Research on Weigh-in-Motion Algorithm of Vehicles Based on BSO-BP

Abstract

:1. Introduction

- Structure and principle of the WIM system.

- Wavelet transform algorithm.

- BSO-BP algorithm.

- Experimental results and analysis.

- Conclusions.

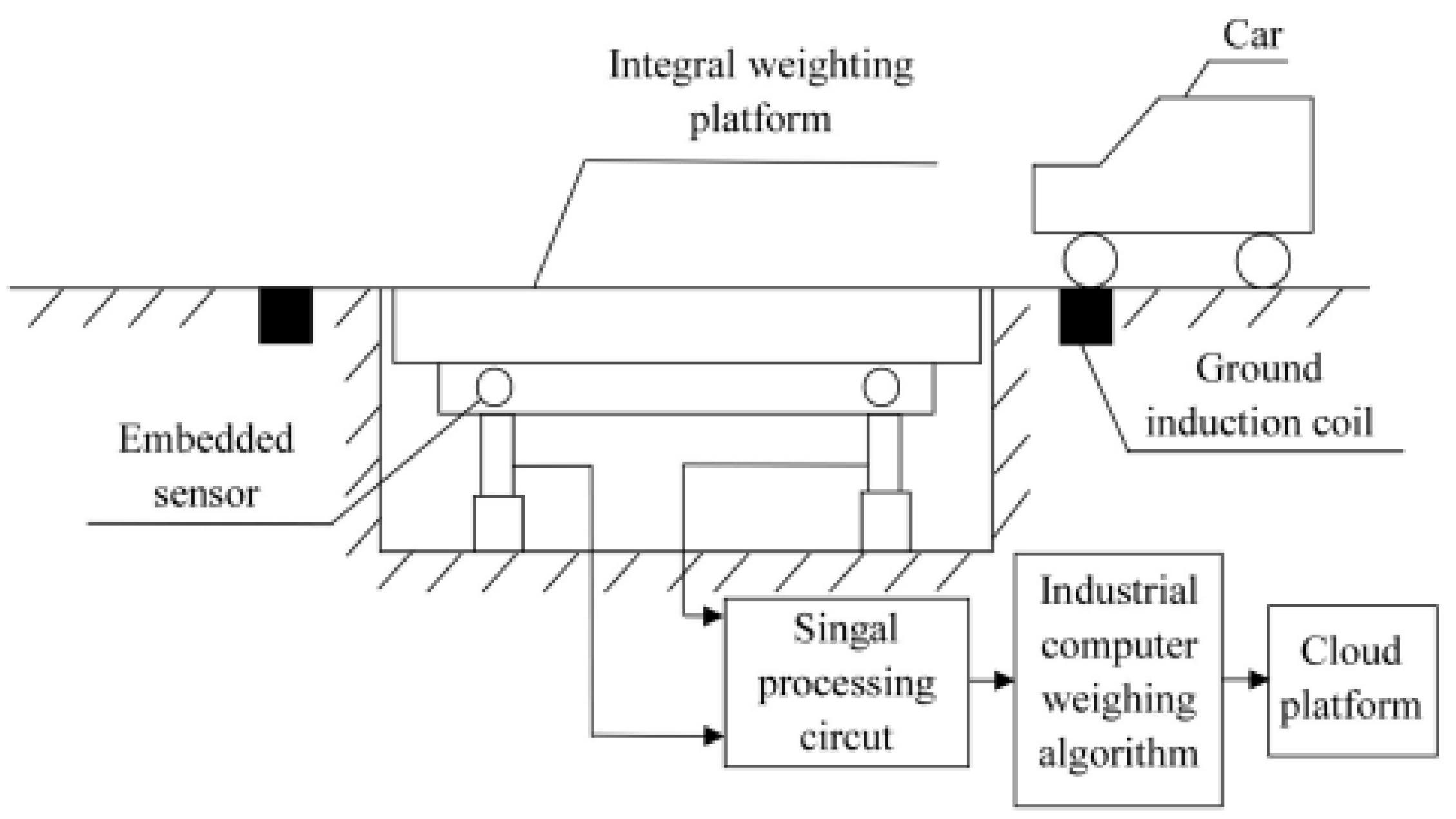

2. Structure and Principle of the WIM System

3. Pre-Processing of the WIM Signal

4. BSO-BP Algorithm

4.1. BP Neural Network

4.2. PSO Algorithm

4.3. Principle of BAS and BSO Algorithms

- Create a normalized random vector b. The calculation formula is as follows:

- 2.

- Create a spatial search model for the left and right antennae:

- 3.

- f(xlk) and f(xrk) are calculated using the fitness function f(x);

- 4.

- Iteratively update the position of the beetle through search behavior:

- 5.

- Update search distance and step size:

4.4. Establishment of the BSO-BP WIM Model

- The data processed by wavelet transform is used as the input sample of BSO-BP neural network;

- Set the size of the beetle swarm, the maximum number of iterations, the inertia weight, and the search space dimension, etc. The search space dimension is calculated as follows:

- 3.

- Randomly generate the position and speed of the beetle. According to formula 25, the fitness function value is calculated. Save the individual optimal value and the group optimal value:

- 4.

- Update the step size of the beetle:

- 5.

- Iterative optimization. Iteratively update the position, velocity and inertia weight of the beetle. The individual optimal value of the beetle and the group optimal value of the beetle swarm are updated according to the fitness value of the beetles;

- 6.

- The final iteration result is taken as the initial weight and threshold value of BP neural network;

- 7.

- Train the BSO-BP WIM model. Continuously update the weight and threshold of the network according to the error until the set accuracy is reached.

5. Experimental Results and Analysis

5.1. Data Pre-Processing

5.2. Establishment of WIM Model and Parameter Selection

5.3. Prediction of Gross Vehicle Weight and Analysis of Results

5.4. Prediction of Axle Weight and Analysis of Results

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Park, S.; On, B.W.; Lee, R.; Park, M.W.; Lee, S.H. A Bi-LSTM and k-NN Based Method for Detecting Major Time Zones of Overloaded Vehicles. Symmetry 2019, 11, 1160. [Google Scholar] [CrossRef] [Green Version]

- Burnos, P.; Gajda, J.; Sroka, R. Accuracy criteria for evaluation of weigh-in-motion systems. Metrol. Meas. Syst. 2018, 25, 743–751. [Google Scholar]

- Oubrich, L.; Ouassaid, M.; Maaroufi, M. Dynamic loads, source of errors of high speed weigh in motion systems. In Proceedings of the 2017 14th International Multi-Conference on Systems, Signals & Devices (SSD), Marrakech, Morocco, 28–31 March 2017; pp. 354–359. [Google Scholar]

- Qin, T.; Lin, M.; Cao, M.; Fu, K.; Ding, R. Effects of Sensor Location on Dynamic Load Estimation in Weigh-in-Motion System. Sensors 2018, 18, 3044. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Burnos, P.; Gajda, J. Thermal Property Analysis of Axle Load Sensors for Weighing Vehicles in Weigh-in-Motion System. Sensors 2016, 16, 2143. [Google Scholar] [CrossRef]

- Kim, S.; Lee, J.; Park, M.S.; Jo, B.W. Vehicle Signal Analysis Using Artificial Neural Networks for a Bridge Weigh-in-Motion System. Sensors 2009, 9, 7943–7956. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Pei, Y.; Zhou, S.; Zhao, Y.; Hu, J.; Yi, W. Novel methodology for identifying the weight of moving vehicles on bridges using structural response pattern extraction and deep learning algorithms. Measurement 2021, 168, 108384. [Google Scholar] [CrossRef]

- Jia, Z.; Fu, K.; Lin, M. Tire-Pavement Contact-Aware Weight Estimation for Multi-Sensor WIM Systems. Sensors 2019, 19, 2027. [Google Scholar] [CrossRef] [Green Version]

- Wang, T.; Yang, L.; Liu, Q. Beetle Swarm Optimization Algorithm: Theory and Application. Filomat 2020, 34, 5121–5137. [Google Scholar] [CrossRef]

- Zhou, L.; Chen, K.; Dong, H.; Chi, S.; Chen, Z. An Improved Beetle Swarm Optimization Algorithm for the Intelligent Navigation Control of Autonomous Sailing Robots. IEEE Access 2021, 9, 5296–5311. [Google Scholar] [CrossRef]

- Zhou, J.; Li, S.; Zhang, W.; Yan, W.; Zhao, Y.; Ji, Y.; Liu, X. Prediction and Suppression of Twisted-wire Pair Crosstalk Based on Beetle Swarm Optimization Algorithm. Appl. Comput. Electrom. 2021, 36, 435–441. [Google Scholar] [CrossRef]

- Wang, L.; Wu, Q.; Lin, F.; Li, S.; Chen, D. A New Trajectory-Planning Beetle Swarm Optimization Algorithm for Trajectory Planning of Robot Manipulators. IEEE Access 2019, 7, 154331–154345. [Google Scholar] [CrossRef]

- Al-Wesabi, F.N.; Alsolai, H.; Hilal, A.M.; Hamza, M.A.; Al Duhayyim, M.; Negm, N. Machine Learning Based Depression, Anxiety, and Stress Predictive Model during COVID-19 Crisis. Cmc Comput. Mater. Contin. 2022, 70, 5803–5820. [Google Scholar] [CrossRef]

- Singh, P.; Kaur, A.; Batth, R.S.; Kaur, S.; Gianini, G. Multi-disease big data analysis using beetle swarm optimization and an adaptive neuro-fuzzy inference system. Neural Comput. Appl. 2021, 33, 10403–10414. [Google Scholar] [CrossRef]

- Hasan, N.; Islam, M.S.; Chen, W.; Kabir, M.A.; Al-Ahmadi, S. Encryption Based Image Watermarking Algorithm in 2DWT-DCT Domains. Sensors 2021, 21, 5540. [Google Scholar] [CrossRef] [PubMed]

- Rohan, A.; Raouf, I.; Kim, H.S. Rotate Vector (RV) Reducer Fault Detection and Diagnosis System: Towards Component Level Prognostics and Health Management (PHM). Sensors 2020, 20, 6845. [Google Scholar] [CrossRef] [PubMed]

- Aileni, R.M.; Pasca, S.; Florescu, A. EEG-Brain Activity Monitoring and Predictive Analysis of Signals Using Artificial Neural Networks. Sensors 2020, 20, 3346. [Google Scholar] [CrossRef] [PubMed]

- Chu, W.; Lin, C.; Kao, K. Fault Diagnosis of a Rotor and Ball-Bearing System Using DWT Integrated with SVM, GRNN, and Visual Dot Patterns. Sensors 2019, 19, 4806. [Google Scholar] [CrossRef] [Green Version]

- Fadhil, A.F.; Kanneganti, R.; Gupta, L.; Eberle, H.; Vaidyanathan, R. Fusion of Enhanced and Synthetic Vision System Images for Runway and Horizon Detection. Sensors 2019, 19, 3802. [Google Scholar] [CrossRef] [Green Version]

- Guo, W.; Xian, Y.; Zhang, D.; Li, B.; Ren, L. Hybrid IRBM-BPNN Approach for Error Parameter Estimation of SINS on Aircraft. Sensors 2019, 19, 3682. [Google Scholar] [CrossRef] [Green Version]

- Song, Y.; Zhao, X.; Li, B.; Hu, Y.; Cui, X. Predicting Spatial Variations in Soil Nutrients with Hyperspectral Remote Sensing at Regional Scale. Sensors 2018, 18, 3086. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Wang, D.; Chen, B.; Yu, L.; Qian, J.; Zi, B. A Clamping Force Estimation Method Based on a Joint Torque Disturbance Observer Using PSO-BPNN for Cable-Driven Surgical Robot End-Effectors. Sensors 2019, 19, 5291. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, J.; Li, M.; Jiang, W.; Huang, Y.; Lin, R. A Design of FPGA-Based Neural Network PID Controller for Motion Control System. Sensors 2022, 22, 889. [Google Scholar] [CrossRef] [PubMed]

- Yao, Z.; Lei, Y.; He, D. Early Visual Detection of Wheat Stripe Rust Using Visible/Near-Infrared Hyperspectral Imaging. Sensors 2019, 19, 952. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Clerc, M.; Kennedy, J. The particle swarm—Explosion, stability, and convergence in a multidimensional complex space. IEEE Trans. Evolut. Comput. 2002, 6, 58–73. [Google Scholar] [CrossRef] [Green Version]

- Khan, A.T.; Cao, X.W.; Li, Z.; Li, S. Enhanced Beetle Antennae Search with Zeroing Neural Network for online solution of constrained optimization. Neurocomputing 2021, 447, 294–306. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, S.; Xu, B. Convergence analysis of beetle antennae search algorithm and its applications. Soft Comput. 2021, 25, 10595–10608. [Google Scholar] [CrossRef]

- Zheng, Q.; Xiang, D.; Fang, J.; Wang, Y.; Zhang, H.; Hu, Z. Research on performance seeking control based on Beetle Antennae Search algorithm. Meas. Control. 2020, 53, 1440–1445. [Google Scholar] [CrossRef]

- Jiang, X.; Li, S. Beetle Antennae Search without Parameter Tuning (BAS-WPT) for Multi-objective Optimization. Filomat 2020, 34, 5113–5119. [Google Scholar] [CrossRef]

- Mu, Y.; Li, B.; An, D.; Wei, Y. Three-Dimensional Route Planning Based on the Beetle Swarm Optimization Algorithm. IEEE Access 2019, 7, 117804–117813. [Google Scholar] [CrossRef]

| Number of Axles | Load | First Axle (kg) | Second Axle (kg) | Third Axle (kg) | Fourth Axle (kg) | Fifth Axle (kg) | Sixth Axle (kg) | Static Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| 2 | Empty | 1870 | 1440 | / | / | / | / | 3310 |

| Full | 2358 | 2932 | / | / | / | / | 5290 | |

| 4 | Empty | 5512 | 4746 | 6326 | 5976 | / | / | 22,560 |

| Full | 7339 | 8001 | 24,756 | 25,434 | / | / | 65,530 | |

| 6 | Empty | 4847 | 2905 | 2981 | 1197 | 1823 | 2957 | 16,710 |

| Full | 5591 | 7123 | 7318 | 10,315 | 11,523 | 12,080 | 53,950 |

| Model | Mean Gross Weight Relative Error/% | Maximum Gross Weight Relative Error/% |

|---|---|---|

| BP | 2.83 | 9.82 |

| PSO-BP | 2.62 | 18.78 |

| BSO-BP | 0.53 | 1.41 |

| Model | Mean Axle Weight Relative Error/% | Maximum Axle Weight Relative Error/% |

|---|---|---|

| BP | 3.51 | 12.28 |

| PSO-BP | 3.12 | 13.52 |

| BSO-BP | 1.61 | 6.69 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, S.; Chen, X.; Fu, Y.; Xu, H.; Hong, K. Research on Weigh-in-Motion Algorithm of Vehicles Based on BSO-BP. Sensors 2022, 22, 2109. https://doi.org/10.3390/s22062109

Xu S, Chen X, Fu Y, Xu H, Hong K. Research on Weigh-in-Motion Algorithm of Vehicles Based on BSO-BP. Sensors. 2022; 22(6):2109. https://doi.org/10.3390/s22062109

Chicago/Turabian StyleXu, Suan, Xing Chen, Yaqiong Fu, Hongwei Xu, and Kaixing Hong. 2022. "Research on Weigh-in-Motion Algorithm of Vehicles Based on BSO-BP" Sensors 22, no. 6: 2109. https://doi.org/10.3390/s22062109