Pressure Sensitive Adhesive Tape: A Versatile Material Platform for Optical Sensors

Abstract

:1. Introduction

2. PSA Tape Constructions and Materials

2.1. Optical Properties of PSA Tape

- (1)

- General-purpose #550 Scotch™ transparent tape, used in the fabrication of many optical sensors that will be reviewed in the next section, is a single-coated PSA 19-mm-wide tape consisting of a 30-µm-thick BOPP backing and a 20-µm-thick acrylic adhesive layer [35]. This sticky tape exhibits an internal transmittance, measured with a spectrophotometer in the spectral range 500–725 nm, which is nearly constant and equal to approximately 99.4%, and its refractive index at room temperature as measured by reflectance interferometry was found to be 1.45 [25].

- (2)

- Luu et al. measured the optical properties of three types of general-purpose PSA tape employed in the implementation of microfluidic systems for optical interrogation [30]: Scotch® permanent double sided tape (19.0 mm wide and 88.9 μm thick), Scotch® gloss finish multitask tape (19.0 mm wide and 50.8 μm thick), and Scotch® shipping packaging tape (47.7 mm wide and 78.7 μm thick). Scotch® permanent double-sided tape is a cellulose film with an acrylate adhesive on both sides. Measurements of the refractive index were conducted with an Abbe refractometer. An experimental value of n = 1.51 at 630-nm-wavelength was found for all tapes. This result is in agreement with published data regarding the refractive index of cellulose (n = 1.47 at 630 nm), the baking material, averaged with that of styrene (n = 1.52 at 630 nm), the adhesive material. The three tapes had an absorption coefficient close to zero and low scattering coefficients (3–4 cm−1).

- (3)

- 3M™ (Saint Paul, MN, USA) Optically Clear Laminating Adhesive 8146-x [36] is a family of unsupported PSA tapes consisting of an acrylic adhesive layer (thickness ranges from 25 µm to 125 µm, depending on the specific tape) sandwiched between two 70-µm-thick release liners made of polyester. The refractive index of these tapes is 1.474 at sodium D-line (589.3 nm) at 25 °C, measured with an Abbe refractometer, and exhibit light transmission >99% when corrected for reflection losses. These adhesive tapes are specifically designed to provide crystal clear, high reliability optical coupling and mechanical joining for various transparent materials. Typical applications include touch screens (for bonding film and glass laminates), transparent graphic overlays and optical management films for LCD.

2.2. Mechanical Properties of PSA Tape

2.3. Temperature Effect

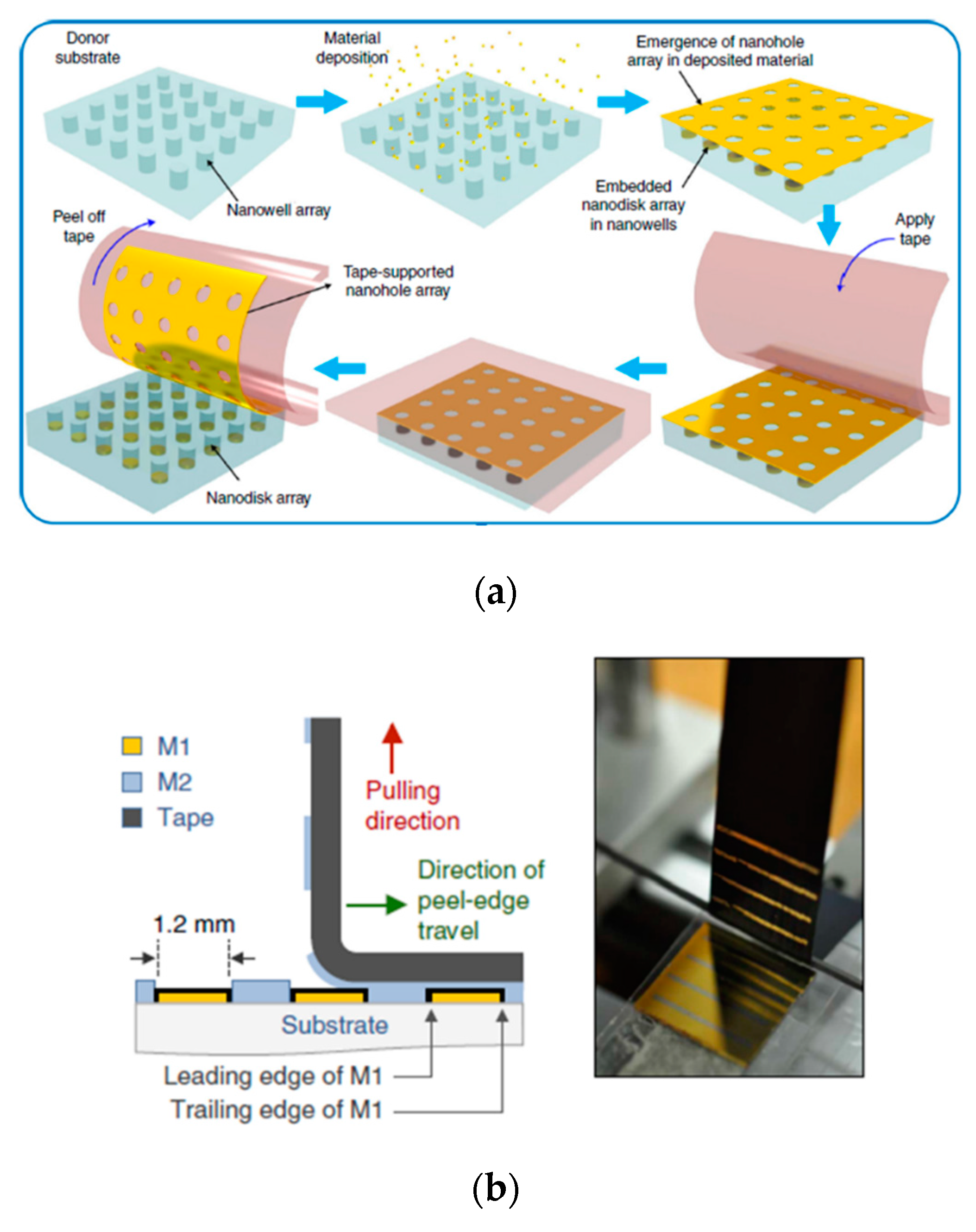

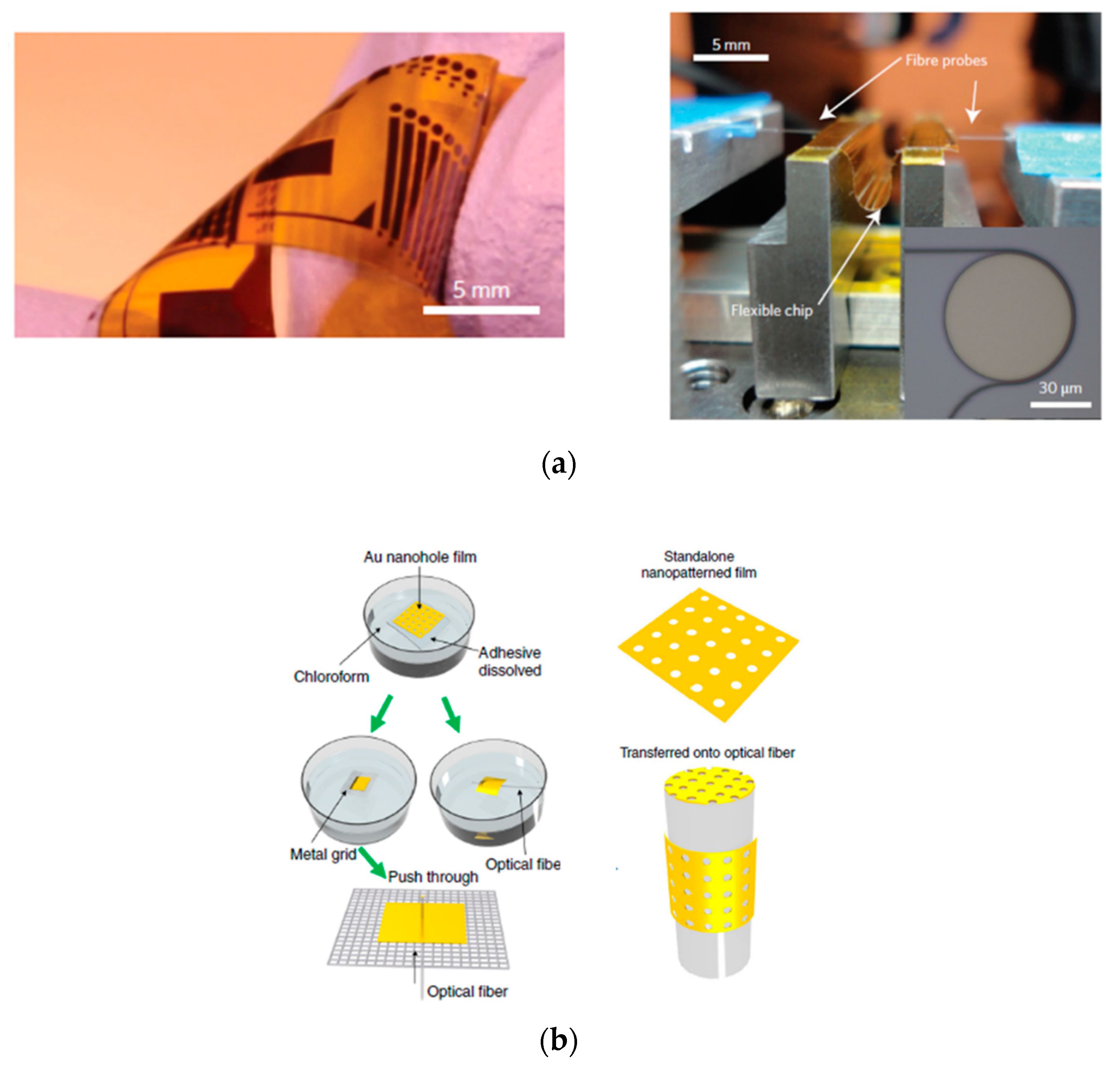

3. Examples of PSA Tape-Based Optical Sensors

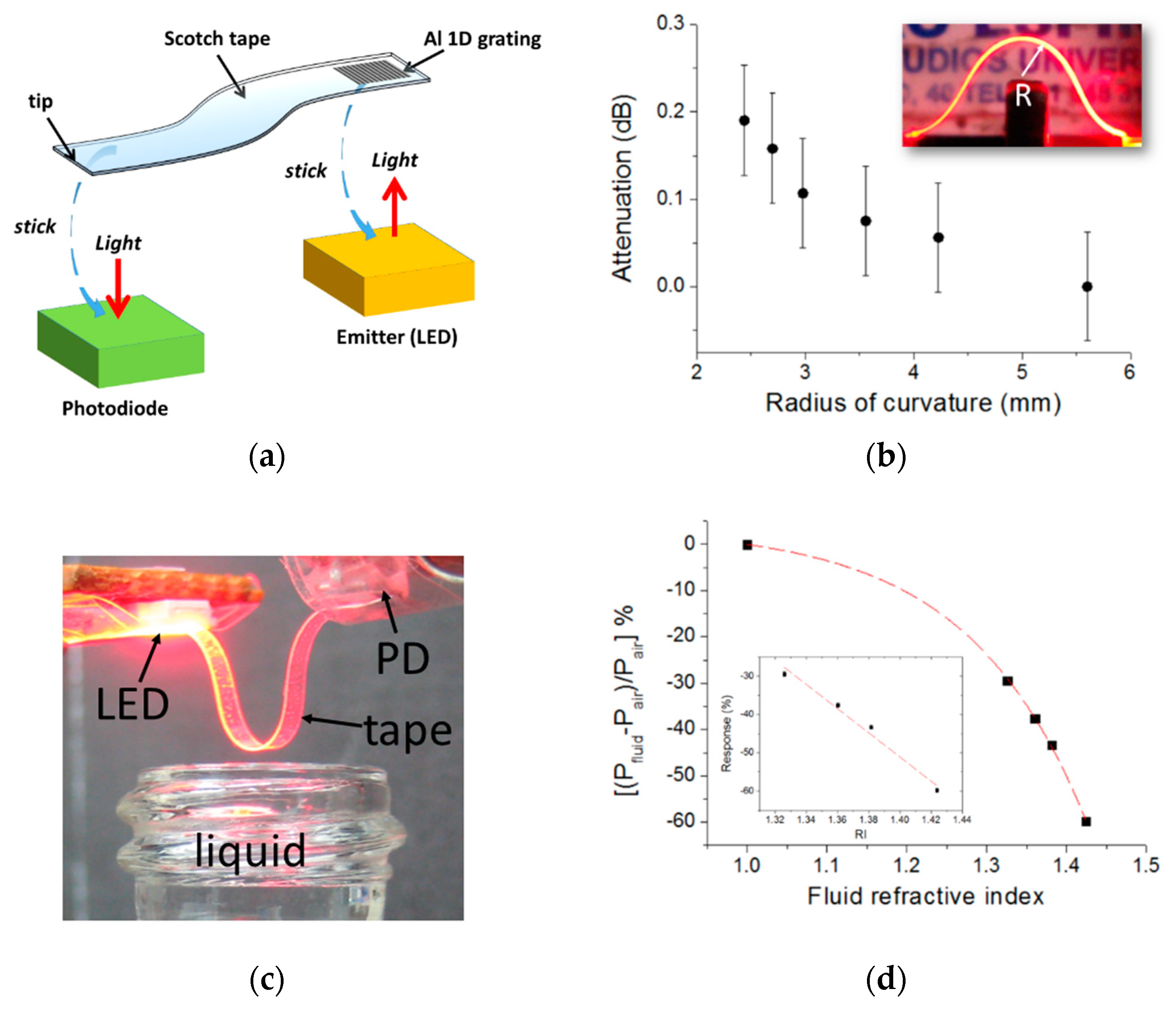

3.1. Liquid Refractive Index Sensing

3.1.1. Guided-Wave Refractive Index Optical Sensors

3.1.2. Free-Space Interrogated Refractive Index Optical Sensors

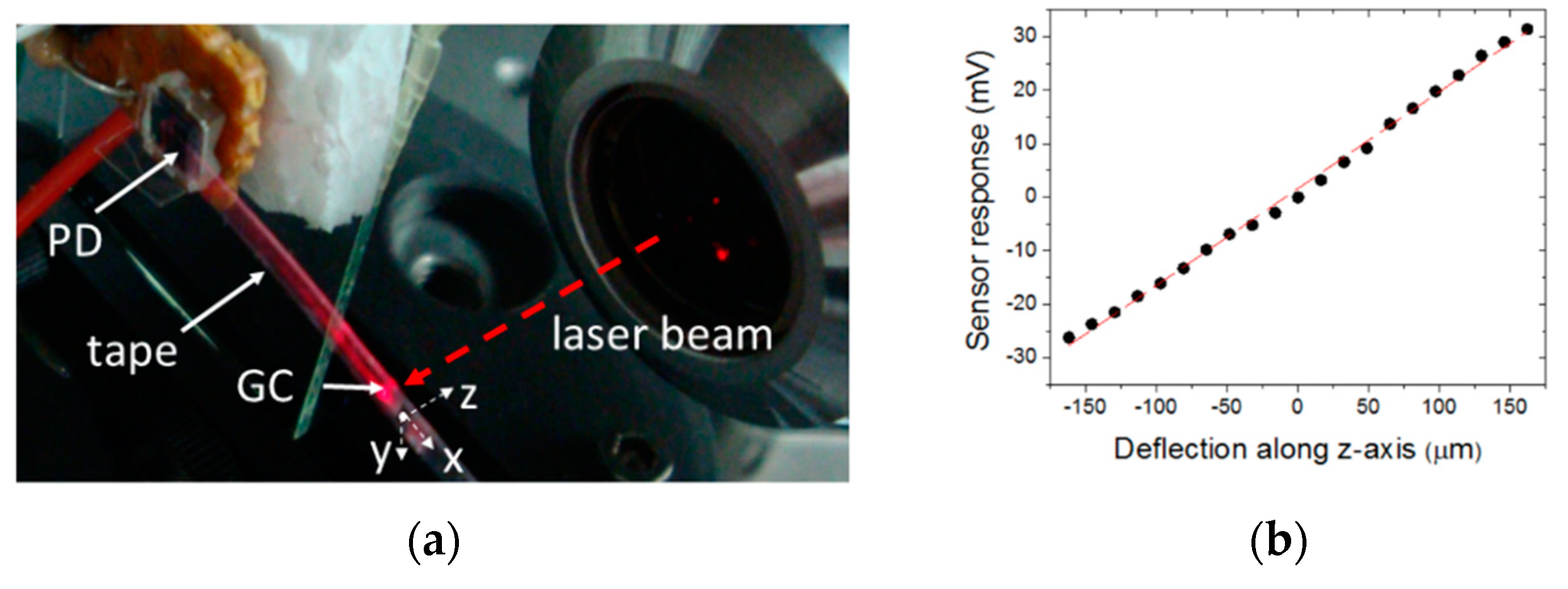

3.2. Opto-Mechanical Sensing

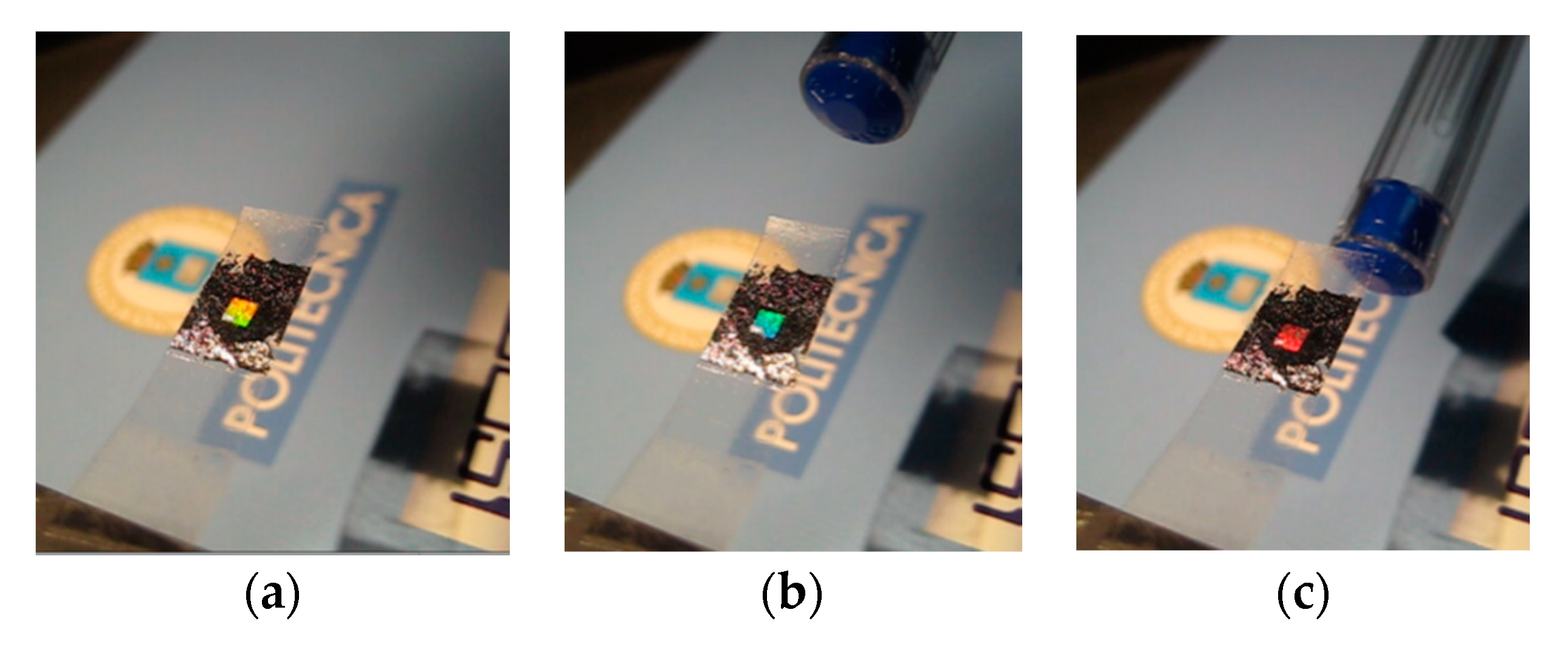

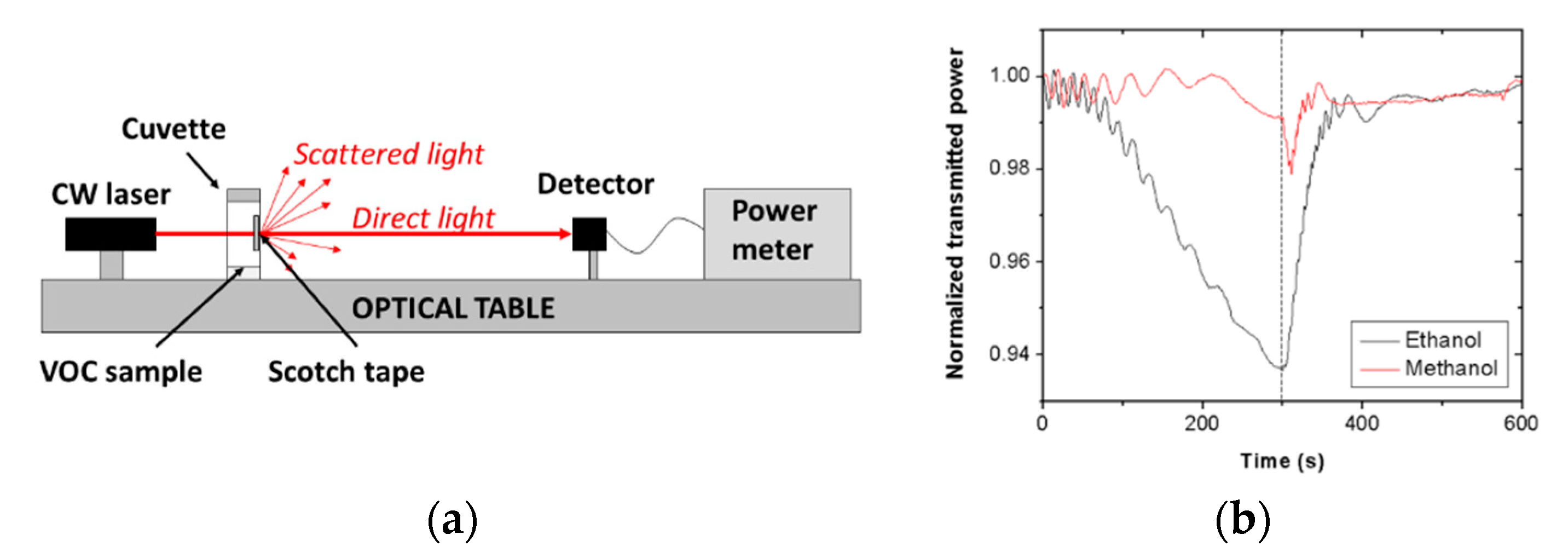

3.3. Volatile Organic Compound Vapor Sensing

4. Discussions

Funding

Conflicts of Interest

References

- Pressure Sensitive Tape Council. Available online: https://www.pstc.org/i4a/pages/index.cfm?pageid=5254 (accessed on 16 June 2020).

- Adhesive and Sealants Industry. Available online: https://www.adhesivesmag.com/articles/88511-pressure-sensitive-adhesives-101 (accessed on 18 June 2020).

- Pressure Sensitive Tape: What to Know. Available online: https://www.packagingtapedepot.com/Pressure-Sensitive-Tape-What-to-Know-kb-16456.html (accessed on 2 July 2020).

- Athavale, S.P. Handbook of Pressure Sensitive Adhesives and Coatings: Pressure Sensitive Adhesive Technologies; Notion Press: Chennai, India, 2018. [Google Scholar]

- Benedek, I.; Feldstein, M.M. Handbook of Pressure-Sensitive Adhesives and Products; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Meitl, M.A.; Zhu, Z.T.; Kumar, V.; Lee, K.J.; Feng, X.; Huang, Y.Y.; Adesida, I.; Nuzzo, R.G.; Rogers, J.A. Transfer printing by kinetic control of adhesion to an elastomeric stamp. Nat. Mater. 2006, 5, 33–38. [Google Scholar] [CrossRef]

- Feng, X.; Meitl, M.A.; Bowen, A.M.; Huang, Y.; Nuzzo, R.G.; Rogers, J.A. Competing Fracture in Kinetically Controlled Transfer Printing. Langmuir 2007, 23, 12555–12560. [Google Scholar] [CrossRef] [PubMed]

- Schmid, H.; Wolf, H.; Allenspach, R.; Riel, H.; Karg, S.; Michel, B.; Delamarche, E. Preparation of metallic films on elastomeric stamps and their application for contact processing and contact printing. Adv. Funct. Mater. 2003, 13, 145–153. [Google Scholar] [CrossRef]

- Bai, W.; Yang, H.; Ma, Y.; Chen, H.; Shin, J.; Liu, Y.; Yang, Q.; Kandela, I.; Liu, Z.; Kang, S.K. Flexible transient optical waveguides and surface-wave biosensors constructed from monocrystalline silicon. Adv. Mater. 2018, 30, 1801584. [Google Scholar] [CrossRef] [PubMed]

- Henzie, J.; Lee, M.H.; Odom, T.W. Multiscale patterning of plasmonic metamaterials. Nat. Nanotechnol. 2007, 2, 549–554. [Google Scholar] [CrossRef]

- Pryce, I.M.; Aydin, K.; Kelaita, Y.A.; Briggs, R.M.; Atwater, H.A. Highly strained compliant optical metamaterials with large frequency tunability. Nano Lett. 2010, 10, 4222–4227. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Li, H.; Li, M. Flexible and tunable silicon photonic circuits on plastic substrates. Sci. Rep. 2012, 2, 622. [Google Scholar] [CrossRef] [Green Version]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [Green Version]

- Radisavljevic, B.; Radenovic, A.; Brivio, J.; Giacometti, V.; Kis, A. Single-layer MoS2 transistors. Nat. Nanotechnol. 2011, 6, 147–150. [Google Scholar] [CrossRef]

- Hong, G.; Zhou, M.; Zhang, R.; Hou, S.; Choi, W.; Woo, Y.S.; Choi, J.Y.; Liu, S.; Zhang, J. Separation of metallic and semiconducting single-walled carbon nanotube arrays by Scotch tape. Angew. Chem. Int. Ed. 2011, 50, 6819–6823. [Google Scholar] [CrossRef]

- Lee, C.H.; Kim, D.R.; Zheng, X.L. Fabricating nanowire devices on diverse substrates by simple transfer-printing methods. Proc. Natl. Acad. Sci. USA 2010, 107, 9950–9955. [Google Scholar] [CrossRef] [Green Version]

- Jeong, J.W.; Yang, S.R.; Hur, Y.H.; Kim, S.W.; Kwang, M.B.; Yim, S.; Jang, H.I.; Park, J.H.; Lee, S.Y.; Park, C.O.; et al. High-resolution nanotransfer printing applicable to diverse surfaces via interface-targeted adhesion switching. Nat. Commun. 2014, 5, 5387. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, X.S.; Park, H.R.; Pelton, M.; Piao, X.; Lindquist, N.C.; Im, H.; Kim, Y.J.; Ahn, J.S.; Ahn, K.J.; Park, N.; et al. Atomic layer lithography of wafer-scale nanogap arrays for extreme confinement of electromagnetic waves. Nat. Commun. 2013, 4, 2361. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, J.Y.; Kang, B.J.; Bahk, Y.M.; Kim, Y.S.; Park, J.; Kim, W.T.; Rhie, J.; Han, S.; Jeon, H.; Park, C.H.; et al. Tunnelling current-voltage characteristics of Angstrom gaps measured with terahertz time-domain spectroscopy. Sci. Rep. 2016, 6, 29103. [Google Scholar] [CrossRef] [PubMed]

- Beesley, D.J.; Semple, J.; Jagadamma, L.K.; Amassian, A.; McLachlan, M.A.; Anthopoulos, T.D.; de Mello, J.C. Sub-15-nm patterning of asymmetric metal electrodes and devices by adhesion lithography. Nat. Commun. 2014, 5, 3933–3937. [Google Scholar] [CrossRef] [Green Version]

- Barrios, C.A.; Canalejas-Tejero, V. Compact discs as versatile cost-effective substrates for releasable nanopatterned aluminium films. Nanoscale 2014, 7, 3435–3439. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, A.; Han, W.; Wang, Y.; Lu, M.; Dong, L. Tape nanolithography: A rapid and simple method for fabricating flexible, wearable nanophotonic devices. Microsyst. Nanoeng. 2018, 4, 31. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, L.; Lin, H.; Qiao, S.; Zou, Y.; Danto, S.; Richardson, K.; Musgraves, J.D.; Lu, N.; Hu, J. Integrated flexible chalcogenide glass photonic devices. Nat. Photon. 2014, 8, 643–649. [Google Scholar] [CrossRef]

- Barrios, C.A.; Canalejas-Tejero, V. Micro-shaping of nanopatterned surfaces by electron beam irradiation. Micromachines 2016, 7, 66. [Google Scholar] [CrossRef] [Green Version]

- Barrios, C.A.; Canalejas-Tejero, V. Light coupling in a Scotch tape waveguide via an integrated metal diffraction grating. Opt. Lett. 2016, 41, 301–304. [Google Scholar] [CrossRef]

- Barrios, C.A.; Canalejas-Tejero, V. An analysis of the surface-normal coupling efficiency of a metal grating coupler embedded in a Scotch tape optical waveguide. Opt. Comm. 2017, 382, 477–484. [Google Scholar] [CrossRef] [Green Version]

- Barrios, C.A. Rapid on-site formation of a free-standing flexible optical link for sensing applications. Sensors 2016, 16, 1643. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barrios, C.A. A deflection optical sensor based on a Scotch tape waveguide with an integrated grating coupler. Sens. Actuators A Phys. 2018, 269, 500–504. [Google Scholar] [CrossRef]

- Zamora, V.; Marx, S.; Arndt-Staufenbiel, N.; Janeczka, C.; Havlik, G.; Queisser, M.; Schröder, H. Laser-microstructured double-sided adhesive tapes for integration of a disposable biochip. Proceedings 2017, 1, 606. [Google Scholar] [CrossRef] [Green Version]

- Luu, L.; Roman, P.A.; Mathews, S.A.; Ramella-Roman, J.C. Microfluidics based phantoms of superficial vascular network. Biomed. Opt. Express 2012, 3, 1350–1364. [Google Scholar] [CrossRef] [Green Version]

- JBC Technologies. Available online: https://www.jbc-tech.com/blog/posts/understanding-pressure-sensitive-adhesive-psa-performance-properties/ (accessed on 20 June 2020).

- Khanjani, J. Pressure Sensitive Adhesive Joints. In Adhesives and Adhesive Joints in Industry Applications; Rudawska, A., Ed.; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef] [Green Version]

- Can-Do National Tape. Available online: https://www.can-dotape.com/adhesive-tape-consultant/pressure-sensitive-adhesive-tape/ (accessed on 21 June 2020).

- Seymour, R.B.; Carraher, C.E. Structure—Property Relationships in Polymers; Plenum Press: New York, NY, USA, 1984. [Google Scholar]

- 3M™ #550 Scotch Transparent Tape Technical Data. Available online: https://www.bag-distribution.fr/Files/108113/153225151920829.pdf (accessed on 1 June 2020).

- 3M™ Optically Clear Adhesive 8146-x Technical Data. Available online: https://multimedia.3m.com/mws/media/944360O/3mtm-optically-clear-adhesive-8146-x-series-tds.pdf (accessed on 10 June 2020).

- Beléndez, A.; Fernández, E.; Francés, J.; Neipp, C. Birefringence of cellotape: Jones representation and experimental analysis. Eur. J. Phys. 2010, 31, 551–561. [Google Scholar] [CrossRef] [Green Version]

- Puerto, D.; Velásquez, P.; Sánchez-López, M.M.; Moreno, I.; Mateos, F. Using cellophane tape to experience interference birefringent filters. In Proceedings of the Ninth International Topical Meeting on Education and Training in Optics and Photonics, Marseille, France, 24–27 October 2005; Volume 9664. [Google Scholar] [CrossRef]

- Fagan, T.J.; Lidsky, M.D. Compensated polarized light microscopy using cellophane adhesive tape. Arthritis Rheum. 1974, 17, 256–262. [Google Scholar] [CrossRef] [PubMed]

- Kinyua, D.M.; Rurimo, G.K.; Karimi, P.M.; Maina, S.N.; Ominde, C.F. Interferometry analysis of cellophane birefringence. Opt. Photonics J. 2013, 3, 337–341. [Google Scholar] [CrossRef]

- Normandin, M.; Legrand, D.G. Form Birefringence in biaxially oriented polypropylene. J. Polym. Sci. Pol. Phys. 1969, 7, 231–240. [Google Scholar] [CrossRef]

- Dias, P.; Hiltner, A.; Baer, E.; Van Dun, J.; Chen, H.; Chum, S.P. Structure and properties of biaxially oriented polypropylenes (BOPP). In Proceedings of the ANTEC 2006 Plastics: Annual Technical Conference, Charlotte, NC, USA, 7–11 May 2006. [Google Scholar]

- 3M™ Scotch® Industrial Box Sealing Tape 371 Technical Data. Available online: https://3m.citrination.com/pif/001226?locale=en-US (accessed on 25 June 2020).

- Goodfellow Polypropylene Material Information. Available online: http://www.goodfellow.com/E/Polypropylene.html (accessed on 25 June 2020).

- Zhang, X.; Qiu, J.; Li, X.; Zhao, J.; Liu, L. Complex refractive indices measurements of polymers in visible and near-infrared bands. Appl. Opt. 2020, 59, 2337–2344. [Google Scholar] [CrossRef]

- Zappe, H. Fundamental of Microoptics; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar] [CrossRef]

- Ubis Technical Sheet. Low Tack PVC Surface Protection PVC Tape. Available online: https://ubis.es/pdf/en/LOWTACPVC.pdf (accessed on 25 June 2020).

- Titow, W. PVC Technology; Elsevier Applied Science Publishers: London, UK, 1984; ISBN 978-0-85334-249-6. [Google Scholar]

- DupontTM Kapton® Summary of Properties. Available online: https://www.dupont.com/content/dam/dupont/amer/us/en/products/ei-transformation/documents/DEC-Kapton-summary-of-properties.pdf (accessed on 25 June 2020).

- Oh, M.C.; Lee, M.H.; Lee, H.J. Polymeric waveguide polarization splitter with a buried birefringent polymer. IEEE Photon. Technol. Lett. 1999, 11, 1114–1146. [Google Scholar]

- 3M™ Polyimide Film Tape 5413 Data Sheet. Available online: https://multimedia.3m.com/mws/media/136011O/3m-polyimide-film-tape-5413-tds.pdf (accessed on 25 June 2020).

- 3M™ Scotch® Cellophane Film Tape 610 Technical Data. Available online: https://3m.citrination.com/pif/000835?locale=en-US (accessed on 25 June 2020).

- Songhan Plastic Technology Co., Ltd. Available online: http://www.lookpolymers.com/pdf/Goodfellow-Cellophane-Rayophane-Regenerated-Cellulose-Fiber.pdf (accessed on 25 June 2020).

- Adhesives Research. Optical Clear Adhesives Product Overview. Available online: https://www.adhesivesresearch.com/wp-content/uploads/2020/07/Optically-Clear-Adhesives-Product-Overview.pdf (accessed on 25 June 2020).

- Sun, S.; Lin, M.; Liu, A. A review on mechanical properties of pressure sensitive adhesives. Int. J. Adhes. Adhes. 2013, 41, 98–106. [Google Scholar] [CrossRef]

- 3M™ Scotch Stretchable Tape 8884 and 8886 Technical Data. Available online: https://www.y-ic.cz/datasheet/70/ATS-09E-36-C2-R0.pdf (accessed on 18 June 2020).

- The Tesa Technology Journal. The Effects of Low Temperature on Pressure Sensitive Adhesives. Available online: https://web.archive.org/web/20140714144531/http://www.tesatape.com/featured/technology_journal/the-effects-of-low-temperatures-on-pressure-sensitive-adhesives,6782722,1.html (accessed on 2 July 2020).

- Shen, F.; Wang, C.; Sun, Z.; Zhou, K.; Zhang, L.; Shu, X. Small period long period fiber grating with improved refractive index sensitivity and dual-parameter sensing ability. Opt. Lett. 2017, 42, 199–202. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shao, M.; Qiao, X.; Jiasurname, Z.; Fusurname, H.; Liu, Y.; Li, H.; Zhao, X. Refractive index measurement based on fiber Bragg grating connected with a multimode fiber core. Opt. Comm. 2015, 351, 70–74. [Google Scholar] [CrossRef]

- Zhou, A.; Liu, Z.; Yuan, L. Fiber-optic dipping liquid analyzer: Theoretical and experimental study of light transmission. Appl. Opt. 2009, 48, 6928–6933. [Google Scholar] [CrossRef] [PubMed]

- Nath, P.; Singh, H.; Datta, P.; Sarma, K. All-fiber optic sensor for measurement of liquid refractive index. Sens. Actuators A Phys. 2008, 148, 16–18. [Google Scholar] [CrossRef]

- Beres, C.; Nazaré, F.; Chagas de Souza, N.; Miguel, M.; Werneck, M.M. Tapered plastic optical fiber based biosensor—Tests and application. Biosens. Bioelectron. 2011, 30, 328–332. [Google Scholar] [CrossRef]

- Chiu, M.H.; Hsu, S.N.; Yang, H. D-type fiber optic sensor used as a refractometer based on total-internal-reflection heterodyne interferometry. Sens. Actuators B Chem. 2004, 101, 322–327. [Google Scholar] [CrossRef]

- Feng, D.; Zhang, M.; Liu, G.; Liu, X.; Jia, D. D-Shaped plastic optical fiber sensor for testing refractive index. IEEE Sens. J. 2014, 14, 1673–1676. [Google Scholar]

- Qazi, H.H.; bin Mohammad, A.B.; Ahmad, H.; Zulkifli, M.Z.; Harun, S.W. Single-mode D-shaped optical fiber sensor for the refractive index monitoring of liquid. J. Mod. Opt. 2016, 63, 750–755. [Google Scholar] [CrossRef]

- Sequeira, F.; Cennamo, N.; Rudnitskaya, A.; Nogueira, R.; Zeni, L.; Bilro, L. D-shaped POF sensors for refractive index sensing—The importance of surface roughness. Sensors 2019, 19, 2476. [Google Scholar] [CrossRef] [Green Version]

- Town, G.E.; Yuan, W.; McCosker, R.; Bang, O. Microstructured optical fiber refractive index sensor. Opt. Lett. 2010, 35, 856–858. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, P.; Shu, X.; Cao, H.; Sugden, K. Ultra-sensitive refractive index sensor based on extremely simple femtosecond-laser-induced structure. Opt. Lett. 2017, 42, 1157–1160. [Google Scholar] [CrossRef] [PubMed]

- Chetia, D.; Gogoi, J.M.; Singh, H.K.; Bezboruah, T. Low-cost refractive index sensor with optical fibers attached to a U-shaped glass tube. IEEE Sens. Lett. 2018, 2, 1–4. [Google Scholar] [CrossRef]

- Zhang, Y.; Lei, M.; Hu, H.; Zhao, Y.; Li, J.; Gao, H. Determination of refractive index by a U-shaped multimode fiber sensor. Instrum. Sci. Technol. 2018, 46, 490–501. [Google Scholar] [CrossRef]

- Bilro, L.; Alberto, N.; Pinto, J.L.; Nogueira, R. Optical sensors based on plastic fibers. Sensors 2012, 12, 12184–12207. [Google Scholar] [CrossRef] [Green Version]

- Peters, K. Polymer optical fiber sensors—A review. Smart Mater. Struct. 2011, 20, 13002. [Google Scholar] [CrossRef]

- Chen, C.H.; Tsao, T.C.; Tang, J.L.; Wu, W.T. A multi-D-shaped optical fiber for refractive index sensing. Sensors 2010, 10, 4794–4804. [Google Scholar] [CrossRef] [Green Version]

- Montero, D.S.; Vázquez, C.; Möllers, I.; Arrúe, J.; Jäger, D. A self-referencing intensity based polymer optical fiber sensor for liquid detection. Sensors 2009, 9, 6446–6455. [Google Scholar] [CrossRef] [Green Version]

- Sharpe, J.C.; Mitchell, J.S.; Lin, L.; Sedoglavich, N.; Blaikie, R. Gold nanohole array substrates as immunobiosensors. J. Anal. Chem. 2008, 80, 2244–2249. [Google Scholar] [CrossRef]

- Lee, S.H.; Johnson, T.W.; Lindquist, N.C.; Im, H.; Norris, D.J.; Oh, S.H. Linewidth-optimized extraordinary optical transmission in water with template-stripped metallic nanohole arrays. Adv. Funct. Mater. 2012, 22, 4439–4446. [Google Scholar] [CrossRef]

- Canalejas-Tejero, V.; Herranz, S.; Bellingham, A.; Moreno-Bondi, M.C.; Barrios, C.A. Passivated aluminum nanohole arrays for label free biosensing applications. ACS Appl. Mater. Interfaces 2014, 6, 1005–1010. [Google Scholar] [CrossRef] [PubMed]

- Barrios, C.A.; Canalejas-Tejero, V.; Herranz, S.; Moreno-Bondi, M.C.; Avella-Oliver, M.; Puchades, R.; Maquieira, A. Aluminum nanohole arrays fabricated on polycarbonate for compact disc-based label-free optical biosensing. Plasmonics 2014, 9, 645–649. [Google Scholar] [CrossRef]

- Takahashi, H.; Dung, N.M.; Matsumoto, K.; Shimoyama, I. Differential pressure sensor using a piezoresistive cantilever. J. Micromech. Microeng. 2012, 22, 55015. [Google Scholar] [CrossRef]

- Binning, G.; Quate, C.F.; Gerber, C.H. Atomic force microscope. Phys. Rev. Lett. 1986, 56, 930–933. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kulkarni, A.; Na, J.; Kim, Y.; Kim, T. The plastic optical fiber cantilever beam as a force sensor. Microw. Opt. Technol. Lett. 2009, 51, 1020–1023. [Google Scholar] [CrossRef]

- Li, Y.C.; Ho, M.H.; Hung, S.J.; Chen, M.H.; Lu, M.S.C. CMOS micromachined capacitive cantilevers for mass sensing. J. Micromech. Microeng. 2006, 16, 2659–2665. [Google Scholar] [CrossRef]

- Fritz, J. Cantilever biosensors. Analyst 2008, 133, 855–863. [Google Scholar] [CrossRef]

- Voiculescu, I.; Liu, F.; Ono, T.; Toda, M. Investigation of bimaterial cantilever beam for heat sensing in liquid. Sens. Actuat. A Phys. 2016, 242, 58–66. [Google Scholar] [CrossRef]

- Hetrick, R.E. A vibrating cantilever magnetic-field sensor. Sens. Actuators 1989, 16, 197–207. [Google Scholar] [CrossRef]

- Ai, M.; Shimazoe, M. Cantilever-type displacement sensor using diffused silicon strain gauges. Sens. Actuators 1981, 2, 297–307. [Google Scholar] [CrossRef]

- Hu, J.; Huang, H.; Bai, M.; Zhan, T.T.; Yang, Z.B.; Yu, Y.; Qu, B. A high sensitive fiber-optic strain sensor with tunable temperature sensitivity for temperature-compensation measurement. Sci. Rep. 2017, 7, 42430. [Google Scholar] [CrossRef] [PubMed]

- Lopez-Higuera, J.M.; Morante, M.A.; Cobo, A. Simple low-frequency optical fiber accelerometer with large rotating machine monitoring applications. J. Lightwave Technol. 1997, 15, 1120–1130. [Google Scholar] [CrossRef]

- Boisen, A.; Dohn, S.; Keller, S.S.; Schmid, S.; Tenje, M. Cantilever-like micromechanical sensors. Rep. Prog. Phys. 2011, 74, 36101. [Google Scholar] [CrossRef]

- Gimzewski, J.K.; Gerber, C.H.; Meyer, E.; Schlittler, R.R. Observation of a chemical reaction using a micromechanical sensor. Chem. Phys. Lett. 1994, 217, 589–594. [Google Scholar] [CrossRef]

- Schönenberger, C.; Alvarado, S.F. A differential interferometer for force microscopy. Rev. Sci. Instrum. 1989, 60, 3131. [Google Scholar] [CrossRef]

- Manalis, S.R.; Minne, S.C.; Atalar, A.; Quate, C.F. Interdigital cantilevers for atomic force microscopy. Appl. Phys. Lett. 1996, 69, 3944–3946. [Google Scholar] [CrossRef]

- Zinoviev, K.; Dominguez, C.; Plaza, J.A.; Busto, V.J.C.; Lechuga, L.M. A novel optical waveguide microcantilever sensor for the detection of nanomechanical forces. J. Lightwave Technol. 2006, 24, 2132–2138. [Google Scholar] [CrossRef] [Green Version]

- Kocabas, C.; Aydinli, A. Design and analysis of an integrated optical sensor for scanning force microscopies. IEEE Sens. J. 2005, 5, 411–418. [Google Scholar] [CrossRef] [Green Version]

- Zinoviev, K.; Dominguez, C.; Plaza, J.A.; Cadarso, V.; Lechuga, L.M. Light coupling into an optical microcantilever by an embedded diffraction grating. Appl. Opt. 2006, 45, 229–234. [Google Scholar] [CrossRef]

- Steinkamp, J.A. A differential amplifier circuit for reducing noise in axial light loss measurements. Cytometry 1983, 4, 83–87. [Google Scholar] [CrossRef] [PubMed]

- Perez-Arancibia, N.O.; Gibson, J.S.; Tsao, T.-C. Laser beam pointing and stabilization by intensity feedback control. In Proceedings of the 2009 American Control Conference Hyatt Regency Riverfront, St. Louis, MO, USA, 10–12 June 2009. Paper ThB07.4. [Google Scholar]

- Lee, S.H.; Lindquist, N.C.; Wittenberg, N.J.; Jordan, L.R.; Oh, S.H. Real-time full-spectral imaging and affinity measurements from 50 microfluidic channels using nanohole surface plasmon resonance. Lab Chip 2012, 12, 3882–3890. [Google Scholar] [CrossRef] [PubMed]

- Othonos, A.; Kalli, K. Fiber Bragg Gratings: Fundamentals and Applications in Telecommunications and Sensing; Artech House: New York, NY, USA, 1999. [Google Scholar]

- Kersey, A.; Davis, M.A.; Patrick, H.J.; Leblanc, M. Fiber grating sensors. J. Light. Technol. 1997, 15, 1442–1463. [Google Scholar] [CrossRef] [Green Version]

- Kinet, D.; Mégret, P.; Goossen, K.W.; Qiu, L.; Heider, D.; Caucheteur, C. Fiber Bragg grating sensors toward structural health monitoring in composite materials: Challenges and solutions. Sensors 2014, 14, 7394–7419. [Google Scholar] [CrossRef] [PubMed]

- Wee, J.; Wells, B.; Hackney, D.; Bradford, P.; Peters, K. Increasing signal amplitude in fiber Bragg grating detection of Lamb waves using remote bonding. Appl. Opt. 2016, 55, 5564–5569. [Google Scholar] [CrossRef]

- Wee, J.; Hackney, D.; Bradford, P.; Peters, K. Experimental study on directionality of ultrasonic wave coupling using surface-bonded fiber Bragg grating sensors. J. Lightwave Technol. 2018, 36, 932–938. [Google Scholar] [CrossRef]

- Wee, J.; Hackney, D.; Peters, K. Preferential directional coupling to ultrasonic sensor using adhesive tape. Opt. Eng. 2019, 58, 72003. [Google Scholar] [CrossRef]

- Gao, J.; Gao, T.; Li, Y.Y.; Sailor, M.J. Vapor sensors based on optical interferometry from oxidized microporous silicon films. Langmuir 2002, 18, 2229–2233. [Google Scholar] [CrossRef]

- Elosua, C.; Matias, I.R.; Bariain, C.; Arregui, F.J. Volatile organic compound optical fiber sensors: A Review. Sensors 2006, 6, 1440–1465. [Google Scholar] [CrossRef] [Green Version]

- Sun, Y.; Shopova, S.I.; Frye-Mason, G.; Fan, X. Rapid chemical-vapor sensing using optofluidic ring resonators. Opt. Lett. 2008, 33, 788–790. [Google Scholar] [CrossRef]

- Zhang, Y.; Qiu, J.; Hu, R.; Li, P.; Gao, L.; Heng, L.; Tang, B.Z.; Jiang, L. A visual and organic vapor sensitive photonic crystal sensor consisting of polymer-infiltrated SiO2 inverse opal. Phys. Chem. Chem. Phys. 2015, 17, 9651–9658. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Gao, H.; Zhang, X.; Pang, J.; Li, Y.; Li, K.; Wu, Y.; Li, S.; Zhu, J.; Wei, Y.; et al. Highly-sensitive optical organic vapor sensor through polymeric swelling induced variation of fluorescent intensity. Nat. Commun. 2018, 9, 3799. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barrios, C.A. Scotch tape optical vapor sensor for ethanol–methanol mixtures. Sensors 2019, 19, 5381. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bucur, B.; Radu, G.L.; Toader, C.N. Analysis of methanol–ethanol mixtures from falsified beverages using a dual biosensors amperometric system based on alcohol dehydrogenase and alcohol oxidase. Eur. Food Res. Technol. 2008, 226, 1335–1342. [Google Scholar] [CrossRef]

- Bag, S.S.; Jana, S. Axially chiral amino acid scaffolds as efficient fluorescent discriminators of methanol-ethanol. New J. Chem. 2017, 41, 13391–13398. [Google Scholar] [CrossRef]

- Horvat, J.; Lewis, R.A. Peeling adhesive tape emits electromagnetic radiation at terahertz frequencies. Opt. Lett. 2009, 34, 2195–2197. [Google Scholar] [CrossRef] [Green Version]

| Material | Refractive Index | Birefrin-Gence | Tensile Strength at Break (N/cm) | Elongation at Break (%) | CTE (K−1) | Thermal Conductivity (W m−1 K−1) |

|---|---|---|---|---|---|---|

| BOPP | 1.50 @ 589.3 nm [41] | ~0.01 a [41,42] | 40 [35] | 30 [35] 160 [43] | 1.0–1.8 × 10−5 [44] | 0.1–0.22 [44] |

| PVC | 1.54 @ 589.3 nm [45] | 0.027 b [46] | 47.5 [47] | 60 [47] | 5 × 10−5 [48] | 0.14–0.17 [48] |

| Polyimide | 1.70 @ 589.3 nm [49] | 0.0263 b [50] | 57.8 [51] | 62 [51] | 2 × 10−5 [49] | 0.120 [49] |

| Cellophane | 1.47 @ 632.8 nm [40] | 0.0041 b [40] 0.0077 b [37] | 40.2 [52] | 15 [52] | 8 × 10−5 [53] | 0.0600 [53] |

| Material | Refractive Index | Haze a (%) | Transmission (%) | Peel Adhesion b (N/cm) |

|---|---|---|---|---|

| Resin/Rubber | 1.52 | 0.04 | 99.8 | 6.7 to Glass |

| Acrylate | 1.47 | <0.5 | >99 | 5.8 to Steel |

| Silicone | 1.41 | 1.0 | 99 | 6.7–7.8 to Glass |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barrios, C.A. Pressure Sensitive Adhesive Tape: A Versatile Material Platform for Optical Sensors. Sensors 2020, 20, 5303. https://doi.org/10.3390/s20185303

Barrios CA. Pressure Sensitive Adhesive Tape: A Versatile Material Platform for Optical Sensors. Sensors. 2020; 20(18):5303. https://doi.org/10.3390/s20185303

Chicago/Turabian StyleBarrios, Carlos Angulo. 2020. "Pressure Sensitive Adhesive Tape: A Versatile Material Platform for Optical Sensors" Sensors 20, no. 18: 5303. https://doi.org/10.3390/s20185303

APA StyleBarrios, C. A. (2020). Pressure Sensitive Adhesive Tape: A Versatile Material Platform for Optical Sensors. Sensors, 20(18), 5303. https://doi.org/10.3390/s20185303