A Simple and Effective Method for Measuring the Density of Non-Newtonian Thickened Tailings Slurry during Hydraulic Transport

Abstract

:1. Introduction

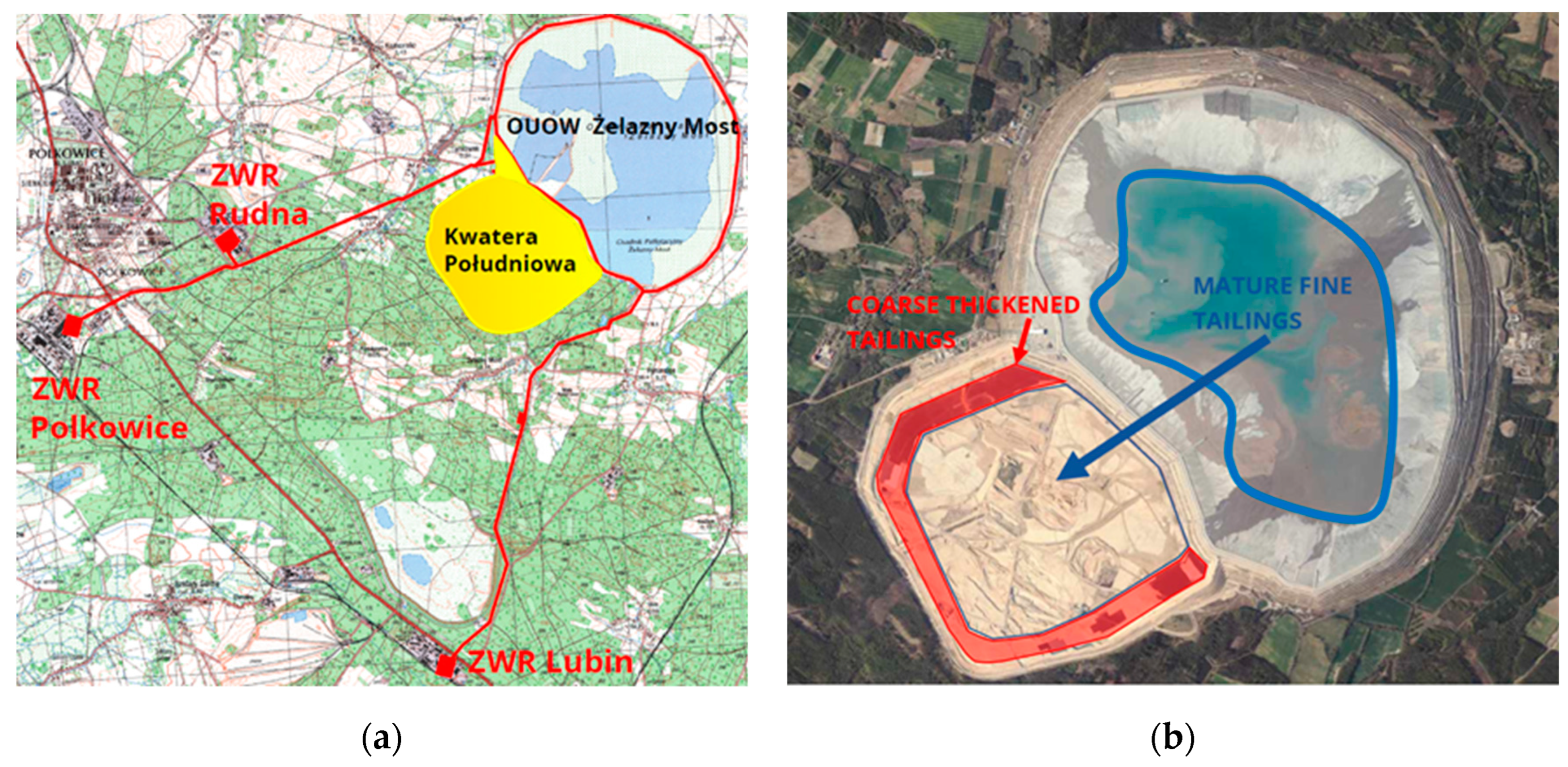

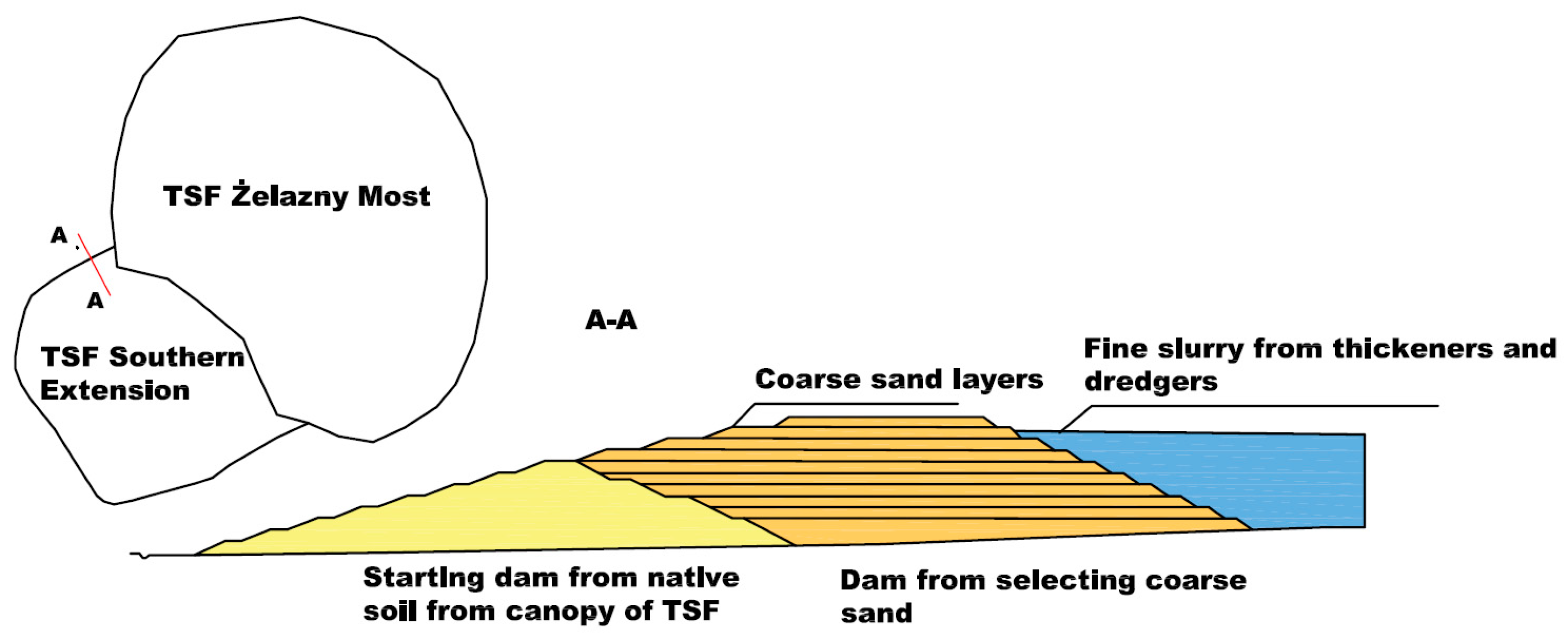

2. Study Site

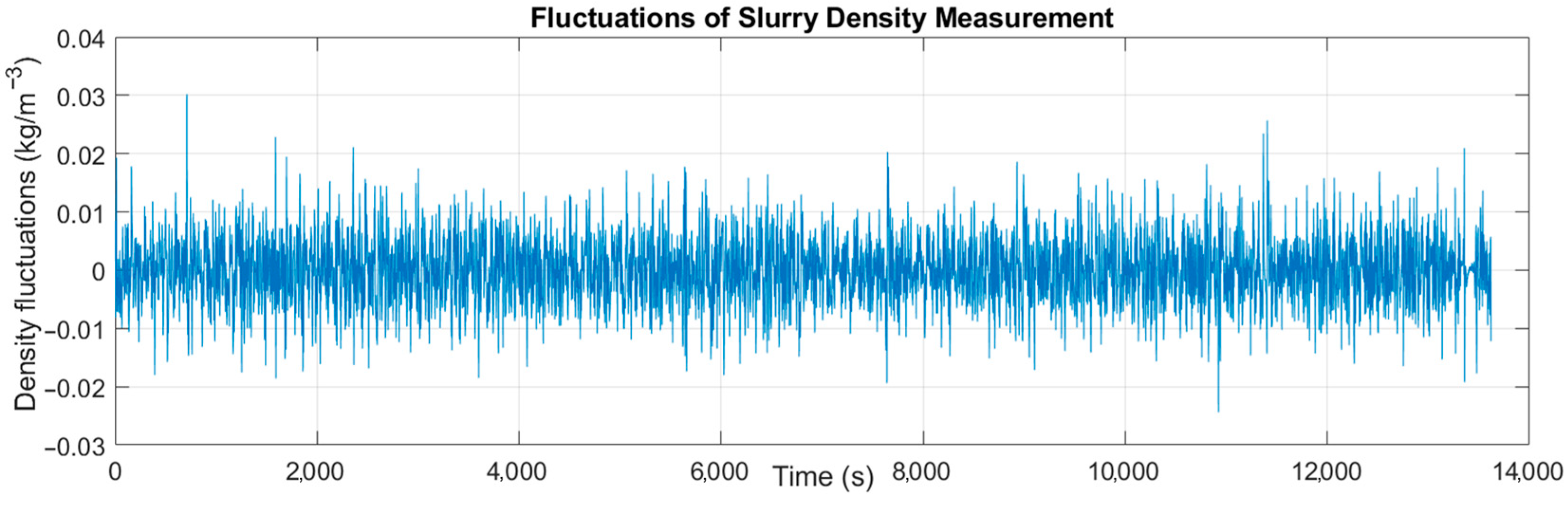

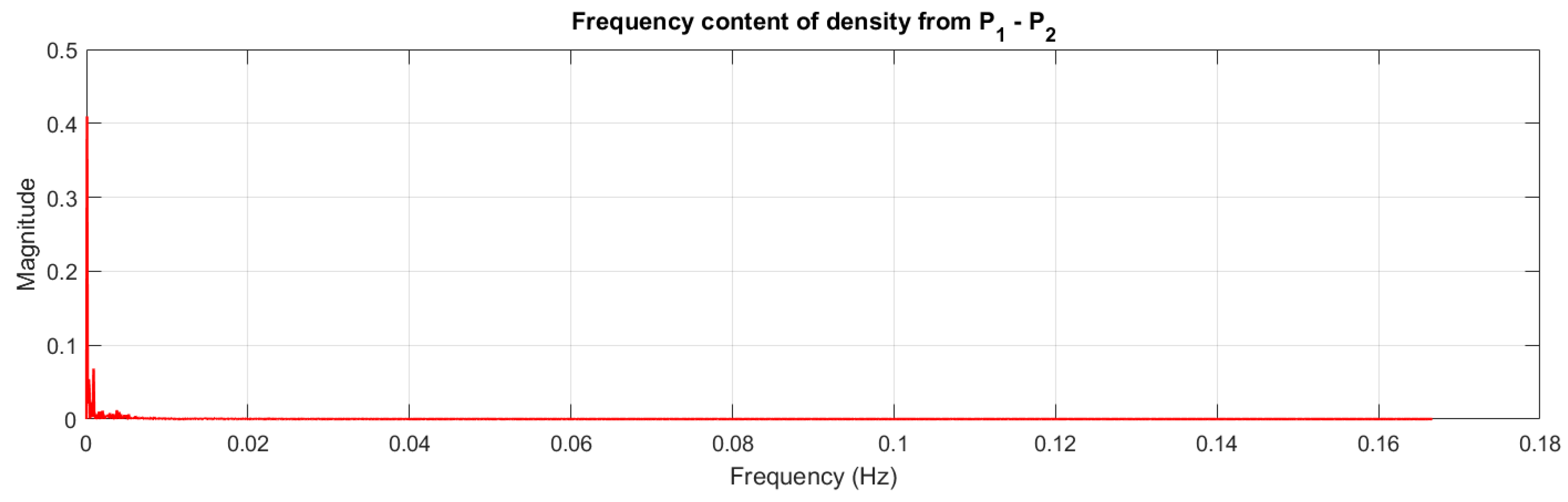

3. Density Measurements of the Thickened Tailings Slurry

3.1. Methods of Measuring Density

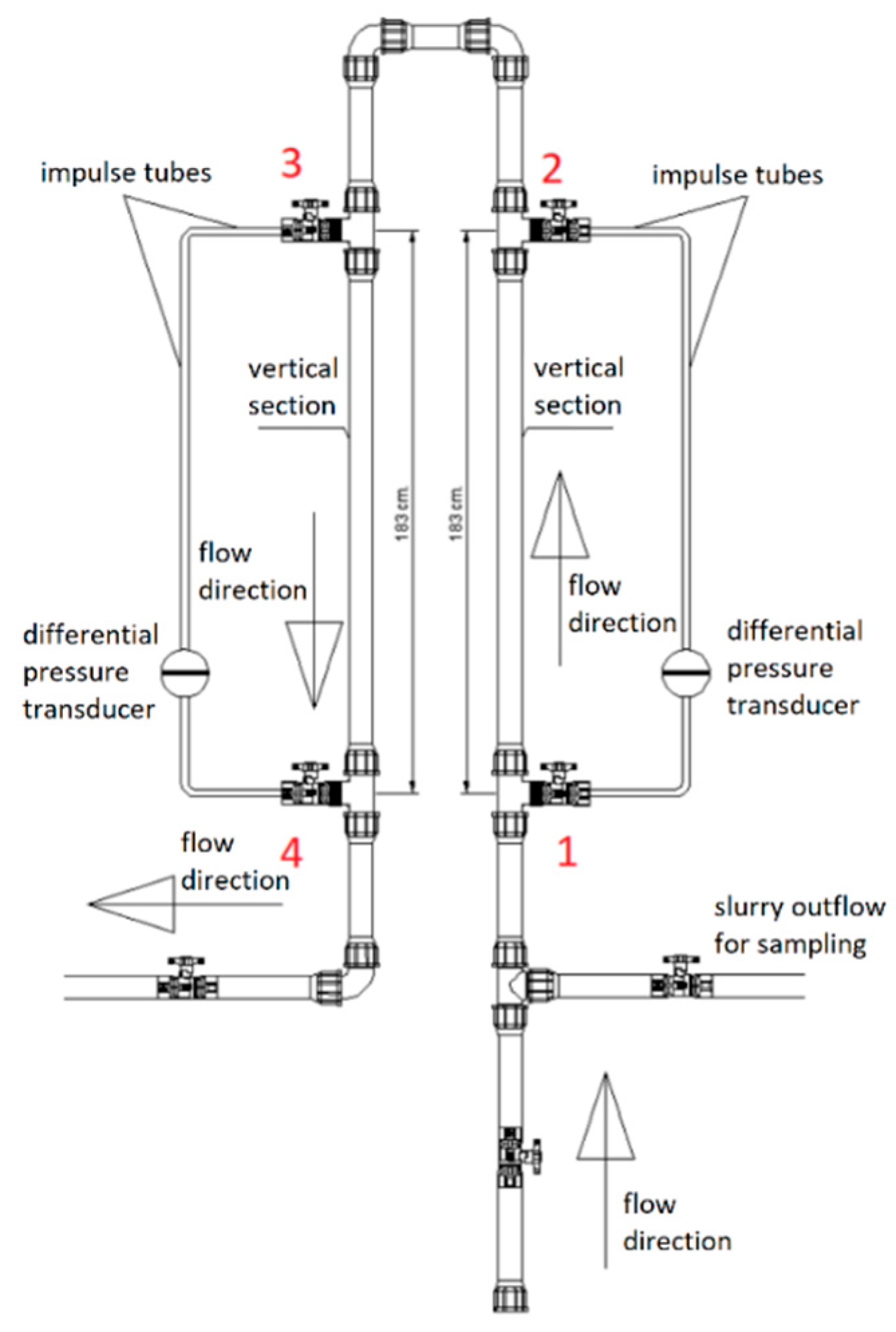

3.2. Measuring Installation and Procedure

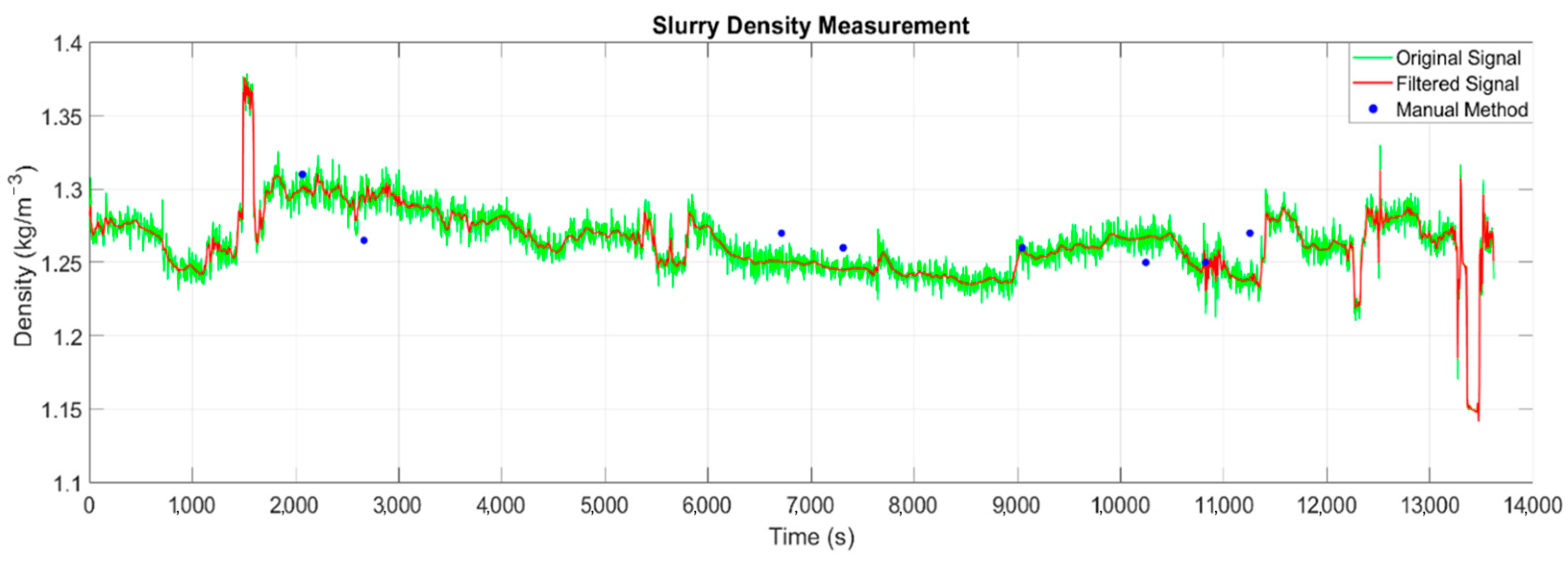

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alshawmar, F.; Fall, M. Dynamic response of thickened tailings in shaking table testing. Geo-Engineering 2021, 12, 28. [Google Scholar] [CrossRef]

- Mizani, S.; He, X.; Simms, P. Application of Lubrication Theory to Modeling Stack Geometry of High Density Mine Tailings. J. Non-Newton. Fluid Mech. 2013, 198, 59–70. [Google Scholar] [CrossRef]

- Sahi, A.; Mahboub, K.; El Belem, T.; Maqsoud, A.; Mbonimpa, M. Dewatering of Mine Tailings Slurries Using Superabsorbent Polymers (SAPs) Reclaimed from Industrial Reject of Baby Diapers: A Preliminary Study. Minerals 2019, 9, 785. [Google Scholar] [CrossRef] [Green Version]

- Azam, S. Statistical modeling of polymer-aided dewatering for tailings thickening. Int. J. Geotech. Eng. 2009, 3, 475–483. [Google Scholar] [CrossRef]

- Joseph-Soly, A.; Asamoah, R.K.; Skinner, W.; Addai-Mensah, J. Superabsorbent dewatering of refractory gold concentrate slurries. Adv. Powder Technol. 2020, 31, 3168–3176. [Google Scholar] [CrossRef]

- Jeong, Y.; Kim, K. Use of an Environmentally Friendly Polymer to Reduce the Water Content in Tailings Slurry. Min. Metall. Explor. 2020, 37, 1475–1486. [Google Scholar] [CrossRef]

- Vlasak, P.; Chara, Z. Laminar and Turbulent Flow Experiments with Yield-Power Law Slurries. Powder Technol. 1999, 104, 200–206. [Google Scholar] [CrossRef]

- Donald East, D.; Fernandez, R. Managing Water to Minimize Risk in Tailings Storage Facility Design, Construction, and Operation. Mine Water Environ. 2021, 40, 36–41. [Google Scholar] [CrossRef]

- Fan, X. Laboratory Modeling of Beach Profiles in Tailings Disposal. Master’s Thesis, University of Alberta, Edmonton, AB, Canada, 1989. [Google Scholar]

- Johnson, J.; Vizcarra, J. Modernization of Chinalco Toromocho Copper Tailings Thickeners. In Proceedings of the 23rd International Conference on Paste, Thickened and Filtered Tailings–PASTE 2020, 2020. [Google Scholar] [CrossRef]

- Golder Associates Ltd. Laboratory Report: Physical & Chemical Property Including Rheology and Flow Loop August; Golder Associates Ltd.: Sudbury, ON, Canada, 2014. [Google Scholar]

- Ogheneochuko, O. Density Measurement of Multiphase Pipe Flows. Ph.D. Thesis, University of Huddersfield, Huddersfield, UK, 2018. [Google Scholar]

- Wilson, K.C.; Addie, G.R.; Sellgren, A.; Clift, R. Slurry Transport Using Centrifugal Pumps, 3rd ed.; Springer: New York, NY, USA, 2006. [Google Scholar]

- Zhang, N.; Zhu, W.; He, H.; Lv, Y. Experimental Study on Sedimentation and Consolidation of Soil Particles in Dredged Slurry. KSCE J. Civ. Eng. 2017, 21, 2596–2606. [Google Scholar] [CrossRef]

- Wang, L.; Li, S.; Yuan, Y.; Sun, Z.; Zhou, T. Measurement of flow rate in solid-liquid two-phase flow in pipes at low volume concentration with venturimeter. Measurement 2019, 138, 409–415. [Google Scholar] [CrossRef]

- Janota, J. Przepływomierze Masowe Coriolisa. In Inżynieria Utrzymanie Ruchu; 2013. [Google Scholar]

- ISD 350-10; Specyfikacja Techniczna Pogłębiarki Refulującej. Rohr-Idreco: Doetinchem, The Netherlands, 2022.

- Peters, J. Innovative approach to production monitoring and process control with ADM nonnuclear density meter. In Proceedings of the WEDA Dredging Summit & Expo ‘22, Houston, TX, USA, 25–28 July; 2022. [Google Scholar]

- Endress+Hauser. Technical Information Gammapilot M FMG60 Radiometric Measurement. 2020. Available online: https://bdih-prod-assetcentralapi-assetcentral-rest-srv.cfapps.eu10.hana.ondemand.com/files/DLA/005056A500261EDABB88726B8CC1A477/TI00363FEN_1720.pdf (accessed on 12 February 2022).

- Tan, Y.; Yue, S. Solid Concentration Estimation by Kalman Filter. Sensors 2020, 20, 2657. [Google Scholar] [CrossRef] [PubMed]

- Krupička, J.; Matoušek, V. Gamma-ray-based measurement of concentration distribution in pipe flow of settling slurry: Vertical profiles and tomographic maps. J. Hydrol. Hydromech. 2014, 62, 126–132. [Google Scholar] [CrossRef] [Green Version]

- Van den Berg, C. IHC Merwede Handbook for Pumps and Slurry Transportation; 2013. [Google Scholar]

- Obie, O.; Lucas, G.P. Description of the Design and Experimental Characterization of a Novel Densitometry System for Measuring Density in Single Phase and Multiphase Pipe Flows. IEEE Sens. J. 2018, 18, 4405–4413. [Google Scholar] [CrossRef]

- Study, C. Demonstration NUCLEAR against ULTRASONIC Density Measurement. 2018. Available online: www.sti-bv.nl (accessed on 17 February 2022).

- Bamberger, J.A.; Greenwood, M.S. Measuring Fluid and Slurry Density and Solids Concentration Non-Invasively. Ultrasonics 2004, 42, 563–567. [Google Scholar] [CrossRef] [PubMed]

- Rhosonics. Density Meters for Challenging Slurry Applications. 2021. Available online: https://rhosonics.com/wp-content/uploads/2021/04/Rhosonics_Brochure_SDM-EN-RevJ-1.pdf (accessed on 17 February 2022).

- Stautberg Greenwood, S.M. Particle size and density of a slurry from ultrasonic backscattering measurements at a solid interface. Rev. Sci. Instrum. 2012, 83, 095101. [Google Scholar] [CrossRef] [Green Version]

- Greenwood, M.S.; Bamberger, J.A. Ultrasonic sensor to measure the density of a liquid or slurry during pipeline transport. Ultrasonics 2002, 40, 413–417. [Google Scholar] [CrossRef]

- Ismail, J.C.; Gamio, S.F.A.; Bukhari, W.Q. Yang Tomography for multi-phase flow measurement in the oil industry. Flow Meas. Instrum. 2005, 16, 145–155. [Google Scholar] [CrossRef]

- Wang, H.; Xia, Z.; Cui, Z. Electromagnetic Sensing and Imaging Methods in Industrial Flow Measurements. In Proceedings of the Photonics & Electromagnetics Research Symposium—Fall, Xiamen, China, 17–20 December 2019; pp. 1449–1457. [Google Scholar] [CrossRef]

- Nowakowski, J.; Hammer, E.; Sankowski, D.; Styra, D.; Wajman, R.; Banasik, R.; Romanowski, A. New Concept of ECT/ERT/GRT Tomography for Multiphase Flow Measurements. Automatyka 2010, 14. [Google Scholar]

- Van Wijk, J.M.; De Hoog, E.; Talmon, A.M.; Van Rhee, C. Concentration and pressure measurements of dense sand and gravel multiphase flows under transient flow conditions in a vertically oriented closed conduit—Assessment of system and sensor performance. Flow Meas. Instrum. 2022, 84. [Google Scholar] [CrossRef]

- Wang, B.; Fan, S.-D.; Jiang, P.; Zhu, H.-H.; Xiong, T.; Wei, W.; Fang, Z.-L. A Novel Method with Stacking Learning of Data-Driven Soft Sensors for Mud Concentration in a Cutter Suction Dredger. Sensors 2020, 20, 6075. [Google Scholar] [CrossRef] [PubMed]

- Shook, C.A.; Roco, M.C. Slurry Flow: Principles and Practice; Elsevier: Amsterdam, The Netherlands, 1991. [Google Scholar] [CrossRef]

- Navarro, F.; Chesneau, C.; Fadili, J.; Sassi, T. Block Thresholding for Wavelet-Based Estimation of Function Derivatives from a Heteroscedastic Multichannel Convolution Model. Electron. J. Stat. 2013, 7, 428–453. [Google Scholar] [CrossRef] [Green Version]

- Cui, P.; Zeng, C.; Lei, Y. Experimental Analysis on the Impact Force of Viscous Debris Flow. Earth Surf. Process. Landf. 2015, 40, 1644–1655. [Google Scholar] [CrossRef]

| Principle of Measurement | Description | Advantages | Disadvantages |

|---|---|---|---|

| Methods based on mass measurements | The volumetric method consists of selecting a sample for a vessel of a given volume and then weighing the sample. | Low costs of the tests, simplicity of the tests, simple equipment, high measurement accuracy. | No possibility of continuous measurements, difficulties in taking a reliable sample. |

| Methods based on pressure measurements | The method consists of measuring the pressure difference between two measuring points while taking into account hydraulic losses [12,13,14,15]. | Low costs of the tests, simple measuring equipment, the possibility of conducting a continuous measurement. | Measurement points should be placed at different ordinates of the system; requires a homogeneous medium and a steady flow. |

| Methods based on the measurement of forces (displacements); mass Coriolis flowmeters | The determination of the size of the force (by measuring the displacement) allows the mass flux to be determined [16]. Additionally, by examining the frequency of the wave, it is possible to determine the density of the medium on the same device. | It is one of the most accurate methods that is used to calibrate other methods; the possibility of conducting a continuous measurement of several parameters. | The high cost of the test due to the technically advanced measuring system, which requires a section that is able to be set into vibration. This is difficult for large installations and when on a vessel. |

| Methods based on acceleration measurements | In a separate section of the pipeline, a specific force is generated and the acceleration caused by it is measured. This allows the density to be determined [17,18]. Mass concentration type method. | The possibility of conducting a continuous measurement; a wide range of diameters of pipes that can be used in measurements. | The high costs of testing a new method; a small network of distributors and maintenance services; the device is placed between the pipeline’s sections. |

| Methods based on radiation | By having the source parameters, the share of radiation absorbed by the medium is examined using radiation intensity [19,20,21,22]. | Widely used; a large network of distributors and maintenance services; the possibility of conducting a continuous measurement; small dimensions of the device when compared to other methods; non-invasive in relation to the pipeline’s network—the possibility of installing on the pipeline. | The high cost of the test; considered to not be environmentally unfriendly due to the use of radioactive elements; requires separate permits and the application of appropriate procedures during its use. |

| Methods based on vibrations | A section of the pipeline is made to vibrate, the parameters of which are recorded. Based on the frequency of the vibrations, the density is determined [23]. | The possibility of conducting a continuous measurement; the relatively low cost of measurements. | A new method; a small network of distributors and maintenance services; devices installed between the sections of the pipeline; requires the dimensions of the pipe that can make it vibrate. |

| Methods based on ultrasounds | The method is based on the measurement of the ultrasonic wave reflection at the boundary of the media [24,25,26,27,28] | The possibility of conducting a continuous measurement; small dimensions of the device; requires installation between the pipeline’s sections of a ring that does not interfere with the pipeline’s cross-section. | High costs of the tests; requires relatively frequent, but simple calibration. |

| Methods based on electromagnetic | Part of industrial process tomography, most popular based on electrical properties are electrical capacitance tomography (ECT), electrical resistance tomography (ERT) and electromagnetic tomography (EMT). Tomography is a cross section thru pipe, using sequence of picture can give information about flow include density. Volumetric concentration type method [29,30,31]. | Give additional information of flow like flow regime, using correlation of images velocity profile. Non-invasive or low-invasive in to the pipe. | A new method, moderate spatial resolution of the image, need to use high-performance computing. |

| Methods based on conductivity | Similar to ERT method, using relation between conductivity and volumetric concentration [32]. | Quick response sensor, non-invasive | A new method, high dependance of temperature, need for precision calibration on particular mixture. |

| Description | Measurement Numbers |

|---|---|

| Measurement is stable | 381-856, 883-903, 969-1000, 1032-1066, 1387-2780, 2841-2902, 3094-3619, 3642-4701, 4709-7750, 4808-5541, 5549-5617, 5730-5817 |

| Starting, stopping, stabilizing, no flow | 1-380, 857-882, 904-968, 1073-1386, 2093-3093, 3620-3641, 4702-4708, 4751-4807, 5618-5729, 5818-6116 |

| Unstable flow, clogging | 1002-1031, 1067-1072, 2781-2840, 5542-548 |

| Time | Manual Measurement | Measurement Using the Developed Apparatus 1 | Error in % |

|---|---|---|---|

| 11:50:00 | 1.310 | 1.301 | 0.70 |

| 12:00:00 | 1.265 | 1.292 | −2.15 |

| 13:20:00 | 1.270 | 1.250 | 1.54 |

| 13:30:00 | 1.260 | 1.245 | 1.21 |

| 14:00:00 | 1.260 | 1.259 | 0.06 |

| 14:20:00 | 1.250 | 1.267 | −1.38 |

| 14:30:00 | 1.250 | 1.233 | 1.38 |

| 14:40:00 | 1.270 | 1.239 | 2.44 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gruszczyński, M.F.; Kostecki, S.; Zieliński, S.; Skrzypczak, Z.; Stefanek, P.; Czaban, S.; Popczyk, M. A Simple and Effective Method for Measuring the Density of Non-Newtonian Thickened Tailings Slurry during Hydraulic Transport. Sensors 2022, 22, 7857. https://doi.org/10.3390/s22207857

Gruszczyński MF, Kostecki S, Zieliński S, Skrzypczak Z, Stefanek P, Czaban S, Popczyk M. A Simple and Effective Method for Measuring the Density of Non-Newtonian Thickened Tailings Slurry during Hydraulic Transport. Sensors. 2022; 22(20):7857. https://doi.org/10.3390/s22207857

Chicago/Turabian StyleGruszczyński, Maciej Filip, Stanisław Kostecki, Szymon Zieliński, Zbigniew Skrzypczak, Paweł Stefanek, Stanisław Czaban, and Marcin Popczyk. 2022. "A Simple and Effective Method for Measuring the Density of Non-Newtonian Thickened Tailings Slurry during Hydraulic Transport" Sensors 22, no. 20: 7857. https://doi.org/10.3390/s22207857

APA StyleGruszczyński, M. F., Kostecki, S., Zieliński, S., Skrzypczak, Z., Stefanek, P., Czaban, S., & Popczyk, M. (2022). A Simple and Effective Method for Measuring the Density of Non-Newtonian Thickened Tailings Slurry during Hydraulic Transport. Sensors, 22(20), 7857. https://doi.org/10.3390/s22207857