Beam Deflection Monitoring Based on a Genetic Algorithm Using Lidar Data

Abstract

:1. Introduction

2. Basic Principles

2.1. Least Square Regression

2.2. Genetic Algorithm

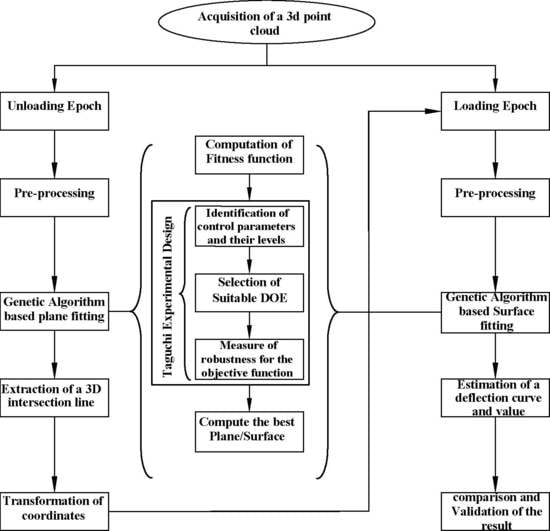

3. Proposed Approach for Computation of Deflection

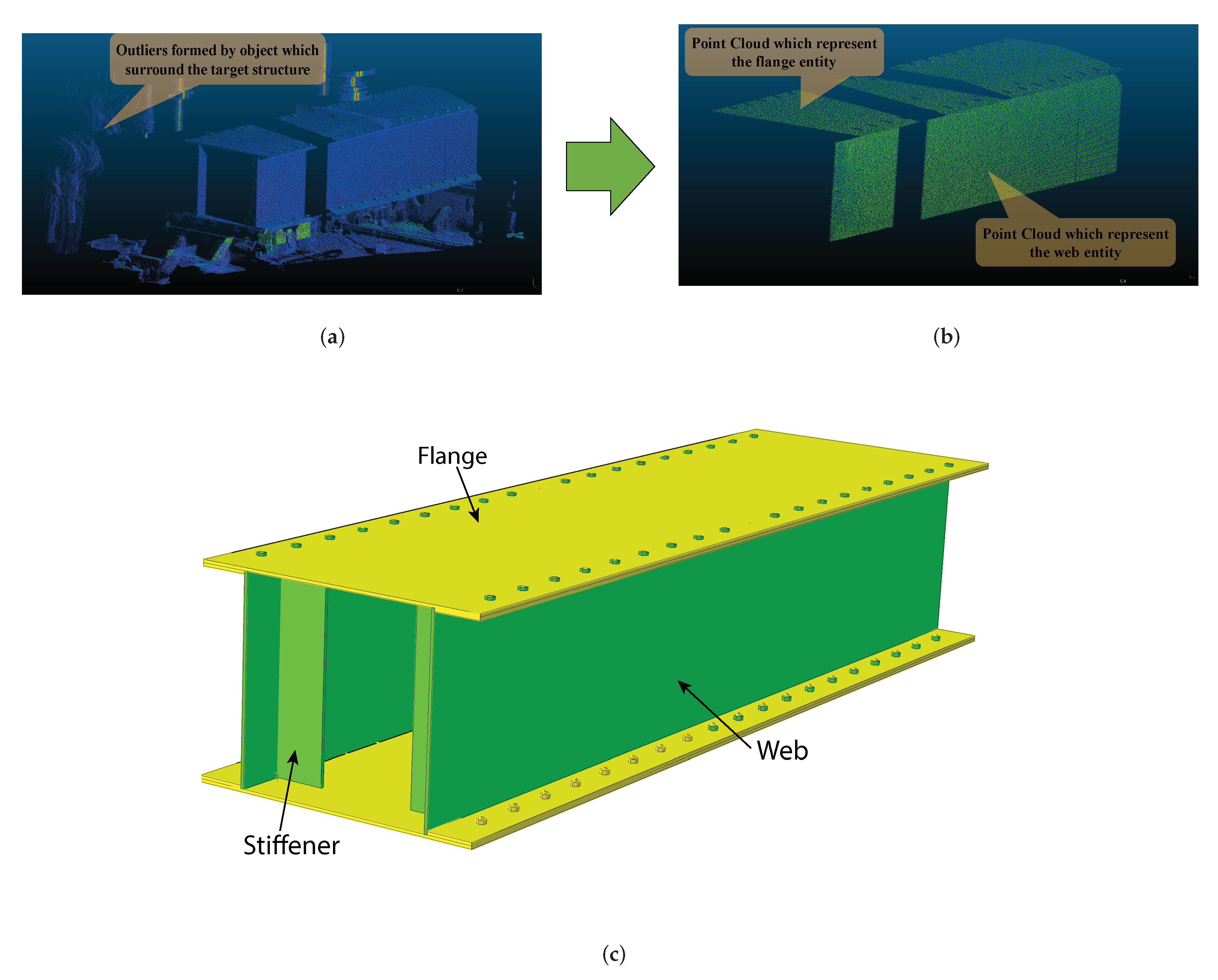

3.1. Acquisition of the Point Cloud and Pre-Processing

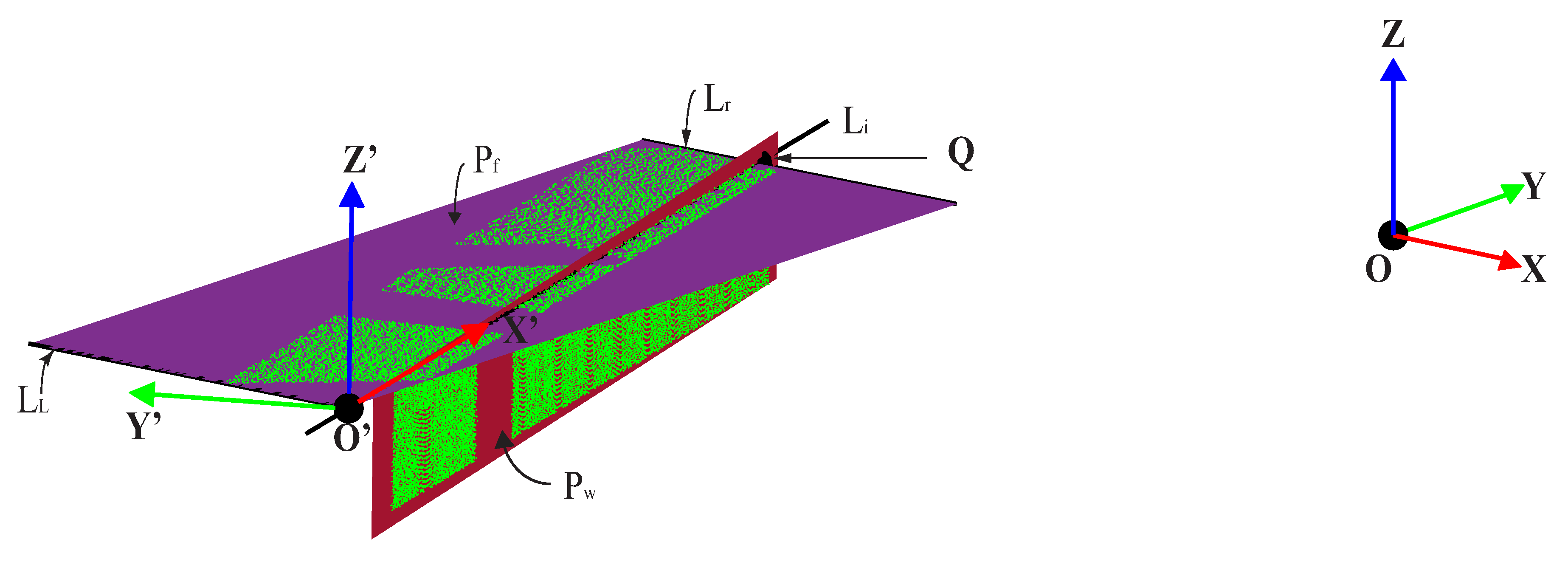

3.2. Characterizing the Point Cloud in Terms of Definable Mathematical Elements

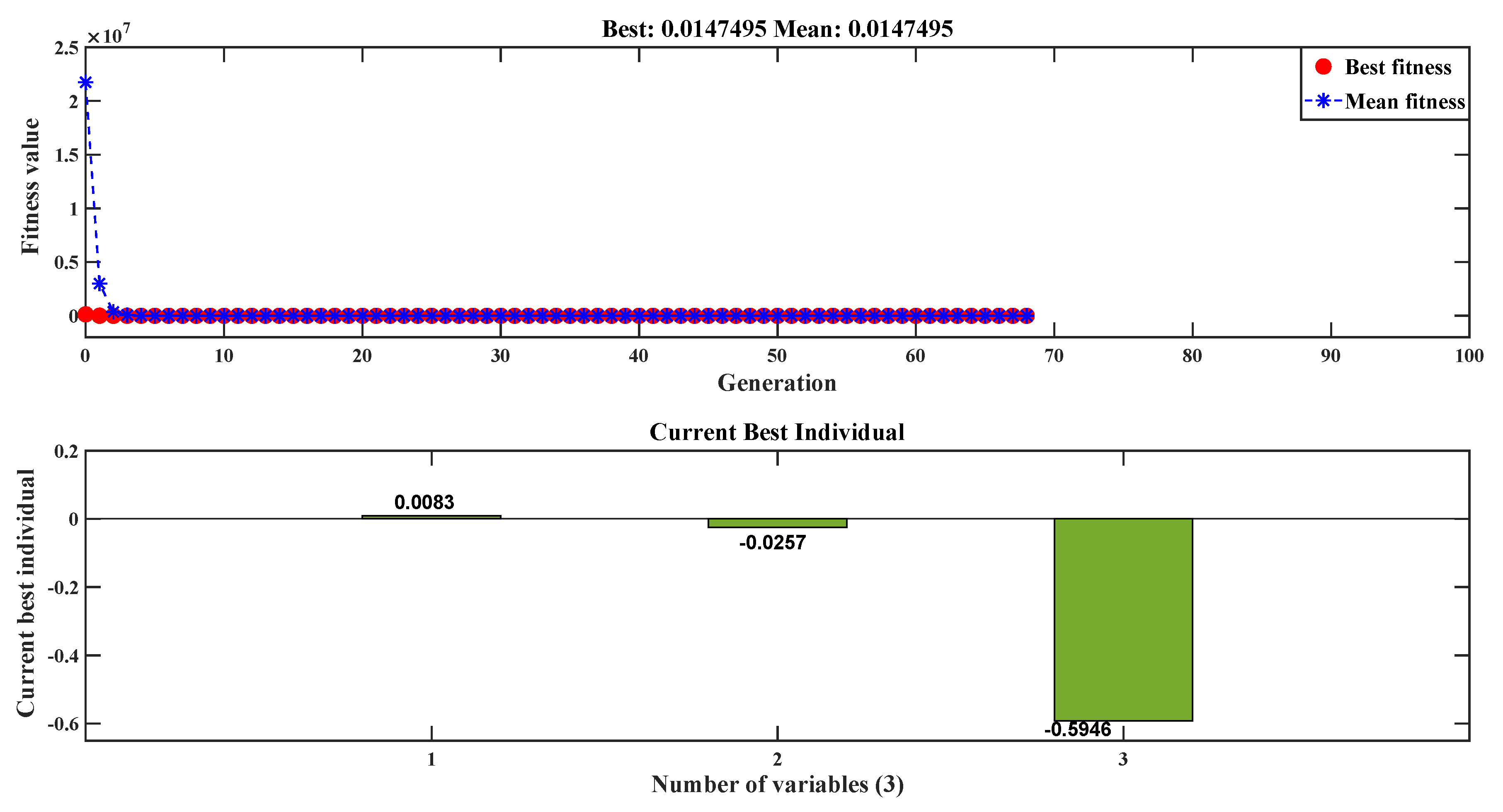

3.2.1. Least Squares Genetic Algorithm(LS-GA) Based Plane Fitting

- Fitness function: The fitness function is a mathematical formulation of the desired optimization problem. It determines how suitable a solution is. The magnitude of the residual, which defines the difference between the model and data examines the individuals formed throughout all generation. This can be described in Equation (4):where is the point model, normally defined as the nearest data point P

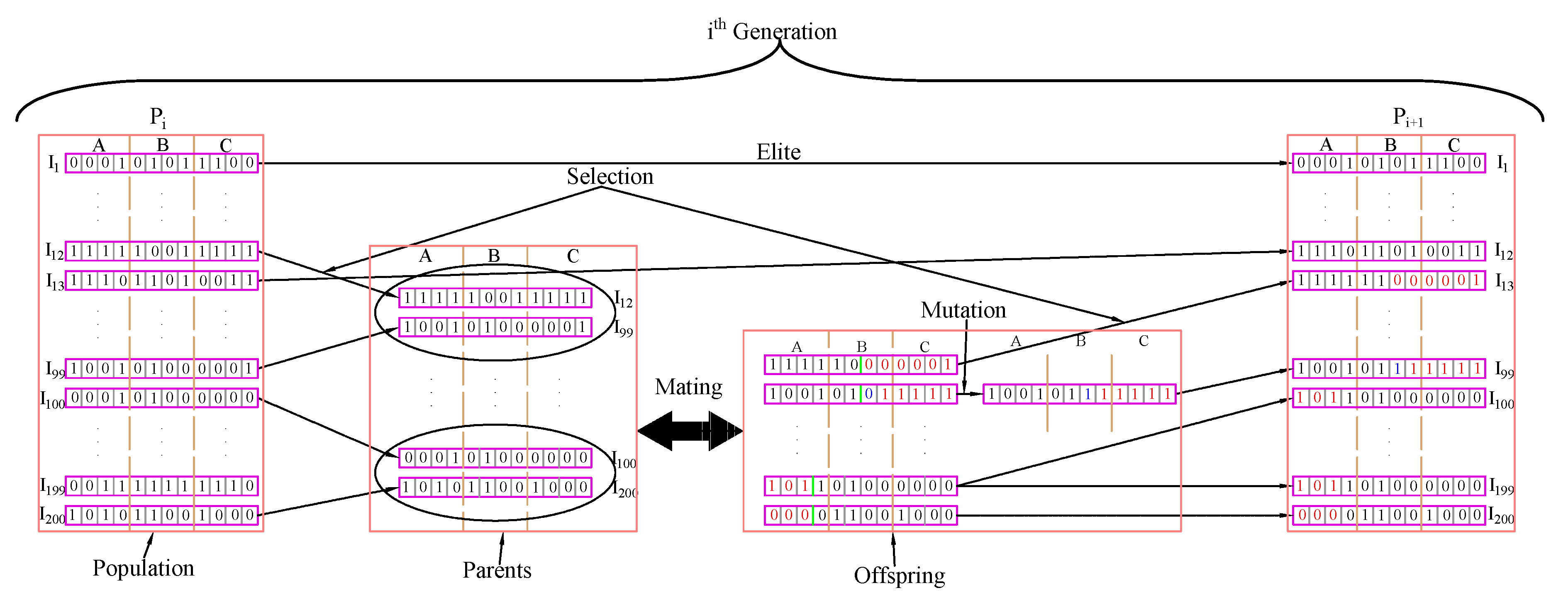

- Population: The population is a set of individuals that have a chance to be the fittest among them. An individual is characterized by a set of variables called its genes. It is a basic building block of for the algorithm. In our case, this refers to the parameter of the regression model. These genes are joined into a string to form a chromosome (individuals). It is simply a series of binary numbers (0 and 1), which encode all values of parameter of the regression model. up to that are shown in Figure 3 are list of chromosomes in the population which have a binary representation of all the parameters A, B, and C of the plane. Our GA is one of the unique behaviors of this optimization techniques; it works only on the number of chromosomes inside the population. The number of chromosomes in the population defined by the user is labeled as the population size. The building block and their corresponding chromosomes in the population is shown in the Figure 3.

- Fitness scaling function: If we consider only multiplying the fitness by some factor, then as the name implies, this does not change the relationships among the population. Rather, a much more sensible fitness scaling is an affine transformation, where scaled(f) = a ∗ f + b, of the fitness value, is seen via formulae, the values are multiplied by some number and then offset by another either up or down. This parameter plays a crucial role in GA by limiting the tendency of the strongest solution to overwhelm the weaker ones thus avoiding premature convergence.

- Selection: The selection is a parameter for choosing two parents from the population for the purpose of mating. This process continues in every single generation until one of the stopping criteria is attained. Parents, i.e., a pair of individuals, are chosen based on their fitness score.

- Crossover/Reproduction: This parameter mainly depicts how the selected individuals mate with each other and create new offspring for the next generation. In this process, part of the individuals is exchanged with its mate based on the user-defined crossover probability.

- Elite Count: This is the number of individuals with the best fitness values in the current generation that have been retained for the next generation. Because of their robust fitness score, more copies of these individuals are achieved in the subsequent generation.

- Crossover fraction: The fraction of individuals in the next generation, other than the elite children, that are created via crossover.

- Mutation: A process of changing of a bit (gen) within a bit string (chromosome). This is done to maintain diversity within the population and prevent premature convergence.

- Migration: An exchange of information (exchange of individuals) between the sub-populations.

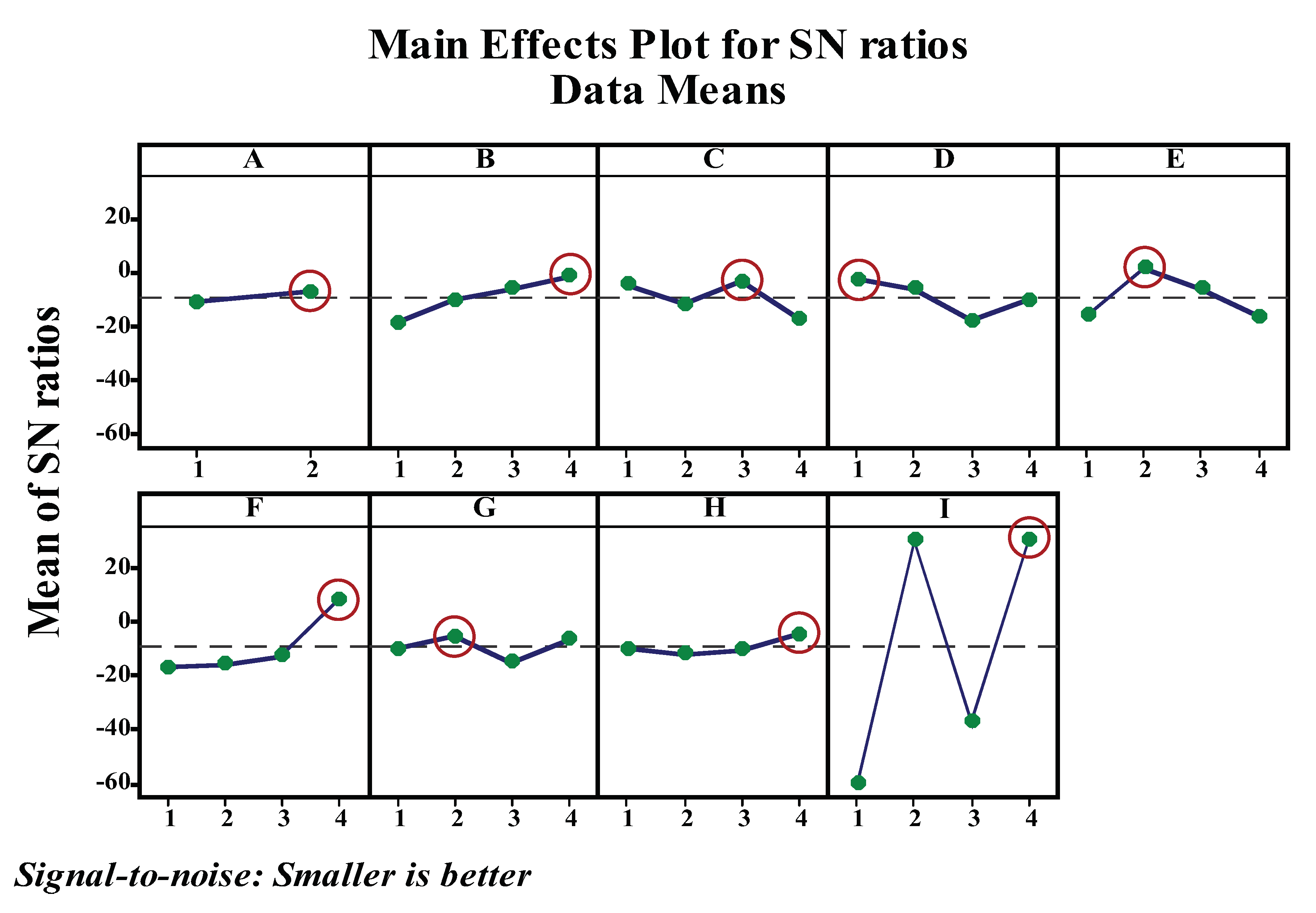

3.2.2. Taguchi Experimental Design

3.2.3. Extraction of the 3D Intersection Line

3.2.4. Transformation of Coordinates

3.3. Estimation of the Deflection Curve from the Loading Scenario

4. Experimental Study

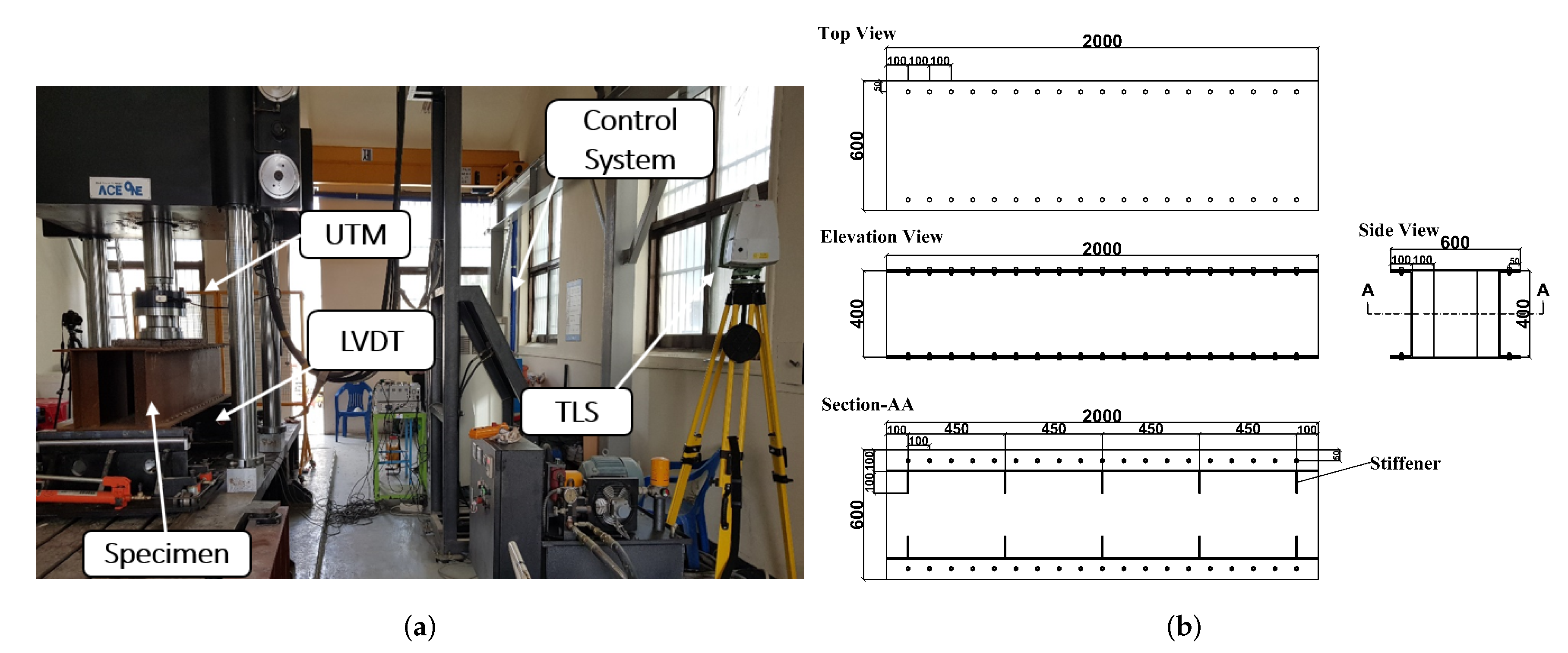

- Universal Testing Machine (UTM): This device is related mainly to the loading. The load is applied perpendicularly midway from the top flange face with the help of a hydraulic system. The loading system is controlled in real time via the UTM, i.e., the hydraulic power unit, load measuring unit and control devices, which are linked with the loading unit. ACE-USS200 model of Servo-Hydraulic Universal Testing Machines, which having 200 ton loading capacity, was utilized for this study. Servo-Hydraulic UTM can be controlled via a multi-functional remote control handset that is located on the frame, a digital control unit or Material Testing Program (MTP) software was installed on the PC connected to the Control Unit. It can carry out tensile and yield, compression, flexure tests with load and displacement controls.

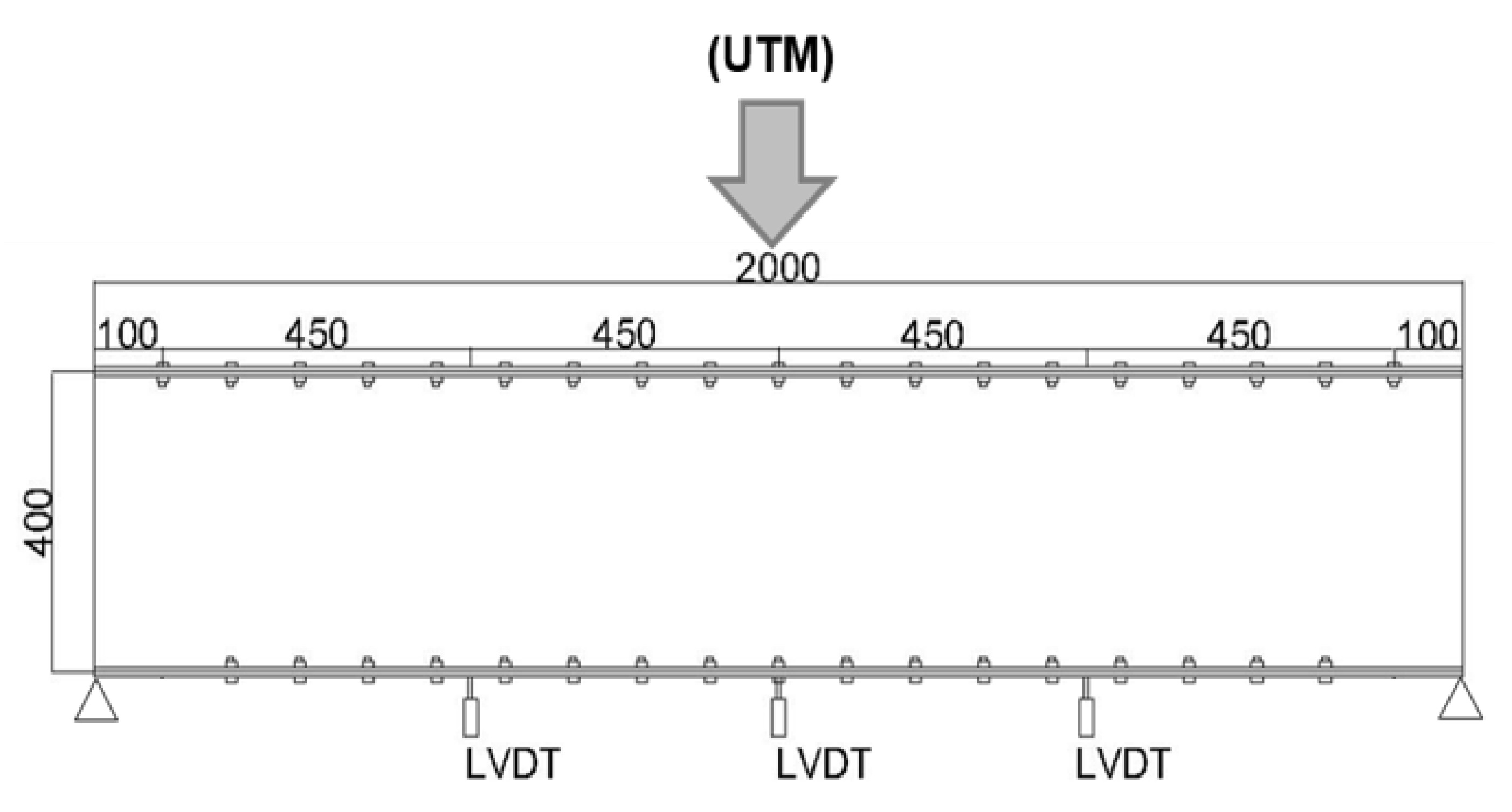

- Linear variable displacement transducer (LVDT): LVDT is a sensor that converts the linear movement of the object the LVDT is coupled to into a variable corresponding to the electrical signal proportional to that movement. This contact sensor measures the real time displacement of a specimen by attaching the rod element, which is a combination of the core, core extension, and probe tip, lightly to the bottom flange face during unloading. CDP-50 type of LVDT was utilized for our experiment.

- Terrestrial laser scanning(TLS): It measures a scanned object by emitting laser pulses and recording the subsequent intensity of their return after reflection. Leica scan station C5 scanner which is operated based on the time of flight principle was utilized for our experimentation. We have used the highest resolution mode of resolution. According to Leica specifications, this kind of mode has 0.02 m × 0.02 m resolution. Furthermore, there are 2530 × 2181 points in the horizontal and vertical directions, respectively.

- Specimen: The beam utilized for this study is a steel box girder, SS 400-6T, which has dimensions of 0.4 m × 0.8 m × 2 m. the specimen has a transverse stiffener, which stiffens the flange and web against out of plane deformation. The specimen is welded every 45 cm throughout the entire span in both the right and left webs inside the box. As a result, transverse deformation of the specimen is trivial in this study.

4.1. Design of the Experiment

- Setting the position of a specimen through the UTM machine keeps all the necessary alignments both horizontally and vertically. The scanner device stands 2.5 m away from the front web face while considering which factors affect the accuracy of the data. Target color, incidence angle, range and intensity are the main factors that affect the point cloud noise and parametric model fitting [13]. Consequently, this setup considers all the results from Bolkas et al. in accordance with the available space in the laboratory.

- The contact sensor (LVDT) is mounted below the specimen at three different positions. One is at the center and the other two LVDTs are fixed 55 cm from the left and right edges individually, as shown in Figure 7. These LVDTs and the UTM machine are connected to a computer.

- The specimen is scanned without any loading by setting the required field of view. The field of view for scanning an object should reduce the outliers caused by objects out side of the target.

- Once we are done scanning the specimen scene without loading, we apply loading via the UTM until the center LVDT reading reaches 1mm. The 1 mm sag is attained at a 57.33 KN loading. Again, the scanning process starts over by pausing the applied load and keeping the 1 mm sag.

- In this fashion, specimen scanning is carried out for different deflection sizes for the corresponding loadings. Table 2 summarizes the induced load for each case along with their corresponding LVDT sensor readings.

- After capturing all the necessary data with the USB, which was plugged in to the scanner during the scanning process, we changed the file format from .PLY to .PTS using cyclone which is a software module of Leica, for the purpose of using the cloud compare software. Once we have the data file format which is capable to utilize via with cloud compare, it is easy to apply manual segmentation of an object entity, removing the outliers and preparing the data for further analysis. one of the advantage of this software regarding with removal of an outliers, it provides segmentation command in different shape using polylines. Figure 2a,b, which depict the data with and with out the outliers respectively, are obtained from this software.

4.2. Validation Results

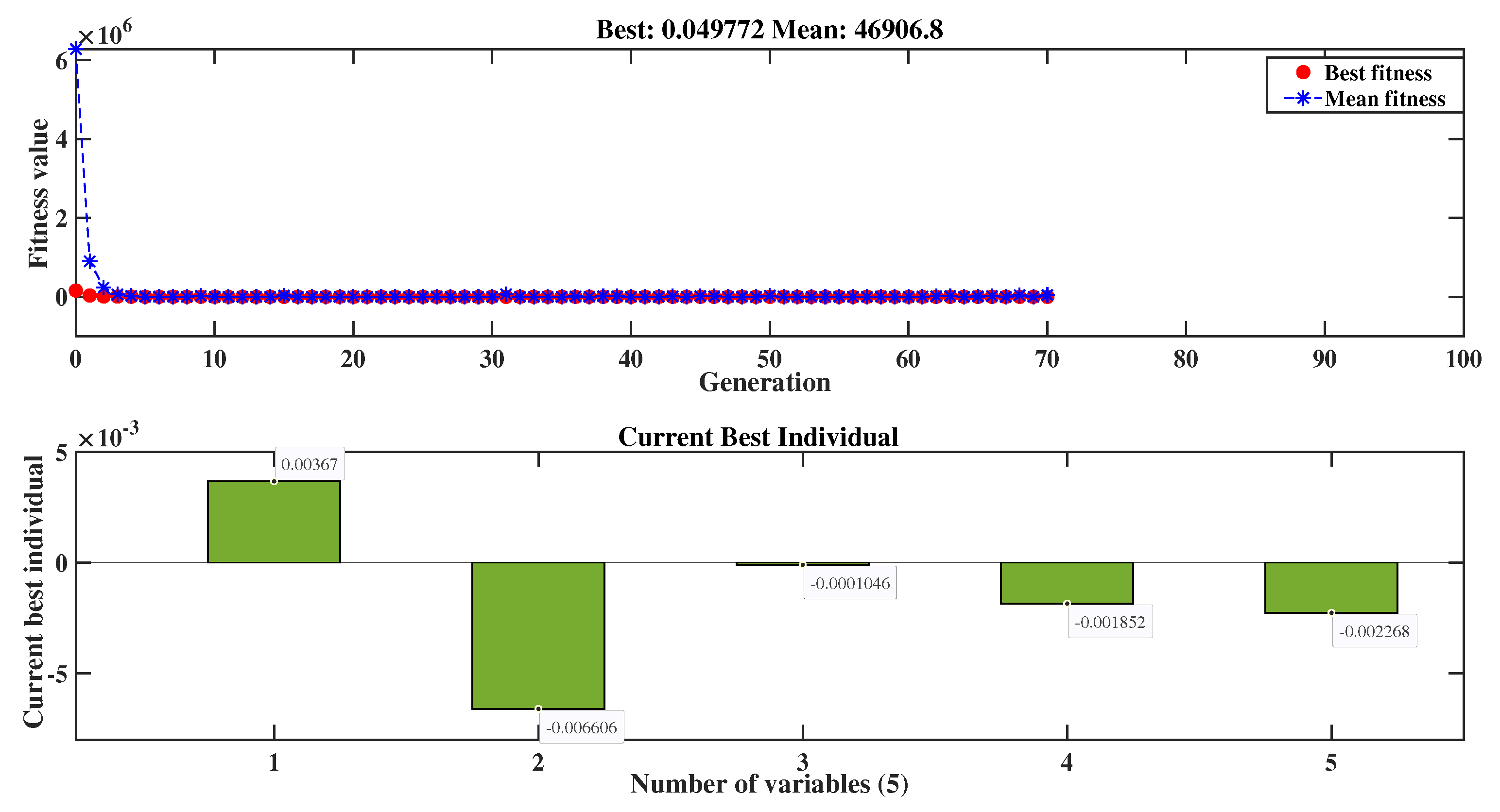

4.2.1. Selection of Optimal Parameters for GA

4.2.2. Computation of Deflection Based on the Genetic Algorithm

- … Equation of a plane that represents the flange part;

- … Equation of a plane that represents the web part.

- dZ/dx = 0,

- Since the specimen has transverse stiffener at 45 cm apart along both sides, it is very stiff along with the loading. However, the stiffness of a specimen is not uniform throughout the span with increasing load. A part of the specimen in between two stiffeners has not been equally disturbed with the part where exactly stiffener is welded. Consequently, the global deflection curve may not be expected exactly as a 2nd degree parabolic.

- Secondly, the nature of a specimen has also its part in affecting the result for the edge LVDTs. Hence, the beam is labelled as a deep beam because of its span-to-depth ratio and the concentrated load with it. Therefore, the shear effect is predominant than flexural in our specimen. This implies that the deflection curve which is expected from the flexural effect is affected to some extent. Even the data shown for edge LVDTs are biased by this effect.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| LIDAR | Light Detection And Ranging |

| TLS | Terrestrial Laser Scanning |

| GA | Genetic Algorithm |

| 3D | Three-Dimesion |

| LVDT | Linear Variable Differential Transformer |

| LS-GA | Least Square Based Genetic Algorithm |

| DOE | Design of Experiemnt |

| RGB | Red Green Blue |

| SNR | Signal to Noise Ratio |

| UTM | Universal Testing Machine |

| OA | Orthogonal Arrays |

References

- Chong, K.P.; Zhu, S.Y. Innovative technologies in manufacturing, mechanics and smart civil infrastructure. Int. J.Smart Nano Mat. 2018, 4, 261–278. [Google Scholar] [CrossRef]

- Maskuriy, R.; Selamat, A.; Ali, K.N.; Maresova, P.; Krejcar, O. Industry 4.0 for the construction industry—How ready is the industry? Appl. Sci. 2019, 9, 2819. [Google Scholar] [CrossRef] [Green Version]

- Giurgiutiu, V.; Cuc, A. Embedded non-destructive evaluation for structural health monitoring, damage detection, and failure prevention. Shock Vibr. Digest 2005, 37, 83. [Google Scholar] [CrossRef]

- Farrar, C.R.; Keith, W. An introduction to structural health monitoring. Philos. Trans. R. Soc. Math. Phys. Eng. Sci. 2007, 365, 303–315. [Google Scholar] [CrossRef]

- Achenbach, J.D. Quantitative nondestructive evaluation. Int. J. Solids Struct. 2000, 37, 13–27. [Google Scholar] [CrossRef]

- Chan, T.H.; Yu, L.; Tam, H.Y.; Ni, Y.Q.; Liu, S.Y.; Chung, W.H.; Cheng, L.K. Fiber bragg grating sensors for structural health monitoring of tsing Ma bridge: Background and experimental observation. Eng. Struct. 2006, 28, 648–659. [Google Scholar] [CrossRef]

- Behnia, A.; Chai, H.K.; Shiotani, T. Advanced structural health monitoring of concrete structures with the aid of acoustic emission. Constr. Build. Mater. 2014, 65, 282–302. [Google Scholar] [CrossRef]

- López-Higuera, J.M.; Cobo, L.R.; Incera, A.Q.; Cobo, A. Fiber optic sensors in structural health monitoring. J. Light. Technol. 2011, 29, 587–608. [Google Scholar]

- Terroba, F.; Frövel, M.; Atienza, R. Structural health and usage monitoring of an unmanned turbojet target drone. Struct. Health Monit. 2019, 18, 635–650. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Tuned Lamb wave excitation and detection with piezoelectric wafer active sensors for structural health monitoring. J. Intell. Mater. Syst. Struct. 2005, 16, 291–305. [Google Scholar] [CrossRef]

- Cha, G.; Park, S.; Oh, T. A terrestrial LiDAR-based detection of shape deformation for maintenance of bridge structures. J. Constr. Eng. Manag. 2019, 145, 04019075. [Google Scholar] [CrossRef]

- Soudarissanane, S.; Lindenbergh, R.; Menenti, M.; Teunissen, P. Scanning geometry: Influencing factor on the quality of terrestrial laser scanning points. Isprs J. Photogramm. Remote. Sens. 2011, 66, 389–399. [Google Scholar] [CrossRef]

- Bolkas, D.; Martinez, A. Effect of target color and scanning geometry on terrestrial LiDAR point-cloud noise and plane fitting. J. Appl. Geod. 2018, 12, 109–127. [Google Scholar] [CrossRef]

- Cabaleiro, M.; Lindenbergh, R.; Gard, W.F.; Arias, P.; Van de Kuilen, J.W.G. Algorithm for automatic detection and analysis of cracks in timber beams from LiDAR data. Constr. Build. Mater. 2017, 130, 41–53. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.; Kim, J. Dynamic displacement measurement of a vibratory object using a terrestrial laser scanner. Meas. Sci. Technol. 2015, 26, 045002. [Google Scholar] [CrossRef]

- Xu, X.; Yang, H.; Neumann, I. Concrete crack measurement and analysis based on terrestrial laser scanning technology. Sens. Transducers 2015, 186, 168–172. [Google Scholar]

- Kitratporn, N.; Takeuchi, W.; Matsumoto, K.; Nagai, K. Structure deformation measurement with terrestrial laser scanner at pathein bridge in myanmar. J. Disaster Res. 2018, 13, 40–49. [Google Scholar] [CrossRef]

- Yang, H.; Omidalizarandi, M.; Xu, X.; Neumann, I. Terrestrial laser scanning technology for deformation monitoring and surface modeling of arch structures. Compos. Struct. 2017, 169, 173–179. [Google Scholar] [CrossRef] [Green Version]

- Lam, S.Y. Application of terrestrial laser scanning methodology in geometric tolerances analysis of tunnel structures. Tunn. Undergr. Space Technol. 2006, 21, 410. [Google Scholar] [CrossRef]

- Park, H.S.; Lee, H.M.; Adeli, H.; Lee, I. A new approach for health monitoring of structures: Terrestrial laser scanning. Comput. Aided Civ. Infrastruct. Eng. 2007, 22, 19–30. [Google Scholar] [CrossRef]

- Cabaleiro, M.; Riveiro, B.; Arias, P.; Caamaño, J.C. Algorithm for beam deformation modeling from LiDAR data. Measurement 2015, 76, 20–31. [Google Scholar] [CrossRef]

- Gordon, S.J.; Lichti, D.; Stewart, M.; Franke, J. Structural Deformation Measurement Using Terrestrial Laser Scanners. In Proceedings of the 11th FIG Symposium on Deformation Measurements, Santorini, Greece, 25–28 May 2003. [Google Scholar]

- Zogg, H.-M.; Ingensand, H. Terrestrial laser scanning for deformation monitoring: Load tests on the Felsenau Viaduct (CH). Int. Arch. Photogramm. Remote. Sens. Spat. Inf. Sci. 2008, 37, 555–562. [Google Scholar]

- Olsen, M.J.; Kuester, F.; Chang, B.J.; Hutchinson, T.C. Terrestrial laser scanning-based structural damage assessment. J. Comput. Civ. Eng. 2010, 24, 264–272. [Google Scholar] [CrossRef]

- Cabaleiro, M.; Riveiro, B.; Arias, P.; Caamaño, J.C. Algorithm for the analysis of deformations and stresses due to torsion in a metal beam from LIDAR data. Struct. Control. Health Monit. 2016, 23, 1032–1046. [Google Scholar] [CrossRef]

- Li, H.; Chang, J.; Xu, F.; Liu, Z.; Yang, Z.; Zhang, L.; Zhang, S.; Mao, R.; Dou, X.; Liu, B. Efficient lidar signal denoising algorithm using variational mode decomposition combined with a whale optimization algorithm. Remote. Sens. 2019, 11, 126. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Zhang, Z.; Peterson, J.; Chandra, S. The Effect of LiDAR Data Density on DEM Accuracy. In Proceedings of the International Congress on Modelling and Simulation (MODSIM07), Christchurch, New Zealand, 10–13 December 2007; pp. 1363–1369. [Google Scholar]

- Mao, J. Noise reduction for lidar returns using local threshold wavelet analysis. Opt. Quantum Electron. 2012, 43, 59–68. [Google Scholar] [CrossRef]

- Fang, H.T.; Huang, D.S. Noise reduction in lidar signal based on discrete wavelet transform. Opt. Commun. 2004, 233, 67–76. [Google Scholar] [CrossRef]

- Salgado, C.M.; Azevedo, C.; Proença, H.; Vieira, S.M. Noise versus outliers. In Secondary Analysis of Electronic Health Records; Springer: Cham, Switzerland, 2016; pp. 163–183. [Google Scholar]

- Jung, B.K.; Cho, J.R.; Jeong, W.B. Sensor placement optimization for structural modal identification of flexible structures using genetic algorithm. J. Mech. Sci. Technol. 2015, 29, 2775–2783. [Google Scholar] [CrossRef]

- Kumar, R.; Ramachandra, L.S.; Roy, D. Techniques based on genetic algorithms for large deflection analysis of beams. Sadhana 2004, 29, 589–604. [Google Scholar] [CrossRef]

- Almongy, H.M.; Almetwaly, E.M. Comparison between Methods of Robust Estimation to Reduce the Effect of Outliers. Available online: https://www.researchgate.net/publication/326557510 (accessed on 10 April 2020).

- Gibson, C.G. Elementary Euclidean geometry: An Introduction; Cambridge University Press: Cambridge, NY, USA, 2003. [Google Scholar]

- Yan, X.; Su, X. Linear Regression Analysis: Theory and Computing; World Scientific: Toh Tuck, Singapore, 2009. [Google Scholar]

- Holland, J.H. Genetic algorithms. Sci. Am. 1992, 267, 66–73. [Google Scholar] [CrossRef]

- Goldberg, D.E. Genetic algorithms in search, optimization, and machine learning. Choice Rev. Online 1989, 27, 0936. [Google Scholar]

- Gulsen, M.; Smith, A.E.; Tate, D.M. A genetic algorithm approach to curve fitting. Int. J. Prod. Res. 1995, 33, 1911–1923. [Google Scholar] [CrossRef]

- Karr, C.L.; Stanley, D.A.; Scheiner, B.J. Genetic Algorithm Applied to Least Squares Curve Fitting; US Department of the Interior: Washington, DC, USA, 1991.

- Messa, K.; Lybanon, M. Curve Fitting Using Genetic Algorithms. Available online: https://apps.dtic.mil/dtic/tr/fulltext/u2/a247206.pdf (accessed on 10 April 2020).

- Shrestha, A.; Mahmood, A. Improving genetic algorithm with fine-tuned crossover and scaled architecture. J. Math. 2016. [Google Scholar] [CrossRef] [Green Version]

- Forouraghi, B. A genetic algorithm for multiobjective robust design. Appl. Intell. 2000, 12, 151–161. [Google Scholar] [CrossRef]

- Majumdar, A.; Debashis, G. Genetic algorithm parameter optimization using Taguchi robust design for multi-response optimization of experimental and historical data. Int. J. Comput. Appl. 2015, 127, 26–32. [Google Scholar] [CrossRef]

- Taguchi, G.; Chowdhury, S.; Wu, Y. Quality engineering: The taguchi method. Taguchi’S Qual. Eng. Handb. 2005, 56–123. [Google Scholar] [CrossRef]

- Dehnad, K. Quality Control, Robust Design, and the Taguchi Method; Springer Science & Business Media: Pittsburgh, PA, USA, 2012. [Google Scholar]

- Galarza, A.I.R.; Seade, J. Introduction to Classical Geometries; Springer Science: Berlin, Germany, 2007. [Google Scholar] [CrossRef]

- Anton, H.; Chris, R. Elementary Linear Algebra, Binder Ready Version: Applications Version; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Agoston, M.K.; Max, K.A. Computer Graphics and Geometric Modeling; Springer: New York, NY, USA, 2005. [Google Scholar]

| Factors | Levels | ||||

|---|---|---|---|---|---|

| Code | GA Parameter | 1/Default | 2 | 3 | 4 |

| A | Migration Direction | Forward | Both | - | - |

| B | Population Size | 50 | 100 | 150 | 200 |

| C | Fitness Scaling Function | Rank | Proportional | Top | Shift Linear |

| D | Selection Function | Stochastic Uniform | Remainder | Roulette | Tournament |

| E | Elite Count | 2 | 5 | 10 | 20 |

| F | Crossover Function | Scattered | Two Point | Heristic | Arthmetic |

| G | Crossover Fraction | 0.8 | 0.6 | 0.4 | 0.2 |

| H | Mutation Function | Gaussian | Uniform | Adaptive Feasible | Constraint Dependent |

| I | Hybrid Function | None | FminSearch | Patternsearch | Fminunc |

| Loading | Nominal | Load | LVDT Reading (mm) | ||

|---|---|---|---|---|---|

| Deflection | (KN) | 0.55 m | 1.00 m | 1.45 mm | |

| Case 1 | 1mm | 57.33 | 1.204 | 1.005 | 1.055 |

| Case 2 | 2mm | 200.47 | 2.086 | 2.014 | 1.99 |

| Case 3 | 3mm | 380.85 | 3.046 | 3.022 | 2.949 |

| Case 4 | 4mm | 480.84 | 4.109 | 4.029 | 4.188 |

| A | B | C | D | E | F | G | H | I | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Rank | SN Ratio | 9 | 4 | 6 | 5 | 3 | 2 | 7 | 8 | 1 |

| Mean | 9 | 4 | 5 | 6 | 8 | 2 | 7 | 3 | 1 | |

| Optimum Level | SN Ratio | 2 | 4 | 3 | 1 | 2 | 4 | 2 | 4 | 4 |

| Mean | 1 | 1 | 4 | 3 | 4 | 3 | 2 | 2 | 1 | |

| Combination | A2 | B4 | C3 | D1 | E2 | F4 | G2 | H4 | I4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maru, M.B.; Lee, D.; Cha, G.; Park, S. Beam Deflection Monitoring Based on a Genetic Algorithm Using Lidar Data. Sensors 2020, 20, 2144. https://doi.org/10.3390/s20072144

Maru MB, Lee D, Cha G, Park S. Beam Deflection Monitoring Based on a Genetic Algorithm Using Lidar Data. Sensors. 2020; 20(7):2144. https://doi.org/10.3390/s20072144

Chicago/Turabian StyleMaru, Michael Bekele, Donghwan Lee, Gichun Cha, and Seunghee Park. 2020. "Beam Deflection Monitoring Based on a Genetic Algorithm Using Lidar Data" Sensors 20, no. 7: 2144. https://doi.org/10.3390/s20072144

APA StyleMaru, M. B., Lee, D., Cha, G., & Park, S. (2020). Beam Deflection Monitoring Based on a Genetic Algorithm Using Lidar Data. Sensors, 20(7), 2144. https://doi.org/10.3390/s20072144