Simultaneous Generation of Surface Plasmon and Lossy Mode Resonances in the Same Planar Platform

Abstract

:1. Introduction

2. Materials and Methods

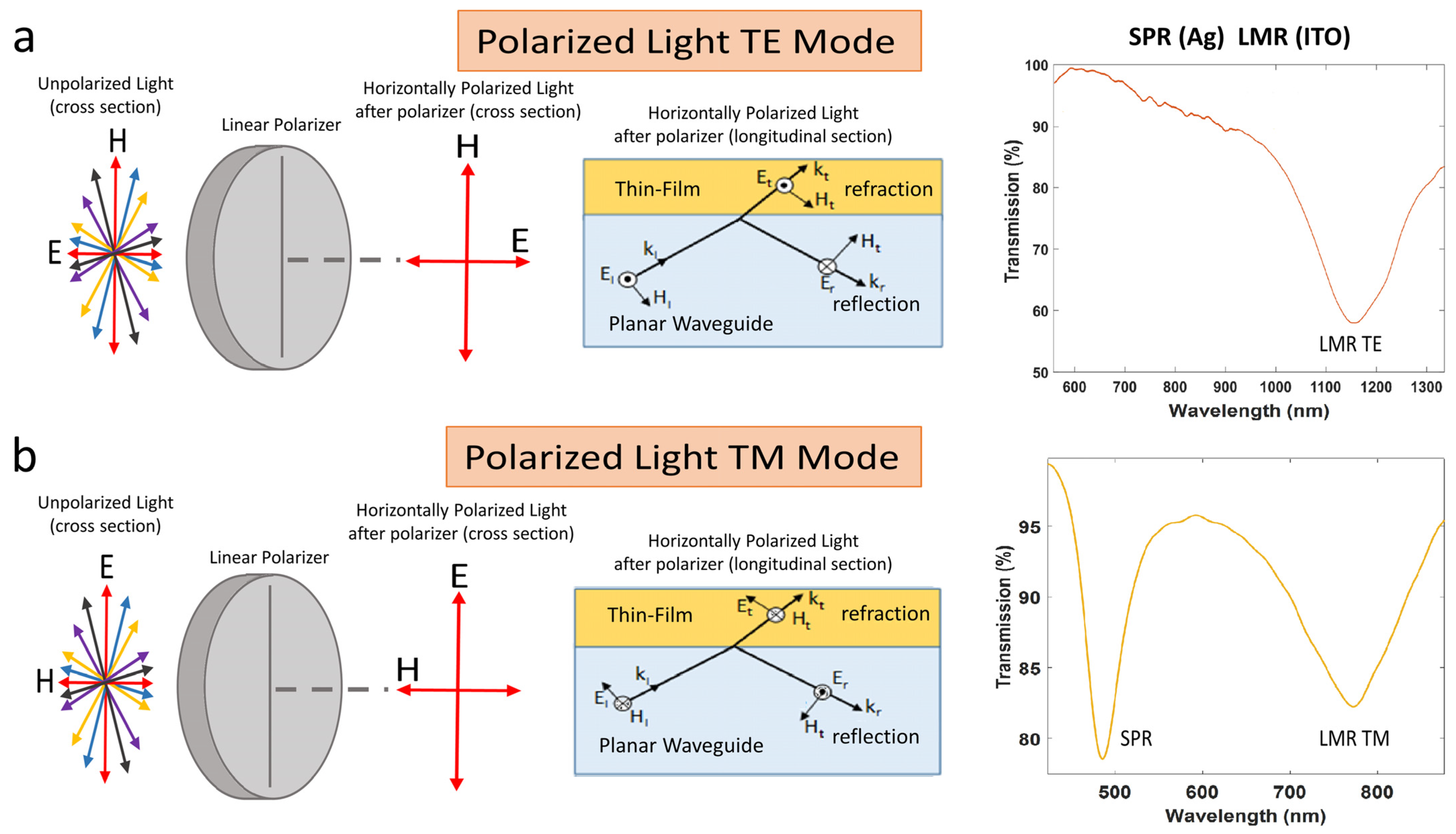

2.1. Experimental Setup

2.2. Thin Film Characterization

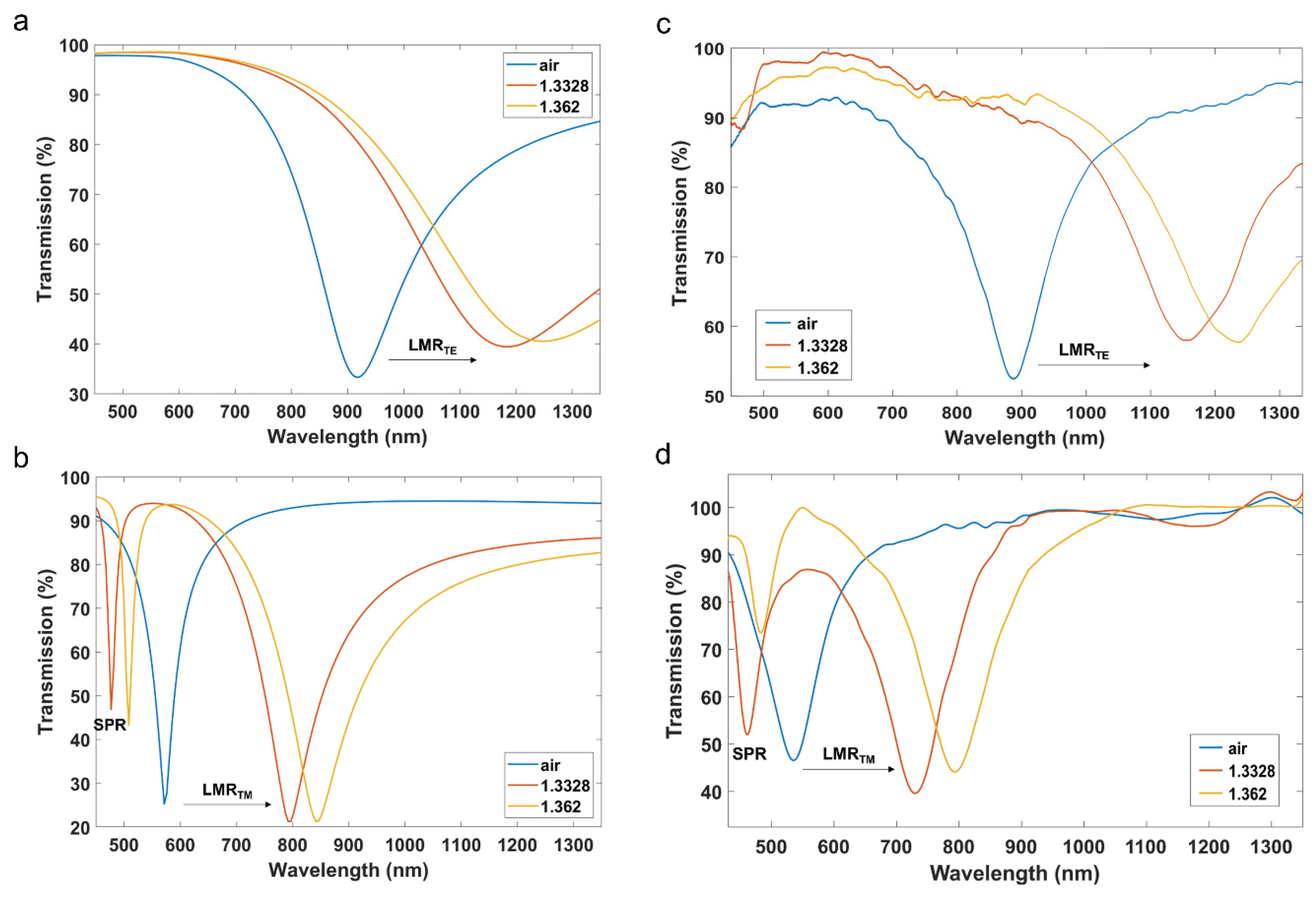

3. Results

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nylander, C.; Liedberg, B.; Lind, T. Gas detection by means of surface plasmon resonance. Sens. Actuators 1982, 3, 79–88. [Google Scholar] [CrossRef]

- Marciniak, M.; Grzegorzewski, J.; Szustakowski, M. Analysis of lossy mode cut-off conditions in planar waveguides with semiconductor guiding layer. IEE Proc. J. Optoelectron. 1993, 140, 247–252. [Google Scholar] [CrossRef]

- Del Villar, I.; Zamarreño, C.R.; Hernaez, M.; Arregui, F.J.; Matias, I.R. Lossy mode resonance generation with indium-tin-oxide-coated optical fibers for sensing applications. J. Light. Technol. 2010, 28, 111–117. [Google Scholar] [CrossRef] [Green Version]

- Slavík, R.; Homola, J. Ultrahigh resolution long range surface plasmon-based sensor. Sens. Actuators B Chem. 2007, 123, 10–12. [Google Scholar] [CrossRef]

- Homola, J.; Yee, S.S.; Gauglitz, G. Surface plasmon resonance sensors: Review. Sens. Actuators B Chem. 1999, 54, 3–15. [Google Scholar] [CrossRef]

- Del Villar, I.; Arregui, F.J.; Zamarreño, C.R.; Corres, J.M.; Bariain, C.; Goicoechea, J.; Elosua, C.; Hernaez, M.; Rivero, P.J.; Socorro, A.B.; et al. Optical sensors based on lossy-mode resonances. Sens. Actuators B Chem. 2017, 240, 174–185. [Google Scholar] [CrossRef]

- Kaur, D.; Sharma, V.K.; Kapoor, A. High sensitivity lossy mode resonance sensors. Sens. Actuators B Chem. 2014, 198, 366–376. [Google Scholar] [CrossRef]

- Batchman, T.E.; McWright, G.M. Mode Coupling Between Dielectric and Semiconductor Planar Waveguides. IEEE J. Quantum Electron. 1982, 18, 782–788. [Google Scholar] [CrossRef]

- Hernaez, M.; Zamarreño, C.R.; del Villar, I.; Arregui, F.J.; Matias, I.R. Optical fiber humidity sensor based on lossy mode resonances. Int. J. Smart Sens. Intell. Syst. 2009, 2, 653–660. [Google Scholar] [CrossRef] [Green Version]

- Yang, F.; Sambles, J.R. Determination of the optical permittivity and thickness of absorbing films using long range modes. J. Mod. Opt. 1997, 44, 1155–1164. [Google Scholar] [CrossRef]

- Rhodes, C.; Franzen, S.; Maria, J.P.; Losego, M.; Leonard, D.N.; Laughlin, B.; Duscher, G.; Weibel, S. Surface plasmon resonance in conducting metal oxides. J. Appl. Phys. 2006, 100, 054905. [Google Scholar] [CrossRef] [Green Version]

- del Villar, I.; Torres, V.; Beruete, M. Experimental demonstration of lossy mode and surface plasmon resonance generation with Kretschmann configuration. Opt. Lett. 2015, 40, 4739. [Google Scholar] [CrossRef] [PubMed]

- Usha, S.P.; Mishra, S.K.; Gupta, B.D. Fiber optic hydrogen sulfide gas sensors utilizing ZnO thin film/ZnO nanoparticles: A comparison of surface plasmon resonance and lossy mode resonance. Sens. Actuators B Chem. 2015, 218, 196–204. [Google Scholar] [CrossRef]

- Śmietana, M.; Sobaszek, M.; Michalak, B.; Niedziałkowski, P.; Białobrzeska, W.; Koba, M.; Sezemsky, P.; Stranak, V.; Karczewski, J.; Bogdanowicz, R.; et al. Optical Monitoring of Electrochemical Processes With ITO-Based Lossy-Mode Resonance Optical Fiber Sensor Applied as an Electrode. J. Light. Technol. 2018, 36, 954–960. [Google Scholar] [CrossRef]

- Tiwari, D.; Mullaney, K.; Korposh, S.; James, S.W.; Lee, S.W.; Tatam, R.P. An ammonia sensor based on Lossy Mode Resonances on a tapered optical fibre coated with porphyrin-incorporated titanium dioxide. Sens. Actuators B Chem. 2017, 242, 645–652. [Google Scholar] [CrossRef] [Green Version]

- Ozcariz, A.; Zamarreño, C.R.; Zubiate, P.; Arregui, F.J. Is there a frontier in sensitivity with Lossy mode resonance (LMR) based refractometers? Sci. Rep. 2017, 7, 10280. [Google Scholar] [CrossRef]

- Del Villar, I.; Hernaez, M.; Zamarreño, C.R.; Sánchez, P.; Fernández-Valdivielso, C.; Arregui, F.J.; Matias, I.R. Design rules for lossy mode resonance based sensors. Appl. Opt. 2012, 51, 4298–4307. [Google Scholar] [CrossRef]

- del Villar, I.; Zamarreño, C.R.; Hernaez, M.; Arregui, F.J.; Matias, I.R. Generation of lossy mode resonances with absorbing thin-films. J. Light. Technol. 2010, 28, 3351–3357. [Google Scholar] [CrossRef] [Green Version]

- Fuentes, O.; Del Villar, I.; Corres, J.M.; Matias, I.R. Lossy mode resonance sensors based on lateral light incidence in nanocoated planar waveguides. Sci. Rep. 2019, 9, 8882. [Google Scholar] [CrossRef] [Green Version]

- Dominguez, I.; Del Villar, I.; Fuentes, O.; Corres, J.M.; Matias, I.R. Dually nanocoated planar waveguides towards multi-parameter sensing. Sci. Rep. 2021, 11, 3669. [Google Scholar] [CrossRef]

- Jiang, Y.; Pillai, S.; Green, M.A. Realistic Silver Optical Constants for Plasmonics. Sci. Rep. 2016, 6, 30605. [Google Scholar] [CrossRef] [PubMed]

- Fuentes, O.; Goicoechea, J.; Corres, J.M.; Del Villar, I.; Ozcariz, A.; Matias, I.R. Generation of lossy mode resonances with different nanocoatings deposited on coverslips. Opt. Express 2020, 28, 288–301. [Google Scholar] [CrossRef] [PubMed]

- Yeh, P.; Yariv, A.; Hong, C.-S. Electromagnetic propagation in periodic stratified media I General theory. J. Opt. Soc. Am. 1977, 67, 423. [Google Scholar] [CrossRef] [Green Version]

- Sharma, A.K.; Gupta, B.D. On the sensitivity and signal to noise ratio of a step-index fiber optic surface plasmon resonance sensor with bimetallic layers. Opt. Commun. 2005, 245, 159–169. [Google Scholar] [CrossRef]

- Rubin, M. Optical properties of soda lime silica glasses. Sol. Energy Mater. 1985, 12, 275–288. [Google Scholar] [CrossRef] [Green Version]

- Sultanova, N.; Kasarova, S.; Nikolov, I. Dispersion Properties of Optical Polymers. Acta Phys. Pol.-Ser. A Gen. Phys. 2009, 116, 585–587. [Google Scholar] [CrossRef]

- Urrutia, A.; Del Villar, I.; Zubiate, P.; Zamarreño, C.R. A comprehensive review of optical fiber refractometers: Toward a standard comparative criterion. Laser & Photonics Rev. 2019, 13, 1900094. [Google Scholar]

| Type of Resonance | Conditions | n, k Conditions |

|---|---|---|

| Surface Plasmon Resonances (SPR) | |>| |>| | |

| Lossy Mode Resonances (LMR) | |>| |>| |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fuentes, O.; Del Villar, I.; Dominguez, I.; Corres, J.M.; Matías, I.R. Simultaneous Generation of Surface Plasmon and Lossy Mode Resonances in the Same Planar Platform. Sensors 2022, 22, 1505. https://doi.org/10.3390/s22041505

Fuentes O, Del Villar I, Dominguez I, Corres JM, Matías IR. Simultaneous Generation of Surface Plasmon and Lossy Mode Resonances in the Same Planar Platform. Sensors. 2022; 22(4):1505. https://doi.org/10.3390/s22041505

Chicago/Turabian StyleFuentes, O., I. Del Villar, I. Dominguez, J. M. Corres, and I. R. Matías. 2022. "Simultaneous Generation of Surface Plasmon and Lossy Mode Resonances in the Same Planar Platform" Sensors 22, no. 4: 1505. https://doi.org/10.3390/s22041505