A Review of Degradation Models and Remaining Useful Life Prediction for Testing Design and Predictive Maintenance of Lithium-Ion Batteries

Abstract

1. Introduction

2. Approaches to Degradation Modelling

- The first category is represented by physics of failure (PoF) models that are used in prognostics and remaining useful life (RUL) estimation to understand the underlying physical mechanisms that lead to the degradation and failure of a system over time. These models are based on the fundamental principles of physics and engineering to predict how various stresses and environmental factors influence the health and performance of a component or system. For this reason, PoF models are not commonly employed in the case of energy storage systems due to the complex non-linear degradation mechanisms that dominate the chemical wear-out of batteries [5,6].

- The second category is called data-driven methods because they rely on the analysis of historical or real-time data to predict the future health and the degradation path of a system. In order to do that, data-driven methods leverage patterns and information directly obtained from the system’s operational data as well as from the environmental conditions (which are usually called covariates). Typically, data-driven models are based on a multi-step procedure, starting from the data collection (either from the actual system or from historical datasets) followed by a feature extraction phase, a preprocessing phase (like anomaly detection, patter recognition, clustering, regression, and so on), and a training phase. After that, the model needs to be validated before it can be actually applied online on the system to estimate the RUL (eventually associated with a confidence interval or an uncertainty assessment). In the context of lithium-ion batteries, common data-driven models can be divided in the following sub-categories:

- –

- Stochastic models based on probabilistic assumptions, which include general path models [7], and stochastic processes like autoregressive integrated moving average (ARIMA) models [8], the Wiener process [9], the Brownian motion process [10], the gamma process [11], and the inverse Gaussian process [12].

- –

- –

- The alternative is represented by machine learning (ML) models. ML is a subset of artificial intelligence that enables systems to learn and make predictions or decisions without being explicitly programmed. It involves designing and developing algorithms and models that can learn patterns and relationships from data and use them to make predictions or take actions. ML algorithms are designed to improve their performance over time through experience, adjusting and optimizing their models based on feedback and new data. In the case of lithium batteries, common ML algorithms for PHM and RUL prediction include but are not limited to: support vector machine [15], relevance vector machine [16], random forest regression [17], artificial neural network [18], variational autoencoders [19], and deep neural networks. Examples of the latter are long short-term memory network (LSTM) [20], temporal transformer network [21], deep neural network [22], and echo state network [23]. An overall review of ML techniques for RUL estimation of batteries in recent years is presented in [24].

3. Specific Degradation Models

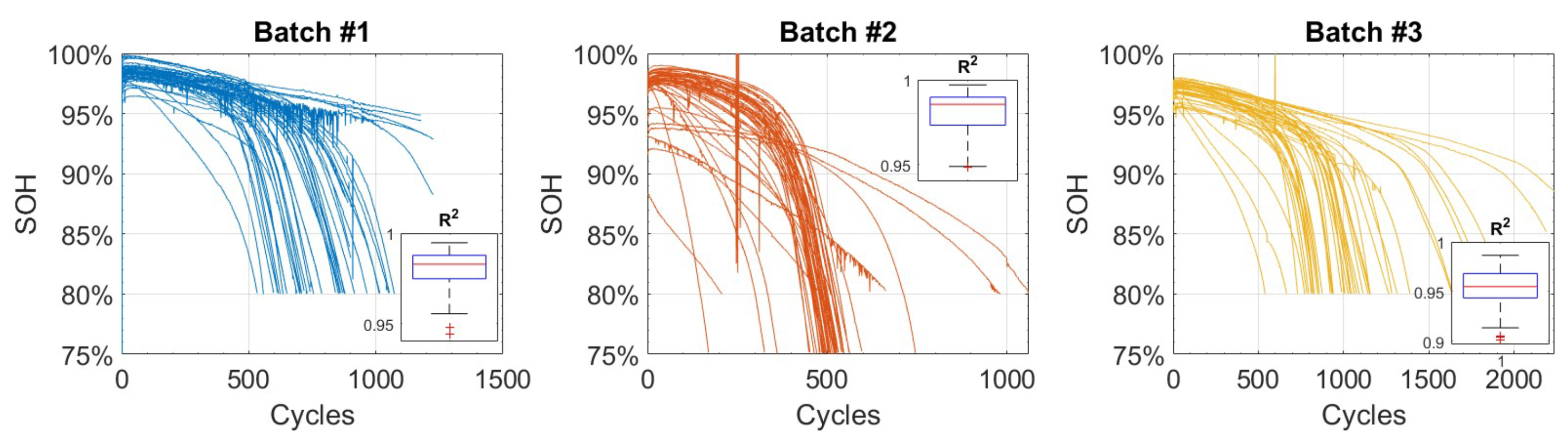

3.1. General Path Models

- is the SoH of the ith battery measured at the measurement time , which is assumed to be common across the units;

- where p is the degree of the polynomial time trend;

- is the vector of length of the regression coefficients for the ith unit;

- is the random noise for ith unit at measurement time t.

- are random parameter vectors of length drawn from a multivariate normal distribution: ;

- noises follow an autoregressive (AR) process of order q:, where ;

- and are independent of each other.

3.2. Stochastic Processes

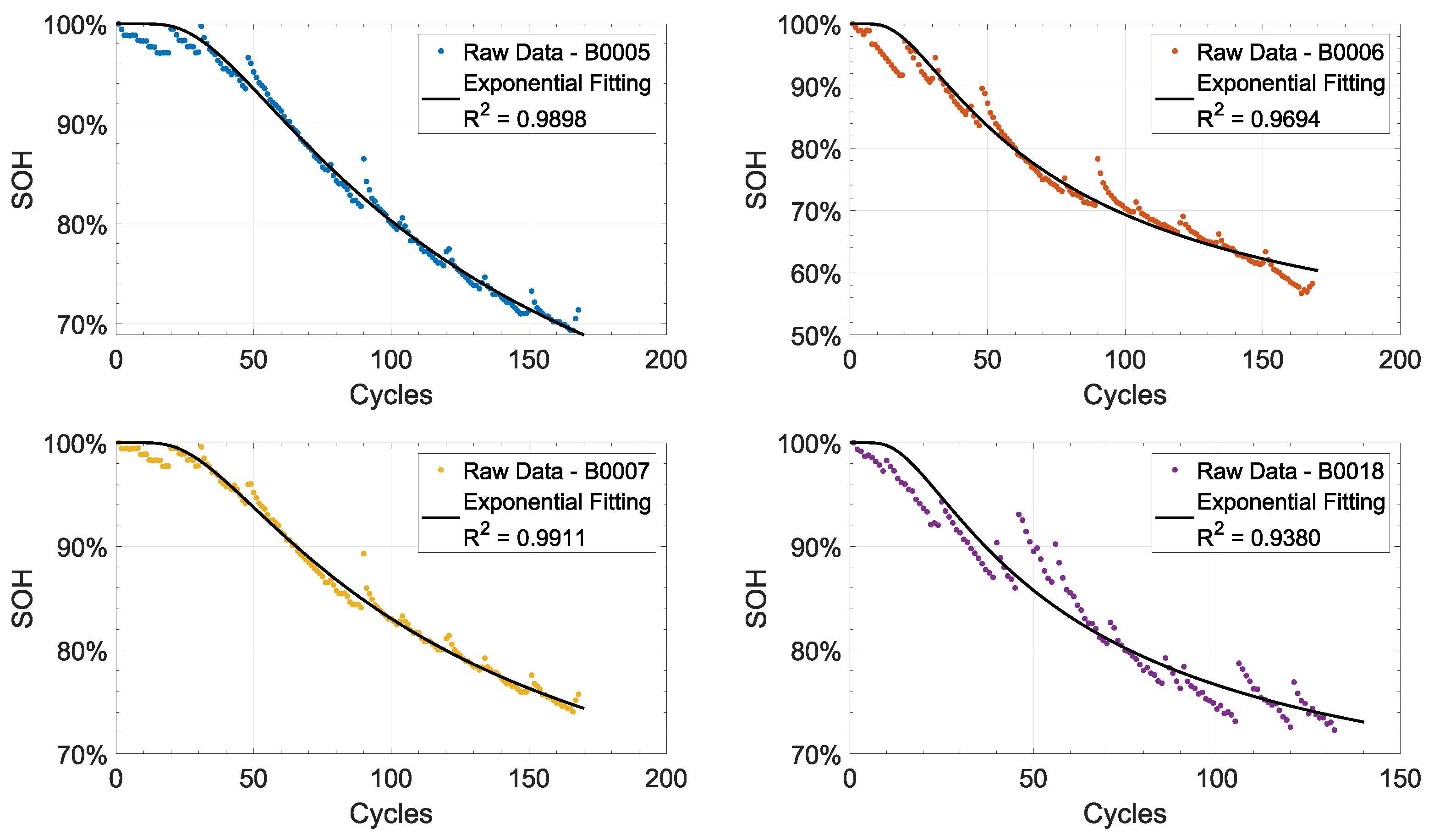

3.3. Exponential Models

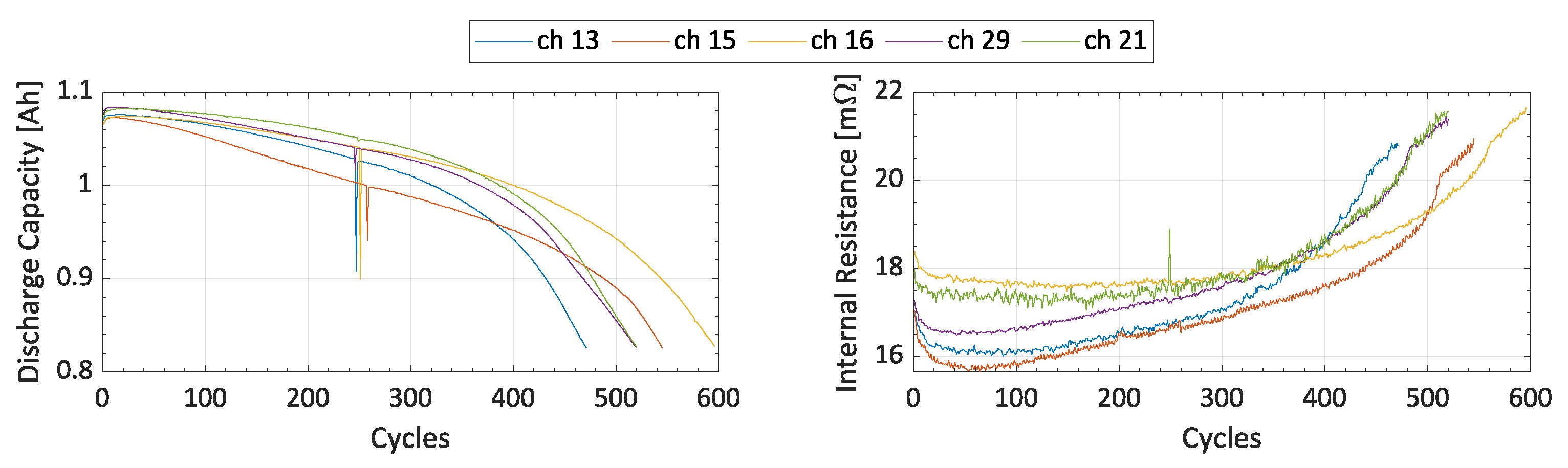

- An exponential decrease of the battery’s discharge capacitance over the battery’s operational lifespan;

- An exponential rise in the equivalent series resistance (ESR) over the battery’s operational lifespan.

- Using it as fitting model in a curve fitting toolbox. This is the most easy and least complex algorithm but, at the same time, it is the less accurate.

- Using it as state space of a Kalman filter or particle filter. This is the most common way found in literature for the double exponential model.

- Using it to train a machine learning (ML) algorithm like regression models and support vector machine.

- Using it to train a deep learning algorithm. The case of a recurrent neural network was investigated and tested in [23], pointing out better performances than the classical filter algorithms and the ML algorithm.

3.4. Polynomial Model

3.5. Transformer Model

- Denoising (optional): data are denoised using methods such as wavelet denoising, or a denoising auto-encoder [30];

- Capacity forecasting: the capacity fade curve is forecasted until it reaches 80% of its original value;

- RUL estimation: in the final step the RUL is estimated as the number of forecasts made in the previous step before reaching the EoL threshold.

3.6. Conv-LSTM with Attention Mechanism

- Convolutional layers: whose purpose is to reduce the dimensionality of the input and at the same time maintain the information contained in it;

- LSTM layers: to obtain temporal information contained in the data;

- Attention mechanism: similar to the self-attention used in Transformers, adds a weight to each sample of the input;

- Dense layers: receive the weighted samples and produce the output.

4. Optimal Accelerated Testing and Maintenance Planning

4.1. Optimal Designs for Accelerated Testing

4.2. Maintenance Planning via Reinforcement Learning

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Saha, B.; Goebel, K. Battery Data Set, Nasa Ames Prognostic Data Repository. 2007. Available online: https://scirp.org/reference/referencespapers?referenceid=3297577 (accessed on 10 January 2024).

- Severson, K.A.; Attia, P.M.; Jin, N.; Perkins, N.; Jiang, B.; Yang, Z.; Chen, M.H.; Aykol, M.; Herring, P.K.; Fraggedakis, D.; et al. Data-driven prediction of battery cycle life before capacity degradation. Nat. Energy 2019, 4, 383–391. [Google Scholar] [CrossRef]

- Hu, X.; Xu, L.; Lin, X.; Pecht, M. Battery lifetime prognostics. Joule 2020, 4, 310–346. [Google Scholar] [CrossRef]

- Patrizi, G.; Picano, B.; Catelani, M.; Fantacci, R.; Ciani, L. Validation of RUL estimation method for battery prognostic under different fast-charging conditions. In Proceedings of the 2022 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Ottawa, ON, Canada, 16–19 May 2022; pp. 1–6. [Google Scholar]

- Safari, M.; Delacourt, C. Mathematical modeling of lithium iron phosphate electrode: Galvanostatic charge/discharge and path dependence. J. Electrochem. Soc. 2010, 158, A63. [Google Scholar] [CrossRef]

- Deshpande, R.D.; Uddin, K. Physics inspired model for estimating ‘cycles to failure’ as a function of depth of discharge for lithium ion batteries. J. Energy Storage 2021, 33, 101932. [Google Scholar] [CrossRef]

- Lu, C.J.; Meeker, W.O. Using degradation measures to estimate a time-to-failure distribution. Technometrics 1993, 35, 161–174. [Google Scholar] [CrossRef]

- Kim, S.; Lee, P.Y.; Lee, M.; Kim, J.; Na, W. Improved State-of-health prediction based on auto-regressive integrated moving average with exogenous variables model in overcoming battery degradation-dependent internal parameter variation. J. Energy Storage 2022, 46, 103888. [Google Scholar] [CrossRef]

- Tang, S.; Guo, X.; Yu, C.; Xue, H.; Zhou, Z. Accelerated degradation tests modeling based on the nonlinear wiener process with random effects. Math. Probl. Eng. 2014, 2014, 560726. [Google Scholar] [CrossRef]

- Ge, Z.Z.; Li, X.Y.; Zhang, J.R.; Jiang, T.M. Planning of step-stress accelerated degradation test with stress optimization. Adv. Mater. Res. 2010, 118, 404–408. [Google Scholar] [CrossRef]

- Tseng, S.T.; Balakrishnan, N.; Tsai, C.C. Optimal step-stress accelerated degradation test plan for gamma degradation processes. IEEE Trans. Reliab. 2009, 58, 611–618. [Google Scholar] [CrossRef]

- Ye, Z.S.; Chen, L.P.; Tang, L.C.; Xie, M. Accelerated degradation test planning using the inverse Gaussian process. IEEE Trans. Reliab. 2014, 63, 750–763. [Google Scholar] [CrossRef]

- He, Z.; Yang, Z.; Cui, X.; Li, E. A method of state-of-charge estimation for EV power lithium-ion battery using a novel adaptive extended Kalman filter. IEEE Trans. Veh. Technol. 2020, 69, 14618–14630. [Google Scholar] [CrossRef]

- Li, L.; Saldivar, A.A.F.; Bai, Y.; Li, Y. Battery remaining useful life prediction with inheritance particle filtering. Energies 2019, 12, 2784. [Google Scholar] [CrossRef]

- Chen, Z.; Sun, M.; Shu, X.; Xiao, R.; Shen, J. Online state of health estimation for lithium-ion batteries based on support vector machine. Appl. Sci. 2018, 8, 925. [Google Scholar] [CrossRef]

- Guo, W.; He, M. An optimal relevance vector machine with a modified degradation model for remaining useful lifetime prediction of lithium-ion batteries. Appl. Soft Comput. 2022, 124, 108967. [Google Scholar] [CrossRef]

- Wang, G.; Lyu, Z.; Li, X. An Optimized Random Forest Regression Model for Li-Ion Battery Prognostics and Health Management. Batteries 2023, 9, 332. [Google Scholar] [CrossRef]

- Ismail, M.; Dlyma, R.; Elrakaybi, A.; Ahmed, R.; Habibi, S. Battery state of charge estimation using an Artificial Neural Network. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo (ITEC), Harbin, China, 7–10 August 2017; pp. 342–349. [Google Scholar]

- Jiao, R.; Peng, K.; Dong, J. Remaining Useful Life Prediction of Lithium-Ion Batteries Based on Conditional Variational Autoencoders-Particle Filter. IEEE Trans. Instrum. Meas. 2020, 69, 8831–8843. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, W.; Yang, K.; Zhang, S. Remaining useful life prediction of lithium-ion batteries based on attention mechanism and bidirectional long short-term memory network. Measurement 2022, 204, 112093. [Google Scholar] [CrossRef]

- Song, W.; Wu, D.; Shen, W.; Boulet, B. A Remaining Useful Life Prediction Method for Lithium-ion Battery Based on Temporal Transformer Network. Procedia Comput. Sci. 2023, 217, 1830–1838. [Google Scholar] [CrossRef]

- Ren, L.; Zhao, L.; Hong, S.; Zhao, S.; Wang, H.; Zhang, L. Remaining Useful Life Prediction for Lithium-Ion Battery: A Deep Learning Approach. IEEE Access 2018, 6, 50587–50598. [Google Scholar] [CrossRef]

- Catelani, M.; Ciani, L.; Fantacci, R.; Patrizi, G.; Picano, B. Remaining useful life estimation for prognostics of lithium-ion batteries based on recurrent neural network. IEEE Trans. Instrum. Meas. 2021, 70, 3524611. [Google Scholar] [CrossRef]

- Li, X.; Yu, D.; Søren Byg, V.; Daniel Ioan, S. The development of machine learning-based remaining useful life prediction for lithium-ion batteries. J. Energy Chem. 2023, 82, 103–121. [Google Scholar] [CrossRef]

- He, W.; Williard, N.; Osterman, M.; Pecht, M. Prognostics of lithium-ion batteries based on Dempster–Shafer theory and the Bayesian Monte Carlo method. J. Power Sources 2011, 196, 10314–10321. [Google Scholar] [CrossRef]

- Wei, J.; Dong, G.; Chen, Z. Remaining useful life prediction and state of health diagnosis for lithium-ion batteries using particle filter and support vector regression. IEEE Trans. Ind. Electron. 2017, 65, 5634–5643. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, M.; Chen, Y.; Zhu, S. Prediction of Lithium-ion battery’s remaining useful life based on relevance vector machine. SAE Int. J. Altern. Powertrains 2016, 5, 30–40. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiong, R.; He, H.; Pecht, M.G. Long short-term memory recurrent neural network for remaining useful life prediction of lithium-ion batteries. IEEE Trans. Veh. Technol. 2018, 67, 5695–5705. [Google Scholar] [CrossRef]

- Martiri, L.; Azzalini, D.; Flammini, B.; Cristaldi, L.; Amigoni, F. Improving Remaining Useful Life Estimation of Lithium-Ion Batteries when Nearing End of Life. In Proceedings of the 2023 IEEE MetroXRAINE, Milan, Italy, 25–27 October 2023; pp. 317–322. [Google Scholar]

- Chen, D.; Hong, W.; Zhou, X. Transformer network for remaining useful life prediction of lithium-ion batteries. IEEE Access 2022, 10, 19621–19628. [Google Scholar] [CrossRef]

- Che, Y.; Deng, Z.; Tang, X.; Lin, X.; Nie, X.; Hu, X. Lifetime and aging degradation prognostics for lithium-ion battery packs based on a cell to pack method. Chin. J. Mech. Eng. 2022, 35, 4. [Google Scholar] [CrossRef]

- Liu, H.; Deng, Z.; Yang, Y.; Lu, C.; Li, B.; Liu, C.; Cheng, D. Capacity evaluation and degradation analysis of lithium-ion battery packs for on-road electric vehicles. J. Energy Storage 2023, 65, 107270. [Google Scholar] [CrossRef]

- Mutagekar, S.; Jhunjhunwala, A. Understanding the Li-ion battery pack degradation in the field using field-test and lab-test data. J. Energy Storage 2022, 53, 105216. [Google Scholar] [CrossRef]

- Naylor Marlow, M.; Chen, J.; Wu, B. Degradation in parallel-connected lithium-ion battery packs under thermal gradients. Commun. Eng. 2024, 3, 2. [Google Scholar] [CrossRef]

- Guida, M.; Postiglione, F.; Pulcini, G. A random-effects model for long-term degradation analysis of solid oxide fuel cells. Reliab. Eng. Syst. Saf. 2015, 140, 88–98. [Google Scholar] [CrossRef]

- Duan, B.; Zhang, Q.; Geng, F.; Zhang, C. Remaining useful life prediction of lithium-ion battery based on extended Kalman particle filter. Int. J. Energy Res. 2020, 44, 1724–1734. [Google Scholar] [CrossRef]

- Xu, D.; Wei, Q.; Chen, Y.; Kang, R. Reliability Prediction Using Physics–Statistics-Based Degradation Model. IEEE Trans. Compon. Packag. Manuf. Technol. 2015, 5, 1573–1581. [Google Scholar]

- Xue, Z.; Zhang, Y.; Cheng, C.; Ma, G. Remaining useful life prediction of lithium-ion batteries with adaptive unscented kalman filter and optimized support vector regression. Neurocomputing 2020, 376, 95–102. [Google Scholar] [CrossRef]

- Ye, L.H.; Chen, S.J.; Shi, Y.F.; Peng, D.H.; Shi, A.P. Remaining useful life prediction of lithium-ion battery based on chaotic particle swarm optimization and particle filter. Int. J. Electrochem. Sci. 2023, 18, 100122. [Google Scholar] [CrossRef]

- Duong, P.L.T.; Raghavan, N. Heuristic Kalman optimized particle filter for remaining useful life prediction of lithium-ion battery. Microelectron. Reliab. 2018, 81, 232–243. [Google Scholar] [CrossRef]

- Wu, Y.; Li, W.; Wang, Y.; Zhang, K. Remaining Useful Life Prediction of Lithium-Ion Batteries Using Neural Network and Bat-Based Particle Filter. IEEE Access 2019, 7, 54843–54854. [Google Scholar] [CrossRef]

- Ansari, S.; Ayob, A.; Hossain Lipu, M.; Hussain, A.; Saad, M.H.M. Particle swarm optimized data-driven model for remaining useful life prediction of lithium-ion batteries by systematic sampling. J. Energy Storage 2022, 56, 106050. [Google Scholar] [CrossRef]

- Xiong, R.; Zhang, Y.; Wang, J.; He, H.; Peng, S.; Pecht, M. Lithium-ion battery health prognosis based on a real battery management system used in electric vehicles. IEEE Trans. Veh. Technol. 2018, 68, 4110–4121. [Google Scholar] [CrossRef]

- Barcellona, S.; Piegari, L. Effect of current on cycle aging of lithium ion batteries. J. Energy Storage 2020, 29, 101310. [Google Scholar] [CrossRef]

- Barcellona, S.; Cristaldi, L.; Faifer, M.; Petkovski, E.; Piegari, L.; Toscani, S. State of health prediction of lithium-ion batteries. In Proceedings of the 2021 IEEE International Workshop on Metrology for Industry 4.0 & IoT (MetroInd4. 0&IoT), Rome, Italy, 7–9 June 2021; pp. 12–17. [Google Scholar]

- Kiefer, J. Optimum Experimental Designs. J. R. Stat. Soc. Ser. Methodol. 1959, 21, 272–319. [Google Scholar] [CrossRef]

- Kiefer, J.; Wolfowitz, J. The equivalence of two extremum problems. Can. J. Math. 1960, 12, 363–366. [Google Scholar] [CrossRef]

- Lim, H.; Yum, B.J. Optimal design of accelerated degradation tests based on Wiener process models. J. Appl. Stat. 2011, 38, 309–325. [Google Scholar] [CrossRef]

- Jiang, P.; Wang, B.X.; Wang, X.; Qin, S. Optimal plan for Wiener constant-stress accelerated degradation model. Appl. Math. Model. 2020, 84, 191–201. [Google Scholar] [CrossRef]

- Guan, Q.; Tang, Y. Optimal design of accelerated degradation test based on Gamma process models. Chin. J. Appl. Probab. Stat. 2013, 29, 213–224. [Google Scholar]

- Duan, F.; Wang, G. Planning of step-stress accelerated degradation test based on non-stationary gamma process with random effects. Comput. Ind. Eng. 2018, 125, 467–479. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, Y.; Ma, X.; Wang, H. Optimal design of constant-stress accelerated degradation tests using the M-optimality criterion. Reliab. Eng. Syst. Saf. 2017, 164, 45–54. [Google Scholar] [CrossRef]

- Wu, Y. An Optimal Design of Accelerated Degradation Tests Based on Degradation Performance. Open J. Stat. 2019, 9, 686. [Google Scholar] [CrossRef]

- Hu, C.H.; Lee, M.Y.; Tang, J. Optimum step-stress accelerated degradation test for Wiener degradation process under constraints. Eur. J. Oper. Res. 2015, 241, 412–421. [Google Scholar] [CrossRef]

- Weaver, B.P.; Meeker, W.Q.; Escobar, L.A.; Wendelberger, J. Methods for planning repeated measures degradation studies. Technometrics 2013, 55, 122–134. [Google Scholar] [CrossRef]

- Weaver, B.P.; Meeker, W.Q. Methods for planning Accelerated Repeated Measures Degradation Tests (with discussion). Appl. Stoch. Models Bus. Ind. 2014, 30, 658–671. [Google Scholar] [CrossRef]

- Fang, G.; Pan, R.; Stufken, J. Optimal setting of test conditions and allocation of test units for accelerated degradation tests with two stress variables. IEEE Trans. Reliab. 2020, 70, 1096–1111. [Google Scholar] [CrossRef]

- Chaloner, K.; Verdinelli, I. Bayesian experimental design: A review. Stat. Sci. 1995, 10, 273–304. [Google Scholar] [CrossRef]

- Ryan, E.G.; Drovandi, C.C.; McGree, J.M.; Pettitt, A.N. A review of modern computational algorithms for Bayesian optimal design. Int. Stat. Rev. 2016, 84, 128–154. [Google Scholar] [CrossRef]

- Kullback, S.; Leibler, R.A. On information and sufficiency. Ann. Math. Stat. 1951, 22, 79–86. [Google Scholar] [CrossRef]

- López-Fidalgo, J.; Tommasi, C.; Trandafir, P. An optimal experimental design criterion for discriminating between non-normal models. J. R. Stat. Soc. Ser. Stat. Methodol. 2007, 69, 231–242. [Google Scholar] [CrossRef]

- Tommasi, C.; López-Fidalgo, J. Bayesian optimum designs for discriminating between models with any distribution. Comput. Stat. Data Anal. 2010, 54, 143–150. [Google Scholar] [CrossRef]

- Shi, Y.; Meeker, W.Q. Bayesian methods for accelerated destructive degradation test planning. IEEE Trans. Reliab. 2011, 61, 245–253. [Google Scholar] [CrossRef]

- Li, X.; Rezvanizaniani, M.; Ge, Z.; Abuali, M.; Lee, J. Bayesian optimal design of step stress accelerated degradation testing. J. Syst. Eng. Electron. 2015, 26, 502–513. [Google Scholar] [CrossRef]

- Li, X.; Hu, Y.; Zio, E.; Kang, R. A Bayesian optimal design for accelerated degradation testing based on the inverse Gaussian process. IEEE Access 2017, 5, 5690–5701. [Google Scholar] [CrossRef]

- Weaver, B.P.; Meeker, W.Q. Bayesian methods for planning accelerated repeated measures degradation tests. Technometrics 2021, 63, 90–99. [Google Scholar] [CrossRef]

- Agrell, C.; Dahl, K.R. Sequential Bayesian optimal experimental design for structural reliability analysis. Stat. Comput. 2021, 31, 27. [Google Scholar] [CrossRef]

- Zhang, P.; Zhu, X.; Xie, M. A model-based reinforcement learning approach for maintenance optimization of degrading systems in a large state space. Comput. Ind. Eng. 2021, 161, 107622. [Google Scholar] [CrossRef]

- Omshi, E.M.; Grall, A.; Shemehsavar, S. A dynamic auto-adaptive predictive maintenance policy for degradation with unknown parameters. Eur. J. Oper. Res. 2020, 282, 81–92. [Google Scholar] [CrossRef]

- Shahraki, A.F.; Yadav, O.P.; Liao, H. A review on degradation modelling and its engineering applications. Int. J. Perform. Eng. 2017, 13, 299. [Google Scholar] [CrossRef]

- Sutton, R.S.; Barto, A.G. Reinforcement Learning: An Introduction; MIT Press: Cambridge, MA, USA, 2018. [Google Scholar]

- Kurniawati, H. Partially observable markov decision processes and robotics. Annu. Rev. Control. Robot. Auton. Syst. 2022, 5, 253–277. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patrizi, G.; Martiri, L.; Pievatolo, A.; Magrini, A.; Meccariello, G.; Cristaldi, L.; Nikiforova, N.D. A Review of Degradation Models and Remaining Useful Life Prediction for Testing Design and Predictive Maintenance of Lithium-Ion Batteries. Sensors 2024, 24, 3382. https://doi.org/10.3390/s24113382

Patrizi G, Martiri L, Pievatolo A, Magrini A, Meccariello G, Cristaldi L, Nikiforova ND. A Review of Degradation Models and Remaining Useful Life Prediction for Testing Design and Predictive Maintenance of Lithium-Ion Batteries. Sensors. 2024; 24(11):3382. https://doi.org/10.3390/s24113382

Chicago/Turabian StylePatrizi, Gabriele, Luca Martiri, Antonio Pievatolo, Alessandro Magrini, Giovanni Meccariello, Loredana Cristaldi, and Nedka Dechkova Nikiforova. 2024. "A Review of Degradation Models and Remaining Useful Life Prediction for Testing Design and Predictive Maintenance of Lithium-Ion Batteries" Sensors 24, no. 11: 3382. https://doi.org/10.3390/s24113382

APA StylePatrizi, G., Martiri, L., Pievatolo, A., Magrini, A., Meccariello, G., Cristaldi, L., & Nikiforova, N. D. (2024). A Review of Degradation Models and Remaining Useful Life Prediction for Testing Design and Predictive Maintenance of Lithium-Ion Batteries. Sensors, 24(11), 3382. https://doi.org/10.3390/s24113382