Utilization of LED Grow Lights for Optical Wireless Communication-Based RF-Free Smart-Farming System

Abstract

:1. Introduction

2. Proposed Architecture and Fundamentals of PPFD for Communication

2.1. Proposed Energy-Efficient Smart-Farming Architecture

2.2. PPFD to Illuminance Conversion

2.3. Design Parameters for Illumination and Communications

3. Results

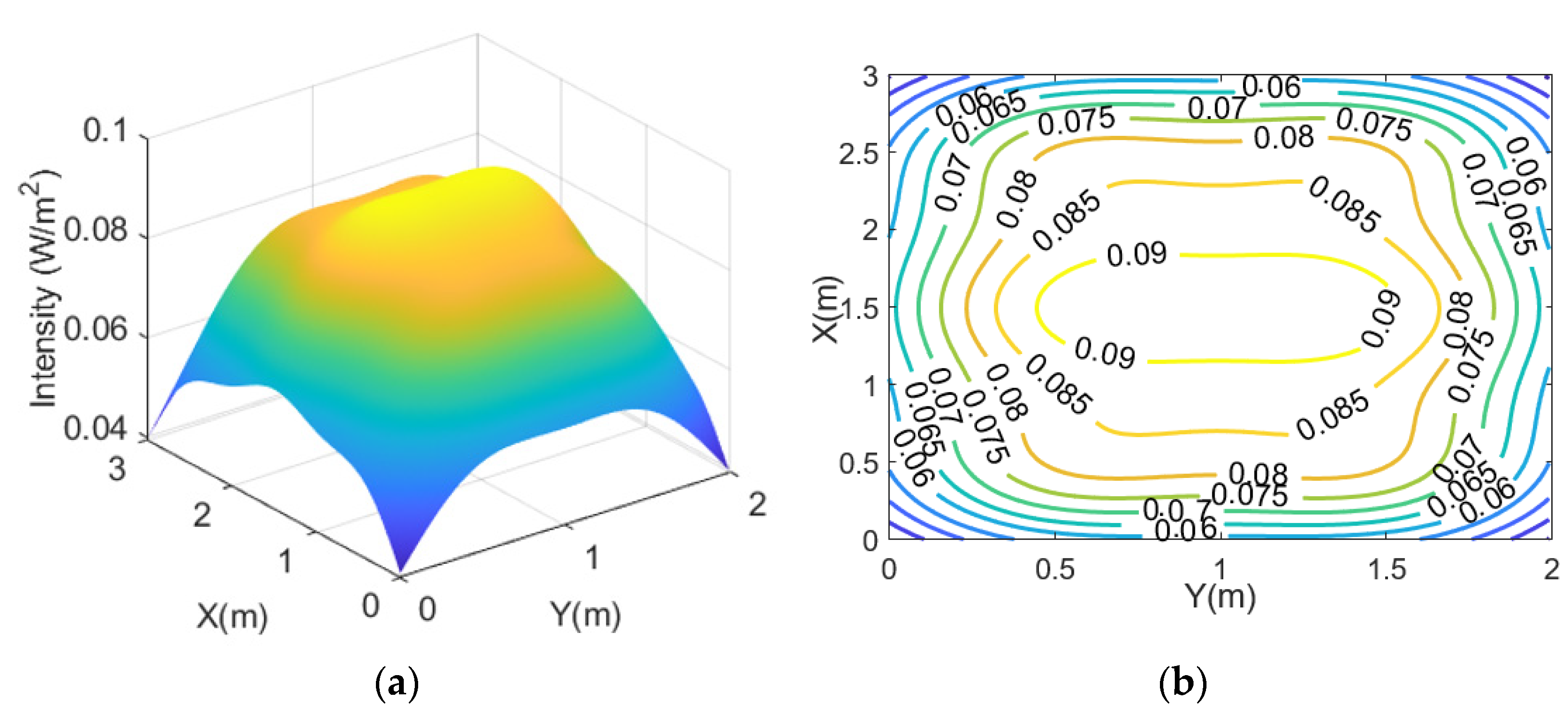

3.1. Simulation Results

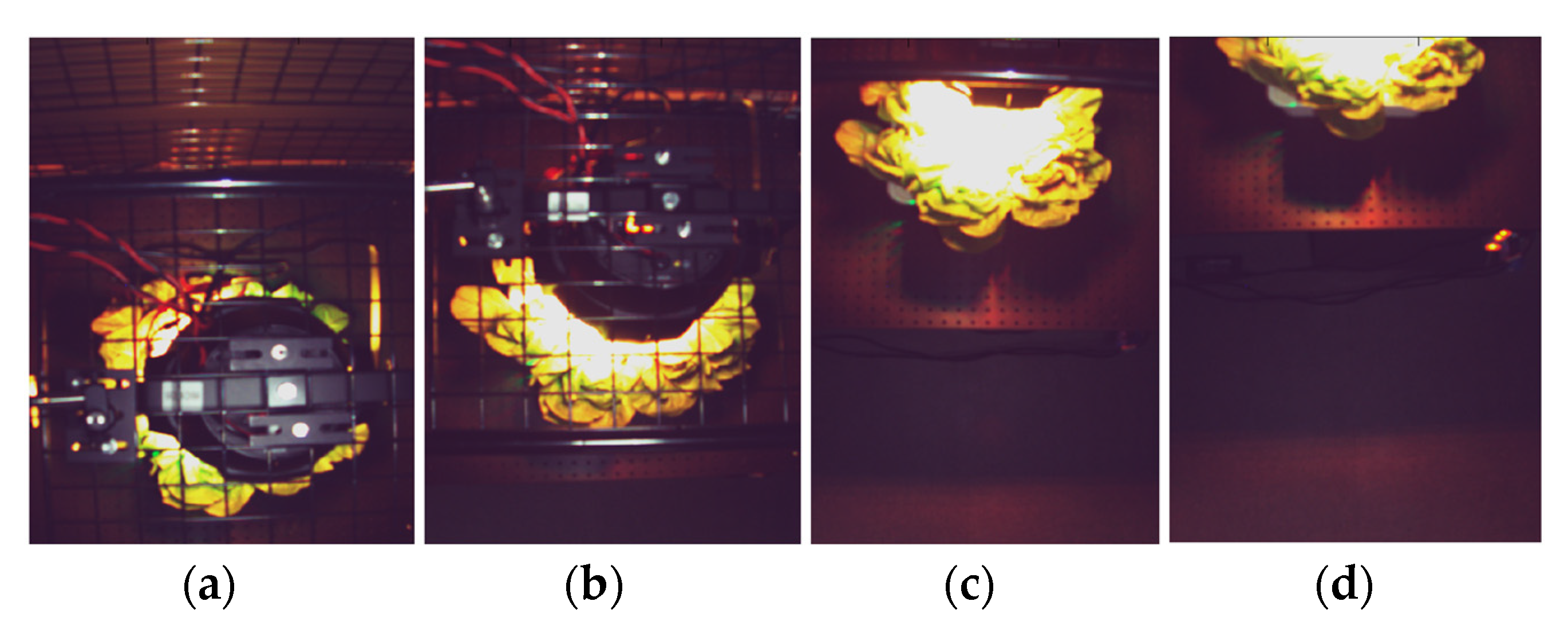

3.2. Proof-of-Concept Demonstration

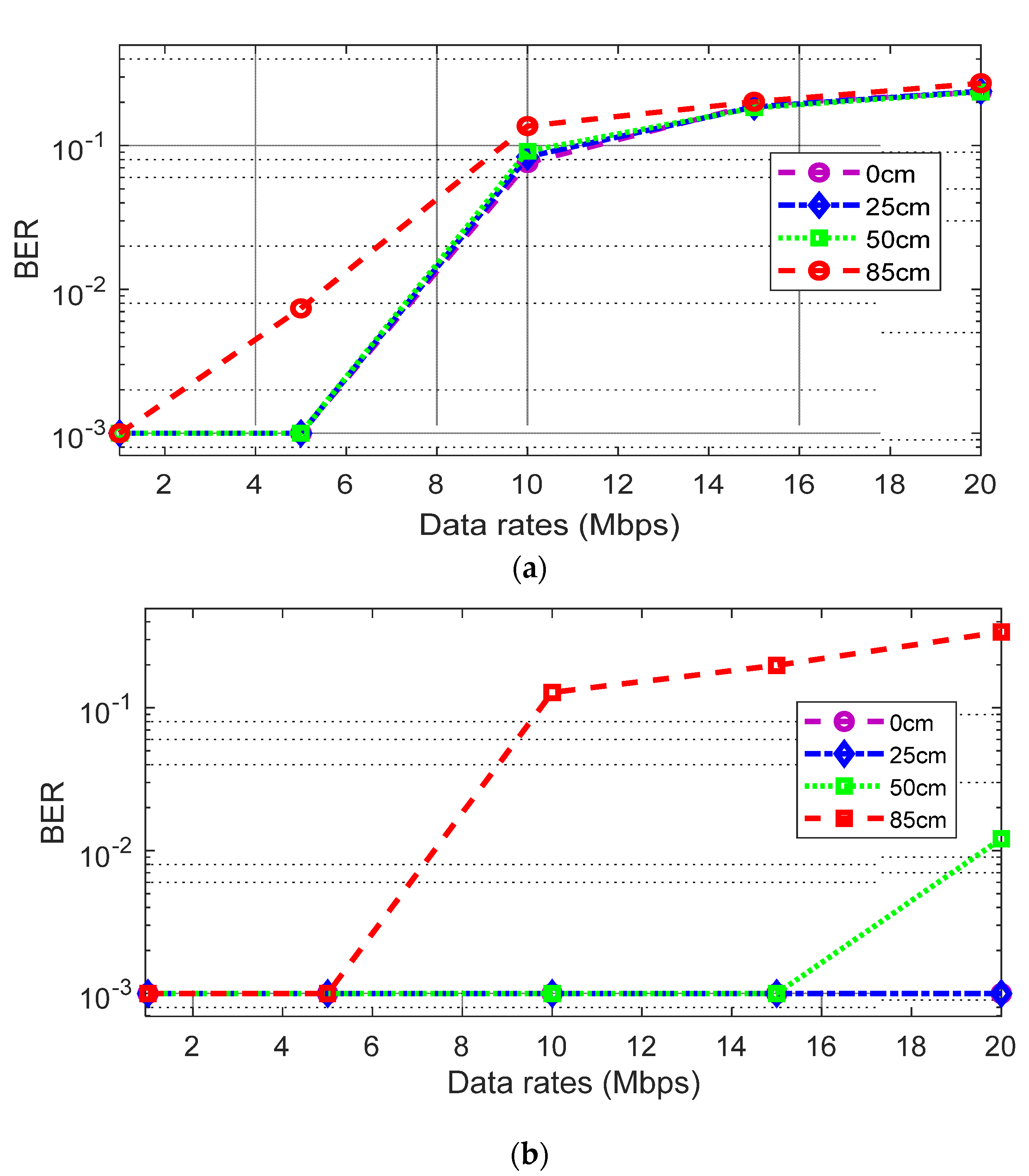

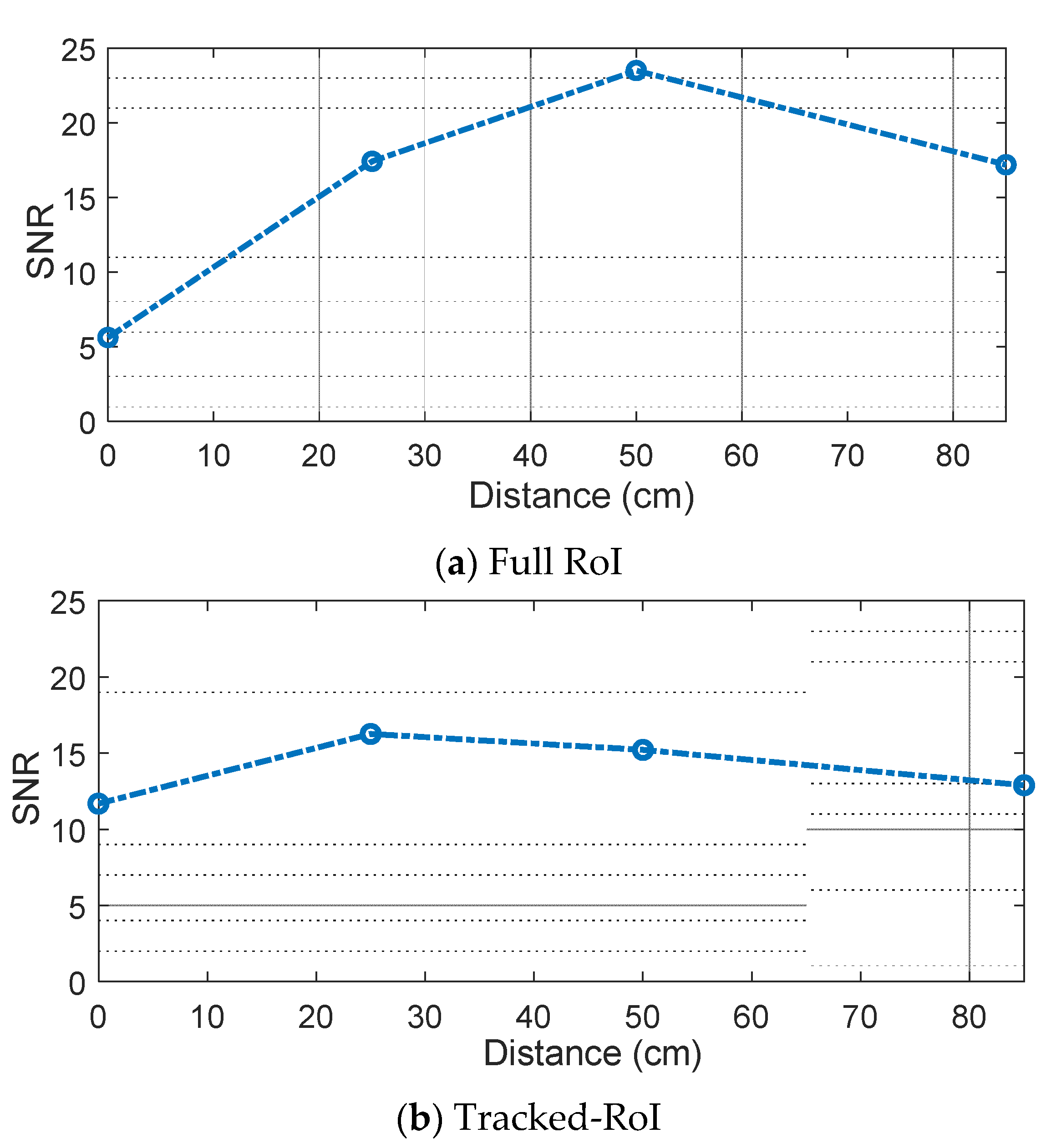

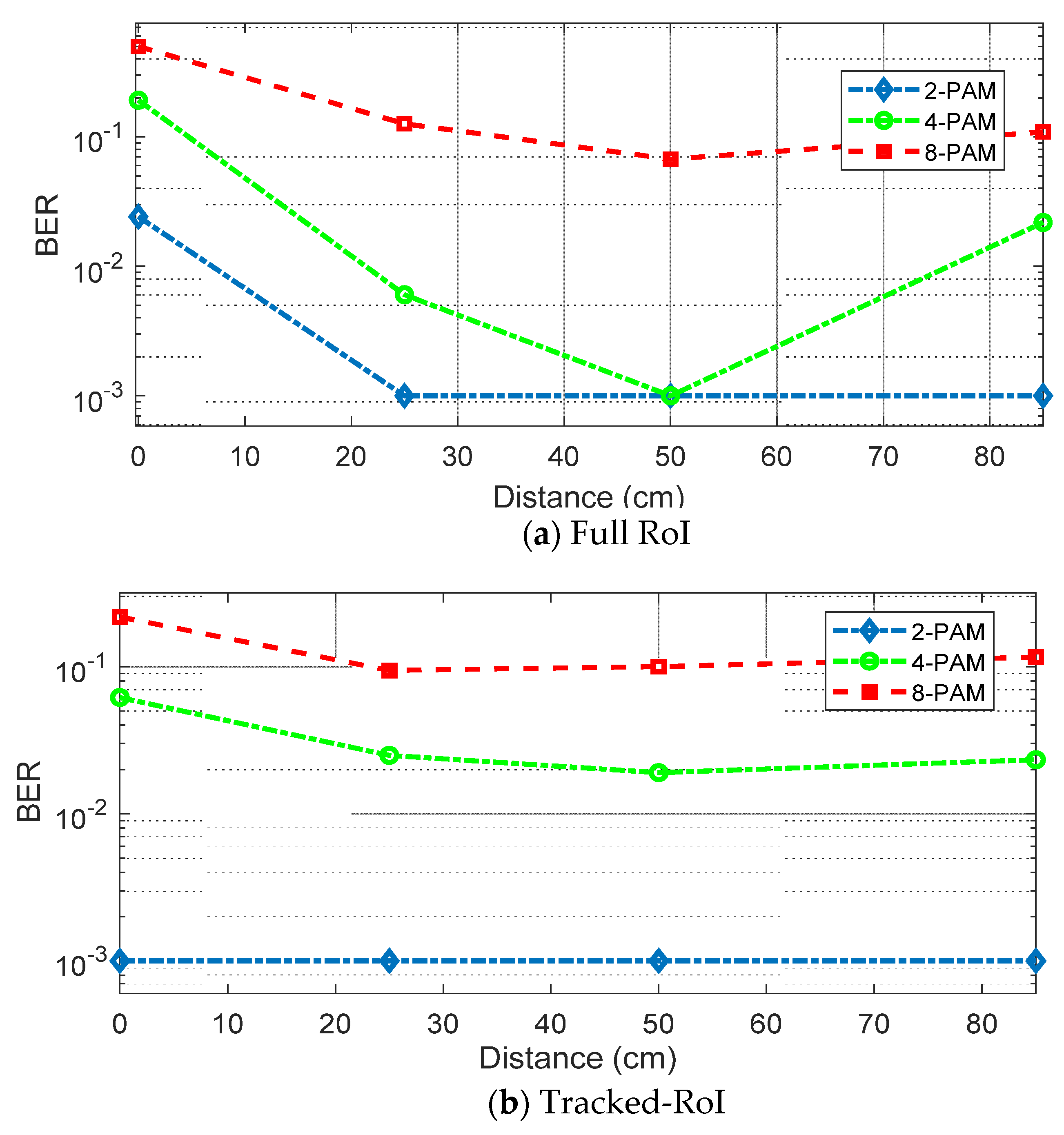

3.2.1. Downlink Communication Performance

3.2.2. Uplink Communication Performance

4. Discussions and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kozai, T. Sustainable plant factory: Closed plant production systems with artificial light for high resource use efficiencies and quality produce. Int. Symp. Soil. Cultiv. 2012, 1004, 27–40. [Google Scholar] [CrossRef]

- Mendez, G.R.; Mukhopadhyay, S.C. A Wi-Fi based smart wireless sensor network for an agricultural environment. In Wireless Sensor Networks and Ecological Monitoring; Springer: Berlin/Heidelberg, Germany, 2013; pp. 247–268. [Google Scholar]

- Kumar, T.U.; Periasamy, A. IoT Based Smart Farming (E-FARM)’S. IJRAMR 2021, 2, 85–87. [Google Scholar]

- Boonyopakom, P.; Thongna, T. Environment Monitoring System through LoRaWAN for Smart Agriculture. In Proceedings of the 5th International Conference on Information Technology (InCIT), Chonburi, Thailand, 21 October 2020; IEEE: Piscataway, NJ, USA; pp. 12–16. [Google Scholar]

- Kalaivani, T.; Allirani, A.; Priya, P. A survey on Zigbee based wireless sensor networks in agriculture. In Proceedings of the 3rd International Conference on Trendz in Information Sciences & Computing (TISC2011), Chennai, India, 8–9 December 2011; IEEE: Piscataway, NJ, USA; pp. 85–89. [Google Scholar]

- Harun, A.N.; Mohamed, N.; Ahmad, R.; Ani, N.N. Improved Internet of Things (IoT) monitoring system for growth optimization of Brassica chinensis. Comput. Electron. Agric. 2019, 164, 104836. [Google Scholar] [CrossRef]

- Jagtap, M.; Shinde, M.A.; Tirodkar, M.S.; Patil, M.A.; Tambe, M.A. Review Paper on Solar Powered & Arduino Controlled Agribot. IJSTE 2017, 4, 5. [Google Scholar]

- Dai, J.; Sugano, M. Low-Cost Sensor Network for Collecting Real-Time Data for Agriculture by Combining Energy Harvesting and LPWA Technology. In Proceedings of the IEEE Global Humanitarian Technology Conference (GHTC), Seattle, WA, USA, 17–20 October 2019; pp. 1–4. [Google Scholar]

- Havas, M.; Sheena Symington, M. Effects of Wi-Fi radiation on germination and growth of broccoli, pea, red clover and garden cress seedlings: A partial replication study. Curr. Chem. Biol. 2016, 10, 65–73. [Google Scholar] [CrossRef]

- Liptai, P.; Dolník, B.; Gumanová, V. Effect of Wi-Fi radiation on seed germination and plant growth-experiment. Ann. Fac. Eng. Hunedoara 2017, 15, 109. [Google Scholar]

- Kadam, K.; Chavan, G.T.; Chavan, U.; Shah, R.; Kumar, P. Smart and Precision Polyhouse Farming Using Visible Light Communication and Internet of Things. In Intelligent Computing and Information and Communication; Springer: Singapore, 2016; Volume 673, pp. 247–256. [Google Scholar]

- Rehman, S.U.; Ullah, S.; Chong, P.H.J.; Yongchareon, S.; Komosny, D. Visible Light Communication: A System Perspective—Overview and Challenges. Sensors 2019, 19, 1153. [Google Scholar] [CrossRef] [Green Version]

- Singh, D.; Basu, C.; Meinhardt-Wollweber, M.; Roth, B. LEDs for energy efficient greenhouse lighting. Renew. Sustain. Energy Rev. 2015, 49, 139–147. [Google Scholar] [CrossRef] [Green Version]

- Lumoindong, C.W.D.; Muslim, A.; Nasreddin, B.M.; Galina, M. Performance and environmental impacts review of Li-Fi and Wi-Fi technologies. J. Environ. Manag. 2018, 3, 68–75. [Google Scholar] [CrossRef] [Green Version]

- Shetty, A. A comparative study and analysis on Li-Fi and Wi-Fi. Int. J. Comput. Appl. 2016, 150, 43–48. [Google Scholar] [CrossRef]

- Pennisi, G.; Orsini, F.; Blasioli, S.; Cellini, A.; Crepaldi, A.; Braschi, I.; Spinelli, F.; Nicola, S.; Fernandez, J.A.; Stanghellini, C.; et al. Resource use efficiency of indoor lettuce (Lactuca sativa L.) cultivation as affected by red: Blue ratio provided by LED lighting. Sci. Rep. 2019, 9, 14127. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.H.; Goins, G.D.; Wheeler, R.M.; Sager, J.C. Green-light supplementation for enhanced lettuce growth under red-and blue-light-emitting diodes. HortScience 2004, 39, 1617–1622. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, S.; Park, S. Energy savings of home growing vegetables by using daylight and LED. In Proceedings of the IEEE Sensors Applications Symposium Proceedings, Galveston, TX, USA, 19–21 February 2013; pp. 202–204. [Google Scholar]

- Zukauskas, A.; Shur, M.S.; Gaska, R. Introduction to Solid State Lighting; John Wiley & Sons: New York, NY, USA, 2002. [Google Scholar]

- Ritchie, R.J. Modelling photosynthetic photon flux density and maximum potential gross photosynthesis. Photosynthetica 2010, 48, 596–609. [Google Scholar] [CrossRef]

- Denault, K.A.; Cantore, M.; Nakamura, S.; DenBaars, S.P.; Seshadri, R. Efficient and stable laser-driven white lighting. AIP Adv. 2013, 3, 072107. [Google Scholar] [CrossRef]

- Zhao, T.; Liu, P.; Zhang, S.; Ma, Q. UAV assisted landing guided by UV LEDs. Appl. Opt. 2020, 59, 5910–5917. [Google Scholar] [CrossRef]

- Chun, H.; Chiang, C.J.; O’Brien, D.C. Visible light communication using OLEDs: Illumination and channel modeling. In Proceedings of the 2012 International Workshop on Optical Wireless Communications (IWOW), Pisa, Italy, 22 October 2012; IEEE: Piscataway, NJ, USA; pp. 1–3. [Google Scholar]

- Kahn, J.M.; Barry, J.R. Wireless infrared communications. Proc. IEEE 1997, 85, 265–298. [Google Scholar] [CrossRef] [Green Version]

- Grubor, J.; Randel, S.; Langer, K.D.; Walewski, J.W. Broadband information broadcasting using LED-based interior lighting. J. Light. Technol. 2008, 26, 3883–3892. [Google Scholar] [CrossRef] [Green Version]

- Lighting Indoor Housevegetables|MU Extension. Available online: https://extension.missouri.edu/publications/g6515 (accessed on 4 May 2021).

- Bian, Z.H.; Yang, Q.C.; Liu, W.K. Effects of light quality on the accumulation of phytochemicals in vegetables produced in controlled environments: A review. J. Sci. Food Agric. 2015, 95, 869–877. [Google Scholar] [CrossRef]

- Berkovich, Y.A.; Konovalova, I.O.; Smolyanina, S.O.; Erokhin, A.N.; Avercheva, O.V.; Bassarskaya, E.M.; Kochetova, G.V.; Zhigalova, T.V.; Yakovleva, O.S.; Tarakanov, I.G. LED crop illumination inside space greenhouses. Reach 2017, 6, 11–24. [Google Scholar] [CrossRef]

- Pennisi, G.; Pistillo, A.; Orsini, F.; Cellini, A.; Spinelli, F.; Nicola, S.; Fernandez, J.A.; Crepaldi, A.; Gianquinto, G.; Marcelis, L.F. Optimal light intensity for sustainable water and energy use in indoor cultivation of lettuce and basil under red and blue LEDs. Sci. Hortic. 2020, 272, 109508. [Google Scholar] [CrossRef]

- Altunbas, S.; Gozukara, G.; Sonmez, N.K.; Maltas, A.S.; Kaplan, M. Relationship between spectral reflectance and vegetable nutrient element-chlorophyll content in lettuce (Lactuca sativa L.) growing. Fresenius Environ. Bull. 2018, 27, 3624–3632. [Google Scholar]

| Red LED | Green LED | Blue LED | |

|---|---|---|---|

| Lux/PPFD | 41.3 | 122.4 | 15.1 |

| Red LED | Green LED | Blue LED | |

|---|---|---|---|

| lm/W | 217.3 | 543.9 | 58.7 |

| Parameters | RGB Photon Flux (μmol·m−2 s−1) | Illuminance (lux) | Intensity (W/m2) |

|---|---|---|---|

| Total (400–700 nm) | 250 | 14,208.6 | 52.1 |

| Red (600–700 nm) | 152.5 | 6298.3 | 29 |

| Green (500–600 nm) | 60 | 7344 | 13.5 |

| Blue (400–500 nm) | 37.5 | 566.3 | 9.6 |

| Geometrical Parameters | Values |

|---|---|

| Room dimension | 3 m × 2 m × 3 m |

| Center location | |

| Vegetableation unit (6 units) (length, width, height) | (0.4 m, 0.45 m, 0.8 m), (0.4 m, 1.55 m, 0.8 m) (1.5 m, 0.45 m, 0.8 m), (1.5 m, 1.55 m, 0.8 m) (2.6 m, 0.45 m, 0.8 m), (2.6 m, 1.55 m, 0.8 m) |

| Grow LED lights (6 units) | 0.3 m above the vegetableation unit |

| Ceiling lights (6 units) | 1.35 m above the vegetableation unit |

| Size | |

| Vegetableation area | 0.3 × 0.3 m2 |

| Grow LED lights | 0.2 × 0.2 m2 |

| Ceiling lights | 0.2 × 0.2 m2 |

| Optical Parameters | Values |

| Photodetector active area | 1 cm2 |

| Reflectance of vegetable (at green wavelength) | 0.22 [30] |

| Lambertian order (ceiling and grow lights) | m = 1 (Φ½ = 60°) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Javed, S.; Issaoui, L.; Cho, S.; Chun, H. Utilization of LED Grow Lights for Optical Wireless Communication-Based RF-Free Smart-Farming System. Sensors 2021, 21, 6833. https://doi.org/10.3390/s21206833

Javed S, Issaoui L, Cho S, Chun H. Utilization of LED Grow Lights for Optical Wireless Communication-Based RF-Free Smart-Farming System. Sensors. 2021; 21(20):6833. https://doi.org/10.3390/s21206833

Chicago/Turabian StyleJaved, Sana, Louey Issaoui, Seonghyeon Cho, and Hyunchae Chun. 2021. "Utilization of LED Grow Lights for Optical Wireless Communication-Based RF-Free Smart-Farming System" Sensors 21, no. 20: 6833. https://doi.org/10.3390/s21206833

APA StyleJaved, S., Issaoui, L., Cho, S., & Chun, H. (2021). Utilization of LED Grow Lights for Optical Wireless Communication-Based RF-Free Smart-Farming System. Sensors, 21(20), 6833. https://doi.org/10.3390/s21206833