Printing Technologies as an Emerging Approach in Gas Sensors: Survey of Literature

Abstract

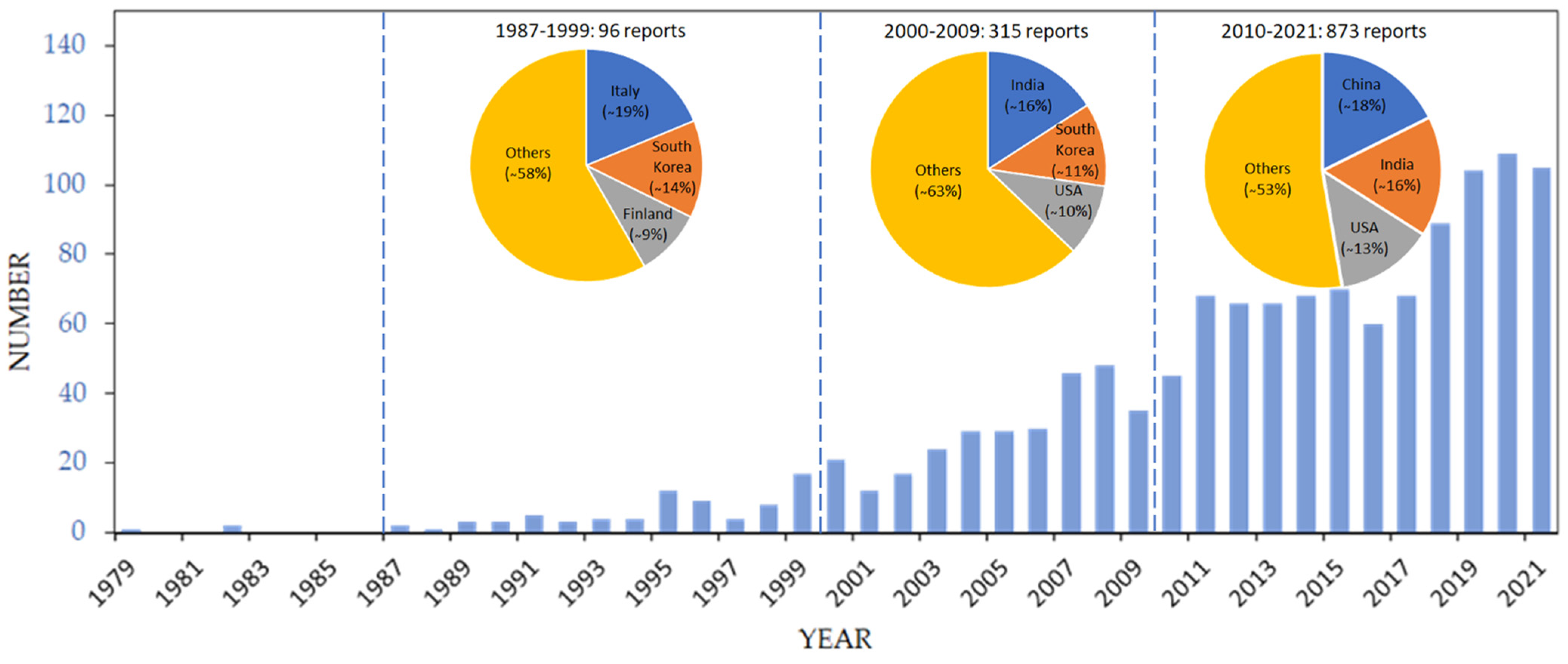

:1. Introduction

- (1)

- general overview and classification of printing methods (contact, non-contact, roll-to-roll);

- (2)

- description of characteristics of semiconductor gas sensors and multisensor arrays to be adjusted via fabrication protocols;

- (3)

- features of each printing method while applying to gas sensor fabrication;

- (4)

- characteristics of functional inks employed as the receptor components to design gas (multi)sensors in frames of various printing approaches.

2. Methods for Printing Functional Coatings on Various Substrates

3. Description of Characteristics of Semiconductor Gas Sensors and Multisensor Arrays

4. Printing Methods to Fabricate Receptor Layers of Gas Sensors

4.1. Ink-Jet Printing

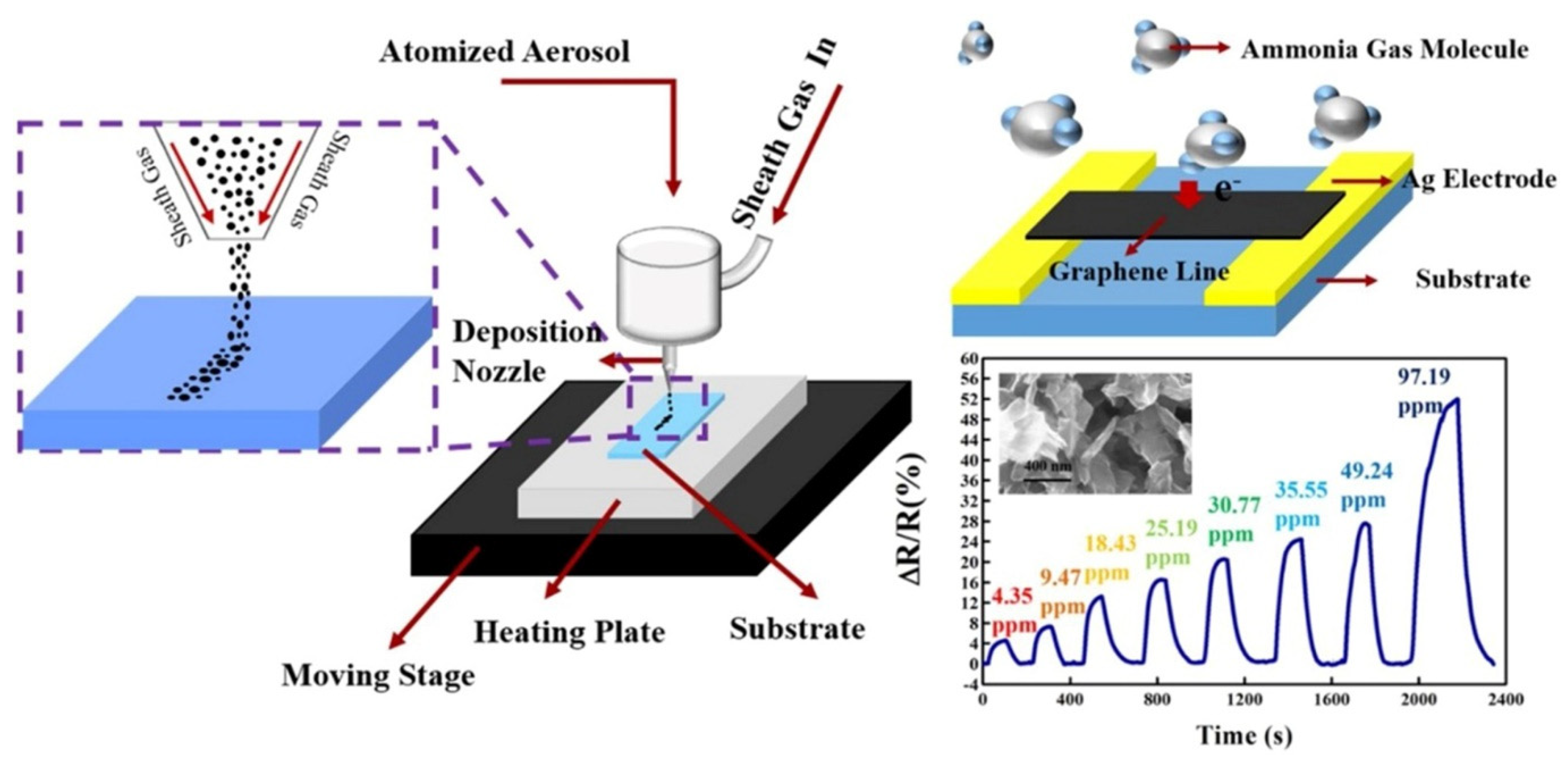

4.2. Aerosol Jet Printing

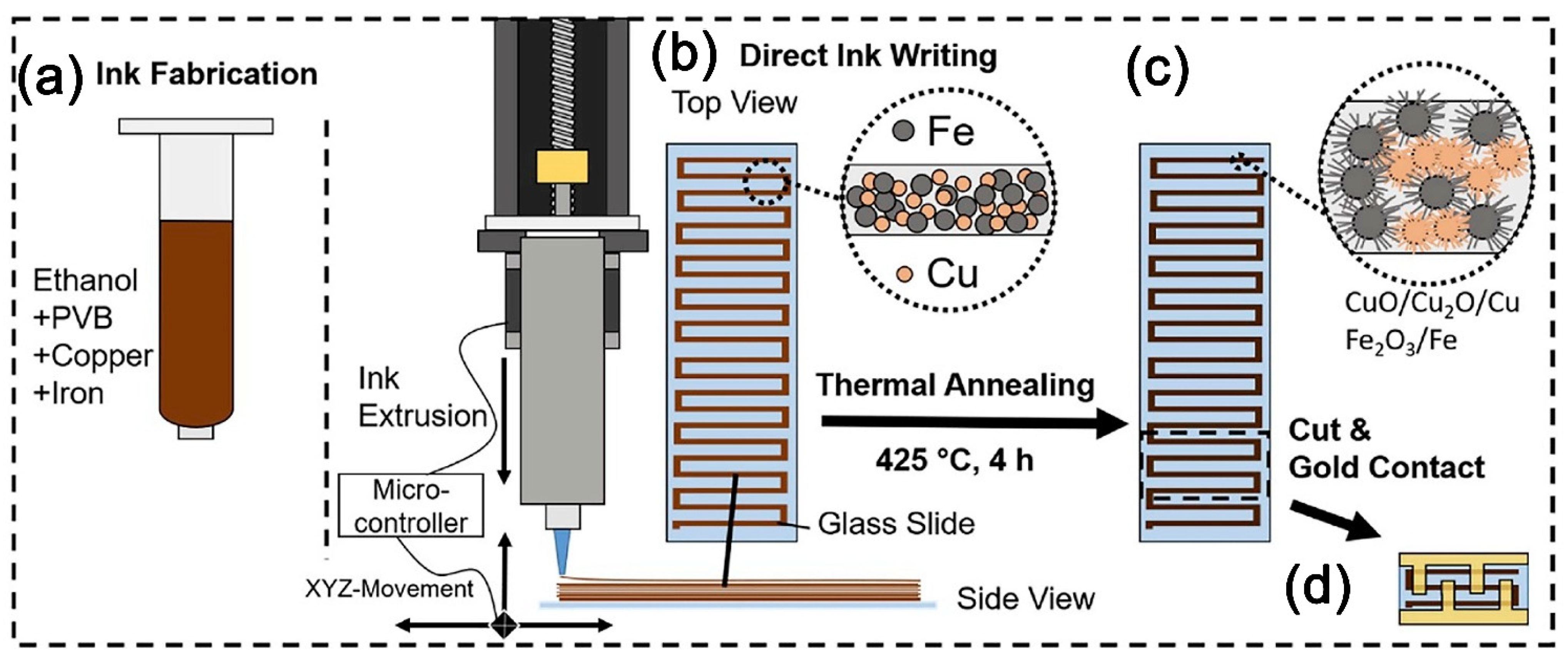

4.3. 3D Printing

4.4. Microextrusion Printing

4.5. Pen Plotter Printing

4.6. Microplotter Printing

4.7. Screen Printing

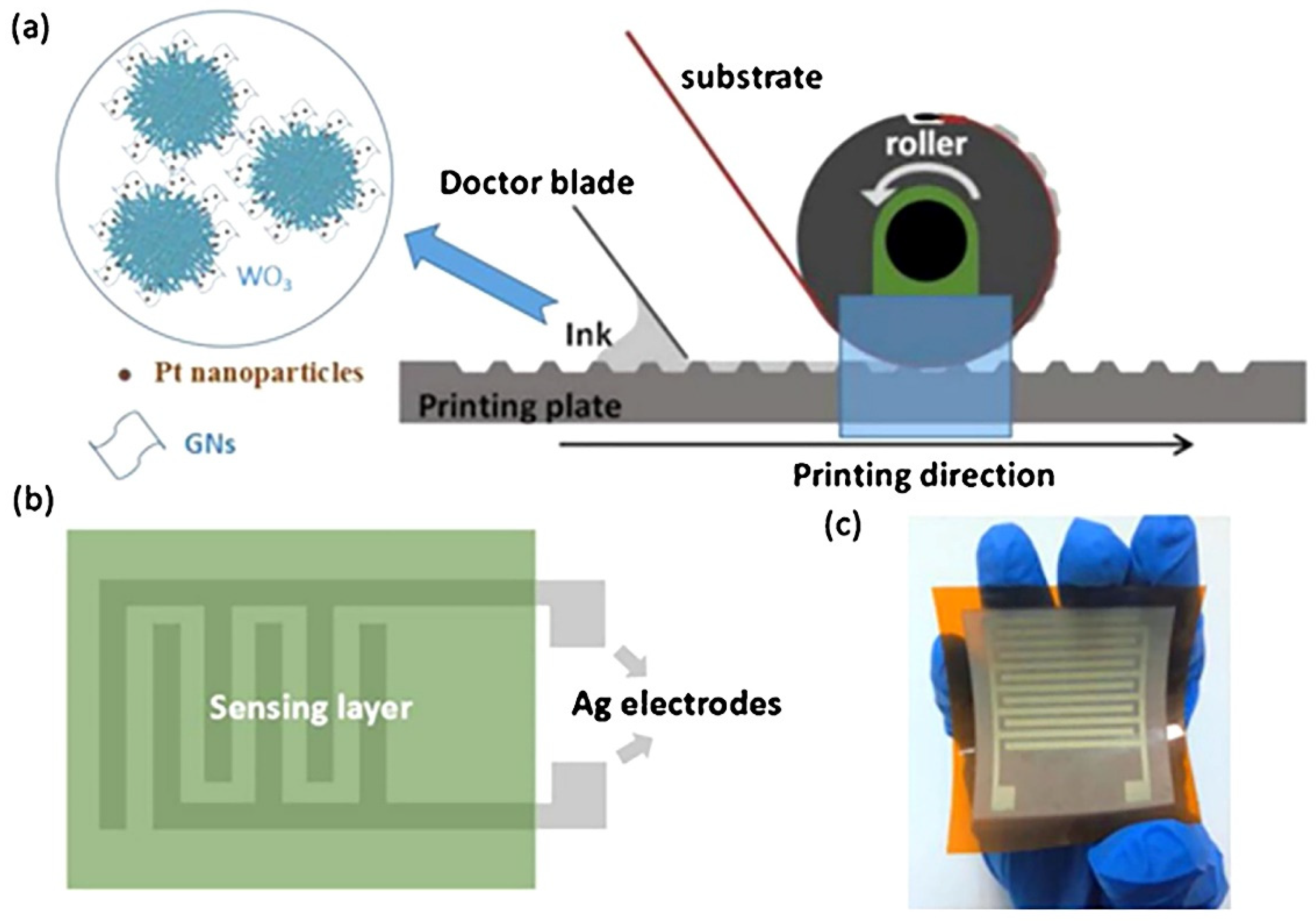

4.8. Gravure Printing

4.9. Flexographic Printing

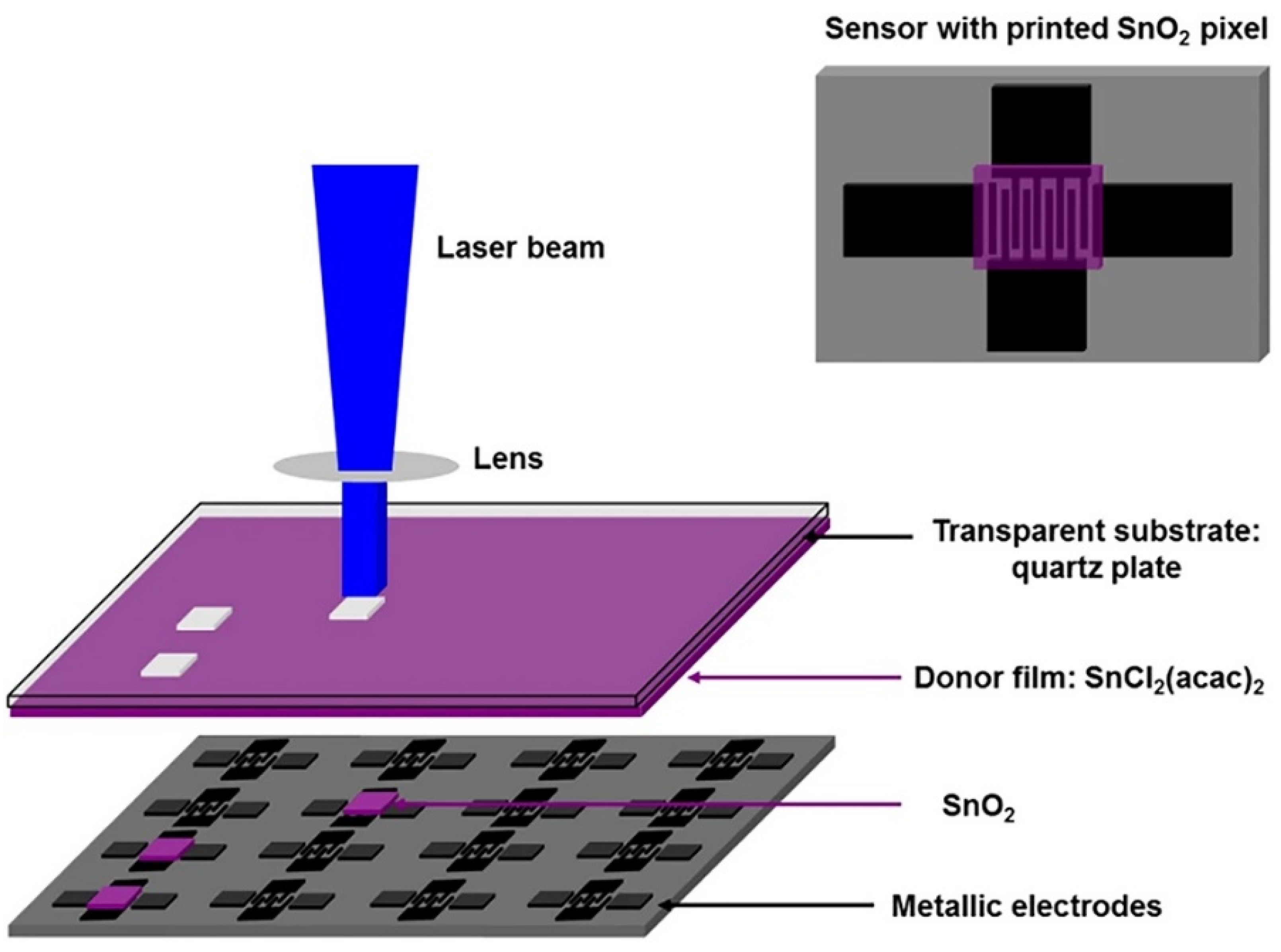

4.10. Laser-Induced Forward Transfer (LIFT)

4.11. Dip-Pen Nanolithography (DPN)

4.12. Nano-Imprinting Lithography (NIL)

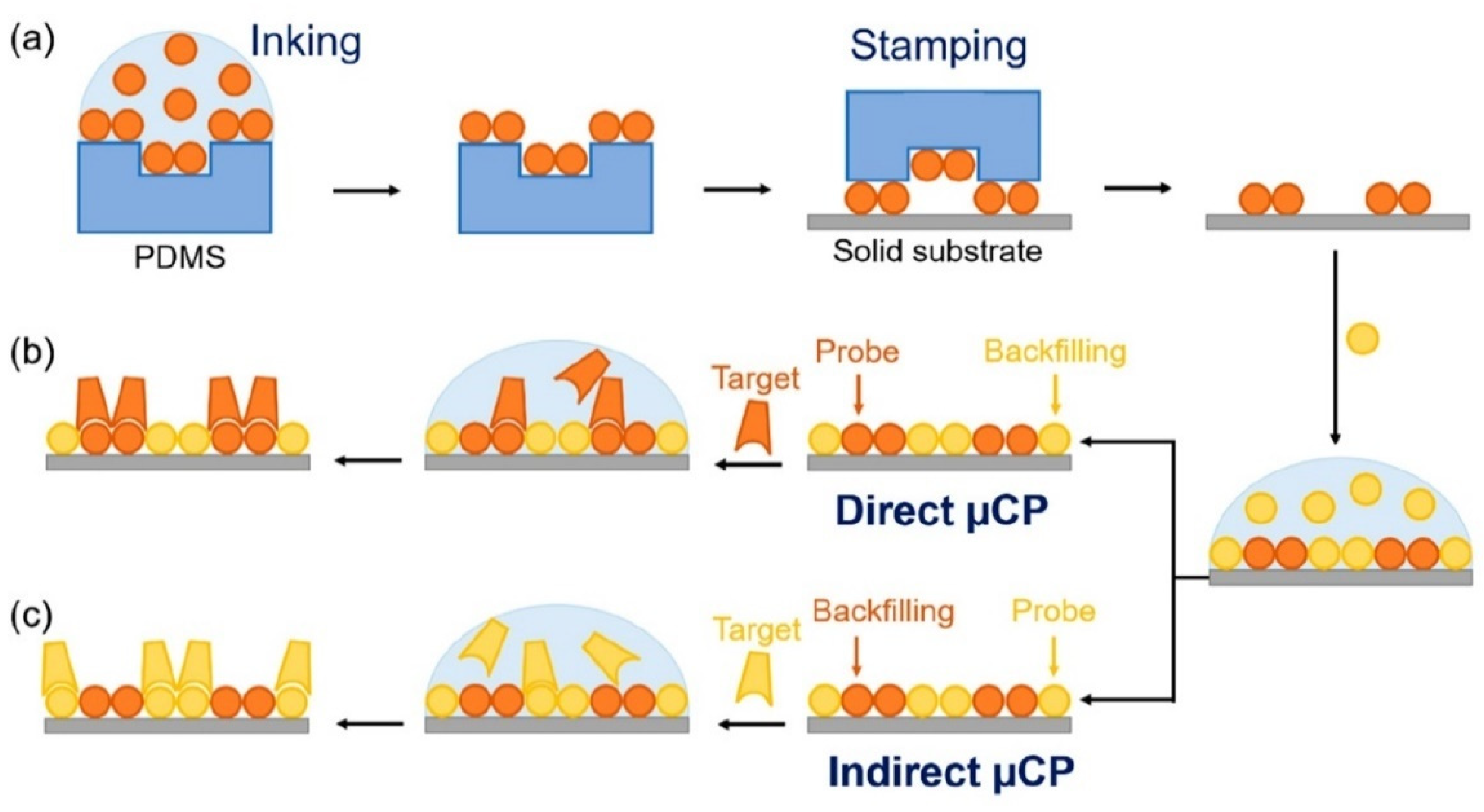

4.13. Microcontact Printing (µCP)

5. Features of Functional Inks Used in the Formation of Receptor Components for Gas Sensors by Various Printing Methods

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Method | Speed; Resolution; Thickness | Ink Viscos-ity, mPa·s | Material | Detected Analyte | Advantages | Disadvantages | Refs. |

|---|---|---|---|---|---|---|---|

| Ink-jet printing | 1–500 m/min; 0.4–50 µm; 0.015–20 um | 1–100 | Au, Pt, NP, Pd, Graphene oxide, CNT, OFETs, SnO2-rGO, SEBS, α-Fe2O3/rGO, TiO2–10%ZrO2, SnO2 | O2, S2−, K+, H2O2, Cl2, Glucose, NH3, NO2, CO2, H2S, Ethanol, Formalde-hyde, CO, Pentane, Heptane, Acetone, H2 | Possibility of programming the coating process; High speed of printing; Biocompatibility; Simple control over the thickness of the coating; Low risk of contamination; Low ink consumption; Possibility of creating the multisensory coating. | The number of cartridges is limited; Software limitations; Clogging of printhead and nozzles. | [16,18,25,30,49,50,54,55,56,204,205,206,207,208,209,210,211,212,213] |

| Aerosol jet printing | 0.1–200 mm/s; 10 µm; 30–1000 nm | 1–1000 | Pt-SWNCTs, Graphene, ZnO, SnO2, Pt/SnO2, TiO2, SrTi 0.7Fe0.3O3-x, Pd/SnO2, Pd/Al2O3, Y2O3-ZrO2 | H2, NH3, CO, Ethanol, O2, Propane, Methane, NO, NO2 | High resolution; Convenient control over the printing; High efficiency; A wide range of ink viscosity is available. | Overspray; Clogging of the nozzle. | [15,18,30,57,58,59,60,63,64,65,66,68,69,70,214,215,216,217] |

| 3D printing | 50–600 mm/min; 50–250 µm; 250–1000 um | 103–109 | CuO, CuO/Cu2O/Cu—Fe2O3/Fe, PBS/graphene | NH3, Acetone, Methanol, Hexane, Toluene, H2O, diethyl ether, 1,4-dioxane, dimethyl carbonate | A wide range of materials is suitable for printing; The method has many types; Possibility to quickly changing applied structures by software and easy to control; Relatively cheap printers; Low material consumption. | Method is too slow for using on a large scale. | [71,74,75,80,82,83,84,218,219,220] |

| Microextru-sion printing | 1–10,000 µm/s; 5–1000 µm; 5–500 um | 1–108 | NiO | H2S | A wide range of materials is suitable for printing; Cheapness of the method; Low ink consumption; Possibility to quickly changing applied structures by software and easy to control. | Method is too slow for using on a large scale. | [86,87,88,89,90,91,93,94,95,96,97,98,99] |

| Pen plotter printing | 50–5000 mm/min; 50 µm; 20–400 nm | 4.25–40 | Co3O4, ITO | H2, Methane, CO, NO2, CO2, NH3 | Continual supply of material; Absence of strict requirements to the rheology of the ink; There are no limitations on the size of substrate; Possibility of using different types of substrates (including flexible) and its size; Possibility to quickly changing applied structures by software; Very cheap method. | Relatively high roughness; Low reproducibility; Method is hard to adapt for a large scale. | [7,101,102,103,104,105,221] |

| Microplot-ter printing | 1–2 mm/s; 5 µm; 75–200 nm | <450 | ZnO/Pt, Mn3O4, TiO2/ZrO2, CeO2/ZrO2, ZnO, TiO2, Cr2O3, Co3O4, SnO2 | CO, NH3, H2, NO2, Benzene, Ethanol, Methanol, Isopropanol, n-butanol | Inexpensive method; Relatively simple method; Possibility to quickly changing applied structures by software and easy to control. | Relatively slow method; Method is hard to adapt for a large scale. | [107,112,114,116,120] |

| Screen printing | 5–150 m/min; 50–100 µm; 3–100 um | 500–50,000 | SnO2, CdS-SnO2, ZnO, Cd-ZnO, CeO2, In2O3, InSnOx, ZnO-SnO2, TiO2/GO | Humidity, Toluene, Ethanol, Methanol, LPG, Acetone, CO, CNG, Hydroxyl-amine | The method is well suited for thick films; A reliable method; Low cost; Low ink consumption. | The method not suited for thin films; High roughness of coatings; Low resolution. | [16,18,25,30,123,124,125,129,132,222,223,224,225,226,227,228,229] |

| Gravure printing | 6–1000 m/min; 0.1–75 µm; 0.1–5 um | 1–1000 | OFETs, PANI, WO3-PEDOT:PSS, WO3, pHEMA, Ag-S-RGO, WO3/Pt-decorated rGO | Acetone, NH3, NO2, NO, H2, Humidity, CO | High resolution; Low ink consumption; Possibility of using different types of substrates; The method is well scalable. | Defects may form during the printing; Expensive cylinders for printing. | [9,16,18,25,30,121,136,137,141,142,145,230,231,232,233,234,235,236,237] |

| Flexogra-phic printing | 6–300 m/min; 50–200 µm; 5–3000 nm | 20–2000 | ZnO | O2 | Fully automated method; High efficiency; Possibility of using different types of substrates (including flexible); Cheap printing plates. | It is necessary to create a printing plate for a new printing scheme. | [18,21,25,30,121,149,151,152,153,155,156,158,159,160] |

| Laser-induced forward transfer (LIFT) | 1–10 m/s; <1 µm; 10–1500 nm | 1–102 | CNF, SnO2, Pd:SnO2 | Humidity, Nitrogen dioxide, Ethanol, Methanol, Methane | A wide range of materials can be used for printing; Solid materials can be used for printing; Accurate control over printing; A wide range of ink viscosity can be used, including pastes and dispersions with a large particle size; Mostly porous structures with a large surface area are obtained; Low ink consumption. | High cost; Complex equipment; Fuzzy edges of coatings. | [15,123,162,163,164,165,167,168,169,172,173,238,239] |

| Dip-pen nanolitho-graphy (DPN) | 0.25–1 µm/s; <1 µm; >5 nm | 27–45 | Doped polypyrrole, PEDOT | CO2, NO | A wide range of materials can be used for printing; Accurate control over printing; Resolution can be controlled by replacing the AFM cantilever/tip. | Many parameters should be controlled; It is difficult to create high resolution structures; Small- scale printing; High requirements for equipment. | [15,176,182,183,240,241] |

| Nano-imprinting lithography (NI) | 0.1–60 µm/s; 10–25 nm; 8–100 nm | - | PEDOT:PSS, ZnO, GO, In(NO3)3, Pd/Au, Pd | NH3, H2, Humidity, Ethanol | Very high resolution; Relatively fast method to create nanoscale coatings; Easy adaptable method to new structures. | Method is too slow for using in a large scale; Defects may form during the printing; Many parameters should be controlled; Mask should be changed quite often. | [25,175,178,184,188,189,190,242,243,244,245] |

| Microcon-tact printing (µCP) | 1–10 mm/s; 2–100 nm; 50–70 nm | 1.9 | ZnO, WO3 | Propane, NO, CO, H2 | The method is easily scalable; The method is quite reliable and simple. | Problems with defects and impurities. | [107,193,196,197,199,200,202,203] |

References

- Brattain, W.H.; Bardeen, J. Surface Properties of Germanium. Bell Syst. Tech. J. 1953, 32, 1–41. [Google Scholar] [CrossRef]

- Lojek, B. History of Semiconductor Engineering, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2007; ISBN 978-3-540-34257-1. [Google Scholar]

- Seiyama, T.; Kato, A.; Fujiishi, K.; Nagatani, M. A New Detector for Gaseous Components Using Semiconductive Thin Films. Anal. Chem. 1962, 34, 1502–1503. [Google Scholar] [CrossRef]

- Baker, A.R. Improvements in or Relating to Electrically Heatable Filaments. UK Patent GB892530, 28 March 1962. [Google Scholar]

- Lundström, I.; Shivaraman, S.; Svensson, C.; Lundkvist, L. A Hydrogen—Sensitive MOS Field—Effect Transistor. Appl. Phys. Lett. 1975, 26, 55–57. [Google Scholar] [CrossRef]

- King, W.H. Piezoelectric Sorption Detector. Anal. Chem. 1964, 36, 1735–1739. [Google Scholar] [CrossRef]

- Wohltjen, H.; Dessy, R. Surface Acoustic Wave Probe for Chemical Analysis. I. Introduction and Instrument Description. Anal. Chem. 1979, 51, 1458–1464. [Google Scholar] [CrossRef]

- Lewis, A.; Edwards, P. Validate Personal Air-Pollution Sensors. Nature 2016, 535, 29–31. [Google Scholar] [CrossRef] [Green Version]

- Hunter, G.W.; Akbar, S.; Bhansali, S.; Daniele, M.; Erb, P.D.; Johnson, K.; Liu, C.-C.; Miller, D.; Oralkan, O.; Hesketh, P.J.; et al. Editors’ Choice—Critical Review—A Critical Review of Solid State Gas Sensors. J. Electrochem. Soc. 2020, 167, 037570. [Google Scholar] [CrossRef]

- Korotcenkov, G.; Sysoev, V.V. Chapter 3: Conductometric Metal Oxide Gas Sensors. In Chemical Sensors: Comprehensive Sensor Technologies; Volume 4: Solid State Devices; Korotcenkov, G., Ed.; Momentum Press: New York, NY, USA, 2011; pp. 53–186. [Google Scholar]

- Graf, M.; Gurlo, A.; Bârsan, N.; Weimar, U.; Hierlemann, A. Microfabricated Gas Sensor Systems with Sensitive Nanocrystalline Metal-Oxide Films. J. Nanoparticle Res. 2006, 8, 823–839. [Google Scholar] [CrossRef] [Green Version]

- Naghdi, S.; Rhee, K.; Hui, D.; Park, S. A Review of Conductive Metal Nanomaterials as Conductive, Transparent, and Flexible Coatings, Thin Films, and Conductive Fillers: Different Deposition Methods and Applications. Coatings 2018, 8, 278. [Google Scholar] [CrossRef] [Green Version]

- Tricoli, A.; Righettoni, M.; Teleki, A. Semiconductor Gas Sensors: Dry Synthesis and Application. Angew. Chem. Int. Ed. 2010, 49, 7632–7659. [Google Scholar] [CrossRef] [PubMed]

- Sampaio, P.G.V.; González, M.O.A.; Oliveira Ferreira, P.; Cunha Jácome Vidal, P.; Pereira, J.P.P.; Ferreira, H.R.; Oprime, P.C. Overview of Printing and Coating Techniques in the Production of Organic Photovoltaic Cells. Int. J. Energy Res. 2020, 44, 9912–9931. [Google Scholar] [CrossRef]

- Mondal, K.; McMurtrey, M.D. Present Status of the Functional Advanced Micro-, Nano-Printings—A Mini Review. Mater. Today Chem. 2020, 17, 100328. [Google Scholar] [CrossRef]

- Tong, S.; Sun, J.; Yang, J. Printed Thin-Film Transistors: Research from China. ACS Appl. Mater. Interfaces 2018, 10, 25902–25924. [Google Scholar] [CrossRef]

- Rim, Y.S.; Bae, S.; Chen, H.; De Marco, N.; Yang, Y. Recent Progress in Materials and Devices toward Printable and Flexible Sensors. Adv. Mater. 2016, 28, 4415–4440. [Google Scholar] [CrossRef]

- Garlapati, S.K.; Divya, M.; Breitung, B.; Kruk, R.; Hahn, H.; Dasgupta, S. Printed Electronics Based on Inorganic Semiconductors: From Processes and Materials to Devices. Adv. Mater. 2018, 30, 1–55. [Google Scholar] [CrossRef]

- Li, D.; Lai, W.-Y.; Zhang, Y.-Z.; Huang, W. Printable Transparent Conductive Films for Flexible Electronics. Adv. Mater. 2018, 30, 1704738. [Google Scholar] [CrossRef]

- Pang, Y.; Cao, Y.; Chu, Y.; Liu, M.; Snyder, K.; MacKenzie, D.; Cao, C. Additive Manufacturing of Batteries. Adv. Funct. Mater. 2020, 30, 1906244. [Google Scholar] [CrossRef]

- Hu, G.; Kang, J.; Ng, L.W.T.; Zhu, X.; Howe, R.C.T.; Jones, C.G.; Hersam, M.C.; Hasan, T. Functional Inks and Printing of Two-Dimensional Materials. Chem. Soc. Rev. 2018, 47, 3265–3300. [Google Scholar] [CrossRef] [Green Version]

- Chung, W.-Y.; Lee, D.-D. Characteristics of α-Fe2O3 Thick Film Gas Sensors. Thin Solid Film. 1991, 200, 329–339. [Google Scholar] [CrossRef]

- Korotcenkov, G. Current Trends in Nanomaterials for Metal Oxide-Based Conductometric Gas Sensors: Advantages and Limitations. Part 1: 1D and 2D Nanostructures. Nanomaterials 2020, 10, 1392. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.; Lorenzelli, L.; Dahiya, R.S. Technologies for Printing Sensors and Electronics over Large Flexible Substrates: A Review. IEEE Sens. J. 2015, 15, 3164–3185. [Google Scholar] [CrossRef]

- Fukuda, K.; Someya, T. Recent Progress in the Development of Printed Thin-Film Transistors and Circuits with High-Resolution Printing Technology. Adv. Mater. 2017, 29, 1602736. [Google Scholar] [CrossRef] [PubMed]

- Huang, Q.; Zhu, Y. Patterning of Metal Nanowire Networks: Methods and Applications. ACS Appl. Mater. Interfaces 2021, 13, 60736–60762. [Google Scholar] [CrossRef] [PubMed]

- Fioravanti, A.; Carotta, M.C. Year 2020: A Snapshot of the Last Progress in Flexible Printed Gas Sensors. Appl. Sci. 2020, 10, 1741. [Google Scholar] [CrossRef] [Green Version]

- Alrammouz, R.; Podlecki, J.; Abboud, P.; Sorli, B.; Habchi, R. A Review on Flexible Gas Sensors: From Materials to Devices. Sens. Actuators A Phys. 2018, 284, 209–231. [Google Scholar] [CrossRef]

- Kathirvelan, J. Recent Developments of Inkjet-Printed Flexible Sensing Electronics for Wearable Device Applications: A Review. Sens. Rev. 2021, 41, 46–56. [Google Scholar] [CrossRef]

- Dai, J.; Ogbeide, O.; Macadam, N.; Sun, Q.; Yu, W.; Li, Y.; Su, B.-L.; Hasan, T.; Huang, X.; Huang, W. Printed Gas Sensors. Chem. Soc. Rev. 2020, 49, 1756–1789. [Google Scholar] [CrossRef]

- Manzanares Palenzuela, C.L.; Pumera, M. (Bio)Analytical Chemistry Enabled by 3D Printing: Sensors and Biosensors. TrAC Trends Anal. Chem. 2018, 103, 110–118. [Google Scholar] [CrossRef]

- Sahner, K.; Tuller, H.L. Novel Deposition Techniques for Metal Oxide: Prospects for Gas Sensing. J. Electroceram. 2010, 24, 177–199. [Google Scholar] [CrossRef]

- Araki, T.; Mandamparambil, R.; Jiu, J.; Sekitani, T.; Suganuma, K. Application of Printed Silver Nanowires Based on Laser-Induced Forward Transfer. In Nanomaterials for 2D and 3D Printing; Wiley: Hoboken, NJ, USA, 2017; pp. 265–273. [Google Scholar] [CrossRef]

- Korotcenkov, G. The Role of Morphology and Crystallographic Structure of Metal Oxides in Response of Conductometric-Type Gas Sensors. Mater. Sci. Eng. R Rep. 2008, 61, 1–39. [Google Scholar] [CrossRef]

- Korotcenkov, G.; Cho, B.K. Metal Oxide Composites in Conductometric Gas Sensors: Achievements and Challenges. Sens. Actuators B Chem. 2017, 244, 182–210. [Google Scholar] [CrossRef]

- Sysoev, V.V.; Kiselev, I.; Trouillet, V.; Bruns, M. Enhancing the Gas Selectivity of Single-Crystal SnO2:Pt Thin-Film Chemiresistor Microarray by SiO2 Membrane Coating. Sens. Actuators B Chem. 2013, 185, 59–69. [Google Scholar] [CrossRef]

- Xu, C.; Tamaki, J.; Miura, N.; Yamazoe, N. Grain Size Effects on Gas Sensitivity of Porous SnO2-Based Elements. Sens. Actuators B Chem. 1991, 3, 147–155. [Google Scholar] [CrossRef]

- Potyrailo, R.A. Multivariable Sensors for Ubiquitous Monitoring of Gases in the Era of Internet of Things and Industrial Internet. Chem. Rev. 2016, 116, 11877–11923. [Google Scholar] [CrossRef]

- Nikolaev, K.G.; Ermolenko, Y.E.; Offenhäusser, A.; Ermakov, S.S.; Mourzina, Y.G. Multisensor Systems by Electrochemical Nanowire Assembly for the Analysis of Aqueous Solutions. Front. Chem. 2018, 6, 256. [Google Scholar] [CrossRef] [Green Version]

- Baldwin, E.A.; Bai, J.; Plotto, A.; Dea, S. Electronic Noses and Tongues: Applications for the Food and Pharmaceutical Industries. Sensors 2011, 11, 4744–4766. [Google Scholar] [CrossRef]

- Kiselev, I.; Sysoev, V.; Kaikov, I.; Koronczi, I.; Adil Akai Tegin, R.; Smanalieva, J.; Sommer, M.; Ilicali, C.; Hauptmannl, M. On the Temporal Stability of Analyte Recognition with an E-Nose Based on a Metal Oxide Sensor Array in Practical Applications. Sensors 2018, 18, 550. [Google Scholar] [CrossRef] [Green Version]

- Korotcenkov, G.; Brinzari, V.; Cho, B.K. In2O3- and SnO2-Based Ozone Sensors: Design and Characterization. Crit. Rev. Solid State Mater. Sci. 2018, 43, 83–132. [Google Scholar] [CrossRef]

- Azizi Machekposhti, S.; Movahed, S.; Narayan, R.J. Physicochemical Parameters That Underlie Inkjet Printing for Medical Applications. Biophys. Rev. 2020, 1, 011301. [Google Scholar] [CrossRef]

- Wu, L.; Dong, Z.; Li, F.; Zhou, H.; Song, Y. Emerging Progress of Inkjet Technology in Printing Optical Materials. Adv. Opt. Mater. 2016, 4, 1915–1932. [Google Scholar] [CrossRef]

- Derby, B. Inkjet Printing of Functional and Structural Materials: Fluid Property Requirements, Feature Stability, and Resolution. Annu. Rev. Mater. Res. 2010, 40, 395–414. [Google Scholar] [CrossRef]

- Soltman, D.; Subramanian, V. Inkjet-Printed Line Morphologies and Temperature Control of the Coffee Ring Effect. Langmuir 2008, 24, 2224–2231. [Google Scholar] [CrossRef] [PubMed]

- Xie, M.; Wu, S.; Chen, Z.; Khan, Q.; Wu, X.; Shao, S.; Cui, Z. Performance Improvement for Printed Indium Gallium Zinc Oxide Thin-Film Transistors with a Preheating Process. RSC Adv. 2016, 6, 41439–41446. [Google Scholar] [CrossRef]

- Kim, Y.H.; Kim, K.H.; Oh, M.S.; Kim, H.J.; Han, J.I.; Han, M.K.; Park, S.K. Ink-Jet-Printed Zinc–Tin–Oxide Thin-Film Transistors and Circuits With Rapid Thermal Annealing Process. IEEE Electron. Device Lett. 2010, 31, 836–838. [Google Scholar] [CrossRef]

- Sui, Y.; Zorman, C.A. Review—Inkjet Printing of Metal Structures for Electrochemical Sensor Applications. J. Electrochem. Soc. 2020, 167, 037571. [Google Scholar] [CrossRef]

- Singh, M.; Haverinen, H.M.; Dhagat, P.; Jabbour, G.E. Inkjet Printing-Process and Its Applications. Adv. Mater. 2010, 22, 673–685. [Google Scholar] [CrossRef]

- Li, J.; Rossignol, F.; Macdonald, J. Inkjet Printing for Biosensor Fabrication: Combining Chemistry and Technology for Advanced Manufacturing. Lab. Chip 2015, 15, 2538–2558. [Google Scholar] [CrossRef]

- Kamyshny, A.; Magdassi, S. Metallic Nanoinks for Inkjet Printing of Conductive 2D and 3D Structures. In Nanomaterials for 2D and 3D Printing; Wiley-VCH Verlag GmbH & Co., KGaA: Weinheim, Germany, 2017; pp. 119–160. [Google Scholar]

- Minemawari, H.; Yamada, T.; Matsui, H.; Tsutsumi, J.Y.; Haas, S.; Chiba, R.; Kumai, R.; Hasegawa, T. Inkjet Printing of Single-Crystal Films. Nature 2011, 475, 364–367. [Google Scholar] [CrossRef]

- Sajedi-Moghaddam, A.; Rahmanian, E.; Naseri, N. Inkjet-Printing Technology for Supercapacitor Application: Current State and Perspectives. ACS Appl. Mater. Interfaces 2020, 12, 34487–34504. [Google Scholar] [CrossRef]

- Alshammari, A.S.; Alenezi, M.R.; Lai, K.T.; Silva, S.R.P. Inkjet Printing of Polymer Functionalized CNT Gas Sensor with Enhanced Sensing Properties. Mater. Lett. 2017, 189, 299–302. [Google Scholar] [CrossRef]

- Simonenko, E.P.; Mokrushin, A.S.; Simonenko, N.P.; Voronov, V.A.; Kim, V.P.; Tkachev, S.V.; Gubin, S.P.; Sevastyanov, V.G.; Kuznetsov, N.T. Ink-Jet Printing of a TiO2–10%ZrO2 Thin Film for Oxygen Detection Using a Solution of Metal Alkoxoacetylacetonates. Thin Solid Film. 2019, 670, 46–53. [Google Scholar] [CrossRef]

- Wilkinson, N.J.; Kay, R.W.; Harris, R.A. Electrohydrodynamic and Aerosol Jet Printing for the Copatterning of Polydimethylsiloxane and Graphene Platelet Inks. Adv. Mater. Technol. 2020, 5, 2000148. [Google Scholar] [CrossRef]

- Zhu, Y.; Yu, L.; Wu, D.; Lv, W.; Wang, L. A High-Sensitivity Graphene Ammonia Sensor via Aerosol Jet Printing. Sens. Actuators A Phys. 2021, 318, 112434. [Google Scholar] [CrossRef]

- Jung, W.; Jung, Y.H.; Pikhitsa, P.V.; Feng, J.; Yang, Y.; Kim, M.; Tsai, H.Y.; Tanaka, T.; Shin, J.; Kim, K.Y.; et al. Three-Dimensional Nanoprinting via Charged Aerosol Jets. Nature 2021, 592, 54–59. [Google Scholar] [CrossRef]

- Efimov, A.A.; Arsenov, P.V.; Minkov, K.N.; Ivanov, V.V. Fabrication of Metallic Lines by Aerosol Jet Printing: Study of the Effect of Substrate Temperature on the Aspect Ratio. Orient. J. Chem. 2018, 34, 2777–2781. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Moon, S.K.; Ngo, T.H. Hybrid Machine Learning Method to Determine the Optimal Operating Process Window in Aerosol Jet 3D Printing. ACS Appl. Mater. Interfaces 2019, 11, 17994–18003. [Google Scholar] [CrossRef]

- Lu, S.; Cardenas, J.A.; Worsley, R.; Williams, N.X.; Andrews, J.B.; Casiraghi, C.; Franklin, A.D. Flexible, Print-in-Place 1D-2D Thin-Film Transistors Using Aerosol Jet Printing. ACS Nano 2019, 13, 11263–11272. [Google Scholar] [CrossRef]

- Chen, G.; Gu, Y.; Tsang, H.; Hines, D.R.; Das, S. The Effect of Droplet Sizes on Overspray in Aerosol-Jet Printing. Adv. Eng. Mater. 2018, 20, 1–13. [Google Scholar] [CrossRef]

- Tu, L.; Yuan, S.; Zhang, H.; Wang, P.; Cui, X.; Wang, J.; Zhan, Y.Q.; Zheng, L.R. Aerosol Jet Printed Silver Nanowire Transparent Electrode for Flexible Electronic Application. J. Appl. Phys. 2018, 123, 174905. [Google Scholar] [CrossRef]

- Lu, S.; Zheng, J.; Cardenas, J.A.; Williams, N.X.; Lin, Y.C.; Franklin, A.D. Uniform and Stable Aerosol Jet Printing of Carbon Nanotube Thin-Film Transistors by Ink Temperature Control. ACS Appl. Mater. Interfaces 2020, 12, 43083–43089. [Google Scholar] [CrossRef] [PubMed]

- Gupta, A.A.; Arunachalam, S.; Cloutier, S.G.; Izquierdo, R. Fully Aerosol-Jet Printed, High-Performance Nanoporous ZnO Ultraviolet Photodetectors. ACS Photonics 2018, 5, 3923–3929. [Google Scholar] [CrossRef]

- Arsenov, P.V.; Vlasov, I.S.; Efimov, A.A.; Minkov, K.N.; Ivanov, V.V. Aerosol Jet Printing of Platinum Microheaters for the Application in Gas Sensors. IOP Conf. Ser. Mater. Sci. Eng. 2019, 473, 012042. [Google Scholar] [CrossRef]

- Exner, J.; Albrecht, G.; Schönauer-Kamin, D.; Kita, J.; Moos, R. Pulsed Polarization-Based NOx Sensors of YSZ Films Produced by the Aerosol Deposition Method and by Screen-Printing. Sensors 2017, 17, 1715. [Google Scholar] [CrossRef] [Green Version]

- Rahman, M.T.; Cheng, C.Y.; Karagoz, B.; Renn, M.; Schrandt, M.; Gellman, A.; Panat, R. High Performance Flexible Temperature Sensors via Nanoparticle Printing. ACS Appl. Nano Mater. 2019, 2, 3280–3291. [Google Scholar] [CrossRef]

- Borghetti, M.; Cantù, E.; Sardini, E.; Serpelloni, M. Future Sensors for Smart Objects by Printing Technologies in Industry 4.0 Scenario. Energies 2020, 13, 5916. [Google Scholar] [CrossRef]

- Rossi, S.; Puglisi, A.; Benaglia, M. Additive Manufacturing Technologies: 3D Printing in Organic Synthesis. ChemCatChem 2018, 10, 1512–1525. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zhang, F.; Yan, Z.; Ma, Q.; Li, X.; Huang, Y.; Rogers, J.A. Printing, Folding and Assembly Methods for Forming 3D Mesostructures in Advanced Materials. Nat. Rev. Mater. 2017, 2, 17019. [Google Scholar] [CrossRef]

- Pawar, A.A.; Halivni, S.; Waiskopf, N.; Ben-Shahar, Y.; Soreni-Harari, M.; Bergbreiter, S.; Banin, U.; Magdassi, S. Rapid Three-Dimensional Printing in Water Using Semiconductor-Metal Hybrid Nanoparticles as Photoinitiators. Nano Lett. 2017, 17, 4497–4501. [Google Scholar] [CrossRef] [Green Version]

- Siebert, L.; Wolff, N.; Ababii, N.; Terasa, M.-I.; Lupan, O.; Vahl, A.; Duppel, V.; Qiu, H.; Tienken, M.; Mirabelli, M.; et al. Facile Fabrication of Semiconducting Oxide Nanostructures by Direct Ink Writing of Readily Available Metal Microparticles and Their Application as Low Power Acetone Gas Sensors. Nano Energy 2020, 70, 104420. [Google Scholar] [CrossRef]

- Chaloeipote, G.; Prathumwan, R.; Subannajui, K.; Wisitsoraat, A.; Wongchoosuk, C. 3D Printed CuO Semiconducting Gas Sensor for Ammonia Detection at Room Temperature. Mater. Sci. Semicond. Process. 2021, 123, 105546. [Google Scholar] [CrossRef]

- Abdalla, A.; Patel, B.A. 3D-Printed Electrochemical Sensors: A New Horizon for Measurement of Biomolecules. Curr. Opin. Electrochem. 2020, 20, 78–81. [Google Scholar] [CrossRef]

- Xu, C.; Liu, T.; Guo, W.; Sun, Y.; Liang, C.; Cao, K.; Guan, T.; Liang, Z.; Jiang, L. 3D Printing of Powder-Based Inks into Functional Hierarchical Porous TiO2 Materials. Adv. Eng. Mater. 2020, 22, 1–8. [Google Scholar] [CrossRef]

- Qiu, Z.; Shu, J.; Liu, J.; Tang, D. Dual-Channel Photoelectrochemical Ratiometric Aptasensor with up-Converting Nanocrystals Using Spatial-Resolved Technique on Homemade 3D Printed Device. Anal. Chem. 2019, 91, 1260–1268. [Google Scholar] [CrossRef]

- Mayer, F.; Richter, S.; Westhauser, J.; Blasco, E.; Barner-Kowollik, C.; Wegener, M. Multimaterial 3D Laser Microprinting Using an Integrated Microfluidic System. Sci. Adv. 2019, 5, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Costantini, M.; Jaroszewicz, J.; Kozoń, Ł.; Szlązak, K.; Święszkowski, W.; Garstecki, P.; Stubenrauch, C.; Barbetta, A.; Guzowski, J. 3D-Printing of Functionally Graded Porous Materials Using On-Demand Reconfigurable Microfluidics. Angew. Chem. Int. Ed. 2019, 58, 7620–7625. [Google Scholar] [CrossRef]

- Dang, W.; Li, T.; Li, B.; Ma, H.; Zhai, D.; Wang, X.; Chang, J.; Xiao, Y.; Wang, J.; Wu, C. A Bifunctional Scaffold with CuFeSe2 Nanocrystals for Tumor Therapy and Bone Reconstruction. Biomaterials 2018, 160, 92–106. [Google Scholar] [CrossRef]

- Liu, S.; Shi, X.; Li, X.; Sun, Y.; Zhu, J.; Pei, Q.; Liang, J.; Chen, Y. A General Gelation Strategy for 1D Nanowires: Dynamically Stable Functional Gels for 3D Printing Flexible Electronics. Nanoscale 2018, 10, 20096–20107. [Google Scholar] [CrossRef]

- Loke, G.; Yuan, R.; Rein, M.; Khudiyev, T.; Jain, Y.; Joannopoulos, J.; Fink, Y. Structured Multimaterial Filaments for 3D Printing of Optoelectronics. Nat. Commun. 2019, 10, 4010. [Google Scholar] [CrossRef] [Green Version]

- Prasad, L.K.; Smyth, H. 3D Printing Technologies for Drug Delivery: A Review. Drug Dev. Ind. Pharm. 2016, 42, 1019–1031. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, Y.; Wei, J.; Du, Y.; Zhang, L.; Lin, F. Preparation of Ordered MAPbI3 Perovskite Needle-Like Crystal Films by Electric Field and Microdroplet Jetting 3D Printing. Cryst. Growth Des. 2020, 20, 1405–1414. [Google Scholar] [CrossRef]

- Nerger, B.A.; Brun, P.T.; Nelson, C.M. Microextrusion Printing Cell-Laden Networks of Type I Collagen with Patterned Fiber Alignment and Geometry. Soft Matter 2019, 15, 5728–5738. [Google Scholar] [CrossRef] [PubMed]

- Udofia, E.N.; Zhou, W. A Guiding Framework for Microextrusion Additive Manufacturing. J. Manuf. Sci. Eng. Trans. ASME 2019, 141, 050801. [Google Scholar] [CrossRef]

- Mokrushin, A.S.; Simonenko, T.L.; Simonenko, N.P.; Gorobtsov, P.Y.; Bocharova, V.A.; Kozodaev, M.G.; Markeev, A.M.; Lizunova, A.A.; Volkov, I.A.; Simonenko, E.P.; et al. Microextrusion Printing of Gas-Sensitive Planar Anisotropic NiO Nanostructures and Their Surface Modification in an H2S Atmosphere. Appl. Surf. Sci. 2022, 578, 151984. [Google Scholar] [CrossRef]

- Murphy, S.V.; Atala, A. 3D Bioprinting of Tissues and Organs. Nat. Biotechnol. 2014, 32, 773–785. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Li, Y.; Mao, S.; Sun, W.; Yao, R. The Influence of Printing Parameters on Cell Survival Rate and Printability in Microextrusion-Based 3D Cell Printing Technology. Biofabrication 2015, 7, 45002. [Google Scholar] [CrossRef]

- Olate-Moya, F.; Arens, L.; Wilhelm, M.; Mateos-Timoneda, M.A.; Engel, E.; Palza, H. Chondroinductive Alginate-Based Hydrogels Having Graphene Oxide for 3D Printed Scaffold Fabrication. ACS Appl. Mater. Interfaces 2020, 12, 4343–4357. [Google Scholar] [CrossRef]

- Yang, R.; Gao, T.; Li, D.; Chen, Y.; Jin, G.; Liang, H.; Niu, F. Transparent and Flexible Force Sensor Based on Microextrusion 3D Printing. Micro Nano Lett. 2018, 13, 1460–1464. [Google Scholar] [CrossRef]

- Sun, G.; An, J.; Chua, C.K.; Pang, H.; Zhang, J.; Chen, P. Layer-by-Layer Printing of Laminated Graphene-Based Interdigitated Microelectrodes for Flexible Planar Micro-Supercapacitors. Electrochem. Commun. 2015, 51, 33–36. [Google Scholar] [CrossRef]

- Seo, H.; Kishimoto, M.; Ding, C.; Iwai, H.; Saito, M.; Yoshida, H. Improvement in the Electrochemical Performance of Anode-Supported Solid Oxide Fuel Cells by Meso- and Nanoscale Structural Modifications. Fuel Cells 2020, 20, 570–579. [Google Scholar] [CrossRef]

- Seo, H.; Iwai, H.; Kishimoto, M.; Ding, C.; Saito, M.; Yoshida, H. Microextrusion Printing for Increasing Electrode–Electrolyte Interface in Anode-Supported Solid Oxide Fuel Cells. J. Power Sources 2020, 450, 227682. [Google Scholar] [CrossRef]

- Seo, H.; Nishi, T.; Kishimoto, M.; Ding, C.; Iwai, H.; Saito, M.; Yoshida, H. Study of Microextrusion Printing for Enlarging Electrode–Electrolyte Interfacial Area in Anode-Supported SOFCs. ECS Trans. 2019, 91, 1923–1931. [Google Scholar] [CrossRef]

- Deng, J.; Wang, M.; Yang, Z.; Yang, Y.; Zhang, P. Preparation of TiO2 Nanoparticles Two-Dimensional Photonic-Crystals: A Novel Scattering Layer of Quantum Dot-Sensitized Solar Cells. Mater. Lett. 2016, 183, 307–310. [Google Scholar] [CrossRef]

- Nathan-Walleser, T.; Lazar, I.M.; Fabritius, M.; Tölle, F.J.; Xia, Q.; Bruchmann, B.; Venkataraman, S.S.; Schwab, M.G.; Mülhaupt, R. 3D Micro-Extrusion of Graphene-Based Active Electrodes: Towards High-Rate AC Line Filtering Performance Electrochemical Capacitors. Adv. Funct. Mater. 2014, 24, 4706–4716. [Google Scholar] [CrossRef]

- Singh, M.; Haring, A.P.; Tong, Y.; Cesewski, E.; Ball, E.; Jasper, R.; Davis, E.M.; Johnson, B.N. Additive Manufacturing of Mechanically Isotropic Thin Films and Membranes via Microextrusion 3D Printing of Polymer Solutions. ACS Appl. Mater. Interfaces 2019, 11, 6652–6661. [Google Scholar] [CrossRef]

- Simonenko, N.P.; Kadyrov, N.S.; Simonenko, T.L.; Simonenko, E.P.; Sevastyanov, V.G.; Kuznetsov, N.T. Preparation of ZnS Nanopowders and Their Use in the Additive Production of Thick-Film Structures. Russ. J. Inorg. Chem. 2021, 66, 1283–1288. [Google Scholar] [CrossRef]

- Simonenko, T.L.; Simonenko, N.P.; Gorobtsov, P.Y.; Mokrushin, A.S.; Solovey, V.R.; Pozharnitskaya, V.M.; Simonenko, E.P.; Glumov, O.V.; Melnikova, N.A.; Lizunova, A.A.; et al. Pen Plotter Printing of Co3O4 Thin Films: Features of the Microstructure, Optical, Electrophysical and Gas-Sensing Properties. J. Alloys Compd. 2020, 832, 154957. [Google Scholar] [CrossRef]

- Mokrushin, A.S.; Fisenko, N.A.; Gorobtsov, P.Y.; Simonenko, T.L.; Glumov, O.V.; Melnikova, N.A.; Simonenko, N.P.; Bukunov, K.A.; Simonenko, E.P.; Sevastyanov, V.G.; et al. Pen Plotter Printing of ITO Thin Film as a Highly CO Sensitive Component of a Resistive Gas Sensor. Talanta 2021, 221, 121455. [Google Scholar] [CrossRef]

- Amin, R.; Ghaderinezhad, F.; Li, L.; Lepowsky, E.; Yenilmez, B.; Knowlton, S.; Tasoglu, S. Continuous-Ink, Multiplexed Pen-Plotter Approach for Low-Cost, High-Throughput Fabrication of Paper-Based Microfluidics. Anal. Chem. 2017, 89, 6351–6357. [Google Scholar] [CrossRef]

- Soum, V.; Cheong, H.; Kim, K.; Kim, Y.; Chuong, M.; Ryu, S.R.; Yuen, P.K.; Kwon, O.S.; Shin, K. Programmable Contact Printing Using Ballpoint Pens with a Digital Plotter for Patterning Electrodes on Paper. ACS Omega 2018, 3, 16866–16873. [Google Scholar] [CrossRef]

- Liu, S.; Cao, R.; Wu, J.; Guan, L.; Li, M.; Liu, J.; Tian, J. Directly Writing Barrier-Free Patterned Biosensors and Bioassays on Paper for Low-Cost Diagnostics. Sens. Actuators B Chem. 2019, 285, 529–535. [Google Scholar] [CrossRef]

- Simonenko, T.L.; Simonenko, N.P.; Gorobtsov, P.Y.; Vlasov, I.S.; Solovey, V.R.; Shelaev, A.V.; Simonenko, E.P.; Glumov, O.V.; Melnikova, N.A.; Kozodaev, M.G.; et al. Microplotter Printing of Planar Solid Electrolytes in the CeO2–Y2O3 System. J. Colloid Interface Sci. 2021, 588, 209–220. [Google Scholar] [CrossRef] [PubMed]

- Fedorov, F.S.; Simonenko, N.P.; Trouillet, V.; Volkov, I.A.; Plugin, I.A.; Rupasov, D.P.; Mokrushin, A.S.; Nagornov, I.A.; Simonenko, T.L.; Vlasov, I.S.; et al. Microplotter-Printed On-Chip Combinatorial Library of Ink-Derived Multiple Metal Oxides as an “Electronic Olfaction” Unit. ACS Appl. Mater. Interfaces 2020, 12, 56135–56150. [Google Scholar] [CrossRef]

- Molazemhosseini, A.; Magagnin, L.; Vena, P.; Liu, C.C. Single-Use Nonenzymatic Glucose Biosensor Based on CuO Nanoparticles Ink Printed on Thin Film Gold Electrode by Micro-Plotter Technology. J. Electroanal. Chem. 2017, 789, 50–57. [Google Scholar] [CrossRef]

- Fragua, D.M.; Abargues, R.; Rodriguez-Canto, P.J.; Sanchez-Royo, J.F.; Agouram, S.; Martinez-Pastor, J.P. Au-ZnO Nanocomposite Films for Plasmonic Photocatalysis. Adv. Mater. Interfaces 2015, 2, 1500156. [Google Scholar] [CrossRef]

- Abargues, R.; Rodriguez-Canto, P.J.; Albert, S.; Suarez, I.; Martínez-Pastor, J.P. Plasmonic Optical Sensors Printed from Ag-PVA Nanoinks. J. Mater. Chem. C 2014, 2, 908–915. [Google Scholar] [CrossRef]

- Dai, Y.; Huang, J.; Zhang, H.; Liu, C.C. Highly Sensitive Electrochemical Analysis of Tunnel Structured MnO2 Nanoparticle-Based Sensors on the Oxidation of Nitrite. Sens. Actuators B Chem. 2019, 281, 746–750. [Google Scholar] [CrossRef]

- Zang, Z.; Tang, X.; Liu, X.; Lei, X.; Chen, W. Fabrication of High Quality and Low Cost Microlenses on a Glass Substrate by Direct Printing Technique. Appl. Opt. 2014, 53, 7868. [Google Scholar] [CrossRef]

- Abargues, R.; Martinez-Marco, M.L.; Rodriguez-Canto, P.J.; Marques-Hueso, J.; Martinez-Pastor, J.P. Metal-Polymer Nanocomposite Resist: A Step towards in-Situ Nanopatterns Metallization. In Advances in Resist Materials and Processing Technology XXX; SPIE: Bellingham, WA USA, 2013; Volume 8682, p. 86820X. [Google Scholar] [CrossRef]

- Robinson, A.P.; Minev, I.; Graz, I.M.; Lacour, S.P. Microstructured Silicone Substrate for Printable and Stretchable Metallic Films. Langmuir 2011, 27, 4279–4284. [Google Scholar] [CrossRef]

- Li, Q.; Li, S.; Yang, D.; Su, W.; Wang, Y.; Zhou, W.; Liu, H.; Xie, S. Designing Hybrid Gate Dielectric for Fully Printing High-Performance Carbon Nanotube Thin Film Transistors. Nanotechnology 2017, 28. [Google Scholar] [CrossRef] [Green Version]

- Cai, L.; Zhang, S.; Miao, J.; Yu, Z.; Wang, C. Fully Printed Stretchable Thin-Film Transistors and Integrated Logic Circuits. ACS Nano 2016, 10, 11459–11468. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Yan, Y.; Gao, Z.; Du, Y.; Dong, H.; Yao, J.; Zhao, Y.S. Full-Color Laser Displays Based on Organic Printed Microlaser Arrays. Nat. Commun. 2019, 10, 870. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, F.F.; Li, Y.J.; Lv, Y.; Dong, H.; Lin, X.; Wang, K.; Yao, J.; Zhao, Y.S. Flat-Panel Laser Displays Based on Liquid Crystal Microlaser Arrays. CCS Chem. 2020, 2, 369–375. [Google Scholar] [CrossRef]

- Wang, X.; Guo, W.; Zhu, Y.; Liang, X.; Wang, F.; Peng, P. Electrical and Mechanical Properties of Ink Printed Composite Electrodes on Plastic Substrates. Appl. Sci. 2018, 8, 2101. [Google Scholar] [CrossRef] [Green Version]

- Mokrushin, A.S.; Nagornov, I.A.; Simonenko, T.L.; Simonenko, N.P.; Gorobtsov, P.Y.; Khamova, T.V.; Kopitsa, G.P.; Evzrezov, A.N.; Simonenko, E.P.; Sevastyanov, V.G.; et al. Chemoresistive Gas-Sensitive ZnO/Pt Nanocomposites Films Applied by Microplotter Printing with Increased Sensitivity to Benzene and Hydrogen. Mater. Sci. Eng. B 2021, 271, 115233. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Wang, Y.; Cheng, T.; Yao, L.Q.; Li, X.; Lai, W.Y.; Huang, W. Printed Supercapacitors: Materials, Printing and Applications. Chem. Soc. Rev. 2019, 48, 3229–3264. [Google Scholar] [CrossRef]

- Xu, C.; Willenbacher, N. How Rheological Properties Affect Fine-Line Screen Printing of Pastes: A Combined Rheological and High-Speed Video Imaging Study. J. Coat. Technol. Res. 2018, 15, 1401–1412. [Google Scholar] [CrossRef]

- Sopeña, P.; Fernández-Pradas, J.M.; Serra, P. Laser-Induced Forward Transfer of Conductive Screen-Printing Inks. Appl. Surf. Sci. 2020, 507, 145047. [Google Scholar] [CrossRef]

- Dubourg, G.; Segkos, A.; Katona, J.; Radović, M.; Savić, S.; Niarchos, G.; Tsamis, C.; Crnojević-Bengin, V. Fabrication and Characterization of Flexible and Miniaturized Humidity Sensors Using Screen-Printed TiO2 Nanoparticles as Sensitive Layer. Sensors 2017, 17, 1854. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Zhang, Q.; Lv, R.; Wu, D.; Zhang, S. Enhancing Formaldehyde Selectivity of SnO2 Gas Sensors with the ZSM-5 Modified Layers. Sensors 2021, 21, 3947. [Google Scholar] [CrossRef]

- Lamas-Ardisana, P.J.; Martínez-Paredes, G.; Añorga, L.; Grande, H.J. Glucose Biosensor Based on Disposable Electrochemical Paper-Based Transducers Fully Fabricated by Screen-Printing. Biosens. Bioelectron. 2018, 109, 8–12. [Google Scholar] [CrossRef] [PubMed]

- Smith, S.; Madzivhandila, P.; Ntuli, L.; Bezuidenhout, P.; Zheng, H.; Land, K. Printed Paper–Based Electrochemical Sensors for Low-Cost Point-of-Need Applications. Electrocatalysis 2019, 10, 342–351. [Google Scholar] [CrossRef]

- Ahammad, A.J.S.; Islam, T.; Hasan, M.M.; Mozumder, M.N.I.; Karim, R.; Odhikari, N.; Pal, P.R.; Sarker, S.; Kim, D.M. Reduced Graphene Oxide Screen-Printed FTO as Highly Sensitive Electrodes for Simultaneous Determination of Dopamine and Uric Acid. J. Electrochem. Soc. 2018, 165, B174–B183. [Google Scholar] [CrossRef]

- He, P.; Cao, J.; Ding, H.; Liu, C.; Neilson, J.; Li, Z.; Kinloch, I.A.; Derby, B. Screen-Printing of a Highly Conductive Graphene Ink for Flexible Printed Electronics. ACS Appl. Mater. Interfaces 2019, 11, 32225–32234. [Google Scholar] [CrossRef] [PubMed]

- Cao, R.; Pu, X.; Du, X.; Yang, W.; Wang, J.; Guo, H.; Zhao, S.; Yuan, Z.; Zhang, C.; Li, C.; et al. Screen-Printed Washable Electronic Textiles as Self-Powered Touch/Gesture Tribo-Sensors for Intelligent Human-Machine Interaction. ACS Nano 2018, 12, 5190–5196. [Google Scholar] [CrossRef] [PubMed]

- Rong, Y.; Ming, Y.; Ji, W.; Li, D.; Mei, A.; Hu, Y.; Han, H. Toward Industrial-Scale Production of Perovskite Solar Cells: Screen Printing, Slot-Die Coating, and Emerging Techniques. J. Phys. Chem. Lett. 2018, 9, 2707–2713. [Google Scholar] [CrossRef]

- Liu, Y.; Ren, W.; Shi, P.; Liu, D.; Zhang, Y.; Liu, M.; Ye, Z.-G.; Jing, W.; Tian, B.; Jiang, Z. A Highly Thermostable In2O3/ITO Thin Film Thermocouple Prepared via Screen Printing for High Temperature Measurements. Sensors 2018, 18, 958. [Google Scholar] [CrossRef] [Green Version]

- Squissato, A.L.; Munoz, R.A.A.; Banks, C.E.; Richter, E.M. An Overview of Recent Electroanalytical Applications Utilizing Screen-Printed Electrodes Within Flow Systems. ChemElectroChem 2020, 7, 2211–2221. [Google Scholar] [CrossRef]

- Merklein, L.; Daume, D.; Braig, F.; Schlisske, S.; Rödlmeier, T.; Mink, M.; Kourkoulos, D.; Ulber, B.; Di Biase, M.; Meerholz, K.; et al. Comparative Study of Printed Multilayer OLED Fabrication through Slot Die Coating, Gravure and Inkjet Printing, and Their Combination. Colloids Interfaces 2019, 3, 32. [Google Scholar] [CrossRef] [Green Version]

- Sico, G.; Montanino, M.; Prontera, C.T.; De Girolamo Del Mauro, A.; Minarini, C. Gravure Printing for Thin Film Ceramics Manufacturing from Nanoparticles. Ceram. Int. 2018, 44, 19526–19534. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Yang, T.Y.; Suhonen, R.; Välimäki, M.; Maaninen, T.; Kemppainen, A.; Jeon, N.J.; Seo, J. Gravure-Printed Flexible Perovskite Solar Cells: Toward Roll-to-Roll Manufacturing. Adv. Sci. 2019, 6, 1802094. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Herzog, N.; Brilmayer, R.; Stanzel, M.; Kalyta, A.; Spiehl, D.; Dörsam, E.; Hess, C.; Andrieu-Brunsen, A. Gravure Printing for Mesoporous Film Preparation. RSC Adv. 2019, 9, 23570–23578. [Google Scholar] [CrossRef] [Green Version]

- Secor, E.B.; Lim, S.; Zhang, H.; Frisbie, C.D.; Francis, L.F.; Hersam, M.C. Gravure Printing of Graphene for Large-Area Flexible Electronics. Adv. Mater. 2014, 26, 4533–4538. [Google Scholar] [CrossRef] [PubMed]

- Subramanian, V.; Cen, J.; de la Fuente Vornbrock, A.; Grau, G.; Kang, H.; Kitsomboonloha, R.; Soltman, D.; Tseng, H.-Y. High-Speed Printing of Transistors: From Inks to Devices. Proc. IEEE 2015, 103, 567–582. [Google Scholar] [CrossRef]

- Li, X.; Kim, N.; Youn, S.; An, T.; Kim, J.; Lim, S.; Kim, S. Sol–Gel-Processed Organic–Inorganic Hybrid for Flexible Conductive Substrates Based on Gravure-Printed Silver Nanowires and Graphene. Polymers 2019, 11, 158. [Google Scholar] [CrossRef] [Green Version]

- Calvi, S.; Maita, F.; Rapisarda, M.; Fortunato, G.; Valletta, A.; Preziosi, V.; Cassinese, A.; Mariucci, L. Gravure Printed Organic Thin Film Transistors: Study on the Ink Printability Improvement. Org. Electron. 2018, 61, 104–112. [Google Scholar] [CrossRef]

- Xiao, Y.; Huang, L.; Zhang, Q.; Xu, S.; Chen, Q.; Shi, W. Gravure Printing of Hybrid MoS2@S-RGO Interdigitated Electrodes for Flexible Microsupercapacitors. Appl. Phys. Lett. 2015, 107, 013906. [Google Scholar] [CrossRef]

- Park, J.D.; Lim, S.; Kim, H. Patterned Silver Nanowires Using the Gravure Printing Process for Flexible Applications. Thin Solid Film. 2015, 586, 70–75. [Google Scholar] [CrossRef]

- Homenick, C.M.; James, R.; Lopinski, G.P.; Dunford, J.; Sun, J.; Park, H.; Jung, Y.; Cho, G.; Malenfant, P.R.L. Fully Printed and Encapsulated SWCNT-Based Thin Film Transistors via a Combination of R2R Gravure and Inkjet Printing. ACS Appl. Mater. Interfaces 2016, 8, 27900–27910. [Google Scholar] [CrossRef] [Green Version]

- Chen, L.; Huang, L.; Lin, Y.; Sai, L.; Chang, Q.; Shi, W.; Chen, Q. Fully Gravure-Printed WO3/Pt-Decorated RGO Nanosheets Composite Film for Detection of Acetone. Sens. Actuators B Chem. 2018, 255, 1482–1490. [Google Scholar] [CrossRef]

- Garcia, A.J.L.; Sico, G.; Montanino, M.; Defoor, V.; Pusty, M.; Mescot, X.; Loffredo, F.; Villani, F.; Nenna, G.; Ardila, G. Low-Temperature Growth of ZnO Nanowires from Gravure-Printed ZnO Nanoparticle Seed Layers for Flexible Piezoelectric Devices. Nanomaterials 2021, 11, 1430. [Google Scholar] [CrossRef] [PubMed]

- Olmos, C.M.; Vaca, A.; Rosero, G.; Peñaherrera, A.; Perez, C.; de Sá Carneiro, I.; Vizuete, K.; Arroyo, C.R.; Debut, A.; Pérez, M.S.; et al. Epoxy Resin Mold and PDMS Microfluidic Devices through Photopolymer Flexographic Printing Plate. Sens. Actuators B Chem. 2019, 288, 742–748. [Google Scholar] [CrossRef]

- Mäkelä, T.; Jussila, S.; Kosonen, H.; Bäcklund, T.G.; Sandberg, H.G.O.; Stubb, H. Utilizing Roll-to-Roll Techniques for Manufacturing Source-Drain Electrodes for All-Polymer Transistors. Synth. Met. 2005, 153, 285–288. [Google Scholar] [CrossRef]

- Alem, S.; Graddage, N.; Lu, J.; Kololuoma, T.; Movileanu, R.; Tao, Y. Flexographic Printing of Polycarbazole-Based Inverted Solar Cells. Org. Electron. 2018, 52, 146–152. [Google Scholar] [CrossRef]

- Tomašegović, T.; Mahović Poljaček, S.; Strižić Jakovljević, M.; Urbas, R. Effect of the Common Solvents on UV-Modified Photopolymer and EPDM Flexographic Printing Plates and Printed Ink Films. Coatings 2020, 10, 136. [Google Scholar] [CrossRef] [Green Version]

- Assaifan, A.K.; Al habis, N.; Ahmad, I.; Alshehri, N.A.; Alharbi, H.F. Scaling-up Medical Technologies Using Flexographic Printing. Talanta 2020, 219, 121236. [Google Scholar] [CrossRef]

- Zhong, Z.W.; Ee, J.H.; Chen, S.H.; Shan, X.C. Parametric Investigation of Flexographic Printing Processes for R2R Printed Electronics. Mater. Manuf. Process. 2020, 35, 564–571. [Google Scholar] [CrossRef]

- Morgan, M.L.; Curtis, D.J.; Deganello, D. Control of Morphological and Electrical Properties of Flexographic Printed Electronics through Tailored Ink Rheology. Org. Electron. 2019, 73, 212–218. [Google Scholar] [CrossRef]

- Morgan, M.L.; Holder, A.; Curtis, D.J.; Deganello, D. Formulation, Characterisation and Flexographic Printing of Novel Boger Fluids to Assess the Effects of Ink Elasticity on Print Uniformity. Rheol. Acta 2018, 57, 105–112. [Google Scholar] [CrossRef] [Green Version]

- Żołek-Tryznowska, Z.; Rombel, M.; Petriaszwili, G.; Dedijer, S.; Kašiković, N. Influence of Some Flexographic Printing Process Conditions on the Optical Density and Tonal Value Increase of Overprinted Plastic Films. Coatings 2020, 10, 816. [Google Scholar] [CrossRef]

- Lloyd, J.S.; Fung, C.M.; Deganello, D.; Wang, R.J.; Maffeis, T.G.G.; Lau, S.P.; Teng, K.S. Flexographic Printing-Assisted Fabrication of ZnO Nanowire Devices. Nanotechnology 2013, 24, 195602. [Google Scholar] [CrossRef] [PubMed]

- Cosnahan, T.; Watt, A.A.R.; Assender, H.E. Flexography Printing for Organic Thin Film Transistors. Mater. Today Proc. 2018, 5, 16051–16057. [Google Scholar] [CrossRef]

- Carlos, E.; Leppäniemi, J.; Sneck, A.; Alastalo, A.; Deuermeier, J.; Branquinho, R.; Martins, R.; Fortunato, E. Printed, Highly Stable Metal Oxide Thin-Film Transistors with Ultra-Thin High-κ Oxide Dielectric. Adv. Electron. Mater. 2020, 6, 1901071. [Google Scholar] [CrossRef]

- Dilfer, S.; Hoffmann, R.C.; Dörsam, E. Characteristics of Flexographic Printed Indium-Zinc-Oxide Thin Films as an Active Semiconductor Layer in Thin Film Field-Effect Transistors. Appl. Surf. Sci. 2014, 320, 634–642. [Google Scholar] [CrossRef]

- Wang, Z.; Winslow, R.; Madan, D.; Wright, P.K.; Evans, J.W.; Keif, M.; Rong, X. Development of MnO2 Cathode Inks for Flexographically Printed Rechargeable Zinc-Based Battery. J. Power Source 2014, 268, 246–254. [Google Scholar] [CrossRef] [Green Version]

- Hoekstra, D.C.; Nickmans, K.; Lub, J.; Debije, M.G.; Schenning, A.P.H.J. Air-Curable, High-Resolution Patternable Oxetane-Based Liquid Crystalline Photonic Films via Flexographic Printing. ACS Appl. Mater. Interfaces 2019, 11, 7423–7430. [Google Scholar] [CrossRef] [Green Version]

- Serra, P.; Piqué, A. Laser-Induced Forward Transfer: Fundamentals and Applications. Adv. Mater. Technol. 2019, 4, 1800099. [Google Scholar] [CrossRef] [Green Version]

- Piqúe, A.; Auyeung, R.C.Y.; Stepnowski, J.L.; Weir, D.W.; Arnold, C.B.; McGill, R.A.; Chrisey, D.B. Laser Processing of Polymer Thin for Chemical Sensor Applications. Surf. Coat. Technol. 2003, 163–164, 293–299. [Google Scholar] [CrossRef]

- Palla Papavlu, A.; Mattle, T.; Temmel, S.; Lehmann, U.; Hintennach, A.; Grisel, A.; Wokaun, A.; Lippert, T. Highly Sensitive SnO2 Sensor via Reactive Laser-Induced Transfer. Sci. Rep. 2016, 6, 25144. [Google Scholar] [CrossRef] [Green Version]

- Bonciu, A.F.; Filipescu, M.; Voicu, S.I.; Lippert, T.; Palla-Papavlu, A. Facile Fabrication of Hybrid Carbon Nanotube Sensors by Laser Direct Transfer. Nanomaterials 2021, 11, 2604. [Google Scholar] [CrossRef]

- Munoz-Martin, D.; Brasz, C.F.; Chen, Y.; Morales, M.; Arnold, C.B.; Molpeceres, C. Laser-Induced Forward Transfer of High-Viscosity Silver Pastes. Appl. Surf. Sci. 2016, 366, 389–396. [Google Scholar] [CrossRef]

- Mitu, B.; Matei, A.; Filipescu, M.; Palla Papavlu, A.; Bercea, A.; Lippert, T.; Dinescu, M. Ferrocene Pixels by Laser-Induced Forward Transfer: Towards Flexible Microelectrode Printing. J. Phys. D Appl. Phys. 2017, 50, 115601. [Google Scholar] [CrossRef]

- Pohl, R.; Visser, C.W.; Römer, G.R.B.E.; Sun, C.; Huis In’T Veld, A.J.; Lohse, D. Imaging of the Ejection Process of Nanosecond Laser-Induced Forward Transfer of Gold. J. Laser Micro Nanoeng. 2015, 10, 154–157. [Google Scholar] [CrossRef]

- Florian, C.; Caballero-Lucas, F.; Fernández-Pradas, J.M.; Artigas, R.; Ogier, S.; Karnakis, D.; Serra, P. Conductive Silver Ink Printing through the Laser-Induced Forward Transfer Technique. Appl. Surf. Sci. 2015, 336, 304–308. [Google Scholar] [CrossRef]

- Florian, C.; Caballero-Lucas, F.; Fernández-Pradas, J.M.; Ogier, S.; Winchester, L.; Karnakis, D.; Geremia, R.; Artigas, R.; Serra, P. Printing of Silver Conductive Lines through Laser-Induced Forward Transfer. Appl. Surf. Sci. 2016, 374, 265–270. [Google Scholar] [CrossRef]

- Constantinescu, C.; Diallo, A.K.; Rapp, L.; Cremillieu, P.; Mazurczyk, R.; Serein-Spirau, F.; Lère-Porte, J.P.; Delaporte, P.; Alloncle, A.P.; Videlot-Ackermann, C. Laser-Induced Forward Transfer of Multi-Layered Structures for OTFT Applications. Appl. Surf. Sci. 2015, 336, 11–15. [Google Scholar] [CrossRef]

- Sopeña, P.; Arrese, J.; González-Torres, S.; Fernández-Pradas, J.M.; Cirera, A.; Serra, P. Low-Cost Fabrication of Printed Electronics Devices through Continuous Wave Laser-Induced Forward Transfer. ACS Appl. Mater. Interfaces 2017, 9, 29412–29417. [Google Scholar] [CrossRef]

- Delaporte, P.; Alloncle, A.P. [INVITED] Laser-Induced Forward Transfer: A High Resolution Additive Manufacturing Technology. Opt. Laser Technol. 2016, 78, 33–41. [Google Scholar] [CrossRef]

- Hu, H.; Kim, H.; Somnath, S. Tip-Based Nanofabrication for Scalable Manufacturing. Micromachines 2017, 8, 90. [Google Scholar] [CrossRef] [Green Version]

- Liu, G.; Hirtz, M.; Fuchs, H.; Zheng, Z. Development of Dip-Pen Nanolithography (DPN) and Its Derivatives. Small 2019, 15, 1900564. [Google Scholar] [CrossRef]

- Liu, G.; Zhou, Y.; Banga, R.S.; Boya, R.; Brown, K.A.; Chipre, A.J.; Nguyen, S.B.T.; Mirkin, C.A. The Role of Viscosity on Polymer Ink Transport in Dip-Pen Nanolithography. Chem. Sci. 2013, 4, 2093–2099. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sanedrin, R.G.; Amro, N.A.; Rendlen, J.; Nelson, M. Temperature Controlled Dip-Pen Nanolithography. Nanotechnology 2010, 21, 115302. [Google Scholar] [CrossRef] [PubMed]

- Corletto, A.; Yu, L.P.; Shearer, C.J.; Gibson, C.T.; Shapter, J.G. Direct-Patterning SWCNTs Using Dip Pen Nanolithography for SWCNT/Silicon Solar Cells. Small 2018, 14, 1800247. [Google Scholar] [CrossRef]

- Ma, H.; Jiang, Z.; Xie, X.; Huang, L.; Huang, W. Multiplexed Biomolecular Arrays Generated via Parallel Dip-Pen Nanolithography. ACS Appl. Mater. Interfaces 2018, 10, 25121–25126. [Google Scholar] [CrossRef] [PubMed]

- Bellido, E.; De Miguel, R.; Ruiz-Molina, D.; Lostao, A.; Maspoch, D. Controlling the Number of Proteins with Dip-Pen Nanolithography. Adv. Mater. 2010, 22, 352–355. [Google Scholar] [CrossRef] [PubMed]

- Shamish, Z.; Zohar, M.; Shamir, D.; Burg, A. Controlling the Size and Pattern Pitch of Ni(OH)2 Nanoclusters Using Dip-Pen Nanolithography to Improve Water Oxidation. Molecules 2020, 25, 2937. [Google Scholar] [CrossRef]

- Lu, H.-H.; Lin, C.-Y.; Hsiao, T.-C.; Fang, Y.-Y.; Ho, K.-C.; Yang, D.; Lee, C.-K.; Hsu, S.-M.; Lin, C.-W. Electrical Properties of Single and Multiple Poly(3,4-Ethylenedioxythiophene) Nanowires for Sensing Nitric Oxide Gas. Anal. Chim. Acta 2009, 640, 68–74. [Google Scholar] [CrossRef]

- Tang, Q.; Shi, S.Q. Preparation of Gas Sensors via Dip-Pen Nanolithography. Sens. Actuators B Chem. 2008, 131, 379–383. [Google Scholar] [CrossRef]

- Liao, C.; Anderson, W.; Antaw, F.; Trau, M. Two-Photon Nanolithography of Tailored Hollow Three-Dimensional Microdevices for Biosystems. ACS Omega 2019, 4, 1401–1409. [Google Scholar] [CrossRef] [Green Version]

- Kidwell, D.A.; Lee, W.K.; Perkins, K.; Gilpin, K.M.; O’Shaughnessy, T.J.; Robinson, J.T.; Sheehan, P.E.; Mulvaney, S.P. Chemistries for Making Additive Nanolithography in OrmoComp Permissive for Cell Adhesion and Growth. ACS Appl. Mater. Interfaces 2019, 11, 19793–19798. [Google Scholar] [CrossRef]

- Chi, T.; Somers, P.; Wilcox, D.A.; Schuman, A.J.; Iyer, V.; Le, R.; Gengler, J.; Ferdinandus, M.; Liebig, C.; Pan, L.; et al. Tailored Thioxanthone-Based Photoinitiators for Two-Photon-Controllable Polymerization and Nanolithographic Printing. J. Polym. Sci. Part. B Polym. Phys. 2019, 57, 1462–1475. [Google Scholar] [CrossRef]

- Ródenas, A.; Gu, M.; Corrielli, G.; Paiè, P.; John, S.; Kar, A.K.; Osellame, R. Three-Dimensional Femtosecond Laser Nanolithography of Crystals. Nat. Photonics 2019, 13, 105–109. [Google Scholar] [CrossRef]

- Tang, N.; Zhou, C.; Xu, L.; Jiang, Y.; Qu, H.; Duan, X. A Fully Integrated Wireless Flexible Ammonia Sensor Fabricated by Soft Nano-Lithography. ACS Sens. 2019, 4, 726–732. [Google Scholar] [CrossRef] [PubMed]

- Bhagoria, P.; Sebastian, E.M.; Jain, S.K.; Purohit, J.; Purohit, R. Nanolithography and Its Alternate Techniques. Mater. Today Proc. 2019, 26, 3048–3053. [Google Scholar] [CrossRef]

- Lim, S.H.; Radha, B.; Chan, J.Y.; Saifullah, M.S.M.; Kulkarni, G.U.; Ho, G.W. Flexible Palladium-Based H2 Sensor with Fast Response and Low Leakage Detection by Nanoimprint Lithography. ACS Appl. Mater. Interfaces 2013, 5, 7274–7281. [Google Scholar] [CrossRef] [PubMed]

- Borowiec, J.; Hampl, J.; Singh, S.; Haefner, S.; Friedel, K.; Mai, P.; Brauer, D.; Ruther, F.; Liverani, L.; Boccaccini, A.R.; et al. 3D Microcontact Printing for Combined Chemical and Topographical Patterning on Porous Cell Culture Membrane. ACS Appl. Mater. Interfaces 2018, 10, 22857–22865. [Google Scholar] [CrossRef] [PubMed]

- Jaywant, S.A.; Arif, K.M. Study of Parameters Affecting Microcontact Printing of Thiols on Gold-Coated Substrate. Int. J. Mod. Phys. B 2020, 34, 2–7. [Google Scholar] [CrossRef]

- Buten, C.; Lamping, S.; Körsgen, M.; Arlinghaus, H.F.; Jamieson, C.; Ravoo, B.J. Surface Functionalization with Carboxylic Acids by Photochemical Microcontact Printing and Tetrazole Chemistry. Langmuir 2018, 34, 2132–2138. [Google Scholar] [CrossRef]

- Zimmermann, M.; Grigoriev, D.; Puretskiy, N.; Böker, A. Characteristics of Microcontact Printing with Polyelectrolyte Ink for the Precise Preparation of Patches on Silica Particles. RSC Adv. 2018, 8, 39241–39247. [Google Scholar] [CrossRef] [Green Version]

- Zimmermann, M.; John, D.; Grigoriev, D.; Puretskiy, N.; Böker, A. From 2D to 3D Patches on Multifunctional Particles: How Microcontact Printing Creates a New Dimension of Functionality. Soft Matter 2018, 14, 2301–2309. [Google Scholar] [CrossRef] [Green Version]

- Perl, A.; Reinhoudt, D.N.; Huskens, J. Microcontact Printing: Limitations and Achievements. Adv. Mater. 2009, 21, 2257–2268. [Google Scholar] [CrossRef]

- Yalcintas, E.P.; Ozutemiz, K.B.; Cetinkaya, T.; Dalloro, L.; Majidi, C.; Ozdoganlar, O.B. Soft Electronics Manufacturing Using Microcontact Printing. Adv. Funct. Mater. 2019, 29, 1906551. [Google Scholar] [CrossRef]

- Sanders, W.C.; Iles, P.; Valcarce, R.; Salisbury, K.; Johnson, G.; Lines, A.; Meyers, J.; Page, C.; Vanweerd, M.; Young, D. Assessing the Electrochemical Behavior of Microcontact-Printed Silver Nanogrids. J. Chem. Educ. 2018, 95, 315–319. [Google Scholar] [CrossRef]

- Pariani, G.; Castagna, R.; Oggioni, L.; Colella, L.; Nardi, A.; Anzani, S.; Bertarelli, C.; Bianco, A. Adaptable Microcontact Printing via Photochromic Optical-Saturable Lithography. Adv. Mater. Technol. 2018, 3, 1700325. [Google Scholar] [CrossRef]

- Juste-Dolz, A.; Avella-Oliver, M.; Puchades, R.; Maquieira, A. Indirect Microcontact Printing to Create Functional Patterns of Physisorbed Antibodies. Sensors 2018, 18, 3163. [Google Scholar] [CrossRef] [Green Version]

- Simfukwe, J.; Mapasha, R.E.; Braun, A.; Diale, M. Biopatterning of Keratinocytes in Aqueous Two-Phase Systems as a Potential Tool for Skin Tissue Engineering. MRS Adv. 2017, 357, 1–8. [Google Scholar] [CrossRef]

- Haviar, S.; Chlupová, Š.; Kúš, P.; Gillet, M.; Matolín, V.; Matolínová, I. Micro-Contacted Self-Assembled Tungsten Oxide Nanorods for Hydrogen Gas Sensing. Int. J. Hydrogen Energy 2017, 42, 1344–1352. [Google Scholar] [CrossRef]

- Lim, H.-J.; Lee, D.Y.; Oh, Y.-J. Gas Sensing Properties of ZnO Thin Films Prepared by Microcontact Printing. Sens. Actuators A Phys. 2006, 125, 405–410. [Google Scholar] [CrossRef]

- Calvert, P. Inkjet Printing for Materials and Devices. Chem. Mater. 2001, 13, 3299–3305. [Google Scholar] [CrossRef]

- Sollami Delekta, S.; Smith, A.D.; Li, J.; Östling, M. Inkjet Printed Highly Transparent and Flexible Graphene Micro-Supercapacitors. Nanoscale 2017, 9, 6998–7005. [Google Scholar] [CrossRef]

- Prévôt, M.E.; Nemati, A.; Cull, T.R.; Hegmann, E.; Hegmann, T. A Zero-Power Optical, Ppt- to Ppm-Level Toxic Gas and Vapor Sensor with Image, Text, and Analytical Capabilities. Adv. Mater. Technol. 2020, 5, 2000058. [Google Scholar] [CrossRef]

- Kiaee, M.M.; Maeder, T.; Brugger, J. Inkjet-Printed Composites for Room-Temperature VOC Sensing: From Ink Formulation to Sensor Characterization. Adv. Mater. Technol. 2021, 6, 2000929. [Google Scholar] [CrossRef]

- Zuo, J.; Tavakoli, S.; Mathavakrishnan, D.; Ma, T.; Lim, M.; Rotondo, B.; Pauzauskie, P.; Pavinatto, F.; MacKenzie, D. Additive Manufacturing of a Flexible Carbon Monoxide Sensor Based on a SnO2-Graphene Nanoink. Chemosensors 2020, 8, 36. [Google Scholar] [CrossRef]

- Kao, H.-L.; Cho, C.-L.; Chang, L.-C.; Chen, C.-B.; Chung, W.-H.; Tsai, Y.-C. A Fully Inkjet-Printed Strain Sensor Based on Carbon Nanotubes. Coatings 2020, 10, 792. [Google Scholar] [CrossRef]

- Cheon, H.J.; Li, X.; Jeong, Y.J.; Sung, M.J.; Li, Z.; Jeon, I.; Tang, X.; Girma, H.G.; Kong, H.; Kwon, S.K.; et al. A Novel Design of Donor-Acceptor Polymer Semiconductors for Printed Electronics: Application to Transistors and Gas Sensors. J. Mater. Chem. C 2020, 8, 8410–8419. [Google Scholar] [CrossRef]

- Pandhi, T.; Chandnani, A.; Subbaraman, H.; Estrada, D. A Review of Inkjet Printed Graphene and Carbon Nanotubes Based Gas Sensors. Sensors 2020, 20, 5642. [Google Scholar] [CrossRef]

- Devabharathi, N.; Umarji, A.M.; Dasgupta, S. Fully Inkjet-Printed Mesoporous SnO2-Based Ultrasensitive Gas Sensors for Trace Amount NO2Detection. ACS Appl. Mater. Interfaces 2020, 12, 57207–57217. [Google Scholar] [CrossRef]

- Wu, T.-C.; Dai, J.; Hu, G.; Yu, W.-B.; Ogbeide, O.; De Luca, A.; Huang, X.; Su, B.-L.; Li, Y.; Udrea, F.; et al. Machine-Intelligent Inkjet-Printed α-Fe2O3/RGO towards NO2 Quantification in Ambient Humidity. Sens. Actuators B Chem. 2020, 321, 128446. [Google Scholar] [CrossRef]

- Sahm, T.; Rong, W.; Bârsan, N.; Mädler, L.; Weimar, U. Sensing of CH4, CO and Ethanol with in Situ Nanoparticle Aerosol-Fabricated Multilayer Sensors. Sens. Actuators B Chem. 2007, 127, 63–68. [Google Scholar] [CrossRef]

- Sahner, K.; Kaspar, M.; Moos, R. Assessment of the Novel Aerosol Deposition Method for Room Temperature Preparation of Metal Oxide Gas Sensor Films. Sens. Actuators B Chem. 2009, 139, 394–399. [Google Scholar] [CrossRef]

- Cabañas, M.V.; Delabouglise, G.; Labeau, M.; Vallet-Regí, M. Application of a Modified Ultrasonic Aerosol Device to the Synthesis of SnO2 and Pt/SnO2 for Gas Sensors. J. Solid State Chem. 1999, 144, 86–90. [Google Scholar] [CrossRef]

- Hsiao, C.C.; Luo, L.S. Gas Sensors Fabricated by Aerosol Deposition. Appl. Mech. Mater. 2014, 541–542, 151–154. [Google Scholar] [CrossRef]

- Zhang, Q.; Sharma, G.; Wong, J.P.S.; Davis, A.Y.; Black, M.S.; Biswas, P.; Weber, R.J. Investigating Particle Emissions and Aerosol Dynamics from a Consumer Fused Deposition Modeling 3D Printer with a Lognormal Moment Aerosol Model. Aerosol Sci. Technol. 2018, 52, 1099–1111. [Google Scholar] [CrossRef] [Green Version]

- Siebert, L.; Lupan, O.; Mirabelli, M.; Ababii, N.; Terasa, M.-I.; Kaps, S.; Cretu, V.; Vahl, A.; Faupel, F.; Adelung, R. 3D-Printed Chemiresistive Sensor Array on Nanowire CuO/Cu2O/Cu Heterojunction Nets. ACS Appl. Mater. Interfaces 2019, 11, 25508–25515. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.; Gray, E.; Chen, B. A Self-Healing, Adaptive and Conductive Polymer Composite Ink for 3D Printing of Gas Sensors. J. Mater. Chem. C 2018, 6, 6200–6207. [Google Scholar] [CrossRef] [Green Version]

- Hong, S.; Zhu, J.; Mirkin, C.A. Multiple Ink Nanolithography: Toward a Multiple-Pen Nano-Plotter. Science 1999, 286, 523–525. [Google Scholar] [CrossRef]

- Izu, N.; Shin, W.; Murayama, N.; Kanzaki, S. Resistive Oxygen Gas Sensors Based on CeO2 Fine Powder Prepared Using Mist Pyrolysis. Sens. Actuators B Chem. 2002, 87, 95–98. [Google Scholar] [CrossRef]

- Neri, G.; Bonavita, A.; Micali, G.; Rizzo, G.; Callone, E.; Carturan, G. Resistive CO Gas Sensors Based on In2O3 and InSnOx Nanopowders Synthesized via Starch-Aided Sol-Gel Process for Automotive Applications. Sens. Actuators B Chem. 2008, 132, 224–233. [Google Scholar] [CrossRef]

- Srivastava, A.; Rashmi; Jain, K. Study on ZnO-Doped Tin Oxide Thick Film Gas Sensors. Mater. Chem. Phys. 2007, 105, 385–390. [Google Scholar] [CrossRef]

- Viricelle, J.P.; Riviere, B.; Pijolat, C. Optimization of SnO2 Screen-Printing Inks for Gas Sensor Applications. J. Eur. Ceram. Soc. 2005, 25, 2137–2140. [Google Scholar] [CrossRef]

- Ambaye, A.D.; Kefeni, K.K.; Mishra, S.B.; Nxumalo, E.N.; Ntsendwana, B. Recent Developments in Nanotechnology-Based Printing Electrode Systems for Electrochemical Sensors. Talanta 2021, 225, 121951. [Google Scholar] [CrossRef] [PubMed]

- Malakootian, M.; Gholami, Z.; Mahmoudi-Moghaddam, H. Electrochemical Determination of Hydroxylamine in Water Samples Using Modified Screen-Printed Electrode with TiO2/GO. Int. J. Environ. Anal. Chem. 2021, 101, 35–47. [Google Scholar] [CrossRef]

- Yadava, L.; Verma, R.; Dwivedi, R. Sensing Properties of CdS-Doped Tin Oxide Thick Film Gas Sensor. Sens. Actuators B Chem. 2010, 144, 37–42. [Google Scholar] [CrossRef]

- Yadav, P.; Sharma, A.K.; Yadav, S.K.; Vishwakarma, A.K.; Yadava, L. Sensing Response of Toluene Gas and Structural Properties of CdS-SnO2 thick Films Sensor. Mater. Today Proc. 2020, 38, 2792–2796. [Google Scholar] [CrossRef]

- Bariya, M.; Shahpar, Z.; Park, H.; Sun, J.; Jung, Y.; Gao, W.; Nyein, H.Y.Y.; Liaw, T.S.; Tai, L.C.; Ngo, Q.P.; et al. Roll-to-Roll Gravure Printed Electrochemical Sensors for Wearable and Medical Devices. ACS Nano 2018, 12, 6978–6987. [Google Scholar] [CrossRef]

- Vaklev, N.L.; Steinke, J.H.G.; Campbell, A.J. Gravure Printed Ultrathin Dielectric for Low Voltage Flexible Organic Field-Effect Transistors. Adv. Mater. Interfaces 2019, 6, 1900173. [Google Scholar] [CrossRef]

- Huang, L.; Wang, Z.; Zhang, J.; Pu, J.; Lin, Y.; Xu, S.; Shen, L.; Chen, Q.; Shi, W. Fully Printed, Rapid-Response Sensors Based on Chemically Modified Graphene for Detecting NO2 at Room Temperature. ACS Appl. Mater. Interfaces 2014, 6, 7426–7433. [Google Scholar] [CrossRef]

- Reddy, A.S.G.; Narakathu, B.B.; Atashbar, M.Z.; Rebros, M.; Rebrosova, E.; Joyce, M.K. Fully Printed Flexible Humidity Sensor. Procedia Eng. 2011, 25, 120–123. [Google Scholar] [CrossRef] [Green Version]

- Kukkola, J.; Jansson, E.; Popov, A.; Lappalainen, J.; Mäklin, J.; Halonen, N.; Tóth, G.; Shchukarev, A.; Mikkola, J.P.; Jantunen, H.; et al. Novel Printed Nanostructured Gas Sensors. Procedia Eng. 2011, 25, 896–899. [Google Scholar] [CrossRef] [Green Version]

- Lin, Y.; Huang, L.; Chen, L.; Zhang, J.; Shen, L.; Chen, Q.; Shi, W. Fully Gravure-Printed NO2 Gas Sensor on a Polyimide Foil Using WO3-PEDOT:PSS Nanocomposites and Ag Electrodes. Sens. Actuators B Chem. 2015, 216, 176–183. [Google Scholar] [CrossRef]

- Syrový, T.; Kuberský, P.; Sapurina, I.; Pretl, S.; Bober, P.; Syrová, L.; Hamáček, A.; Stejskal, J. Gravure-Printed Ammonia Sensor Based on Organic Polyaniline Colloids. Sens. Actuators B Chem. 2016, 225, 510–516. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J.; Zhang, S.; Huang, J. OFET Chemical Sensors: Chemical Sensors Based on Ultrathin Organic Field-Effect Transistors. Polym. Int. 2021, 70, 414–425. [Google Scholar] [CrossRef]

- Papazoglou, S.; Zergioti, I. Laser Induced Forward Transfer (LIFT) of Nano-Micro Patterns for Sensor Applications. Microelectron. Eng. 2017, 182, 25–34. [Google Scholar] [CrossRef]

- Tsouti, V.; Boutopoulos, C.; Goustouridis, D.; Zergioti, I.; Normand, P.; Tsoukalas, D.; Chatzandroulis, S. A Chemical Sensor Microarray Realized by Laser Printing of Polymers. Sens. Actuators B Chem. 2010, 150, 148–153. [Google Scholar] [CrossRef]

- Saha, S.K.; Culpepper, M.L. An Ink Transport Model for Prediction of Feature Size in Dip Pen Nanolithography. J. Phys. Chem. C 2010, 114, 15364–15369. [Google Scholar] [CrossRef]

- Lukyanenko, A.V.; Smolyarova, T.E. Alternative Technology for Creating Nanostructures Using Dip Pen Nanolithography. Semiconductors 2018, 52, 636–638. [Google Scholar] [CrossRef]

- Boudot, M.; Cattoni, A.; Grosso, D.; Faustini, M. Ethanol–Water Co-Condensation into Hydrophobic Mesoporous Thin Films: Example of a Photonic Ethanol Vapor Sensor in Humid Environment. J. Sol. Gel. Sci. Technol. 2017, 81, 95–104. [Google Scholar] [CrossRef]

- Khare, H.S.; Gosvami, N.N.; Lahouij, I.; Milne, Z.B.; McClimon, J.B.; Carpick, R.W. Nanotribological Printing: A Nanoscale Additive Manufacturing Method. Nano Lett. 2018, 18, 6756–6763. [Google Scholar] [CrossRef]

- Jung, W.B.; Cho, S.Y.; Suh, B.L.; Yoo, H.W.; Jeon, H.J.; Kim, J.; Jung, H.T. Polyelemental Nanolithography via Plasma Ion Bombardment: From Fabrication to Superior H2 Sensing Application. Adv. Mater. 2019, 31, 1805343. [Google Scholar] [CrossRef]

- Jang, B.; Cho, S.; Park, C.; Lee, H.; Song, M.J.; Lee, W. Palladium Nanogap-Based H2 Sensors on a Patterned Elastomeric Substrate Using Nanoimprint Lithography. Sens. Actuators B Chem. 2015, 221, 593–598. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simonenko, N.P.; Fisenko, N.A.; Fedorov, F.S.; Simonenko, T.L.; Mokrushin, A.S.; Simonenko, E.P.; Korotcenkov, G.; Sysoev, V.V.; Sevastyanov, V.G.; Kuznetsov, N.T. Printing Technologies as an Emerging Approach in Gas Sensors: Survey of Literature. Sensors 2022, 22, 3473. https://doi.org/10.3390/s22093473

Simonenko NP, Fisenko NA, Fedorov FS, Simonenko TL, Mokrushin AS, Simonenko EP, Korotcenkov G, Sysoev VV, Sevastyanov VG, Kuznetsov NT. Printing Technologies as an Emerging Approach in Gas Sensors: Survey of Literature. Sensors. 2022; 22(9):3473. https://doi.org/10.3390/s22093473

Chicago/Turabian StyleSimonenko, Nikolay P., Nikita A. Fisenko, Fedor S. Fedorov, Tatiana L. Simonenko, Artem S. Mokrushin, Elizaveta P. Simonenko, Ghenadii Korotcenkov, Victor V. Sysoev, Vladimir G. Sevastyanov, and Nikolay T. Kuznetsov. 2022. "Printing Technologies as an Emerging Approach in Gas Sensors: Survey of Literature" Sensors 22, no. 9: 3473. https://doi.org/10.3390/s22093473

APA StyleSimonenko, N. P., Fisenko, N. A., Fedorov, F. S., Simonenko, T. L., Mokrushin, A. S., Simonenko, E. P., Korotcenkov, G., Sysoev, V. V., Sevastyanov, V. G., & Kuznetsov, N. T. (2022). Printing Technologies as an Emerging Approach in Gas Sensors: Survey of Literature. Sensors, 22(9), 3473. https://doi.org/10.3390/s22093473