Interface Pressure System to Compare the Functional Performance of Prosthetic Sockets during the Gait in People with Trans-Tibial Amputation

Abstract

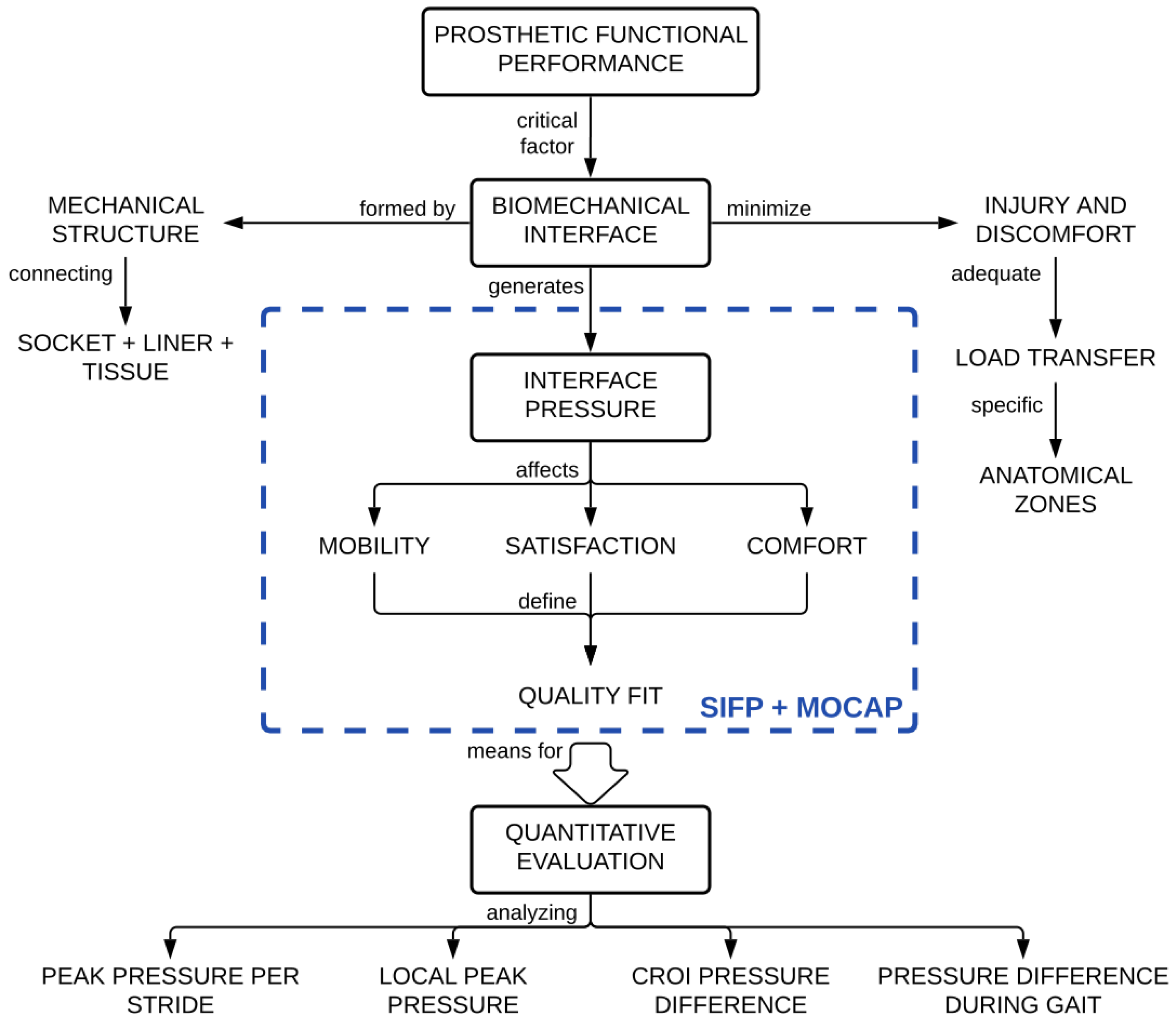

:1. Introduction

The Gait Cycle on the Amputee and the Residuum

- To compare the performance of our socket interface pressure (SIFP) device versus the F-Socket due that both of the them are products able to evaluate the functional performance of prosthesis sockets.

- To evaluate the quality of fit and the functional performance of prosthesis sockets during the gait using the stump/socket pressure distribution of a unilateral amputee by means of a integrated socket interface pressure system. The system comprises a Kinect motion capture system, a portable SIFP device (Bluetooth-enabled), and a MATLAB® code. The system senses the pressure at the CROI of the residual lower limb during the gait and displays pressure graphs and gait graphs in real time.

- To detect via the sensitive range of the 6 sensor array, variations between sockets and pressure values at the CROI which could lead to detect pain points that negatively affect posture and gait of the amputee.

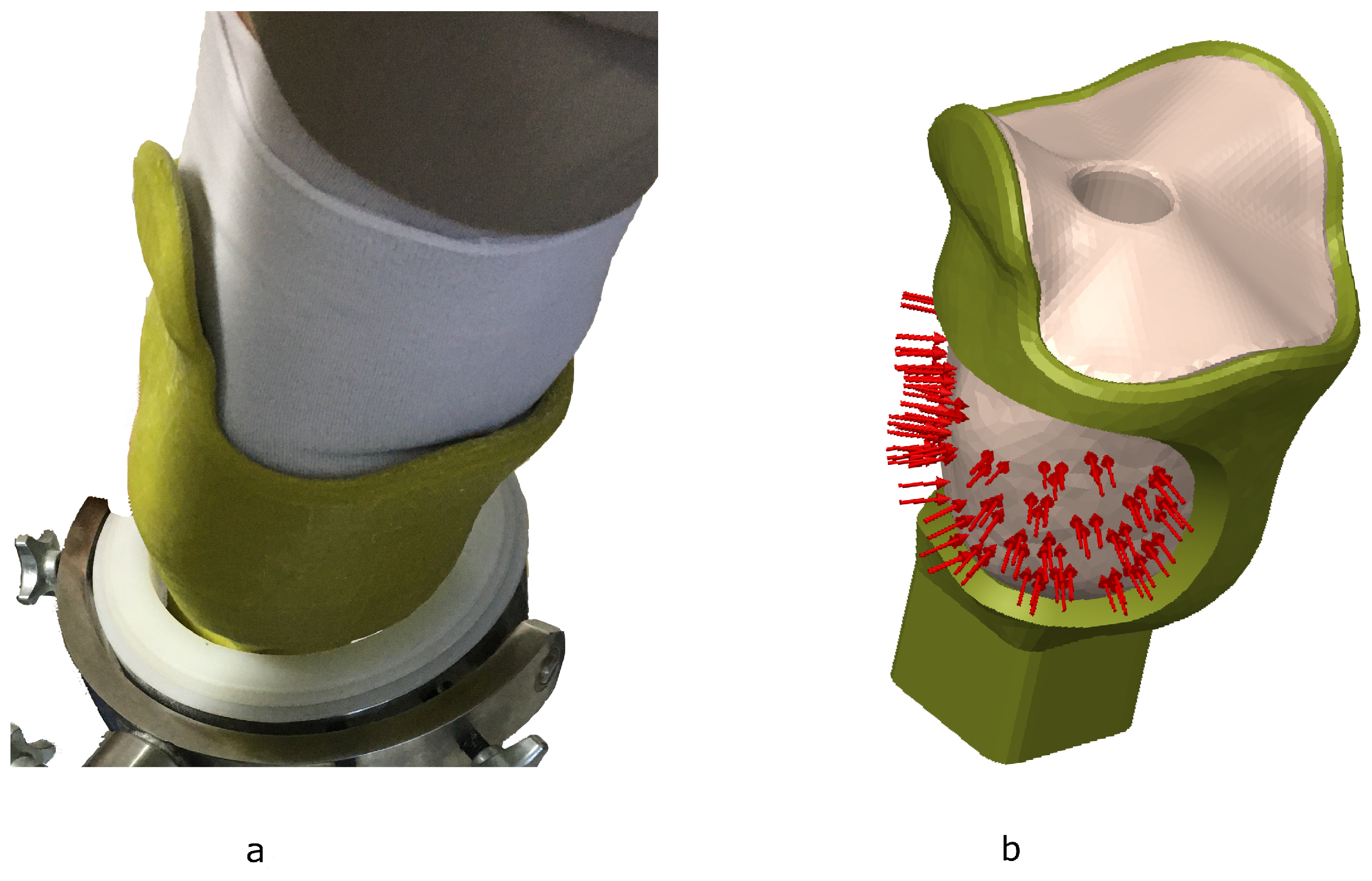

2. Materials and Methods

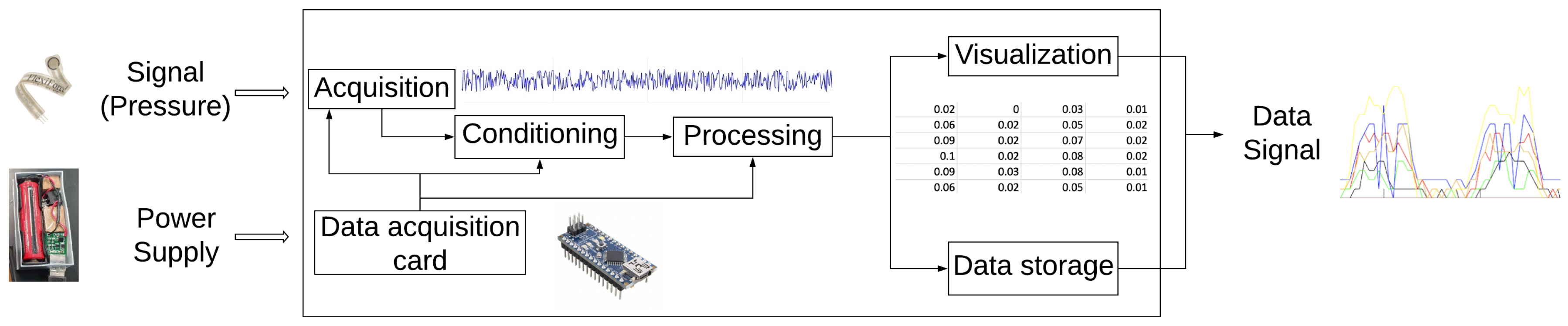

2.1. Materials and Equipment

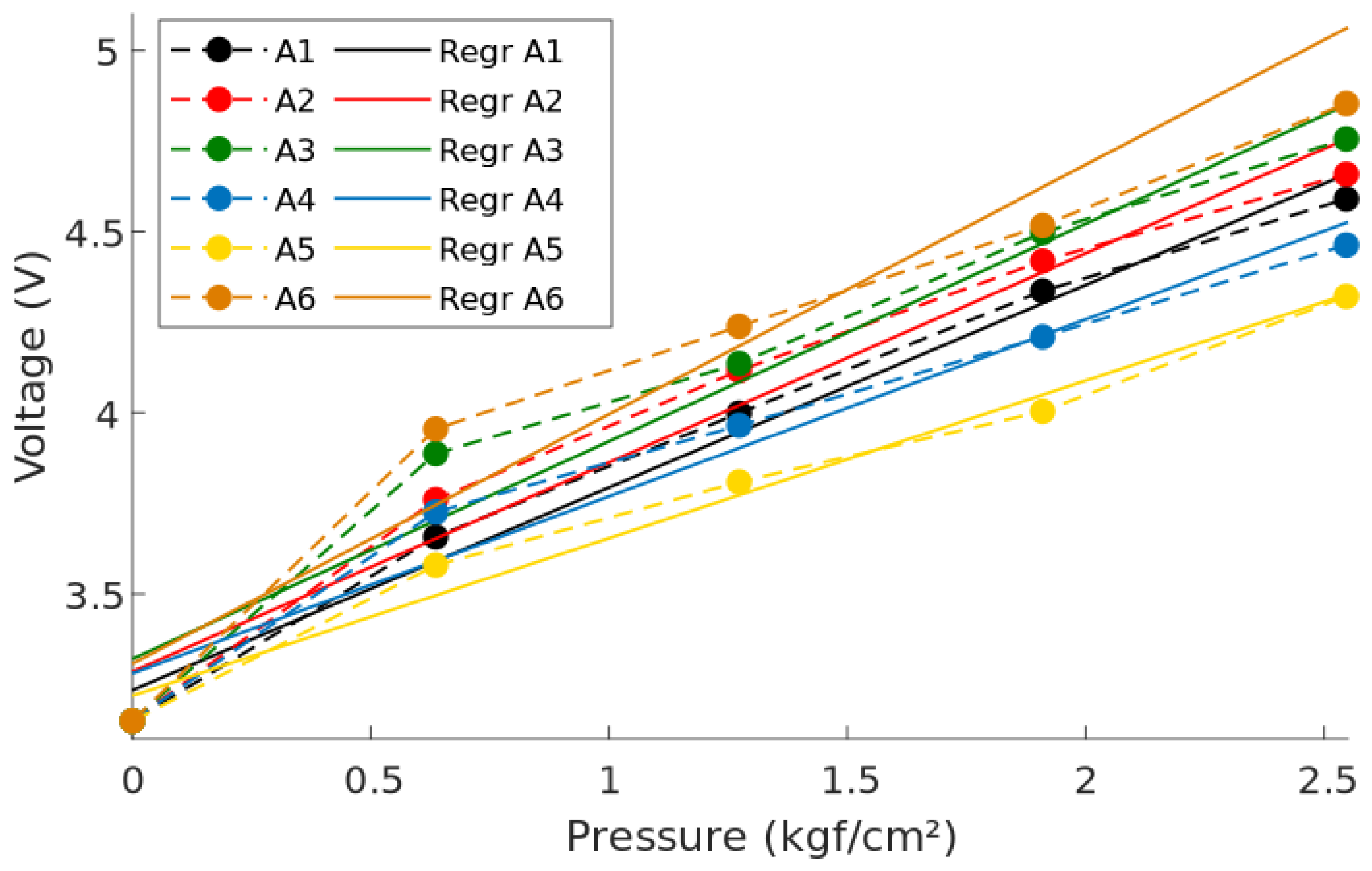

Pressure System Characterization and Linearization

- Place 1/3 of the test weight on the sensor. Leave the weight on the sensor for approximately 3 s then remove the weight from the sensor.

- Place 2/3 of the test weight on the sensor. Leave the weight on the sensor for the same amount of time then remove the weight from the sensor.

- Place the full test weight on the sensor. Wait the approximate amount of time again then remove the weight from the sensor.

2.2. Subject Selection and Protocol

- Candidates whose residual limb shows significant morphological changes during the study.

- Candidates that have the presence of metal implants or unsafe conditions for imaging studies or that prevent a CT study.

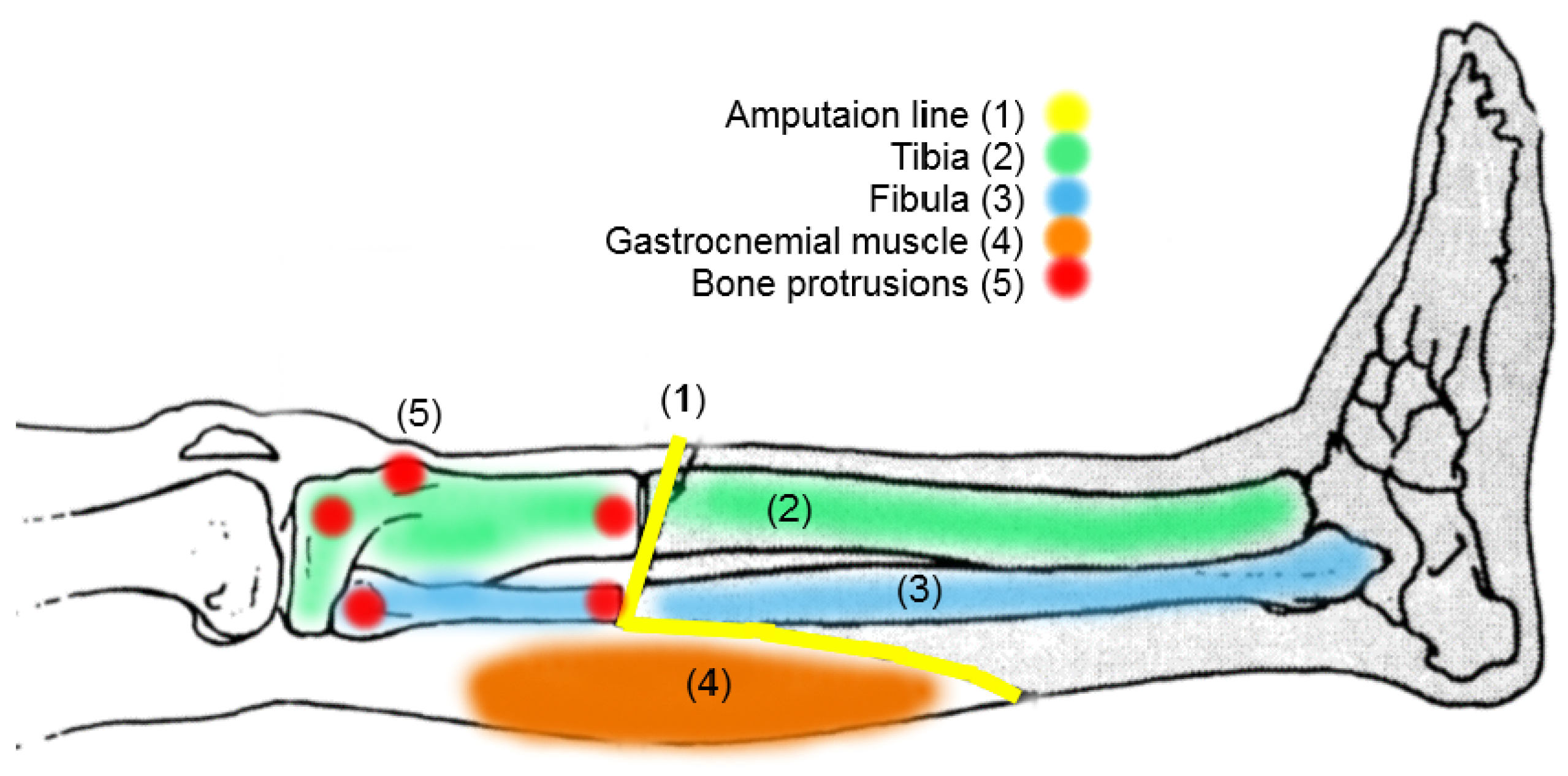

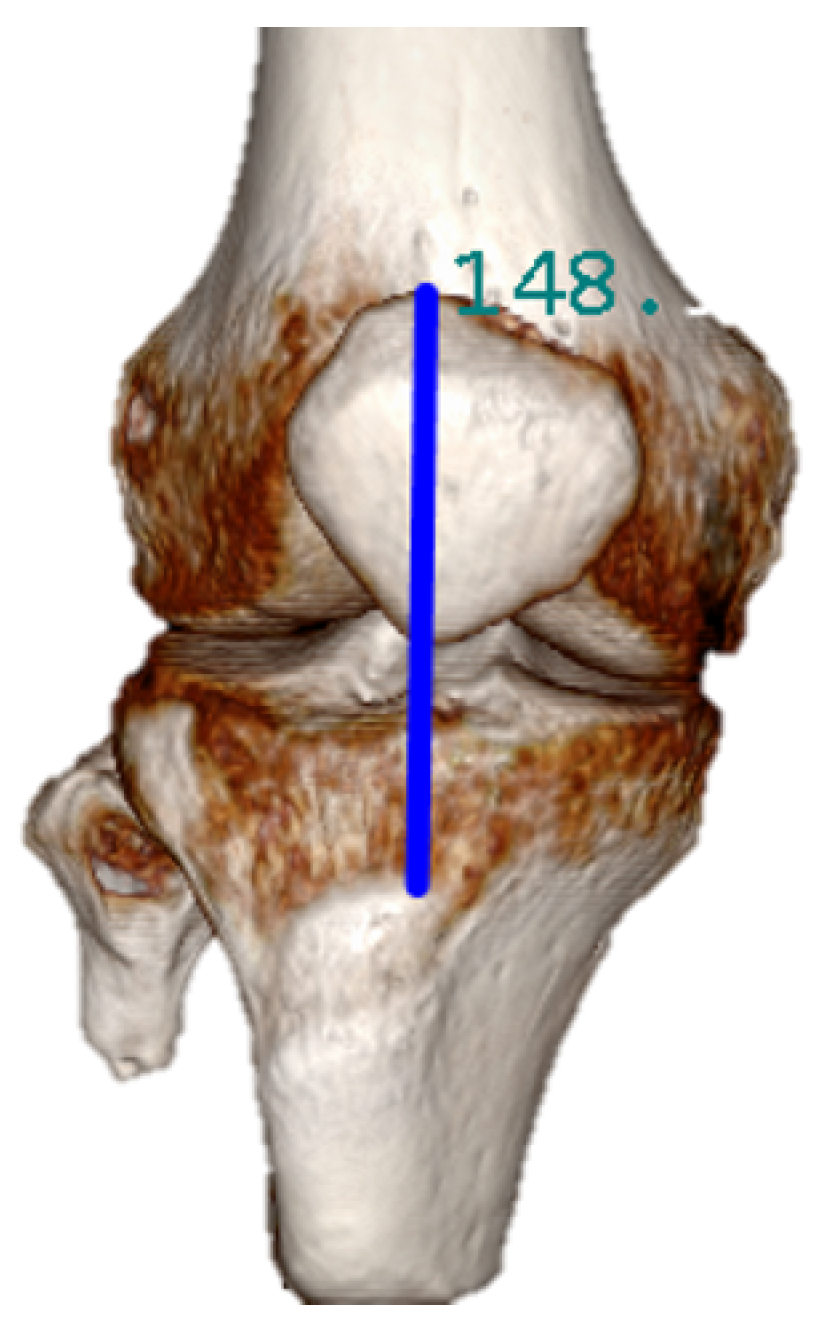

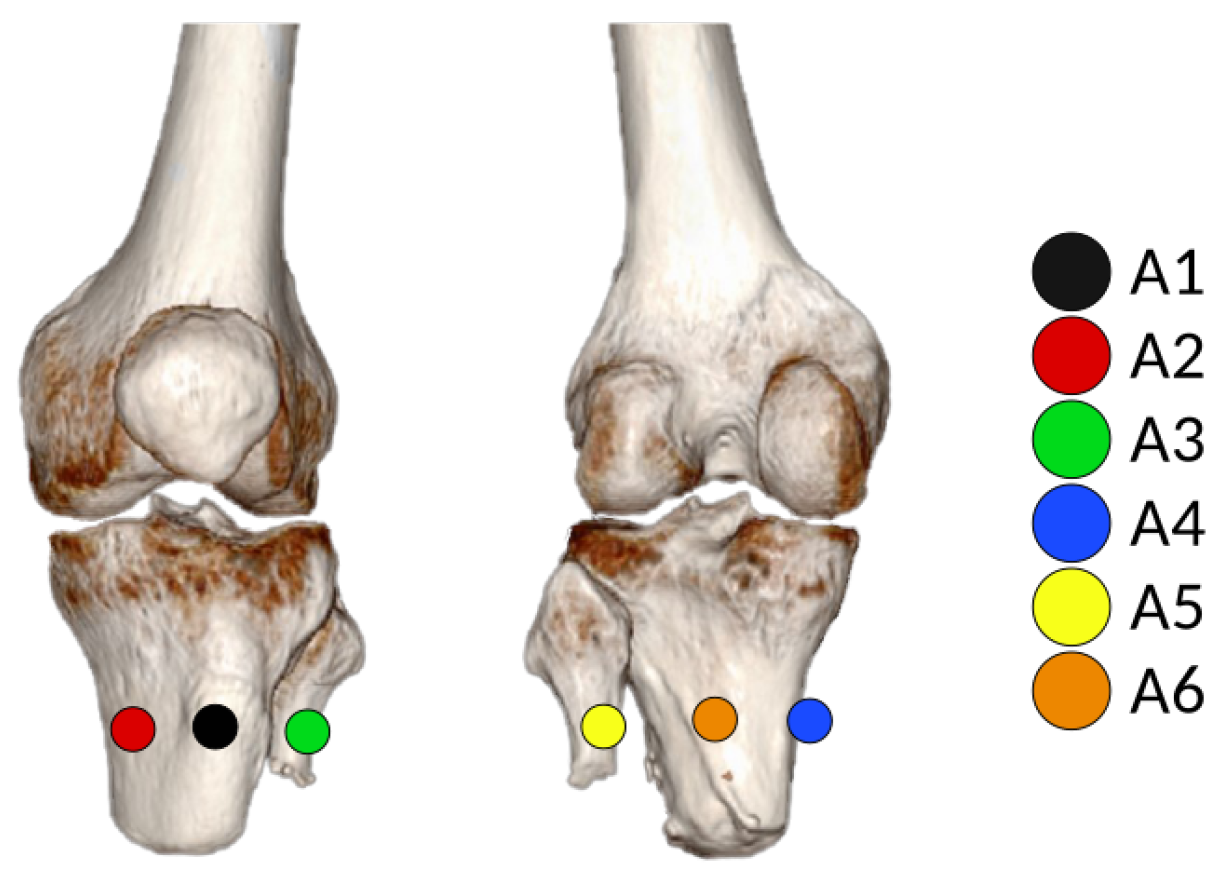

2.3. Croi Location

2.4. Motion Capture Subsystem

2.4.1. Parameters to Measure

2.4.2. Materials and Setup for Motion Capture

- Kinect v2 -Body Tracking Setting

- Kinect v1 for Windows -Skeleton Tracking Setting

- Treadmill NordicTrack® C97OPRO

- -

- Configurable and maximum speed of 19.2 km/h

- -

- Units of measure of the International System

- -

- 60”X 20” track

- -

- Front and side support handles

- -

- Screen that includes speed display, distance traveled, and travel time

- -

- Control keypad

- 1 Workstation Precision 5820 Tower

- -

- Intel Xeon Processor W family

- -

- Graphic card Radeon Pro WX

- -

- 16GB RAM

- -

- Operating System Windows 10.

- Software

- -

- Kinect® for Windows Developer Toolkit V1.8

- -

- Kinect SDK

- -

- Microsoft Speech Platform SDK

- -

- MATLAB® R2018b

- *

- Image Acquisition Toolbox SupportPackage for Kinect for Windows Sensor

- *

- Microsoft Kinect for Windows Supportfrom Image Acquisition Toolbox

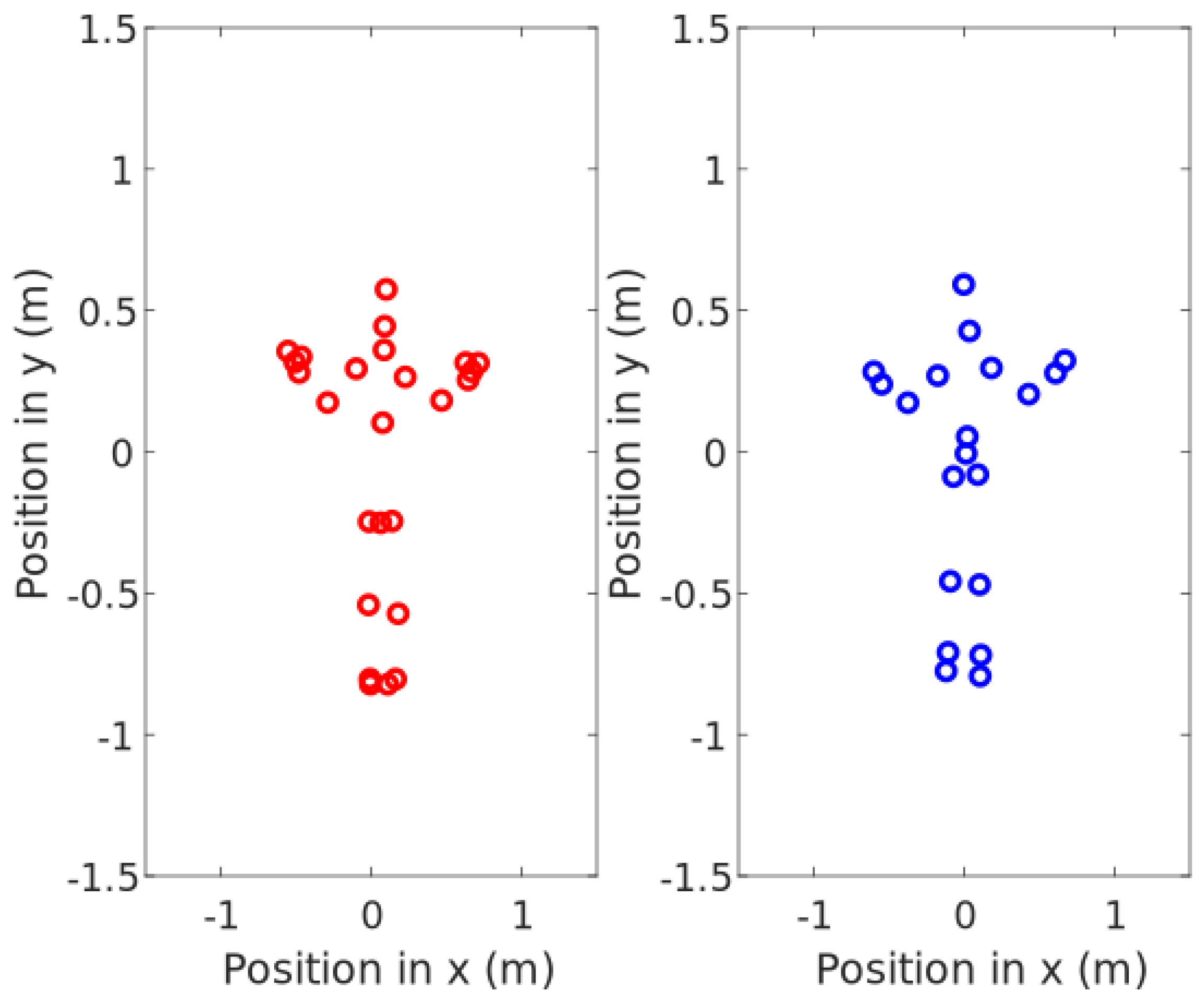

2.4.3. Software Algorithm in MATLAB® for Motion Capture

2.5. Comparison between F-Socket and SIFP

2.6. Subject Test Procedure

- The prosthetic socket is removed by the participant or with help.

- The SIFP device is placed on the participant and fitted to his waist.

- The CROIs are identified with non-permanent marks and the sensors of the SIFP device are placed at the CROIs, as shown in Figure 18.

- A nylon stocking is placed on the residual limb and over the sensor arrangement in order to prevent possible sensor motion inside the socket.

- The prosthetic socket to be tested is donned onto the residual limb by the participant or with help.

- A pressure sensing test is performed with the participant at rest sitting in a chair.

- The participant proceeds to perform a physical activity (walk on a treadmill) for 10 min at 1.4 m/s as follows:

- (a)

- The motion capture program is started.

- (b)

- The participant is asked to step onto a yellow mark on the floor facing the Kinect and wave with both hands in order to get detected by the camera. If the participant is not detected by the camera, the data will not be saved, and the legend SUBJECT NOT DETECTED will pop up.

- (c)

- The participant is now asked to stand on the treadmill facing to the Kinect and wave again towards it. By now, the camera should have detected the participant. If so, in the central figure, the points of the coordinates of the camera will appear in a central figure projecting the participant’s movement in real time, as seen in Figure 11.

- (d)

- The stopwatch is started as soon as the treadmill is set on the 1.4 m/s speed, and the participant is walking comfortably.

- (e)

- The participant walks for ten minutes, trying to remain as straight as possible and trying to replicate his normal gait.

- (f)

- When the stopwatch hits the ten-minute mark, the data capture is stopped to be recorded, and the work space of MATLAB® is saved.

- The participant gets off the treadmill, removes the prosthetic socket, and removes the pressure sensors.

- All the equipment is removed from the residuum of the participant.

3. Results

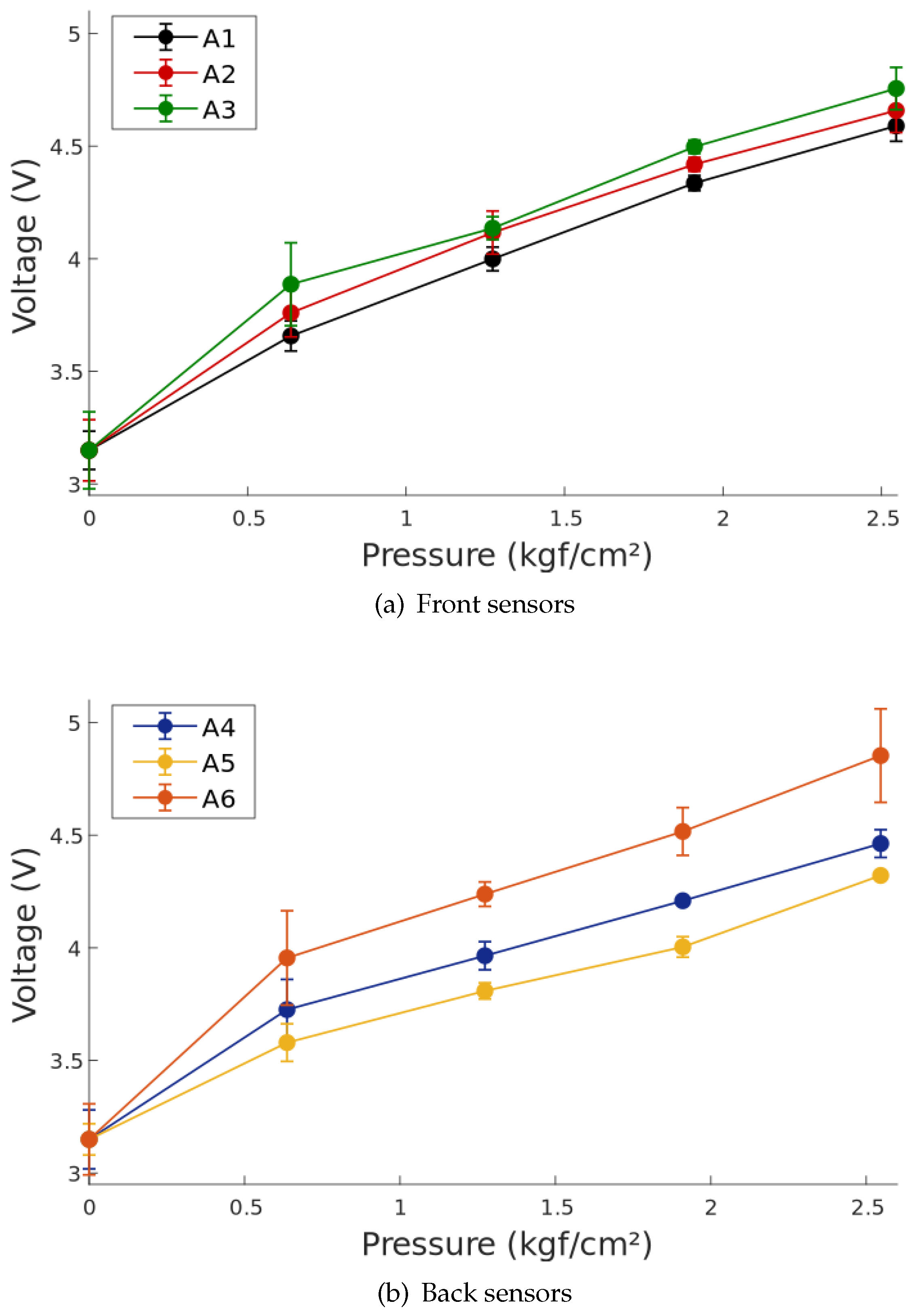

3.1. Static Characterization

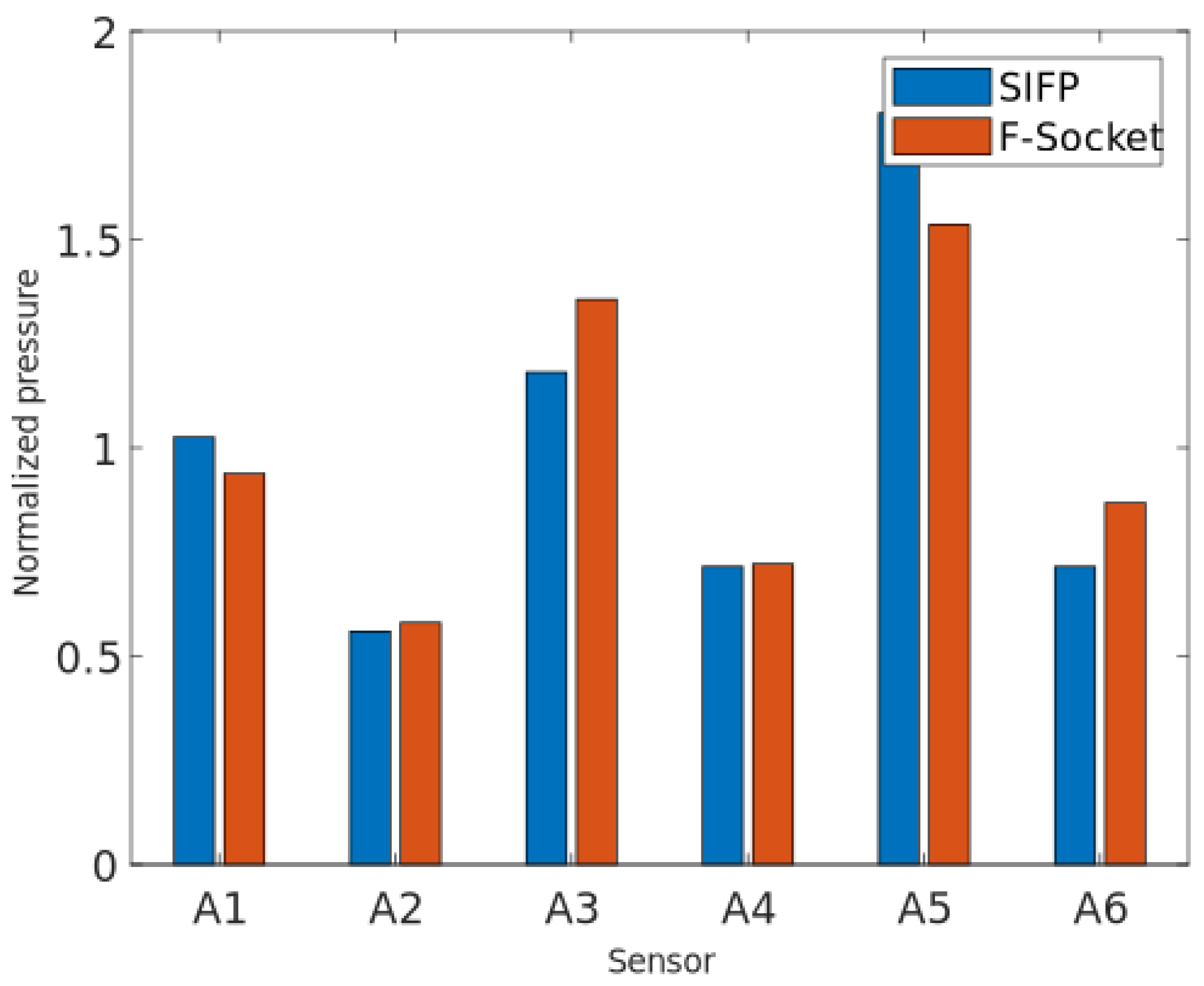

3.2. Comparison Results between F-Socket System and Socket Interface Pressure Device

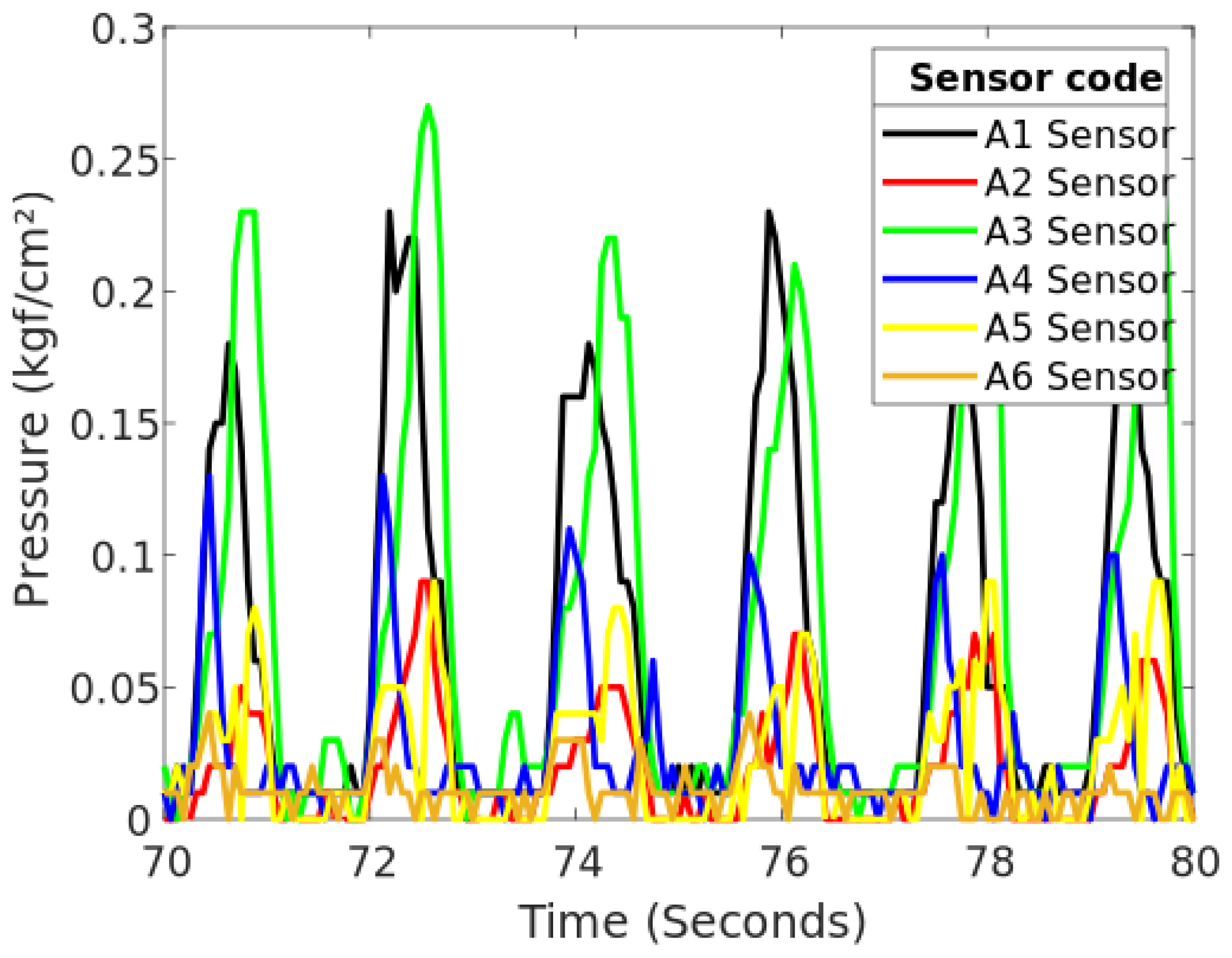

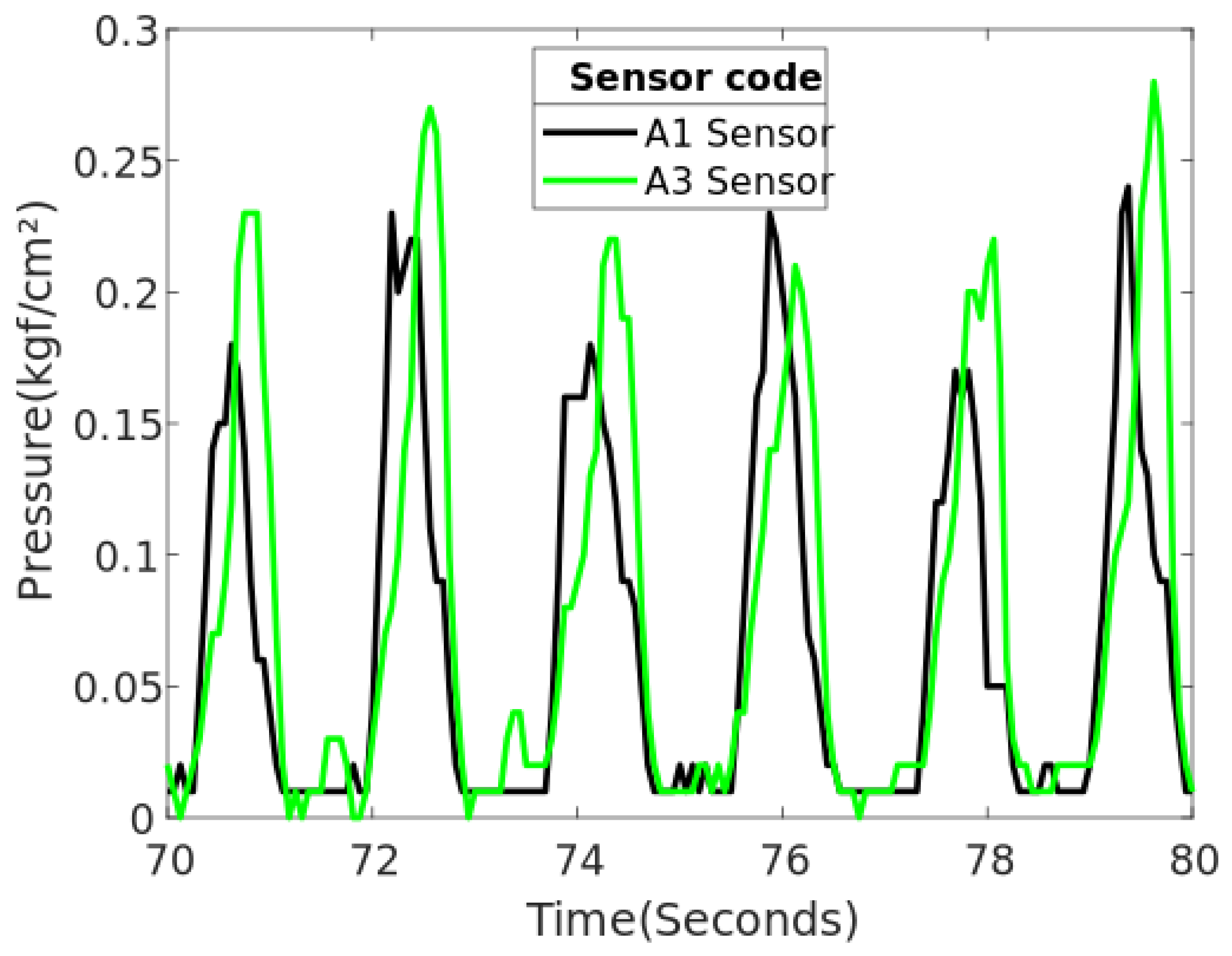

3.3. SIFP System Test

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Moerman, K.M.; Sengeh, D.M.; Herr, H.M. Automated and Data-driven Computational Design of Patient-Specific Bio-mechanical Interfaces. IEEE Access 2016, 1. [Google Scholar] [CrossRef]

- Jia, X.; Zhang, M.; Lee, W.C. Load transfer mechanics between trans-tibial prosthetic socket and residual limb - Dynamic effects. J. Biomech. 2004, 37, 1371–1377. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dudek, N.L.; Marks, M.B.; Marshall, S.C.; Chardon, J.P. Dermatologic conditions associated with use of a lower-extremity prosthesis. Arch. Phys. Med. Rehabil. 2005, 86, 659–663. [Google Scholar] [CrossRef] [PubMed]

- Convery, P.; Buis, A.W. Socket/stump interface dynamic pressure distributions recorded during the prosthetic stance phase of gait of a trans-tibial amputee wearing a hydrocast socket. Prosthetics Orthot. Int. 1999, 23, 107–112. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goh, J.C.; Lee, P.V.; Chong, S.Y. Stump/socket pressure profiles of the pressure cast prosthetic socket. Clin. Biomech. 2003, 18, 237–243. [Google Scholar] [CrossRef]

- Rajtukova, V.; Hudak, R.; Zivcak, J.; Halfarova, P.; Kudrikova, R. Pressure distribution in transtibial prostheses socket and the stump interface. Procedia Eng. 2014, 96, 374–381. [Google Scholar] [CrossRef] [Green Version]

- Sanders, J.E.; Zachariah, S.G.; Jacobsen, A.K.; Fergason, J.R. Changes in interface pressures and shear stresses over time on trans-tibial amputee subjects ambulating with prosthetic limbs: Comparison of diurnal and six-month differences. J. Biomech. 2005, 38, 1566–1573. [Google Scholar] [CrossRef] [PubMed]

- Dou, P.; Jia, X.; Suo, S.; Wang, R.; Zhang, M. Pressure distribution at the stump/socket interface in transtibial amputees during walking on stairs, slope and non-flat road. Clin. Biomech. 2006, 21, 1067–1073. [Google Scholar] [CrossRef] [PubMed]

- Wolf, S.I.; Alimusaj, M.; Fradet, L.; Siegel, J.; Braatz, F. Pressure characteristics at the stump/socket interface in transtibial amputees using an adaptive prosthetic foot. Clin. Biomech. 2009, 24, 860–865. [Google Scholar] [CrossRef] [PubMed]

- Ali, S.; Osman, N.A.A.; Mortaza, N.; Eshraghi, A.; Gholizadeh, H.; Wan Abas, W.A.B.B. Clinical investigation of the interface pressure in the trans-tibial socket with Dermo and Seal-In X5 liner during walking and their effect on patient satisfaction. Clin. Biomech. 2012, 27, 943–948. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ali, S.; Osman, N.A.A.; Eshraghi, A.; Gholizadeh, H.; Abas, W.A.B.B.W.o. Interface pressure in transtibial socket during ascent and descent on stairs and its effect on patient satisfaction. Clin. Biomech. 2013, 28, 994–999. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sengeh, D.M.; Herr, H. A variable-impedance prosthetic socket for a transtibial amputee designed from magnetic resonance imaging data. JPO J. Prosthetics Orthot. 2013, 25, 129–137. [Google Scholar] [CrossRef] [Green Version]

- Adriana, A.M.; Tatiana, B.S.; Vanessa, G.U.; Juan, R.R.; Marlly, Z.G. Marcha: Descripción, métodos, herramientas de evaluación y parámetros de normalidad reportados en la literatura. (Gait: Description, methods, assessment tools and normality parameters reported in the literature). CES Mov. Y Salud 2013, 1, 29–43. [Google Scholar]

- Manske, R.C. Fundamental Orthopedic Management for the Physical Therapist Assistant-E-Book; Elsevier: Amsterdam, The Netherlands, 2015; pp. 188–200. [Google Scholar]

- Berger, N.; Edelstein, J.; Fishman, S.; Springer, W. Lower Limb Prosthetics, 1st ed.; Collaboration of Prosthetics and Orthotics staff and Faculty, New York University School of Medicine and Postgraduate Medical School: New York, NY, USA, 1988. [Google Scholar]

- Hansen, J.T. Netter’s Clinical Anatomy E-Book; Elsevier Health Sciences: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Zhang, M.; Lee, W.C. Quantifying the regional load-bearing ability of trans-tibial stumps. Prosthetics Orthot. Int. 2006, 30, 25–34. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gailey, R.S.; Roach, K.E.; Applegate, E.; Cho, B.; Cunniffe, B.; Licht, S.; Maguire, M.; Nash, M.S. The Amputee Mobility Predictor: An instrument to assess determinants of the lower-limb amputee’s ability to ambulate. Arch. Phys. Med. Rehabil. 2002, 83, 613–627. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Eshraghi, A.; Osman, N.A.A.; Gholizadeh, H.; Ali, S.; Sævarsson, S.K.; Abas, W.A.B.W. An experimental study of the interface pressure profile during level walking of a new suspension system for lower limb amputees. Clin. Biomech. 2013, 28, 55–60. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ali, S.; Osman, N.A.A.; Naqshbandi, M.M.; Eshraghi, A.; Kamyab, M.; Gholizadeh, H. Qualitative study of prosthetic suspension systems on transtibial amputees’ satisfaction and perceived problems with their prosthetic devices. Arch. Phys. Med. Rehabil. 2012, 93, 1919–1923. [Google Scholar] [CrossRef] [PubMed]

| Sensor ID | Sensibility | Offset | R² | Av Error (%) |

|---|---|---|---|---|

| A1 | 0.5591 | 3.2344 | 0.9842 | 6.13% |

| A2 | 0.5775 | 3.2552 | 0.9647 | 9.34% |

| A3 | 0.6006 | 3.3203 | 0.951 | 10.59% |

| A4 | 0.4886 | 3.2803 | 0.9576 | 7.87% |

| A5 | 0.4349 | 3.2188 | 0.9806 | 4.79% |

| A6 | 0.6888 | 3.3071 | 0.9206 | 14.70% |

| Average | 0.5475 | 3.2813 | 0.9654 | 8.00% |

| Pressure Peaks per Gait Cycle | ||||||

|---|---|---|---|---|---|---|

| Sensors Gait Cycle | A1 | A2 | A3 | A4 | A5 | A6 |

| 1 | 0.08 kgf/cm (7.84 kPa) | 0.02 kgf/cm (1.96 kPa) | 0.09 kgf/cm (8.83 kPa) | 0.08 kgf/cm (7.84 kPa) | 0.02 kgf/cm (1.96 kPa) | 0.22 kgf/cm (21.57 kPa) |

| 2 | 0.09 kgf/cm (8.83 kPa) | 0.02 kgf/cm (1.96 kPa) | 0.11 kgf/cm (10.79 kPa) | 0.02 kgf/cm (1.96 kPa) | 0.02 kgf/cm (1.96 kPa) | 0.19 kgf/cm (18.63 kPa) |

| 3 | 0.09 kgf/cm (8.83 kPa) | 0.02 kgf/cm (1.96 kPa) | 0.11 kgf/cm (10.79 kPa) | 0.12 kgf/cm (11.77 kPa) | 0.02 kgf/cm (1.96 kPa) | 0.18 kgf/cm (17.65 kPa) |

| Pressure Peaks per Gait Cycle | ||||||

|---|---|---|---|---|---|---|

| Sensors Gait Cycle | A1 | A2 | A3 | A4 | A5 | A6 |

| 1 | 0.18 kgf/cm (17.65 kPa) | 0.23 kgf/cm (22.55 kPa) | 0.18 kgf/cm (17.65 kPa) | 0.23 kgf/cm (22.55 kPa) | 0.17 kgf/cm (16.67 kPa) | 0.24 kgf/cm (23.53 kPa) |

| 2 | 0.05 kgf/cm (4.90 kPa) | 0.09 kgf/cm (8.83 kPa) | 0.05 kgf/cm (4.90 kPa) | 0.07 kgf/cm (6.86 kPa) | 0.07 kgf/cm (6.86 kPa) | 0.06 kgf/cm (5.88 kPa) |

| 3 | 0.23 kgf/cm (22.55 kPa) | 0.27 kgf/cm (26.47 kPa) | 0.22 kgf/cm (21.57 kPa) | 0.21 kgf/cm (20.59 kPa) | 0.20 kgf/cm (19.61 kPa) | 0.28 kgf/cm (27.45 kPa) |

| 4 | 0.13 kgf/cm (12.74 kPa) | 0.13 kgf/cm (12.74 kPa) | 0.11 kgf/cm (10.79 kPa) | 0.10 kgf/cm (9.80 kPa) | 0.10 kgf/cm (9.80 kPa) | 0.10 kgf/cm (9.80 kPa) |

| 5 | 0.08 kgf/cm (7.84 kPa) | 0.09 kgf/cm (8.83 kPa) | 0.08 kgf/cm (7.84 kPa) | 0.07 kgf/cm (6.86 kPa) | 0.09 kgf/cm (8.83 kPa) | 0.09 kgf/cm (8.83 kPa) |

| 6 | 0.04 kgf/cm (3.92 kPa) | 0.03 kgf/cm (2.94 kPa) | 0.03 kgf/cm (2.94 kPa) | 0.04 kgf/cm (3.92 kPa) | 0.02 kgf/cm (1.96 kPa) | 0.02 kgf/cm (1.96 kPa) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibarra Aguila, S.; Sánchez, G.J.; Sauvain, E.E.; Alemon, B.; Fuentes-Aguilar, R.Q.; Huegel, J.C. Interface Pressure System to Compare the Functional Performance of Prosthetic Sockets during the Gait in People with Trans-Tibial Amputation. Sensors 2020, 20, 7043. https://doi.org/10.3390/s20247043

Ibarra Aguila S, Sánchez GJ, Sauvain EE, Alemon B, Fuentes-Aguilar RQ, Huegel JC. Interface Pressure System to Compare the Functional Performance of Prosthetic Sockets during the Gait in People with Trans-Tibial Amputation. Sensors. 2020; 20(24):7043. https://doi.org/10.3390/s20247043

Chicago/Turabian StyleIbarra Aguila, Salvador, Gisel J. Sánchez, Eric E. Sauvain, B. Alemon, Rita Q. Fuentes-Aguilar, and Joel C. Huegel. 2020. "Interface Pressure System to Compare the Functional Performance of Prosthetic Sockets during the Gait in People with Trans-Tibial Amputation" Sensors 20, no. 24: 7043. https://doi.org/10.3390/s20247043