Computational Modeling and Parametric Analysis of SMA Hybrid Composite Plates under Thermal Environment

Abstract

1. Introduction

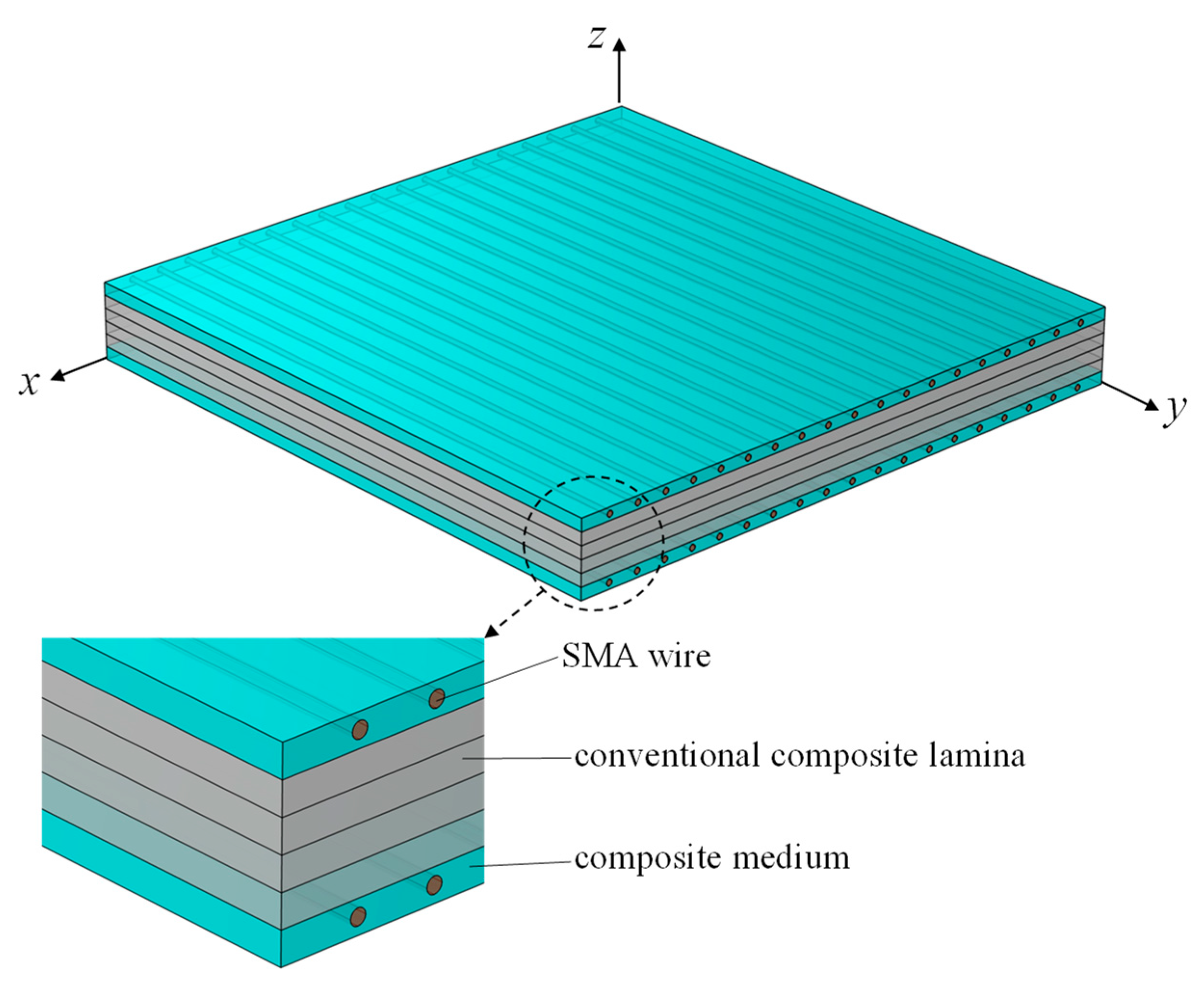

2. Theoretical Model

2.1. Constitutive Relation of SMA

2.2. Equation of Motion

2.3. Finite Element Method—Problem Formulation

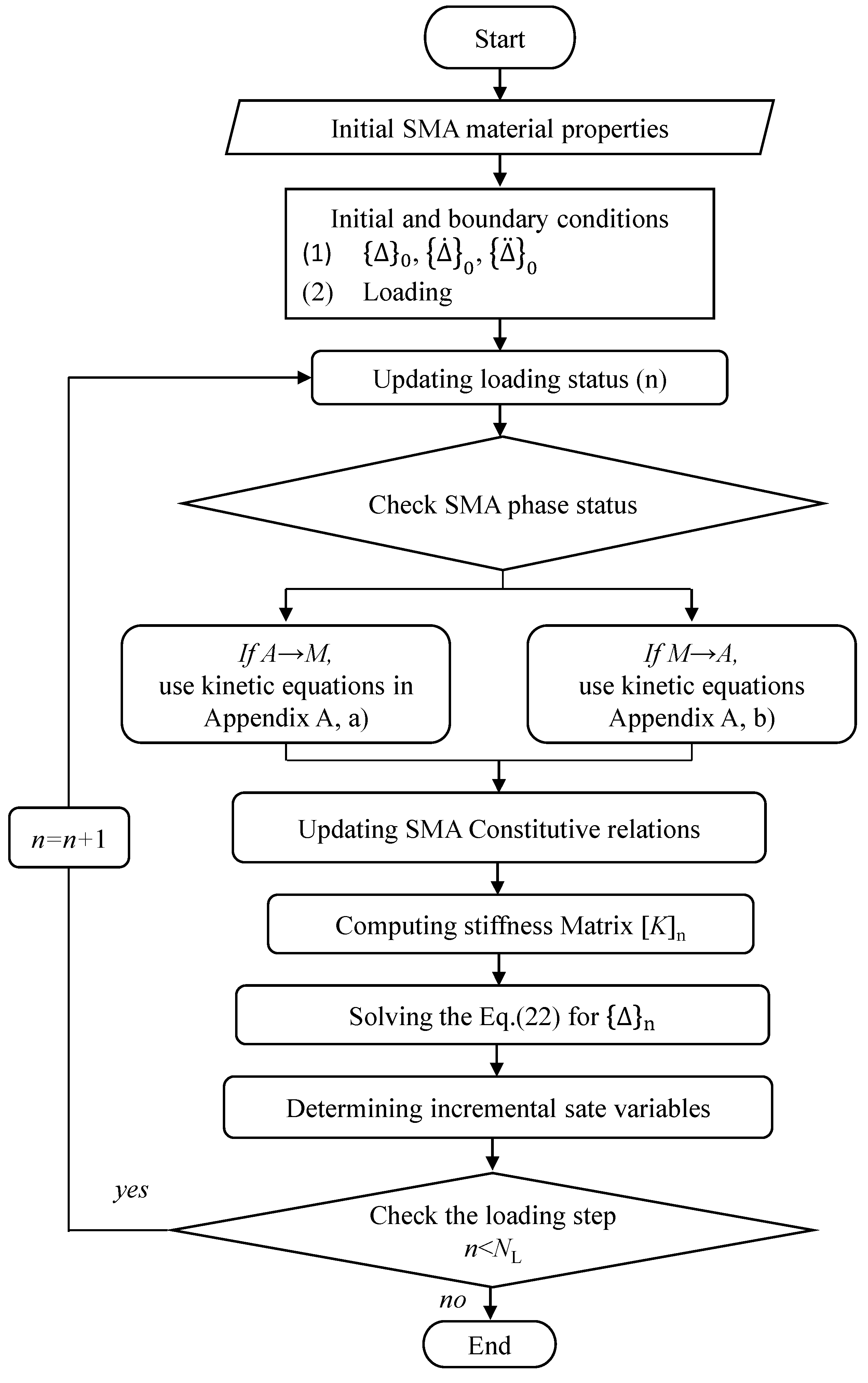

2.4. Solution Algorithm

3. Results and Discussion

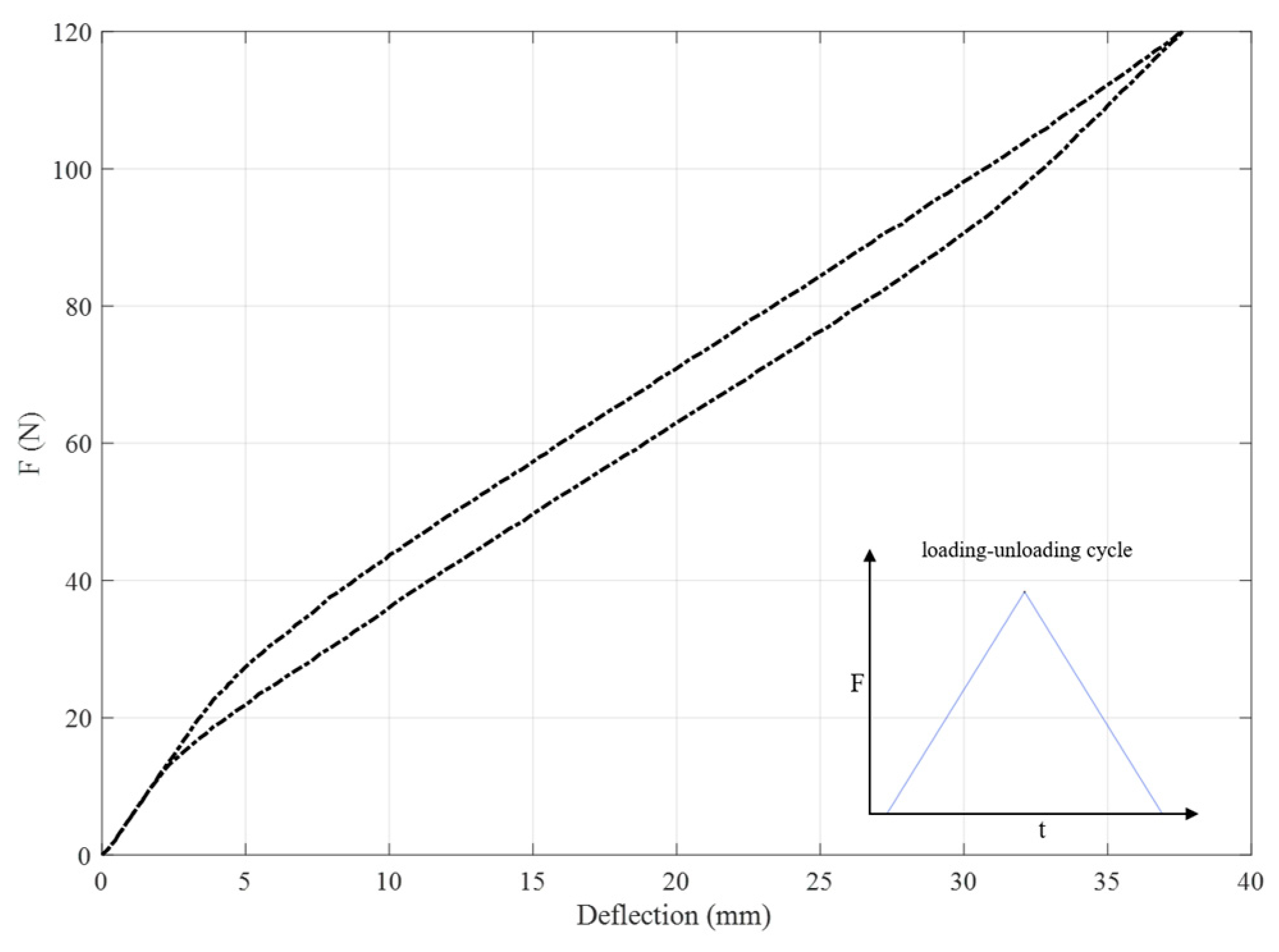

3.1. Validation of Developed Model

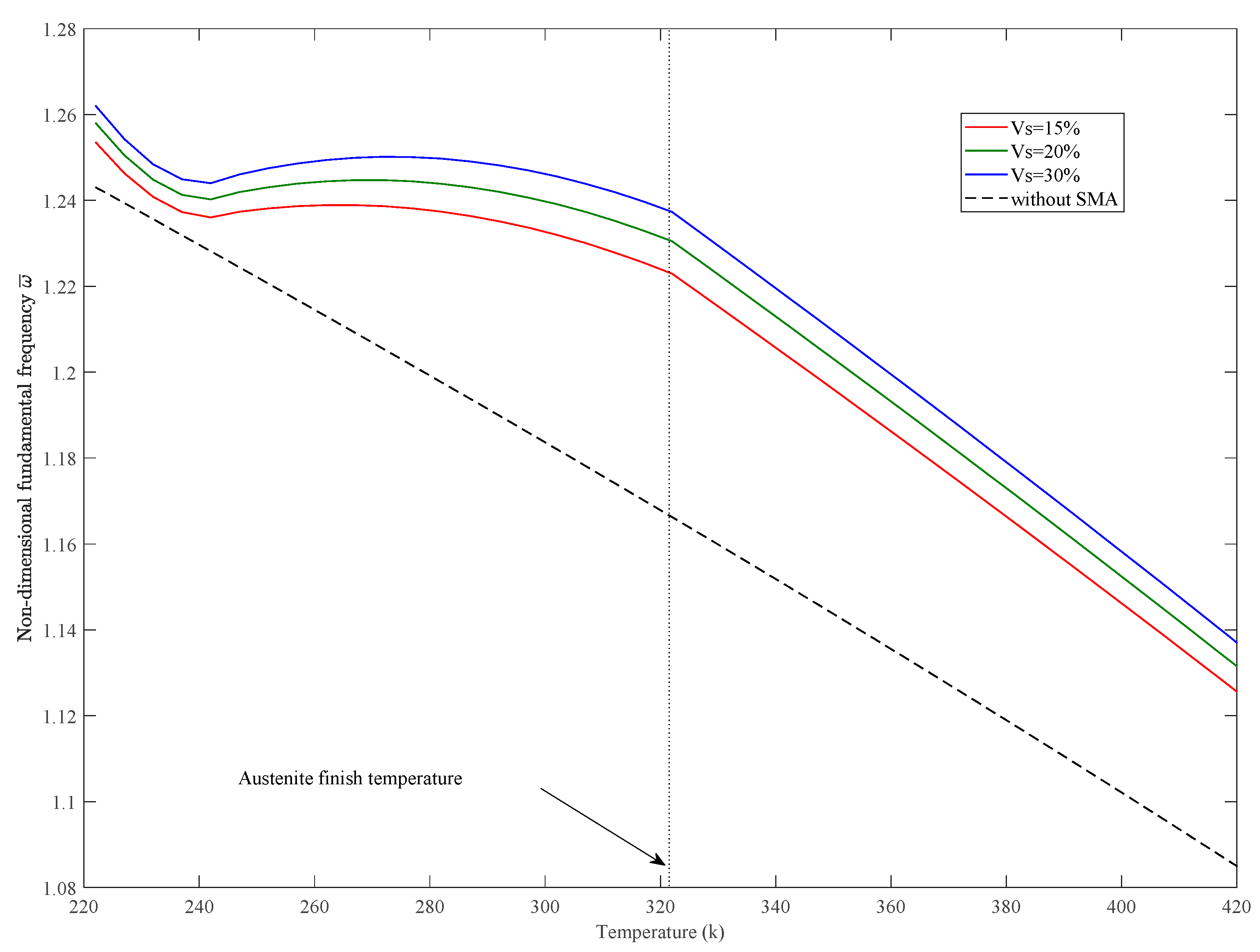

3.2. Validation of Developed Model (Parametric Investigations)

4. Conclusions

- The results of thermal static deflection and free vibration indicate that by embedding SMA wire into conventional composite laminates, the load-carrying capacity can be significantly increased under a thermal environment. The results can be implemented for the active property tuning (APT) application, where the stiffness of the host structure can be modified by the change in the Young’s modulus of SMA wires with heating.

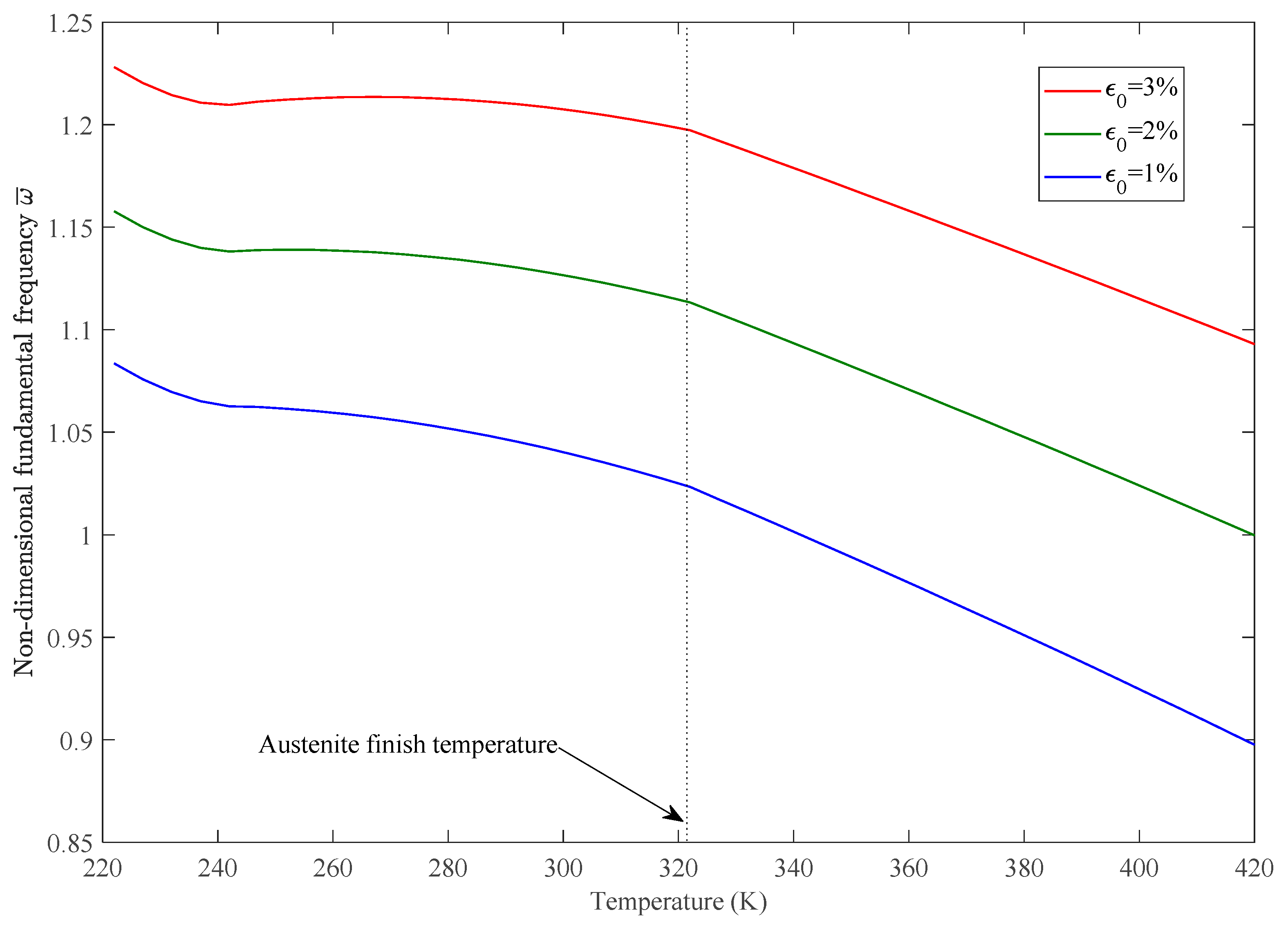

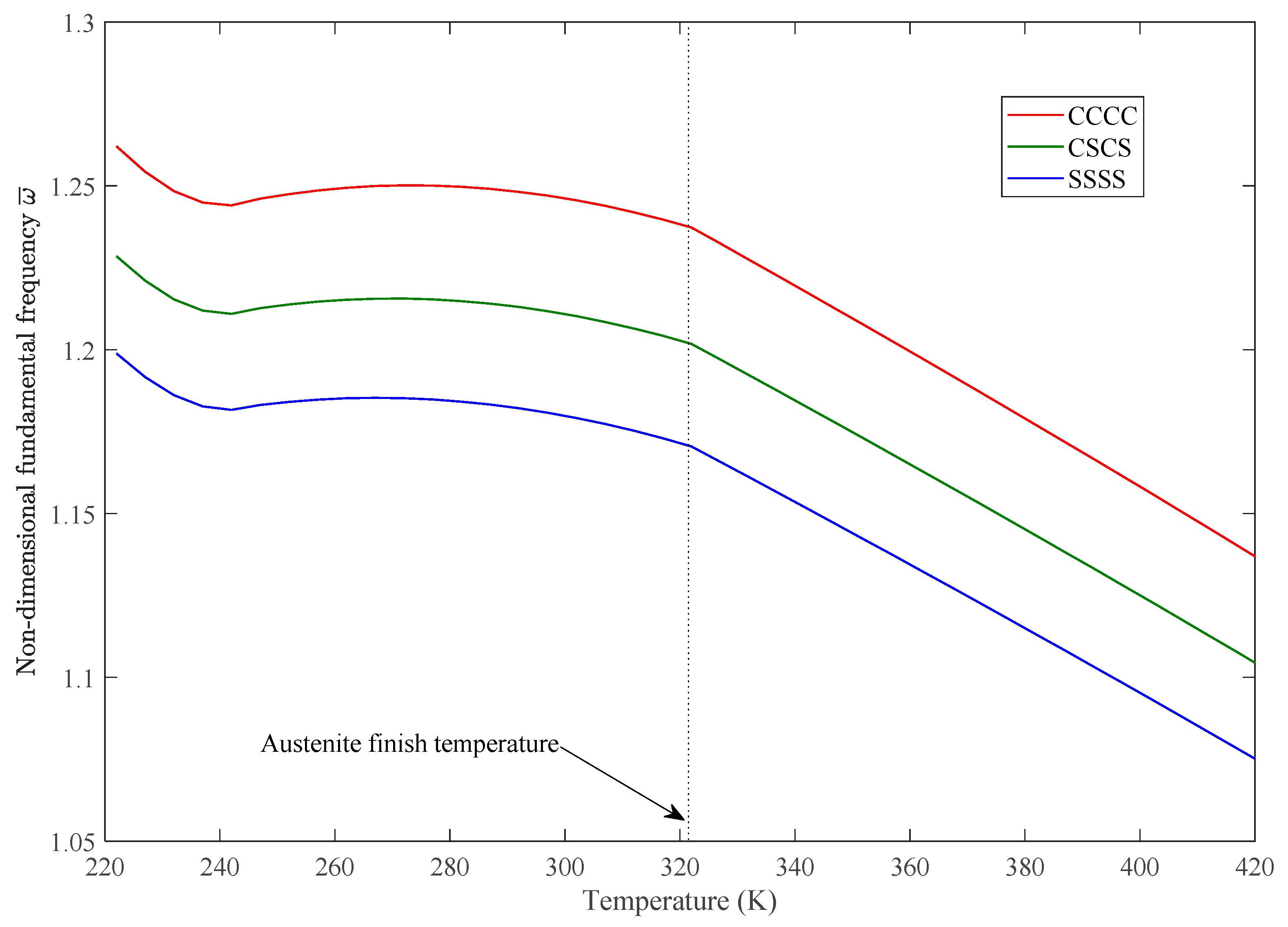

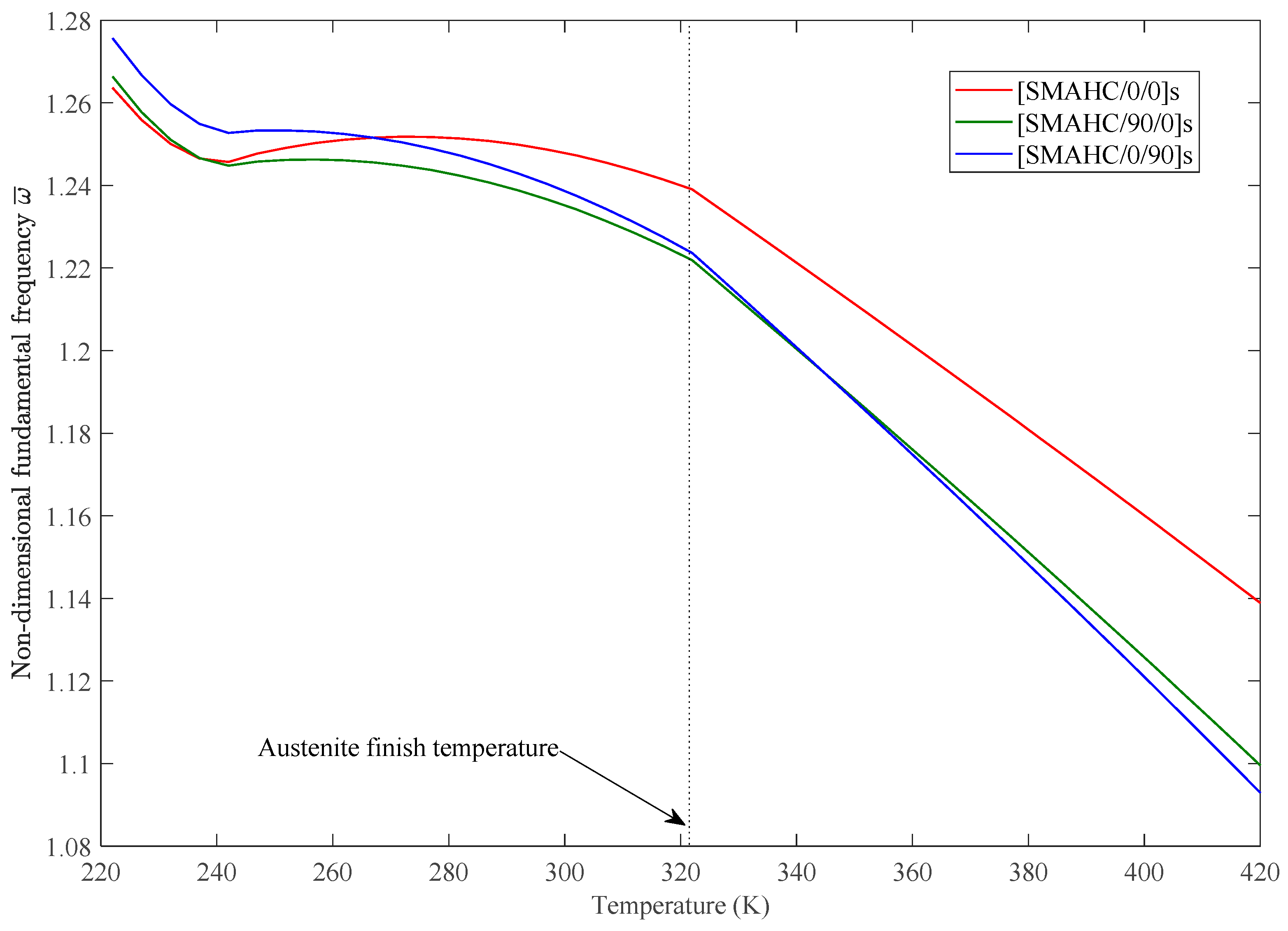

- Thermal frequencies of SMAHC plates exhibit a non-uniform behavior, whereas thermal frequencies of composite plates without SMA decrease with increasing temperature.

- The SMAHC plate has higher structural stiffness, which leads to higher thermal frequencies and lower static deflections compared to the results from conventional composite plates.

- By increasing the SMA volume fraction and pre-strain, the stiffness of the SMAHC plate is increased accordingly. These results can be employed for the active strain energy tuning (ASET) application, where the generation of high recovery stresses within the host structure can be implemented by preparing initial strains before embedding the SMA wires into a composite medium.

- SMAHC plates with different stacking sequences exhibit significant thermal vibration behaviors at different temperature zones. For design purposes, to ensure better structural performances in thermal environment, it is recommended to use an SMAHC plate with the proper stacking sequence according to its service temperatures.

- Geometrical nonlinearities should be considered for simulation of large strain recoverability of SMA elements.

- A more realistic description of the kinematics of composite laminates, such as higher-order shear deformation theory or layer-wise theory, is recommended in order to accurately determine the stress state at the layer level.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

- (a.)

- Phase transformation to martensite: If and then:andIf and then:andwhere

- (b.)

- Phase transformation to austenite: If and then:

Appendix B

Appendix C

References

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Jani, J.M.; Leary, M.; Subic, A. Shape memory alloys in automotive applications. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Bach, Switzerland, 2014; Volume 663, pp. 248–253. [Google Scholar]

- Abavisani, I.; Rezaifar, O.; Kheyroddin, A. Multifunctional properties of shape memory materials in civil engineering applications: A state-of-the-art review. J. Build Eng. 2021, 44, 102657. [Google Scholar] [CrossRef]

- Rogers, C.; Liang, C.; Jia, J. Behavior of shape memory alloy reinforced composite plates. I-Model formulations and control concepts. In Proceedings of the 30th Structures, Structural Dynamics and Materials Conference, Mobile, AL, USA, 3–5 April 1989; p. 1389. [Google Scholar] [CrossRef]

- Rogers, C.; Barker, D. Experimental studies of active strain energy tuning of adaptive composites. In Proceedings of the 31st Structures, Structural Dynamics and Materials Conference, Long Beach, CA, USA, 2–4 April 1990; p. 1086. [Google Scholar] [CrossRef]

- Epps, J.; Chandra, R. Shape memory alloy actuation for active tuning of composite beams. Smart Mater. Struc. 1997, 6, 251. [Google Scholar] [CrossRef]

- Song, G.; Kelly, B.; Agrawal, B.N. Active position control of a shape memory alloy wire actuated composite beam. Smart Mater. Struct. 2000, 9, 711. [Google Scholar] [CrossRef]

- Rogers, C.A.; Liang, C.; Jia, J. Structural modification of simply-supported laminated plates using embedded shape memory alloy fibers. Comput. Struct. 1991, 38, 569–580. [Google Scholar] [CrossRef]

- Yang, Z.; Deng, T.; Li, J.; Xu, C. Experimental Study on Self-Centering Performance of the SMA Fiber Reinforced ECC Composite Beam. Materials 2022, 15, 3062. [Google Scholar] [CrossRef] [PubMed]

- Thompson, S.P.; Loughlan, J. Adaptive post-buckling response of carbon fiber composite plates employing SMA actuators. Compos. Struct. 1997, 38, 667–678. [Google Scholar] [CrossRef]

- Kim, E.H.; Lee, I.; Roh, J.H.; Bae, J.S.; Choi, I.H.; Koo, K.N. Effects of shape memory alloys on low velocity impact characteristics of composite plate. Compos. Struct. 2011, 93, 2903–2909. [Google Scholar] [CrossRef]

- Kuang, K.S.C.; Quek, S.T.; Cantwell, W.J. Active control of a smart composite with shape memory alloy sheet using a plastic optical fiber sensor. Sens. Act. A Phys. 2013, 201, 182–187. [Google Scholar] [CrossRef]

- Abdullah, E.J.; Majid, D.L.; Romli, F.I.; Gaikwad, P.S.; Yuan, L.G.; Harun, N.F. Active control of strain in a composite plate using shape memory alloy actuators. Int. J. Mech. Mater. Des. 2015, 11, 25–39. [Google Scholar] [CrossRef]

- Wang, E.; Tian, Y.; Wang, Z.; Jiao, F.; Guo, C.; Jiang, F. A study of shape memory alloy NiTi fiber/plate reinforced (SMAFR/SMAPR) Ti-Al laminated composites. J. Alloys Compd. 2017, 696, 1059–1066. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Z.; Li, H.; Sun, M.; Wang, F.; Chen, B. Influence of embedding SMA fibres and SMA fibre surface modification on the mechanical performance of BFRP composite laminates. Materials 2018, 11, 70. [Google Scholar] [CrossRef] [PubMed]

- Thompson, S.P.; Loughlan, J. Enhancing the post-buckling response of a composite panel structure utilising shape memory alloy actuators–a smart structural concept. Compos. Struct. 2001, 51, 21–36. [Google Scholar] [CrossRef]

- Birman, V. Stability of functionally graded shape memory alloy sandwich panels. Smart Mater. Struct. 1997, 6, 278. [Google Scholar] [CrossRef]

- Li, H.; Wang, Z.; Yu, Z.; Sun, M.; Liu, Y. The low velocity impact response of foam core sandwich panels with a shape memory alloy hybrid face-sheet. Materials 2018, 11, 2076. [Google Scholar] [CrossRef] [PubMed]

- Lu, P.; Cui, F.S.; Tan, M.J. A theoretical model for the bending of a laminated beam with SMA fiber embedded layer. Compos. Struct. 2009, 90, 458–464. [Google Scholar] [CrossRef]

- Asadi, H.; Bodaghi, M.; Shakeri, M.; Aghdam, M.M. An analytical approach for nonlinear vibration and thermal stability of shape memory alloy hybrid laminated composite beams. Eur. J. Mech. A Solids 2013, 42, 454–468. [Google Scholar] [CrossRef]

- Asadi, H.; Eynbeygi, M.; Wang, Q. Nonlinear thermal stability of geometrically imperfect shape memory alloy hybrid laminated composite plates. Smart Mater. Struct. 2014, 23, 075012. [Google Scholar] [CrossRef]

- Kabir, M.Z.; Tehrani, B.T. Closed-form solution for thermal, mechanical, and thermo-mechanical buckling and post-buckling of SMA composite plates. Compos. Struct. 2017, 168, 535–548. [Google Scholar] [CrossRef]

- Bayat, Y.; EkhteraeiToussi, H. Exact solution of thermal buckling and post buckling of composite and SMA hybrid composite beam by layerwise theory. Aerosp. Sci. Technol. 2017, 67, 484–494. [Google Scholar] [CrossRef]

- Fahimi, P.; Eskandari, A.H.; Baghani, M.; Taheri, A. A semi-analytical solution for bending response of SMA composite beams considering SMA asymmetric behavior. Compos. Part B 2019, 163, 622–633. [Google Scholar] [CrossRef]

- Khalili, S.M.R.; Dehkordi, M.B.; Carrera, E.; Shariyat, M. Non-linear dynamic analysis of a sandwich beam with pseudoelastic SMA hybrid composite faces based on higher order finite element theory. Compos. Struct. 2013, 96, 243–255. [Google Scholar] [CrossRef]

- Tawfik, M.; Ro, J.J.; Mei, C. Thermal post-buckling and aeroelastic behaviour of shape memory alloy reinforced plates. Smart Mater. Struct. 2002, 11, 297. [Google Scholar] [CrossRef]

- Kumar, C.N.; Singh, B.N. Thermal buckling and post-buckling of laminated composite plates with SMA fibers using layerwise theory. Int. J. Comput. Methods Eng. Sci. Mech. 2009, 10, 423–429. [Google Scholar] [CrossRef]

- Ibrahim, H.H.; Tawfik, M.; Negm, H.M. Thermal buckling and nonlinear flutter behavior of shape memory alloy hybrid composite plates. J. Vib. Control. 2011, 17, 321–333. [Google Scholar] [CrossRef]

- Lee, H.J.; Lee, J.J. A numerical analysis of the buckling and postbuckling behavior of laminated composite shells with embedded shape memory alloy wire actuators. Smart Mater. Struct. 2000, 9, 780. [Google Scholar] [CrossRef]

- Roh, J.H.; Oh, I.K.; Yang, S.M.; Han, J.H.; Lee, I. Thermal post-buckling analysis of shape memory alloy hybrid composite shell panels. Smart Mater. Struct. 2004, 13, 1337. [Google Scholar] [CrossRef]

- Karimiasl, M.; Ebrahimi, F.; Akgöz, B. Buckling and post-buckling responses of smart doubly curved composite shallow shells embedded in SMA fiber under hygro-thermal loading. Compos. Struct. 2019, 223, 110988. [Google Scholar] [CrossRef]

- Nejati, M.; Ghasemi-Ghalebahman, A.; Soltanimaleki, A.; Dimitri, R.; Tornabene, F. Thermal vibration analysis of SMA hybrid composite double curved sandwich panels. Compos. Struct. 2019, 224, 111035. [Google Scholar] [CrossRef]

- Panda, S.K.; Singh, B.N. Nonlinear finite element analysis of thermal post-buckling vibration of laminated composite shell panel embedded with SMA fibre. Aerosp. Sci. Technol. 2013, 29, 47–57. [Google Scholar] [CrossRef]

- Ghomshei, M.M.; Tabandeh, N.; Ghazavi, A.; Gordaninejad, F. Nonlinear transient response of a thick composite beam with shape memory alloy layers. Compos. Part B 2005, 36, 9–24. [Google Scholar] [CrossRef]

- Cho, H.K.; Rhee, J. Nonlinear finite element analysis of shape memory alloy (SMA) wire reinforced hybrid laminate composite shells. Int. J. Non-Linear Mech. 2012, 47, 672–678. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, R.; Shi, D.; Wang, Q. A simplified plate theory for vibration analysis of composite laminated sector, annular and circular plate. Thin-Walled Struct. 2019, 143, 106252. [Google Scholar] [CrossRef]

- Belardi, V.G.; Fanelli, P.; Vivio, F. On the radial bending of shear-deformable composite circular plates with rectilinear orthotropy. Eur. J. Mech. A/Solids 2021, 86, 104157. [Google Scholar] [CrossRef]

- Gao, C.; Pang, F.; Li, H.; Jia, D.; Tang, Y. Steady and transient vibration analysis of uniform and stepped annular/circular plates based on FSDT. Acta Mech. 2022, 233, 1061–1082. [Google Scholar] [CrossRef]

- Tabrizikahou, A.; Kuczma, M.; Łasecka-Plura, M. Out-of-Plane Behavior of Masonry Prisms Retrofitted with Shape Memory Alloy Stripes: Numerical and Parametric Analysis. Sensors 2022, 22, 8004. [Google Scholar] [CrossRef]

- Brinson, L.C. One-dimensional constitutive behavior of shape memory alloys: Thermomechanical derivation with non-constant material functions and redefined martensite internal variable. J. Intell. Mater. Syst. Struct. 1993, 4, 229–242. [Google Scholar] [CrossRef]

- Reddy, J.N. Mechanics of Laminated Composite Plates and Shells: Theory and Analysis; CRC Press: New York, NY, USA, 2003; pp. 132–133. [Google Scholar]

- Roodgar Saffari, P.; Sher, W.; Thongchom, C. Size Dependent Buckling Analysis of a FG-CNTRC Microplate of Variable Thickness under Non-Uniform Biaxial Compression. Buildings 2022, 12, 2238. [Google Scholar] [CrossRef]

- Ebrahimi-Mamaghani, A.; Forooghi, A.; Sarparast, H.; Alibeigloo, A.; Friswell, M.I. Vibration of viscoelastic axially graded beams with simultaneous axial and spinning motions under an axial load. Appl. Math. Model. 2021, 90, 131–150. [Google Scholar] [CrossRef]

- Newmark, N.M. A method of computation for structural dynamics. J. Eng. Mech. Div. 1959, 85, 67–94. [Google Scholar] [CrossRef]

| Property | Variable | Value |

|---|---|---|

| The Young’s modulus (austenite) | EA | 67 GPa |

| The Young’s modulus (martensite) | EM | 26.3 GPa |

| Austenite start temperature | As | 34.5 °C |

| Austenite finish temperature | Af | 49 °C |

| Martensite start temperature | Ms | 18.4 °C |

| Martensite finish temperature | Mf | 9 °C |

| Critical transformation stress | , | 100 MPa, 170 MPa |

| Slope of martensite limit curve | CM | 8.0 MPa/°C |

| Slope of austenite limit curve | CA | 13.8 MPa/°C |

| Maximum transformation strain | 0.067 | |

| Density | 6648.1 kg/m3 | |

| Thermal expansion | , | 11 × (°C), 6.6 × (°C) |

| Configuration | Obtained Property | Gr/E (Ref. [35]/Present Study) | SMAHC Plate (Ref. [35]/Present Study) |

|---|---|---|---|

| I. layup | Deflection (mm) Natural frequency (Hz) | 37.6/37.4 | 65.0/64.7 |

| 52.2/52.3 | 39.4/39.9 | ||

| 86.4/87.1 | 63.2/64.5 | ||

| 231.7/232.8 | 167.2/169.4 | ||

| II. layup | Deflection (mm) Natural frequency (Hz) | 163.7/163.3 | 288.8/288.5 |

| 25.7/25.7 | 19.3/19.4 | ||

| 123/123.6 | 97.5/98.2 | ||

| 157.3/158.9 | 116/117.3 | ||

| III. layup | Deflection (mm) Natural frequency (Hz) | 146.2/146 | 160.9/160.4 |

| 26.4/26.9 | 25.1/25.4 | ||

| 69.8/70.7 | 54.1/55.2 | ||

| 165.5/166.2 | 157.5/159.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Stachiv, I. Computational Modeling and Parametric Analysis of SMA Hybrid Composite Plates under Thermal Environment. Sensors 2023, 23, 1344. https://doi.org/10.3390/s23031344

Li W, Stachiv I. Computational Modeling and Parametric Analysis of SMA Hybrid Composite Plates under Thermal Environment. Sensors. 2023; 23(3):1344. https://doi.org/10.3390/s23031344

Chicago/Turabian StyleLi, Wei, and Ivo Stachiv. 2023. "Computational Modeling and Parametric Analysis of SMA Hybrid Composite Plates under Thermal Environment" Sensors 23, no. 3: 1344. https://doi.org/10.3390/s23031344

APA StyleLi, W., & Stachiv, I. (2023). Computational Modeling and Parametric Analysis of SMA Hybrid Composite Plates under Thermal Environment. Sensors, 23(3), 1344. https://doi.org/10.3390/s23031344