Developing a Novel Terahertz Fabry–Perot Microcavity Biosensor by Incorporating Porous Film for Yeast Sensing

Abstract

:1. Introduction

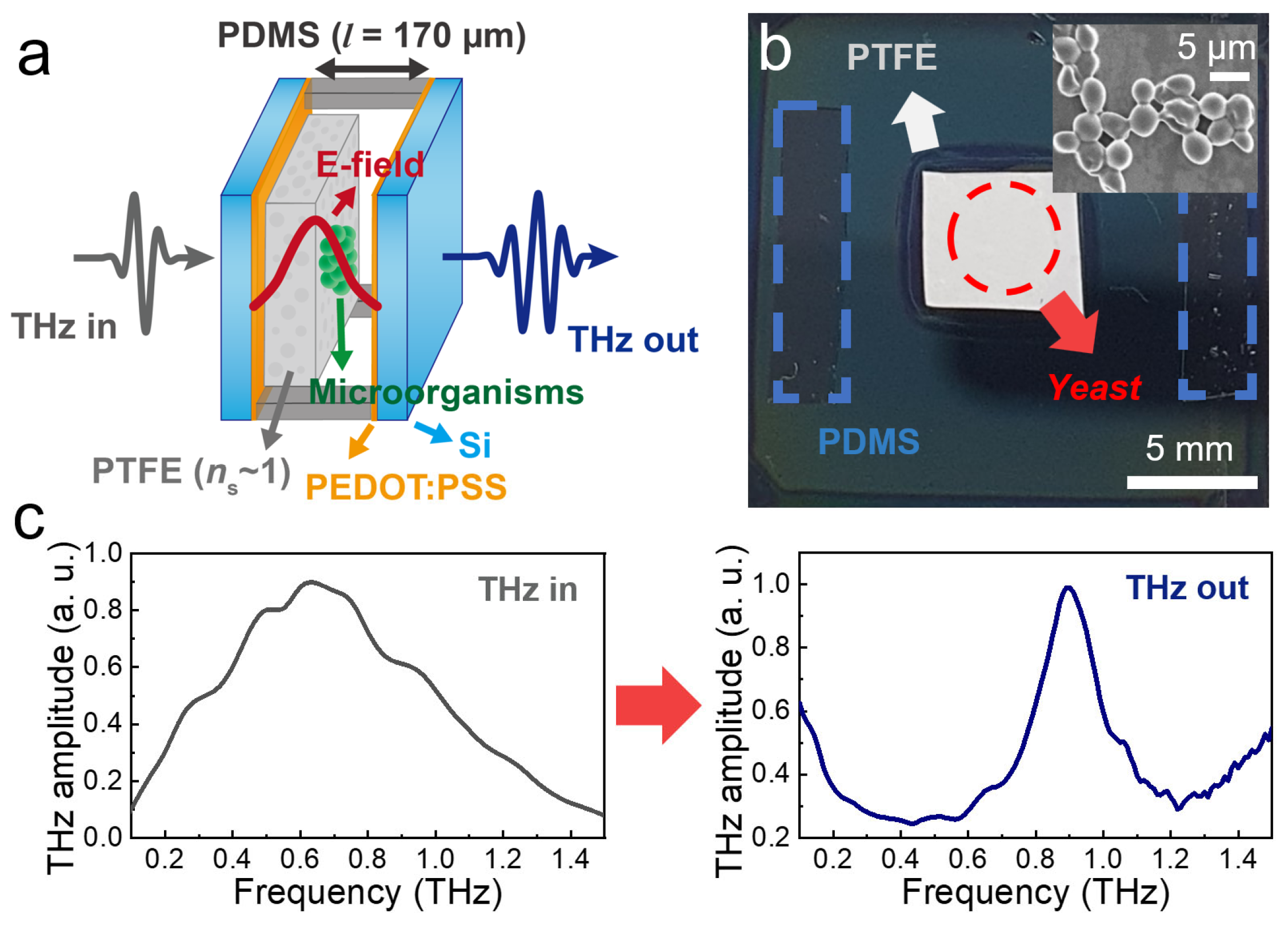

2. Device Fabrication and Experimental Setup

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Menikh, A.; MacColl, R.; Mannella, C.A.; Zhang, X.C. Terahertz biosensing technology: Frontiers and progress. Chem. Phys. Chem. 2002, 3, 655–658. [Google Scholar] [CrossRef] [PubMed]

- Siegel, P.H. Terahertz technology in biology and medicine. IEEE Trans. Microw. Theory Tech. 2004, 52, 2438–2447. [Google Scholar] [CrossRef]

- Nagel, M.; Först, M.; Kurz, H. THz biosensing devices: Fundamentals and technology. J. Phys. Condens. Matter 2006, 18, S601–S618. [Google Scholar] [CrossRef]

- Xu, W.; Xie, L.; Zhu, J.; Tang, L.; Singh, R.; Wang, C.; Ma, Y.; Chen, H.T.; Ying, Y. Terahertz biosensing with a graphene-metamaterial heterostructure platform. Carbon 2019, 141, 247–252. [Google Scholar] [CrossRef]

- Zhou, R.; Wang, C.; Xu, W.; Xie, L. Biological applications of terahertz technology based on nanomaterials and nanostructures. Nanoscale 2019, 11, 3445–3457. [Google Scholar] [CrossRef]

- Peng, Y.; Shi, C.; Zhu, Y.; Gu, M.; Zhuang, S. Terahertz spectroscopy in biomedical field: A review on signal-to-noise ratio improvement. PhotoniX 2020, 1, 12. [Google Scholar] [CrossRef] [Green Version]

- Ahmadivand, A.; Gerislioglu, B.; Ahuja, R.; Kumar Mishra, Y. Terahertz plasmonics: The rise of toroidal metadevices towards immunobiosensings. Mater. Today 2020, 32, 108–130. [Google Scholar] [CrossRef]

- Yoon, S.A.; Cha, S.H.; Jun, S.W.; Park, S.J.; Park, J.Y.; Lee, S.; Kim, H.S.; Ahn, Y.H. Identifying different types of microorganisms with terahertz spectroscopy. Biomed. Opt. Express 2020, 11, 406–416. [Google Scholar] [CrossRef] [PubMed]

- Varshney, G.; Giri, P. Bipolar charge trapping for absorption enhancement in a graphene-based ultrathin dual-band terahertz biosensor. Nanoscale Adv. 2021, 3, 5813–5822. [Google Scholar] [CrossRef]

- Serdyukov, D.S.; Goryachkovskaya, T.N.; Mescheryakova, I.A.; Kuznetsov, S.A.; Popik, V.M.; Peltek, S.E. Fluorescent bacterial biosensor E. Coli/pTdcR-TurboYFP sensitive to terahertz radiation. Biomed. Opt. Express 2021, 12, 705–721. [Google Scholar] [CrossRef]

- Yu, W.; Shi, J.; Huang, G.; Zhou, J.; Zhan, X.; Guo, Z.; Tian, H.; Xie, F.; Yang, X.; Fu, W. THz-ATR Spectroscopy Integrated with Species Recognition Based on Multi-Classifier Voting for Automated Clinical Microbial Identification. Biosensors 2022, 12, 378. [Google Scholar] [CrossRef] [PubMed]

- Klokkou, N.T.; Rowe, D.J.; Bowden, B.M.; Sessions, N.P.; West, J.J.; Wilkinson, J.S.; Apostolopoulos, V. Structured surface wetting of a PTFE flow-cell for terahertz spectroscopy of proteins. Sens. Actuators B Chem. 2022, 352, 131003. [Google Scholar] [CrossRef]

- Roh, Y.; Lee, S.H.; Kwak, J.; Song, H.S.; Shin, S.; Kim, Y.K.; Wu, J.W.; Ju, B.K.; Kang, B.; Seo, M. Terahertz imaging with metamaterials for biological applications. Sens. Actuators B Chem. 2022, 352, 130993. [Google Scholar] [CrossRef]

- Fu, X.; Liu, Y.; Chen, Q.; Fu, Y.; Cui, T.J. Applications of Terahertz Spectroscopy in the Detection and Recognition of Substances. Front. Phys. 2022, 10, 427. [Google Scholar] [CrossRef]

- Markelz, A.G.; Mittleman, D.M. Perspective on Terahertz Applications in Bioscience and Biotechnology. ACS Photonics 2022, 9, 1117–1126. [Google Scholar] [CrossRef]

- Xue, J.; Zhang, Y.; Guang, Z.; Miao, T.; Ali, Z.; Qiao, D.; Yao, Y.; Wu, K.; Zhou, L.; Meng, C.; et al. Ultra-High Sensitivity Terahertz Microstructured Fiber Biosensor for Diabetes Mellitus and Coronary Heart Disease Marker Detection. Sensors 2023, 23, 2020. [Google Scholar] [CrossRef]

- Tian, H.; Huang, G.; Xie, F.; Fu, W.; Yang, X. THz biosensing applications for clinical laboratories: Bottlenecks and strategies. TrAC Trends Anal. Chem. 2023, 163, 117057. [Google Scholar] [CrossRef]

- Zhan, X.; Liu, Y.; Chen, Z.; Luo, J.; Yang, S.; Yang, X. Revolutionary approaches for cancer diagnosis by terahertz-based spectroscopy and imaging. Talanta 2023, 259, 124483. [Google Scholar] [CrossRef]

- Elhelw, A.R.; Ibrahim, M.S.S.; Rashed, A.N.Z.; Mohamed, A.E.N.A.; Hameed, M.F.O.; Obayya, S.S.A. Highly Sensitive Bilirubin Biosensor Based on Photonic Crystal Fiber in Terahertz Region. Photonics 2023, 10, 68. [Google Scholar] [CrossRef]

- Park, S.J.; Hong, J.T.; Choi, S.J.; Kim, H.S.; Park, W.K.; Han, S.T.; Park, J.Y.; Lee, S.; Kim, D.S.; Ahn, Y.H. Detection of microorganisms using terahertz metamaterials. Sci. Rep. 2014, 4, 4988. [Google Scholar] [CrossRef]

- Zhang, C.; Liang, L.; Ding, L.; Jin, B.; Hou, Y.; Li, C.; Jiang, L.; Liu, W.; Hu, W.; Lu, Y.; et al. Label-free measurements on cell apoptosis using a terahertz metamaterial-based biosensor. Appl. Phys. Lett. 2016, 108, 241105. [Google Scholar] [CrossRef]

- Lee, D.K.; Kang, J.H.; Kwon, J.; Lee, J.S.; Lee, S.; Woo, D.H.; Kim, J.H.; Song, C.S.; Park, Q.H.; Seo, M. Nano metamaterials for ultrasensitive Terahertz biosensing. Sci. Rep. 2017, 7, 8146. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Park, S.J.; Cha, S.H.; Shin, G.A.; Ahn, Y.H. Sensing viruses using terahertz nano-gap metamaterials. Biomed. Opt. Express 2017, 8, 3551–3558. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, R.; Zou, B.; Zhang, G.; Xu, D.; Yang, Y. High-sensitivity identification of aflatoxin B1 and B2 using terahertz time-domain spectroscopy and metamaterial-based terahertz biosensor. J. Phys. D Appl. Phys. 2020, 53, 195401. [Google Scholar] [CrossRef]

- Yang, K.; Yu, W.; Huang, G.; Zhou, J.; Yang, X.; Fu, W. Highly sensitive detection of: Staphylococcus aureus by a THz metamaterial biosensor based on gold nanoparticles and rolling circle amplification. RSC Adv. 2020, 10, 26824–26833. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Geng, Z.; Fang, W. Exploring performance of THz metamaterial biosensor based on flexible thin-film. Opt. Express 2020, 28, 26370–26384. [Google Scholar] [CrossRef]

- Li, D.; Hu, F.; Zhang, H.; Chen, Z.; Huang, G.; Tang, F.; Lin, S.; Zou, Y.; Zhou, Y. Identification of Early-Stage Cervical Cancer Tissue Using Metamaterial Terahertz Biosensor with Two Resonant Absorption Frequencies. IEEE J. Sel. Top. Quantum Electron. 2021, 27, 8600107. [Google Scholar] [CrossRef]

- Tabassum, S.; Nayemuzzaman, S.K.; Kala, M.; Kumar Mishra, A.; Mishra, S.K. Metasurfaces for Sensing Applications: Gas, Bio and Chemical. Sensors 2022, 22, 6896. [Google Scholar] [CrossRef]

- Chen, K.; Ruan, C.; Zhan, F.; Song, X.; Fahad, A.K.; Zhang, T.; Shi, W. Ultra-sensitive terahertz metamaterials biosensor based on luxuriant gaps structure. iScience 2023, 26, 105781. [Google Scholar] [CrossRef]

- Hou, X.; Hu, F.; Zhang, L.; Jiang, M.; Zeng, L.; Zou, Y.; Li, D.; Liu, S.; Liu, W.; Hu, Z. Cancer biomarkers ultrasensitive detection based on terahertz frequency-comb-like. IEEE Sens. J. 2023, 23, 10413–10419. [Google Scholar] [CrossRef]

- El-Wasif, Z.; Ismail, T.; Hamdy, O. Design and optimization of highly sensitive multi-band terahertz metamaterial biosensor for coronaviruses detection. Opt. Quantum Electron. 2023, 55, 604. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Lou, J.; Yu, Y.; Sun, L.; Sun, L.; Fang, G.; Chang, C. An ultra-sensitive metasurface biosensor for instant cancer detection based on terahertz spectra. Nano Res. 2023, 16, 7304–7311. [Google Scholar] [CrossRef]

- Jun, S.W.; Ahn, Y.H. Terahertz thermal curve analysis for label-free identification of pathogens. Nat. Commun. 2022, 13, 3470. [Google Scholar] [CrossRef] [PubMed]

- Ji, G.; Kim, H.S.; Cha, S.H.; Lee, H.T.; Kim, H.J.; Lee, S.W.; Ahn, K.J.; Kim, K.H.; Ahn, Y.H.; Park, H.R. Terahertz virus-sized gold nanogap sensor. Nanophotonics 2023, 12, 147–154. [Google Scholar] [CrossRef]

- Geng, Z.; Zhang, X.; Fan, Z.; Lv, X.; Chen, H. A Route to Terahertz Metamaterial Biosensor Integrated with Microfluidics for Liver Cancer Biomarker Testing in Early Stage. Sci. Rep. 2017, 7, 16378. [Google Scholar] [CrossRef] [Green Version]

- Meng, K.; Park, S.J.; Burnett, A.D.; Gill, T.; Wood, C.D.; Rosamond, M.; Li, L.H.; Chen, L.; Bacon, D.R.; Freeman, J.R.; et al. Increasing the sensitivity of terahertz split ring resonator metamaterials for dielectric sensing by localized substrate etching. Opt. Express 2019, 27, 23164–23172. [Google Scholar] [CrossRef]

- Cha, S.H.; Park, S.J.; Ahn, Y.H. Investigation of sensitivity distribution in thz metamaterials using surface functionalization. Curr. Opt. Photonics. 2019, 3, 566–570. [Google Scholar] [CrossRef]

- Yu, E.S.; Lee, S.H.; Lee, G.; Park, Q.H.; Chung, A.J.; Seo, M.; Ryu, Y.S. Nanoscale Terahertz Monitoring on Multiphase Dynamic Assembly of Nanoparticles under Aqueous Environment. Adv. Sci. 2021, 8, 2004826. [Google Scholar] [CrossRef]

- Kotsifaki, D.G.; Truong, V.G.; Chormaic, S.N. Fano-resonant, asymmetric, metamaterial-assisted tweezers for single nanoparticle trapping. Nano Lett. 2020, 20, 3388–3395. [Google Scholar] [CrossRef] [Green Version]

- Braakman, R.; Blake, G.A. Principles and promise of Fabry-Perot resonators at terahertz frequencies. J. Appl. Phys. 2011, 109, 063102. [Google Scholar] [CrossRef] [Green Version]

- Konstantinidis, K.; Feresidis, A.P.; Tian, Y.; Shang, X.; Lancaster, M.J. Micromachined terahertz Fabry-Perot cavity highly directive antennas. IET Microw. Antennas Propag. 2015, 9, 1436–1443. [Google Scholar] [CrossRef] [Green Version]

- Tang, J.; Ye, Y.; Xu, J.; Zheng, Z.; Jin, X.; Jiang, L.; Jiang, J.; Xiang, Y. High-sensitivity terahertz refractive index sensor in a multilayered structure with graphene. Nanomaterials 2020, 10, 500. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rho, D.; Breaux, C.; Kim, S. Label-free optical resonator-based biosensors. Sensors 2020, 20, 5901. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Chen, N.; Zhou, X.; Gong, P.; Wang, S.; Zhang, Y.; Zhao, Y. A review of specialty fiber biosensors based on interferometer configuration. J. Biophotonics 2021, 14, e202100068. [Google Scholar] [CrossRef]

- Tang, S.; Zou, M.; Zhao, C.; Jiang, Y.; Chen, R.; Xu, Z.; Yang, C.; Wang, X.; Dong, B.; Wang, Y.; et al. Fabry-Perot Interferometer Based on a Fiber-Tip Fixed-Supported Bridge for Fast Glucose Concentration Measurement. Biosensors 2022, 12, 391. [Google Scholar] [CrossRef]

- Papari, G.P.; Pellegrino, A.L.; Malandrino, G.; Andreone, A. Sensing enhancement of a Fabry-Perot THz cavity using switchable VO2 mirrors. Opt. Express 2022, 30, 19402–19415. [Google Scholar] [CrossRef]

- Sreekanth, K.V.; Sreejith, S.; Han, S.; Mishra, A.; Chen, X.; Sun, H.; Lim, C.T.; Singh, R. Biosensing with the singular phase of an ultrathin metal-dielectric nanophotonic cavity. Nat. Commun. 2018, 9, 369. [Google Scholar] [CrossRef] [Green Version]

- Sreekanth, K.V.; Sreejith, S.; Alapan, Y.; Sitti, M.; Lim, C.T.; Singh, R. Microfluidics Integrated Lithography-Free Nanophotonic Biosensor for the Detection of Small Molecules. Adv. Opt. Mater. 2019, 7, 1801313. [Google Scholar] [CrossRef]

- Barra-Burillo, M.; Muniain, U.; Catalano, S.; Autore, M.; Casanova, F.; Hueso, L.E.; Aizpurua, J.; Esteban, R.; Hillenbrand, R. Microcavity phonon polaritons from the weak to the ultrastrong phonon–photon coupling regime. Nat. Commun. 2021, 12, 6206. [Google Scholar] [CrossRef]

- Mavrona, E.; Rajabali, S.; Appugliese, F.; Andberger, J.; Beck, M.; Scalari, G.; Faist, J. THz Ultrastrong Coupling in an Engineered Fabry-Perot Cavity. ACS Photonics 2021, 8, 2692–2698. [Google Scholar] [CrossRef]

- Kašalynas, I.; Venckevičius, R.; Minkevičius, L.; Sešek, A.; Wahaia, F.; Tamošiūnas, V.; Voisiat, B.; Seliuta, D.; Valušis, G.; Švigelj, A.; et al. Spectroscopic terahertz imaging at room temperature employing microbolometer terahertz sensors and its application to the study of carcinoma tissues. Sensors 2016, 16, 432. [Google Scholar] [CrossRef] [PubMed]

- Jahn, D.; Soltani, A.; Balzer, J.C.; Withayachumnankul, W.; Koch, M. Fabry-Pérot interferometer for sensing polar liquids at terahertz frequencies. J. Appl. Phys. 2017, 121, 204502. [Google Scholar] [CrossRef]

- Shi, X.; Zhao, Z.; Han, Z. Highly sensitive and selective gas sensing using the defect mode of a compact terahertz photonic crystal cavity. Sens. Actuators B Chem. 2018, 274, 188–193. [Google Scholar] [CrossRef]

- Tu, X.; Jiang, C.; Xiao, P.; Zhai, S.; Jia, X.; Wu, Y.; Meng, Q.; Chen, B.; Kang, L.; Wu, P. Fabry–Pérot cavity-coupled microbolometer terahertz detector with a continuously tunable air spacer gap. Opt. Lett. 2019, 44, 1019–1022. [Google Scholar] [CrossRef] [PubMed]

- Hindle, F.; Bocquet, R.; Pienkina, A.; Cuisset, A.; Mouret, G. Terahertz gas phase spectroscopy using a high-finesse Fabry–Pérot cavity. Optica 2019, 6, 1449–1454. [Google Scholar] [CrossRef] [Green Version]

- Zhang, T.; Zhang, D.; Zhang, H.F. Realization of double Fano resonances with a InSb-doped Fabry-Perot cavity. Results Phys. 2022, 35, 105417. [Google Scholar] [CrossRef]

- Rane, S.; Punjal, A.; Prabhu, S.S.; Chowdhury, D.R. Fourier Transformed Terahertz Spectroscopy Inspired Detection of Evanescent Orders in All Dielectric Sub-Wavelength Grating. IEEE J. Sel. Top. Quantum Electron. 2023, 29, 8500406. [Google Scholar] [CrossRef]

- Riccardi, E.; Pistore, V.; Consolino, L.; Sorgi, A.; Cappelli, F.; Eramo, R.; De Natale, P.; Li, L.; Davies, A.G.; Linfield, E.H.; et al. Terahertz Sources Based on Metrological-Grade Frequency Combs. Laser Photonics Rev. 2023, 17, 2200412. [Google Scholar] [CrossRef]

- Zhao, J.; Yan, J.; Han, Y.; Lao, L.; Peng, Y.; Zhu, Y. Paper-folding-based terahertz anti-resonant cavity. Opt. Lett. 2023, 48, 704–707. [Google Scholar] [CrossRef]

- Moradi, H.; Zhoulideh, M.; Ghafariasl, M. Tunable and ultrasensitive sensor covering terahertz to telecommunication range based on a Fabry–Perot interference of graphene plasmonic waves. Opt. Commun. 2023, 542, 129592. [Google Scholar] [CrossRef]

- Kim, H.S.; Ha, N.Y.; Park, J.Y.; Lee, S.; Kim, D.S.; Ahn, Y.H. Phonon-Polaritons in Lead Halide Perovskite Film Hybridized with THz Metamaterials. Nano Lett. 2020, 20, 6690–6696. [Google Scholar] [CrossRef] [PubMed]

- Park, S.J.; Ahn, Y.H. Accurate measurement of THz dielectric constant using metamaterials on a quartz substrate. Curr. Opt. Photonics. 2017, 1, 637–641. [Google Scholar] [CrossRef]

- Du, Y.; Cui, X.; Li, L.; Tian, H.; Yu, W.X.; Zhou, Z.X. Dielectric Properties of DMSO-Doped-PEDOT: PSS at THz Frequencies. Phys. Status Solidi 2018, 255, 1700547. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.S.; Jun, S.W.; Ahn, Y.H. Developing a Novel Terahertz Fabry–Perot Microcavity Biosensor by Incorporating Porous Film for Yeast Sensing. Sensors 2023, 23, 5797. https://doi.org/10.3390/s23135797

Kim HS, Jun SW, Ahn YH. Developing a Novel Terahertz Fabry–Perot Microcavity Biosensor by Incorporating Porous Film for Yeast Sensing. Sensors. 2023; 23(13):5797. https://doi.org/10.3390/s23135797

Chicago/Turabian StyleKim, Hwan Sik, Seung Won Jun, and Yeong Hwan Ahn. 2023. "Developing a Novel Terahertz Fabry–Perot Microcavity Biosensor by Incorporating Porous Film for Yeast Sensing" Sensors 23, no. 13: 5797. https://doi.org/10.3390/s23135797