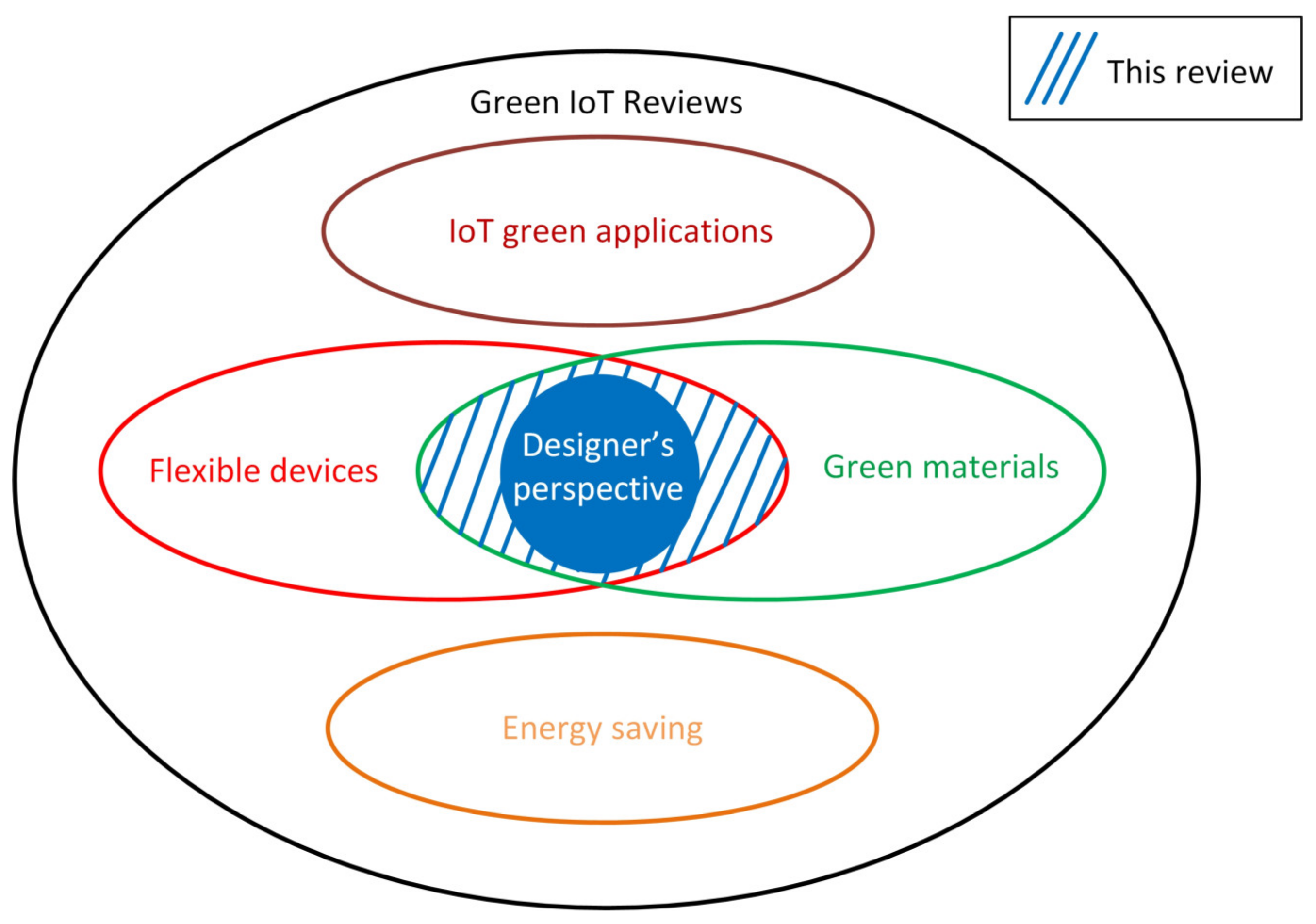

A Brief Review on Flexible Electronics for IoT: Solutions for Sustainability and New Perspectives for Designers

Abstract

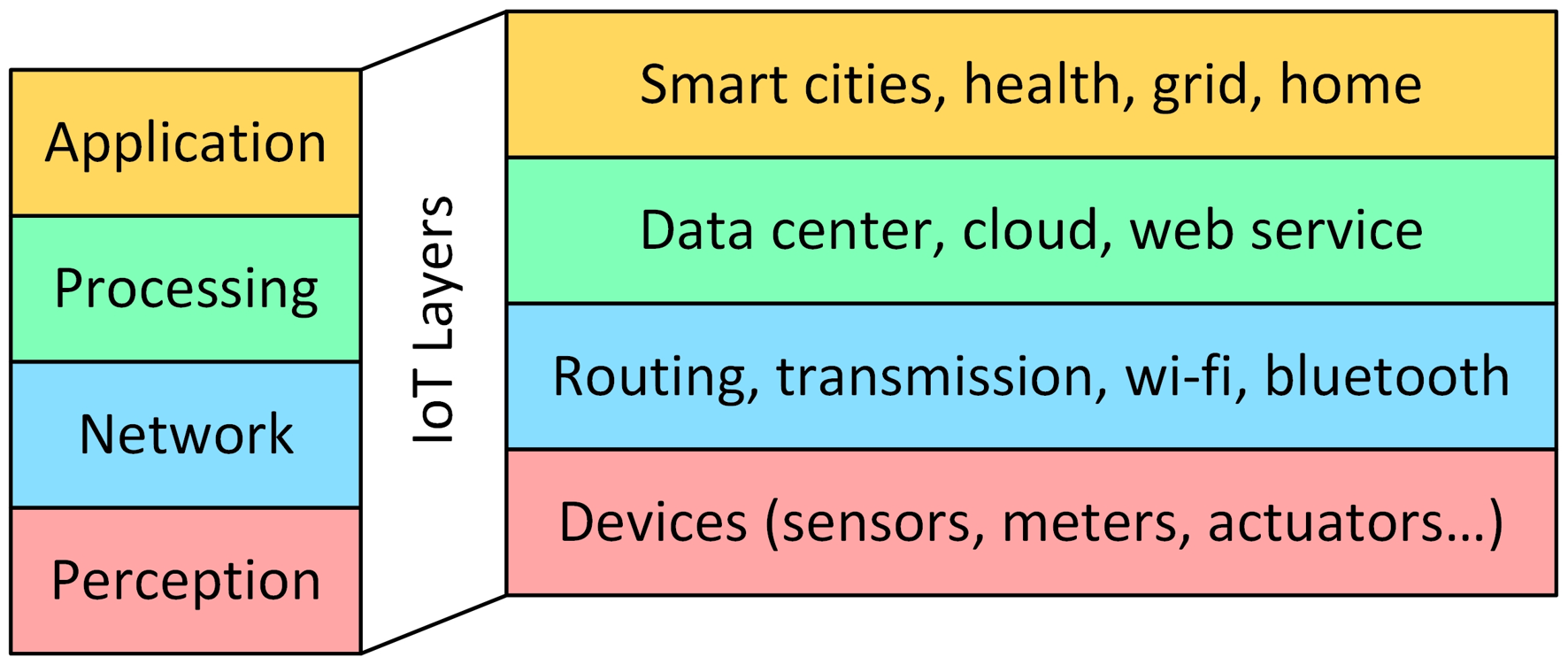

:1. Introduction

2. Green Substrates: Paper and “Nanopaper”

3. Perception Layer Devices

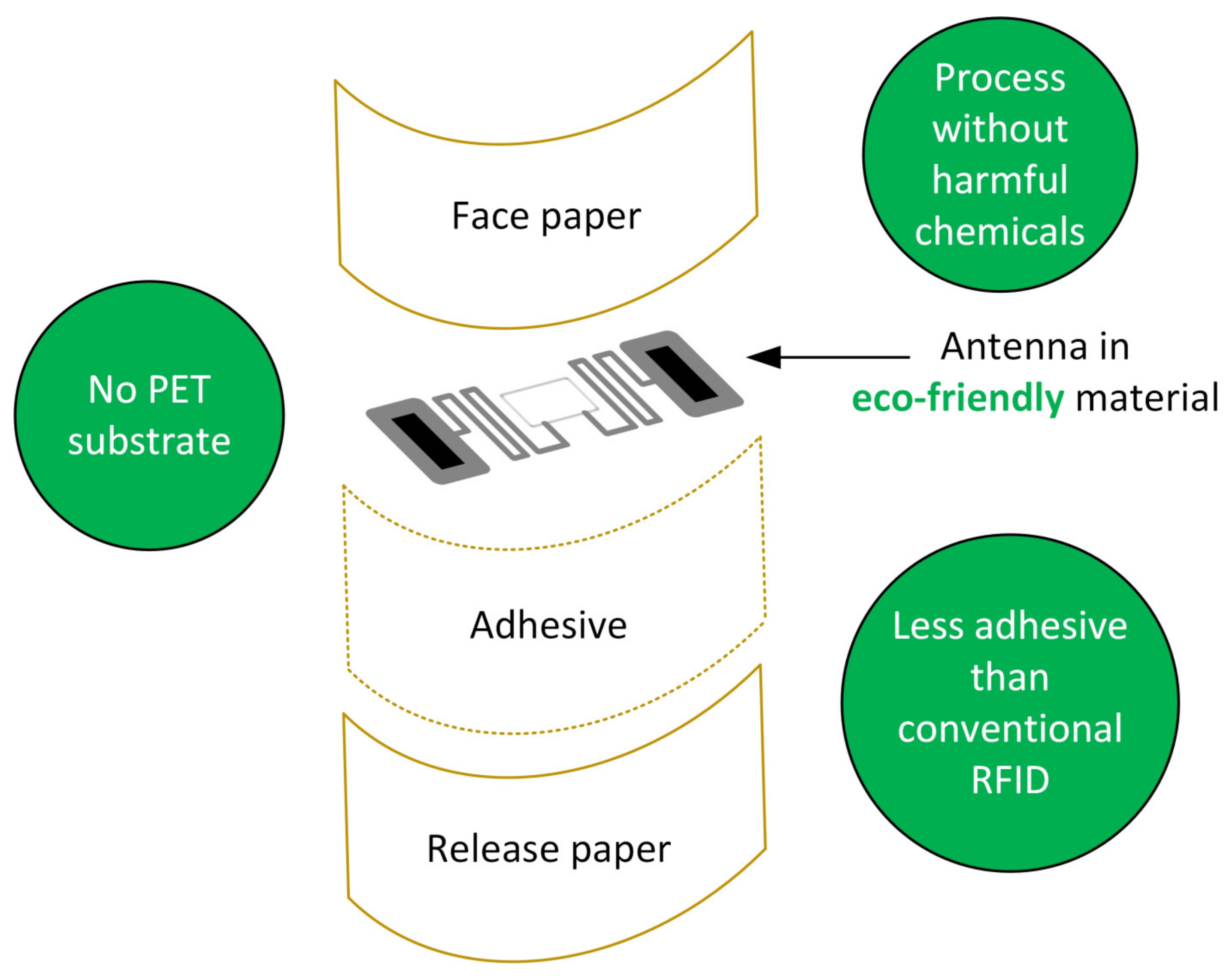

3.1. RFIDs

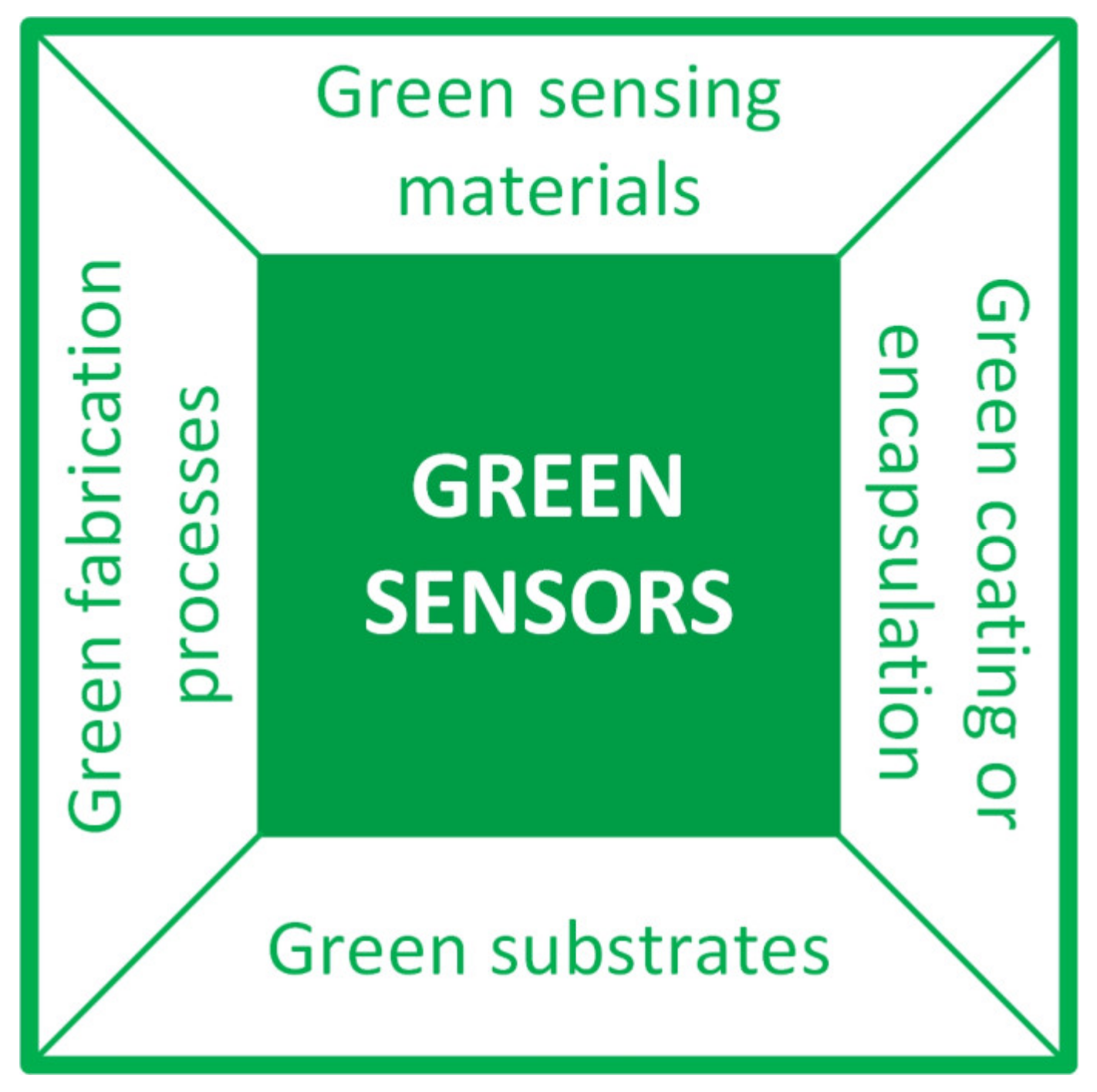

3.2. Sensors

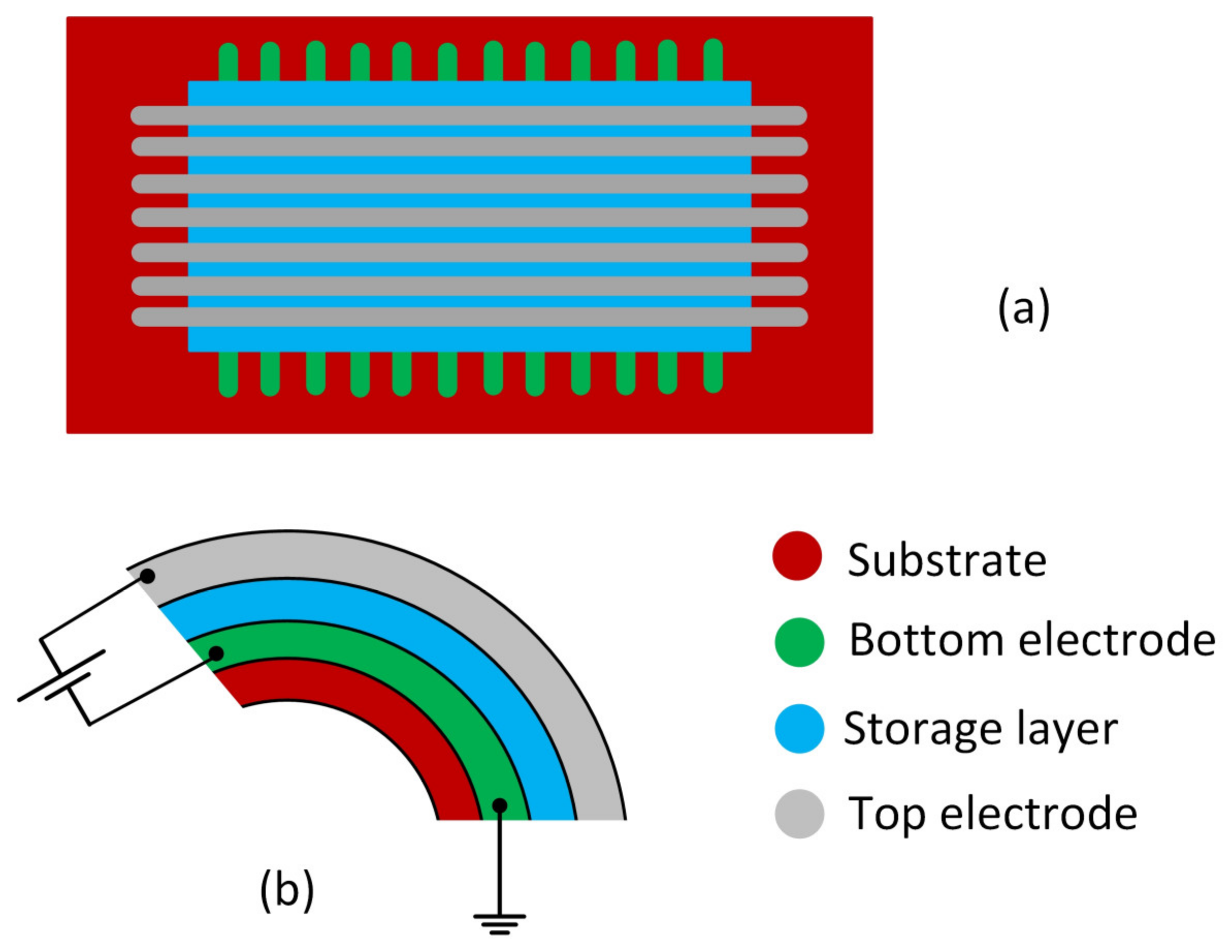

3.3. Memories

3.4. Energy Harvesters

4. Discussion: The Perspective of the Designer

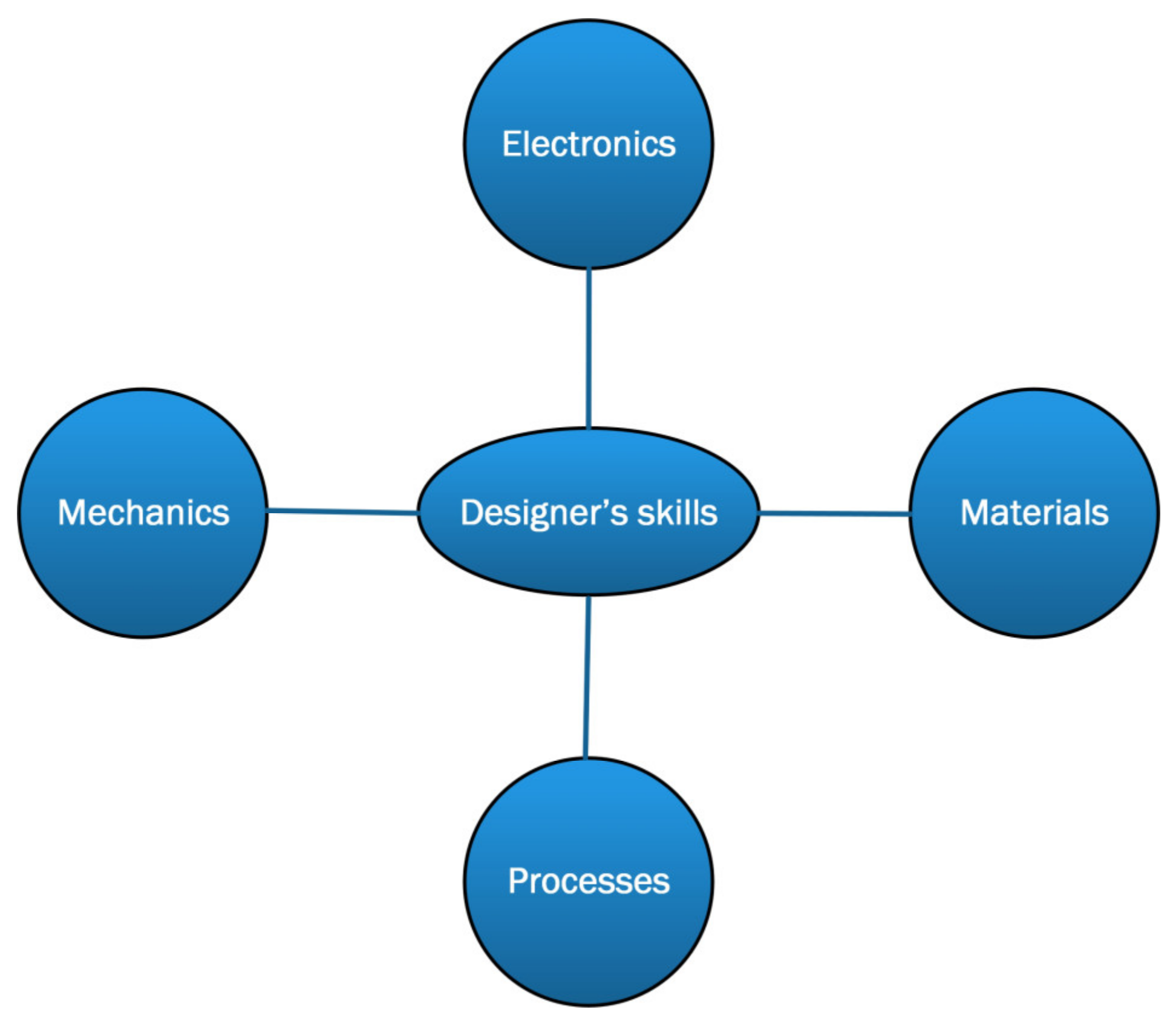

4.1. Designer’s Skills and Competencies

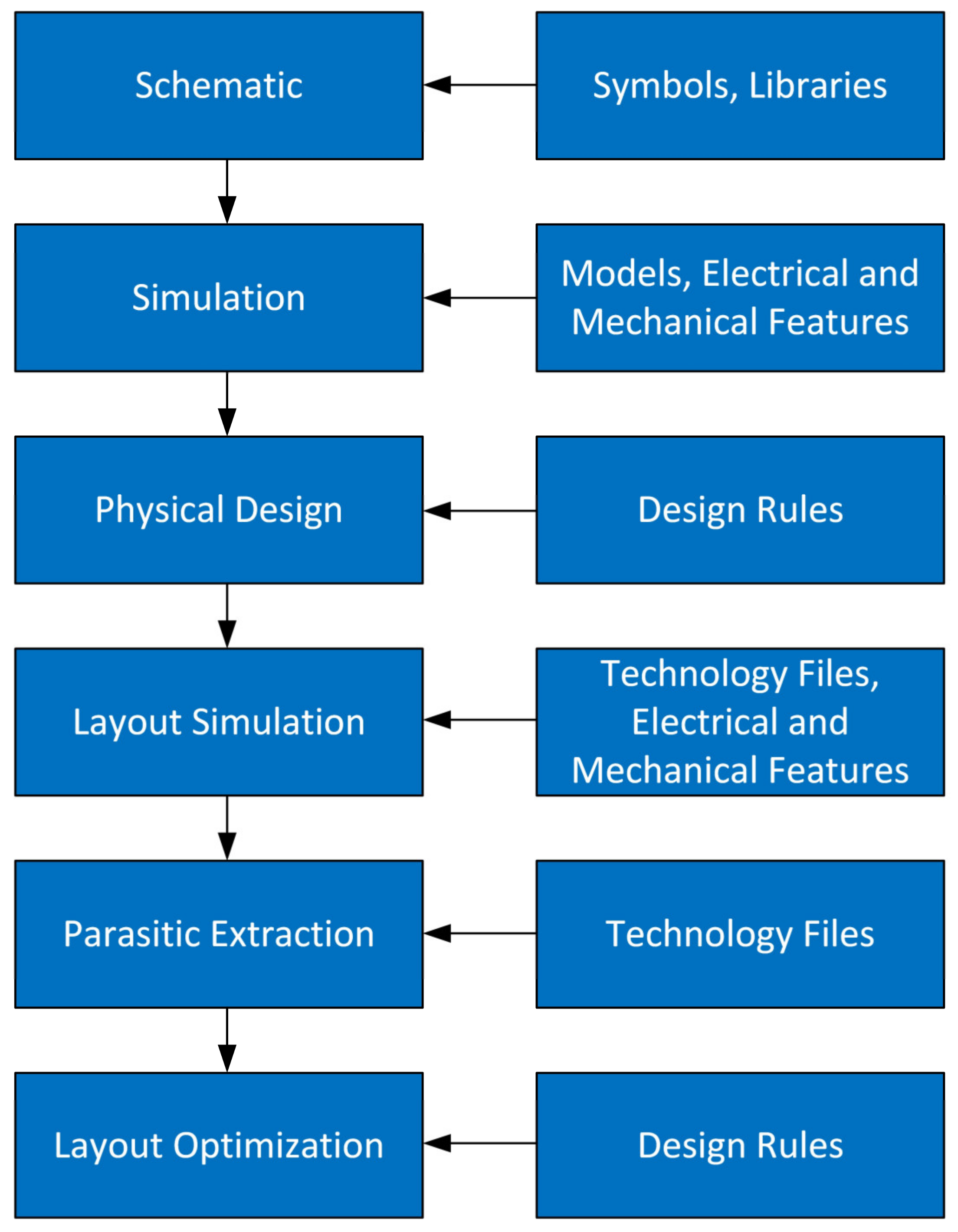

4.2. Required Features of Design Tools

4.3. New Characterization Methods

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Weiss, E.B. United Nations Conference on Environment and Development. Int. Leg. Mater. 1992, 31, 814–817. [Google Scholar] [CrossRef]

- Whaiduzzaman, M.; Barros, A.; Chanda, M.; Barman, S.; Sultana, T.; Rahman, M.S.; Roy, S.; Fidge, C. A Review of Emerging Technologies for IoT-Based Smart Cities. Sensors 2022, 22, 9271. [Google Scholar] [CrossRef] [PubMed]

- Deepaisarn, S.; Yiwsiw, P.; Chaisawat, S.; Lerttomolsakul, T.; Cheewakriengkrai, L.; Tantiwattanapaibul, C.; Buaruk, S.; Sornlertlamvanich, V. Automated Street Light Adjustment System on Campus with AI-Assisted Data Analytics. Sensors 2023, 23, 1853. [Google Scholar] [CrossRef] [PubMed]

- García-Castellano, M.; González-Romo, J.M.; Gómez-Galán, J.A.; García-Martín, J.P.; Torralba, A.; Pérez-Mira, V. ITERL: A Wireless Adaptive System for Efficient Road Lighting. Sensors 2019, 19, 5101. [Google Scholar] [CrossRef] [PubMed]

- Abarro, C.C.; Caliwag, A.C.; Valverde, E.C.; Lim, W.; Maier, M. Implementation of IoT-Based Low-Delay Smart Streetlight Monitoring System. IEEE Internet Things J. 2022, 9, 18461. [Google Scholar] [CrossRef]

- Liu, C.-H.; Hsiao, C.-Y.; Gu, J.-C.; Liu, K.-Y.; Yan, S.-F.; Chiu, C.H.; Ho, M.C. HCL Control Strategy for an Adaptive Roadway Lighting Distribution. Appl. Sci. 2021, 11, 9960. [Google Scholar] [CrossRef]

- Ordaz-García, O.O.; Ortiz-López, M.; Quiles-Latorre, F.J.; Arceo-Olague, J.G.; Solís-Robles, R.; Bellido-Outeiriño, F.J. DALI Bridge FPGA-Based Implementation in a Wireless Sensor Node for IoT Street Lighting Applications. Electronics 2020, 9, 1803. [Google Scholar] [CrossRef]

- Guerrero-Ulloa, G.; Andrango-Catota, A.; Abad-Alay, M.; Hornos, M.J.; Rodríguez-Domínguez, C. Development and Assessment of an Indoor Air Quality Control IoT-Based System. Electronics 2023, 12, 608. [Google Scholar] [CrossRef]

- Kim, J.; Bang, J.; Choi, A.; Moon, H.J.; Sung, M. Estimation of Occupancy Using IoT Sensors and a Carbon Dioxide-Based Machine Learning Model with Ventilation System and Differential Pressure Data. Sensors 2023, 23, 585. [Google Scholar] [CrossRef]

- Rollo, F.; Bachechi, C.; Po, L. Anomaly Detection and Repairing for Improving Air Quality Monitoring. Sensors 2023, 23, 640. [Google Scholar] [CrossRef]

- Zhu, Y.; Al-Ahmed, S.A.; Shakir, M.Z.; Olszewska, J.I. LSTM-Based IoT-Enabled CO2 Steady-State Forecasting for Indoor Air Quality Monitoring. Electronics 2023, 12, 107. [Google Scholar] [CrossRef]

- Hawchar, A.; Ould, S.; Bennett, N.S. Carbon Dioxide Monitoring inside an Australian Brewery Using an Internet-of-Things Sensor Network. Sensors 2022, 22, 9752. [Google Scholar] [CrossRef] [PubMed]

- García, L.; Garcia-Sanchez, A.-J.; Asorey-Cacheda, R.; Garcia-Haro, J.; Zúñiga-Cañón, C.-L. Smart Air Quality Monitoring IoT-Based Infrastructure for Industrial Environments. Sensors 2022, 22, 9221. [Google Scholar] [CrossRef]

- Starace, G.; Tiwari, A.; Colangelo, G.; Massaro, A. Advanced Data Systems for Energy Consumption Optimization and Air Quality Control in Smart Public Buildings Using a Versatile Open Source Approach. Electronics 2022, 11, 3904. [Google Scholar] [CrossRef]

- Kharbouch, A.; Berouine, A.; Elkhoukhi, H.; Berrabah, S.; Bakhouya, M.; El Ouadghiri, D.; Gaber, J. Internet-of-Things Based Hardware-in-the-Loop Framework for Model-Predictive-Control of Smart Building Ventilation. Sensors 2022, 22, 7978. [Google Scholar] [CrossRef]

- Yasin, A.; Delaney, J.; Cheng, C.-T.; Pang, T.Y. The Design and Implementation of an IoT Sensor-Based Indoor Air Quality Monitoring System Using Off-the-Shelf Devices. Appl. Sci. 2022, 12, 9450. [Google Scholar] [CrossRef]

- Khan, M.A.; Kim, H.-c.; Park, H. Leveraging Machine Learning for Fault-Tolerant Air Pollutants Monitoring for a Smart City Design. Electronics 2022, 11, 3122. [Google Scholar] [CrossRef]

- Alvear-Puertas, V.E.; Burbano-Prado, Y.A.; Rosero-Montalvo, P.D.; Tözün, P.; Marcillo, F.; Hernandez, W. Smart and Portable Air-Quality Monitoring IoT Low-Cost Devices in Ibarra City, Ecuador. Sensors 2022, 22, 7015. [Google Scholar] [CrossRef] [PubMed]

- Pastor-Fernández, A.; Cerezo-Narváez, A.; Montero-Gutiérrez, P.; Ballesteros-Pérez, P.; Otero-Mateo, M. Use of Low-Cost Devices for the Control and Monitoring of CO2 Concentration in Existing Buildings after the COVID Era. Appl. Sci. 2022, 12, 3927. [Google Scholar] [CrossRef]

- Montanaro, T.; Sergi, I.; Basile, M.; Mainetti, L.; Patrono, L. An IoT-Aware Solution to Support Governments in Air Pollution Monitoring Based on the Combination of Real-Time Data and Citizen Feedback. Sensors 2022, 22, 1000. [Google Scholar] [CrossRef]

- Sridhar, K.; Radhakrishnan, P.; Swapna, G.; Kesavamoorthy, R.; Pallavi, L.; Thiagarajan, R. A modular IOT sensing platform using hybrid learning ability for air quality prediction. Meas. Sens. 2023, 25, 100609. [Google Scholar] [CrossRef]

- Fadda, M.; Anedda, M.; Girau, R.; Pau, G.; Giusto, D.D. A Social Internet of Things Smart City Solution for Traffic and Pollution Monitoring in Cagliari. IEEE Internet Things J. 2023, 10, 2373. [Google Scholar] [CrossRef]

- Meng, Q.; Lu, P.; Zhu, S. A Smartphone-enabled IoT System for Vibration and Noise Monitoring of Rail Transit. IEEE Internet Things J. 2023, 10, 8907. [Google Scholar] [CrossRef]

- Alashaikh, A.S.; Alhazemi, F.M. Efficient Mobile Crowdsourcing for Environmental Noise Monitoring. IEEE Access 2022, 10, 77251. [Google Scholar] [CrossRef]

- Segura-Garcia, J.; Calero, J.M.A.; Pastor-Aparicio, A.; Marco-Alaez, R.; Felici-Castell, S.; Wang, Q. 5G IoT System for Real-Time Psycho-Acoustic Soundscape Monitoring in Smart Cities with Dynamic Computational Offloading to the Edge. IEEE Internet Things J. 2021, 8, 12467. [Google Scholar] [CrossRef]

- Monti, L.; Vincenzi, M.; Mirri, S.; Pau, G.; Salomoni, P. RaveGuard: A Noise Monitoring Platform Using Low-End Microphones and Machine Learning. Sensors 2020, 20, 5583. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, M.; Dong, R. Time-Series Prediction of Environmental Noise for Urban IoT Based on Long Short-Term Memory Recurrent Neural Network. Appl. Sci. 2020, 10, 1144. [Google Scholar] [CrossRef]

- Mydlarz, C.; Sharma, M.; Lockerman, Y.; Steers, B.; Silva, C.; Bello, J.P. The Life of a New York City Noise Sensor Network. Sensors 2019, 19, 1415. [Google Scholar] [CrossRef]

- Segura Garcia, J.; Pérez Solano, J.J.; Cobos Serrano, M.; Navarro Camba, E.A.; Felici Castell, S.; Soriano Asensi, A.; Montes Suay, F. Spatial Statistical Analysis of Urban Noise Data from a WASN Gathered by an IoT System: Application to a Small City. Appl. Sci. 2016, 6, 380. [Google Scholar] [CrossRef]

- Arisdakessian, S.; Wahab, O.A.; Mourad, A.; Otrok, H.; Guizani, M. A Survey on IoT Intrusion Detection: Federated Learning, Game Theory, Social Psychology, and Explainable AI as Future Directions. IEEE Internet Things J. 2023, 10, 4059. [Google Scholar] [CrossRef]

- Lorenzo, O.G.; Suárez-García, A.; Peña, D.G.; Fuente, M.G.; Granados-López, D. A Low-Cost Luxometer Benchmark for Solar Illuminance Measurement System Based on the Internet of Things. Sensors 2022, 22, 7107. [Google Scholar] [CrossRef] [PubMed]

- Al-Begain, K.; Khan, M.; Alothman, B.; Joumaa, C.; Alrashed, E. A DDoS Detection and Prevention System for IoT Devices and Its Application to Smart Home Environment. Appl. Sci. 2022, 12, 11853. [Google Scholar] [CrossRef]

- Jhuang, Y.-Y.; Yan, Y.-H.; Horng, G.-J. GDPR Personal Privacy Security Mechanism for Smart Home System. Electronics 2023, 12, 831. [Google Scholar] [CrossRef]

- Perumal, T.; Ramanujam, E.; Suman, S.; Sharma, A.; Singhal, H. Internet of Things Centric-Based Multiactivity Recognition in Smart Home Environment. IEEE Internet Things J. 2023, 10, 1724. [Google Scholar] [CrossRef]

- Condon, F.; Martínez, J.M.; Eltamaly, A.M.; Kim, Y.-C.; Ahmed, M.A. Design and Implementation of a Cloud-IoT-Based Home Energy Management System. Sensors 2023, 23, 176. [Google Scholar] [CrossRef] [PubMed]

- Iliev, Y.; Ilieva, G. A Framework for Smart Home System with Voice Control Using NLP Methods. Electronics 2023, 12, 116. [Google Scholar] [CrossRef]

- Xu, B.; Hussain, B.; Wang, Y.; Cheng, H.C.; Yue, C.P. Smart Home Control System Using VLC and Bluetooth Enabled AC Light Bulb for 3D Indoor Localization with Centimeter-Level Precision. Sensors 2022, 22, 8181. [Google Scholar] [CrossRef]

- Chen, X.; Fu, Z.; Song, Z.; Yang, L.; Ndifon, A.M.; Su, Z.; Liu, Z.; Gao, S. An IoT and Wearables-Based Smart Home for ALS Patients. IEEE Internet Things J. 2022, 9, 20945. [Google Scholar] [CrossRef]

- Barber, R.; Ortiz, F.J.; Garrido, S.; Calatrava-Nicolás, F.M.; Mora, A.; Prados, A.; Vera-Repullo, J.A.; Roca-González, J.; Méndez, I.; Mozos, Ó.M. A Multirobot System in an Assisted Home Environment to Support the Elderly in Their Daily Lives. Sensors 2022, 22, 7983. [Google Scholar] [CrossRef]

- Philip, A.; Islam, S.N.; Phillips, N.; Anwar, A. Optimum Energy Management for Air Conditioners in IoT-Enabled Smart Home. Sensors 2022, 22, 7102. [Google Scholar] [CrossRef]

- Nyangaresi, V.O.; Abduljabbar, Z.A.; Mutlaq, K.A.-A.; Ma, J.; Honi, D.G.; Aldarwish, A.J.Y.; Abduljaleel, I.Q. Energy Efficient Dynamic Symmetric Key Based Protocol for Secure Traffic Exchanges in Smart Homes. Appl. Sci. 2022, 12, 12688. [Google Scholar] [CrossRef]

- Putrada, A.G.; Abdurohman, M.; Perdana, D.; Nuha, H.H. Machine Learning Methods in Smart Lighting Toward Achieving User Comfort: A Survey. IEEE Access 2022, 10, 45137. [Google Scholar] [CrossRef]

- Lee, C.-T.; Chen, L.-B.; Chu, H.-M.; Hsieh, C.-J. Design and Implementation of a Leader-Follower Smart Office Lighting Control System Based on IoT Technology. IEEE Access 2022, 10, 28066. [Google Scholar] [CrossRef]

- Griva, A.I.; Boursianis, A.D.; Wan, S.; Sarigiannidis, P.; Psannis, K.E.; Karagiannidis, G.; Goudos, S.K. LoRa-Based IoT Network Assessment in Rural and Urban Scenarios. Sensors 2023, 23, 1695. [Google Scholar] [CrossRef] [PubMed]

- Rai, S.C.; Nayak, S.P.; Acharya, B.; Gerogiannis, V.C.; Kanavos, A.; Panagiotakopoulos, T. ITSS: An Intelligent Traffic Signaling System Based on an IoT Infrastructure. Electronics 2023, 12, 1177. [Google Scholar] [CrossRef]

- Dzemydienė, D.; Burinskienė, A.; Čižiūnienė, K.; Miliauskas, A. Development of E-Service Provision System Architecture Based on IoT and WSNs for Monitoring and Management of Freight Intermodal Transportation. Sensors 2023, 23, 2831. [Google Scholar] [CrossRef]

- Xu, H.; Berres, A.; Yoginath, S.B.; Sorensen, H.; Nugent, P.; Severino, J.; Tennille, S.A.; Moore, A.; Jones, W.; Sanyal, J. Smart Mobility in the Cloud: Enabling Real-Time Situational Awareness and Cyber-Physical Control Through a Digital Twin for Traffic. IEEE Trans. Intell. Transp. Syst. 2023, 24, 3145. [Google Scholar] [CrossRef]

- Kumar, P.; Kumar, S.V.; Priya, L. Smart and Safety Traffic System for the Vehicles on the Road. In IOT with Smart Systems. Smart Innovation, Systems and Technologies; Choudrie, J., Mahalle, P., Perumal, T., Joshi, A., Eds.; Springer: Singapore, 2023; 312p. [Google Scholar] [CrossRef]

- Chakravarty, P.D.; Pandya, J.D.; Dave, A.; Rathod, Y.; Iyer, S.S. Emergency Vehicle-Based Vehicle Detection Model. In Futuristic Trends for Sustainable Development and Sustainable Ecosystems; Ortiz-Rodriguez, F., Ed.; IGI Global: Hershey, PA, USA, 2022; pp. 137–146. [Google Scholar] [CrossRef]

- Cao, J.; Zhang, J.; Liu, M.; Yin, S.; An, Y. Green Logistics of Vehicle Dispatch under Smart IoT. Sens. Mater. 2022, 34, 3317. [Google Scholar] [CrossRef]

- Mejjaouli, S. Internet of Things based Decision Support System for Green Logistics. Sustainability 2022, 14, 14756. [Google Scholar] [CrossRef]

- Raji, C.G.; Shamna, S.K.; Murshidha; Fathimathul, F.V.P.; Shiljiya, K.T. Emergency Vehicles Detection during Traffic Congestion. In Proceedings of the 2022 6th International Conference on Trends in Electronics and Informatics (ICOEI), Tirunelveli, India, 28–30 April 2022; pp. 32–37. [Google Scholar] [CrossRef]

- Phan, A.-C.; Trieu, T.-N.; Phan, T.-C. Driver drowsiness detection and smart alerting using deep learning and IoT. Internet Things 2023, 22, 100705. [Google Scholar] [CrossRef]

- Kuo, Y.-H.; Leung, J.M.Y.; Yan, Y. Public transport for smart cities: Recent innovations and future challenges. Eur. J. Oper. Res. 2023, 306, 1001. [Google Scholar] [CrossRef]

- Rosayyan, P.; Paul, J.; Subramaniam, S.; Ganesan, S.I. An optimal control strategy for emergency vehicle priority system in smart cities using edge computing and IOT sensors. Meas. Sens. 2023, 26, 100697. [Google Scholar] [CrossRef]

- Mohammed, K.; Abdelhafid, M.; Kamal, K.; Ismail, N.; Ilias, A. Intelligent driver monitoring system: An Internet of Things-based system for tracking and identifying the driving behavior. Comput. Stand. Interfaces 2023, 84, 103704. [Google Scholar] [CrossRef]

- Hari Prasad, S.A.; Kumar, R. IoT cloud system for traffic monitoring and vehicular accidents prevention. AIP Conf. Proc. 2023, 2427, 020055. [Google Scholar] [CrossRef]

- Saxena, A.K.; Tripathi, R.C.; Khan, G. Design of a smart public transport system based on IoT. AIP Conf. Proc. 2023, 2427, 020031. [Google Scholar] [CrossRef]

- Alanazi, F. Development of Smart Mobility Infrastructure in Saudi Arabia: A Benchmarking Approach. Sustainability 2023, 15, 3158. [Google Scholar] [CrossRef]

- ElKashlan, M.; Elsayed, M.S.; Jurcut, A.D.; Azer, M. A Machine Learning-Based Intrusion Detection System for IoT Electric Vehicle Charging Stations (EVCSs). Electronics 2023, 12, 1044. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, Y.; Wang, W.; Dev, K.; Khowaja, S.A. Flexible Data Integrity Checking with Original Data Recovery in IoT-Enabled Maritime Transportation Systems. IEEE Trans. Intell. Transp. Syst. 2023, 24, 2618. [Google Scholar] [CrossRef]

- Rocha, D.; Teixeira, G.; Vieira, E.; Almeida, J.; Ferreira, J. A Modular In-Vehicle C-ITS Architecture for Sensor Data Collection, Vehicular Communications and Cloud Connectivity. Sensors 2023, 23, 1724. [Google Scholar] [CrossRef]

- Ghani Khan, M.U.; Elhadef, M.; Mehmood, A. Intelligent Urban Cities: Optimal Path Selection Based on Ad Hoc Network. IEEE Access 2023, 11, 19259. [Google Scholar] [CrossRef]

- Vitali, G.; Arru, M.; Magnanini, E. A Scalable Device for Undisturbed Measurement of Water and CO2 Fluxes through Natural Surfaces. Sensors 2023, 23, 2647. [Google Scholar] [CrossRef]

- Zou, X.; Liu, W.; Huo, Z.; Wang, S.; Chen, Z.; Xin, C.; Bai, Y.; Liang, Z.; Gong, Y.; Qian, Y.; et al. Current Status and Prospects of Research on Sensor Fault Diagnosis of Agricultural Internet of Things. Sensors 2023, 23, 2528. [Google Scholar] [CrossRef] [PubMed]

- Saban, M.; Bekkour, M.; Amdaouch, I.; El Gueri, J.; Ait Ahmed, B.; Chaari, M.Z.; Ruiz-Alzola, J.; Rosado-Muñoz, A.; Aghzout, O. A Smart Agricultural System Based on PLC and a Cloud Computing Web Application Using LoRa and LoRaWan. Sensors 2023, 23, 2725. [Google Scholar] [CrossRef]

- Senoo, E.E.K.; Akansah, E.; Mendonça, I.; Aritsugi, M. Monitoring and Control Framework for IoT, Implemented for Smart Agriculture. Sensors 2023, 23, 2714. [Google Scholar] [CrossRef] [PubMed]

- Garg, G.; Gupta, S.; Mishra, P.; Vidyarthi, A.; Singh, A.; Ali, A. CROPCARE: An Intelligent Real-Time Sustainable IoT System for Crop Disease Detection Using Mobile Vision. IEEE Internet Things J. 2023, 10, 2840. [Google Scholar] [CrossRef]

- Elashmawy, R.; Uysal, I. Precision Agriculture Using Soil Sensor Driven Machine Learning for Smart Strawberry Production. Sensors 2023, 23, 2247. [Google Scholar] [CrossRef]

- Fathy, C.; Ali, H.M. A Secure IoT-Based Irrigation System for Precision Agriculture Using the Expeditious Cipher. Sensors 2023, 23, 2091. [Google Scholar] [CrossRef]

- Dutta, M.; Gupta, D.; Sahu, S.; Limkar, S.; Singh, P.; Mishra, A.; Kumar, M.; Mutlu, R. Evaluation of Growth Responses of Lettuce and Energy Efficiency of the Substrate and Smart Hydroponics Cropping System. Sensors 2023, 23, 1875. [Google Scholar] [CrossRef] [PubMed]

- Bertocco, M.; Parrino, S.; Peruzzi, G.; Pozzebon, A. Estimating Volumetric Water Content in Soil for IoUT Contexts by Exploiting RSSI-Based Augmented Sensors via Machine Learning. Sensors 2023, 23, 2033. [Google Scholar] [CrossRef]

- Contreras-Castillo, J.; Guerrero-Ibañez, J.A.; Santana-Mancilla, P.C.; Anido-Rifón, L. SAgric-IoT: An IoT-Based Platform and Deep Learning for Greenhouse Monitoring. Appl. Sci. 2023, 13, 1961. [Google Scholar] [CrossRef]

- Postolache, S.; Sebastião, P.; Viegas, V.; Postolache, O.; Cercas, F. IoT-Based Systems for Soil Nutrients Assessment in Horticulture. Sensors 2023, 23, 403. [Google Scholar] [CrossRef]

- Habib, S.; Alyahya, S.; Islam, M.; Alnajim, A.M.; Alabdulatif, A.; Alabdulatif, A. Design and Implementation: An IoT-Framework-Based Automated Wastewater Irrigation System. Electronics 2023, 12, 28. [Google Scholar] [CrossRef]

- Azfar, S.; Nadeem, A.; Ahsan, K.; Mehmood, A.; Siddiqui, M.S.; Saeed, M.; Ashraf, M. An IoT-Based System for Efficient Detection of Cotton Pest. Appl. Sci. 2023, 13, 2921. [Google Scholar] [CrossRef]

- Singh, R.; Singh, R.; Gehlot, A.; Akram, S.V.; Priyadarshi, N.; Twala, B. Horticulture 4.0: Adoption of Industry 4.0 Technologies in Horticulture for Meeting Sustainable Farming. Appl. Sci. 2022, 12, 12557. [Google Scholar] [CrossRef]

- Bristow, N.; Rengaraj, S.; Chadwick, D.R.; Kettle, J.; Jones, D.L. Development of a LoRaWAN IoT Node with Ion-Selective Electrode Soil Nitrate Sensors for Precision Agriculture. Sensors 2022, 22, 9100. [Google Scholar] [CrossRef]

- Shaikh, F.K.; Karim, S.; Zeadally, S.; Nebhen, J. Recent Trends in Internet-of-Things-Enabled Sensor Technologies for Smart Agriculture. IEEE Internet Things J. 2022, 9, 23583. [Google Scholar] [CrossRef]

- Gamal, Y.; Soltan, A.; Said, L.A.; Madian, H.A.; Radwan, A.G. Smart Irrigation Systems: Overview. IEEE Access, 2023; Early Access. [Google Scholar] [CrossRef]

- Nadeem, A.; Chatzichristodoulou, D.; Quddious, A.; Shoaib, N.; Vassiliou, L.; Vryonides, P.; Nikolaou, S. UHF IoT Humidity and Temperature Sensor for Smart Agriculture Applications Powered from an Energy Harvesting System. In Proceedings of the 2022 IEEE International Conference on Internet of Things and Intelligence Systems (IoTaIS), Bali, Indonesia, 24–26 November 2022; pp. 186–190. [Google Scholar] [CrossRef]

- Kour, K.; Gupta, D.; Gupta, K.; Anand, D.; Elkamchouchi, D.H.; Pérez-Oleaga, C.M.; Ibrahim, M.; Goyal, N. Monitoring Ambient Parameters in the IoT Precision Agriculture Scenario: An Approach to Sensor Selection and Hydroponic Saffron Cultivation. Sensors 2022, 22, 8905. [Google Scholar] [CrossRef]

- Arrubla-Hoyos, W.; Ojeda-Beltrán, A.; Solano-Barliza, A.; Rambauth-Ibarra, G.; Barrios-Ulloa, A.; Cama-Pinto, D.; Arrabal-Campos, F.M.; Martínez-Lao, J.A.; Cama-Pinto, A.; Manzano-Agugliaro, F. Precision Agriculture and Sensor Systems Applications in Colombia through 5G Networks. Sensors 2022, 22, 7295. [Google Scholar] [CrossRef]

- Ryalat, M.; ElMoaqet, H.; AlFaouri, M. Design of a Smart Factory Based on Cyber-Physical Systems and Internet of Things towards Industry 4.0. Appl. Sci. 2023, 13, 2156. [Google Scholar] [CrossRef]

- Haricha, K.; Khiat, A.; Issaoui, Y.; Bahnasse, A.; Ouajji, H. Recent technological progress to empower Smart Manufacturing: Review and Potential Guidelines. IEEE Access 2023. [Google Scholar] [CrossRef]

- Chen, H.; Jeremiah, S.R.; Lee, C.; Park, J.H. A Digital Twin-Based Heuristic Multi-Cooperation Scheduling Framework for Smart Manufacturing in IIoT Environment. Appl. Sci. 2023, 13, 1440. [Google Scholar] [CrossRef]

- Noor-A-Rahim, M.; John, J.; Firyaguna, F.; Sherazi, H.H.R.; Kushch, S.; Vijayan, A.; O’Connell, E.; Pesch, D.; O’Flynn, B.; O’Brien, W.; et al. Wireless Communications for Smart Manufacturing and Industrial IoT: Existing Technologies, 5G and Beyond. Sensors 2023, 23, 73. [Google Scholar] [CrossRef] [PubMed]

- Hsu, C.-H.; Cheng, S.-J.; Chang, T.-J.; Huang, Y.-M.; Fung, C.-P.; Chen, S.-F. Low-Cost and High-Efficiency Electromechanical Integration for Smart Factories of IoT with CNN and FOPID Controller Design under the Impact of COVID-19. Appl. Sci. 2022, 12, 3231. [Google Scholar] [CrossRef]

- Yu, W.; Liu, Y.; Dillon, T.; Rahayu, W.; Mostafa, F. An Integrated Framework for Health State Monitoring in a Smart Factory Employing IoT and Big Data Techniques. IEEE Internet Things J. 2022, 9, 2443. [Google Scholar] [CrossRef]

- Kwak, K.-J.; Park, J.-M. A Study on Semantic-Based Autonomous Computing Technology for Highly Reliable Smart Factory in Industry 4.0. Appl. Sci. 2021, 11, 10121. [Google Scholar] [CrossRef]

- Hsu, T.-C.; Tsai, Y.-H.; Chang, D.-M. The Vision-Based Data Reader in IoT System for Smart Factory. Appl. Sci. 2022, 12, 6586. [Google Scholar] [CrossRef]

- Abril-Jiménez, P.; Merino-Barbancho, B.; Fico, G.; Martín Guirado, J.C.; Vera-Muñoz, C.; Mallo, I.; Lombroni, I.; Cabrera Umpierrez, M.F.; Arredondo Waldmeyer, M.T. Evaluating IoT-Based Services to Support Patient Empowerment in Digital Home Hospitalization Services. Sensors 2023, 23, 1744. [Google Scholar] [CrossRef]

- Ahmed, S.T.; Kumar, V.; Kim, J. AITel: eHealth Augmented Intelligence based Telemedicine Resource Recommendation Framework for IoT devices in Smart cities. IEEE Internet Things J. 2023. [Google Scholar] [CrossRef]

- Le, N.T.; Thwe Chit, M.M.; Truong, T.L.; Siritantikorn, A.; Kongruttanachok, N.; Asdornwised, W.; Chaitusaney, S.; Benjapolakul, W. Deployment of Smart Specimen Transport System Using RFID and NB-IoT Technologies for Hospital Laboratory. Sensors 2023, 23, 546. [Google Scholar] [CrossRef]

- Chang, J.; Ong, H.; Wang, T.; Chen, H.-H. A Fully Automated Intelligent Medicine Dispensary System Based on AIoT. IEEE Internet Things J. 2022, 9, 23954. [Google Scholar] [CrossRef]

- Rathee, G.; Saini, H.; Kerrache, C.A.; Herrera-Tapia, J. A Computational Framework for Cyber Threats in Medical IoT Systems. Electronics 2022, 11, 1705. [Google Scholar] [CrossRef]

- Rybak, G.; Strzecha, K.; Krakós, M. A New Digital Platform for Collecting Measurement Data from the Novel Imaging Sensors in Urology. Sensors 2022, 22, 1539. [Google Scholar] [CrossRef] [PubMed]

- Fan, L. Usage of Narrowband Internet of Things in Smart Medicine and Construction of Robotic Rehabilitation System. IEEE Access 2022, 10, 6246. [Google Scholar] [CrossRef]

- Nasser, A.R.; Hasan, A.M.; Humaidi, A.J.; Alkhayyat, A.; Alzubaidi, L.; Fadhel, M.A.; Santamaría, J.; Duan, Y. IoT and Cloud Computing in Health-Care: A New Wearable Device and Cloud-Based Deep Learning Algorithm for Monitoring of Diabetes. Electronics 2021, 10, 2719. [Google Scholar] [CrossRef]

- Wang, B.; Hu, X.; Zhang, J.; Xu, C.; Gao, Z. Intelligent Internet of Things in Mammography Screening Using Multicenter Transformation between Unified Capsules. IEEE Internet Things J. 2023, 10, 1536. [Google Scholar] [CrossRef]

- Firouzi, F.; Jiang, S.; Chakrabarty, K.; Farahani, B.; Daneshmand, M.; Song, J.; Mankodiya, K. Fusion of IoT, AI, Edge–Fog–Cloud, and Blockchain: Challenges, Solutions, and a Case Study in Healthcare and Medicine. IEEE Internet Things J. 2023, 10, 3686. [Google Scholar] [CrossRef]

- Kim, B.; Kim, S.; Lee, M.; Chang, H.; Park, E.; Han, T. Application of an Internet of Medical Things (IoMT) to Communications in a Hospital Environment. Appl. Sci. 2022, 12, 12042. [Google Scholar] [CrossRef]

- Alsharif, M.H.; Jahid, A.; Kelechi, A.H.; Kannadasan, R. Green IoT: A Review and Future Research Directions. Symmetry 2023, 15, 757. [Google Scholar] [CrossRef]

- Khan, F.A.; Noor, R.M.; Kiah, M.L.M.; Ahmedy, I.; Yamani, M.; Soon, T.K.; Ahmad, M. Performance Evaluation and Validation of QCM (Query Control Mechanism) for QoS-Enabled Layered-Based Clustering for Reactive Flooding in the Internet of Things. Sensors 2020, 20, 283. [Google Scholar] [CrossRef]

- Hakola, L.; Jansson, E. Sustainable substrate for printed electronics. In Printing for Fabrication 2019: Materials, Applications, and Process—Technical Program and Proceedings; The Society for Imaging Science and Technology, IS&T: Cambridge, MA, USA, 2019; pp. 132–137. [Google Scholar]

- Jansson, E.; Lyytikäinen, J.; Tanninen, P.; Eiroma, K.; Leminen, V.; Immonen, K.; Hakola, L. Suitability of Paper-Based Substrates for Printed Electronics. Materials 2022, 15, 957. [Google Scholar] [CrossRef]

- Prenzel, T.M.; Gehring, F.; Fuhs, F.; Albrecht, S. Influence of design properties of printed electronics on their environmental profile. Matér. Tech. 2021, 109, 506. [Google Scholar] [CrossRef]

- Gudrun, S.; Halvor, K.; Thordur, M. Greenhouse Gas Emissions from Silicon Production -Development of Carbon Footprint with Changing Energy Systems. In Proceedings of the Proceedings of the 16th International Ferro-Alloys Congress (INFACON XVI), Virtual, 12 September 2021. [Google Scholar] [CrossRef]

- Khan, Y.; Thielens, A.; Muin, S.; Ting, J.; Baumbauer, C.; Arias, A.C. A New Frontier of Printed Electronics: Flexible Hybrid Electronics. Adv. Mater. 2020, 32, 1905279. [Google Scholar] [CrossRef]

- Hussein, R.N.; Schlingman, K.; Noade, C.; Carmichael, R.S.; Carmichael, T.B. Shellac-paper composite as a green substrate for printed electronics. Flex. Print. Electron. 2022, 7, 045007. [Google Scholar] [CrossRef]

- Agate, S.; Joyce, M.; Lucia, L.; Pal, L. Cellulose and nanocellulose-based flexible-hybrid printed electronics and conductive composites—A review. Carbohydr. Polym. 2018, 198, 249. [Google Scholar] [CrossRef]

- Liyanage, S.; Acharya, S.; Parajuli, P.; Shamshina, J.L.; Abidi, N. Production and Surface Modification of Cellulose Bioproducts. Polymers 2021, 13, 3433. [Google Scholar] [CrossRef] [PubMed]

- Koga, H.; Nogi, M. Flexible Paper Electronics. In Organic Electronics Materials and Devices; Ogawa, S., Ed.; Springer: Tokyo, Japan, 2015. [Google Scholar] [CrossRef]

- Jaiswal, A.K.; Kumar, V.; Jansson, E.; Huttunen, O.-H.; Yamamoto, A.; Vikman, M.; Khakalo, A.; Hiltunen, J.; Behfar, M.H. Biodegradable Cellulose Nanocomposite Substrate for Recyclable Flexible Printed Electronics. Adv. Electron. Mater. 2023, 9, 2201094. [Google Scholar] [CrossRef]

- Liang, Y.; Wei, Z.; Wang, H.E.; Wang, R.; Zhang, X. Flexible freestanding conductive nanopaper based on PPy:PSS nanocellulose composite for supercapacitors with high performance. Sci. China Mater. 2023, 66, 964. [Google Scholar] [CrossRef]

- Zhong, J.; Li, G.; Guo, R.; Ning, H.; Zhang, H.; Fang, Z.; Fu, X.; Wei, X.; Yao, R.; Peng, J. Bilayer Metal Oxide Channel Thin Film Transistor with Flat Interface Based on Smooth Transparent Nanopaper Substrate. IEEE Electron Device Lett. 2022, 43, 2113. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, D.; Shi, Q.; Yang, B.; Guo, P.; Fang, L.; Dai, S.; Xiong, L. Bioinspired organic optoelectronic synaptic transistors based on cellulose nanopaper and natural chlorophyll-a for neuromorphic systems. Npj Flex Electron. 2022, 6, 30. [Google Scholar] [CrossRef]

- Liang, Y.; Wei, Z.; Wang, H.-E.; Flores, M.; Wang, R.; Zhang, X. Flexible and freestanding PANI: PSS/CNF nanopaper electrodes with enhanced electrochemical performance for supercapacitors. J. Power Sources 2022, 548, 232071. [Google Scholar] [CrossRef]

- Cunha, I.; Ferreira, S.H.; Martins, J.; Fortunato, E.; Gaspar, D.; Martins, R.; Pereira, L. Foldable and Recyclable Iontronic Cellulose Nanopaper for Low-Power Paper. Electron. Adv. Sustain. Syst. 2022, 6, 2200177. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, J.; Zhong, J. Nanocellulose Paper for Flexible Electronic Substrate. In Emerging Nanotechnologies in Nanocellulose; Hu, L., Jiang, F., Chen, C., Eds.; NanoScience and Technology: Danville, CA, USA, 2023; 211p. [Google Scholar] [CrossRef]

- Moon, R.J.; Schueneman, G.T.; Simonsen, J. Overview of Cellulose Nanomaterials, Their Capabilities and Applications. JOM 2016, 68, 2383. [Google Scholar] [CrossRef]

- Varshney, S.; Mishra, N.; Gupta, M.K. Progress in nanocellulose and its polymer based composites: A review on processing, characterization, and applications. Polym. Compos. 2021, 42, 3660. [Google Scholar] [CrossRef]

- Liu, W.; Liu, K.; Du, H.; Zheng, T.; Zhang, N.; Xu, T.; Pang, B.; Zhang, X.; Si, C. Cellulose Nanopaper: Fabrication, Functionalization, and Applications. Nano-Micro. Lett. 2022, 14, 104. [Google Scholar] [CrossRef] [PubMed]

- Lizundia, E.; Delgado-Aguilar, M.; Mutjé, P.; Fernández, E.; Robles-Hernandez, B.; de la Fuente, M.R.; Vilas, J.L. Cu-coated cellulose nanopaper for green and low-cost electronics. Cellulose 2016, 23, 1997. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Xu, J.; Wu, Q.; Li, D.; Chen, G.; He, M.; Tian, J. Fabrication of transparent and superhydrophobic nanopaper via coating hybrid SiO2/MWCNTs composite. Carbohydr. Polym. 2019, 225, 115229. [Google Scholar] [CrossRef]

- Seydibeyoğlu, M.Ö.; Dogru, A.; Wang, J.; Rencheck, M.; Han, Y.; Wang, L.; Seydibeyoğlu, E.A.; Zhao, X.; Ong, K.; Shatkin, J.A.; et al. Review on Hybrid Reinforced Polymer Matrix Composites with Nanocellulose, Nanomaterials, and Other Fibers. Polymers 2023, 15, 984. [Google Scholar] [CrossRef]

- Faraco, T.A.; Fontes, M.d.L.; Paschoalin, R.T.; Claro, A.M.; Gonçalves, I.S.; Cavicchioli, M.; Farias, R.L.d.; Cremona, M.; Ribeiro, S.J.L.; Barud, H.d.S.; et al. Review of Bacterial Nanocellulose as Suitable Substrate for Conformable and Flexible Organic Light-Emitting Diodes. Polymers 2023, 15, 479. [Google Scholar] [CrossRef]

- Jain, K.; Wang, Z.; Garma, L.D.; Engel, E.; Ciftci, G.C.; Fager, C.; Larsson, P.A.; Wågberg, L. 3D printable composites of modified cellulose fibers and conductive polymers and their use in wearable electronics. Appl. Mater. Today 2023, 30, 101703. [Google Scholar] [CrossRef]

- Chen, Z.; Hu, Y.; Shi, G.; Zhuo, H.; Ali, M.A.; Jamróz, E.; Zhang, H.; Zhong, L.; Peng, X. Advanced Flexible Materials from Nanocellulose. Adv. Funct. Mater. 2023, 33, 2214245. [Google Scholar] [CrossRef]

- Wang, X.; Li, X.; Wang, B.; Chen, J.; Zhang, L.; Zhang, K.; He, M.; Xue, Y.; Yang, G. Preparation of Salt-Induced Ultra-Stretchable Nanocellulose Composite Hydrogel for Self-Powered Sensors. Nanomaterials 2023, 13, 157. [Google Scholar] [CrossRef] [PubMed]

- Duroc, Y. From Identification to Sensing: RFID Is One of the Key Technologies in the IoT Field. Sensors 2022, 22, 7523. [Google Scholar] [CrossRef] [PubMed]

- Bukova, B.; Tengler, J.; Brumercikova, E.; Brumercik, F.; Kissova, O. Environmental Burden Case Study of RFID Technology in Logistics Centre. Sensors 2023, 23, 1268. [Google Scholar] [CrossRef]

- Wilczkiewicz, B.; Jankowski-Mihułowicz, P.; Węglarski, M. Test Platform for Developing Processes of Autonomous Identification in RFID Systems with Proximity-Range Read/Write Devices. Electronics 2023, 12, 617. [Google Scholar] [CrossRef]

- Gendy, M.E.G.; Tham, P.; Harrison, F.; Yuce, M.R. Comparing Efficiency and Performance of IoT BLE and RFID-Based Systems for Achieving Contract Tracing to Monitor Infection Spread among Hospital and Office Staff. Sensors 2023, 23, 1397. [Google Scholar] [CrossRef]

- Altaf, S.; Haroon, M.; Ahmad, S.; Nasr, E.A.; Zaindin, M.; Huda, S.; Rehman, Z.u. Radio-Frequency-Identification-Based 3D Human Pose Estimation Using Knowledge-Level Technique. Electronics 2023, 12, 374. [Google Scholar] [CrossRef]

- Chen, K.; Ma, Y.; Liu, H.; Liang, X.; Fu, Y. Trajectory-Robust RFID Relative Localization Based on Phase Profile Correlation. IEEE Trans. Instrum. Meas. 2023, 72, 8000613. [Google Scholar] [CrossRef]

- Mahapatra, S.; Kannan, V.; Seshadri, S.; Ravi, V.; Sofana Reka, S. An IoT-Based Wristband for Automatic People Tracking, Contact Tracing and Geofencing for COVID-19. Sensors 2022, 22, 9902. [Google Scholar] [CrossRef]

- Osmólska, E.; Stoma, M.; Starek-Wójcicka, A. Application of Biosensors, Sensors, and Tags in Intelligent Packaging Used for Food Products—A Review. Sensors 2022, 22, 9956. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, X.; Li, L.; Liu, X.; Li, Q. Timing: Tag Interference Modeling for RFID Localization in Dense Deployment. IEEE Sens. J. 2022, 22, 23464. [Google Scholar] [CrossRef]

- Li, D.; Cao, W.; Wang, C.; Tong, Y. UHF RFID reader antenna with switchable far-field and near-field working state. Electron. Lett. 2022, 58, 931. [Google Scholar] [CrossRef]

- Benedetti, D.; Maselli, G. Robust RFID Tag Identification. Sensors 2022, 22, 8406. [Google Scholar] [CrossRef] [PubMed]

- Lubna; Zahid, A.; Mufti, N.; Ullah, S.; Nawaz, M.W.; Sharif, A.; Imran, M.A.; Abbasi, Q.H. IoT Enabled Vacant Parking Slot Detection System Using Inkjet-printed RFID Tags. IEEE Sens. J. 2023, 23, 7828. [Google Scholar] [CrossRef]

- Sharif, A.; Althobaiti, T.; Alotaibi, A.A.; Ramzan, N.; Imran, M.A.; Abbasi, Q.H. Inkjet-Printed UHF RFID Sticker for Traceability and Spoilage Sensing of Fruits. IEEE Sens. J. 2023, 23, 733. [Google Scholar] [CrossRef]

- Raso, E.; Bianco, G.M.; Bracciale, L.; Marrocco, G.; Occhiuzzi, C.; Loreti, P. Privacy-Aware Architectures for NFC and RFID Sensors in Healthcare Applications. Sensors 2022, 22, 9692. [Google Scholar] [CrossRef]

- Zohra, F.T.; Salim, O.; Masoumi, H.; Karmakar, N.C.; Dey, S. Health Monitoring of Conveyor Belt Using UHF RFID and Multi-Class Neural Networks. Electronics 2022, 11, 3737. [Google Scholar] [CrossRef]

- Song, Z.; Rahmadya, B.; Sun, R.; Takeda, S. An RFID-Based Wireless Vibration and Physical-Shock Sensing System Using Edge Processing. IEEE Sens. J. 2022, 22, 20010. [Google Scholar] [CrossRef]

- Solar, H.; Beriain, A.; Rezola, A.; del Rio, D.; Berenguer, R. A 22-m Operation Range Semi-Passive UHF RFID Sensor Tag with Flexible Thermoelectric Energy Harvester. IEEE Sens. J. 2022, 22, 19797. [Google Scholar] [CrossRef]

- Montanaro, T.; Sergi, I.; Motroni, A.; Buffi, A.; Nepa, P.; Pirozzi, M.; Catarinucci, L.; Colella, R.; Chietera, F.P.; Patrono, L. An IoT-Aware Smart System Exploiting the Electromagnetic Behavior of UHF-RFID Tags to Improve Worker Safety in Outdoor Environments. Electronics 2022, 11, 717. [Google Scholar] [CrossRef]

- Behera, S.K. Chipless RFID Sensors for Wearable Applications: A Review. IEEE Sens. J. 2022, 22, 1105. [Google Scholar] [CrossRef]

- Subrahmannian, A.; Behera, S.K. Chipless RFID Sensors for IoT-Based Healthcare Applications: A Review of State of the Art. IEEE Trans. Instrum. Meas. 2022, 71, 1. [Google Scholar] [CrossRef]

- Das, R.; Chang, Y.H.; Dyson, M. RFID Forecast, Players and Opportunities 2022–2032, The Complete Analysis of the Global RFID Industry. Available online: https://www.idtechex.com/en/research-report/rfid-forecasts-players-and-opportunities-2022-2032/849 (accessed on 1 May 2023).

- Condemi, A.; Cucchiella, F.; Schettini, D. Circular Economy and E-Waste: An Opportunity from RFID TAGs. Appl. Sci. 2019, 9, 3422. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, C.; Cheng, S.-Y.; Xu, Z.-Q.; Sun, X.; Xu, Y.-H.; Chen, J.-J.; Jiang, Z.; Liang, K.; Feng, Z.-S. Flexible RFID Tag Metal Antenna on Paper-Based Substrate by Inkjet Printing Technology. Adv. Funct. Mater. 2019, 29, 1902579. [Google Scholar] [CrossRef]

- Huang, X.J.; Wang, S.C.; Xie, F.; Tong, M.S. Design of an UHF RFID Tag Antenna with a Paper Substrate. In Proceedings of the 2018 IEEE International Symposium on Antennas and Propagation & USNC/URSI National Radio Science Meeting, Boston, MA, USA, 8–13 July 2018; pp. 1363–1364. [Google Scholar]

- Morales-Guerra, J.; Umaña-Idarraga, F.; Giraldo-Escobar, W.; Gonzalez-Valencia, E.; Reyes-Vera, E. Performance analysis of a Compact, Flexible and Biodegradable UHF RFID Tag Antenna. In Proceedings of the 2021 International Conference on Electromagnetics in Advanced Applications (ICEAA), Honolulu, HI, USA, 9–13 August 2021; pp. 357–360. [Google Scholar] [CrossRef]

- Gupta, D.; Sood, D.; Yu, M.; Kumar, M. Compact Biodegradable UHF RFID Tag for Short Life Cycle Applications. In Proceedings of the 2021 IEEE Indian Conference on Antennas and Propagation (InCAP), Jaipur, India, 13–16 December 2021; pp. 399–401. [Google Scholar] [CrossRef]

- Kim, S. Inkjet-Printed Electronics on Paper for RF Identification (RFID) and Sensing. Electronics 2020, 9, 1636. [Google Scholar] [CrossRef]

- Kumar, M.; Sharma, A.; Zuazola, I.J.G. A biodegradable multi-platform tolerant passive UHF RFID tag antenna for short-life cycle IoT applications. In Proceedings of the 2021 IEEE Indian Conference on Antennas and Propagation (InCAP), Jaipur, India, 13–16 December 2021; pp. 391–394. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, Y.; Li, Y.-Z.; Cheng, P.; Cheng, S.-Y.; Liang, Q.; Xu, Z.-Q.; Chen, H.-J.; Feng, Z.-S. A facile process combined with roll-to-roll flexographic printing and electroless deposition to fabricate RFID tag antenna on paper substrates. Compos. Part B Eng. 2021, 224, 109194. [Google Scholar] [CrossRef]

- Sidibe, A.; Mir, L.L.; Dhuiège, B.; Depres, G.; Takacs, A.; Mennekens, J. A Thin Paper UHF Antenna on Nanocelloluse Based Substrate for Battery-free Geolocation Tags. In Proceedings of the 2022 IEEE International Symposium on Antennas and Propagation and USNC-URSI Radio Science Meeting (AP-S/URSI), Denver, CO, USA, 10–15 July 2022; pp. 125–126. [Google Scholar] [CrossRef]

- Hussain, M.; Amin, Y.; Lee, K.-G. A Compact and Flexible UHF RFID Tag Antenna for Massive IoT Devices in 5G System. Sensors 2020, 20, 5713. [Google Scholar] [CrossRef] [PubMed]

- Mostaccio, G.; Bianco, M.; Amendola, S.; Marrocco, G.; Occhiuzzi, C. RFID for Food Industry 4.0—Current Trends and Monitoring of Fruit Ripening. In Proceedings of the 2022 IEEE 12th International Conference on RFID Technology and Applications (RFID-TA), Cagliari, Italy, 12–14 September 2022; pp. 109–112. [Google Scholar] [CrossRef]

- Machiels, J.; Appeltans, R.; Bauer, D.K.; Segers, E.; Henckens, Z.; Van Rompaey, W.; Adons, D.; Peeters, R.; Geiβler, M.; Kuehnoel, K.; et al. Screen Printed Antennas on Fiber-Based Substrates for Sustainable HF RFID Assisted E-Fulfilment Smart Packaging. Materials 2021, 14, 5500. [Google Scholar] [CrossRef] [PubMed]

- Marques, A.H.F.; dos Santos, D.; de Oliveira Vieira, K.; Quadros, M.H.; Rebello, P.H.P.; Ferro, V.L.D.; Santos, E.D.; Fellegara, H.; Valério, P.; Fugikawa-Santos, L.; et al. Environmentally Friendly, Semi-transparent, Screen Printed Antenna for RFID Tag Applications. Braz. J. Phys. 2021, 51, 434. [Google Scholar] [CrossRef]

- StoraEnso. Available online: https://www.storaenso.com/en/newsroom/news/2020/1/eco-rfid-explained--a-look-behind-the-worlds-greenest-tag (accessed on 1 May 2023).

- BioplasticsNew. Available online: https://bioplasticsnews.com/2020/01/12/stora-enso-sustainable-rfid-tag/ (accessed on 1 May 2023).

- Avery Dennison. Available online: https://rfid.averydennison.com/en/home/products-solutions/rfid-sustainable-tags.html (accessed on 1 May 2023).

- Yang, W.; Cheng, X.; Guo, Z.; Sun, Q.; Wanga, J.; Wang, C. Design, fabrication and applications of flexible RFID antennas based on printed electronic materials and technologies. J. Mater. Chem. C 2023, 11, 406. [Google Scholar] [CrossRef]

- Piro, B.; Tran, H.V.; Thu, V.T. Sensors Made of Natural Renewable Materials: Efficiency, Recyclability or Biodegradability—The Green Electronics. Sensors 2020, 20, 5898. [Google Scholar] [CrossRef]

- Siti, F.K.; Mariatti, M.; Jang-Kyo, K. Green Strategies to Printed Sensors for Healthcare Applications. Polym. Rev. 2020, 61, 116. [Google Scholar] [CrossRef]

- Kalambate, P.K.; Rao, Z.; Wu, D.J.; Shen, Y.; Boddula, R.; Huang, Y. Electrochemical (bio) sensors go green. Biosens. Bioelectron. 2020, 163, 112270. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Shang, S.; Mo, S.; Wang, P.; Wang, H. Eco-friendly Strategies for the Material and Fabrication of Wearable Sensors. Int. J. Precis. Eng. Manuf.-Green Tech. 2021, 8, 1323. [Google Scholar] [CrossRef]

- Ponnamma, D.; Parangusan, H.; Deshmukh, K.; Kar, P.; Muzaffar, A.; Pasha, S.K.K.; Ahamed, M.B.; Al-Maadeed, M.A.A. Green synthesized materials for sensor, actuator, energy storage and energy generation: A review. Polym.-Plast. Technol. Mater. 2020, 59, 1–62. [Google Scholar] [CrossRef]

- Guan, M.; Liu, Y.; Du, H.; Long, Y.; An, X.; Liu, H.; Cheng, B. Durable, breathable, sweat-resistant, and degradable flexible sensors for human motion detection. Chem. Eng. J. 2023, 462, 142151. [Google Scholar] [CrossRef]

- Altay, B.N.; Aksoy, B.; Banerjee, D.; Maddipatla, D.; Fleming, P.D.; Bolduc, M.; Cloutier, S.G.; Atashbar, M.Z.; Gupta, R.B.; Demir, M. Lignin-Derived Carbon-Coated Functional Paper for Printed Electronics. ACS Appl. Electron. Mater. 2021, 3, 3904. [Google Scholar] [CrossRef]

- Zhao, P.; Zhang, R.; Tong, Y.; Zhao, X.; Tang, Q.; Liu, Y. All-Paper, All-Organic, Cuttable, and Foldable Pressure Sensor with Tuneable Conductivity Polypyrrole. Adv. Electron. Mater. 2020, 6, 1901426. [Google Scholar] [CrossRef]

- Sun, B.; Chen, Y.; Zhou, G.; Zhou, Y.; Guo, T.; Zhu, S.; Mao, S.; Zhao, Y.; Shao, J.; Li, Y. A Flexible Corn Starch-Based Biomaterial Device Integrated with Capacitive-Coupled Memristive Memory, Mechanical Stress Sensing, Synapse, and Logic Operation Functions. Adv. Electron. Mater. 2023, 9, 2201017. [Google Scholar] [CrossRef]

- Ma, X.; Hu, Q.; Dai, Y.; He, P.; Zhang, X. Disposable sensors based on biodegradable polylactic acid piezoelectret films and their application in wearable electronics. Sens. Actuators A Phys. 2022, 346, 113834. [Google Scholar] [CrossRef]

- Ketabi, M.; Al Shboul, A.; Mahinnezhad, S.; Izquierdo, R. Aerosol-jet printing of flexible green graphene humidity sensors for IoT applications. In Proceedings of the 2021 IEEE Sensors, Sydney, Australia, 31 October–3 November 2021; pp. 1–4. [Google Scholar] [CrossRef]

- Liu, X.; Fu, T.; Ward, J.; Gao, H.; Yin, B.; Woodard, T.; Lovley, D.R.; Yao, J. Multifunctional Protein Nanowire Humidity Sensors for Green Wearable Electronics. Adv. Electron. Mater. 2020, 6, 2000721. [Google Scholar] [CrossRef]

- Ma, J.; Jiang, Y.; Shen, L.; Ma, H.; Sun, T.; Lv, F.; Kiran, A.; Zhu, N. Wearable biomolecule smartsensors based on one-step fabricated berlin green printed arrays. Biosens. Bioelectron. 2019, 144, 111637. [Google Scholar] [CrossRef] [PubMed]

- Xiang, H.; Li, Z.; Liu, H.; Chen, T.; Zhou, H.; Huang, W. Green flexible electronics based on starch. Npj Flex Electron 2022, 6, 15. [Google Scholar] [CrossRef]

- Xu, M.; Cai, H.; Liu, Z.; Chen, F.; Chen, L.; Chen, X.; Cheng, X.; Dai, F.; Li, Z. Breathable, Degradable Piezoresistive Skin Sensor Based on a Sandwich Structure for High-Performance Pressure Detection. Adv. Electron. Mater. 2021, 7, 2100368. [Google Scholar] [CrossRef]

- Tang, D.; Abdalkarim, S.Y.H.; Dong, Y.; Yu, H.-Y. One-pot strategy to fabricate conductive cellulose nanocrystal-polyethylenedioxythiophene nanocomposite: Synthesis mechanism, modulated morphologies and sensor assembly. Carbohydr. Polym. 2023, 311, 120758. [Google Scholar] [CrossRef]

- Li, C.; Li, G.; Li, G.; Yu, D.; Song, Z.; Liu, X.; Wang, H.; Liu, W. Cellulose Fiber-Derived Carbon Fiber Networks for Durable Piezoresistive Pressure Sensing. ACS Appl. Electron. Mater. 2021, 3, 2389. [Google Scholar] [CrossRef]

- Ko, W.-Y.; Huang, L.-T.; Lin, K.-J. Green technique solvent-free fabrication of silver nanoparticle–carbon nanotube flexible films for wearable sensors. Sens. Actuators A Phys. 2021, 317, 112437. [Google Scholar] [CrossRef]

- Lahcen, A.A.; Rauf, S.; Beduk, T.; Durmus, C.; Aljedaibi, A.; Timur, S.; Alshareef, H.N.; Amine, A.; Wolfbeis, O.S.; Salama, K.N. Electrochemical sensors and biosensors using laser-derived graphene: A comprehensive review. Biosens. Bioelectron. 2020, 168, 112565. [Google Scholar] [CrossRef]

- Ismail, Z. Laser writing of graphene on cellulose paper and analogous material for green and sustainable electronic: A concise review. Carbon Lett. 2022, 32, 1227. [Google Scholar] [CrossRef]

- Singh, A.T.; Lantigua, D.; Meka, A.; Taing, S.; Pandher, M.; Camci-Unal, G. Paper-Based Sensors: Emerging Themes and Applications. Sensors 2018, 18, 2838. [Google Scholar] [CrossRef]

- Tai, H.; Duan, Z.; Wang, Y.; Wang, S.; Jiang, Y. Paper-Based Sensors for Gas, Humidity, and Strain Detections: A Review. ACS Appl. Mater. Interfaces 2020, 12, 31037. [Google Scholar] [CrossRef]

- Korotcenkov, G. Paper-Based Humidity Sensors as Promising Flexible Devices: State of the Art: Part 1. General Consideration. Nanomaterials 2023, 13, 1110. [Google Scholar] [CrossRef] [PubMed]

- Korotcenkov, G.; Simonenko, N.P.; Simonenko, E.P.; Sysoev, V.V.; Brinzari, V. Paper-Based Humidity Sensors as Promising Flexible Devices, State of the Art, Part 2: Humidity-Sensor Performances. Nanomaterials 2023, 13, 1381. [Google Scholar] [CrossRef] [PubMed]

- Duan, Z.; Yuan, Z.; Jiang, Y.; Yuan, L.; Tai, H. Amorphous carbon material of daily carbon ink: Emerging applications in pressure, strain, and humidity sensors. J. Mater. Chem. C 2023, 11, 5585. [Google Scholar] [CrossRef]

- Liu, H.; Xiang, H.; Li, Z.; Meng, Q.; Li, P.; Ma, Y.; Zhou, H.; Huang, W. Flexible and degradable multimodal sensor fabricated by transferring laser-induced porous carbon on starch film. ACS Sustain. Chem. Eng. 2020, 8, 527. [Google Scholar] [CrossRef]

- Liu, S.; Chen, C.; Zhang, D.; Dong, G.; Zheng, D.; Jiang, Y.; Zhou, G.; Liu, J.-M.; Kempa, K.; Gao, J. Recyclable and flexible starch-Ag networks and its application in joint sensor. Nanoscale Res. Lett. 2019, 14, 127. [Google Scholar] [CrossRef]

- Zhang, S.; Li, H.; Yang, Z.; Chen, B.; Li, K.; Lai, X.; Zeng, X. Degradable and stretchable bio-based strain sensor for human motion detection. J. Colloid Interface Sci. 2022, 626, 554. [Google Scholar] [CrossRef]

- Liu, H.; Xiang, H.; Ma, Y.; Li, Z.; Meng, Q.; Li, P.; Zhou, H.; Huang, W. Flexible, Degradable, and Cost-Effective Strain Sensor Fabricated by a Scalable Papermaking Procedure. ACS Sustain. Chem. Eng. 2018, 6, 15749. [Google Scholar] [CrossRef]

- Liu, X.; Wang, X.; Liu, Y.; Yao, Y.; Zhu, X.; Hu, Y.; Wan, T.; Cheng, B. Synthesis of Poly(ether carbonate)-Based Polyurethane for Biodegradable–Recyclable Pressure Sensors. ACS Sustain. Chem. Eng. 2023, 11, 4258. [Google Scholar] [CrossRef]

- Rivadeneyra, A.; Marín-Sánchez, A.; Wicklein, B.; Salmerón, J.F.; Castillo, E.; Bobinger, M.; Salinas-Castillo, A. Cellulose nanofibers as substrate for flexible and biodegradable moisture sensors. Compos. Sci. Technol. 2021, 208, 108738. [Google Scholar] [CrossRef]

- Yoshida, A.; Wang, Y.-F.; Tachibana, S.; Hasegawa, A.; Sekine, T.; Takeda, Y.; Hong, J.; Kumaki, D.; Shiba, T.; Tokito, S. Printed, all-carbon-based flexible humidity sensor using a cellulose nanofiber/graphene nanoplatelet composite. Carbon Trends 2022, 7, 100166. [Google Scholar] [CrossRef]

- Falco, A.; Marín-Sánchez, A.; Loghin, F.C.; Castillo, E.; Salinas-Castillo, A.; Salmerón, J.F.; Rivadeneyra, A. Paper and Salt: Biodegradable NaCl-Based Humidity Sensors for Sustainable Electronics. Front. Electron. 2022, 3, 838472. [Google Scholar] [CrossRef]

- Kumar, R.; Rahman, H.; Ranwa, S.; Kumar, A.; Kumar, G. Development of cost effective metal oxide semiconductor based gas sensor over flexible chitosan/PVP blended polymeric substrate. Carbohydr. Polym. 2020, 239, 116213. [Google Scholar] [CrossRef]

- Molina, A.; Oliva, J.; Oliva, A.I.; Garces, L.; Rodriguez-Gonzalez, V. Enhancing the gas detection response of biodegradable NO2 sensors by creating on their surface oxygen-vacancies/zinc-interstitial defects. Synth. Met. 2023, 295, 117348. [Google Scholar] [CrossRef]

- Shahrbabaki, Z.; Farajikhah, S.; Ghasemian, M.B.; Oveissi, F.; Rath, R.J.; Yun, J.; Dehghani, F.; Naficy, S. A Flexible and Polymer-Based Chemiresistive CO2 Gas Sensor at Room Temperature. Adv. Mater. Technol. 2023, 8, 2201510. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, X.; Wu, Z.; Abdurahman, K.; Cao, Y.; Duan, H.; Jia, D. Mechanical, electromagnetic shielding and gas sensing properties of flexible cotton fiber/polyaniline composites. Compos. Sci. Technol. 2020, 188, 107966. [Google Scholar] [CrossRef]

- Arena, A.; Branca, C.; Ciofi, C.; D’Angelo, G.; Romano, V.; Scandurra, G. Polypyrrole and Graphene Nanoplatelets Inks as Electrodes for Flexible Solid-State Supercapacitor. Nanomaterials 2021, 11, 2589. [Google Scholar] [CrossRef]

- Rajan, K.; Garofalo, E.; Chiolerio, A. Wearable Intrinsically Soft, Stretchable, Flexible Devices for Memories and Computing. Sensors 2018, 18, 367. [Google Scholar] [CrossRef] [PubMed]

- Yan, K.; Li, J.; Pan, L.; Shi, Y. Inkjet printing for flexible and wearable electronics. APL Mater. 2020, 8, 120705. [Google Scholar] [CrossRef]

- Jia, H.; Gu, S.-Y.; Chang, K. 3D printed self-expandable vascular stents from biodegradable shape memory polymer. Adv. Polym. Technol. 2018, 37, 3222–3228. [Google Scholar] [CrossRef]

- Gao, H.; Li, J.; Zhang, F.; Liu, Y.; Leng, J. The research status and challenges of shape memory polymer-based flexible electronics. Mater. Horiz. 2019, 6, 931–944. [Google Scholar] [CrossRef]

- Delfag, M.; Rachovitis, G.; Gonzalez, Y.; Jehn, J.; Youssef, A.H.; Schindler, C.; Ruediger, A. Fully printed ZnO-based valency-change memories for flexible and transparent applications. Flex. Print. Electron. 2022, 7, 045001. [Google Scholar] [CrossRef]

- Tang, P.; Chen, J.; Qiu, T.; Ning, H.; Fu, X.; Li, M.; Xu, Z.; Luo, D.; Yao, R.; Peng, J. Recent Advances in Flexible Resistive Random Access Memory. Appl. Syst. Innov. 2022, 5, 91. [Google Scholar] [CrossRef]

- Huang, W.-Y.; Chang, Y.-C.; Sie, Y.-F.; Yu, C.-R.; Wu, C.-Y.; Hsu, Y.-L. Bio-Cellulose Substrate for Fabricating Fully Biodegradable Resistive Random Access Devices. ACS Appl. Polym. Mater. 2021, 3, 4478. [Google Scholar] [CrossRef]

- Arshad, N.; Irshad, M.S.; Abbasi, M.S.; Rehman, S.U.; Ahmed, I.; Javed, M.Q.; Ahmad, S.; Sharaf, M.; Al Firdausi, M.D. Green thin film for stable electrical switching in a low-cost washable memory device: Proof of concept. RSC Adv. 2021, 11, 4327. [Google Scholar] [CrossRef] [PubMed]

- Jiang, T.; Meng, X.; Zhou, Z.; Wu, Y.; Tian, Z.; Liu, Z.; Lu, G.; Eginlidil, M.; Yu, H.-D.; Liu, J.; et al. Highly flexible and degradable memory electronics comprised of all-biocompatible materials. Nanoscale 2021, 13, 724. [Google Scholar] [CrossRef] [PubMed]

- Raeis-Hosseini, N.; Lee, J.-S. Controlling the resistive switching behavior in starch-based flexible biomemristors. ACS Appl. Mater. Interfaces 2016, 8, 7326. [Google Scholar] [CrossRef]

- Lam, J.-Y.; Jang, G.-W.; Huang, C.-J.; Tung, S.-H.; Chen, W.-C. Environmentally Friendly Resistive Switching Memory Devices with DNA as the Active Layer and Bio-Based Polyethylene Furanoate as the Substrate. ACS Sustain. Chem. Eng. 2020, 8, 5100. [Google Scholar] [CrossRef]

- Chang, Y.-C.; Lee, C.-J.; Wang, L.-W.; Wang, Y.-H. Air-stable gelatin composite memory devices on a paper substrate. Org. Electron. 2019, 65, 77. [Google Scholar] [CrossRef]

- Xinglong, J.; Li, S.; Shuai, Z.; Yu, J.; Kian, L.; Chao, W.; Rong, Z. Biodegradable and Flexible Resistive Memory for Transient Electronics. J. Phys. Chem. C 2018, 122, 16909–16915. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y.; Zhang, P.; Wen, D. Flexible Transient Resistive Memory Based on Biodegradable Composites. Nanomaterials 2022, 12, 3531. [Google Scholar] [CrossRef]

- Rahmani, H.; Shetty, D.; Wagih, M.; Ghasempour, Y.; Palazzi, V.; Carvalho, N.B.; Correia, R.; Costanzo, A.; Vital, D.; Alimenti, F.; et al. Next-Generation IoT Devices: Sustainable Eco-Friendly Manufacturing, Energy Harvesting, and Wireless Connectivity. IEEE J. Microw. 2023, 3, 237. [Google Scholar] [CrossRef]

- Thakur, A.; Devi, P. Paper-based flexible devices for energy harvesting, conversion and storage applications: A review. Nano Energy 2022, 94, 106927. [Google Scholar] [CrossRef]

- He, J.; Qian, S.; Niu, X.; Zhang, N.; Qian, J.; Hou, X.; Mu, J.; Geng, W.; Chou, X. Piezoelectric-enhanced triboelectric nanogenerator fabric for biomechanical energy harvesting. Nano Energy 2019, 64, 103933. [Google Scholar] [CrossRef]

- López, O.L.; Alves, H.; Souza, R.D.; Montejo-Sánchez, S.; Fernández, E.M.G.; Latva-Aho, M. Massive wireless energy transfer: Enabling sustainable IoT toward 6G era. IEEE Internet Things J. 2021, 8, 8816. [Google Scholar] [CrossRef]

- Yang, X.; Daoud, W.A. An experimental and computational investigation of (α-methylbenzylidene)carbene. Adv. Funct. Mater. 2016, 26, 8194. [Google Scholar] [CrossRef]

- Briscoe, J.; Dunn, S. Piezoelectric nanogenerators—A review of nanostructured piezoelectric energy harvesters. Nano Energy 2015, 14, 15. [Google Scholar] [CrossRef]

- Rana, M.M.; Khan, A.A.; Zhu, W.; Al Fattah, F.; Kokilathasan, S.; Rassel, S.; Bernard, R.; Ababou-Girard, S.; Turban, P.; Xu, S.; et al. Enhanced piezoelectricity in lead-free halide perovskite nanocomposite for self-powered wireless electronics. Nano Energy 2022, 101, 107631. [Google Scholar] [CrossRef]

- Martinez-Lopez, A.G.; Tinoco, J.C.; Elvira-Hernández, E.A.; Herrera-May, A.L. Solution-processed ZnO energy harvester devices based on flexible substrates. Microsyst. Technol. 2023, 29, 205. [Google Scholar] [CrossRef]

- Pattipaka, S.; Bae, Y.M.; Jeong, C.K.; Park, K.-I.; Hwang, G.-T. Perovskite Piezoelectric-Based Flexible Energy Harvesters for Self-Powered Implantable and Wearable IoT Devices. Sensors 2022, 22, 9506. [Google Scholar] [CrossRef] [PubMed]

- Sahu, M.; Hajra, S.; Panda, S.; Rajaitha, M.; Panigrahi, B.K.; Rubahn, H.-G.; Mishra, Y.K.; Kim, H.J. Waste textiles as the versatile triboelectric energy-harvesting platform for self-powered applications in sports and athletics. Nano Energy 2022, 97, 107208. [Google Scholar] [CrossRef]

- Naval, S.; Jain, A.; Mallick, D. Direct current triboelectric nanogenerators: A review. J. Micromech. Microeng. 2023, 33, 013001. [Google Scholar] [CrossRef]

- Dong, X.; Liu, Z.; Yang, P.; Chen, X. Harvesting Wind Energy Based on Triboelectric Nanogenerators. Nanoenergy Adv. 2022, 2, 245. [Google Scholar] [CrossRef]

- Syamini, J.; Chandran, A. Mylar Interlayer-Mediated Performance Enhancement of a Flexible Triboelectric Nanogenerator for Self-Powered Pressure Sensing Application. ACS Appl. Electron. Mater. 2023, 5, 1002. [Google Scholar] [CrossRef]

- Singh, V.; Singh, B. MoS2-PVDF/PDMS based flexible hybrid piezo-triboelectric nanogenerator for harvesting mechanical energy. J. Alloy. Compd. 2023, 941, 168850. [Google Scholar] [CrossRef]

- Hajra, S.; Padhan, A.M.; Sahu, M.; Alagarsamy, P.; Lee, K.; Kim, H.J. Lead-free flexible Bismuth Titanate-PDMS composites: A multifunctional colossal dielectric material for hybrid piezo-triboelectric nanogenerator to sustainably power portable electronics. Nano Energy 2021, 89, 106316. [Google Scholar] [CrossRef]

- Sahu, M.; Vivekananthan, V.; Hajra, S.; Abisegapriyan, K.S.; Raj, N.P.M.J.; Kim, S.-J. Synergetic enhancement of energy harvesting performance in triboelectric nanogenerator using ferroelectric polarization for self-powered IR signaling and body activity monitoring. J. Mater. Chem. A 2020, 8, 22257. [Google Scholar] [CrossRef]

- Varghese, H.; Abdul Hakkeem, H.M.; Chauhan, K.; Thouti, E.; Pillai, S.; Chandran, A. A high-performance flexible triboelectric nanogenerator based on cellulose acetate nanofibers and micropatterned PDMS films as mechanical energy harvester and self-powered vibrational sensor. Nano Energy 2022, 98, 107339. [Google Scholar] [CrossRef]

- Sriphan, S.; Vittayakorn, N. Hybrid piezoelectric-triboelectric nanogenerators for flexible electronics: Recent advances and perspectives. J. Sci. Adv. Mater. Devices 2022, 7, 100461. [Google Scholar] [CrossRef]

- Van Toan, N.; Tuoi, T.T.K.; Sui, H.; Trung, N.H.; Samat, K.F.; Ono, T. Ultra-flexible thermoelectric generator based on silicone rubber sheet and electrodeposited thermoelectric material for waste heat harvesting. Energy Rep. 2022, 8, 5026. [Google Scholar] [CrossRef]

- Kim, S.; Na, Y.; Nam, C.; Jeong, C.K.; Kim, K.T.; Park, K.-I. Highly tailorable, ultra-foldable, and resorbable thermoelectric paper for origami-enabled energy generation. Nano Energy 2022, 103 Pt A, 107824. [Google Scholar] [CrossRef]

- Zhang, Y.; Park, S.-J. Flexible Organic Thermoelectric Materials and Devices for Wearable Green Energy Harvesting. Polymers 2019, 11, 909. [Google Scholar] [CrossRef] [PubMed]

- Bakytbekov, A.; Nguyen, T.Q.; Zhang, G.; Strano, M.S.; Salama, K.N.; Shamim, A. Synergistic multi-source ambient RF and thermal energy harvester for green IoT applications. Energy Rep. 2023, 9, 1875. [Google Scholar] [CrossRef]

- Yu, B.-Y.; Wang, Z.-H.; Ju, L.; Zhang, C.; Liu, Z.-G.; Tao, L.; Lu, W.-B. Flexible and Wearable Hybrid RF and Solar Energy Harvesting System. IEEE Trans. Antennas Propag. 2022, 70, 2223. [Google Scholar] [CrossRef]

- SCAPS-1D. Available online: https://scaps.elis.ugent.be/ (accessed on 1 May 2023).

- Tara, A.; Bharti, V.; Sharma, S.; Gupta, R. Device Simulation of FASnI3 Based Perovskite Solar Cell with Zn(O0.3,S0.7) as Electron Transport Layer Using SCAPS-1D. Opt. Mater. 2021, 119, 111362. [Google Scholar] [CrossRef]

- Husainat, A.; Ali, W.; Cofie, P.; Attia, J.; Fuller, J. Simulation and Analysis of Methylammonium Lead Iodide (CH3NH3PbI3) Perovskite Solar Cell with Au Contact Using SCAPS 1D Simulator. Am. J. Opt. Photonics 2019, 7, 33. [Google Scholar] [CrossRef]

- Hasanzadeh Azar, M.; Aynehband, S.; Abdollahi, H.; Alimohammadi, H.; Rajabi, N.; Angizi, S.; Kamraninejad, V.; Teimouri, R.; Mohammadpour, R.; Simchi, A. SCAPS Empowered Machine Learning Modelling of Perovskite Solar Cells: Predictive Design of Active Layer and Hole Transport Materials. Photonics 2023, 10, 271. [Google Scholar] [CrossRef]

- Valletta, A.; Demirkol, A.S.; Maira, G.; Frasca, M.; Vinciguerra, V.; Occhipinti, L.G.; Fortuna, L.; Mariucci, L.; Fortunato, G. A Compact SPICE Model for Organic TFTs and Applications to Logic Circuit Design. IEEE Trans. Nanotechnol. 2016, 15, 754. [Google Scholar] [CrossRef]

- Kim, J.-H.; Seo, Y.; Jang, J.T.; Park, S.; Kang, D.; Park, J.; Han, M.; Kim, C.; Park, D.-W.; Kim, D.H. Reliability-Aware SPICE Compatible Compact Modeling of IGZO Inverters on a Flexible Substrate. Appl. Sci. 2021, 11, 4838. [Google Scholar] [CrossRef]

- Jung, S.; Kwon, J.; Tokito, S.; Horowitz, G.; Bonnassieux, Y.; Jung, S. Compact modelling and SPICE simulation for three-dimensional, inkjet-printed organic transistors, inverters and ring oscillators. J. Phys. D Appl. Phys. 2019, 52, 444005. [Google Scholar] [CrossRef]

- Kong, S.; Lim, H.; Hoessinger, Q.; Guichard, E. TCAD modeling of mechanical stress for simulation of thin film transistor on flexible substrate. SID Symp Dig. Tech Pap. 2019, 50, 1606. [Google Scholar] [CrossRef]

- Lim, H.; Kong, S.; Guichard, E.; Hoessinger, A. A general approach for deformation induced stress on flexible electronics. In Proceedings of the International Conference on Simulation of Semiconductor Processes and Devices (SISPAD), Austin, TX, USA, 24–26 September 2018. [Google Scholar]

- Dash, T.; Mohapatra, E.; Maiti, C.K. Deformation-induced stress/strain mapping and performance evaluation of a-IGZO thin-film transistors for flexible electronic applications. J. Soc. Inf. Disp. 2021, 29, 130. [Google Scholar] [CrossRef]

- Vukovic, A.; Altinozen, A.; Dimitrijevic, T.; Sewell, P. Simulation Platform for Flexible Electronics. In Proceedings of the 2021 15th International Conference on Advanced Technologies, Systems and Services in Telecommunications (TELSIKS), Nis, Serbia, 20–22 October 2021; pp. 135–138. [Google Scholar] [CrossRef]

- SILVACO. Available online: https://silvaco.com/webinar/spice-modeling-for-flexible-electronics/ (accessed on 1 May 2023).

- CADENCE-PCB. Available online: https://resources.pcb.cadence.com/blog/2023-designing-a-flex-pcb-prototype-pcb-design-tips-and-considerations (accessed on 29 May 2023).

- Scandurra, G.; Ciofi, C.; Smulko, J.; Wen, H. A review of design approaches for the implementation of low-frequency noise measurement systems. Rev. Sci. Instrum. 2022, 93, 111101. [Google Scholar] [CrossRef]

- Song, Y.; Lee, T. Electronic noise analyses on organic electronic devices. J. Mater. Chem. C 2017, 5, 7123. [Google Scholar] [CrossRef]

- Landi, G.; Pagano, S.; Neitzert, H.C.; Mauro, C.; Barone, C. Noise Spectroscopy: A Tool to Understand the Physics of Solar Cells. Energies 2023, 16, 1296. [Google Scholar] [CrossRef]

- Battistoni, S.; Sajapin, R.; Erokhin, V.; Verna, A.; Cocuzza, M.; Marasso, S.L.; Iannotta, S. Effects of noise sourcing on organic memristive devices. Chaos Solitons Fractals 2020, 141, 110319. [Google Scholar] [CrossRef]

- Ke, L.; Zhao, X.Y.; Kumar, R.S.; Chua, S.J. Low-frequency noise measurement and analysis in organic light-emitting diodes. IEEE Electron Device Lett. 2006, 27, 7–555. [Google Scholar] [CrossRef]

- Martin, S.; Dodabalapur, A.; Bao, Z.; Crone, B.; Katz, H.E.; Li, W.; Passner, A.; Rogers, J.A. Flicker noise properties of organic thin-film transistors. J. Appl. Phys. 2000, 87, 3381. [Google Scholar] [CrossRef]

- Barone, C.; Maccagnani, P.; Dinelli, F.; Bertoldo, M.; Capelli, R.; Cocchi, M.; Seri, M.; Pagano, S. Electrical conduction and noise spectroscopy of sodium-alginate gold-covered ultrathin films for flexible green electronics. Sci. Rep. 2022, 12, 9861. [Google Scholar] [CrossRef]

- Fu, Z.; Hannula, M.; Jauho, A.; Väisänen, K.-L.; Välimäki, M.; Keskinen, J.; Mäntysalo, M. Cyclic Bending Reliability and Failure Mechanism of Printed Biodegradable Flexible Supercapacitor on Polymer Substrate. ACS Appl. Mater. Interfaces 2022, 14, 40145. [Google Scholar] [CrossRef]

- Jeong, J.-H.; Kim, J.-H.; Oh, C.-S. Quantitative evaluation of bending reliability for a flexible near-field communication tag. Microelectron. Reliab. 2017, 75, 121. [Google Scholar] [CrossRef]

- Suhaimi, M.I.; Nordin, A.N.; Md Ralib, A.A.; Voiculescu, I.; Mak, W.C.; Ming, L.L.; Samsudin, Z. Mechanical durability of screen-printed flexible silver traces for wearable devices. Sens. Bio-Sens. Res. 2022, 38, 100537. [Google Scholar] [CrossRef]

- Kim, T.; Kim, J.; Yun, H.; Lee, J.-S.; Lee, J.-H.; Song, J.-Y.; Joo, Y.-C.; Lee, W.-J.; Kim, B.-J. Electrical Reliability of Flexible Silicon Package Integrated on Polymer Substrate during Repeated Bending Deformations. ASME J. Electron. Packag. 2022, 144, 041017. [Google Scholar] [CrossRef]

- Maita, F.; Maiolo, L.; Minotti, A.; Pecora, A.; Ricci, D.; Metta, G.; Scandurra, G.; Giusi, G.; Ciofi, C.; Fortunato, G. Ultraflexible Tactile Piezoelectric Sensor Based on Low-Temperature Polycrystalline Silicon Thin-Film Transistor Technology. IEEE Sens. J. 2015, 15, 3819. [Google Scholar] [CrossRef]

- Saleh, R.; Barth, M.; Eberhardt, W.; Zimmermann, A. Bending Setups for Reliability Investigation of Flexible Electronics. Micromachines 2021, 12, 78. [Google Scholar] [CrossRef] [PubMed]

- Kovac, O.; Lukacs, P. Automatic Evaluation of Flexible Electronic Bending Test. In Proceedings of the 2021 44th International Spring Seminar on Electronics Technology (ISSE), Bautzen, Germany, 5–9 May 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Wright, D.N.; Vardøy, A.S.; Belle, B.D.; Taklo, M.M.V. Bending machine for testing reliability of flexible electronics. In Proceedings of the 2017 IMAPS Nordic Conference on Microelectronics Packaging (NordPac), Gothenburg, Sweden, 18–20 June 2017; pp. 47–52. [Google Scholar] [CrossRef]

- Scandurra, G.; Arena, A.; Giusi, G.; Cannatà, G.; Ciofi, C. Low frequency noise measurements as an early indicator of degradation for devices on plastic substrates subjected to mechanical stress. In Proceedings of the 2017 International Conference on Noise and Fluctuations (ICNF), Vilnius, Lithuania, 20–23 June 2017; pp. 1–4. [Google Scholar] [CrossRef]

- Harris, K.D.; Elias, A.L.; Chung, H.J. Flexible electronics under strain: A review of mechanical characterization and durability enhancement strategies. J. Mater. Sci. 2016, 51, 2771. [Google Scholar] [CrossRef]

- Kim, C.; Kim, C.H. Universal Testing Apparatus Implementing Various Repetitive Mechanical Deformations to Evaluate the Reliability of Flexible Electronic Devices. Micromachines 2018, 9, 492. [Google Scholar] [CrossRef]

| Substrate Material | Climate Change Impact kg CO2 eq. */Sheet *** | Resource Use kg Sb eq. **/Sheet *** |

|---|---|---|

| Paper | 1.3 × 10−4 | 5.2 × 10−11 |

| PET (polyethylene terephthalate) | 1.5 × 10−3 | 1.8 × 10−10 |

| PEI (polyetherimide) | 1.3 × 10−2 | 2.0 × 10−9 |

| PEEK (polyether ether ketone) | 7.4 × 10−3 | 2.2 × 10−9 |

| Printing Technique | Substrate Material | Sheet Resistance mΩ/Square | Volume Resistivity (Ω·cm) |

|---|---|---|---|

| Flexo-printing | P1 * | 177 ± 19 | 2.2 × 10−6 |

| P2 ** | 169 ± 16 | 1.6 × 10−6 | |

| PET *** | 260 ± 23 | 2.1 × 10−6 | |

| Rotary screen-printing | P1 | 45.3 ± 1.3 | 4.1 × 10−5 |

| P2 | 39.4 ± 0.6 | 3.4 × 10−5 | |

| PET | 52.3 ± 2.5 | 4.7 × 10−5 |

| Substrate Material | Young’s Modulus [GPa] |

|---|---|

| Paper | Up to 3.5 * |

| PET | 2.8 |

| PEN | 3.0 |

| PDMS | Up to 3.7 ** |

| Sample * | Status | Biodegradation ** |

|---|---|---|

| CNF 50%, HEC 50% | Printed | 74% |

| CNF 50%, HEC 50% | Unprinted | 78% |

| MCC | Unprinted | 94% |

| TPU | Unprinted | No degradation |

| Material | Dimensions (mm2) | Gain (dBi) | Reading Range (m) | Ref. |

|---|---|---|---|---|

| Paper substrate | 63.6 × 25 | 2.37 | - | [155] |

| Copper ink on paper dielectric substrate | 81.95 × 14.5 | 1.81 | - | [156] |

| Graphene ink on paper substrate | 16 × 65 | −5 | 3.5 | [157] |

| Bioresorbable copper-based paint on a bioresorbable cellulose-based substrate | 79 × 8 | −0.5 | 10.2–12.7 | [159] |

| Sustainable conductive ink on cellulose-based substrate | 36 × 120 | 1.7 | - | [161] |

| Paper substrate | 101.2 × 10.5 | 2.75 | 6.88 | [162] |

| Paper substrate | 92.4 × 10 | 3.1 | 9.22 | [162] |

| Technology | Ink Viscosity (cP) | Line Width (μm) | Layer Thickness (μm) | Speed (m/s) |

|---|---|---|---|---|

| Inkjet | 10–30 | 30–50 | 1 | Slow |

| Flexo | 50–500 | 50–100 | <1 | ~8 |

| Screen | 500–5000 | 30–50 | 5–100 | ~1 |

| EHD | 1–15,000 | 0.1 | <1 | slow |

| AJ | 1–1000 | 5 | <1 | slow |

| Sensing | Material | Main Characteristics | Bending Cycles | Ref. |

|---|---|---|---|---|

| Strain | Gauge Factor | |||

| Starch, porous carbon | 134.2 | >1000 | [194] | |

| Paper/MXene/sizing agent (PMS) | 161 (bending angle of 0–120°) | 100,000 (bending deformation of 30°) | [174] | |

| Starch, egg white, Ag | - | >1000 | [195] | |

| Candle soot (CS) particles, chitosan, potato starch (PS), polyvinyl alcohol (PVA), Fe3+ ions | 1.49 at 0 to 60% strain; 2.71 at 60–100% strain | >1000 | [196] | |

| Graphite powder and cellulose fibers from waste printing papers | 27 | 1000 | [197] | |

| Pressure | Pressure range and/or sensitivity | |||

| Polylactic acid piezoelectric film (DS-PLA) | 0.03–62 kPa | 1.08 million at a pressure of 4.3 kPa | [178] | |

| Starch, porous carbon | 0–250 kPa | >1000 | [194] | |

| Poly(ether carbonate)-based Polyurethane | 0.62–62.5 kPa | 6250 | [198] | |

| PPy, paper | 4.8 kPa−1 at < 5.5 kPa, 1.7 kPa−1 at 5.5–40 kPa | 3D | [176] | |

| Polyaniline, silk fibroin, poly (lactic-co-glycolic acid), K-carrageenan | 165.3 kPa, 2.54 kPa−1 | >2000 | [183] | |

| PDA–CCFN | 0 to 50 kPa | 1000, by repeatedly loading and unloading a pressure of 20 kPa | [185] | |

| AgCNT@textile-PDMS | 0.02 kPa−1 and 0.004 kPa−1 in the low-pressure (<11.67 kPa) and high-pressure (~11.67–33.3 kPa) | - | [186] | |

| Humidity | RH linear range and/or sensitivity | |||

| PEDOT:PSS electrode, CNF film | 20% to 85%RH | - | [199] | |

| Graphene inks | 30%RH to 90%RH linear range; 0.55/%RH at 25 °C | - | [179] | |

| E-PNs, G. sulfurreducens, Au electrodes, PI substrate | 20% to 95%RH; >6% relative conductance change per 1% RH change | >1000 bending cycles | [179] | |

| Cellulose nanofiber/graphene nanoplatelet | 30%RH to 90%RH | >1000 bending cycles | [200] | |

| Common kitchen salt (NaCl) | 40% RH up to 85% RH | - | [201] | |

| Sensitivity | ||||

| H2O2, glucose | BGC printed inks | 27.25 μA mM−1 cm−2 | 70 cycles by 10% stretching and 1800 consecutive 90° bending cycles | [180] |

| H2 gas | Chitosan/polyvinylpyrrolidone (CHP) polymeric substrate; ZnO thin film | 24% and 46% towards 0.5% and 2% H2 | - | [202] |

| NO2 gas | Dried mango peel, graphene, ZnO and carbon nanotubes | ΔR/R0 = 0.21 at 100 ppm and RH = 35% | 300 | [203] |

| CO2 gas | p(D-co-M) | 104–106 ppm detection range | - | [204] |

| NH3 | Cotton fibers/polyaniline (PANI) | 100 ppm NH3 | Stability in bending from 0° to 60° | [205] |

| Substrate | Materials | Biodegradable | Recyclable |

|---|---|---|---|

| Inorganic Materials | Carbon | Yes | Yes |

| Magnetic | Yes, except for ceramics | Not always, but reusable | |

| Metals (thin foils) | Mo, Fe, W, or Zn | Not always, but reusable | |

| Organic Materials | Polymers | Yes | Yes |

| Textiles | Yes | Yes | |

| Silk | Yes | Yes | |

| Paper and cellulose-based | Yes | Yes |

| Material | On/Off Current Ratio | Operation Voltage (V) | Data Retention Time (s) | Pros for Sustainability | Ref. |

|---|---|---|---|---|---|

| Al/gelatin/Ag sandwiched structure on a bio-cellulose film | >104 | <3 | 7 × 103 | Fully biodegradable device | [213] |

| Ag/pectin/FTO | 104 | <3 | 108 | Biocompatibility derived from use of natural pectin | [214] |

| Carbon dot (CD)-polyvinyl pyrrolidone (PVP) nanocomposite and a silver nanowire (Ag NW) network buried in a flexible gelatin film | >102 | −1.12 | >104 | Fully biocompatible | [215] |

| Au/starch/ITO/PET | 103 | 0.25 | 103 | Biocompatible materials | [216] |

| Au/starch–chitosan/ITO/PET | 100 | 0.25 | 104 | Biocompatible materials | [216] |

| Poly(ethylene furanoate) (PEF) as substrate; deoxyribonucleic acid (DNA) as active layer | 104 | −2 | 104 | Biomaterials | [217] |

| Iron (Fe) ions in gelatin matrixes on paper substrates | 105 | <4.2 | 7 × 104 | Gelatin materials are biodegradable and recyclable | [218] |

| W/silk fibroin/Mg | 105 | 2.0 | - | Good biodegradability | [219] |

| Egg protein and graphene quantum dot composites | 1.19 × 104 | 0.3 | 104 | Good biodegradability | [220] |

| Energy Source | Type of EH | Material | Output *** | Pros for Sustainability | Ref. |

|---|---|---|---|---|---|

| Body motion | PENG * | ZnO nanorods on the surface of paper | Vo = 15 mV; Io = 10 nA | Cost-effective; paper substrate | [226] |

| Mechanical | PENG | Lead-free organic inorganic hybrid perovskite | Vo = 94.5 Vpp, Io = 19.1 μApp; output power density of 18.95 μW/cm2 | Lead-free | [227] |

| Body motion | PENG | ZnO | Vo = 15 mV | Eco-friendly, low temperature and low-cost process | [228] |

| Body motion | TENG ** | Worn-out textiles from the waste bin | Vo = 4.2 V; Io = 2.7 nA | Promote the eco-friendly concept of recycling, reuse | [230] |

| Wind | TENG | Rabbit fur | For wind speed of 6 m/s, peak power = 11.9 mW; conversion efficiency of 15.4% | Smart-farming applications without environment deterioration | [232] |

| Mechanical | TENG | Polyvinyl butyral (PVB); indium oxide (IO); Mylar | Vo = 700 V; Io = 1.52 mA/m2 | Energy-saving | [233] |

| Wind, Mechanical | TENG | Natural leaf as an electrification layer and electrode | P ≈45 mW m−2 | Natural materials | [232] |

| Wind | TENG | Plant leaf and leaf powder | Io = 60 μA; Vo = 1000 V | Natural materials | [232] |

| Vibrational | TENG | Cellulose acetate nanofibers (CANF) and micro-patterned PDMS | Vo = 400 V; Io = mA/m2 | Cellulose-based; biocompatible and biodegradable material | [237] |

| Mechanical | PTENG | MoS2-PVDF | Vo = 35.3 V | Energy saving for smart wearable devices | [234] |

| Biomechanical | PTENG | Bi4Ti3O12 (BiTO)/polydimethylsiloxane (PDMS) | Vo = 300 V; Io = 4.7 μA | Simple and cost-effective fabrication technique | [235] |

| Hand clapping | PTENG | PVDF; Textured PDMS and skin | Vo = 750 V, Io = 400 μA | Human skin-based; can promote additional health benefit for people | [238] |

| Waste heat energy | Thermoelectric | Silicon rubber sheet, electrodeposited n-type thermoelectric material | Vo = 1 V under a temperature difference T of 60 °C. | Mountable on complex geometries for powering wireless IoT sensing systems in smart agriculture, smart home, industry application, and environment monitoring | [239] |

| Thermal | Thermoelectric | Origami and kirigami-enabled resorbable TE paper, with a self-assembled inorganic particle network layer below the cellulose polymer bio-matrix layer | Vo = 38.55 mV, Io = 12.14 μA for a temperature difference of 24 K | Significant implications in the field of green technology; completely decomposed without carbon emission in water | [240] |

| RF and solar | Rectenna; solar cell | Ti and Au on PDMS; amorphous silicon | 2613.6 μW in sunny outdoor. Additional 3.3–37.5% hybrid output dc-power when the RF source power is varied from 9 to 14 dBm | Energy saving: high efficiency | [243] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scandurra, G.; Arena, A.; Ciofi, C. A Brief Review on Flexible Electronics for IoT: Solutions for Sustainability and New Perspectives for Designers. Sensors 2023, 23, 5264. https://doi.org/10.3390/s23115264

Scandurra G, Arena A, Ciofi C. A Brief Review on Flexible Electronics for IoT: Solutions for Sustainability and New Perspectives for Designers. Sensors. 2023; 23(11):5264. https://doi.org/10.3390/s23115264

Chicago/Turabian StyleScandurra, Graziella, Antonella Arena, and Carmine Ciofi. 2023. "A Brief Review on Flexible Electronics for IoT: Solutions for Sustainability and New Perspectives for Designers" Sensors 23, no. 11: 5264. https://doi.org/10.3390/s23115264

APA StyleScandurra, G., Arena, A., & Ciofi, C. (2023). A Brief Review on Flexible Electronics for IoT: Solutions for Sustainability and New Perspectives for Designers. Sensors, 23(11), 5264. https://doi.org/10.3390/s23115264