1. Introduction

Steel fiber-reinforced concrete (SFRC) has been used as a building material because it exhibits improved mechanical properties compared to conventional concrete [

1]. The non-destructive testing techniques with microwaves are widely used to examine mechanical properties, the degree of curing, the cracks of building materials, and so on. These methods have a low cost, are relatively easy to use, and consume a low amount of power [

2,

3,

4]. There are also studies using the microwave method to examine the distribution of fiber distributions [

5,

6]. Although steel fibers are added to strengthen the mechanical properties of concrete, they also have electrical conductivity, which provides the potential to generate intentional electromagnetic phenomena, such as shielding, absorbing, reflecting, and so on [

7,

8]. When a significant amount of electromagnetic waves is reflected due to the inclusion of steel fibers, the transmission characteristic becomes small, and a shielding room is required to accurately measure it. In this study, instead of measuring both the transmission and reflection characteristics, a method that can measure the dielectric constant by measuring only reflection characteristics was applied to solve the problem.

Concrete with sufficient curing and drying is considered to require a mixture of various types of dielectric materials. The equivalent relative permittivity of typical concrete varies depending on the composition of the mixture such as cement and aggregate and is known to have a value of approximately 5–10 in microwave frequencies. Meanwhile, the imaginary part of the relative permittivity, which determines the attenuation of the electromagnetic wave propagating inside the concrete, has a value of 1 or less [

9]. When a conductive material is added in the dielectric, the effect of the electrical conductivity of these conductive inclusions appears as an imaginary part of the effective permittivity of the mixture [

10]. Reinforced concrete with rebar exhibits an electromagnetic shielding effect at low frequencies and has a large-scale wire-mesh structure [

11]. In the case of the SFRC, the electromagnetic properties are changed by the electrically small steel fiber. As the content of the steel fiber increases, the properties of the entire mixed concrete become more likely to be conductive; as a result, the reflection increases and the transmission decreases [

12].

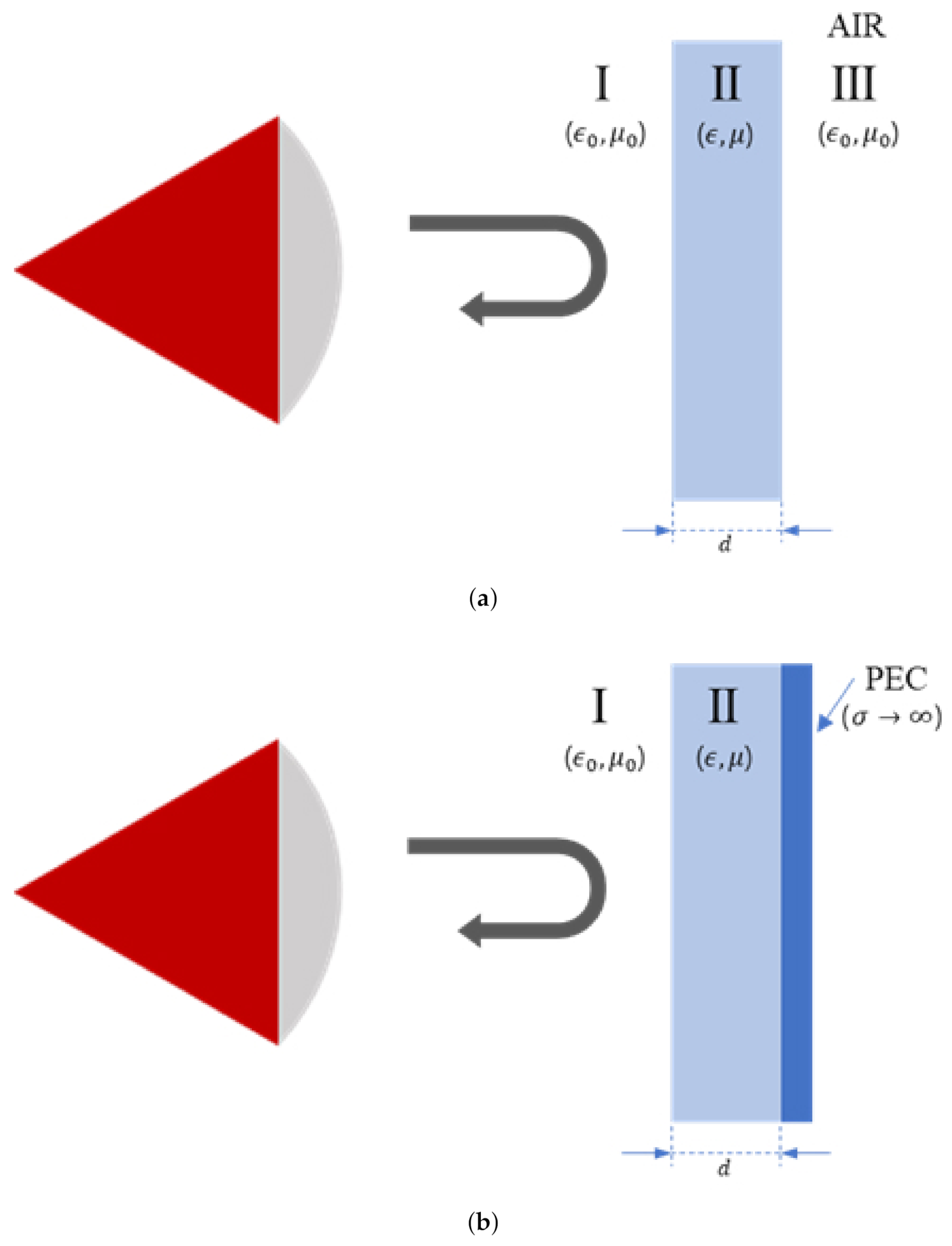

Permittivity and permeability are fundamental material properties that determine the behavior of electromagnetic waves in a material. The electrical conductivity can be regarded as an imaginary part of the permittivity. There are several measurement methods to determine these properties. One of the methods involves measuring resistance, capacitance, and inductance by making a material a component of the circuit, which is applicable in DC or low frequencies under 100 MHz. To measure the permittivity and permeability in microwave frequencies, the reflection method, the reflection/transmission method, and the resonator method are used [

13]. The procedure of the reflection/transmission method is explained as follows. First, a sample is placed between two-port transmission lines, and the reflection and transmission characteristics of the electromagnetic wave for the sample are measured. The permittivity and permeability are then determined. The Nicolson–Ross–Weir (NRW) method is a well-known method for extracting permittivity and permeability from the measured S-parameter using a 2-port system [

14]. Several studies have been conducted to estimate the accurate permittivity based on this method [

15]. This method can conveniently measure the material characteristics in a wide frequency range but requires a thin and planar sample. Moreover, if the magnitude of reflection and transmission are around 1 or 0, respectively, it is challenging to estimate the permittivity and permeability simultaneously. In this case, the impedance is the only parameter that can be measured accurately. If the sample does not have magnetic properties, the permittivity can be determined from the impedance.

To determine the homogeneity condition of the mixture, the sample must be sufficiently large compared to the inclusion particles. The length of the steel fiber used in this study was 19.5 mm, and it was contiguous to 30 mm, which is the wavelength of the frequency at 10 GHz. The thickness of the sample used for the reflection/transmission method was close to the half-wavelength. It should be noted that there is no guarantee that the distribution of the direction of the fiber is isotropic. The size of the sample should be sufficiently large to ensure homogeneity and effective and accurate measurements. However, this is not comparable to the condition of the sample thickness for reflection/transmission methods. As the thickness of the SFRC sample increases, the transmission of electromagnetic waves through the sample becomes small. Considering all of these situations, we measured only the reflection from, and the impedance of, the SFRC sample [

16]. The conversion method of the reflection-only method in this case is similar to the method of the NRW-based transmission/reflection method.

In this study, detailed steps to measure the impedance of the SFRC sample are discussed. The 1-port calibration process is processed in the vector network analyzer and the free-space measurement system. The time-gating process is additionally conducted to eliminate the multi-reflections from the external environments. The free-space method was used to examine the effective characteristics of rectangular concrete blocks. The frequencies of the measurements are within the X-band range (from 8.2 to 12.4 GHz). The focused beam horn antenna was selected to minimize the effects of the experimental circumstances [

17]. The 1-port calibration method for the focused beam environment with reflectors in several positions was proposed to improve the accuracy of the measured reflections. The conversion method for reflection was applied to examine the transmission characteristics of the SFRC samples. The results of the measurement are as follows. The magnitude of the reflection coefficient increases, while the phase decreases as the fiber content increases. The impedance exhibits characteristics opposite to those of the reflections. Note that, with an increase in the steel fiber, the imaginary part of the permittivity is increased, and the real part of the permittivity is decreased, which sometimes even changes to a negative value, which is considered to be due to the plasmon effect. The electromagnetic properties of the SFRC are changed from dielectric to conductor as the fiber content increases, even at a very low frequency compared to the plasma frequency of the general metal. It is believed that the metallic structure was formed with the increase in fiber content. The 1-port reflection calibration method with the focused beam lens horn antenna and the result of the complex permittivity of the SFRC in the X-band are the contributions of this article.

3. Measurements

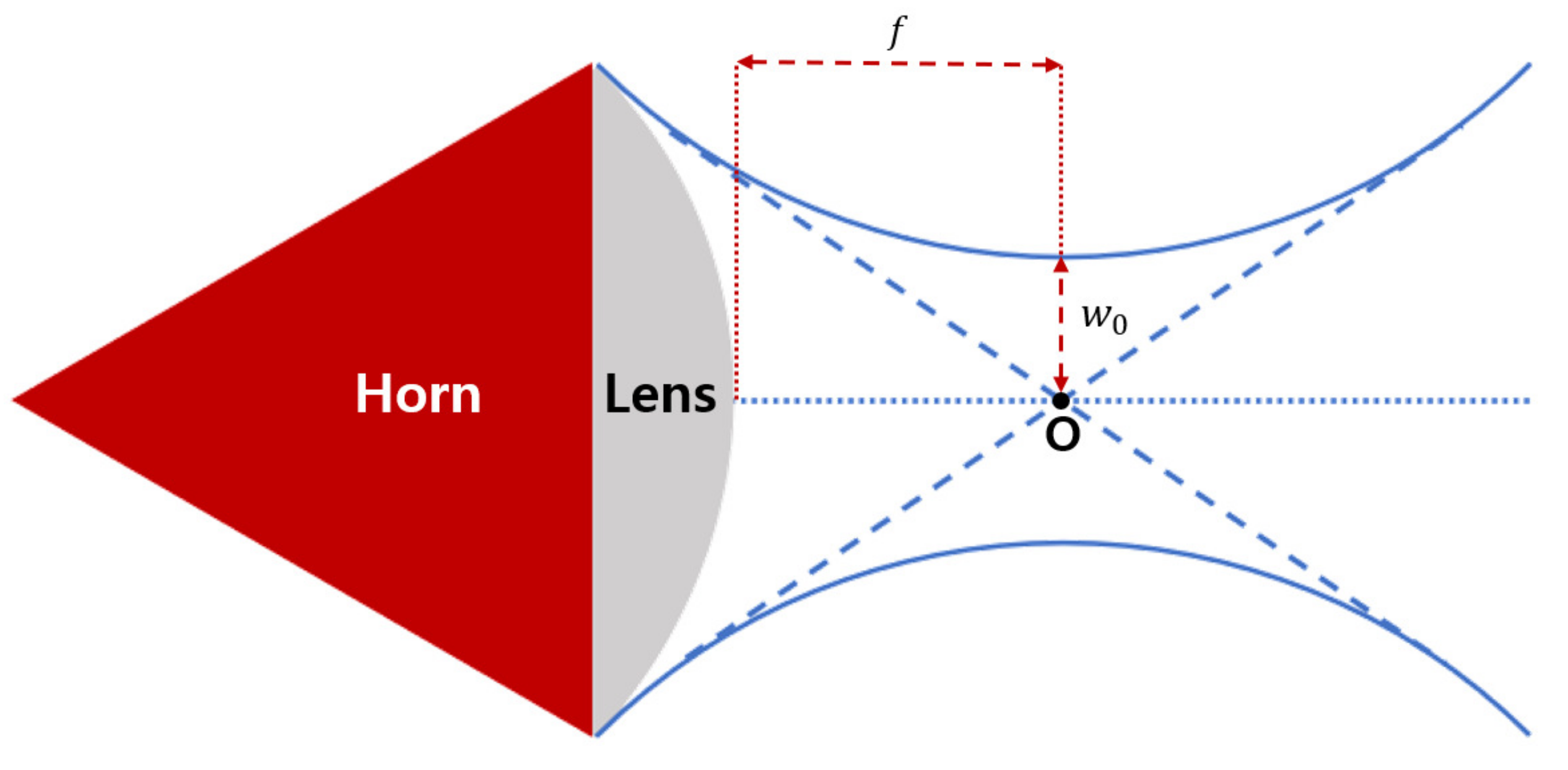

The free-space measurement environment for measuring the reflections from a concrete sample is as follows. In this study, a focused beam lens horn antenna whose band ranges from 8.2 to 12.4 GHz was used, and the S-parameters were measured using the VNA. The gain of the used lens horn antenna is over 30 dB, and a typical

is −20 dB. The diameter of the lens is 222 mm, and the material of the lens is polytetrafluoroethylene (PTFE). After 1-port SOL calibration using a commercial calibration kit, the reflections from the SFRC were measured by applying additional 1-port SSL calibration in free space, which was above in

Section 2.2. An aluminum plate with a size of 300 mm × 300 mm × 3 mm was used as a reflector. The size of the concrete blocks was 300 mm × 300 mm × 100 mm, whose cross section was sufficiently larger than the 3 dB beamwaist of the antenna. Five concrete samples with 0.2%, 0.3%, 0.4%, 0.5%, and 1.0% steel fiber content (volume fraction) were measured. The radius and the length of the steel fiber were 0.1 mm and 19.5 mm, respectively. The concrete blocks had approximately 15,000 fibers per 0.1% fiber content. In this experiment, the measurements were performed at five points on the surface of the SFRC. One is placed at center and the others are spaced at 50 mm above, below, left, and right from the center.Some specimens of the fiber content were manufactured twice and measured; however, since there was no significant difference in the results, only one was produced for the remaining specimens. The diagram and the realized measurement system are shown in

Figure 7a,b.

The specimens without steel fiber and 0.1% steel fiber cases were also measured, and no significant differences in the measurement results were observed for and . In this case, multiple reflections can exist, and the assumption of is not valid. Thus, it is challenging to accurately measure the impedance. Note that the use of and to obtain the permeability would be inappropriate in addition to determining whether there are multiple reflections. This is due to the fact that the thickness of the specimen is quite large and that the surface on the opposite side is far out of focus of the lens antenna. Therefore, impedance measurements were performed for specimens containing 0.2% or more steel fibers, which is considered to have a shielding effect of a certain degree by satisfying the condition .

4. Results and Discussion

The magnitude and phase of the reflection characteristics for the specimens are shown in

Figure 8. The magnitude and angle of the impedance for the SFRC samples are calculated as shown in

Figure 9. The magnitude of the impedance is expressed as a relative value with respect to the impedance of the free space,

. The relative complex permittivity (

) calculated from the impedance, assuming that the relative permeability (

) of the specimens is unity, is shown in

Figure 10 for five different steel fiber concentrations.

It is interesting to note that the magnitude of the reflections increased as the content of the steel fiber increased. The impedances obtained from these reflections decrease in magnitude as the steel fiber content increases. As for the complex permittivity, the real part gradually decreased, whereas the imaginary part increased as the steel fiber content increased. In particular, in the case of the 1.0% steel fiber specimen, the real part of the permittivity is negative. This can be attributed to the change in the properties of the concrete block from those of a dielectric to those of a conductor with the increase in steel fiber content.

Figure 11 shows the results plotted on the complex plane. The direction of the arrow indicates an increase in frequency. Note that the relation between the reflection coefficient and impedance is known as the Smith chart.

Table 1 shows the measured values of each specimen at the center frequency 10.3 GHz.

The negative value of the real part of the permittivity in the SFRC with a high steel fiber content

can be considered the plasmon effect of the metallic structure at low frequencies [

23]. The Drude or Lorentz-oscillation model can be used to explain this result:

The least square estimation result of the measured value and that obtained by the Drude model is shown in

Figure 10e. The modeled value of the plasma frequency

is 40 GHz, and the resonant frequency

is 0.2 GHz. The random distribution of the steel fiber has self-inductance and results in a plasmon effect.

Notably, there are certain issues regarding the electromagnetic properties of the SFRC that need to be considered. The random distribution of steel fibers may generate some magnetic properties owing to the ferromagnetism of the steel, and an effective ring resonator can also be formed by arbitrary connections of steel fibers. Moreover, the homogeneity of the steel fiber in the concrete block is an important factor in determining the reflections. If the distribution of the location or direction of the fibers is not homogeneous or isotropic, the phase of the reflection and the results of the impedance and permittivity change accordingly.

The 1-port free space measurement system can only measure the reflection characteristics with the absorptive or reflective specimen. If the specimen has a magnetic property, the calculated value of permittivity from the impedance may not be accurate. The impedance is the only material parameter that is correctly measured in this case. The other limitation of the method is that the distance between the antenna and the sample is a sensitive factor that determines the phase of the reflection characteristics, which is important for determining the impedance. The dislocation of a 1 mm result in a phase difference such as occurs at the frequency 10 GHz, whose wavelength is 30 mm. In order to ensure that the error of the phase of the reflection is less than , an accuracy of distance adjustment within about 0.1 mm in the X-band is required.

5. Conclusions

The reflective characteristics of steel fiber-reinforced concrete were measured using the 1-port free-space measurement technique. The accuracy of the reflection characteristics calibrated with reflectors at both the delay and advance was at least 1% compared to when only one additional reflector was used. The impedance and complex permittivity were estimated from these reflective characteristics. As the content of steel fibers increased from 0.2 vol.% to 1.0 vol.%, the magnitude of the reflections increased from 0.4 to 0.8, but the phase of the reflections showed a decrease from a degree of 170 to 150. It was confirmed that the impedance and complex permittivity results exhibited the same trend. The real part of the permittivity decreases from 5.5 to −7, and the imaginary part increases from 2 to 7 at the center frequency of 10.3 GHz. The negative value of the real part of the permittivity in the SFRC with a steel fiber content of 1.0 vol.% shows that, as the content of steel fibers in the concrete increased, the properties of the SFRC changed from those of a dielectric to those of a conductor with plasmon effects.

This study regards a method for determining electromagnetic properties of building materials by measuring reflection properties, when it is difficult to measure the insignificant transmission properties of the specimen. It can be applied to simulations that can aid in the electromagnetic analysis of large structures containing steel fibers. If a database is built for more diverse concrete and steel fibers conditions, conversely, it can be used to determine the distribution or dimensions of the steel fiber in the building materials from the reflection characteristics. Furthermore, it will be possible to proceed with measurement and result analysis for more diverse conductive inclusions such as carbon fiber.