. [Google Scholar] [CrossRef] [PubMed]

- Gatta, G.D. Does porous mean soft? On the elastic behaviour and structural evolution of zeolites under pressure. Z. Krist. Cryst. Mater. 2008, 223, 160–170. [Google Scholar] [CrossRef]

- Bau, W.H.; Fischer, R.X. The flexibility of the T–X–T hinges between the coordination tetrahedra in various zeolitic frameworks: An empirical structural study. Mineral. Petrol. 2023, 117, 165–179. [Google Scholar]

- Li, Z.; Nevitt, M.V.; Ghose, S. Elastic constants of sodalite Na4Al3Si3O12Cl. Appl. Phys. Lett. 1989, 55, 1730–1731. [Google Scholar] [CrossRef]

- Ulian, G.; Valdrè, G. Structural and Elastic Behaviour of Sodalite Na8(Al6Si6O24)Cl2 at High-Pressure by First-Principle Simulations. Minerals 2022, 12, 1323. [Google Scholar] [CrossRef]

- Hazen, R.M.; Sharp, Z.D. Compressibility of sodalite and scapolite. Am. Mineral. 1988, 73, 1120–1122. [Google Scholar]

- Elhachemi, K.; Khellafi, H.; Bendouba, M.; Djebli, A. Quantification of Young's modulus of kaolin, sodalite and nanocomposite based polycaprolactone/sodalite using atomic force microscopy. Mater. Res. Express 2024, 11, 075008. [Google Scholar] [CrossRef]

- Hargis, C.W.; Moon, J.; Lothenbach, B.; Winnefeld, F.; Wenk, H.-R.; Monteiro, P.J.M. Calcium sulfoaluminate sodalite (Ca4Al6O12SO4) crystal structure evaluation and bulk modulus determination. J. Am. Ceram. Soc. 2014, 97, 892–898. [Google Scholar] [CrossRef]

- Fütterer, K.; Depmeier, W.; Altorfer, F.; Behrens, P.; Felsche, J. Compression mechanism in trioxane silica sodalite, [Si12O24]·2C3H6O3. Z. Krist. Cryst. Mater. 1994, 209, 517–523. [Google Scholar] [CrossRef]

- Dann, S.E.; Weller, M.T.; Rainford, B.D.; Adroja, D.T. Synthesis, structure, optical properties, and magnetism of the manganese chalcogenide ceryllosilicate and beryllogermanate sodalites. Inorg. Chem. 1997, 36, 5278–5283. [Google Scholar] [CrossRef]

- Harrison, W.T.A.; Gier, T.E.; Stucky, G.D. Two lithium chloroberyllo(phosphate/arsenate) sodalites: Li4Cl(BePO4)3 and Li4Cl(BeAsO4)3. Acta Crystallogr. Sect. C Cryst. Struct. Commun. 1994, 50, 471–473. [Google Scholar] [CrossRef]

- Johnson, G.M.; Weller, M.T. Synthesis and characterisation of gallium and germanium containing sodalites. Stud. Surf. Sci. Catal. 1997, 105, 269–275. [Google Scholar] [CrossRef]

- Moran, K.L.; Gier, T.E.; Harrison, W.T.A.; Stucky, G.D.; Eckert, H.; Eichele, K.; Wasylishen, R.E. Synthesis and characterization of mixed ZnSe/GaP semiconductor species included in the sodalite structure. J. Am. Chem. Soc. 1993, 115, 10553–10558. [Google Scholar] [CrossRef]

- Moon, D.J.; Lim, W.T. Minireview of pentatomic cations in sodalite cavities. J. Porous Mater. 2020, 27, 563–564. [Google Scholar] [CrossRef]

- Kim, S.H.; Ha, S.G.; Heo, N.H.; Seff, K. A crystallographic study of the decomposition of NO in fully indium exchanged zeolite Y. In+, In3+, and In3+–NO3– complexes with facially coordinating nitrate ions are in supercages. Distorted cubic In4O44+ clusters fill sodalite cavities. J. Phys. Chem. C 2011, 115, 20248–20257. [Google Scholar] [CrossRef]

- Frank, S.M.; Barber, T.L.; Lambregts, M.J. Powder diffraction of sodalite in a multiphase ceramic used to immobilize radioactive waste. Powder Diffr. 2005, 20, 212–214. [Google Scholar] [CrossRef]

- Riley, B.J.; Peterson, J.A.; Chong, S.; Vienna, J.D. Influence of ion site occupancies on the unit cell parameters, specific volumes, and densities of M8(AlSiO4)6X2 sodalites where M = Li, Na, K, Rb, and Ag and X = Cl, Br, and I. Phys. Chem. Miner. 2021, 48, 3. [Google Scholar] [CrossRef]

- Shannon, R.D. Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Cryst A 1976, 32, 751–767. [Google Scholar] [CrossRef]

- Taylor, D.; Henderson, C.M.B. A computer model for the cubic sodalite structure. Phys. Chem. Miner. 1978, 2, 325–336. [Google Scholar] [CrossRef]

- Borhade, A.V.; Dholi, A.G.; Tope, D.P.; Wakchaure, S.G. Solvithermal synthesis and crystal structure of aluminogermanate halide sodalites using organic solvent. Indian J. Pure Appl. Phys. 2012, 50, 576–582. [Google Scholar]

- Shchipalkina, N.V.; Zubkova, N.N.; Kotelnikov, A.R.; Koshlyakova, N.N.; Pekov, I.V.; Ksenofontov, D.A.; Britvin, S.N. Crystal chemistry and Raman spectroscopy of two synthetic sodalite-type aluminosilicates with [MoO4]2− and [WO4]2− groups. Phys. Chem. Miner. 2021, 48, 19. [Google Scholar] [CrossRef]

- Mattigod, S.V.; McGrail, B.P.; McCready, D.E.; Wang, L.-Q.; Parker, K.E.; Young, J.S. Synthesis and structure of perrhenate sodalite. Microporous Mesoporous Mater. 2006, 91, 139–144. [Google Scholar] [CrossRef]

- Gramenitskii, E.N.; Kotel’nikov, A.R.; Shchekina, T.I.; Yakubovich, O.V.; Devyatova, V.N.; Zubkov, E.S.; Suk, N.I.; Vigasina, M.F.; Kotel’nikova, Z.A. Composition, structure, and conditions of formation of fluorine-bearing sodalite: Experimental evidence. Geochem. Int. 2018, 56, 521–534. [Google Scholar] [CrossRef]

- Yakubovich, O.V.; Kotel’nikov, A.R.; Shchekina, T.I.; Gramenitskiy, E.N.; Zubkov, E.S. New representative in the dodalite dtructure type with extraframework anions [AlF6]3−. Crystallogr. Rep. 2011, 56, 190–197. [Google Scholar] [CrossRef]

- Van Peteghem, J.K.; Burley, B.J. Studies on solid solution between sodalite, nosean and haüyne. Can. Mineral. 1963, 3, 808–816. [Google Scholar]

- Ito, T.; Nakajima, Y.; Morimoto, N.; Sadanaga, R. On the polysynthetic structure of haüyne. Acta Crystallogr. 1966, 21, A55. [Google Scholar]

- Taylor, D. The sodalite group of minerals, Contrib. Mineral. Petrol. 1967, 16, 172–188. [Google Scholar] [CrossRef]

- Schulz, H. Struktur- and Überstrukturuntersuchungen an Nosean-Einkristallen. Z. Kristallogr. 1970, 131, 114–138. (In German) [Google Scholar] [CrossRef]

- Tsuchiya, N.; Takéuchi, Y. Fine texture of hauyne having modulated structure. Z. Kristallogr. 1985, 173, 273–281. [Google Scholar] [CrossRef]

- Hassan, I.; Buseck, P.R. Cluster ordering and antiphase domain boundaries in haüyne. Can. Mineral. 1989, 27, 173–180. [Google Scholar]

- Xu, H.; Veblen, D.R. Transmission electron microscopy study of optically anisotropic and isotropic haüyne. Am. Mineral. 1995, 80, 87–93. [Google Scholar] [CrossRef]

- Sapozhnikov, A.N. Modulated structure of lazurite from deposits in southwestern Pamir. Sov. Phys. Crystallogr. 1992, 37, 470–472. [Google Scholar]

- Sapozhnikov, N.; Ivanov, V.G.; Levitsky, V.I.; Piskunova, L.F. Structural-mineralogical peculiarities of lazurite from the south-western Pamir. Zap. Vses. Mineral. Obsh. 1993, 122, 108–115. (In Russian) [Google Scholar]

- Evsyunin, V.G.; Sapozhnikov, A.N.; Rastsvetaeva, R.K.; Kashaev, A.A. Modulated structure of orthorhombic lazurite. Crystallogr. Rep. 1998, 43, 999–1002. [Google Scholar]

- Rastsvetaeva, R.K.; Bolotina, N.B.; Sapozhnikov, A.N.; Kashaev, A.A.; Schoenleber, A.; Chapuis, G. Average structure of cubic lazurite with a three-dimensional incommensurate modulation. Crystallogr. Rep. 2002, 47, 404–407. [Google Scholar] [CrossRef]

- Bolotina, N.B.; Rastsvetaeva, R.K.; Sapozhnikov, A.N.; Kashaev, A.A.; Shönleber, A.; Chapuis, G. Incommensurately modulated structure of isotropic lazurite as a product of twinning of two-dimensionally modulated domains. Crystallogr. Rep. 2003, 48, 721–727. [Google Scholar] [CrossRef]

- Bolotina, N.B.; Rastsvetaeva, R.K.; Chapuis, G.; Schönleber, A.; Sapozhnikov, A.N.; Kashaev, A.A. On the symmetry of optically isotropic modulated lazurites from the Baikal region. Ferroelectrics 2004, 305, 95–98. [Google Scholar] [CrossRef]

- Bolotina, N.B.; Rastsvetaeva, R.K.; Sapozhnikov, A.N. Average structure of incommensurately modulated monoclinic lazurite. Crystallogr. Rep. 2006, 51, 589–595. [Google Scholar] [CrossRef]

- Bolotina, N.B. Isotropic lazurite: A cubic single crystal with an incommensurate three-dimensional modulation of the structure. Crystallogr. Rep. 2006, 51, 968–976. [Google Scholar] [CrossRef]

- Bolotina, N. Forms and origin of structure modulation in lazurites. Philos. Mag. 2007, 87, 2679–2685. [Google Scholar] [CrossRef]

- Tauson, V.L.; Sapozhnikov, A.N.; Kaneva, E.V.; Lipko, S.V. Reversion of incommensurate modulation in cubic lazurite: Example of reversible forced equilibrium? Nat. Resour. 2014, 5, 761–771. [Google Scholar] [CrossRef][Green Version]

- Demyanets, L.N. The growth of germanium bromide sodalite crystals under hydrothermal conditions. Crystallogr. Rep. 1997, 42, 1053–1055. [Google Scholar]

- Weippert, V.; Chau, T.; Witthaut, K.; Eisenburger, L.; Johrendt, D. BaGe8As14: A semiconducting sodalite-type compound. Chem. Commun. 2021, 57, 1332–1335. [Google Scholar] [CrossRef] [PubMed]

- Weller, M.T.; Haworth, K.E. Synthesis and thermal decomposition of sodalites Na8[SiAlO4]6·(XO4)2, X = CI, Mn. J. Chem. Soc. Chem. Commun. 1991, 10, 734–735. [Google Scholar] [CrossRef]

- Vidal, L.; Paillaud, J.; Gabelica, Z. A novel monoclinic AlPO4-sodalite formed in the presence of dimethylformamide as template and solvent. Microporous Mesoporous Mater. 1998, 24, 189–197. [Google Scholar] [CrossRef]

- Depmeier, W.; Yamamoto, A. Powder profile refinement of a commensurately modulated aluminate sodalite. Mater. Sci. Forum 1991, 79, 763–768. [Google Scholar] [CrossRef]

- Sapozhnikov, A.N.; Tauson, V.L.; Matveeva, L.N. Discrete change of the modulation wave in the structure of cubic lazurite from the Baikal Lake area during its annealing. Zap. Vseross. Mineral. Obsh. 2001, 130, 121–132. (In Russian) [Google Scholar]

- Petersen, H.; Robben, L.; Šehović, M.; Gesing, T.M. Synthesis, temperature-dependent X-ray diffraction and Raman spectroscopic characterization of the sodalite to nosean phase transformation of |Na7.7(1)(MnO4)1.7(2)(H2O)0.8(2)|[AlSiO4]6. Microporous Mesoporous Mater. 2017, 242, 144–151. [Google Scholar] [CrossRef]

- Bolotina, N.B.; Chukanov, N.V.; Schäfer, C. Growth twins and deformation twins of sodalite-type microporous compounds. Microporous Mesoporous Mater. 2022, 344, 112193. [Google Scholar] [CrossRef]

- Borhade, A.V.; Dholi, A.G. Synthesis and crystal structure of chlorate-enclathrated in aluminogermanate sodalite Na8[AlGeO4]6(ClO3)2. Mater. Sci. Pol. 2013, 31, 246–252. [Google Scholar] [CrossRef]

- Yoshimori, T.; Asano, Y.; Toriumi, Y.; Shiota, T. Investigation on the drying and decomposition of sodium oxalate. Talanta 1978, 25, 603–605. [Google Scholar] [CrossRef] [PubMed]

- Robben, L. Cage reactions in sodalites—A phenomenological approach using cellular automata. Microporous Mesoporous Mater. 2020, 294, 109874. [Google Scholar] [CrossRef]

- Borhade, A.V.; Dholi, A.G.; Kshirsagar, T.A. Synthesis and characterization of a new aluminogermanate thiocyanate aluminogermanate sodalite Na8[AlGeO4]6(SCN)2. Russ. J. Phys. Chem. A 2020, 94, 370–375. [Google Scholar] [CrossRef]

- Borhade, A.V.; Wakchaure, S.G.; Dholi, A.G.; Kshirsagar, T.A. Hydrothermal synthesis, characterization, and thermal properties of alumino silicate azide sodalite, Na8[AlSiO4]6(N3)2. Russ. J. Phys. Chem. A 2017, 91, 1183–1189. [Google Scholar] [CrossRef]

- Herbstein, F.H.; Ron, G.; Weissman, A. The thermal decomposition of potassium permanganate and related substances. Part I. Chemical aspects. J. Chem. Soc. A 1971, 1821–1826. [Google Scholar] [CrossRef]

- Šehović, M.; Robben, L.; Gesing, T.M. Carbon dioxide uptake in nitrite-sodalite: Reaction kinetics and template ordering of the carbonate-nosean formation. Z. Krist. Cryst. Mater. 2015, 230, 263–269. [Google Scholar] [CrossRef]

- Gobeltz-Hautecoeur, N.; Demortier, A.; Lede, B.; Lelieur, J.P.; Duhayon, C. Occupancy of the sodalite cages in the blue ultramarine pigments. Inorg. Chem. 2002, 41, 2848–2854. [Google Scholar] [CrossRef]

- Pokrovski, G.S.; Dubrovinsky, L.S. The S3− ion is stable in geological fluids at elevated temperatures and pressures. Science 2011, 331, 1052–1054. [Google Scholar] [CrossRef]

- Pokrovski, G.S.; Dubessy, J. Stability and abundance of the trisulfur radical ion S3− in hydrothermal fluids. Earth Planet. Sci. Lett. 2015, 411, 298–309. [Google Scholar] [CrossRef]

- Caggiani, M.C.; Mangone, A.; Acquafredda, P. Blue coloured haüyne from Mt. Vulture (Italy) volcanic rocks: SEM-EDS and Raman investigation of natural and heated crystals. J. Raman Spectrosc. 2022, 53, 1–13. [Google Scholar] [CrossRef]

- Ballirano, O.; Maras, A. Crystal chemical and structural characterization of an unusual CO3-bearing sodalite-group mineral. Eur. J. Mineral. 2005, 17, 805–812. [Google Scholar] [CrossRef]

- Rastsvetaeva, R.K.; Ivanova, A.G.; Chukanov, N.V.; Verin, I.A. Crystal structure of alloriite. Dokl. Earth Sci. 2007, 415, 815–819. [Google Scholar] [CrossRef]

- Chukanov, N.V.; Zubkova, N.V.; Pekov, I.V.; Giester, G.; Pushcharovsky, D.Y. Sulfite analogue of alloriite from Sacrofano, Latium, Italy: Crystal chemistry and specific features of genesis. Geol. Ore Depos. 2021, 63, 793–804. [Google Scholar] [CrossRef]

- Chukanov, N.V.; Zubkova, N.V.; Varlamov, D.A.; Pekov, I.V.; Belakovskiy, D.I.; Britvin, S.N.; Van, K.V.; Ermolaeva, V.N.; Vozchikova, S.A.; Pushcharovsky, D.Y. Steudelite, (Na3)[(K,Na)17Ca7]Ca4(Al24Si24O96)(SO3)6F6·4H2O, a new cancrinite-group mineral with afghanite-type framework topology. Phys. Chem. Miner. 2022, 49, 1. [Google Scholar] [CrossRef]

- Zubkova, N.V.; Chukanov, N.V.; Varlamov, D.A.; Vigasina, M.F.; Pekov, I.V.; Ksenofontov, D.A.; Pushcharovsky, D.Y. Sulfite-bearing analogue of marinellite. Zap. Vseross. Mineral. Obsh. 2022, 151, 84–100. [Google Scholar] [CrossRef]

- Buhl, J.-C. Hydrothermal synthesis and characterization of nitrite sodalite single crystals. J. Cryst. Growth 1991, 108, 143–149. [Google Scholar] [CrossRef]

- Matussek, T.; Buhl, J.-C. Stability and thermal behaviour of BH4-anions inside pores of sodium-potassium-tetrahydroborate aluminosilicate sodalite (Na1–xKx)8[AlSiO4]6(BH4)2; x~0.5. React. Kinet. Catal. Lett. 2009, 97, 281–288. [Google Scholar] [CrossRef]

- Gilbert, M.R. Pressureless sintering of sodalite waste-forms for the immobilization of pyroprocessing wastes. Mater. Res. Soc. Symp. Proc. 2015, 1744, 61–66. [Google Scholar] [CrossRef]

- Richmann, M.K.; Reed, D.T.; Kropf, A.J.; Aase, S.B.; Lewis, M.A. EXAFS/XANES studies of plutonium-loaded sodalite/glass waste forms. J. Nucl. Mater. 2001, 297, 303–312. [Google Scholar] [CrossRef]

- Pierce, E.M.; Lilova, K.; Missimer, D.M.; Lukens, W.W.; Wu, L.; Fitts, J.; Rawn, C.; Huq, A.; Leonard, D.N.; Eskelsen, J.R.; et al. Structure and thermochemistry of perrhenate sodalite and mixed guest perrhenate/pertechnetate sodalite. Environ. Sci. Technol. 2017, 51, 997–1006. [Google Scholar] [CrossRef] [PubMed]

- Anenburg, M.; Le Losq, C. Perrhenate sodalite growth from alkali silicate melts by noble metal catalysis. SN Appl. Sci. 2019, 1, 372. [Google Scholar] [CrossRef]

- Lilova, K.; Pierce, E.M.; Wu, L.; Jubb, A.M.; Subramani, T.; Navrotsky, A. Energetics of salt-bearing sodalites, Na8Al6Si6O24X2 (X = SO4, ReO4, Cl, I): A treatment option for pertechnetate-enriched nuclear waste streams. ACS Earth Space Chem. 2020, 4, 2153–2161. [Google Scholar] [CrossRef]

- Dickson, J.O.; Harsh, J.B.; Flury, M.; Pierce, E.M. Immobilization and exchange of perrhenate in sodalite and cancrinite. Microporous Mesoporous Mater. 2015, 214, 115–120. [Google Scholar] [CrossRef][Green Version]

- Dickson, J.O.; Harsh, J.B.; Flury, M.; Lukens, W.W.; Pierce, E.M. Competitive incorporation of perrhenate and nitrate into sodalite. Environ. Sci. Technol. 2014, 48, 12851–12857. [Google Scholar] [CrossRef]

- Petersen, H.; Robben, L.; Gesing, T.M. On the nature of the phase transitions of aluminosilicate perrhenate sodalite. Z. Krist. Cryst. Mater. 2020, 235, 213–223. [Google Scholar] [CrossRef]

- Luksic, S.A.; Riley, B.J.; Parker, K.E.; Hrma, P. Sodalite as a vehicle to increase Re retention in waste glass stimulant during vitrification. J. Nucl. Mater. 2016, 479, 331–337. [Google Scholar] [CrossRef]

- Dickson, J.O.; Harsh, J.B.; Lukens, W.W.; Pierce, E.M. Perrhenate incorporation into binary mixed sodalites: The role of anion size and implications for technetium-99 sequestration. Chem. Geol. 2015, 395, 138–143. [Google Scholar] [CrossRef]

- Hirabayashi, D.; Tanada, Y.; Sugiyama, T.; Enokida, Y. Low-temperature conversion of spent adsorbent to iodine sodalite by a mechanochemical route. J. Am. Inst. Chem. Eng. 2012, 58, 2441–2447. [Google Scholar] [CrossRef]

- Sheppard, G.P.; Hriljac, J.A.; Maddrell, E.R.; Hyatt, N.C. Silver zeolites: Iodide occlusion and conversion to sodalite—A potential 129I waste form? Mat. Res. Soc. Symp. Proc. 2006, 932, 1–8. [Google Scholar] [CrossRef]

- Vance, E.R.; Gregg, D.J.; Grant, C.; Stopic, A.; Maddrell, E.R. Silver iodide sodalite for 129I immobilization. J. Nucl. Mater. 2016, 480, 177–181. [Google Scholar] [CrossRef]

- Maddrell, E.; Gandy, A.; Stennett, M. The durability of iodide sodalite. J. Nucl. Mater. 2014, 449, 168–172. [Google Scholar] [CrossRef]

- Maddrell, E.R.; Vance, E.R.; Grant, C.; Aly, Z.; Stopic, A.; Palmer, T.; Harrison, J.; Gregg, D.J. Silver iodide sodalite—Wasteform/Hip canister interactions and aqueous durability. J. Nucl. Mater. 2019, 517, 71–79. [Google Scholar] [CrossRef]

- Lepry, W.C.; Riley, B.J.; Crum, J.V.; Rodriguez, C.P.; Pierce, D.A. Solution-based approaches for making high-density sodalite waste forms to immobilize spent electrochemical salts. J. Nucl. Mater. 2013, 442, 350–359. [Google Scholar] [CrossRef]

- De Angelis, G.; Nannicini, R.; Martini, F.; Mazzocchia, C.; Modica, G. Different methods to synthesize sodalite, as a matrix for conditioning chloride spent salts from pyroprocesses. Radiochim. Acta 2008, 96, 303–310. [Google Scholar] [CrossRef]

- Giacobbo, F.; da Ros, M.; Macerata, E.; Mariani, M.; Giola, M.; de Angelis, G.; Capone, M.; Fedeli, C. An experimental study on Sodalite and SAP matrices for immobilization of spent chloride salt waste. J. Nucl. Mater. 2018, 499, 512–527. [Google Scholar] [CrossRef]

- Capone, M.; Fedeli, C.; de Angelis, G.; da Ros, M.; Giacobbo, F.; Giola, M.; Macerata, E.; Mariani, M. A study on sodalite pellets as matrix for spent chloride salts confinement. J. Mater. Res. Soc. 2017, 1, 4261–4267. [Google Scholar] [CrossRef]

- Riley, B.J.; Lepry, W.C.; Crum, J.V. Solution-Derived Sodalite Made with Si- and Ge-Ethoxide Precursors for Immobilizing Electrorefiner Salt. J. Nucl. Mater. 2016, 468, 140–146. [Google Scholar] [CrossRef]

- Riley, B.J.; Vienna, J.D.; Frank, S.M.; Kroll, J.O.; Peterson, J.A.; Canfield, N.L.; Zhu, Z.; Zhang, J.; Kruska, K.; Schreiber, D.K.; et al. Glass binder development for a glass-bonded sodalite ceramic waste form. J. Nucl. Mater. 2017, 489, 42–63. [Google Scholar] [CrossRef]

- Borhade, A.V.; Dholi, A.G.; Wakchaure, G.; Tope, D.R. Chemical modification of coal fly ash into iodate sodalite and its use for the removal of Cd2+, Pb2+, and Zn2+ from their aqueous solutions. Desalination Water Treat. 2012, 50, 157–169. [Google Scholar] [CrossRef]

- Esfandiana, H.; Parvinia, M.; Khoshandama, B.; Samadi-Maybodi, A. Removal of diazinon from aqueous solutions in batch systems using Cu-modified sodalite zeolite: An application of response surface methodology. Int. J. Eng. Trans. Appl. 2015, 28, 1552–1563. [Google Scholar] [CrossRef]

- Canfield, G.M.; Bizimis, M.; Latturner, S.E. Sodalite ion exchange in polyethylene oxide oligomer solvents. J. Mater. Chem. 2007, 17, 4530–4534. [Google Scholar] [CrossRef]

- van den Berg, A.W.C. Opportunities and Limitations of Hydrogen Storage in Zeolitic Clathrates. Ph.D. Thesis, Technische Universiteit Delft, Delft, The Netherlands, 2006; 245p. [Google Scholar]

- van den Berg, A.W.C.; Bromley, S.T.; Flikkema, E.; Wojdel, J.; Maschmeyer, T.; Jansen, J.C. Molecular-dynamics analysis of the diffusion of molecular hydrogen in all-silica sodalite. J. Chem. Phys. 2004, 120, 10285–10289. [Google Scholar] [CrossRef] [PubMed]

- van den Berg, A.W.C.; Bromley, S.T.; Flikkema, E.; Jansen, J.C. Effect of cation distribution on self-diffusion of molecular hydrogen in Na3Al3Si3O12 sodalite: A molecular dynamics study. J. Chem. Phys. 2004, 121, 10209–10216. [Google Scholar] [CrossRef]

- van den Berg, A.W.C.; Bromley, S.T.; Jansen, J.C. Thermodynamic limits on hydrogen storage in sodalite framework materials: A molecular mechanics investigation. Microporous Mesoporous Mater. 2005, 78, 63–71. [Google Scholar] [CrossRef]

- Weitkamp, J.; Ernst, S.; Cubero, F.; Wester, F. Nitrido-sodalite Zn6[P12N24] as a material for reversible hydrogen encapsulation. Adv. Mater. 1997, 9, 247–248. [Google Scholar] [CrossRef]

- Dincă, M.; Dailly, A.; Tsay, C.; Long, J.R. Expanded sodalite-type metal–organic frameworks: Increased stability and H2 adsorption through ligand-directed catenation. Inorg. Chem. 2008, 47, 11–13. [Google Scholar] [CrossRef]

- Dincă, M.; Dailly, A.; Liu, Y.; Brown, C.M.; Neumann, D.A.; Long, J.R. Hydrogen storage in microporous metal-organic framework with exposed Mn2+ coordination sites. J. Am. Chem. Soc. 2006, 128, 16876–16883. [Google Scholar] [CrossRef]

- Luo, J.H.; Xu, H.W.; Liu, Y.; Zhao, Y.S.; Daemen, L.L.; Brown, C.; Timofeeva, T.V.; Ma, S.Q.; Zhou, H.C. Hydrogen adsorption in a highly stable porous rare-earth metal-organic framework: Sorption properties and neutron diffraction studies. J. Am. Chem. Soc. 2008, 130, 9626–9627. [Google Scholar] [CrossRef]

- Prasad, T.K.; Hong, D.H.; Suh, M.P. High gas sorption and metal-ion exchange of microporous metal-organic frameworks with incorporated imide groups. Chem. Eur. J. 2010, 16, 14043–14050. [Google Scholar] [CrossRef]

- Sumida, K. Design and Synthesis of Metal-Organic Frameworks for Hydrogen Storage and Carbon Dioxide Capture. Ph.D. Thesis, University of California, Berkeley, CA, USA, 2012. [Google Scholar]

- Yang, S.J.; Im, J.H.; Nishihara, H.; Jung, H.; Lee, K.; Kyotani, T.; Park, C.R. General relationship between hydrogen adsorption capacities at 77 and 298 K and pore characteristics of the porous adsorbents. J. Phys. Chem. C 2012, 116, 10529–10540. [Google Scholar] [CrossRef]

- Pillai, Z.S.; Prasad, P.P.M.H.; Latheef, A.S.A.; Pillai, A. Synthesis and fine tuning of MOF for hydrogen storage. In Recent Trends in the Application of Metal-Organic Frameworks; Chandrasekhar, A., Jacob, G., Eds.; IntechOpen Limited: London, UK, 2023; pp. 1–18. [Google Scholar] [CrossRef]

- Leonard, A.D.; Hudson, J.L.; Fan, H.; Booker, R.; Simpson, L.J.; O’Neill, K.J.; Parilla, P.A.; Heben, M.J.; Pasquali, M.; Kittrell, C.; et al. Nanoengineered carbon scaffolds for hydrogen storage. J. Am. Chem. Soc. 2009, 131, 723–728. [Google Scholar] [CrossRef] [PubMed]

- Basova, T.V.; Polyakov, M.S. Hybrid materials based on carbon nanotubes and polyaromatic molecules: Methods of functionalization and sensor properties. Macroheterocycles 2020, 13, 91–112. [Google Scholar] [CrossRef]

- Gong, Y.-N.; Meng, M.; Zhong, D.-C.; Huang, Y.-L.; Jiang, L.; Lu, T.-B. Counter-cation modulation of hydrogen and methane storage in a sodalite-type porous metal–organic framework. Chem. Commun. 2012, 48, 12002–12004. [Google Scholar] [CrossRef] [PubMed]

- Sumida, K.; Horike, S.; Kaye, S.S.; Herm, Z.R.; Queen, W.L.; Brown, C.M.; Grandjean, F.; Long, G.J.; Dailly, A.; Long, J.R. Hydrogenstorage and carbon dioxide capture in an iron-based sodalite-type metal–organic framework (Fe-BTT) discovered via high-throughput methods. Chem. Sci. 2010, 1, 184–191. [Google Scholar] [CrossRef]

- Gygi, D.; Bloch, E.D.; Mason, J.A.; Hudson, M.R.; Gonzalez, M.I.; Siegelman, R.L.; Darwish, T.A.; Queen, W.L.; Brown, C.M.; Long, J.R. Hydrogen Storage in the Expanded Pore Metal–Organic Frameworks M2(dobpdc) (M = Mg, Mn, Fe, Co, Ni, Zn). Chem. Mater. 2016, 26, 1128–1138. [Google Scholar] [CrossRef]

- Buhl, J.-C.; Schomborg, L.; Rüscher, C.H. Tetrahydroborate sodalite nanocrystals: Low temperature synthesis and thermally controlled intra-cage reactions for hydrogen release of nano- and micro crystals. Microporous Mesoporous Mater. 2010, 132, 210–218. [Google Scholar] [CrossRef]

- Buhl, J.-C.; Rüscher, C.H.; Schomborg, L.; Stemme, F. Nanocrystalline NaBH4-enclathrated zeolite SOD: A model for the improvement of safeness and reactivity of boron hydride based hydrogen storage systems. Clean Technol. 2010, 236–239. [Google Scholar]

- Buhl, J.-C.; Gesing, T.M.; Rüscher, C.H. Synthesis, crystal structure and thermal stability of tetrahydroborate sodalite Na8[AlSiO4]6(BH4)2. Microporous Mesoporous Mater. 2005, 80, 57–63. [Google Scholar] [CrossRef]

- Rüscher, C.H.; Stemme, F.; Schomborg, L.; Buhl, J.-C. Low-temperature hydrogen release from borontetrahydride-sodalite and its reloading: Observations in in-situ and ex-situ TIR experiments. Ceram. Environ. Energy Appl. 2010, 217, 65–70. [Google Scholar]

- Kumar, S.; Jain, A.; Miyaoka, H.; Ichikawa, T.; Kojima, Y. Study on the thermal decomposition of NaBH4 catalyzed by ZrCl4. Int. J. Hydrogen Energy 2017, 42, 22432–22437. [Google Scholar] [CrossRef]

- Martelli, P.; Caputo, R.; Remhof, A.; Mauron, P.; Borgschulte, A.; Züttel, A. Stability and decomposition of NaBH4. J. Phys. Chem. 2010, 114, 7173–7177. [Google Scholar] [CrossRef]

- Buhl, J.-C.; Stemme, F.; Poltz, I. Hydrothermal stability of NaBH4 enclathrated sodalites with aluminosilicate and gallosilicate framework. Microporous Mesoporous Mater. 2009, 126, 276–282. [Google Scholar] [CrossRef]

- Buhl, J.-C. NaBH4 Sodalites, synthesized by modified methods: (1) autothermal synthesis and (2) crossover reaction from gel to melt flow. Adv. Chem. Eng. Sci. 2017, 7, 108–124. [Google Scholar] [CrossRef][Green Version]

- Zheng, Z.; Guliants, V.V.; Misture, S. Sodalites as ultramicroporous frameworks for hydrogen separation at elevated temperatures: Thermal stability, template removal, and hydrogen accessibility. J. Porous Mater. 2009, 16, 343–347. [Google Scholar] [CrossRef]

- De Luca, G.; Pullumbi, P.; Barbieri, G.; Famà, A.D.; Bernardo, P.; Drioli, E. Gusev and Suter calculation of the diffusion coefficients of light gases in silicalite-1 membrane and silica-sodalite zeolite. Sep. Purif. Technol. 2004, 36, 215–228. [Google Scholar] [CrossRef]

- Yao, J.; Zhang, L.; Wang, H. Synthesis of nanocrystalline sodalite with organic additives. Mater. Lett. 2008, 62, 4028–4030. [Google Scholar] [CrossRef]

- Asgari, M.; Jawahery, S.; Bloch, E.D.; Hudson, M.R.; Flacau, R.; Vlaisavljevich, B.; Long, J.R.; Brown, C.M.; Queen, W.L. An experimental and computational study of CO2 adsorption in the sodalite-type M-BTT (M = Cr, Mn, Fe, Cu) metal–organic frameworks featuring open metal sites. Chem. Sci. 2018, 9, 4579–4588. [Google Scholar] [CrossRef]

- Eterigho-Ikelegbe, O.; Bada, S.; Daramola, M.O.; Falcon, R. Synthesis of high purity hydroxy sodalite nanoparticles via poreplugging hydrothermal method for inorganic membrane development: Effect of synthesis variables on crystallinity, crystal size and morphology. Mater. Today Proc. 2021, 38, 675–681. [Google Scholar] [CrossRef]

- Qin, J.-S.; Du, D.-Y.; Li, W.-L.; Zhang, J.-P.; Li, S.-L.; Su, Z.-M.; Wang, X.-L.; Xu, Q.; Shao, K.-Z.; Lan, Y.-Q. N-rich zeolite-like metal–organic framework with sodalite topology: High CO2 uptake, selective gas adsorption and efficient drug delivery. Chem. Sci. 2012, 3, 2114–2118. [Google Scholar] [CrossRef]

- Asgari, M.; Semino, R.; Schouwink, P.A.; Kochetygov, I. Understanding how ligand functionalization influences CO2 and N2 adsorption in a sodalite metaloorganic framework. Chem Mater. 2020, 32, 1526–1536. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Jiang, Y.; Hu, S.; Peng, S.; Xu, C.; Lu, A. Dehydrated Na6[AlSiO4]6 sodalite as a promising SO2 sorbent material: A first principles thermodynamics prediction. J. Am. Ceram. Soc. 2019, 103, 3663–3672. [Google Scholar] [CrossRef]

- Navarro, J.A.R.; Barea, E.; Salas, J.M.; Masciocchi, N.; Galli, S.; Sironi, A.; Ania, C.O.; Parra, J.B. H2, N2, CO, and CO2 sorption properties of a series of robust sodalite-type microporous coordination polymers. Inorg. Chem. 2006, 45, 2397–2399. [Google Scholar] [CrossRef] [PubMed]

- Fasolin, S.; Romano, M.; Boldrini, S.; Ferrario, A.; Fabrizio, M.; Armelao, L.; Barison, S. Single-step process to produce alumina supported hydroxy-sodalite zeolite membranes. J. Mater Sci. 2019, 54, 2049–2058. [Google Scholar] [CrossRef]

- Yang, G.; Guo, H.; Kang, Z.; Feng, S.; Zhao, L.; Mintova, S. Sandwich-type H2/CO2 membranes comprising of graphene oxide and sodalite crystals with adjustable morphology and size. Microporous Mesoporous Mater. 2020, 300, 110120. [Google Scholar] [CrossRef]

- Eterigho-Ikelegbe, O.; Bada, S.O.; Daramola, M.O. Preparation and evaluation of nanocomposite sodalite/α-Al2O3 tubular membranes for H2/CO2 separation. Membranes 2020, 10, 312. [Google Scholar] [CrossRef]