Nonprehensile Manipulation of Parts on a Horizontal Circularly Oscillating Platform with Dynamic Dry Friction Control

Abstract

:1. Introduction

2. Theoretical Analysis

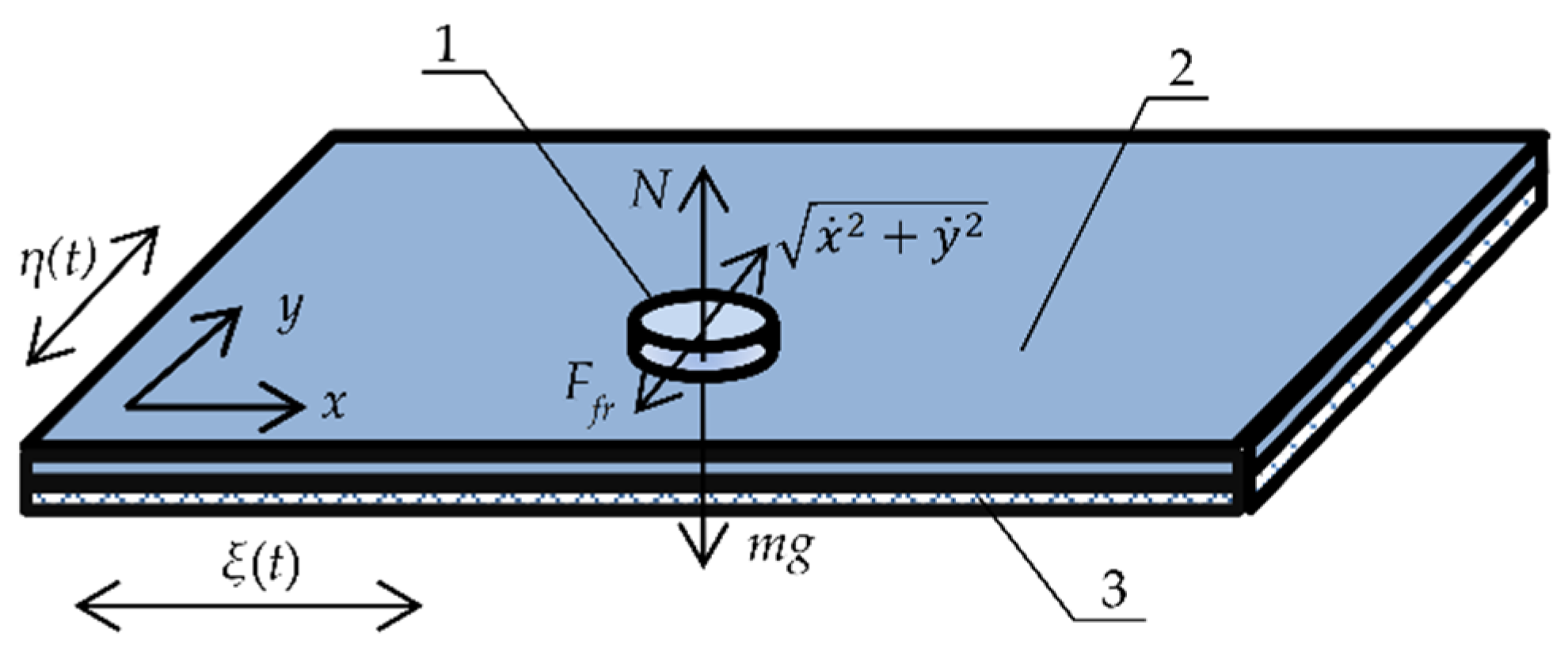

2.1. Dynamics of Manipulation Employing Dry Friction Control

2.2. Modeling Results

3. Experimental Analysis

3.1. Methodology

3.2. Experimental Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Rosyid, A.; El-Khasawneh, B. Multibody Dynamics of Nonsymmetric Planar 3PRR Parallel Manipulator with Fully Flexible Links. Appl. Sci. 2020, 10, 4816. [Google Scholar] [CrossRef]

- Fomin, A.; Antonov, A.; Glazunov, V.; Rodionov, Y. Inverse and forward kinematic analysis of a 6-DOF parallel manipulator utilizing a circular guide. Robotics 2021, 10, 31. [Google Scholar] [CrossRef]

- Fomin, A.; Antonov, A.; Glazunov, V.; Carbone, G. Dimensional (Parametric) Synthesis of the Hexapod-Type Parallel Mechanism with Reconfigurable Design. Machines 2021, 9, 117. [Google Scholar] [CrossRef]

- Ren, J.; Cao, Q. Dynamic Modeling and Frequency Characteristic Analysis of a Novel 3-PSS Flexible Parallel Micro-Manipulator. Micromachines 2021, 12, 678. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Li, Y.; Xiao, S. Development of a novel large stroke 2-DOF micromanipulator for micro/nano manipulation. Microsyst. Technol. 2017, 23, 2993–3003. [Google Scholar] [CrossRef]

- Xiao, S.; Li, Y. Optimal Design, Fabrication, and Control of an XY Micropositioning Stage Driven by Electromagnetic Actuators. IEEE Trans. Ind. Electron. 2012, 60, 4613–4626. [Google Scholar] [CrossRef]

- Xu, Q.; Li, Y. Dynamics modeling and sliding mode control of an XY micropositioning stage. In Proceedings of the International Symposium on Robot Control, Gifu, Japan, 9–12 September 2009; IFAC: New York, NJ, USA, 2009; pp. 781–786. [Google Scholar]

- Li, Z.; Liu, P.; Yan, P. Design and Analysis of a Novel Flexure-Based Dynamically Tunable Nanopositioner. Micromachines 2021, 12, 212. [Google Scholar] [CrossRef]

- Fan, C.; Shirafuji, S.; Ota, J. Modal Planning for Cooperative Non-Prehensile Manipulation by Mobile Robots. Appl. Sci. 2019, 9, 462. [Google Scholar] [CrossRef] [Green Version]

- Feemster, M.; Piepmeier, J.A.; Biggs, H.; Yee, S.; ElBidweihy, H.; Firebaugh, S.L. Autonomous microrobotic manipulation using visual servo control. Micromachines 2020, 11, 132. [Google Scholar] [CrossRef] [Green Version]

- Hogan, F.R.; Rodriguez, A. Reactive planar non-prehensile manipulation with hybrid model predictive control. Int. J. Robot. Res. 2020, 39, 755–773. [Google Scholar] [CrossRef]

- Fragapane, G.; Ivanov, D.; Peron, M.; Sgarbossa, F.; Strandhagen, J.O. Increasing flexibility and productivity in Industry 4.0 production networks with autonomous mobile robots and smart intralogistics. Ann. Oper. Res. 2020, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Jung, E.; Kim, I. Hybrid Imitation Learning Framework for Robotic Manipulation Tasks. Sensors 2021, 21, 3409. [Google Scholar] [CrossRef]

- Jancauskas, A.; Buinevicius, K.; Bogdevičius, M.; Matuliauskas, A.; Mištinas, V.; Ragulskis, L. Motion of vibration manipulators with self stopping device in one direction with interactions of two non deformable elements in one direction. Mechanika 2020, 26, 526–531. [Google Scholar] [CrossRef]

- Rizwan, M.; Shiakolas, P.S. On the optimum synthesis of a microconveyor platform for micropart translocation using differential evolution. Inverse Probl. Sci. Eng. 2013, 21, 1335–1351. [Google Scholar] [CrossRef]

- Qian, J.; Huang, W.; Yang, R.; Lam, R.H.W.; Lee, J.E. A two-chip acoustofluidic particle manipulation platform with a detachable and reusable surface acoustic wave device. Analyst 2020, 145, 7752–7758. [Google Scholar] [CrossRef] [PubMed]

- Cao, H.X.; Jung, D.; Lee, H.; Go, G.; Nan, M.; Choi, E.; Kim, C.; Park, J.; Kang, B. Micromotor Manipulation Using Ultrasonic Active Traveling Waves. Micromachines 2021, 12, 192. [Google Scholar] [CrossRef]

- Janusas, T.; Urbaite, S.; Palevicius, A.; Nasiri, S.; Janusas, G. Biologically Compatible Lead-Free Piezoelectric Composite for Acoustophoresis Based Particle Manipulation Techniques. Sensors 2021, 21, 483. [Google Scholar] [CrossRef] [PubMed]

- Röthlisberger, M.; Schuck, M.; Kulmer, L.; Kolar, J.W. Contactless Picking of Objects Using an Acoustic Gripper. Actuators 2021, 10, 70. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, X.; Kojima, M.; Huang, Q.; Arai, T. Advances in Micromanipulation Actuated by Vibration-Induced Acoustic Waves and Streaming Flow. Appl. Sci. 2020, 10, 1260. [Google Scholar] [CrossRef] [Green Version]

- Bohringer, K.F.; Bhatt, V.; Goldberg, K.Y. Sensorless manipulation using transverse vibrations of a plate. In Proceedings of the 1995 IEEE International Conference on Robotics and Automation, Nagoya, Japan, 21–27 May 1995; IEEE: Piscataway, NJ, USA, 1995; pp. 1989–1996. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Q.; Sariola, V.; Latifi, K.; Liimatainen, V. Controlling the motion of multiple objects on a Chladni plate. Nat. Commun. 2016, 7, 1–10. [Google Scholar] [CrossRef]

- Usadi, L.N.; Yee, S.; ElBidweihy, H.; Firebaugh, S. Manipulation of Microrobots Using Chladni Plates and Multimode Membrane Resonators. Eng. Proc. 2021, 4, 39. [Google Scholar] [CrossRef]

- Hou, Z.; Zhou, Z.; Li, J.; Pei, Y. The multi-frequency metastructure vibration motor design for dynamic rotary and morphology manipulation of objects. Extrem. Mech. Lett. 2020, 36, 100667. [Google Scholar] [CrossRef]

- Kashima, R.; Koyama, D.; Matsukawa, M. Two-dimensional noncontact transportation of small objects in air using flexural vibration of a plate. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2015, 62, 2161–2168. [Google Scholar] [CrossRef]

- Frei, P.U.; Wiesendanger, M.; Büchi, R.; Ruf, L. Simultaneous planar transport of multiple objects on individual trajectories using friction forces. In Distributed Manipulation; Böhringer, K.F., Choset, H., Eds.; Springer: Boston, MA, USA, 2000; pp. 49–64. [Google Scholar] [CrossRef]

- Umbanhowar, P.; Vose, T.H.; Mitani, A.; Hirai, S.; Lynch, K.M. The effect of anisotropic friction on vibratory velocity fields. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, Saint Paul, MN, USA, 14–19 May 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 2584–2591. [Google Scholar] [CrossRef]

- Mayyas, M. Parallel Manipulation Based on Stick-Slip Motion of Vibrating Platform. Robotics 2020, 9, 86. [Google Scholar] [CrossRef]

- Higashimori, M.; Yamaguchi, K.; Shibata, A. Omnidirectional Nonprehensile Manipulation Using Only One Actuator. Robotics 2018, 7, 34. [Google Scholar] [CrossRef] [Green Version]

- Reznik, D.; Canny, J.; Goldberg, K. Analysis of part motion on a longitudinally vibrating plate. In Proceedings of the 1997 IEEE/RSJ International Conference on Intelligent Robot and Systems, Grenoble, France, 11 September 1997; IEEE: Piscataway, NJ, USA, 1997; pp. 421–427. [Google Scholar] [CrossRef] [Green Version]

- Reznik, D.S.; Canny, J.F.; Alldrin, N. Leaving on a plane jet. In Proceedings of the 2001 IEEE/RSJ International Conference on Intelligent Robots and Systems, Maui, HI, USA, 29 October–3 November 2001; IEEE: Piscataway, NJ, USA, 2001; pp. 202–207. [Google Scholar] [CrossRef]

- Viswarupachari, C.; DasGupta, A.; Pratik Khastgir, S. Vibration induced directed transport of particles. J. Vib. Acoust. 2012, 134, 051005. [Google Scholar] [CrossRef]

- Liutkauskienė, K.; Kilikevičius, S.; Česnavičius, R.; Bakšys, B.; Paukštaitis, L. Manipulation of small parts being assembled on a horizontally vibrating plate. Mechanika 2019, 25, 377–382. [Google Scholar] [CrossRef] [Green Version]

- Fedaravičius, A.; Tarasevičius, K.; Sližys, E. Investigation of vibrational transportation by controlled dry friction. Mechanika 1997, 11, 27–33. [Google Scholar]

- Dunst, P.; Bornmann, P.; Hemsel, T.; Sextro, W. Vibration-Assisted Handling of Dry Fine Powders. Actuators 2018, 7, 18. [Google Scholar] [CrossRef] [Green Version]

- Kapelke, S.; Seemann, W. On the effect of longitudinal vibrations on dry friction: Modelling aspects and experimental investigations. Tribol. Lett. 2018, 66, 79. [Google Scholar] [CrossRef]

- Benad, J.; Nakano, K.; Popov, V.; Popov, M. Active control of friction by transverse oscillations. Friction 2019, 7, 74–85. [Google Scholar] [CrossRef] [Green Version]

- Gutowski, P.; Leus, M. Computational model of friction force reduction at arbitrary direction of tangential vibrations and its experimental verification. Tribol. Int. 2020, 143, 106065. [Google Scholar] [CrossRef]

- Menga, N.; Bottiglione, F.; Carbone, G. Dynamically induced friction reduction in micro-structured interfaces. Sci. Rep. 2021, 11, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Littmann, W.; Storck, H.; Wallaschek, J. Sliding friction in the presence of ultrasonic oscillations: Superposition of longitudinal oscillations. Arch. Appl. Mech. 2001, 71, 549–554. [Google Scholar] [CrossRef]

- Bakšys, B.; Ramanauskytė, K. Vibratory positioning and search of automatically assembled parts on a horizontally vibrating plane. J. Vibroeng. 2009, 11, 56–67. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kilikevičius, S.; Liutkauskienė, K.; Fedaravičius, A. Nonprehensile Manipulation of Parts on a Horizontal Circularly Oscillating Platform with Dynamic Dry Friction Control. Sensors 2021, 21, 5581. https://doi.org/10.3390/s21165581

Kilikevičius S, Liutkauskienė K, Fedaravičius A. Nonprehensile Manipulation of Parts on a Horizontal Circularly Oscillating Platform with Dynamic Dry Friction Control. Sensors. 2021; 21(16):5581. https://doi.org/10.3390/s21165581

Chicago/Turabian StyleKilikevičius, Sigitas, Kristina Liutkauskienė, and Algimantas Fedaravičius. 2021. "Nonprehensile Manipulation of Parts on a Horizontal Circularly Oscillating Platform with Dynamic Dry Friction Control" Sensors 21, no. 16: 5581. https://doi.org/10.3390/s21165581