Local Strain Effects on Lattice Defect Dynamics and Interstitial Dislocation Loop Formation in Irradiated Tungsten–Molybdenum Alloys: A Molecular Dynamics Study

Abstract

:1. Introduction

2. Results and Discussion

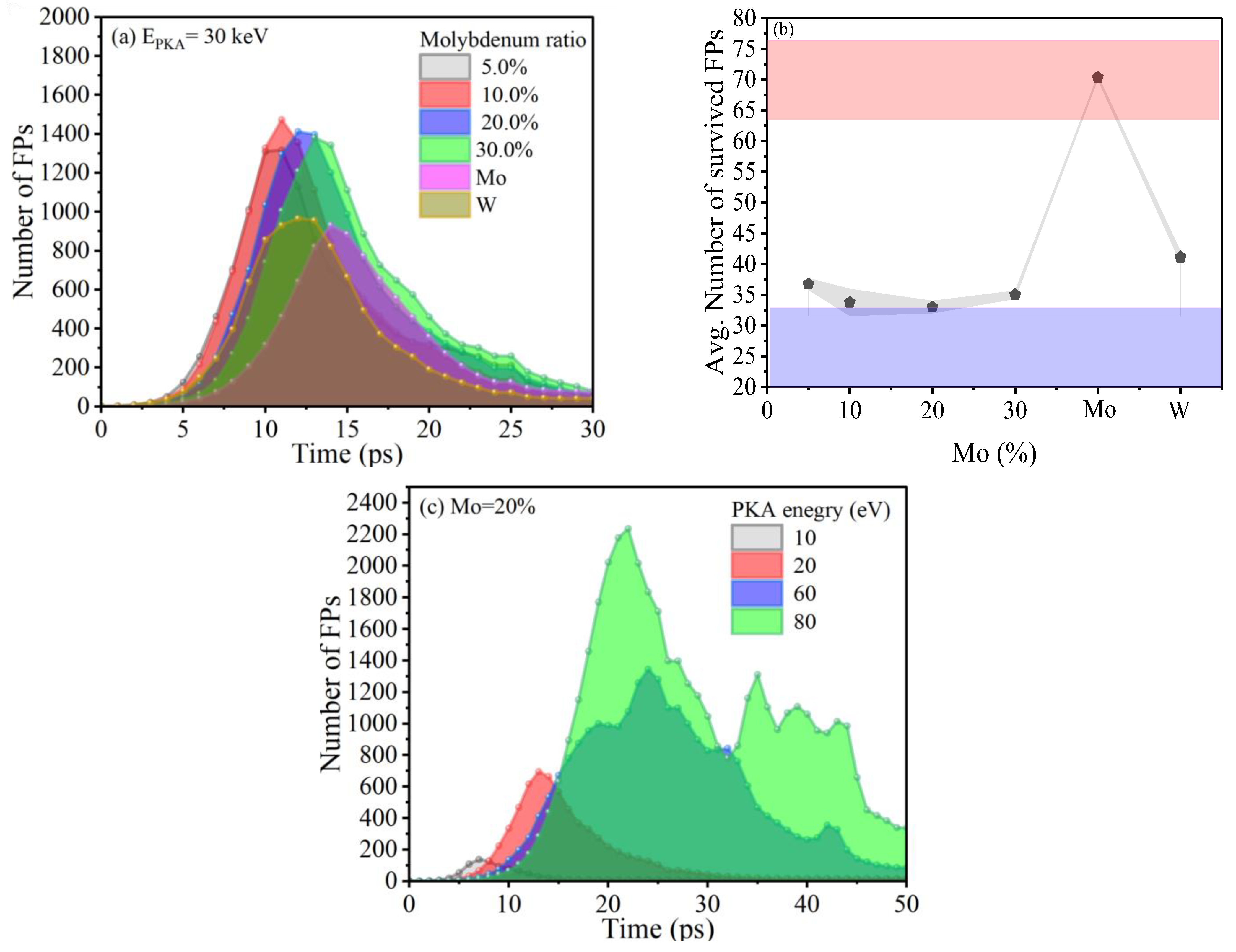

2.1. The Effect of Mo Alloying Ratio on the Survived Frenkel Pairs in W

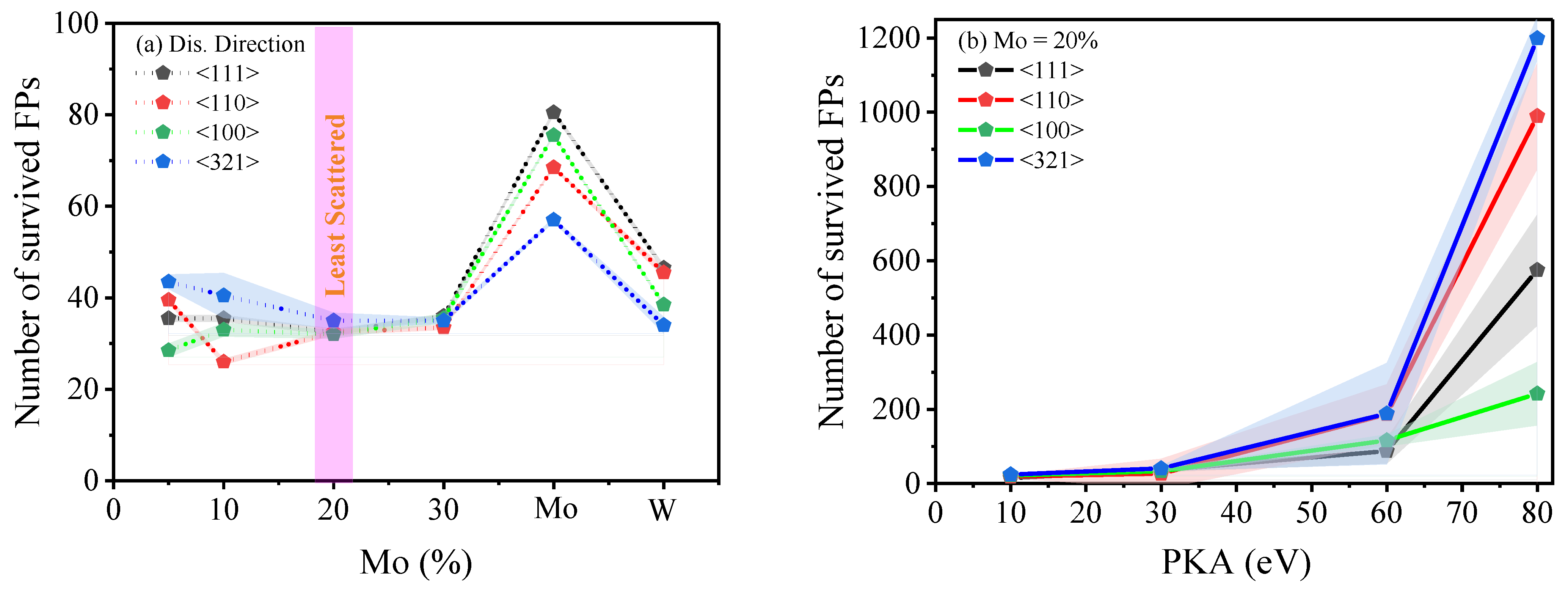

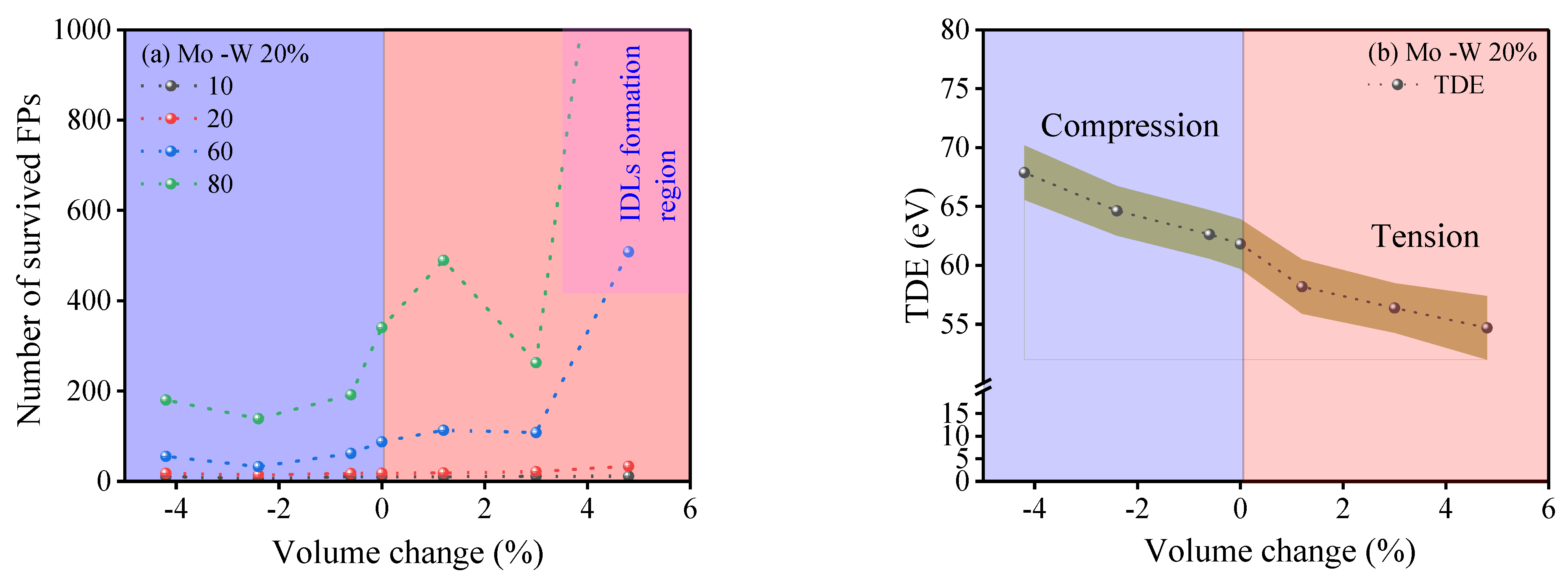

2.2. The Influence of Displacement Direction and Strain on the Formation of Survived Frenkel Pairs

2.3. The Influence of Strain on Cluster and Dislocation Loop Formation

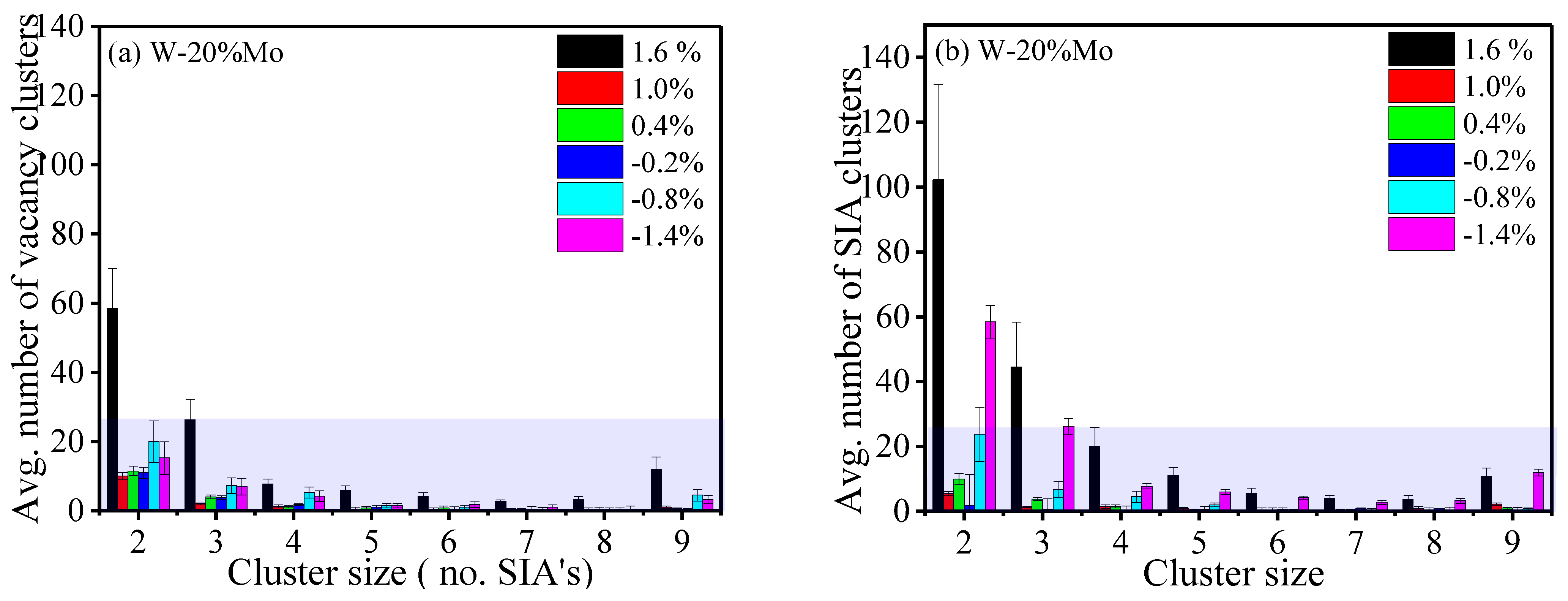

2.3.1. Cluster Analysis

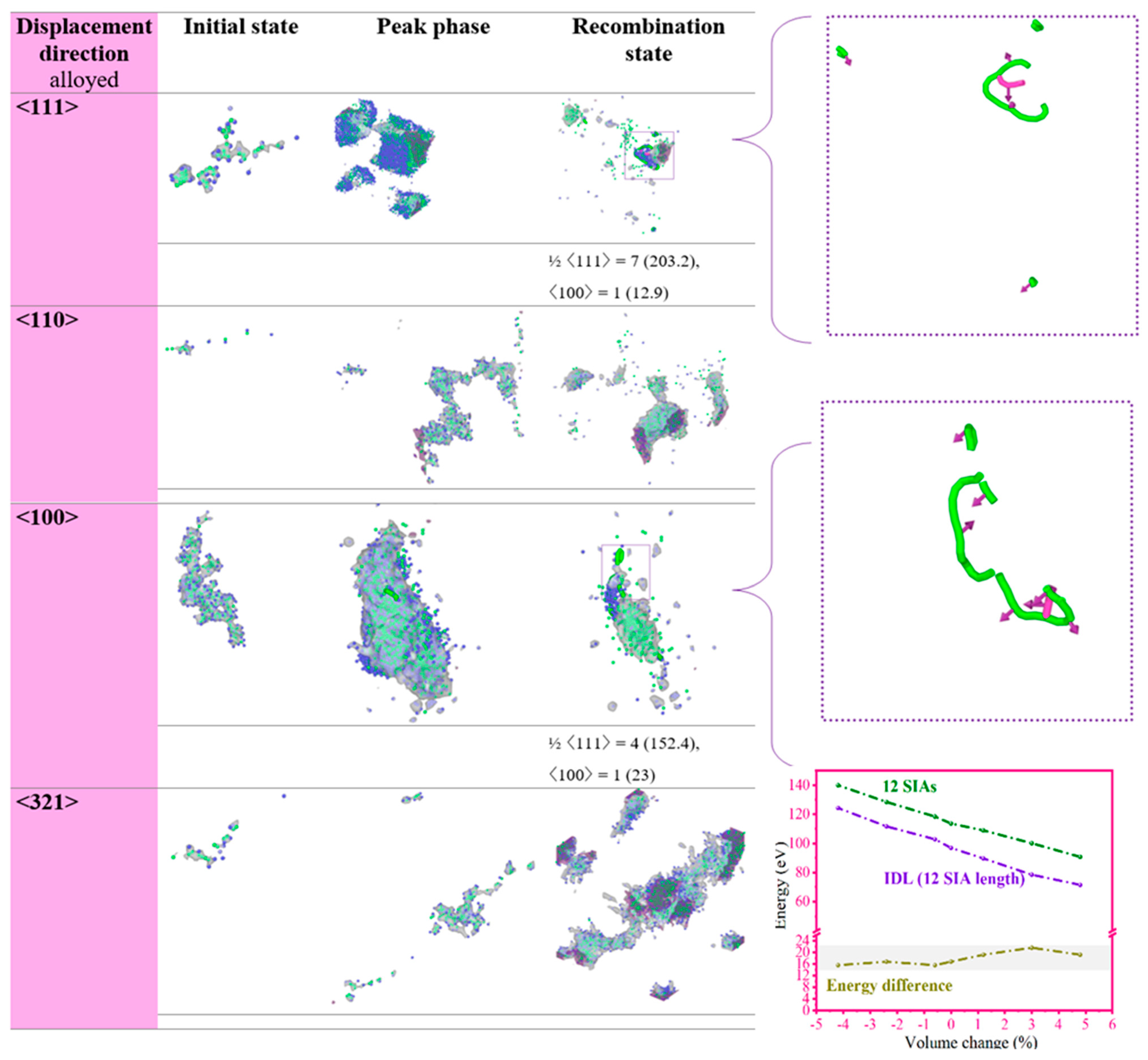

2.3.2. Formation of Interstitial Dislocation Loops

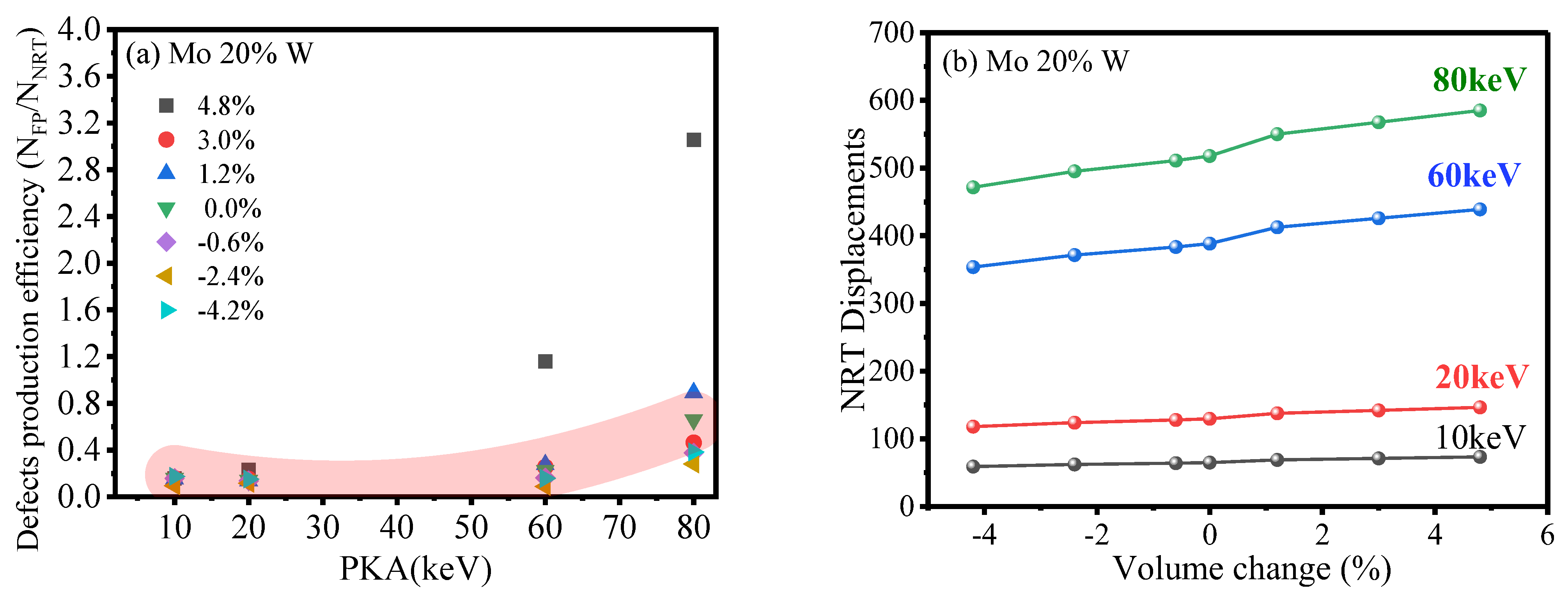

2.3.3. Extra Exploration on Point Defects and Their Formation Efficiency

3. Simulation Methods

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tietz, T.E.; Wilson, J.W. Behavior and Properties of Refractory Metals; Stanford University Press: Redwood City, CA, USA, 1965. [Google Scholar]

- Mathaudhu, S.N.; Hartwig, K.T. Grain refinement and recrystallization of heavily worked tantalum. Mater. Sci. Eng. A 2006, 426, 128–142. [Google Scholar] [CrossRef]

- Brooks, J.; El-Guebaly, L.; Hassanein, A.; Sizyuk, T. Plasma-facing material alternatives to tungsten. Nucl. Fusion 2015, 55, 43002. [Google Scholar] [CrossRef]

- Nogami, S.; Ozawa, I.; Asami, D.; Matsuta, N.; Nakabayashi, S.; Baumgärtner, S.; Lied, P.; Yabuuchi, K.; Miyazawa, T.; Kikuchi, Y.; et al. Tungsten–tantalum alloys for fusion reactor applications. J. Nucl. Mater. 2022, 566, 153740. [Google Scholar] [CrossRef]

- Novakowski, T.J.; Tripathi, J.K.; Hassanein, A. Effect of high-flux, low-energy He+ ion irradiation on Ta as a plasma-facing material. Sci. Rep. 2016, 6, 39746. [Google Scholar] [CrossRef]

- Watanabe, N. Neutronics of pulsed spallation neutron sources. Rep. Prog. Phys. 2003, 66, 339–381. [Google Scholar] [CrossRef]

- Villagrasa-Roussel, C.; Broeders, C.H.M.; Konobeyev, A.Y. Irradiation damages in tantalum spallation target. Kerntechnik 2006, 71, 113–123. [Google Scholar] [CrossRef]

- Sola, E.L.; Calviani, M.; Avigni, P.; Battistin, M.; Descarrega, J.B.; Espadanal, J.C.; Fraser, M.A.; Gilardoni, S.; Goddard, B.; Grenier, D.; et al. Design of a high power production target for the beam dump facility at CERN. Phys. Rev. Accel. Beams 2019, 22, 113001. [Google Scholar] [CrossRef]

- ZLin, Z.; Lavernia, E.; Mohamed, F. High-temperature deformation in a Ta–W alloy. Acta Mater. 1999, 47, 1181–1194. [Google Scholar] [CrossRef]

- Zhou, J.-Q.; Khan, A.S.; Cai, R.; Chen, L. Comparative Study on Constitutive Modeling of Tantalum and Tantalum Tungsten Alloy. J. Iron Steel Res. Int. 2006, 13, 68–74. [Google Scholar] [CrossRef]

- Gavrilyuk, M.I.; Ershova, V.T.; Mikheev, N.I. High-temperature properties of tungsten-molybdenum alloys. Met. Sci. Heat Treat. 1968, 9, 538–539. [Google Scholar] [CrossRef]

- Jiang, D.; Wu, M.; Liu, D.; Li, F.; Chai, M.; Liu, S. Structural Stability, Electronic Structures, Mechanical Properties and Debye Temperature of Transition Metal Impurities in Tungsten: A First-Principles Study. Metals 2019, 9, 967. [Google Scholar] [CrossRef]

- Das, B.; Patra, A. Fabrication of W-Ti-Mo alloys and its microstructure, mechanical properties prepared by mechanical alloying. Mater. Today Proc. 2020, 26, 2845–2852. [Google Scholar] [CrossRef]

- Zhu, K.; Li, X.; Zhu, Z.; Chen, R.; Su, Y.; Guo, J.; Rettenmayr, M.; Liu, D. Analysis of W/Mo alloying on hydrogen permeation performance of dual phase Nb-Ti-Ni alloys based on hydrogen chemical potentials. J. Membr. Sci. 2019, 584, 290–299. [Google Scholar] [CrossRef]

- Koskenniemi, M.; Byggmästar, J.; Nordlund, K.; Djurabekova, F. Efficient atomistic simulations of radiation damage in W and W–Mo using machine-learning potentials. J. Nucl. Mater. 2023, 577, 154325. [Google Scholar] [CrossRef]

- Phasha, M.; Bolokang, A.; Kebede, M. First-principles investigation of W V and W Mo alloys as potential plasma facing materials (PFMs) for nuclear application. Int. J. Refract. Met. Hard Mater. 2021, 95, 105448. [Google Scholar] [CrossRef]

- Was, G.S. Fundamentals of Radiation Materials Science: Metals and Alloys; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Psakhie, S.G.; Zolnikov, K.P.; Kryzhevich, D.S.; Zheleznyakov, A.V.; Chernov, V.M. Evolution of atomic collision cascades in vanadium crystal with internal structure. Crystallogr. Rep. 2009, 54, 1002–1010. [Google Scholar] [CrossRef]

- López-Suárez, M.; Neri, I.; Rurali, R. Band gap engineering of MoS2 upon compression. J. Appl. Phys. 2016, 119, 165105. [Google Scholar] [CrossRef]

- Sun, M.; Ren, Q.; Wang, S.; Yu, J.; Tang, W. Electronic properties of Janus silicene: New direct band gap semiconductors. J. Phys. D Appl. Phys. 2016, 49, 445305. [Google Scholar] [CrossRef]

- Wang, S.-K.; Wang, J. Spin and valley filter in strain engineered silicene. Chin. Phys. B 2015, 24, 037202. [Google Scholar] [CrossRef]

- Rurali, R. Colloquium: Structural, electronic, and transport properties of silicon nanowires. Rev. Mod. Phys. 2010, 82, 427–449. [Google Scholar] [CrossRef]

- Frederiksen, T.; Brandbyge, M.; Lorente, N.; Jauho, A.-P. Inelastic Scattering and Local Heating in Atomic Gold Wires. Phys. Rev. Lett. 2004, 93, 256601. [Google Scholar] [CrossRef] [PubMed]

- Yi, X.; Jenkins, M.L.; Kirk, M.A.; Zhou, Z.; Roberts, S.G. In-situ TEM studies of 150 keV W+ ion irradiated W and W-alloys: Damage production and microstructural evolution. Acta Mater. 2016, 112, 105–120. [Google Scholar] [CrossRef]

- Yi, X.; Jenkins, M.L.; Hattar, K.; Edmondson, P.D.; Roberts, S.G. Characterisation of radiation damage in W and W-based alloys from 2 MeV self-ion near-bulk implantations. Acta Mater. 2015, 92, 163–177. [Google Scholar] [CrossRef]

- Mason, D.R.; Yi, X.; Kirk, M.A.; Dudarev, S.L. Elastic trapping of dislocation loops in cascades in ion-irradiated tungsten foils. J. Phys. Condens. Matter 2014, 26, 375701. [Google Scholar] [CrossRef]

- Sand, A.E.; Dudarev, S.L.; Nordlund, K. High-energy collision cascades in tungsten: Dislocation loops structure and clustering scaling laws. Europhys. Lett. 2013, 103, 46003. [Google Scholar] [CrossRef]

- English, C.; Jenkins, M. Molecular ion irradiations of molybdenum. Philos. Mag. 2010, 90, 821–843. [Google Scholar] [CrossRef]

- Fang, Z.Z.; Wang, X.; Ryu, T.; Hwang, K.S.; Sohn, H. Synthesis, sintering, and mechanical properties of nanocrystalline cemented tungsten carbide—A review. Int. J. Refract. Met. Hard Mater. 2009, 27, 288–299. [Google Scholar] [CrossRef]

- Deb, S.K. Optical and photoelectric properties and colour centres in thin films of tungsten oxide. Philos. Mag. 1973, 27, 801–822. [Google Scholar] [CrossRef]

- Jansen, H.J.F.; Freeman, A.J. Total-energy full-potential linearized augmented-plane-wave method for bulk solids: Electronic and structural properties of tungsten. Phys. Rev. B 1984, 30, 561–569. [Google Scholar] [CrossRef]

- Choi, S.I.; Banisalman, M.J.; Lee, G.-G.; Kwon, J.; Yoon, E.; Kim, J.H. Using rate theory to better understand the stress effect of irradiation creep in iron and its based alloy. J. Nucl. Mater. 2020, 536, 152198. [Google Scholar] [CrossRef]

- Fu, B.; Fitzgerald, S.; Hou, Q.; Wang, J.; Li, M. Effect of collision cascades on dislocations in tungsten: A molecular dynamics study. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2017, 393, 169–173. [Google Scholar] [CrossRef]

- Boev, A.O.; Zolnikov, K.P.; Nelasov, I.V.; Lipnitskii, A.G. Effect of titanium on the primary radiation damage and swelling of vanadium-titanium alloys. Lett. Mater. 2018, 8, 263–267. [Google Scholar] [CrossRef]

- Zhong, Y.; Nordlund, K.; Ghaly, M.; Averback, R.S. Defect production in tungsten: A comparison between field-ion microscopy and molecular-dynamics simulations. Phys. Rev. B 1998, 58, 2361–2364. [Google Scholar] [CrossRef]

- Cui, J.; Hou, Q.; Li, M.; Qiu, M. Molecular dynamics simulations of cascade overlap with void/helium bubbles in tungsten. Nuclear Materials and Energy 2022, 32, 101232. [Google Scholar] [CrossRef]

- Ipatova, I.; Wady, P.; Shubeita, S.; Barcellini, C.; Impagnatiello, A.; Jimenez-Melero, E. Radiation-induced void formation and ordering in Ta-W alloys. J. Nucl. Mater. 2017, 495, 343–350. [Google Scholar] [CrossRef]

- Salman, M.B.; Park, M.; Banisalman, M.J. A Molecular Dynamics Study of Tungsten’s Interstitial Dislocation Loops Formation Induced by Irradiation under Local Strain. Solids 2022, 3, 219–230. [Google Scholar] [CrossRef]

- Banisalman, M.; Oda, T. Molecular Dynamics Study for the Uniaxial Stress Effect on the Threshold Displacement Energy and Defect Formation Energies in Tungsten. In Proceedings of the KNS 2018—Transactions of the Korean Nuclear Society Autumn Meeting, Jeju, Republic of Korea, 16–18 May 2018. [Google Scholar]

- Wei, G.; Byggmästar, J.; Cui, J.; Nordlund, K.; Ren, J.; Djurabekova, F. Effects of lattice and mass mismatch on primary radiation damage in W-Ta and W-Mo binary alloys. J. Nucl. Mater. 2023, 583, 154534. [Google Scholar] [CrossRef]

- Wang, D.; Gao, N.; Wang, Z.; Gao, X.; He, W.; Cui, M.; Pang, L.; Zhu, Y. Effect of strain field on displacement cascade in tungsten studied by molecular dynamics simulation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2016, 384, 68–75. [Google Scholar] [CrossRef]

- Jiang, D.; Zhou, Q.; Xue, L.; Wang, T.; Hu, J. First-principles study the phase stability and mechanical properties of binary W-Mo alloys. Fusion Eng. Des. 2018, 130, 56–61. [Google Scholar] [CrossRef]

- Chen, Y.; Liao, X.; Gao, N.; Hu, W.; Gao, F.; Deng, H. Interatomic potentials of W–V and W–Mo binary systems for point defects studies. J. Nucl. Mater. 2020, 531, 152020. [Google Scholar] [CrossRef]

- Liu, Y.; Feng, K.; Wang, H.; Cai, J.; Zhang, Z. Thermodynamic mechanism of phase formation for W-Mo-Cu composite by electric field sintering. Int. J. Refract. Met. Hard Mater. 2022, 109, 105986. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, W.; Liu, Y.; Li, R.; Meng, F.; Song, J.; Qi, Y. A first principles investigation of W1-xMox (x=0−68.75 at.%) alloys: Structural, electronic, mechanical and thermal properties. J. Alloy. Compd. 2020, 829, 154480. [Google Scholar] [CrossRef]

- Calder, A.; Bacon, D.; Barashev, A.; Osetsky, Y. On the origin of large interstitial clusters in displacement cascades. Philos. Mag. 2010, 90, 863–884. [Google Scholar] [CrossRef]

- Miyashiro, S.; Fujita, S.; Okita, T. MD simulations to evaluate the influence of applied normal stress or deformation on defect production rate and size distribution of clusters in cascade process for pure Cu. J. Nucl. Mater. 2011, 415, 1–4. [Google Scholar] [CrossRef]

- Fu, J.; Chen, Y.; Fang, J.; Gao, N.; Hu, W.; Jiang, C.; Zhou, H.-B.; Lu, G.-H.; Gao, F.; Deng, H. Molecular dynamics simulations of high-energy radiation damage in W and W–Re alloys. J. Nucl. Mater. 2019, 524, 9–20. [Google Scholar] [CrossRef]

- Malerba, L.; Terentyev, D.; Olsson, P.; Chakarova, R.; Wallenius, J. Molecular dynamics simulation of displacement cascades in Fe–Cr alloys. J. Nucl. Mater. 2004, 329–333, 1156–1160. [Google Scholar] [CrossRef]

- Terentyev, D.A.; Malerba, L.; Chakarova, R.; Nordlund, K.; Olsson, P.; Rieth, M.; Wallenius, J. Displacement cascades in Fe–Cr: A molecular dynamics study. J. Nucl. Mater. 2006, 349, 119–132. [Google Scholar] [CrossRef]

- Salman, M.B.; Park, M.; Banisalman, M.J. Revealing the Effects of Strain and Alloying on Primary Irradiation Defects Evolution in Tantalum through Atomistic Simulations. Met. Mater. Int. 2023, 29, 3618–3629. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO—The Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Stukowski, A.; Bulatov, V.V.; Arsenlis, A. Automated identification and indexing of dislocations in crystal interfaces. Model. Simul. Mater. Sci. Eng. 2012, 20, 85007. [Google Scholar] [CrossRef]

- Yan, W.-L.; Sygnatowicz, M.; Lu, G.-H.; Liu, F.; Shetty, D.K. First-principles study on surface stability of tantalum carbides. Surf. Sci. 2016, 644, 24–28. [Google Scholar] [CrossRef]

- Salman, M.B.; Kilic, M.E.; Banisalman, M.J. Formation of Interstitial Dislocation Loops by Irradiation in Alpha-Iron under Strain: A Molecular Dynamics Study. Crystals 2021, 11, 317. [Google Scholar] [CrossRef]

- Setyawan, W.; Nandipati, G.; Roche, K.J.; Heinisch, H.L.; Wirth, B.D.; Kurtz, R.J. Displacement cascades and defects annealing in tungsten, Part I: Defect database from molecular dynamics simulations. J. Nucl. Mater. 2015, 462, 329–337. [Google Scholar] [CrossRef]

- Fitzgerald, S. Crowdion–solute interactions: Analytical modelling and stochastic simulation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2015, 352, 14–17. [Google Scholar] [CrossRef]

- Stoller, R. Evaluation of neutron energy spectrum effects and RPV thru-wall attenuation based on molecular dynamics cascade simulations. Nucl. Eng. Des. 2000, 195, 129–136. [Google Scholar] [CrossRef]

- Miyashiro, S.; Fujita, S.; Okita, T.; Okuda, H. MD simulations to evaluate effects of applied tensile strain on irradiation-induced defect production at various PKA energies. Fusion Eng. Des. 2012, 87, 1352–1355. [Google Scholar] [CrossRef]

- Banisalman, M.J.; Oda, T. Atomistic simulation for strain effects on threshold displacement energies in refractory metals. Comput. Mater. Sci. 2019, 158, 346–352. [Google Scholar] [CrossRef]

- Norgett, M.; Robinson, M.; Torrens, I. A proposed method of calculating displacement dose rates. Nucl. Eng. Des. 1975, 33, 50–54. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Daw, M.S.; Baskes, M.I. Embedded-atom method: Derivation and application to impurities, surfaces, and other defects in metals. Phys. Rev. B 1984, 29, 6443–6453. [Google Scholar] [CrossRef]

- Park, S.; Banisalman, M.J.; Oda, T. Characterization and quantification of numerical errors in threshold displacement energy calculated by molecular dynamics in bcc-Fe. Comput. Mater. Sci. 2019, 170, 109189. [Google Scholar] [CrossRef]

- Banisalman, M.J.; Park, S.; Oda, T. Evaluation of the threshold displacement energy in tungsten by molecular dynamics calculations. J. Nucl. Mater. 2017, 495, 277–284. [Google Scholar] [CrossRef]

- Chen, Y.; Fang, J.; Liu, L.; Hu, W.; Gao, N.; Gao, F.; Deng, H. Development of the interatomic potentials for W-Ta system. Comput. Mater. Sci. 2019, 163, 91–99. [Google Scholar] [CrossRef]

- Biget, M.; Maury, F.; Vajda, P.; Lucasson, A. Near-threshold displacements in tantalum single crystals. Phys. Rev. B 1979, 19, 820–830. [Google Scholar] [CrossRef]

- Fu, J.; Ding, W.; Zheng, M.; Mao, X. Molecular dynamics study on threshold displacement energies in Fe-Cr alloys. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2018, 419, 1–7. [Google Scholar] [CrossRef]

- Rycroft, C.H. VORO++: A three-dimensional Voronoi cell library in C++. Chaos Interdiscip. J. Nonlinear Sci. 2009, 19, 041111. [Google Scholar] [CrossRef]

- Salman, M.B.; Park, M.; Banisalman, M.J. Atomistic Study for the Tantalum and Tantalum–Tungsten Alloy Threshold Displacement Energy under Local Strain. Int. J. Mol. Sci. 2023, 24, 3289. [Google Scholar] [CrossRef]

- Stukowski, A.; Albe, K. Extracting dislocations and non-dislocation crystal defects from atomistic simulation data. Model. Simul. Mater. Sci. Eng. 2010, 18, 85001. [Google Scholar] [CrossRef]

| Displacement Direction at 80 KeV | −1.4% | −0.8% | −0.2% | 0.4% | 1.0% | 1.6% |

|---|---|---|---|---|---|---|

| <100> | 0 | 0 | 0 | 1A (101.5) | 0 | 7A (203.2) 1B (12.9) |

| <110> | 0 | 0 | 0 | 0 | 0 | 0 |

| <111> | 0 | 0 | 0 | 2A (44.5) 2B (42.5) | 6 A (163.1) | 4A (152.4) 1B (23) |

| <321> | 00 | 1A (19.27) | 0 | 0 | 2A (101.6) | 0 |

| PKA Energy (keV) | System Count (Atoms) | System Size (Å) | Estimated NRT Displacements | Simulation Duration (ps) |

|---|---|---|---|---|

| 5 | 432,000 | 16 | 33 (26) | 50 |

| 10 | 432,000 | 16 | 66 (52) | 50 |

| 15 | 432,000 | 16 | 99 (78) | 50 |

| 30 | 432,000 | 16 | 198 (157) | 50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alnairi, M.M.; Banisalman, M.J. Local Strain Effects on Lattice Defect Dynamics and Interstitial Dislocation Loop Formation in Irradiated Tungsten–Molybdenum Alloys: A Molecular Dynamics Study. Int. J. Mol. Sci. 2024, 25, 10777. https://doi.org/10.3390/ijms251910777

Alnairi MM, Banisalman MJ. Local Strain Effects on Lattice Defect Dynamics and Interstitial Dislocation Loop Formation in Irradiated Tungsten–Molybdenum Alloys: A Molecular Dynamics Study. International Journal of Molecular Sciences. 2024; 25(19):10777. https://doi.org/10.3390/ijms251910777

Chicago/Turabian StyleAlnairi, Marzoqa M., and Mosab Jaser Banisalman. 2024. "Local Strain Effects on Lattice Defect Dynamics and Interstitial Dislocation Loop Formation in Irradiated Tungsten–Molybdenum Alloys: A Molecular Dynamics Study" International Journal of Molecular Sciences 25, no. 19: 10777. https://doi.org/10.3390/ijms251910777