Residual Creep Life Assessment of High-Temperature Components in Power Industry

Abstract

:1. Introduction

2. Review of Methodologies

2.1. ECCC Recommendations

2.2. EPRI Research in Power Generation Industry

2.3. Damage Mechanisms and Life Assessment of High Temperature Components

- Level 1: The assessment is performed using plant records, design stresses and temperatures, and minimum values of material properties from the literature.

- Level 2: Actual measurements of dimensions and temperature, simplified stress calculations, and inspections coupled with the use of minimum material properties from the literature are required in this assessment.

- Level 3: This assessment involves in-depth inspection, refined stress analysis, detailed plant monitoring records and the generation of actual material data from samples removed from the component.

2.4. Power Plant Life Management and Performance Improvement

2.5. Coal Power Plant Materials and Life Assessment

- Stage 1 is the calculation stage, based on the equipment history, taking into account operational pressure, temperature, incidental events, and the number of startups and shutdowns. It requires the compilation of relevant information, which can be obtained from technical drawings, original material list, material properties, database of operation conditions, and a detailed database of failures that occurred during the life of the equipment.

- Stage 2 assessment involves NDT of the pressure components. This assessment can be improved from stage 1, because stage 1 can provide relevant information to select the best zone in which to perform NDT.

- Stage 3 assessment relates to destructive testing. This assessment requires the removal of a small amount of material from the equipment. A comparison of the results of all tests performed is then required.

- The RLA assessment can be performed in either two-level or three-level approaches. Level I assessment is usually a preliminary residual life calculation using historical data. The results from this assessment can be used to plan for the inspection to be carried out on the critical components. Level II and/or III assessment usually involves NDT or destructive tests to improve the accuracy of the residual life calculation.

- A review of the history records of the components is required. If there is operating data available, the review can be performed using the operating records. If not, a preliminary review can be performed using the design data.

- RLA calculation/assessment procedures are carried out in both Level I and II assessments to obtain the residual life value of the components. There are various standards and guidelines available in the industry for the evaluation of the most appropriate models to be used for the components.

- The two-level or three-level approach applies to all types of systems in the power industry. However, the details of the assessment procedures will vary depending on the components and dominant damage mechanisms.

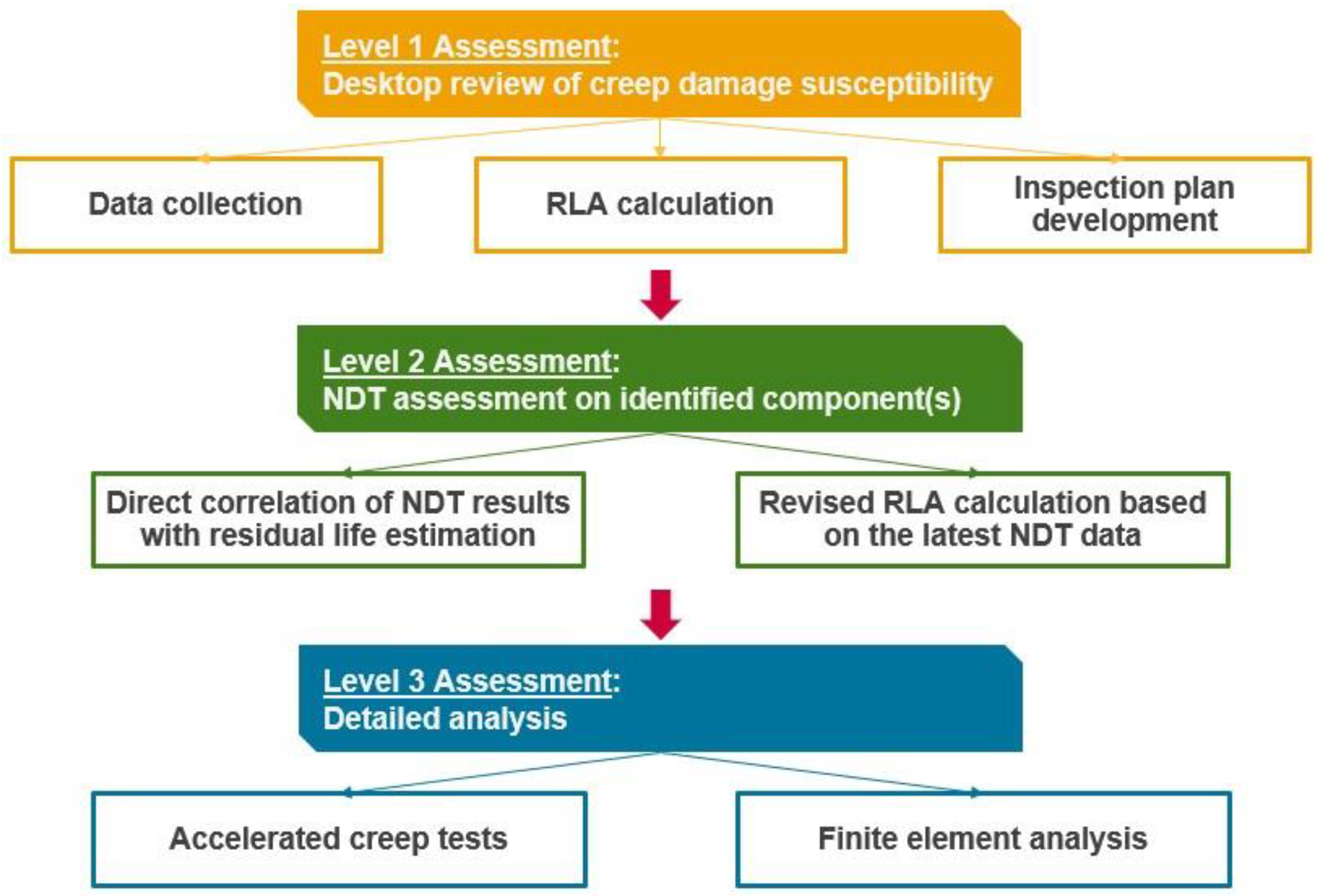

3. Proposed Methodology

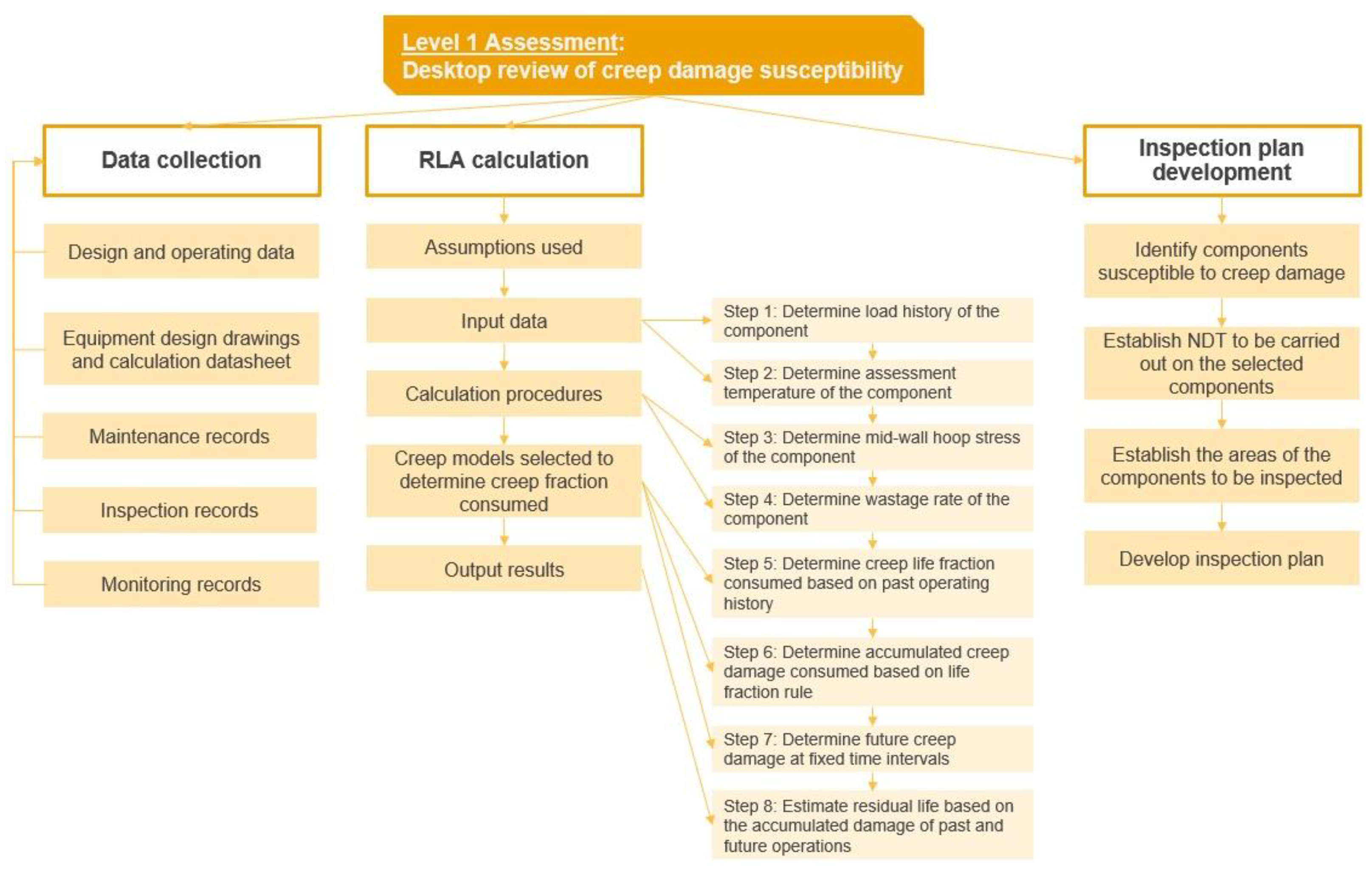

3.1. Level 1

- Data collection;

- RLA calculations;

- Inspection plan development.

3.1.1. Data Collection

3.1.2. RLA Calculation

- The effect of the tube fins on the stress is ignored. Internal burst pressure tests on integral low-finned tubes show that the plain ends of a finned tube are its weakest points because the helical fins act as reinforcement rings.

- If the tube metal temperature is taken from the operation records (i.e., no internal oxide thickness measurement is available), the increase in the tube metal temperature resulting from the build-up of steam-side deposits or oxide scale is ignored.

- The creep properties of the component assessed are assumed to be similar to the data used for a different standard when calculating the creep life fraction consumed.

- Step 1—determine the load history of the component

- 2.

- Step 2—determine the assessment temperature of the componentThe temperature data can be obtained from the following sources:

- ○

- Thermocouples;

- ○

- Maximum operating temperature data;

- ○

- Metal temperature estimation based on internal oxide thickness measurement.

- 3.

- Step 3—determine the mid-wall hoop stress

- P: operating pressure (MPa);

- OD: outer diameter (mm);

- t: measured thickness (mm);

- nBN: Bailey–Norton coefficient;

- R0: outer radius (mm);

- Lf: Lorentz factor.

- 4.

- Step 4—determine the wastage rate of the component

- wastage rate: (mm/h);

- toxide: thickness of internal oxide (mm).

- 5.

- Step 5—determine the creep life fraction consumed by the component

- Top: running hours (h);

- Trupture: time to rupture (h).

- API 530 [26]

- API 579-1 [19]

- PD 6525 [28]

- BS EN 12952-4 [30]

- 6.

- Step 6—determine the accumulated creep damage consumed

- ti: the time spent under condition i (h);

- tri: the time to rupture under condition i (h);

- εi: the strain accumulated under condition i (%);

- εri: the strain to rupture under condition i (%).

- 7.

- Step 7—determine the future creep damage at fixed time intervals

- 8.

- Step 8—estimate the residual creep life

- Other time–temperature parameter models for calculations;

- A rough estimation can be performed based on the extent of microstructural degradation on the condition that in situ metallographic replication was conducted previously;

- If hardness data are available, an estimation based on these results can be performed using LMP methods.

3.1.3. Inspection Plan Development

- Component to be inspected;

- Susceptible damage mechanisms;

- Parts of a component that are prone to certain damage mechanisms;

- Non-destructive technique to be used to address the type and extent of the damage.

3.2. Level 2

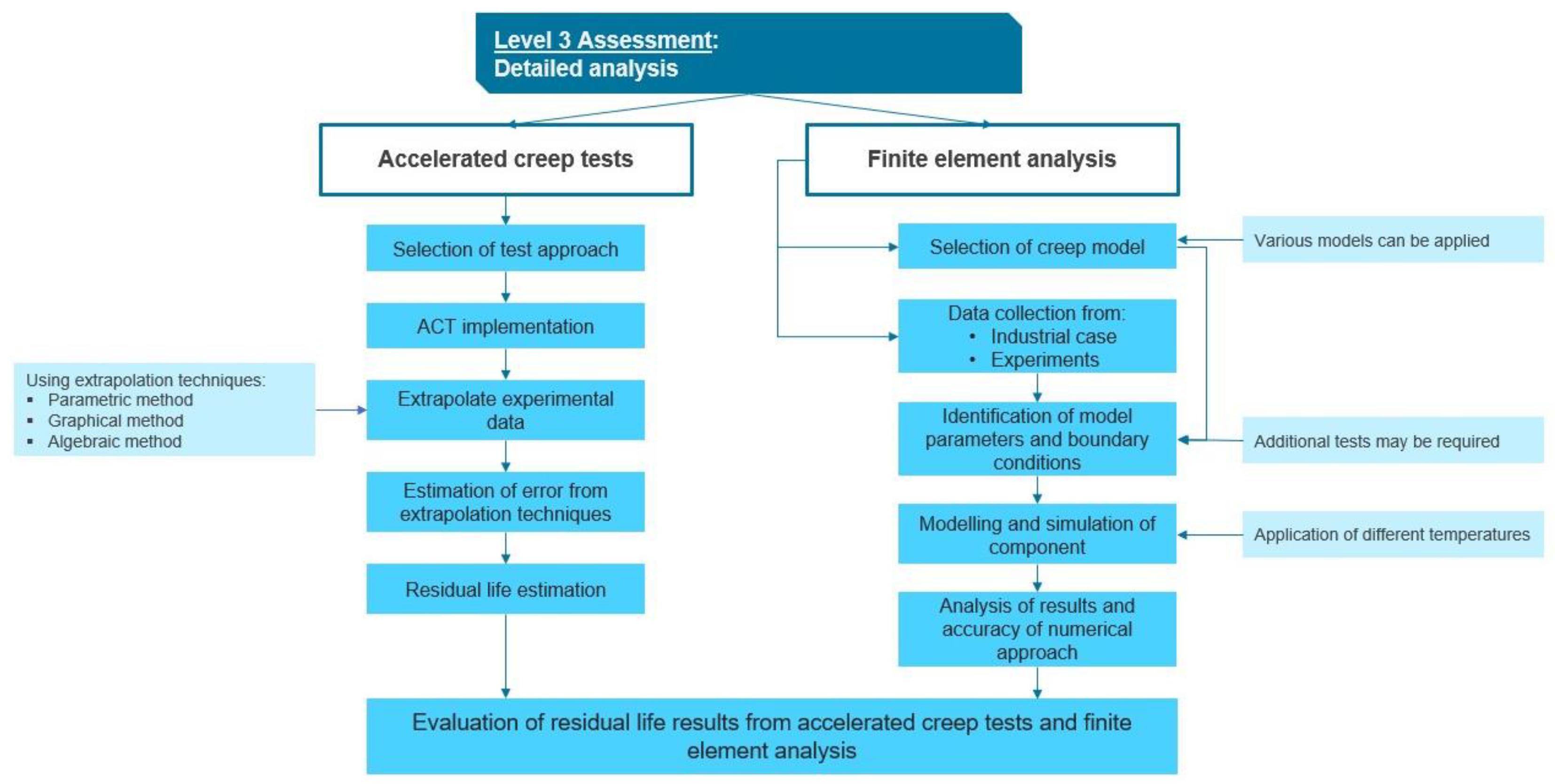

3.3. Level 3

3.3.1. Accelerated Creep Tests

- Both test temperature and/or applied stress are elevated over the in-service condition. This means that both temperature and applied stress parameters are different for all tests;

- The test temperature is elevated while the applied stress is maintained constant for all tests at a level representative of the in-service condition (iso-stress rupture test).

- Parametric method, which is the most used method for high-temperature components in the power industry;

- Graphical method (theoretical and empirical), but not widely employed;

- Algebraic method, although little advancement of this method for extrapolation of creep test data was observed over the years;

3.3.2. Finite Element Analysis

4. Case Study and Discussion

- Material: ASTM A213 Grade T91;

- Outer diameter: 60.33 mm;

- Design thickness: min. nominal 5.537 mm, min. allowable 4.037 mm;

- Design temperature: 580 °C;

- Operating pressure: 180 bars;

4.1. Level 1

4.2. Level 2

4.3. Level 3

4.4. Discussion

5. Conclusions

- L1 assessment is expected to provide a preliminary overview of the susceptible areas for creep damage based on design and operating history, as well as past inspection data.

- L2 assessment is intended to establish the extent of creep damage if a component is detected as prone to creep in L1. It is based on the results from non-destructive testing.

- L3, or detailed analysis, of components is proposed for cases when a more accurate life prediction, compared to L1 and L2, is necessary. It is especially the case if components already have some extent of creep damage, for instance, identified creep pores or diametrical strain. Accelerated uniaxial creep tests are meant to provide relatively precise results using extrapolation methods, whereas finite element analysis is aimed at identification of thermo-mechanical behavior over time and of structural durability in complex cases with the minimization of time of assessment in comparison with accelerated testing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

- Field metallographic replication (FMR)

- In situ hardness test

- Dimensional inspection

- Internal oxide thickness measurement/wall thickness measurement

- Advanced ultrasonic techniques (UT) (time-of-flight diffraction test (TOFD), phased-array ultrasonic test (PAUT), and electromagnetic acoustic transducer (EMAT) test).

- Acoustic Emission Test (AET)

- Scanning Force Microscopy (SFM)

- Electromagnetic methods (Eddy current testing, remote field testing, near-field testing, surface Eddy current testing, pulsed Eddy current, internal rotary inspection system, magnetic flux leakage testing, magnetic particle inspection).

Appendix B

- API 530 Calculation of Heater tube Thickness in Petroleum Refineries

- σ: hoop stress (ksi);

- C: Larson Miller Constant with minimum and average values provided for each material specification;

- T: assessment temperature (°F);

- Ld: time to rupture (h);

- A0, A1, A2, A3: coefficients depending on material specification of component. The coefficient data are provided in the WRC bulletin 541 [27].

- 2.

- PD 6525 Part 1: Elevated Temperature Properties for Steels for Pressure Purposes Part 1: Stress Rupture Properties

- T: Temperature (K);

- t: time to rupture (h);

- σ: hoop stress (MPa);

- r: a temperature exponent provided in Appendix B of the standard PD 6525 Part 1 [28];

- Ta, log(ta), a–e: constants provided in Appendix B of the standard PD 6525 Part 1 [28].

References

- Oakey, J.E. Power Plant Life Management and Performance Improvement; Woodhead Publishing: Cambridge, UK, 2011; 704p. [Google Scholar]

- Viswanathan, R. Damage Mechanisms and Life Assessment of High-Temperature Components; Carnes Publication Services Inc.: Verona, WI, USA, 1989; 503p. [Google Scholar]

- Thombre, S.C.; Kotwal, M.R. Residual Life Assessment. Int. J. Eng. Res. Technol. IJERT 2015, 4, 8. [Google Scholar]

- Electric Power Research Institute. Fossil Plant High-Energy Piping Damage: Theory and Practice, Volume 1: Piping Fundamentals; EPRI: Palo Alto, CA, USA, 2007; 370p. [Google Scholar]

- Paddea, S.; Masuyama, F.; Shibli, A. Coal Power Plant Materials and Life Assessment; Woodhead Publishing: Philadelphia, PA, USA, 2014; 402p. [Google Scholar]

- ECCC Recommendations. Guidance for the Assessment of Creep Rupture Data—Recommendations for the Assessment of Post Exposure (Ex Service) Creep Data; ECCC: Venice, Italy, 2005; Volume 5, Part III, Issue 2; 109p. [Google Scholar]

- ECCC Recommendations. High Temperature Component Analysis—Overview of Assessment & Design Procedures; ECCC: Venice, Italy, 2005; Volume 9, Part II, Issue 1; 89p. [Google Scholar]

- Electric Power Research Institute. Generic Guidelines for the Life Extension of Fossil Fuel Power Plant (CS-4778); EPRI: Palo Alto, CA, USA, 1986; 386p. [Google Scholar]

- Rackley, S.A. Carbon Capture and Storage; Elsevier Inc.: Philadelphia, PA, USA, 2017; pp. 37–71. [Google Scholar]

- Power Technology. Available online: https://www.power-technology.com/projects/yuhuancoal/ (accessed on 15 December 2021).

- International Centre for Sustainable Carbon. Available online: https://www.sustainable-carbon.org/blogs/worlds-first-ausc-power-plant-will-it-happen-in-india/ (accessed on 15 December 2021).

- Cerjak, H.; Mayr, P. Creep strength of welded joints of ferritic steels. In Creep-Resistant Steels; Woodhead Publishing: Cambridge, UK, 2008; pp. 472–503. [Google Scholar]

- Spigarelli, S.; Quadrini, E. Analysis of the creep behaviour of modified P91 (9Cr-1Mo-NbV) welds. Mater. Des. 2002, 23, 547–552. [Google Scholar] [CrossRef]

- Abe, F. Strengthening mechanisms in steel for creep and creep rupture. In Creep-Resistant Steels; Woodhead Publishing: Cambridge, UK, 2008; pp. 279–304. [Google Scholar]

- Kassner, M. Fundamentals of Creep in Metals and Alloys; Elsevier: Amsterdam, The Netherlands, 2009; 312p. [Google Scholar]

- National Board of Boiler and Pressure Vessel Inspections. Available online: https://www.nationalboard.org/Index.aspx?pageID=181 (accessed on 29 December 2021).

- ECCC European Creep Collaborative Committee. Available online: https://www.eccc-creep.com/eccc-recommendations-volumes (accessed on 21 December 2022).

- Electric Power Research Institute. Boiler and Heat Recovery Steam Generator Tube Failures: Theory and Practice Volume 1: Fundamental; EPRI: Palo Alto, CA, USA, 2007; 302p. [Google Scholar]

- American Petroleum Institute (API). Fitness for Service, API 579-1; API: Washington, DC, USA, 2021; 1478p. [Google Scholar]

- Electric Power Research Institute. Life Assessment of Boiler Pressure Parts Volume 7: Life Assessment Technology for Superheater/Reheater Tubes; EPRI: San Diego, CA, USA, 1993; 122p. [Google Scholar]

- Electric Power Research Institute. Guidelines for the Nondestructive Examination of Boilers; EPRI: Palo Alto, CA, USA, 2007; 226p. [Google Scholar]

- AS 1228; Pressure Equipment—Boilers. Standards Australia: Sydney, Australia, 2016; 278p.

- Xu, C.; Gao, W. Pilling-Bedworth ratio for oxidation of alloys. Mater. Res. Innov. 2000, 3, 231–235. [Google Scholar] [CrossRef]

- Cramer, S.D.; Covino, B.S., Jr. (Eds.) Volume 13A: Corrosion: Fundamental, Tesing and Protection; ASM International: Phoenix, AZ, USA, 2003; 1135p. [Google Scholar]

- Hovinga, M.N. Standard Recommendations for Pressure Part Inspection during a Boiler Life Extension Program. In Proceedings of the International Conference on Life Management and Life Extension of Power Plant, Xi’an, China, 18–20 May 2000; 7p. [Google Scholar]

- American Petroleum Institute (API). Calculation of Heater-Tube Thickness in Petroleum Refineries, API 530; API: Washington, DC, USA, 2015; 264p. [Google Scholar]

- The Welding Research Council. Evaluation of Material Strength Data for Use in Conjunction with API 530; WRC: New York, NY, USA, 2011; 150p. [Google Scholar]

- PD 6525; Part 1: Elevated Temperature Properties for Steels for Pressure Purposes. BSI: London, UK, 1990; 126p.

- Abdallah, Z.; Gray, V.; Whittaker, M.; Perkins, K. A critical analysis of the conventionally employed creep lifing method. Materials 2014, 7, 3371–3398. [Google Scholar] [CrossRef] [PubMed]

- BS EN 12952-4; Water Tube Boilers and Auxiliary Installations. BSI: London, UK, 2011; 21p.

- PCC-3-2017; Inspection Planning Using Risk-Based Methods. ASME: Little Falls, NJ, USA, 2017; 93p.

- Electric Power Research Institute. Guidelines on Nondestructive Examination of HRSG; EPRI: Palo Alto, CA, USA, 2007; 290p. [Google Scholar]

- American Petroleum Institute (API). API 571; Damage Mechanism Affecting Fixed Equipment in the Refining Industry; API: Washington, DC, USA, 2020; 400p, p. 400. [Google Scholar]

- Viswanathan, R. Life assessment Technology for fossil power plants. Sadhana 1995, 20, 301–329. [Google Scholar] [CrossRef]

- Viswanathan, R. Accelerated stress rupture testing for creep life prediction—Its value and limitations. J. Press. Vessel. Technol. 1998, 120, 105–115. [Google Scholar] [CrossRef]

- Penny, R.K.; Marriott, D.L. Extrapolation of creep strain and rupture data. In Design for Creep; Springer: Dordrecht, The Netherlands, 1995; pp. 200–248. [Google Scholar]

- Combe, C.; Cardey, P.-F.; Morillot, H. Creep Handbook. Estimation of Remaining Creep Life; CETIM: Senlis, France, 2014; 136p. [Google Scholar]

- Bonetti, R.; Morris, A.; Shipway, P.H.; Sun, W. Requirements for developing high temperature creep life models for ageing pipework systems using power plant condition monitoring and inspection data. Int. J. Press. Vessel. Pip. 2020, 188, 104233. [Google Scholar] [CrossRef]

- Abdallah, Z.; Perkins, K.; Arnold, C. Creep Lifing Models and Techniques. In Creep; IntechOpen: London, UK, 2008; pp. 115–149. [Google Scholar]

- Zharkova, N.A.; Botvina, L.R. Estimate of the Life of a Material under Creep Conditions in the Phase-Transition Theory. Dokl. Phys. 2003, 48, 379–381. [Google Scholar] [CrossRef]

- Sreeranganathan, A. Remaining Life Assessment of Coker Heater Tubes. In Proceedings of the Canada Coking Conference, Fort McMurray, AB, Canada, 22–26 October 2012. [Google Scholar]

- Ayubali, A.A.; Singh, A.; Shanmugavel, B.P.; Padmanabhan, K.A. A phenomenological model for predicting long-term high temperature creep life of materials from short-term high temperature creep test data. Int. J. Mech. Sci. 2021, 202, 106505. [Google Scholar] [CrossRef]

- Pan, J.P.; Tu, S.H.; Sun, G.L.; Zhu, X.W.; Tan, L.J.; Hu, B. High-temperature creep properties and life predictions for T91 and T92 steels. IOP Conf. Ser. Mater. Sci. Eng. 2018, 292, 012098. [Google Scholar] [CrossRef]

- Holdsworth, S.R. Constitutive equations for creep curves and predicting service life. In Creep-Resistant Steels; Woodhead Publishing: Cambridge, UK, 2008; pp. 403–420. [Google Scholar]

- Holdsworth, S.; Askins, M.; Baker, A.; Gariboldi, E.; Holmstrom, S.; Klenk, A.; Ringel, M.; Merckling, G.; Sandstrom, R.; Schwienheer, M.; et al. Factors influencing creep model equation selection. (on behalf of Working Group 1 of the European Creep Collaborative Committee). Int. J. Press. Vessel. Pip. 2008, 85, 80–88. [Google Scholar] [CrossRef]

- Chen, H.; Zhu, G.R.; Gong, J.M. Creep Life Prediction for P91/12Cr1MoV Dissimilar Joint Based on the Omega Method. Procedia Eng. 2015, 130, 1143–1147. [Google Scholar] [CrossRef]

- Ellis, F.V. Life Assessment Using Metallographic and Mechanical Methods. Mater. Charact. 1994, 32, 79–87. [Google Scholar] [CrossRef]

- Grunloh, H.J.; Hoosic, P.T.; Berasi, M.L.; Sherlock, T.P.; Evans, R.S.; Lawrie, W.E.; Buttram, J.D.; Flora, J.H. Life Assessment of Boiler Pressure Parts Volume 6: Guidelines for NDE of Heavy Section Components; EPRI: Palo Alto, CA, USA, 1994; 216p. [Google Scholar]

- Abe, F.; Kern, T.-U.; Viswanathan, R. Creep-Resistant Steels; Woodhead Publishing: Cambridge, UK, 2008; 701p. [Google Scholar]

- Jankauskas, A.; Mažeika, L.; Nageswaran, C. Ultrasonic NDT technique for detection of creep damage in welded steel pipes. In Proceedings of the 12th ECNDT, Gothenburg, Sweden, 11–15 June 2018. [Google Scholar]

- Budimir, M.; Nageswaran, C.; Mažeika, L.; Arvanitis, A.; Alexandros, A.; Itty, P.-A. An ultrasonic non-destructive testing system for detection and quantification of early stage subsurface creep damage in the thermal power generation industry. In Proceedings of the 26th International Conference Nuclear Energy for New Europe, Bled, Slovenia, 11–14 September 2017. [Google Scholar]

- TWI. Ultrasonic Plant Inspection Project Findings Published. Available online: https://www.twi-global.com/media-and-events/press-releases/2022/ultrasonic-plant-inspection-project-findings-published (accessed on 20 January 2022).

- TeamInc. High Energy Piping Creep Inspection. Available online: https://www.teaminc.com/assets/PDFs/TEAM_HEP%20MPA%20Brochure_LTR-WEB.pdf (accessed on 12 May 2022).

- Electric Power Research Institute. Detection and Classification of Subsurface Damage Occurring in Elevated Temperature Girth Welds; EPRI: Palo Alto, CA, USA, 2009; 94p. [Google Scholar]

- Inspectioneering. Overview of Time-of-Flight Diffraction (TOFD). Available online: https://inspectioneering.com/tag/tofd (accessed on 20 May 2022).

- NDT. An overview TOFD Method and Its Mathematical Model. Available online: https://www.ndt.net/article/v05n04/mondal/mondal.htm (accessed on 5 May 2022).

- BINDT. TOFD. Available online: https://www.bindt.org/What-is-NDT/Index-of-acronyms/T/TOFD/ (accessed on 20 May 2022).

- Olympus. Phased Array Tutorial. Available online: https://www.olympus-ims.com/en/ndt-tutorials/intro/breif-history/ (accessed on 1 June 2022).

- TWI. What Is Phased Array Ultrasonic Testing (PAUT) and How Does It Work? Available online: https://www.twi-global.com/technical-knowledge/faqs/what-is-phased-array-ultrasonic-testing#HowDoesPhasedArrayWork (accessed on 1 June 2022).

- Inspectioneering. Overview of Phased Array Ultrasonic Testing (PAUT). Available online: https://inspectioneering.com/tag/paut (accessed on 1 June 2022).

- Innerspec. EMAT Technology. Available online: https://www.innerspec.com/emat-technology (accessed on 1 June 2022).

- Inspectioneering. Overview of Electro Magnetic Acoustic Transducers (EMAT). Available online: https://inspectioneering.com/tag/emat (accessed on 1 June 2022).

- Alers, G. A History of EMATs. AIP Conf. Proc. 2008, 975, 801–808. [Google Scholar]

- Novotest. Electromagnetic-Acoustic Transducers (EMAT). Available online: http://novotest.biz/electromagnetic-acoustic-transducers-emat/ (accessed on 1 June 2022).

- Inspectioneering. Overview of Nondestructive Testing (NDT). Available online: https://inspectioneering.com/tag/nondestructive+testing (accessed on 20 May 2022).

- BINDT. Acoustic Emission (AE). Available online: https://www.bindt.org/What-is-NDT/Acoustic-emission-AE/ (accessed on 2 June 2022).

- Flyability. Acoustic Emission Testing: A Guide. Available online: https://www.flyability.com/acoustic-emission-testing (accessed on 2 June 2022).

- NDT. What is Acoustic Emission? Available online: https://www.ndt.net/article/az/ae_idx.htm (accessed on 2 June 2022).

- Coulter, J.E.; Sherlock, T.P.; Stevens, D.M. Acoustic Emission Monitoring of Cracks in Fossil Fuel Boilers: Final Report CS-5264; EPRI: Palo Alto, CA, USA, 1987. [Google Scholar]

- Morgan, B.C.; Rodgers, J.M. Acoustic Emission Monitoring of High-Energy Headers Volume 1: Acoustic Emission Monitoring Guidelines for Superheater Outlet Headers Report TR-107839; EPRI: Palo Alto, CA, USA, 1997. [Google Scholar]

- Morgan, B.C.; Foster, C.L. Acoustic Emission Monitoring of High-Energy Steam Piping Volume 1: Acoustic Emission Monitoring Guidelines for Hot Reheat Piping Report TR-105265; EPRI: Palo Alto, CA, USA, 1995. [Google Scholar]

- Shibli, A. Power Plant Asset Management and Condition/Life Assessment. In Proceedings of the ETD Webinar, Leatherhead, UK, 29 March 2022. [Google Scholar]

- ETD. Integrity Scanning Force Microscope (I-SFM). Available online: https://www.etd-consulting.com/advanced-inspection-and-monitoring-tools/ (accessed on 2 June 2022).

- ETD. Plant Services Brochure 2022. Available online: https://www.etd-consulting.com/wp-content/uploads/2022/03/ETD_Plant-Services-Brochure_2022.pdf (accessed on 2 June 2022).

- NDTS. Electromagnetic Testing. Available online: https://www.ndts.co.in/electromagnetic-testing/ (accessed on 2 June 2022).

- NDT. Electromagnetic Testing Inspections. Available online: http://2020ndt.com/electromagnetic-testing-inspections/ (accessed on 2 June 2022).

- Versa Integrity Group. Electromagnetic Testing (ET). Available online: https://www.versaintegrity.com/services/advanced-services/electromagnetic-testing/#:~:text=Electromagnetic%20testing%20%28ET%29%20is%20the%20primary%20NDT%20method,as%20steam%20erosion%2C%20baffle%20fret-wear%2C%20pitting%2C%20and%20cracking (accessed on 2 June 2022).

| Information Gathered | Mandatory/ Optional | Remarks |

|---|---|---|

| Design and operating data | Mandatory | These parameters are readily available from clients most of the time. |

| Equipment data | Mandatory | The important parameters required for calculation are outer diameter, thickness, and material specification. For L1 calculation, the above data will be extracted from the inspection records, if available. If there are no inspection records, the parameters for calculation will be extracted from the design data of the equipment. |

| Maintenance records | Mandatory | |

| Inspection records | Mandatory | |

| Monitoring records | Optional | - |

| Period | Running Hours | Wall Thickness | Oxide Thickness | Hardness |

|---|---|---|---|---|

| 1 | 55,000 h | 5.5 mm | 0.22 mm | 220 HV |

| 2 | 85,000 h | 5.2 mm | 0.32 mm | 210 HV |

| 3 | 120,000 h | 4.8 mm | 0.42 mm | 200 HV |

| Period | Running Hours | Oxidation Rate | Wastage Rate | Hoop Stress | Tube Metal Temperature |

|---|---|---|---|---|---|

| 1 | 55,000 h | 1.91×10−6 mm/h | 2.49×10−6 mm/h | 91.0 MPa | 568 °C |

| 2 | 85,000 h | 1.59×10−6 mm/h | 6.67×10−6 mm/h | 94.8 MPa | 577 °C |

| 3 | 120,000 h | 1.36×10−6 mm/h | 1.14×10−5 mm/h | 103.5 MPa | 583 °C |

| Parameters | Average Properties | Minimum Properties | ||

|---|---|---|---|---|

| API 530 (LMP) | PD 6525 (MHP) | API 530 (LMP) | PD 6525 (MHP) | |

| Time to rupture 1 | 4.96 × 105 h | 6.71 × 105 h | 1.49 × 105 h | 1.16 × 105 h |

| Creep life fraction consumed 1 | 0.041 | 0.031 | 0.138 | 0.183 |

| Estimated residual life | 82,000 h 9.3 years | 96,000 h 10.9 years | 46,000 h 4.5 years | 40,000 h 4.5 years |

| Parameters | Average Properties | Minimum Properties | ||

|---|---|---|---|---|

| API 530 (LMP) | PD 6525 (MHP) | API 530 (LMP) | PD 6525 (MHP) | |

| Time to rupture 1 | 1.30 × 105 h | 1.99 × 105 h | 3.91 × 104 h | 6.52 × 102 h |

| Creep life fraction consumed 1 | 0.188 | 0.134 | 0.624 | 0.801 |

| Estimated residual life | 75,000 h 8.5 years | 89,000 h 10.1 years | 45,000 h 5.1 years | 39,000 h 4.4 years |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pivdiablyk, I.; Di Goh, Z.; Chye, L.K.; Shandro, R.; Lefebvre, F. Residual Creep Life Assessment of High-Temperature Components in Power Industry. Sensors 2023, 23, 2163. https://doi.org/10.3390/s23042163

Pivdiablyk I, Di Goh Z, Chye LK, Shandro R, Lefebvre F. Residual Creep Life Assessment of High-Temperature Components in Power Industry. Sensors. 2023; 23(4):2163. https://doi.org/10.3390/s23042163

Chicago/Turabian StylePivdiablyk, Ivanna, Zhu Di Goh, Liam Kok Chye, Robert Shandro, and Fabien Lefebvre. 2023. "Residual Creep Life Assessment of High-Temperature Components in Power Industry" Sensors 23, no. 4: 2163. https://doi.org/10.3390/s23042163