The Progress of Research into Flexible Sensors in the Field of Smart Wearables

Abstract

:1. Introduction

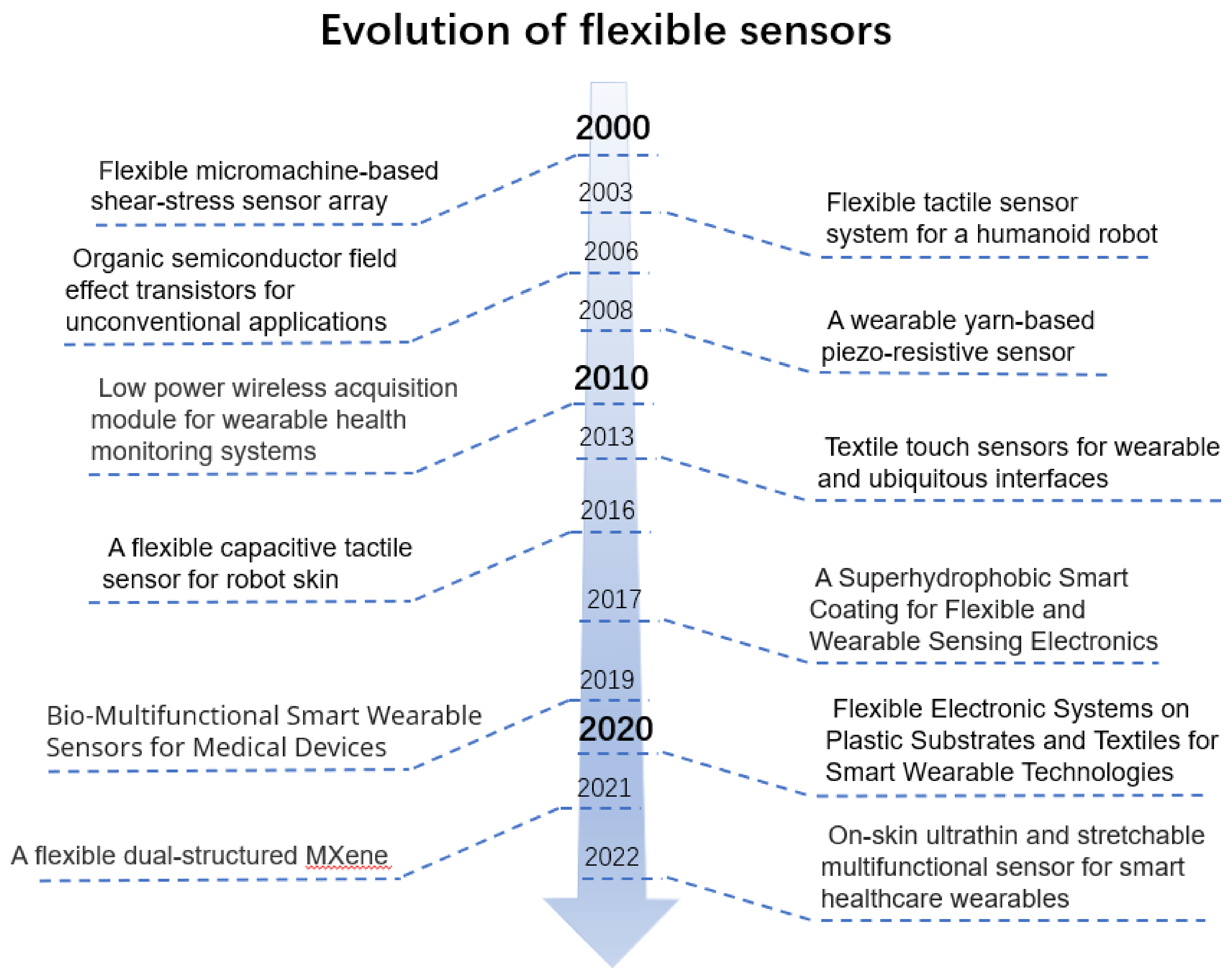

Research History of Flexible Sensors

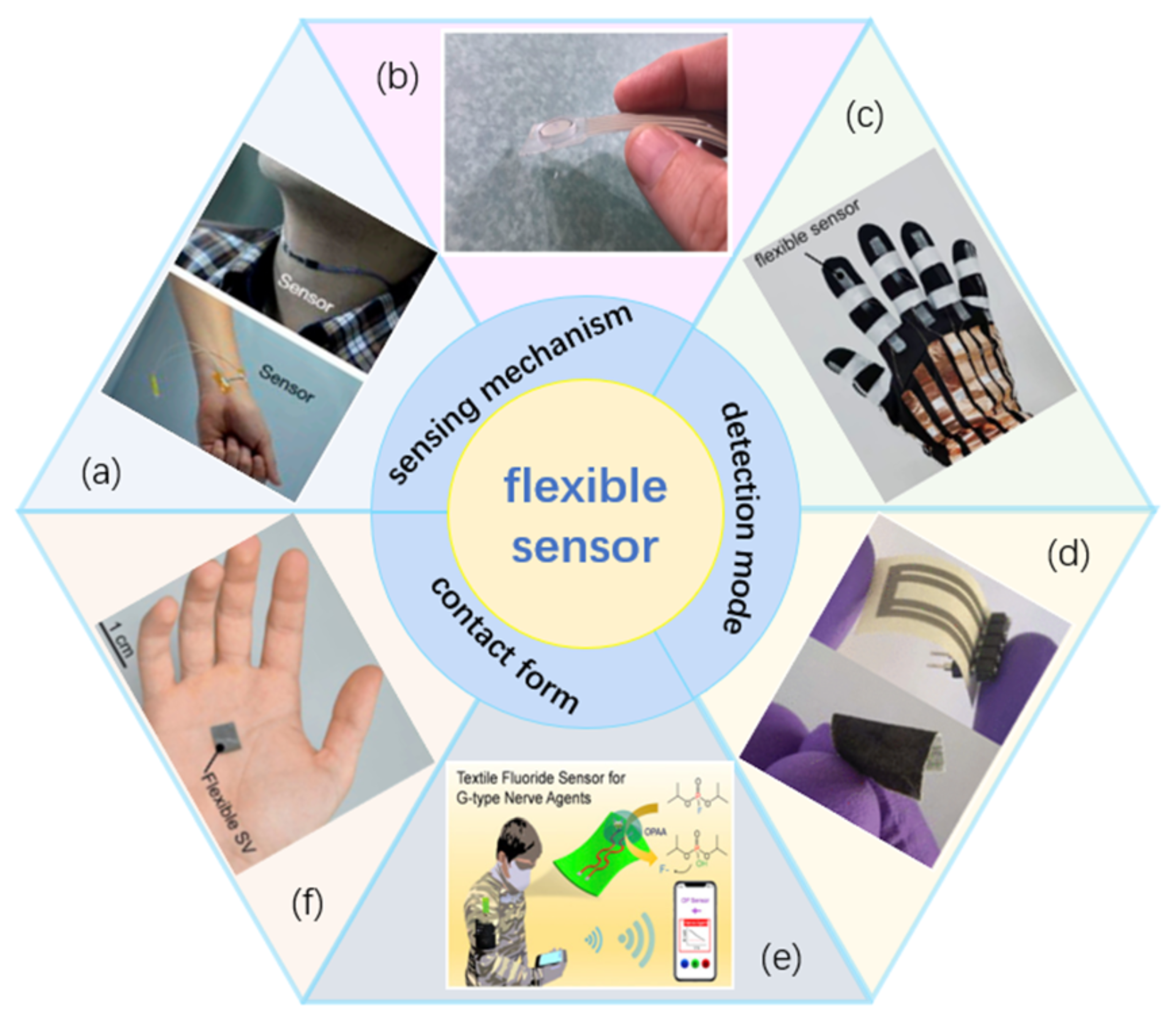

2. Sensory Mechanisms of Flexible Sensors

2.1. Resistive Flexible Sensor

2.2. Piezoelectric Flexible Sensors

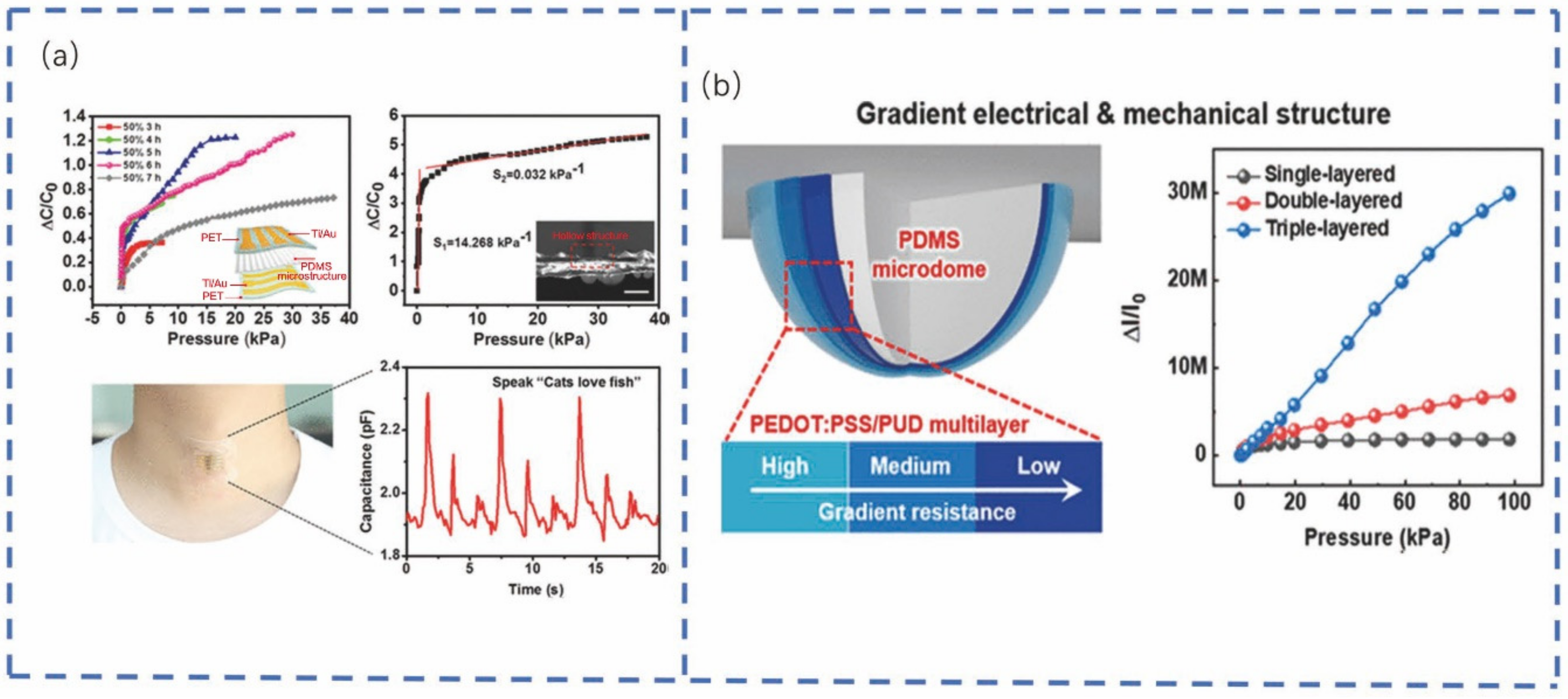

2.3. Flexible Capacitive Sensors

2.4. Flexible Friction/Triboelectric Sensors

3. Detection Methods of Flexible Sensors

3.1. Physical Sensors

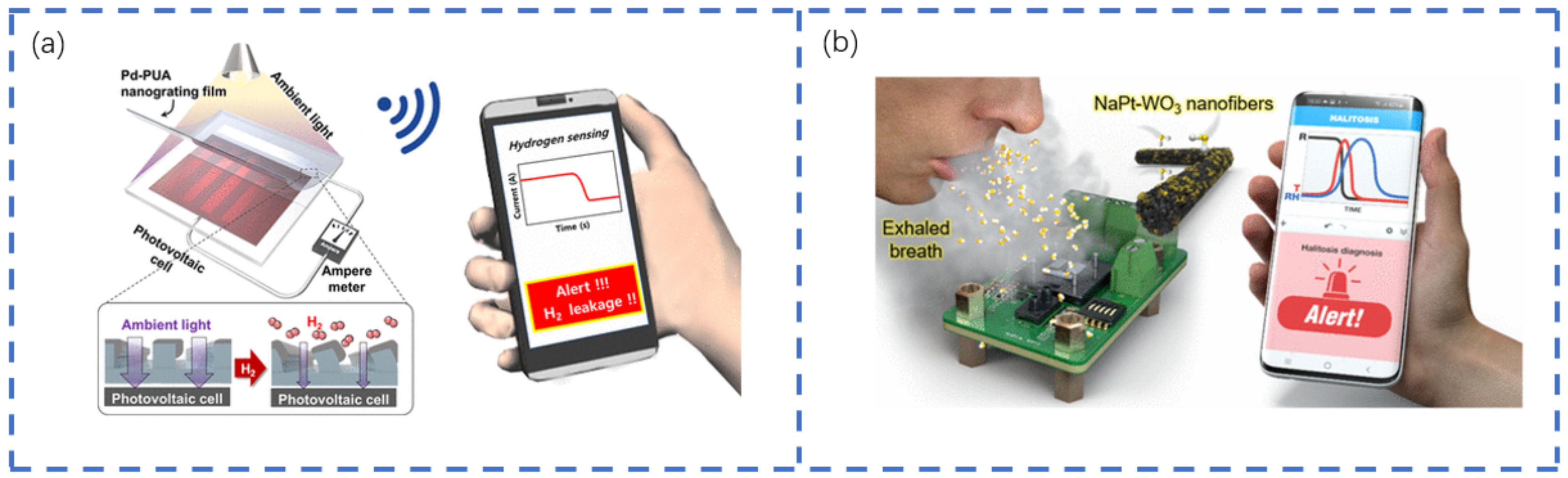

3.2. Chemical Sensors

4. Contact Forms of Flexible Sensors

4.1. Contact Flexible Sensors

4.2. Non-Contact Flexible Sensors

5. Commonly Used Materials for Flexible Sensors

5.1. Flexible Substrates

5.2. Metallic Materials

5.3. Organic Materials

5.4. Inorganic Semiconductors

5.5. Carbon Materials

5.6. Two-Dimensional Materials

6. Applications of Flexible Sensors

6.1. Electronic Skin

6.2. Health Monitoring

6.3. Motion Monitoring

6.4. Smart Healthcare

6.5. Human–Computer Interaction

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Wang, K.; Lou, Z.; Wang, L.; Zhao, L.; Zhao, S.; Wang, D.; Shen, G. Bioinspired interlocked structure-induced high deformability for two-dimensional titanium carbide (mxene)/natural microcapsule-based flexible pressure sensors. ACS Nano 2019, 13, 9139–9147. [Google Scholar] [CrossRef] [PubMed]

- Yan, T.; Wang, Z.; Pan, Z.J. Flexible strain sensors fabricated using carbon-based nanomaterials: A review. Curr. Opin. Solid State Mater. Sci. 2018, 22, 213–228. [Google Scholar] [CrossRef]

- Zheng, H.; Lin, N.; He, Y.; Zuo, B. Self-healing, self-adhesive silk fibroin conductive hydrogel as a flexible strain sensor. ACS Appl. Mater. Interfaces 2021, 13, 40013–40031. [Google Scholar] [CrossRef] [PubMed]

- Gholami, M.; Napier, C.; Patiño, A.G.; Cuthbert, T.J.; Menon, C. Fatigue monitoring in running using flexible textile wearable sensors. Sensors 2020, 20, 5573. [Google Scholar] [CrossRef]

- Moiş, G.D.; Sanislav, T.; Folea, S.C.; Zeadally, S. Performance evaluation of energy-autonomous sensors using power-harvesting beacons for environmental monitoring in internet of things (IOT). Sensors 2018, 18, 1709. [Google Scholar] [CrossRef] [Green Version]

- Lou, Z.; Li, L.; Wang, L.; Shen, G. Recent progress of self-powered sensing systems for wearable electronics. Small 2017, 13, 1701791. [Google Scholar] [CrossRef]

- Kim, S.; Amjadi, M.; Lee, T.I.; Jeong, Y.; Kwon, D.; Kim, M.S.; Kim, K.; Kim, T.S.; Oh, Y.S.; Park, I. Wearable, ultrawide-range, and bending-insensitive pressure sensor based on carbon nanotube network-coated porous elastomer sponges for human interface and healthcare devices. ACS Appl. Mater. Interfaces 2019, 11, 23639–42368. [Google Scholar] [CrossRef]

- Liu, G.; Tan, Q.; Kou, H.; Zhang, L.; Wang, J.; Lv, W.; Dong, H.; Xiong, J. A flexible temperature sensor based on reduced graphene oxide for robot skin used in internet of things. Sensors 2018, 18, 1400. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Liu, H.; Yang, S.; Shi, X.; Zhang, D.; Shan, C.; Mi, L.; Liu, C.; Shen, C.; Guo, Z. Ultrasensitive and highly compressible piezoresistive sensor based on polyurethane sponge coated with a cracked cellulose nanofibril/silver nanowire layer. ACS Appl. Mater. Interfaces 2019, 11, 10922–10932. [Google Scholar] [CrossRef]

- Choi, H.; Jeong, H.Y.; Lee, D.S.; Choi, C.G.; Choi, S.Y. Flexible NO2 gas sensor using multilayer graphene films by chemical vapor deposition. Carbon Lett. 2013, 14, 186–189. [Google Scholar] [CrossRef] [Green Version]

- Bariya, M.; Shahpar, Z.; Park, H.; Sun, J.; Jung, Y.; Gao, W.; Nyein, H.Y.; Liaw, T.S.; Tai, L.C.; Ngo, Q.P.; et al. Roll-to-roll gravure printed electrochemical sensors for wearable and medical devices. ACS Nano 2018, 12, 6978–6987. [Google Scholar] [CrossRef]

- Ahn, H.Y.; Kim, J.G.; Gong, M.S. Preparation of flexible resistive humidity sensors with different electrode gaps by screen printing and their humidity-sensing properties. Macromol. Res. 2012, 20, 174–180. [Google Scholar] [CrossRef]

- Yang, T.; Deng, W.; Chu, X.; Wang, X.; Hu, Y.; Fan, X.; Song, J.; Gao, Y.; Zhang, B.; Tian, G.; et al. Hierarchically microstructure-bioinspired flexible piezoresistive bioelectronics. ACS Nano 2021, 15, 11555–11563. [Google Scholar] [CrossRef]

- Sun, P.; Wu, D.; Liu, C. High-sensitivity tactile sensor based on Ti2C-PDMS sponge for wireless human-computer interaction. Nanotechnology 2021, 32, 295506. [Google Scholar] [CrossRef]

- Jiang, F.; Lee, G.B.; Tai, Y.C.; Ho, C.M. A flexible micromachine-based shear-stress sensor array and its application to separation-point detection. Sens. Actuators A Phys. 2000, 79, 194–203. [Google Scholar] [CrossRef]

- Kerpa, O.; Weiss, K.; Worn, H. Development of a flexible tactile sensor system for a humanoid robot. In Proceedings of the 2003 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2003), Las Vegas, NV, USA, 27 October–1 November 2003; pp. 1–6. [Google Scholar]

- Manunza, I.; Sulis, A.; Bonfiglio, A. Organic semiconductor field effect transistors for unconventional applications: Flexible sensors and wearable devices. In Proceedings of the International Workshop on Wearable and Implantable Body Sensor Networks (BSN’06), Cambridge, MA, USA, 3–5 April 2006. [Google Scholar]

- Huang, C.T.; Shen, C.L.; Tang, C.F.; Chang, S.H. A wearable yarn-based piezo-resistive sensor. Sens. Actuators A Phys. 2008, 141, 396–403. [Google Scholar] [CrossRef]

- Figueiredo, C.P.; Becher, K.; Hoffmann, K.P.; Mendes, P.M. Low power wireless acquisition module for wearable health monitoring systems. In Proceedings of the 2010 Annual International Conference of the IEEE Engineering in Medicine and Biology, Buenos Aires, Argentina, 31 August–4 September 2010; pp. 704–707. [Google Scholar]

- Roh, J.-S. Textile touch sensors for wearable and ubiquitous interfaces. Text. Res. J. 2013, 84, 739–750. [Google Scholar] [CrossRef]

- Ji, Z.; Zhu, H.; Liu, H.; Chen, T.; Sun, L. A flexible capacitive tactile sensor for robot skin. In Proceedings of the 2016 International Conference on Advanced Robotics and Mechatronics (ICARM), Macau, China, 18–20 August 2016; pp. 207–212. [Google Scholar]

- Li, L.; Bai, Y.; Li, L.; Wang, S.; Zhang, T. A superhydrophobic smart coating for flexible and wearable sensing electronics. Adv. Mater. 2017, 29, 1702517. [Google Scholar] [CrossRef]

- Wang, L.; Lou, Z.; Jiang, K.; Shen, G. Bio-multifunctional smart wearable sensors for medical devices. Adv. Intell. Syst. 2019, 1, 19000040. [Google Scholar] [CrossRef] [Green Version]

- Baeg, K.J.; Lee, J. Flexible electronic systems on plastic substrates and textiles for smart wearable technologies. Adv. Mater. Technol. 2020, 5, 2000071. [Google Scholar] [CrossRef]

- Guo, L.; Li, Z.; Hu, W.; Liu, T.; Zheng, Y.; Yuan, M.; Dai, Y.; Ning, R.; Zhu, Y.; Tao, K.; et al. A flexible dual-structured mxene for ultra-sensitive and ultra-wide monitoring of anatomical and physiological movements. J. Mater. Chem. A 2021, 9, 26867–26874. [Google Scholar] [CrossRef]

- Zhang, S.; Chhetry, A.; Zahed, M.; Sharma, S.; Park, C.; Yoon, S.; Park, J.Y. On-skin ultrathin and stretchable multifunctional sensor for smart healthcare wearables. NPJ Flex. Electron. 2022, 6, 11. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric nanogenerators as new energy technology and self-powered sensors-principles, problems and perspectives. Faraday Discuss. 2014, 176, 447–458. [Google Scholar] [CrossRef]

- Vollmer, M. Infrared. Eur. J. Phys. 2013, 34, s49–s50. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.J.; Xiang, T. Robot soft grabbing with new piezoresistive tactile sensor. Adv. Mater. Res. 2013, 744, 501–504. [Google Scholar] [CrossRef]

- Qin, J.; Yin, L.J.; Hao, Y.N.; Zhong, S.L.; Zhang, D.L.; Bi, K.; Zhang, Y.X.; Zhao, Y.; Dang, Z.M. Flexible and stretchable capacitive sensors with different microstructures. Adv. Mater. 2021, 33, e2008267. [Google Scholar] [CrossRef]

- Chen, J.; Zheng, J.; Gao, Q.; Zhang, J.; Zhang, J.; Omisore, O.M.; Wang, L.; Li, H. Polydimethylsiloxane (pdms)-based flexible resistive strain sensors for wearable applications. Appl. Sci. 2018, 8, 345. [Google Scholar] [CrossRef] [Green Version]

- Dejke, V.; Eng, M.P.; Brinkfeldt, K.; Charnley, J.; Lussey, D.; Lussey, C. Development of prototype low-cost qtss wearable flexible more enviro-friendly pressure, shear, and friction sensors for dynamic prosthetic fit monitoring. Sensors 2021, 21, 3764. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Han, W.; Xu, K.; Zhang, Y.; Lu, Y.; Nie, Z.; Du, Y.; Zhu, J.; Huang, W. Metallic sandwiched-aerogel hybrids enabling flexible and stretchable intelligent sensor. Nano Lett. 2020, 20, 3449–3458. [Google Scholar] [CrossRef] [PubMed]

- Ammu, S.; Dua, V.; Agnihotra, S.R.; Surwade, S.P.; Phulgirkar, A.; Patel, S.; Manohar, S.K. Flexible, all-organic chemiresistor for detecting chemically aggressive vapors. J. Am. Chem. Soc. 2012, 134, 4553–4556. [Google Scholar] [CrossRef]

- Goud, K.Y.; Sandhu, S.S.; Teymourian, H.; Yin, L.; Tostado, N.; Raushel, F.M.; Harvey, S.P.; Moores, L.C.; Wang, J. Textile-based wearable solid-contact flexible fluoride sensor: Toward biodetection of g-type nerve agents. Biosens. Bioelectron. 2021, 182, 113172. [Google Scholar] [CrossRef]

- Makushko, P.; Oliveros Mata, E.S.; Cañón Bermúdez, G.S.; Hassan, M.; Laureti, S.; Rinaldi, C.; Fagiani, F.; Barucca, G.; Schmidt, N.; Zabila, Y.; et al. Flexible magnetoreceptor with tunable intrinsic logic for on-skin touchless human-machine interfaces. Adv. Funct. Mater. 2021, 31, 2101089. [Google Scholar] [CrossRef]

- Lee, J.; Lim, M.; Yoon, J.; Kim, M.S.; Choi, B.; Kim, D.M.; Kim, D.H.; Park, I.; Choi, S.J. Transparent, flexible strain sensor based on a solution-processed carbon nanotube network. ACS Appl. Mater. Interfaces 2017, 9, 26279–26285. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, N.; Li, L.; Hu, X.; Zou, Z.; Wang, J.; Luo, S.; Gao, Y. A highly flexible and sensitive piezoresistive sensor based on mxene with greatly changed interlayer distances. Nat. Commun. 2017, 8, 1207. [Google Scholar] [CrossRef] [Green Version]

- Chowdhury, S.A.; Saha, M.C.; Patterson, S.; Robison, T.; Liu, Y. Highly conductive polydimethylsiloxane/carbon nanofiber composites for flexible sensor applications. Adv. Mater. Technol. 2019, 4, 1800398. [Google Scholar] [CrossRef] [Green Version]

- Yu, Z.; Xu, J.; Gong, H.; Li, Y.; Li, L.; Wei, Q.; Tang, D. Bioinspired self-powered piezoresistive sensors for simultaneous monitoring of human health and outdoor UV light intensity. ACS Appl. Mater. Interfaces 2022, 14, 5101–5111. [Google Scholar] [CrossRef]

- Li, X.P.; Li, Y.; Li, X.; Song, D.; Min, P.; Hu, C.; Zhang, H.B.; Koratkar, N.; Yu, Z.Z. Highly sensitive, reliable and flexible piezoresistive pressure sensors featuring polyurethane sponge coated with mxene sheets. J. Colloid Interface Sci. 2019, 542, 54–62. [Google Scholar] [CrossRef]

- Ding, Y.; Yang, J.; Tolle, C.; Zhu, Z. Conductive sponge prepared via one-step dip coating as piezoresistive pressure sensor for human motion detection. ACS Appl. Mater. Interfaces 2018, 10, 16077–16086. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhan, P.; Ren, M.; Zheng, G.; Dai, K.; Mi, L.; Shen, C. Significant stretchability enhancement of a crack-based strain sensor combined with high sensitivity and superior durability for motion monitoring. ACS Appl. Mater. Interfaces 2019, 11, 7405–7414. [Google Scholar] [CrossRef]

- Yang, Z.; Pang, Y.; Han, X.L.; Yang, Y.; Ling, J.; Jian, M.; Ren, T.L. Graphene textile strain sensor with negative resistance variation for human motion detection. ACS Nano 2018, 12, 9134–9141. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, D.Y.; Pang, Y.; Li, Y.X.; Wang, Q.; Zhang, T.Y.; Ren, T.L. Simultaneously detecting subtle and intensive human motions based on a silver nanoparticles bridged graphene strain sensor. ACS Appl. Mater. Interfaces 2018, 10, 3948–3954. [Google Scholar] [CrossRef]

- Larimi, S.R.; Nejad, H.R.; Oyatsi, M.; O’Brien, A.; Hoorfar, M.; Najjaran, H. Low-cost ultra-stretchable strain sensors for monitoring human motion and bio-signals. Sens. Actuators A Phys. 2018, 271, 182–191. [Google Scholar] [CrossRef]

- Jung, Y.H.; Hong, S.K.; Wang, H.S.; Han, J.H.; Pham, T.X.; Park, H.; Lee, K.J. Flexible piezoelectric acoustic sensors and machine learning for speech processing. Adv. Mater. 2020, 32, e1904020. [Google Scholar] [CrossRef]

- Curry, E.J.; Ke, K.; Chorsi, M.T.; Wrobel, K.S.; Miller, A.N., III; Patel, A.; Nguyen, T.D. Biodegradable piezoelectric force sensor. Proc. Natl. Acad. Sci. USA 2018, 115, 909–914. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Shao, J.; Tian, H.; Li, X.; Tian, Y.; Wang, C. Flexible three-axial tactile sensors with microstructure-enhanced piezoelectric effect and specially-arranged piezoelectric arrays. Smart Mater. Struct. 2018, 27, 025018. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, L.; Yang, X.; Li, T.; Chen, X.; Li, X.; Zhang, J. Enhanced flexible piezoelectric sensor by the integration of P (VDF-TrFE)/AgNWs film with a-IGZO TFT. IEEE Electron. Device Lett. 2018, 40, 111–114. [Google Scholar] [CrossRef]

- Kim, K.B.; Jang, W.; Cho, J.Y.; Woo, S.B.; Jeon, D.H.; Ahn, J.H.; Sung, T.H. Transparent and flexible piezoelectric sensor for detecting human movement with a boron nitride nanosheet (BNNS). Nano Energy 2018, 54, 91–98. [Google Scholar] [CrossRef]

- Wang, J.; Jiang, J.; Zhang, C.; Sun, M.; Han, S.; Zhang, R.; Liu, H. Energy-efficient, fully flexible, high-performance tactile sensor based on piezotronic effect: Piezoelectric signal amplified with organic field-effect transistors. Nano Energy 2020, 76, 105050. [Google Scholar] [CrossRef]

- Yang, Y.; Pan, H.; Xie, G.; Jiang, Y.; Chen, C.; Su, Y.; Tai, H. Flexible piezoelectric pressure sensor based on polydopamine-modified BaTiO3/PVDF composite film for human motion monitoring. Sens. Actuators A Phys. 2020, 301, 111789. [Google Scholar] [CrossRef]

- Jiang, J.; Tu, S.; Fu, R.; Li, J.; Hu, F.; Yan, B.; Chen, S. Flexible piezoelectric pressure tactile sensor based on electrospun BaTiO3/polyv (vinylidene fluoride) nanocomposite membrane. ACS Appl. Mater. Interfaces 2020, 12, 33989–33998. [Google Scholar] [CrossRef] [PubMed]

- Yu, N.; Mugo, S.M. A flexible-imprinted capacitive sensor for rapid detection of adrenaline. Talanta 2019, 204, 602–606. [Google Scholar]

- Golabzaei, S.; Khajavi, R.; Shayanfar, H.A.; Yazdanshenas, M.E.; Talebi, N. Fabrication and characterization of a flexible capacitive sensor on pet fabric. Int. J. Cloth. Sci. Technol. 2018, 30, 687–697. [Google Scholar] [CrossRef]

- Zhou, Q.; Ji, B.; Wei, Y.; Hu, B.; Gao, Y.; Xu, Q.; Zhou, B. A bio-inspired cilia array as the dielectric layer for flexible capacitive pressure sensors with high sensitivity and a broad detection range. J. Mater. Chem. A 2019, 7, 27334–27346. [Google Scholar] [CrossRef]

- Xiong, Y.; Shen, Y.; Tian, L.; Hu, Y.; Zhu, P.; Sun, R.; Wong, C.P. A flexible, ultra-highly sensitive and stable capacitive pressure sensor with convex microarrays for motion and health monitoring. Nano Energy 2020, 70, 104436. [Google Scholar] [CrossRef]

- Li, M.; Liang, J.; Wang, X.; Zhang, M. Ultra-sensitive flexible pressure sensor based on microstructured electrode. Sensors 2020, 20, 371. [Google Scholar] [CrossRef] [Green Version]

- Mo, F.; Huang, Y.; Li, Q.; Wang, Z.; Jiang, R.; Gai, W.; Zhi, C. A highly stable and durable capacitive strain sensor based on dynamically super-tough hydro/organo-gels. Adv. Funct. Mater. 2021, 31, 2010830. [Google Scholar] [CrossRef]

- Keum, K.; Eom, J.; Lee, J.H.; Heo, J.S.; Park, S.K.; Kim, Y.H. Fully-integrated wearable pressure sensor array enabled by highly sensitive textile-based capacitive ionotronic devices. Nano Energy 2021, 79, 105479. [Google Scholar] [CrossRef]

- Wang, Z.L.; Chen, J.; Lin, L. Progress in triboelectric nanogenerators as a new energy technology and self-powered sensors. Energy Environ. Sci. 2015, 8, 2250–2282. [Google Scholar] [CrossRef]

- Ning, C.; Cheng, R.; Jiang, Y.; Sheng, F.; Yi, J.; Shen, S.; Zhang, Y.; Peng, X.; Dong, K.; Wang, Z.L. Helical fiber strain sensors based on triboelectric nanogenerators for self-powered human respiratory monitoring. ACS Nano 2022, 16, 2811–2821. [Google Scholar] [CrossRef]

- Zhang, D.; Xu, Z.; Yang, Z.; Song, X. High-performance flexible self-powered tin disulfide nanoflowers/reduced graphene oxide nanohybrid-based humidity sensor driven by triboelectric nanogenerator. Nano Energy 2020, 67, 104251. [Google Scholar] [CrossRef]

- Zhu, M.; Sun, Z.; Chen, T.; Lee, C. Low cost exoskeleton manipulator using bidirectional triboelectric sensors enhanced multiple degree of freedom sensory system. Nat. Commun. 2021, 12, 2692. [Google Scholar] [CrossRef]

- Chen, T.; Shi, Q.; Zhu, M.; He, T.; Sun, L.; Yang, L.; Lee, C. Triboelectric self-powered wearable flexible patch as 3d motion control interface for robotic manipulator. ACS Nano 2018, 12, 11561–11571. [Google Scholar] [CrossRef]

- Yan, J.; Ma, Y.; Li, X.; Zhang, C.; Cao, M.; Chen, W.; Luo, S.; Zhu, M.; Gao, Y. Flexible and high-sensitivity piezoresistive sensor based on mxene composite with wrinkle structure. Ceram. Int. 2020, 46, 23592–23598. [Google Scholar] [CrossRef]

- Li, S.; Li, R.; González, O.G.; Chen, T.; Xiao, X. Highly sensitive and flexible piezoresistive sensor based on c-mwcnts decorated tpu electrospun fibrous network for human motion detection. Compos. Sci. Technol. 2021, 203, 108617. [Google Scholar] [CrossRef]

- Shi, J.; Wang, L.; Dai, Z.; Zhao, L.; Du, M.; Li, H.; Fang, Y. Multiscale hierarchical design of a flexible piezoresistive pressure sensor with high sensitivity and wide linearity range. Small 2018, 14, e1800819. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, R.; Xiao, C.; Zhao, H.; Wang, Y.; Geng, D.; Zhou, W. Laser direct writing of highly ordered two-level hierarchical microstructures for flexible piezoresistive sensor with enhanced sensitivity. Adv. Mater. Interfaces 2021, 9, 2101596. [Google Scholar] [CrossRef]

- Xu, H.; Gao, L.; Wang, Y.; Cao, K.; Hu, X.; Wang, L.; Lu, Y. Flexible waterproof piezoresistive pressure sensors with wide linear working range based on conductive fabrics. Nanomicro Lett. 2020, 12, 159. [Google Scholar] [CrossRef]

- Xu, M.; Cai, H.; Liu, Z.; Chen, F.; Wang, Y.; Dai, F.; Li, Z. Skin-friendly corrugated multilayer microspherical sensor fabricated with silk fibroin, poly (lactic-co-glycolic acid), polyaniline, and kappa-carrageenan for wide range pressure detection. Int. J. Biol. Macromol. 2022, 194, 755–762. [Google Scholar] [CrossRef]

- He, Z.; Chen, W.; Liang, B.; Liu, C.; Yang, L.; Lu, D.; Gui, X. Capacitive pressure sensor with high sensitivity and fast response to dynamic interaction based on graphene and porous nylon networks. ACS Appl. Mater. Interfaces 2018, 10, 12816–12823. [Google Scholar] [CrossRef]

- Yang, J.; Luo, S.; Zhou, X.; Li, J.; Fu, J.; Yang, W.; Wei, D. Flexible, tunable, and ultrasensitive capacitive pressure sensor with microconformal graphene electrodes. ACS Appl. Mater. Interfaces 2019, 11, 14997–15006. [Google Scholar] [CrossRef]

- Wei, P.; Guo, X.; Qiu, X.; Yu, D. Flexible capacitive pressure sensor with sensitivity and linear measuring range enhanced based on porous composite of carbon conductive paste and polydimethylsiloxane. Nanotechnology 2019, 30, 455501. [Google Scholar] [CrossRef]

- Qiu, J.; Guo, X.; Chu, R.; Wang, S.; Zeng, W.; Qu, L.; Xing, G. Rapid-response, low detection limit, and high-sensitivity capacitive flexible tactile sensor based on three-dimensional porous dielectric layer for wearable electronic skin. ACS Appl. Mater. Interfaces 2019, 11, 40716–40725. [Google Scholar] [CrossRef]

- Ma, L.; Shuai, X.; Hu, Y.; Liang, X.; Zhu, P.; Sun, R.; Wong, C.P. A highly sensitive and flexible capacitive pressure sensor based on a micro-arrayed polydimethylsiloxane dielectric layer. J. Mater. Chem. C 2018, 6, 13232–13240. [Google Scholar] [CrossRef]

- Luo, S.; Zhou, X.; Tang, X.; Li, J.; Wei, D.; Tai, G.; Yang, J. Microconformal electrode-dielectric integration for flexible ultrasensitive robotic tactile sensing. Nano Energy 2021, 80, 105580. [Google Scholar] [CrossRef]

- Mo, L.; Meng, X.; Zhao, J.; Pan, Y.; Sun, Z.; Guo, Z.; Li, L. Full printed flexible pressure sensor based on microcapsule controllable structure and composite dielectrics. Flex. Print. Electron. 2021, 6, 014001. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y.; Liu, Q.; Zhu, Y.; Wang, H.; Xie, Z.; Zi, Y. A metal-electrode-free, fully integrated, soft triboelectric sensor array for self-powered tactile sensing. Microsyst. Nanoeng. 2020, 6, 59. [Google Scholar] [CrossRef]

- Yang, P.; Shi, Y.; Li, S.; Tao, X.; Liu, Z.; Wang, X.; Chen, X. Monitoring the degree of comfort of shoes in-motion using triboelectric pressure sensors with an ultrawide detection range. ACS Nano 2022, 16, 4654–4665. [Google Scholar] [CrossRef]

- Yu, J.; Hou, X.; Cui, M.; Shi, S.; He, J.; Sun, Y.; Chou, X. Flexible pdms-based triboelectric nanogenerator for instantaneous force sensing and human joint movement monitoring. Sci. China Mater. 2019, 62, 1423–1432. [Google Scholar] [CrossRef] [Green Version]

- Fang, Y.; Zou, Y.; Xu, J.; Chen, G.; Zhou, Y.; Deng, W.; Chen, J. Ambulatory cardiovascular monitoring via a machine-learning-assisted textile triboelectric sensor. Adv. Mater. 2021, 33, e2104178. [Google Scholar] [CrossRef]

- Zhao, G.; Zhang, X.; Cui, X.; Wang, S.; Liu, Z.; Deng, L.; Li, L. Piezoelectric polyacrylonitrile nanofiber film-based dual-function self-powered flexible sensor. ACS Appl. Mater. Interfaces 2018, 10, 15855–15863. [Google Scholar] [CrossRef]

- Zhang, T.; Wen, Z.; Lei, H.; Gao, Z.; Chen, Y.; Zhang, Y.; Sun, X. Surface-microengineering for high-performance triboelectric tactile sensor via dynamically assembled ferrofluid template. Nano Energy 2021, 87, 106215. [Google Scholar] [CrossRef]

- Banstola, B.; Murray, K.K. Pulsed valve matrix-assisted ionization. Analyst 2017, 142, 1672–1675. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Huang, H.; Guo, L.; Zhang, Y.; Ma, T. The role of polarization in photocatalysis. Angew. Chem. Int. Ed. Engl. 2019, 58, 10061–10073. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.G.; Shi, X.; Zhao, L.D.; Zou, J. High-performance snse thermoelectric materials: Progress and future challenge. Prog. Mater. Sci. 2018, 97, 283–346. [Google Scholar] [CrossRef] [Green Version]

- Ouyang, W.; Teng, F.; He, J.H.; Fang, X. Enhancing the photoelectric performance of photodetectors based on metal oxide semiconductors by charge-carrier engineering. Adv. Funct. Mater. 2019, 29, 1807672. [Google Scholar] [CrossRef]

- Yan, Y.; Geng, L.D.; Tan, Y.; Ma, J.; Zhang, L.; Sanghadasa, M.; Priya, S. Colossal tunability in high frequency magnetoelectric voltage tunable inductors. Nat. Commun. 2018, 9, 4998. [Google Scholar] [CrossRef]

- Pang, Y.; Jian, J.; Tu, T.; Yang, Z.; Ling, J.; Li, Y.; Ren, T.L. Wearable humidity sensor based on porous graphene network for respiration monitoring. Biosens. Bioelectron. 2018, 116, 123–129. [Google Scholar] [CrossRef]

- Park, C.H.; Schroeder, V.; Kim, B.J.; Swager, T.M. Ionic liquid-carbon nanotube sensor arrays for human breath related volatile organic compounds. ACS Sens. 2018, 3, 2432–2437. [Google Scholar] [CrossRef]

- Falina, S.; Syamsul, M.; Rhaffor, N.A.; Sal Hamid, S.; Mohamed Zain, K.A.; Abd Manaf, A.; Kawarada, H. Ten years progress of electrical detection of heavy metal ions (hmis) using various field-effect transistor (fet) nanosensors: A review. Biosensors 2021, 11, 478. [Google Scholar] [CrossRef]

- Tessarolo, M.; Possanzini, L.; Campari, E.G.; Bonfiglioli, R.; Violante, F.S.; Bonfiglio, A.; Fraboni, B. Adaptable pressure textile sensors based on a conductive polymer. Flex. Print. Electron. 2018, 3, 034001. [Google Scholar] [CrossRef]

- Khalili, N.; Asif, H.; Naguib, H.E. Towards development of nanofibrous large strain flexible strain sensors with programmable shape memory properties. Smart Mater. Struct. 2018, 27, 055002. [Google Scholar] [CrossRef]

- Li, H.; Zhang, J.; Chen, J.; Luo, Z.; Zhang, J.; Alhandarish, Y.; Wang, L. A supersensitive, multidimensional flexible strain gauge sensor based on Ag/PDMS for human activities monitoring. Sci. Rep. 2020, 10, 4639. [Google Scholar] [CrossRef]

- Kumar, A.; Hsieh, P.Y.; Shaikh, M.O.; Kumar, R.R.; Chuang, C.H. Flexible temperature sensor utilizing mwcnt doped peg-pu copolymer nanocomposites. Micromachines 2022, 13, 4639. [Google Scholar] [CrossRef]

- Sempionatto, J.R.; Mishra, R.K.; Martín, A.; Tang, G.; Nakagawa, T.; Lu, X.; Wang, J. Wearable ring-based sensing platform for detecting chemical threats. ACS Sens. 2017, 2, 1531–1538. [Google Scholar] [CrossRef] [Green Version]

- Nakata, S.; Shiomi, M.; Fujita, Y.; Arie, T.; Akita, S.; Takei, K. A wearable ph sensor with high sensitivity based on a flexible charge-coupled device. Nat. Electron. 2018, 1, 596–603. [Google Scholar] [CrossRef]

- Sun, S.; Zhang, X.; Song, X.; Liang, S.; Wang, L.; Yang, Z. Bottom-up assembly of hierarchical Cu2O nanospheres: Controllable synthesis, formation mechanism and enhanced photochemical activities. Crystengcomm 2012, 14, 3545–3553. [Google Scholar] [CrossRef]

- Chen, M.M.; Cheng, S.B.; Ji, K.; Gao, J.; Liu, Y.L.; Wen, W.; Huang, W.H. Construction of a flexible electrochemiluminescence platform for sweat detection. Chem. Sci. 2019, 10, 6295–6303. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.L.; Liu, R.; Qin, Y.; Qiu, Q.F.; Chen, Z.; Cheng, S.B.; Huang, W.H. Flexible electrochemical urea sensor based on surface molecularly imprinted nanotubes for detection of human sweat. Anal. Chem. 2018, 90, 13081–13087. [Google Scholar] [CrossRef]

- Seo, M.H.; Kang, K.; Yoo, J.Y.; Park, J.; Lee, J.S.; Cho, I.; Park, I. Chemo-mechanically operating palladium-polymer nanograting film for a self-powered H2 gas sensor. ACS Nano 2020, 14, 16813–16822. [Google Scholar] [CrossRef]

- Shin, H.; Kim, D.H.; Jung, W.; Jang, J.S.; Kim, Y.H.; Lee, Y.; Kim, I.D. Surface activity-tuned metal oxide chemiresistor: Toward direct and quantitative halitosis diagnosis. ACS Nano 2021, 15, 14207–14217. [Google Scholar] [CrossRef]

- Bezdek, M.J.; Luo SX, L.; Ku, K.H.; Swager, T.M. A chemiresistive methane sensor. Proc. Natl. Acad. Sci. USA 2021, 118, e2022515118. [Google Scholar] [CrossRef]

- Di, X.; Ma, Q.; Xu, Y.; Yang, M.; Wu, G.; Sun, P. High-performance ionic conductive poly (vinyl alcohol) hydrogels for flexible strain sensors based on a universal soaking strategy. Mater. Chem. Front. 2021, 5, 315–323. [Google Scholar] [CrossRef]

- Xia, S.; Song, S.; Gao, G. Robust and flexible strain sensors based on dual physically cross-linked double network hydrogels for monitoring human-motion. Chem. Eng. J. 2018, 354, 817–824. [Google Scholar] [CrossRef]

- Sun, J.; Lu, G.; Zhou, J.; Yuan, Y.; Zhu, X.; Nie, J. Robust physically linked double-network ionogel as a flexible bimodal sensor. ACS Appl. Mater. Interfaces 2020, 12, 14272–14279. [Google Scholar] [CrossRef]

- Li, F.; Wang, R.; Song, C.; Zhao, M.; Ren, H.; Wang, S.; Hao, Y. A skin-inspired artificial mechanoreceptor for tactile enhancement and integration. ACS Nano 2021, 15, 16422–16431. [Google Scholar] [CrossRef]

- Su, Q.; Zou, Q.; Li, Y.; Chen, Y.; Teng, S.Y.; Kelleher, J.T.; Wang, S. A stretchable and strain-unperturbed pressure sensor for motion interference–free tactile monitoring on skins. Sci. Adv. 2021, 7, eabi4563. [Google Scholar] [CrossRef]

- Bell, C.; Nammari, A.; Uttamchandani, P.; Rai, A.; Shah, P.; Moore, A.L. Flexible electronics-compatible non-enzymatic glucose sensing via transparent cuo nanowire networks on pet films. Nanotechnology 2017, 28, 245502. [Google Scholar] [CrossRef]

- Lim, J.M.; Ryu, M.Y.; Yun, J.W.; Park, T.J.; Park, J.P. Electrochemical peptide sensor for diagnosing adenoma-carcinoma transition in colon cancer. Biosens. Bioelectron. 2017, 98, 330–337. [Google Scholar] [CrossRef]

- Thakur, N.; Kumar, M.; Adhikary, S.D.; Mandal, D.; Nagaiah, T.C. Pvim-Co5POM/MNC composite as a flexible electrode for the ultrasensitive and highly selective non-enzymatic electrochemical detection of cholesterol. Chem. Commun. 2019, 55, 5021–5024. [Google Scholar] [CrossRef] [PubMed]

- Yoon, J.; Sim, M.; Oh, T.S.; Yoon, Y.S.; Kim, D.J. Flexible electrochemical sensor based on NiCu(OOH) for monitoring urea in human sweat. J. Electrochem. Soc. 2021, 168, 117510. [Google Scholar] [CrossRef]

- Li, R.; Qi, H.; Ma, Y.; Deng, Y.; Liu, S.; Jie, Y.; Yin, L. A flexible and physically transient electrochemical sensor for real-time wireless nitric oxide monitoring. Nat. Commun. 2020, 11, 3207. [Google Scholar] [CrossRef] [PubMed]

- Reid, D.O.; Smith, R.E.; Garcia-Torres, J.; Watts, J.F.; Crean, C. Solvent treatment of wet-spun pedot: Pss fibers for fiber-based wearable pH sensing. Sensors 2019, 19, 4213. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Naim, A.M.; Wickramasinghe, K.; De Silva, A.; Perera, M.V.; Lalitharatne, T.D.; Kappel, S.L. Low-cost active dry-contact surface emg sensor for bionic arms. In Proceedings of the 2020 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Toronto, ON, Canada, 11–14 October 2020; pp. 3327–3332. [Google Scholar]

- Yao, Y.; Rakheja, S.; Marcotte, P. Relationship among hand forces imparted on a viscoelastic hand-handle interface. Measurement 2019, 145, 525–534. [Google Scholar] [CrossRef]

- Peng, Y.; Que, M.; Lee, H.E.; Bao, R.; Wang, X.; Lu, J.; Pan, C. Achieving high-resolution pressure mapping via flexible GaN/ZnO nanowire LEDs array by piezo-phototronic effect. Nano Energy 2019, 58, 633–640. [Google Scholar] [CrossRef]

- Chen, W.; Feng, F.; Chen, D.; Lin, W.; Chen, S.C. Precision non-contact displacement sensor based on the near-field characteristics of fiber specklegrams. Sens. Actuators A Phys. 2019, 296, 1–6. [Google Scholar] [CrossRef]

- Guo, H.; Tan, Y.J.; Chen, G.; Wang, Z.; Susanto, G.J.; See, H.H.; Tee, B.C. Artificially innervated self-healing foams as synthetic piezo-impedance sensor skins. Nat. Commun. 2020, 11, 5747. [Google Scholar] [CrossRef]

- Zhang, W.; Wu, Z.; Hu, J.; Cao, Y.; Guo, J.; Long, M.; Jia, D. Flexible chemiresistive sensor of polyaniline coated filter paper prepared by spraying for fast and non-contact detection of nitroaromatic explosives. Sens. Actuators B Chem. 2020, 304, 127233. [Google Scholar] [CrossRef]

- Tang, Y.; Zhou, H.; Sun, X.; Diao, N.; Wang, J.; Zhang, B.; Mao, Y. Triboelectric touch-free screen sensor for noncontact gesture recognizing. Adv. Funct. Mater. 2019, 30, 1907891. [Google Scholar] [CrossRef]

- Lu, L.; Jiang, C.; Hu, G.; Liu, J.; Yang, B. Flexible noncontact sensing for human-machine interaction. Adv. Mater. 2021, 33, e2100218. [Google Scholar] [CrossRef]

- Tang, H.; Li, Y.; Ye, H.; Hu, F.; Gao, C.; Tao, L.; Zhang, G. High-performance humidity sensor using schottky-contacted sns nanoflakes for noncontact healthcare monitoring. Nanotechnology 2020, 31, 055501. [Google Scholar] [CrossRef]

- Viola, F.A.; Spanu, A.; Ricci, P.C.; Bonfiglio, A.; Cosseddu, P. Ultrathin, flexible and multimodal tactile sensors based on organic field-effect transistors. Sci. Rep. 2018, 8, 8073. [Google Scholar] [CrossRef] [Green Version]

- Jia, W.; Zhang, Q.; Cheng, Y.; Zhao, D.; Liu, Y.; Zhang, W.; Sang, S. Flexible and highly sensitive piezoresistive pressure sensor with sandpaper as a mold. Nano 2019, 14, 1950081. [Google Scholar] [CrossRef]

- Zhou, Q.; Ji, B.; Hu, B.; Li, S.; Xu, Y.; Gao, Y.; Zhou, B. Tilted magnetic micropillars enabled dual-mode sensor for tactile/touchless perceptions. Nano Energy 2020, 78, 105382. [Google Scholar] [CrossRef]

- Zhao, P.; Zhang, R.; Tong, Y.; Zhao, X.; Zhang, T.; Tang, Q.; Liu, Y. Strain-discriminable pressure/proximity sensing of transparent stretchable electronic skin based on pedot:pss/swcnt electrodes. ACS Appl. Mater. Interfaces 2020, 12, 55083–55093. [Google Scholar] [CrossRef]

- Xu, J.; Pei, L.; Li, J.; Pang, H.; Li, Z.; Li, B.; Gong, X. Flexible, self-powered, magnetism/pressure dual-mode sensor based on magnetorheological plastomer. Compos. Sci. Technol. 2019, 183, 107820. [Google Scholar] [CrossRef]

- Guan, F.; Xie, Y.; Wu, H.; Meng, Y.; Shi, Y.; Gao, M.; Pei, Q. Silver nanowire-bacterial cellulose composite fiber-based sensor for highly sensitive detection of pressure and proximity. ACS Nano 2020, 14, 15428–15439. [Google Scholar] [CrossRef]

- Ge, J.; Wang, X.; Drack, M.; Volkov, O.; Liang, M.; Cañón Bermúdez, G.S.; Makarov, D. A bimodal soft electronic skin for tactile and touchless interaction in real time. Nat. Commun. 2019, 10, 4405. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, Q.; Liu, D.; Lin, L.; Wu, J. Bridging interdigitated electrodes by electrochemical-assisted deposition of graphene oxide for constructing flexible gas sensor. Sens. Actuators B Chem. 2019, 286, 591–599. [Google Scholar] [CrossRef]

- Shanglin, Y.; Rong, F. Flexible-substrate fluxgate current sensor based on mems technology. Sens. Mater. 2020, 32, 3083–3094. [Google Scholar] [CrossRef]

- Jia, Z.; Li, Z.; Ma, S.; Zhang, W.; Chen, Y.; Luo, Y.; Kong, L. Constructing conductive titanium carbide nanosheet (mxene) network on polyurethane/polyacrylonitrile fibre framework for flexible strain sensor. J. Colloid Interface Sci. 2021, 584, 1–10. [Google Scholar] [CrossRef]

- Li, S.; Wang, T.; Yang, Z.; He, J.; Wang, J.; Zhao, L.; Lu, G. Room temperature high performance nh3 sensor based on go-rambutan-like polyaniline hollow nanosphere hybrid assembled to flexible pet substrate. Sens. Actuators B Chem. 2018, 273, 726–734. [Google Scholar] [CrossRef]

- Lin, S.; Feng, W.; Miao, X.; Zhang, X.; Chen, S.; Chen, Y.; Zhang, Y. A flexible and highly sensitive nonenzymatic glucose sensor based on dvd-laser scribed graphene substrate. Biosens. Bioelectron. 2018, 110, 89–96. [Google Scholar] [CrossRef]

- Song, Y.; Chen, H.; Su, Z.; Chen, X.; Miao, L.; Zhang, J.; Zhang, H. Highly compressible integrated supercapacitor-piezoresistance-sensor system with cnt-pdms sponge for health monitoring. Small 2017, 13, 1702091. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, J.; Ladani, R.B.; Ravindran, A.R.; Mouritz, A.P.; Kinloch, A.J.; Wang, C.H. Novel electrically conductive porous pdms/carbon nanofiber composites for deformable strain sensors and conductors. ACS Appl. Mater. Interfaces 2017, 9, 14207–14215. [Google Scholar] [CrossRef]

- Al-Shedivat, M.; Naous, R.; Cauwenberghs, G.; Salama, K.N. Memristors empower spiking neurons with stochasticity. IEEE J. Emerg. Sel. Top. Circuits Syst. 2015, 5, 242–253. [Google Scholar] [CrossRef]

- Liu, J.; Ma, H.; Yang, Y.; Yang, W.; Jiao, Z.; Yu, Y. Study on direct writing of gallium metal for the flexible sensor. Adv. Mater. Sci. Eng. 2021, 2021, 9980534. [Google Scholar] [CrossRef]

- Chen, R. Liquid metal based flexible pressure sensor for tactile sensing of robots. J. Phys. Conf. Ser. 2021, 1885, 052025. [Google Scholar] [CrossRef]

- Almog, R.; Shashar, E.; Sverdlov, Y.; Shacham-Diamand, Y. Decorating metal oxide nanostructures with noble metal np for bio-sensing applications. In ECS Meeting Abstracts; IOP Publishing: Bristol, UK, 2021. [Google Scholar]

- Yin, R.; Yang, S.; Li, Q.; Zhang, S.; Liu, H.; Han, J.; Liu, C.; Shen, C. Flexible conductive ag nanowire/cellulose nanofibril hybrid nanopaper for strain and temperature sensing applications. Sci. Bull. 2020, 65, 899–908. [Google Scholar] [CrossRef]

- Shi, R.; Lou, Z.; Chen, S.; Shen, G. Flexible and transparent capacitive pressure sensor with patterned microstructured composite rubber dielectric for wearable touch keyboard application. Sci. China Mater. 2018, 61, 1587–1595. [Google Scholar] [CrossRef] [Green Version]

- Deng, W.; Zhang, X.; Jia, R.; Huang, L.; Zhang, X.; Jie, J. Organic molecular crystal-based photosynaptic devices for an artificial visual-perception system. NPG Asia Mater. 2019, 11, 77. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Sun, L.; Wang, C.; Yang, F.; Ren, X.; Zhang, X.; Dong, H.; Hu, W. Organic crystalline materials in flexible electronics. Chem. Soc. Rev. 2019, 48, 1492–1530. [Google Scholar] [CrossRef]

- Lai, S.; Viola, F.A.; Cosseddu, P.; Bonfiglio, A. Floating gate, organic field-effect transistor-based sensors towards biomedical applications fabricated with large-area processes over flexible substrates. Sensors 2018, 18, 688. [Google Scholar] [CrossRef]

- Matsui, H.; Takeda, Y.; Tokito, S. Flexible and printed organic transistors: From materials to integrated circuits. Org. Electron. 2019, 75, 105432. [Google Scholar] [CrossRef]

- Zhang, L.; Guo, Y.Y.H.; Liu, G.; Tan, Q. Na-doped zno and rgo composite-based flexible acetone gas sensor operated in room temperature. IEEE Access 2020, 8, 171568–171574. [Google Scholar] [CrossRef]

- Shirley, J.A.; Florence, S.E.; Sreeja, B.S.; Padmalaya, G.; Radha, S. Zinc oxide nanostructure-based textile pressure sensor for wearable applications. J. Mater. Sci. Mater. Electron. 2020, 31, 16519–16530. [Google Scholar] [CrossRef]

- Sholehah, A.; Karmala, K.; Huda, N.; Utari, L.; Septiani, N.L.; Yuliarto, B. Structural effect of ZnO-Ag chemoresistive sensor on flexible substrate for ethylene gas detection. Sens. Actuators A Phys. 2021, 331, 112934. [Google Scholar] [CrossRef]

- Van der Spek, D.; Van Arendonk, J.A.; Bovenhuis, H. Genome-wide association study for claw disorders and trimming status in dairy cattle. J. Dairy Sci. 2015, 98, 1286–1295. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Wang, T.; Han, Y.; Lv, W.; Li, B.; Su, C.; Zeng, M.; Yang, J.; Hu, N.; Su, Y.; et al. Wearable NO2 sensing and wireless application based on zns nanoparticles/nitrogen-doped reduced graphene oxide. Sens. Actuators B Chem. 2021, 345, 130423. [Google Scholar] [CrossRef]

- Mamleyev, E.R.; Heissler, S.; Nefedov, A.; Weidler, P.G.; Nordin, N.; Kudryashov, V.V.; Länge, K.; MacKinnon, N.; Sharma, S. Laser-induced hierarchical carbon patterns on polyimide substrates for flexible urea sensors. NPJ Flex. Electron. 2019, 3, 2. [Google Scholar] [CrossRef]

- Qi, Y.; Hu, Y.; Wu, X.; Wu, W.; Bao, J.; Yang, H.; Zhao, J.; Hou, C.; Huo, D. Self-supporting flexible enzyme-free sensor based on CoS-PPy-CP for glucose detection. J. Electrochem. Soc. 2021, 168, 10507. [Google Scholar] [CrossRef]

- Patil, A.B.; Meng, Z.; Wu, R.; Ma, L.; Xu, Z.; Shi, C.; Qiu, W.; Liu, Q.; Zhang, Y.; Lin, Y.; et al. Tailoring the meso-structure of gold nanoparticles in keratin-based activated carbon toward high-performance flexible sensor. Nanomicro Lett. 2020, 12, 117. [Google Scholar] [CrossRef]

- Zhang, Q.; An, C.; Fan, S.; Shi, S.; Zhang, R.; Zhang, J.; Li, Q.; Zhang, D.; Hu, X.; Liu, J. Flexible gas sensor based on graphene/ethyl cellulose nanocomposite with ultra-low strain response for volatile organic compounds rapid detection. Nanotechnology 2018, 29, 285501. [Google Scholar] [CrossRef]

- Chuang, L.; Wei-Wei, L.; Li, C.; Dan, X.; Bao-Jun, L.; Lan, X.; Xiao-Kuo, Y.; Dan-Na, D.; Jia-Hao, L.; Ya-Bo, C. Flexible nitrogen dioxide gas sensor based on reduced graphene oxide sensing material using silver nanowire electrode. Acta Phys. Sin. 2020, 69, 20191390. [Google Scholar]

- Li, Y.; Jia, W.; Hou, X.; Zhang, L.; He, J.; Mu, J.; Wang, C.; Yu, J.; Bi, K.; Cui, M.; et al. Enhanced-sensitivity and highly flexible stress/strain sensor based on pzt nanowires-modified graphene with wide range carrier mobility. J. Mater. Sci. Mater. Electron. 2020, 31, 8436–8445. [Google Scholar] [CrossRef]

- Liang, B.; Chen, W.; He, Z.; Yang, R.; Lin, Z.; Du, H.; Shang, Y.; Cao, A.; Tang, Z.; Gui, X. Highly sensitive, flexible mems based pressure sensor with photoresist insulation layer. Small 2017, 13, 1702422. [Google Scholar] [CrossRef]

- Hao, B.; Mu, L.; Ma, Q.; Yang, S.; Ma, P.C. Stretchable and compressible strain sensor based on carbon nanotube foam/polymer nanocomposites with three-dimensional networks. Compos. Sci. Technol. 2018, 163, 162–170. [Google Scholar] [CrossRef]

- Huang, W.; Dai, K.; Zhai, Y.; Liu, H.; Zhan, P.; Gao, J.; Zheng, G.; Liu, C.; Shen, C. Flexible and lightweight pressure sensor based on carbon nanotube/thermoplastic polyurethane-aligned conductive foam with superior compressibility and stability. ACS Appl. Mater. Interfaces 2017, 9, 42266–42277. [Google Scholar] [CrossRef]

- Zhou, T.; Zhang, T. Recent progress of nanostructured sensing materials from 0D to 3D: Overview of structure-property-application relationship for gas sensors. Small Methods 2021, 5, e2100515. [Google Scholar] [CrossRef] [PubMed]

- Park, Y.J.; Sharma, B.K.; Shinde, S.M.; Kim, M.S.; Jang, B.; Kim, J.H.; Ahn, J.H. All MoS2-based large area, skin-attachable active-matrix tactile sensor. ACS Nano 2019, 13, 3023–3030. [Google Scholar] [CrossRef]

- Yang, T.; Xiang, H.; Qin, C.; Liu, Y.; Zhao, X.; Liu, H.; Li, H.; Ouzounian, M.; Hong, G.; Chen, H.; et al. Highly sensitive 1T-MoS2 pressure sensor with wide linearity based on hierarchical microstructures of leaf vein as spacer. Adv. Electron. Mater. 2020, 6, 1900916. [Google Scholar] [CrossRef]

- Yue, Y.; Liu, N.; Liu, W.; Li, M.; Ma, Y.; Luo, C.; Wang, S.; Rao, J.; Hu, X.; Su, J.; et al. 3D hybrid porous mxene-sponge network and its application in piezoresistive sensor. Nano Energy 2018, 50, 79–87. [Google Scholar] [CrossRef]

- Chen, Z.; Hu, Y.; Zhuo, H.; Liu, L.; Jing, S.; Zhong, L.; Peng, X.; Sun, R.C. Compressible, elastic, and pressure-sensitive carbon aerogels derived from 2d titanium carbide nanosheets and bacterial cellulose for wearable sensors. Chem. Mater. 2019, 31, 3301–3312. [Google Scholar] [CrossRef]

- Yang, K.; Yin, F.; Xia, D.; Peng, H.; Yang, J.; Yuan, W. A highly flexible and multifunctional strain sensor based on a network-structured mxene/polyurethane mat with ultra-high sensitivity and a broad sensing range. Nanoscale 2019, 11, 9949–9957. [Google Scholar] [CrossRef] [PubMed]

- Dong, K.; Wu, Z.; Deng, J.; Wang, A.C.; Zou, H.; Chen, C.; Hu, D.; Gu, B.; Sun, B.; Wang, Z.L. A stretchable yarn embedded triboelectric nanogenerator as electronic skin for biomechanical energy harvesting and multifunctional pressure sensing. Adv. Mater. 2018, 30, e1804944. [Google Scholar] [CrossRef]

- Zeng, X.; Wang, Z.; Zhang, H.; Yang, W.; Xiang, L.; Zhao, Z.; Peng, L.M.; Hu, Y. Tunable, ultrasensitive, and flexible pressure sensors based on wrinkled microstructures for electronic skins. ACS Appl. Mater. Interfaces 2019, 11, 21218–21226. [Google Scholar] [CrossRef]

- Lee, Y.; Myoung, J.; Cho, S.; Park, J.; Kim, J.; Lee, H.; Lee, Y.; Lee, S.; Baig, C.; Ko, H. Bioinspired gradient conductivity and stiffness for ultrasensitive electronic skins. ACS Nano 2021, 15, 1795–1804. [Google Scholar] [CrossRef]

- Kano, S.; Kim, K.; Fujii, M. Fast-response and flexible nanocrystal-based humidity sensor for monitoring human respiration and water evaporation on skin. ACS Sens. 2017, 2, 828–833. [Google Scholar] [CrossRef]

- Sun, X.; Qin, Z.; Ye, L.; Zhang, H.; Yu, Q.; Wu, X.; Li, J.; Yao, F. Carbon nanotubes reinforced hydrogel as flexible strain sensor with high stretchability and mechanically toughness. Chem. Eng. J. 2020, 382, 12282. [Google Scholar] [CrossRef]

- Xu, H.; Xiang, J.X.; Lu, Y.F.; Zhang, M.K.; Li, J.J.; Gao, B.B.; Zhao, Y.J.; Gu, Z.Z. Multifunctional wearable sensing devices based on functionalized graphene films for simultaneous monitoring of physiological signals and volatile organic compound biomarkers. ACS Appl. Mater. Interfaces 2018, 10, 11785–11793. [Google Scholar] [CrossRef]

- Wang, Y.; Hao, J.; Huang, Z.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. Flexible electrically resistive-type strain sensors based on reduced graphene oxide-decorated electrospun polymer fibrous mats for human motion monitoring. Carbon 2018, 126, 360–371. [Google Scholar] [CrossRef]

- Yang, H.; Gong, L.H.; Zheng, Z.; Yao, X.F. Highly stretchable and sensitive conductive rubber composites with tunable piezoresistivity for motion detection and flexible electrodes. Carbon 2020, 158, 893–903. [Google Scholar] [CrossRef]

- Ergen, O.; Celik, E.; Unal, A.H.; Erdolu, M.Y.; Sarac, F.E.; Unal, U. Real time chemical and mechanical human motion monitoring with aerogel-based wearable sensors. Lab Chip 2020, 20, 2689–2695. [Google Scholar] [CrossRef] [PubMed]

- Pu, J.H.; Zhao, X.; Zha, X.J.; Li, W.D.; Ke, K.; Bao, R.Y.; Liu, Z.Y.; Yang, M.B.; Yang, W. A strain localization directed crack control strategy for designing mxene-based customizable sensitivity and sensing range strain sensors for full-range human motion monitoring. Nano Energy 2020, 74, 104814. [Google Scholar] [CrossRef]

- Ma, J.; Wang, P.; Chen, H.; Bao, S.; Chen, W.; Lu, H. Highly sensitive and large-range strain sensor with a self-compensated two-order structure for human motion detection. ACS Appl. Mater. Interfaces 2019, 11, 8527–8536. [Google Scholar] [CrossRef]

- Anwar, S.; Prasad, R.; Chowdhary, B.S.; Anjum, M.R. A telemedicine platform for disaster management and emergency care. Wirel. Pers. Commun. 2019, 106, 191–204. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, L.; Li, J.; Liu, R.; Lou, L.; Zhao, S.; Chen, H.; Wang, Q.; Wu, X.; Ji, R.; et al. Improved research of adjustable external fixation device for lower limbs based on semiconductor refrigeration sheet. Chin. J. Med. Instrum. 2020, 44, 499–502. [Google Scholar]

- Liu, F.; Chen, Z.; Wang, J. Intelligent medical iot system based on wsn with computer vision platforms. Concurr. Comput. Pract. Exp. 2018, 33, e5036. [Google Scholar] [CrossRef]

- Feng, R.; Mu, Y.; Zeng, X.; Jia, W.; Liu, Y.; Jiang, X.; Gong, Q.; Hu, Y. A flexible integrated bending strain and pressure sensor system for motion monitoring. Sensors 2021, 21, 3969. [Google Scholar] [CrossRef]

- Yu, D.; Zheng, Z.; Liu, J.; Xiao, H.; Huangfu, G.; Guo, Y. Superflexible and lead-free piezoelectric nanogenerator as a highly sensitive self-powered sensor for human motion monitoring. Nanomicro Lett. 2021, 13, 117. [Google Scholar] [CrossRef]

- Wan, H.; Zhao, J.; Lo, L.W.; Cao, Y.; Sepúlveda, N.; Wang, C. Multimodal artificial neurological sensory-memory system based on flexible carbon nanotube synaptic transistor. ACS Nano. 2021, 15, 14587–14597. [Google Scholar] [CrossRef]

- Zhao, J.; Guo, H.; Pang, Y.K.; Xi, F.; Yang, Z.W.; Liu, G.; Guo, T.; Dong, G.; Zhang, C.; Wang, Z.L. Flexible organic tribotronic transistor for pressure and magnetic sensing. ACS Nano 2017, 11, 11566–11573. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Ren, Z.; Liu, F.; Zhao, L.; Ling, Q.; Gu, H. Multifunctional self-healing dual network hydrogels constructed via host-guest interaction and dynamic covalent bond as wearable strain sensors for monitoring human and organ motions. ACS Appl. Mater. Interfaces 2021, 13, 14612–14622. [Google Scholar] [CrossRef] [PubMed]

| Classification | Material | Preparation Method | Linear Range KPa | Sensitivity KPa−1 | Cyclic Stability (Times) | References No. |

|---|---|---|---|---|---|---|

| Flexible piezoresistive sensor | MXene, Polyacrylate | Coating Techniques | 0–16 | 148.26 | 13,000 | [67] |

| TPU, C-MWCNTS | Electrospinning | 0–10 | 2 | 1000 | [68] | |

| PDMS, Graphene | Spraying | 0–25 | 1.2 | 1000 | [69] | |

| PDMS, C-MWCNTS | Laser processing | 0.2–30 | 11.06 | 1000 | [70] | |

| PDMS, IPA | Laser engraving | 20–800 | 6.417 | 1000 | [71] | |

| SiO2, PANI, PLGA | Electrospinning | 10–380 | 0.071 | 2000 | [72] | |

| Flexible capacitive sensor | Graphene, PDMS | Laser processing | 0–600 | 0.33 | 1000 | [73] |

| Graphene, PDMS | Chemical vapor deposition | 1–10 | 3.19 | 500 | [74] | |

| PDMS, CCP, NaCl | Forming and dissolving | 0–10 | 1.1 | 11,000 | [75] | |

| PS, GNP, MWCNTs | Dip coating | 0–5 | 0.062 | 2000 | [76] | |

| PDMS, AgNWs, PET | Spin coating | 0–2 | 2.04 | 1000 | [77] | |

| GNWs, PDMS, ZnO | Spin coating | 0–22 | 22.3 | 2000 | [78] | |

| AgNWs, PDMS | Screen printing | 0–10 | 2.1 | 3600 | [79] | |

| Flexible triboelectric sensor | PVA, PEI | Template assist | 5–50 | 0.063 | 2000 | [80] |

| PU, AC | Curing print | 0–10 | 0.94 | 1300 | [81] | |

| TMAH, PDMS, P(VDF-TrFE) | Direct deposition | 0–900 | 2.97 | 40,000 | [82] | |

| CNT, FEP, PDMS | Spin coating | - | 0.21 | 10,000 | [83] | |

| PAN, C/BTO | Carbon electrospinning | 0.15–25 | 1.12 | 60,000 | [84] | |

| Organic-based ferrofluids, PEG, PEGDA | - | 0–44 | 6.75 | 20,000 | [85] |

| Classification | Material | Preparation Method | Linearity Range | Sensitivity | Lower Limit of Detection | References |

|---|---|---|---|---|---|---|

| Physical Flexible Sensors | PVA, NaCl | Water Bath Heating | 24.8–587 KPa | - | 24.8 KPa | [106] |

| AAm, AC, SDS, KPS, TMEDA | Fine emulsion polymerization method | 54–935 KPa | - | 54 KPa | [107] | |

| [EMIM]Cl, PHEA, PEGDA | Hybrid heating | 0–170 KPa | - | 0 | [108] | |

| PDMS, Basic Elastomer | Anisotropic etching | 0.05–6 KPa | 317.19 KPa−1 | 0.05 KPa | [109] | |

| Silver Nano, TMAH, PDMS | Synergy of microstructures | 1–10 KPa | 2 KPa−1 | 1 KPa | [110] | |

| Chemical Flexible Sensors | CuO Nanowires, PET | Thermal Oxidation | 0–12 mM | - | 0.05 mM | [111] |

| PET, ITO | Laser Scribing | PH 4–10 | −55 mV/pH | PH 4 | [112] | |

| PVIM, MNC, Co5POM | - | 1 fM–5 mM | 210 µAµM−1cm−2 | 1 fM | [113] | |

| PDMS, Basic Elastomer | Anisotropic Etching | 2.00–30.00 mM | 10.72 µAµM−1cm−2 | 10 | [114] | |

| PLLA–PTMC, AuNano film, polybutylenol film | Electrochemical deposition | 0.01–100 μM | - | 3.97 nM | [115] | |

| PEDOT, PSS | Wet spinning | PH 3–7 | −56 ± 7 mVpH−1 | PH 3 | [116] |

| Classification | Material | Preparation Method | KPa Linearity Range KPa | KPa−1 Sensitivity KPa−1 | Cycling Stability (Times) | Reference |

|---|---|---|---|---|---|---|

| Contact Flexible sensors | PEN, PVDF-TrFE | Chemical Vapor Deposition | 40–200 | 0.15 | 200 | [126] |

| AGNW, PVP, PET | Sandpaper forming | 0–4 | 0.0328 | - | [127] | |

| PDMS, CIP, PEGDA | Spin coating | 0–2 | 0.301 | 5000 | [128] | |

| Non-contact Flexible sensors | PEDOT, PSS, EG, OTS, PDMS | Spray coating | 1–5 | 0.1 | 2000 | [129] |

| PPG, TDI, copper powder | Ultrasonication | 1.3–38.2 | - | 500 | [130] | |

| PVP, TEMPO, AgNW | Wet Spinning | 0–460 | 5.49 | 1200 | [131] | |

| SiO2, Si wafer, SigmaAldrich | Photolithography | 0.72–11.6 | - | 5000 | [132] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, Y.; Guo, C.; Li, H.; Yang, H.; Xiong, F.; Chen, D. The Progress of Research into Flexible Sensors in the Field of Smart Wearables. Sensors 2022, 22, 5089. https://doi.org/10.3390/s22145089

Yin Y, Guo C, Li H, Yang H, Xiong F, Chen D. The Progress of Research into Flexible Sensors in the Field of Smart Wearables. Sensors. 2022; 22(14):5089. https://doi.org/10.3390/s22145089

Chicago/Turabian StyleYin, Yunlei, Cheng Guo, Hong Li, Hongying Yang, Fan Xiong, and Dongyi Chen. 2022. "The Progress of Research into Flexible Sensors in the Field of Smart Wearables" Sensors 22, no. 14: 5089. https://doi.org/10.3390/s22145089