Research on Transformer Omnidirectional Partial Discharge Ultrasound Sensing Method Combining F-P Cavity and FBG

Abstract

:1. Introduction

2. Working Principle

2.1. Working Principle of the FBG Sensor

2.2. Working Principle of the F-P Sensor

3. Development of the Sensor and Construction of the Sensing System

3.1. Development of the Sensor

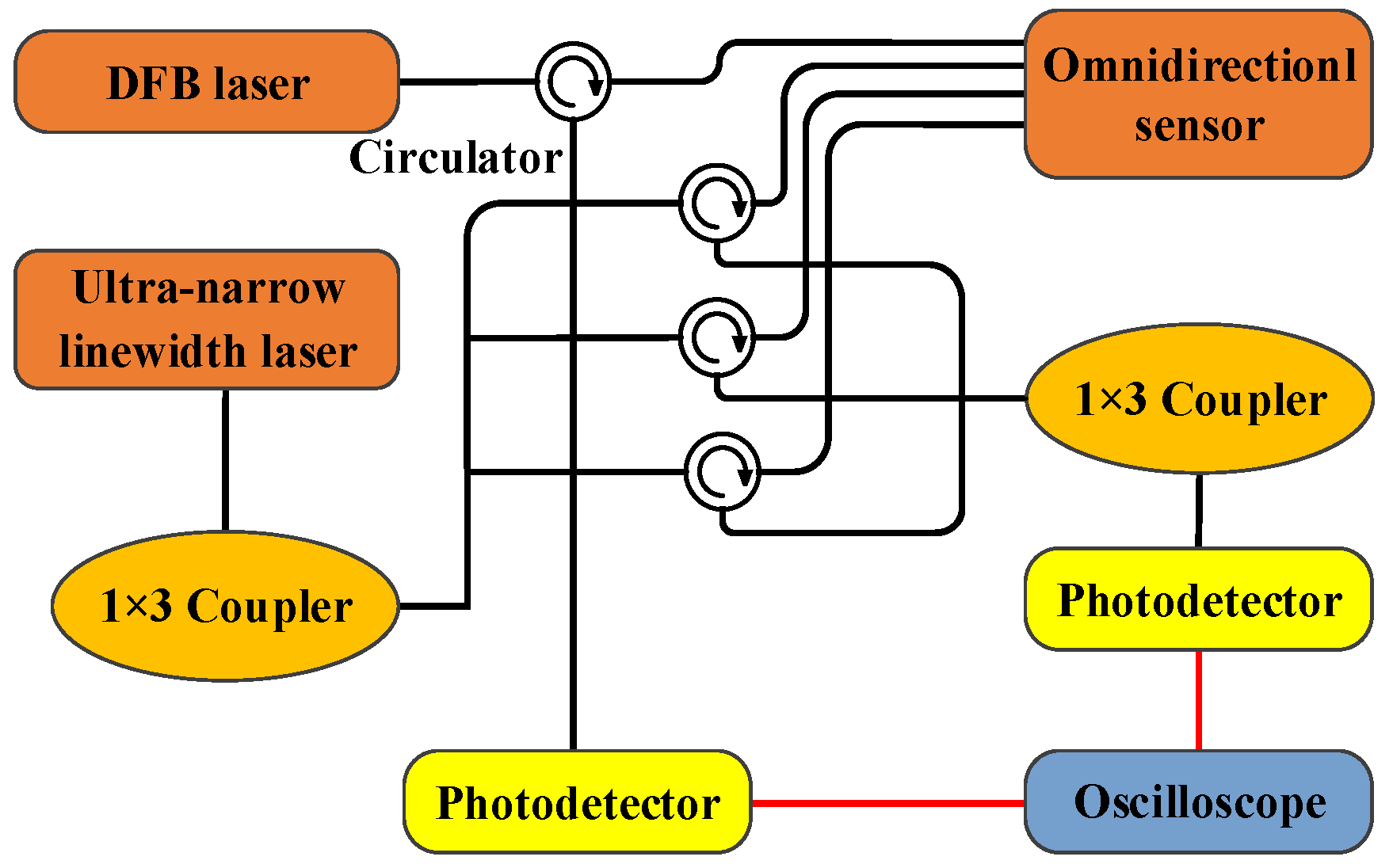

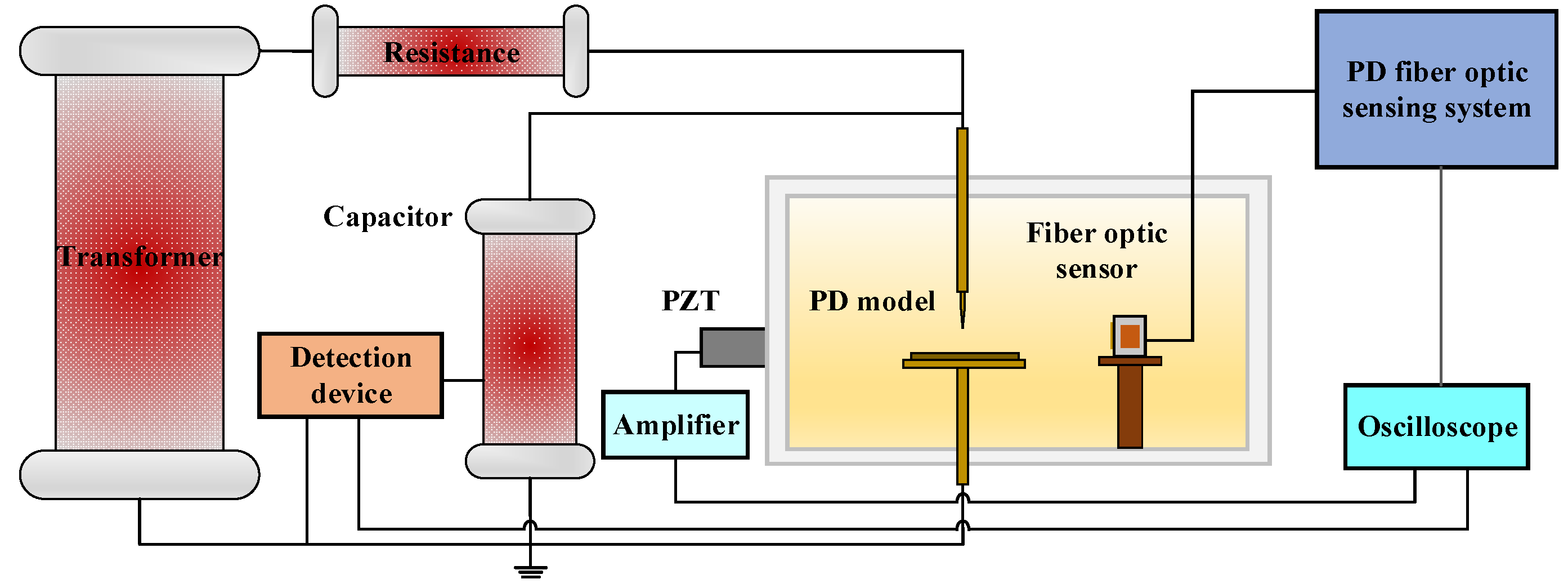

3.2. Construction of Sensing System

4. Performance Tests of Fiber Optic Omnidirectional Sensor

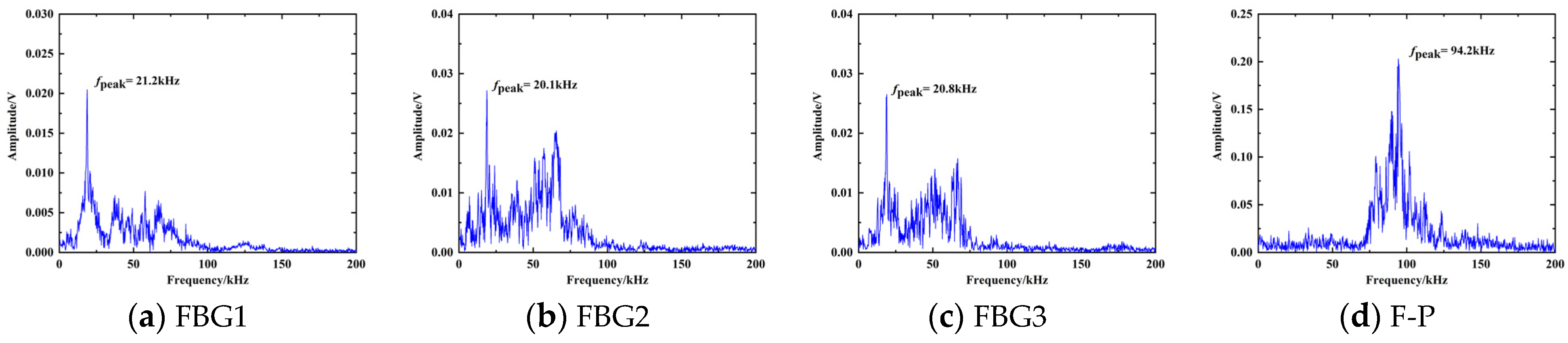

4.1. Frequency Response Test

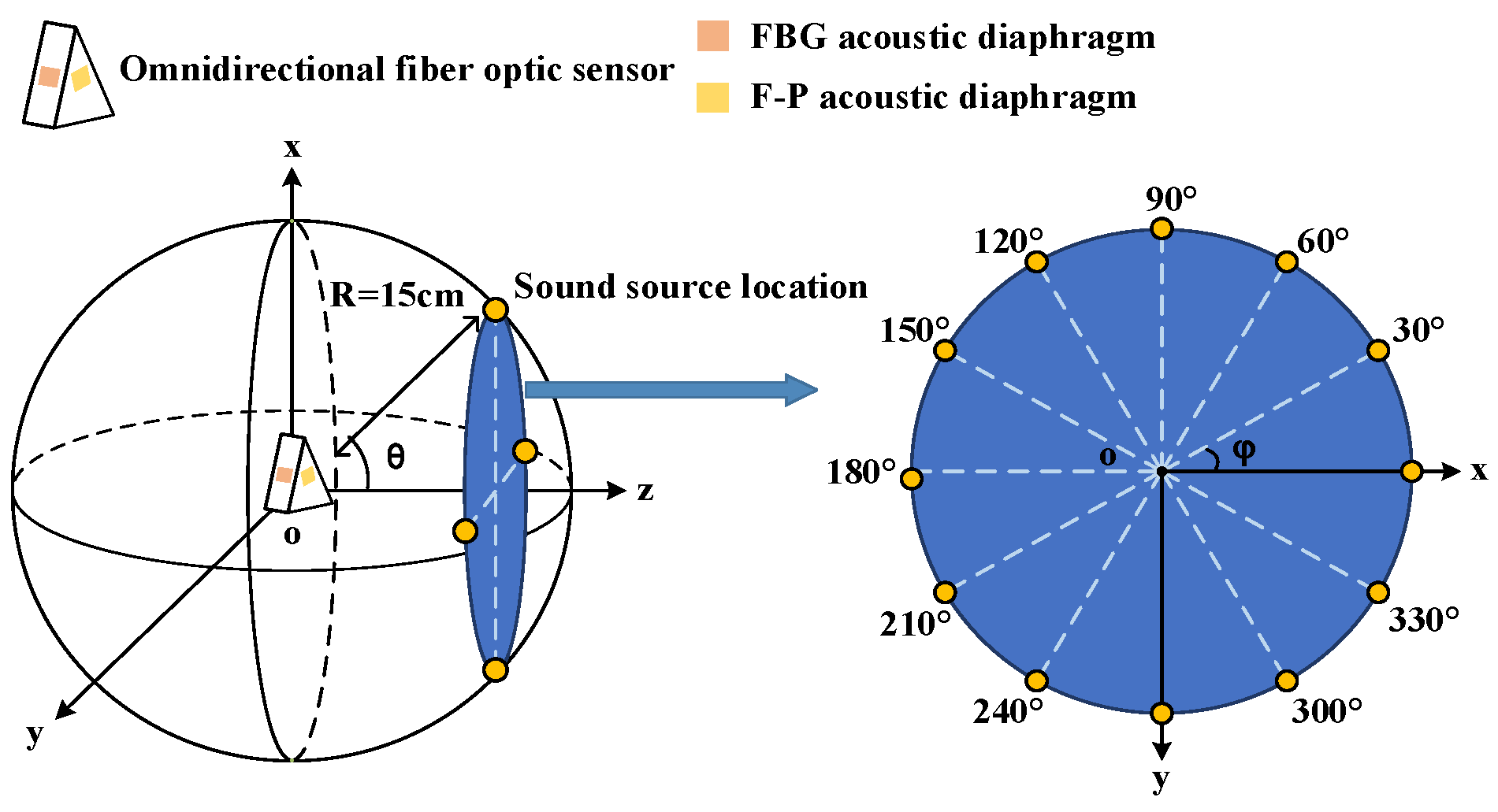

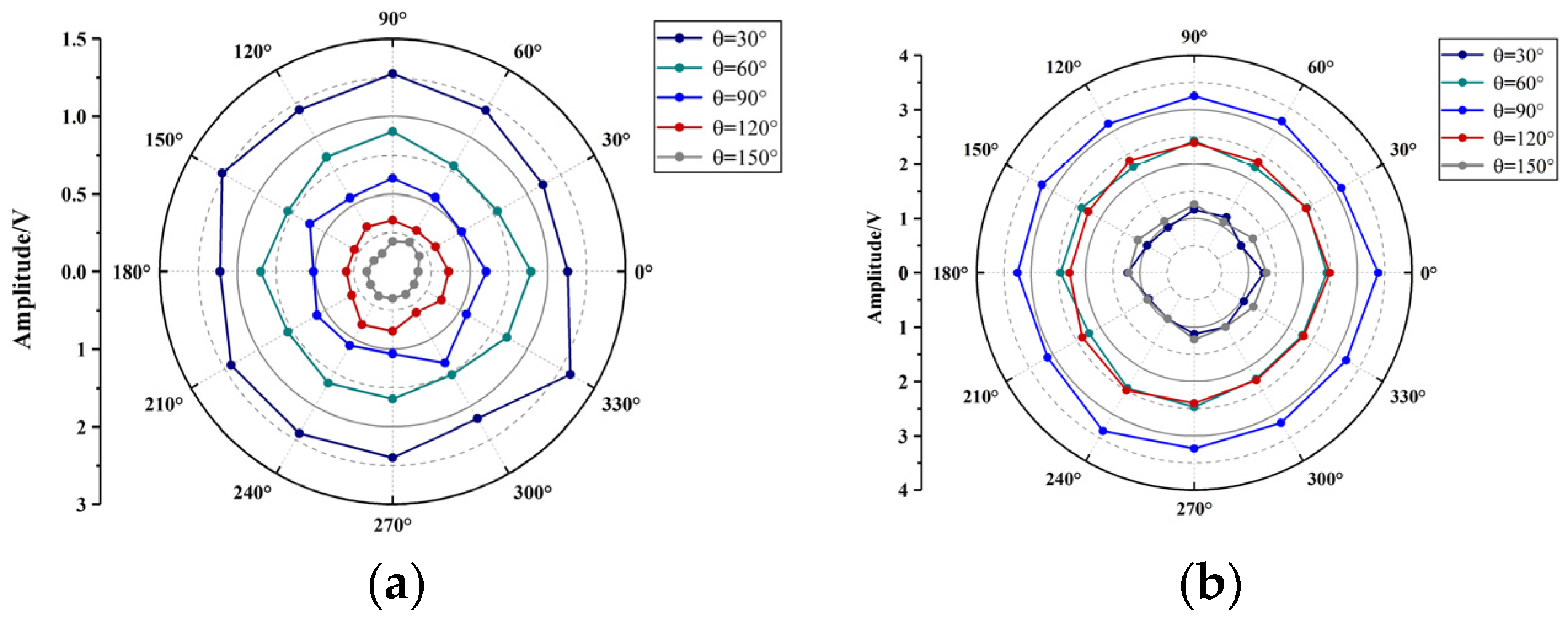

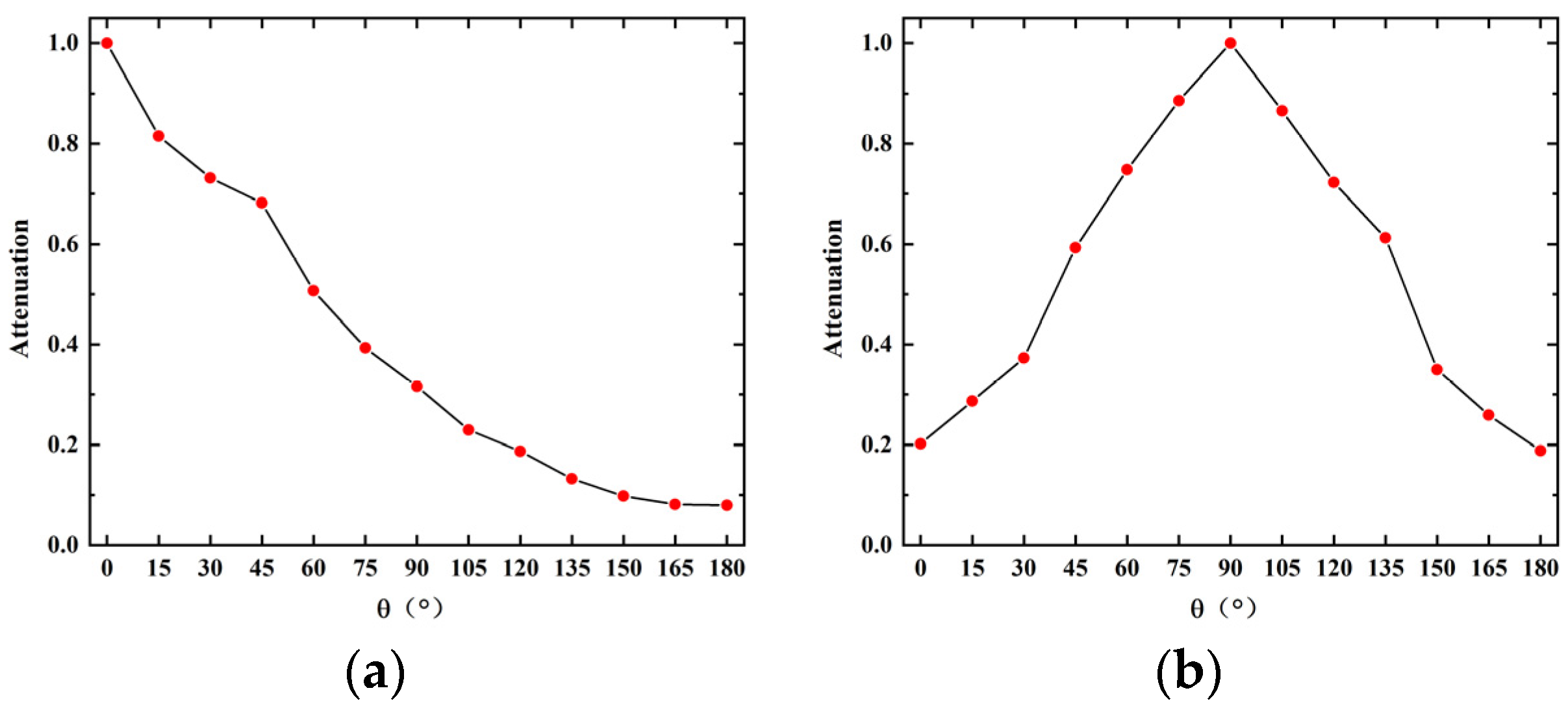

4.2. Directional Response Test

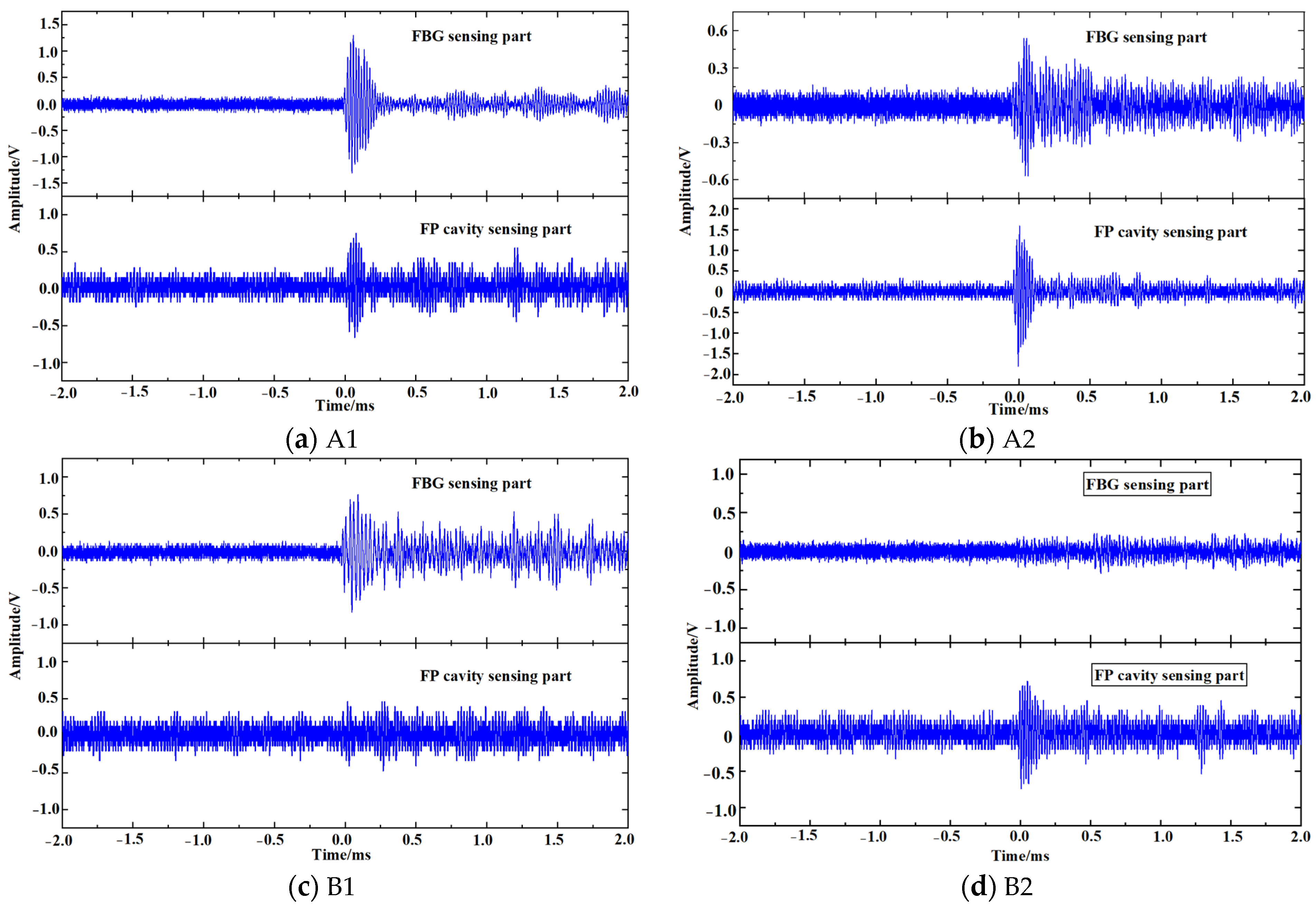

4.3. PD Detection Performance Test

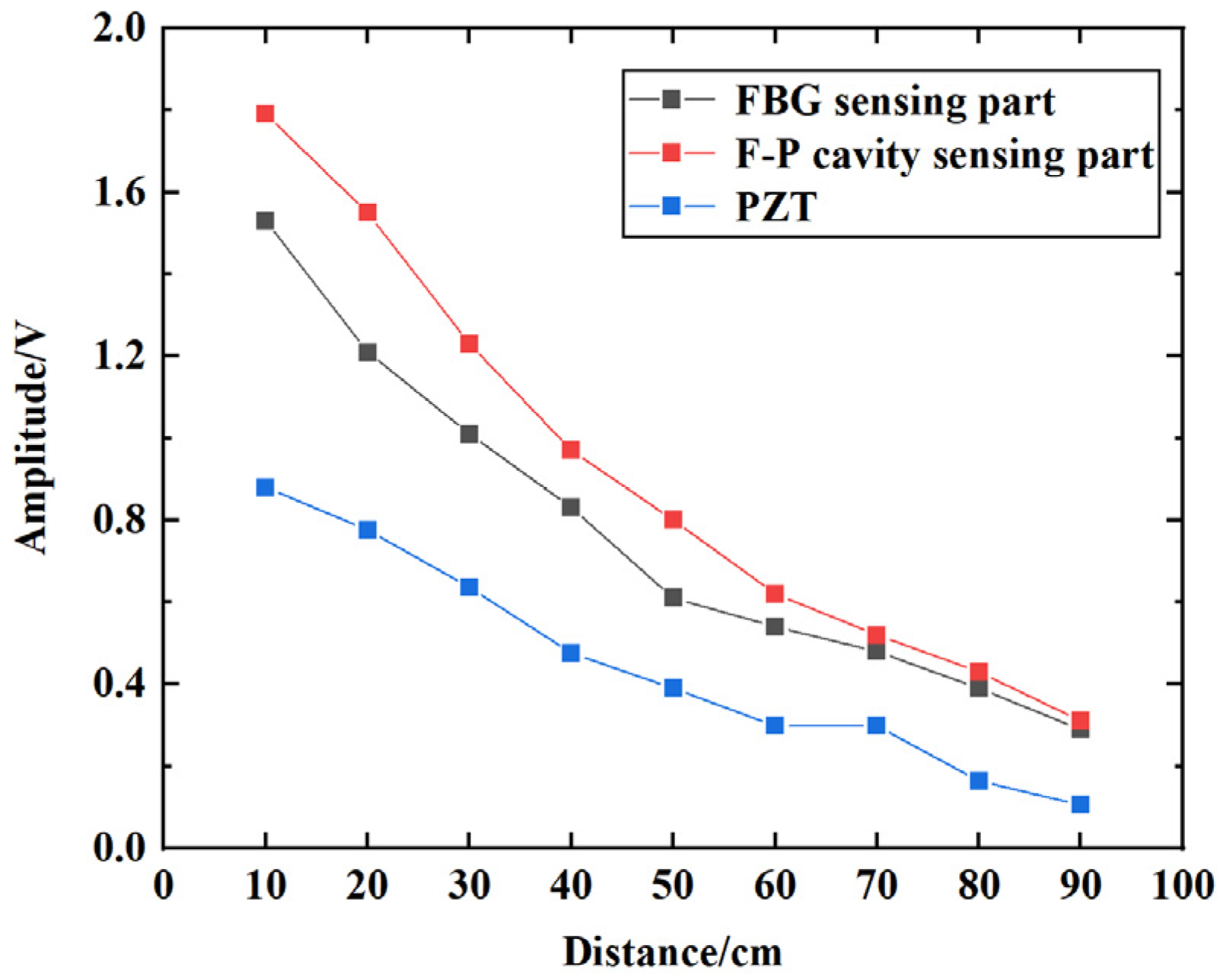

4.4. Distance Attenuation Response Test

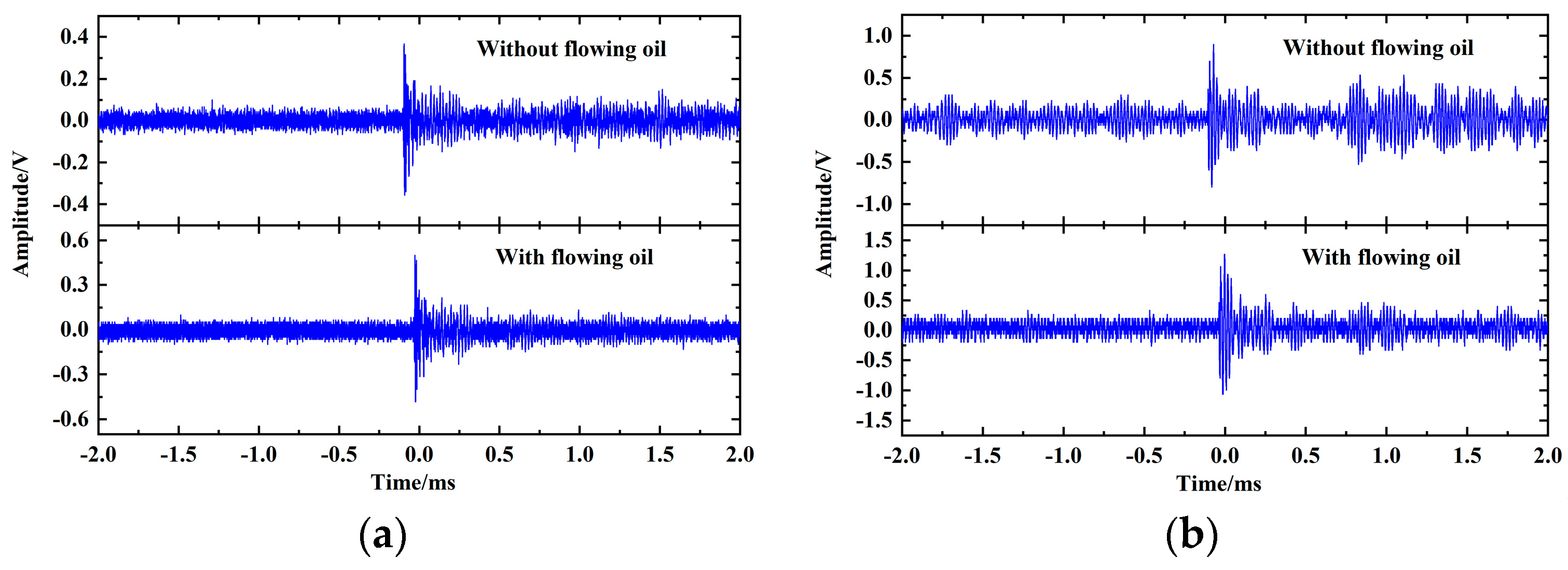

4.5. Anti-Interference Performance Test

5. Conclusions

- (1)

- The fiber optic omnidirectional sensor for PD developed in this paper has the F-P cavity sensing part and the FBG sensing part. The resonant frequency of FBG acoustic diaphragm is around 20 kHz and that of F-P cavity acoustic diaphragm is 94 kHz. The sensitivity of the fiber optic sensor is higher than that of the PZT. The lower limit of PD detection is 68.72 pC for the FBG sensing part and 47.97 pC for the F-P cavity sensing part.

- (2)

- The directional testing of the sensor and its testing within a transformer simulation model indicate that the sensor’s design, encapsulating four acoustic diaphragms, significantly widened the highly sensitive detection range, ensuring a more comprehensive capture of PD ultrasound signals from all directions.

- (3)

- As the distance between the PD source and the sensor increases, the peak-to-peak value of the PD signal detected by the sensor decreases. The rate of decrease is higher in the F-P cavity compared to the FBG. Through the design of different resonant frequencies for the F-P cavity and FBG diaphragm, the sensing needs of high-frequency PD ultrasonic signals and long-distance PD ultrasonic signals are both accommodated. Additionally, the sensor can detect obvious pulsed ultrasound signals in case of oil flowing, which means it has a strong anti-interference ability.

- (4)

- In the future, the introduction of more diaphragms with different resonant frequencies can be considered to improve the sensor’s ability to cover the typical acoustic frequencies of PDs. In addition, by combining artificial intelligence algorithms and array signal processing algorithms, this sensor is expected to be used in localization studies of PDs.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Chen, W.; Li, Z.; Du, L.; Jiang, T.; Cai, N.; Song, R.; Li, M.; Wang, J.; Wang, Z. Experimental study on the transition process from partial discharge to arc discharge of oil–paper insulation based on fibre-optic sensors. IET Gener. Transm. Dis. 2023, 17, 461–468. [Google Scholar] [CrossRef]

- Xing, C.; Zang, Q.; He, R.; Zhao, J.; Wang, L.; Dai, L.; Shi, R.; Wang, S.; Ma, G. Phase stability control of optical fiber partial discharge ultrasonic sensing system. Sensors 2022, 22, 8495. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.Y.; Ma, G.M.; Zhang, M.; Zhang, H.C.; Li, C.R. A high sensitivity optical fiber interferometer sensor for acoustic emission detection of partial discharge in power transformer. IEEE Sens. J. 2019, 21, 24–32. [Google Scholar] [CrossRef]

- Lu, P.; Buric, M.P.; Byerly, K.; Moon, S.R.; Nazmunnahar, M.; Simizu, S.; Leary, A.M.; Beddingfield, R.B.; Sun, C.; Zandhuis, P.; et al. Real-time monitoring of temperature rises of energized transformer cores with distributed optical fiber sensors. IEEE Trans. Power Deliv. 2019, 34, 1588–1598. [Google Scholar] [CrossRef]

- Ma, G.; Wang, Y.; Qin, W.; Zhou, H.; Yan, C.; Jiang, J.; Ju, Y. Optical sensors for power transformer monitoring: A review. High Volt. 2021, 6, 367–386. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, W.; Wu, K.; Tian, H.; Song, R.; Song, Y.; Liu, H.; Wang, J. Partial discharge pattern recognition based on a multifrequency F-P sensing array, AOK time-frequency representation, and deep learning. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 1701–1710. [Google Scholar] [CrossRef]

- Zhang, W.; Lu, P.; Ni, W.; Xiong, W.; Liu, D.; Zhang, J. Gold-diaphragm based Fabry-Perot ultrasonic sensor for partial discharge detection and localization. IEEE Photonics J. 2020, 12, 1–12. [Google Scholar] [CrossRef]

- Vidakovic, M.; McCague, C.; Armakolas, I.; Sun, T.; Carlton, J.S.; Grattan, K.T.V. Fibre Bragg Grating-based cascaded acoustic sensors for potential marine structural condition monitoring. J. Lightwave Technol. 2016, 34, 4473–4478. [Google Scholar] [CrossRef]

- Talebi, V.; Soofi, H. Distributed strain sensing, employing apodized π-phase shifted FBG: Application in power transformer oil breakdown detection. Optik 2022, 268, 169781. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, W.C.; Zhao, H. Response Bandwidth Design of Fabry-Perot Sensors for Partial Discharge Detection Based on Frequency Analysis. J. Sens. 2019. [Google Scholar] [CrossRef]

- Yu, F.; Liu, Q.; Gan, X.; Hu, M.; Zhang, T.; Li, C.; Kang, F.; Terrones, M.; Lv, R. Ultrasensitive Pressure Detection of Few-Layer MoS2. Adv. Mater. 2017, 29, 1603266. [Google Scholar] [CrossRef]

- Si, W.; Fu, C.; Li, D.; Li, H.; Yuan, P.; Yu, Y. Directional sensitivity of a MEMS-based fiber-optic extrinsic Fabry-Perot ultrasonic sensor for partial discharge detection. Sensors 2018, 18, 1975. [Google Scholar] [CrossRef] [PubMed]

- Wu, G.; Hu, X.; Liu, X.; Dong, Z.; Yue, Y.; Cai, C.; Qi, Z.M. Fabrication of glass diaphragm based fiber-optic microphone for sensitive detection of airborne and waterborne sounds. Sensors 2022, 22, 2218. [Google Scholar] [CrossRef] [PubMed]

- Meng, Z.; Chen, W.; Wang, J.; Hu, X.; Chen, M.; Zhang, Y. Recent progress in fiber-optic hydrophones. Photonic Sens. 2021, 11, 109–122. [Google Scholar] [CrossRef]

- Chen, J.; Chang, T.; Fu, Q.; Lang, J.; Gao, W.; Wang, Z.; Yu, M.; Zhang, Y.; Cui, H.-L. A fiber-optic interferometric tri-component geophone for ocean floor seismic monitoring. Sensors 2016, 17, 47. [Google Scholar] [CrossRef] [PubMed]

- Cranch, G.A.; Miller, G.A.; Kirkendall, C.K. Fiber-optic, cantilever-type acoustic motion velocity hydrophone. J. Acoust. Soc. Am. 2012, 132, 103–114. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Sheng, Q.; Hou, W.; Han, M. Optical fiber vector flow sensor based on a silicon Fabry–Perot interferometer array. Opt. Lett. 2016, 41, 4629–4632. [Google Scholar] [CrossRef] [PubMed]

- Gao, C.; Wang, W.; Song, S.; Wang, S.; Yu, L.; Wang, Y. Localization of partial discharge in transformer oil using Fabry-Pérot optical fiber sensor array. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 2279–2286. [Google Scholar] [CrossRef]

- Kuhn, G.G.; Sousa, K.M.; Martelli, C.; Bavastri, C.A.; da Silva, J.C.C. Embedded FBG sensors in carbon fiber for vibration and temperature measurement in power transformer iron core. IEEE Sens. J. 2020, 20, 13403–13410. [Google Scholar] [CrossRef]

- Deng, J.G.; Nie, D.X.; Pi, B.X.; Xia, L.; Wei, L. Hot-spot temperature and temperature decay rate measurement in the oil immersed power transformer through FBG based quasi-distributed sensing system. Microw. Opt. Technol. Let. 2017, 59, 472–475. [Google Scholar] [CrossRef]

- Zhang, Z.; Lei, J.; Chen, W.; Yang, T.; Song, Y.; Wu, K.; Liu, F. Oil-paper insulation partial discharge ultrasonic multifrequency sensing array based on fibre-optic Fabry-Perot sensor. High Volt. 2022, 7, 325–335. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, G.; Chen, W.; Wu, K.; Liu, H.; Wang, J.; Zhang, Z. Research on Transformer Omnidirectional Partial Discharge Ultrasound Sensing Method Combining F-P Cavity and FBG. Sensors 2023, 23, 9642. https://doi.org/10.3390/s23249642

Qian G, Chen W, Wu K, Liu H, Wang J, Zhang Z. Research on Transformer Omnidirectional Partial Discharge Ultrasound Sensing Method Combining F-P Cavity and FBG. Sensors. 2023; 23(24):9642. https://doi.org/10.3390/s23249642

Chicago/Turabian StyleQian, Guochao, Weigen Chen, Kejie Wu, Hong Liu, Jianxin Wang, and Zhixian Zhang. 2023. "Research on Transformer Omnidirectional Partial Discharge Ultrasound Sensing Method Combining F-P Cavity and FBG" Sensors 23, no. 24: 9642. https://doi.org/10.3390/s23249642