MCML-BF: A Metal-Column Embedded Microstrip Line Transmission Structure with Bias Feeders for Beam-Scanning Leakage Antenna Design

Abstract

1. Introduction

2. Liquid Crystal and Holographic Antenna Principle

2.1. Liquid Crystal

2.2. Holographic Antenna Principle

3. Design and Simulation Results

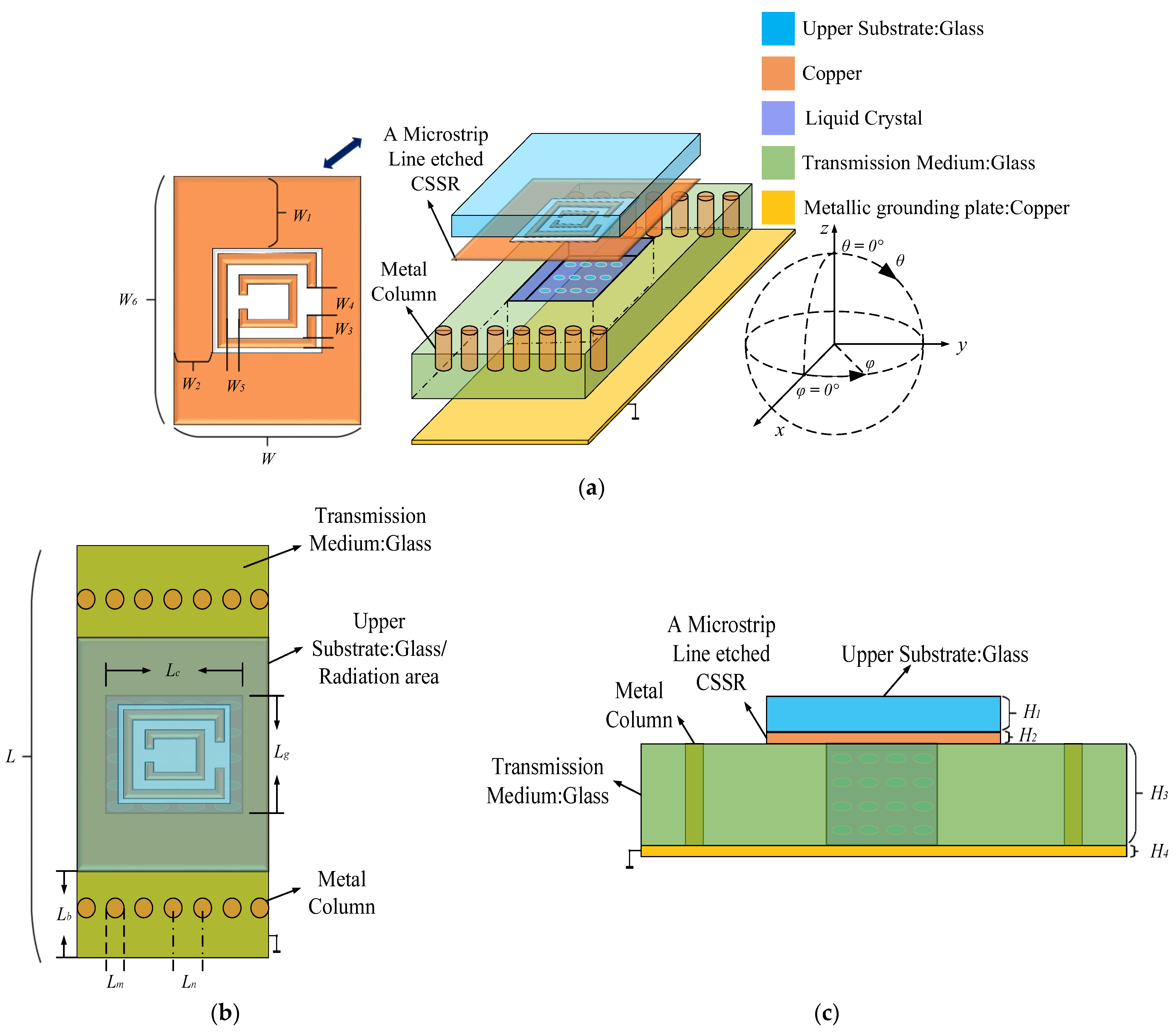

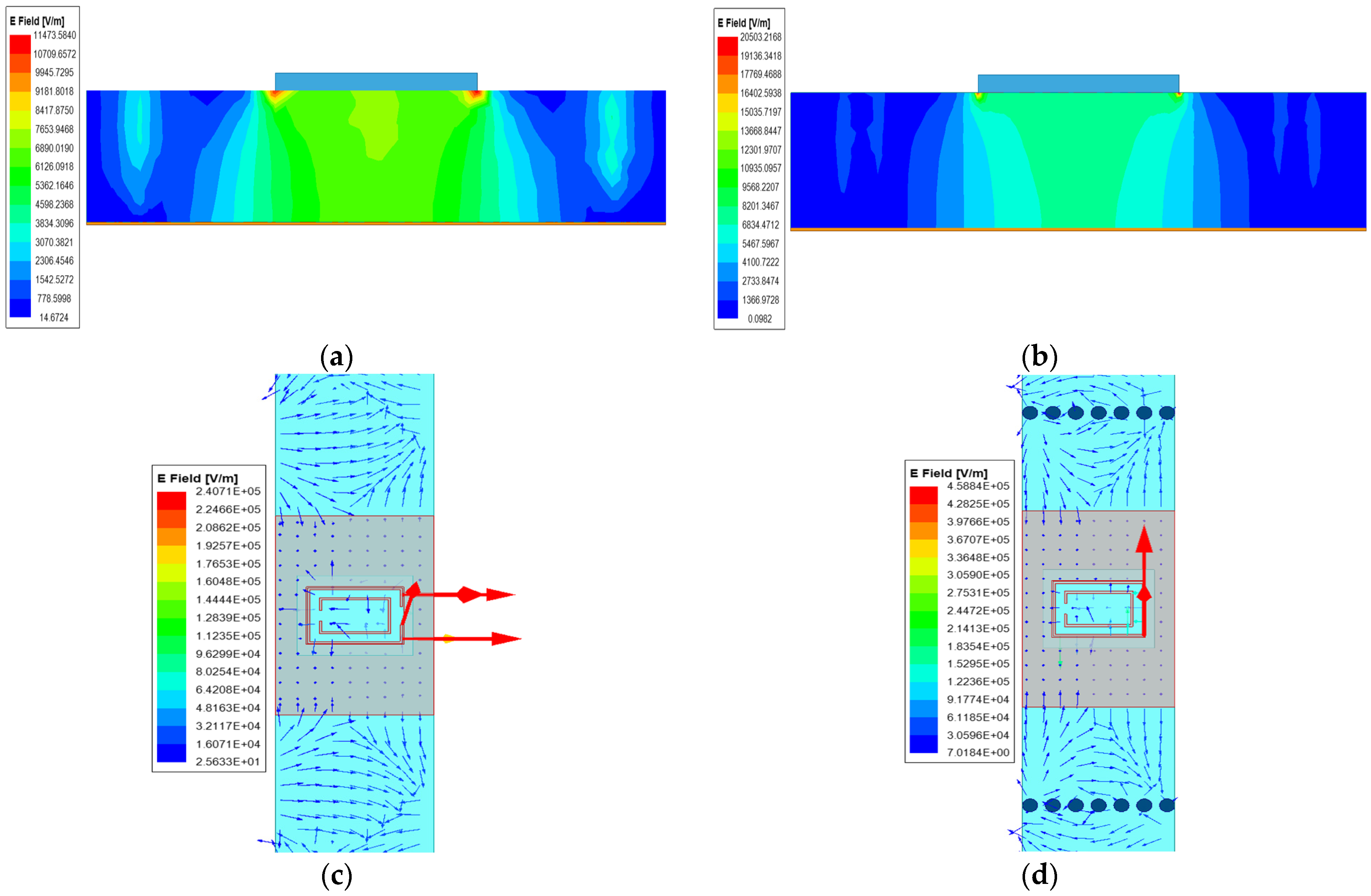

3.1. Antenna Unit Cell

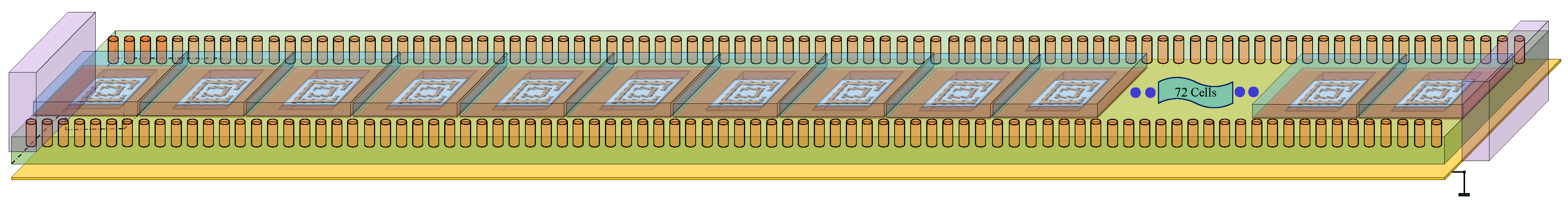

3.2. Antenna Array

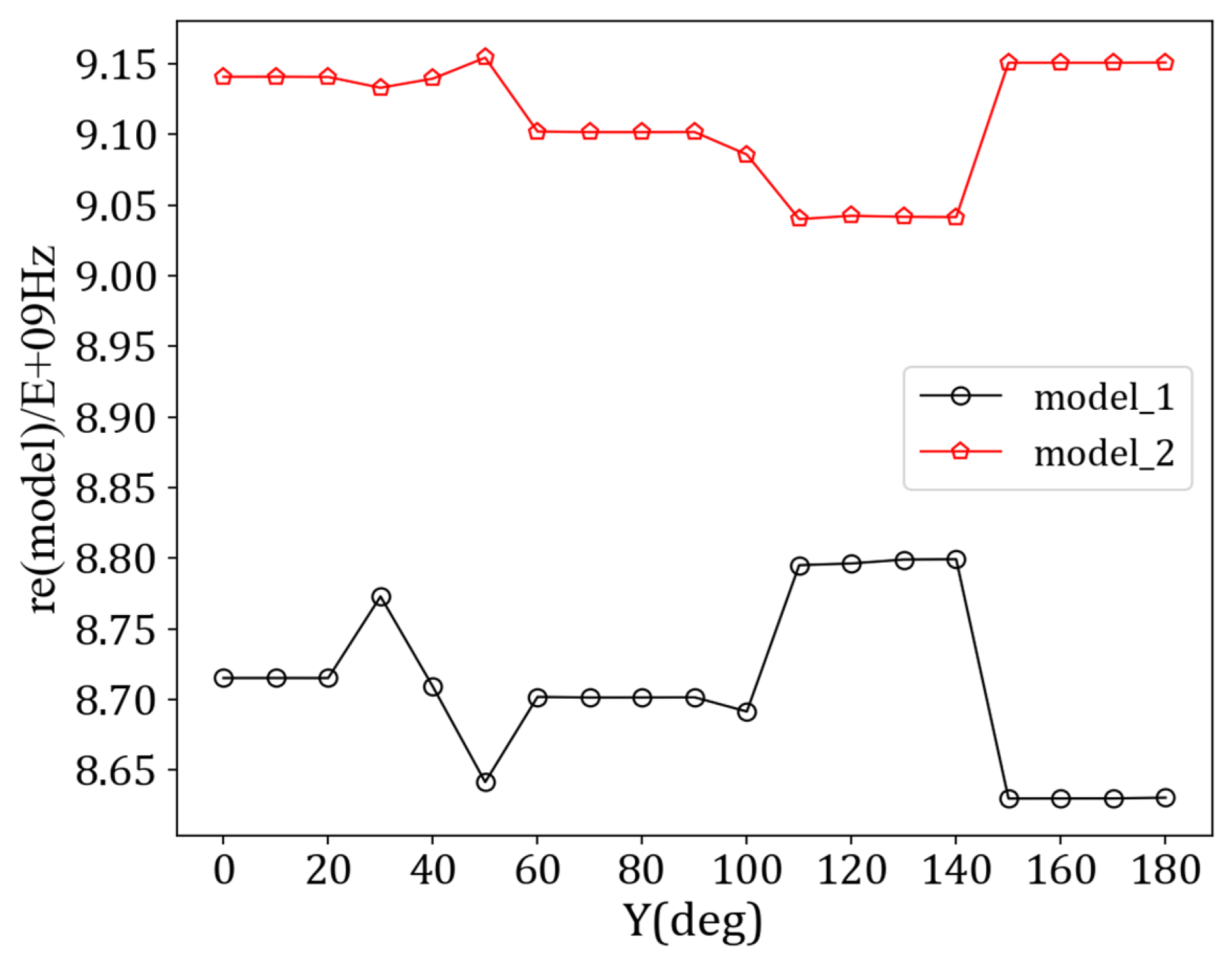

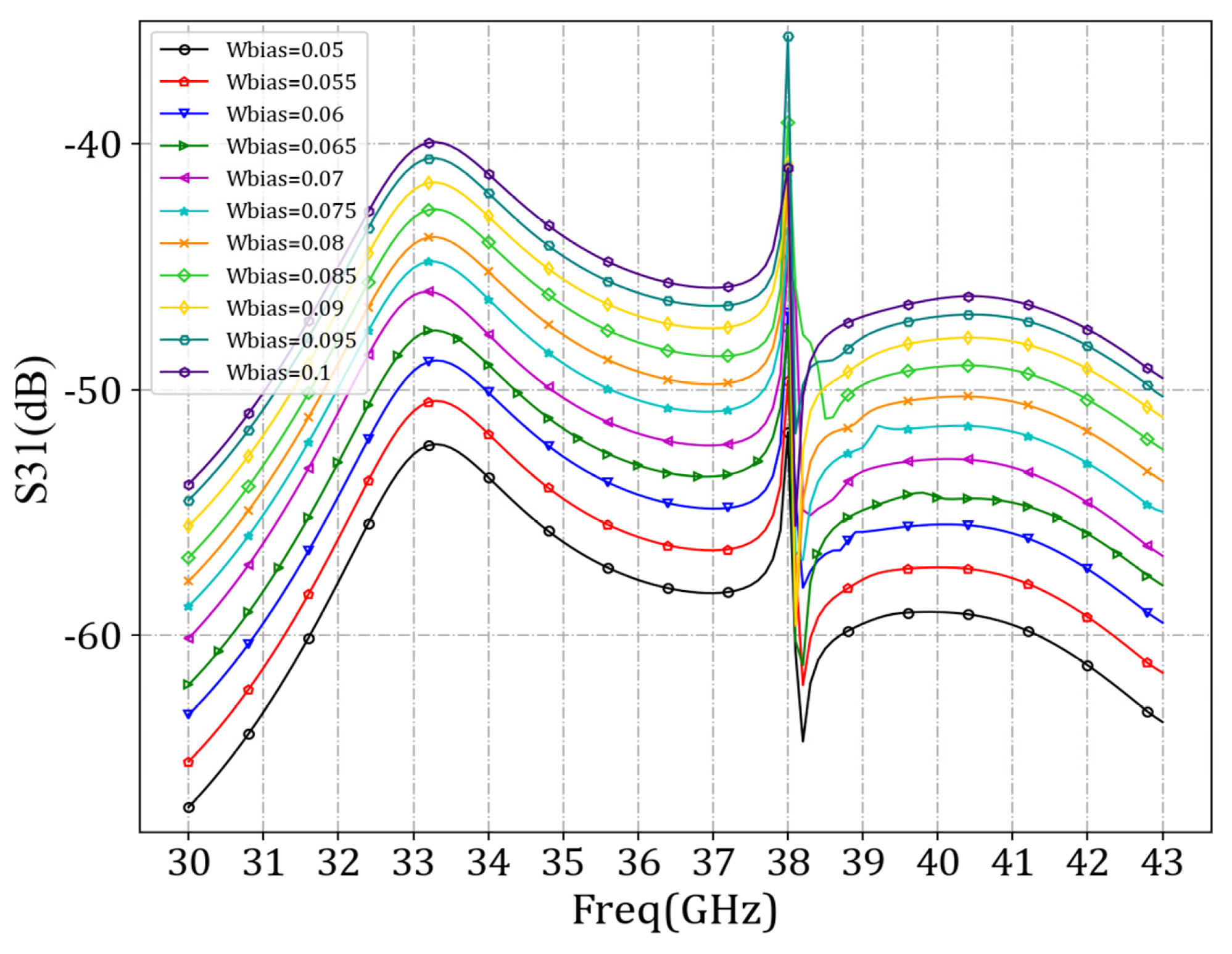

3.3. Bias Feeder Design and Comparative Experiments

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shen, F.; Hu, Q.; Gong, C. Determining the Antenna Phase Center for the High-Precision Positioning of Smartphones. Sensors 2024, 24, 2243. [Google Scholar] [CrossRef] [PubMed]

- Wei, D.; Zhang, P. A Linearly and Circularly Polarization-Reconfigurable Leaky Wave Antenna Based on SSPPs-HSIW. Electronics 2023, 12, 2602. [Google Scholar] [CrossRef]

- Menzione, F.; Paonni, M. 3D Galileo Reference Antenna Pattern for Space Service Volume Applications. Sensors 2024, 24, 2220. [Google Scholar] [CrossRef] [PubMed]

- Al-Gburi, A.J.A.; Zakaria, Z.; Alsariera, H.; Akbar, M.F.; Ibrahim, I.M.; Ahmad, K.S.; Al-Bawri, S.S. Broadband circular polarised printed antennas for indoor wireless communication systems: A comprehensive review. Micromachines 2022, 13, 1048. [Google Scholar] [CrossRef] [PubMed]

- Ushikoshi, D.; Higashiura, R.; Tachi, K.; Fathnan, A.A.; Mahmood, S.; Takeshita, H.; Wakatsuchi, H. Pulse-driven self-reconfigurable meta-antennas. Nat. Commun. 2023, 14, 633. [Google Scholar] [CrossRef] [PubMed]

- Munoz-Martin, J.F.; Onrubia, R.; Pascual, D.; Park, H.; Camps, A.; Rüdiger, C.; Monerris, A. Untangling the incoherent and coherent scattering components in GNSS-R and novel applications. Remote Sens. 2020, 12, 1208. [Google Scholar] [CrossRef]

- Xu, F.; Wu, K.; Zhang, X. Periodic leaky-wave antenna for millimeter wave applications based on substrate integrated waveguide. IEEE Trans. Antennas Propag. 2009, 58, 340–347. [Google Scholar]

- Liu, J.; Jackson, D.R.; Long, Y. Substrate integrated waveguide (SIW) leaky-wave antenna with transverse slots. IEEE Trans. Antennas Propag. 2011, 60, 20–29. [Google Scholar] [CrossRef]

- Morshed, K.M.; Karmokar, D.K.; Esselle, K.P.; Matekovits, L. Beam-Switching Antennas for 5G Millimeter-Wave Wireless Terminals. Sensors 2023, 23, 6285. [Google Scholar] [CrossRef]

- Hu, C.C.; Jou, C.F.; Wang, C.J.; Lee, S.H.; Wu, J.J. Coplanar waveguide to coplanar strips-fed active leaky-wave antenna. Microw. Opt. Technol. Lett. 1998, 19, 335–338. [Google Scholar] [CrossRef]

- Xiao, S.; Wang, B.Z.; Yang, X.S.; Wang, G. A novel reconfiguration CPW leaky-wave antenna for millimeter-wave application. Int. J. Infrared Millim. Waves 2002, 23, 1637–1648. [Google Scholar] [CrossRef]

- Ali, M.Z.; Khan, Q.U. High gain backward scanning substrate integrated waveguide leaky wave antenna. IEEE Trans. Antennas Propag. 2020, 69, 562–565. [Google Scholar] [CrossRef]

- Fu, Z.; Jiang, D.; Zhang, T.; Li, X. Ku-band liquid-crystal-based frequency reconfigurable comb siw slot leaky-wave antenna. In Proceedings of the 2018 International Conference on Microwave and Millimeter Wave Technology (ICMMT), Chengdu, China, 7–11 May 2018; pp. 1–3. [Google Scholar]

- Geng, Y.; Wang, J.; Li, Z.; Li, Y.; Chen, M.; Zhang, Z. Dual-beam and tri-band SIW leaky-wave antenna with wide beam scanning range including broadside direction. IEEE Access 2019, 7, 176361–176368. [Google Scholar] [CrossRef]

- Ranjan, R.; Ghosh, J. SIW-based leaky-wave antenna supporting wide range of beam scanning through broadside. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 606–610. [Google Scholar] [CrossRef]

- Xu, J.; Hong, W.; Tang, H.; Kuai, Z.; Wu, K. Half-mode substrate integrated waveguide (HMSIW) leaky-wave antenna for millimeter-wave applications. IEEE Antennas Wirel. Propag. Lett. 2008, 7, 85–88. [Google Scholar]

- Cheng, Y.J.; Hong, W.; Wu, K.; Fan, Y. Millimeter-wave substrate integrated waveguide long slot leaky-wave antennas and two-dimensional multibeam applications. IEEE Trans. Antennas Propag. 2010, 59, 40–47. [Google Scholar] [CrossRef]

- Saghati, A.P.; Mirsalehi, M.M.; Neshati, M.H. A HMSIW circularly polarized leaky-wave antenna with backward, broadside, and forward radiation. IEEE Antennas Wirel. Propag. Lett. 2014, 13, 451–454. [Google Scholar] [CrossRef]

- Liu, C.Y.; Chu, Q.X.; Huang, J.Q. Double-side radiating leaky-wave antenna based on composite right/left-handed coplanar-waveguide. Prog. Electromagn. Res. Lett. 2010, 14, 11–19. [Google Scholar] [CrossRef]

- Cheng, Y.J.; Guo, Y.X.; Bao, X.Y.; Ng, K.B. Millimeter-wave low temperature co-fired ceramic leaky-wave antenna and array based on the substrate integrated image guide technology. IEEE Trans. Antennas Propag. 2013, 62, 669–676. [Google Scholar] [CrossRef]

- Malhat, H.A.; Elhenawy, A.S.; Zainud-Deen, S.H.; Al-Shalaby, N.A. Planar reconfigurable plasma leaky-wave antenna with electronic beam-scanning for MIMO applications. Wirel. Pers. Commun. 2023, 128, 1–18. [Google Scholar] [CrossRef]

- Cao, X.W.; Deng, C.J.; Kamal, S. Fixed-frequency beam steering leaky-wave antenna with integrated 2-bit phase shifters. IEEE Trans. Antennas Propag. 2022, 70, 11246–11251. [Google Scholar] [CrossRef]

- Du, H.; Wang, J.; Li, Z.; Zheng, W.; Zhang, L. A Broadband Fixed-Beam Leaky-Wave Antenna with Switchable Beam Direction. IEEE Antennas Wirel. Propag. Lett. 2023, 23, 169–173. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, J.H.; Zhao, H.Y.; Zheng, L.; Geng, Y.J.; Li, Y.J.; Chen, M.; Zhan, Z. A leaky-wave antenna with capability of fixed frequency beamforming scanning. IEEE Trans. Antennas Propag. 2023, 71, 7585–7590. [Google Scholar] [CrossRef]

- Apaydin, N.; Sertel, K.; Volakis, J.L. Nonreciprocal and magnetically scanned leaky-wave antenna using coupled CRLH lines. IEEE Trans. Antennas Propag. 2014, 62, 2954–2961. [Google Scholar] [CrossRef]

- Esquius-Morote, M.; Gómez-Dı, J.S.; Perruisseau-Carrier, J. Sinusoidally modulated graphene leaky-wave antenna for electronic beamscanning at THz. IEEE Trans. Terahertz Sci. Technol. 2014, 4, 116–122. [Google Scholar] [CrossRef]

- Cheng, Y.; Wu, L.S.; Tang, M.; Zhang, Y.P.; Mao, J.F. A sinusoidally-modulated leaky-wave antenna with gapped graphene ribbons. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 3000–3004. [Google Scholar] [CrossRef]

- Soleimani, H.; Homayoon, O. A novel 2D leaky wave antenna based on complementary graphene patch cell. J. Phys. D Appl. Phys. 2020, 53, 255301. [Google Scholar] [CrossRef]

- Al-Shalaby, N.A.; Elhenawy, A.S.; Zainud-Deen, S.H.; Malhat, H.A. Electronic beam-scanning strip-coded graphene leaky-wave antenna using single structure. Plasmonics 2021, 16, 1427–1438. [Google Scholar] [CrossRef]

- Fuscaldo, W.; Tofani, S.; Zografopoulos, D.C.; Baccarelli, P.; Burghignoli, P.; Beccherelli, R.; Galli, A. Tunable Fabry–Perot cavity THz antenna based on leaky-wave propagation in nematic liquid crystals. Antennas Wirel. Propag. Lett. 2017, 16, 2046–2049. [Google Scholar] [CrossRef]

- Martini, E.; Pavone, S.; Albani, M.; Maci, S.; Martorelli, V.; Giodanengo, G.; Ferraro, A.; Beccherelli, R.; Toso, G.; Vecchi, G. Reconfigurable antenna based on liquid crystals for continuous beam scanning with a single control. In Proceedings of the 2019 IEEE International Symposium on Antennas and Propagation and USNC-URSI Radio Science Meeting, Atlanta, GA, USA, 7–12 July 2019; pp. 449–450. [Google Scholar]

- Torabi, E.; Rozhkova, A.; Chen, P.-Y.; Erricolo, D. Compact and reconfigurable leaky wave antenna based on a tunable substrate integrated embedded metasurface. In Proceedings of the 2020 IEEE International Symposium on Antennas and Propagation and North American Radio Science Meeting, Toronto, ON, Canada, 5–10 July 2020; pp. 163–164. [Google Scholar]

- Fu, J.H.; Li, A.; Chen, W.; Lv, B.; Wang, Z.; Li, P.; Wu, Q. An electrically controlled CRLH-inspired circularly polarized leaky-wave antenna. IEEE Antennas Wirel. Propag. Lett. 2016, 16, 760–763. [Google Scholar] [CrossRef]

- Zvolensky, T.; Chicherin, D.; Räisänen, A.V.; Simovski, C. Leaky-wave antenna based on micro-electromechanical systems-loaded microstrip line. IET Microw. Antennas Propag. 2011, 5, 357–363. [Google Scholar] [CrossRef]

- Li, J.; He, M.; Wu, C.; Zhang, C. Radiation-pattern-reconfigurable graphene leaky-wave antenna at terahertz band based on dielectric grating structure. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 1771–1775. [Google Scholar] [CrossRef]

- Damm, C.; Maasch, M.; Gonzalo, R.; Jakoby, R. Tunable composite right/left-handed leaky wave antenna based on a rectangular waveguide using liquid crystals. In Proceedings of the 2010 IEEE MTT-S International Microwave Symposium, Anaheim, CA, USA, 23–28 May 2010; pp. 13–16. [Google Scholar]

- Roig, M.; Maasch, M.; Damm, C.; Jakoby, R. Steerable Ka-Band leaky wave antenna based on liquid crystal material. In Proceedings of the 2013 7th International Congress on Advanced Electromagnetic Materials in Microwaves and Optics, Piscataway, NJ, USA, 16–21 September 2013; pp. 540–545. [Google Scholar]

- Liu, X.X. Study of Liquid Crystal Electronically Controlled Scanning Leaky-Wave Antennas. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2015; pp. 22–49. [Google Scholar]

- Gao, Y.; Lyu, Y.L.; Meng, F.Y.; Wu, Q. Electrically steerable leaky-wave antenna capable of both forward and backward radiation based on liquid crystal. Asia-Pac. Microw. Conf. (APMC) 2015, 2, 1–3. [Google Scholar]

- Liu, Y.L.; He, Z.Y.; Feng, W.; Li, K.; WANG, D.C. Design of Microstrip Leaky Wave Antenna Based on Liquid Crystal Material. Proc. Natl. Microw. Millim. Wave Conf. 2017, 2, 49–52. [Google Scholar]

- Gao, F. Reconfigurable Holographic Metamaterial Antenna Research. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2018. [Google Scholar]

- Wang, Z.; Fu, Z.H.; Wu, T.H.; Jiang, D. Beam-scanning leaky-wave antennas based on liquid crystal materials. In Proceedings of the 2019 Annual National Conference on Antennas, Atlanta, GA, USA, 16–18 October 2019; pp. 292–294. [Google Scholar]

- Liu, Q. Study of Liquid Crystal-Based Beam-Scanning Holographic Hypersurface Leaky-Wave Antennas. Master’s Thesis, University of Electronic Science and Technology of China, Chengdu, China, 2020. [Google Scholar]

- Zhang, W.; Yang, W.; Jiang, D.; Hu, W.; Pan, P. Design of mm-wave Reconfigurable holographic antenna based on liquid crystal material. In Proceedings of the 2022 IEEE Conference on Antenna Measurements and Applications (CAMA), Guangzhou, China, 14–17 November 2022; pp. 1–5. [Google Scholar]

- Hou, S.; Fang, S.; Wang, Y.; Wang, M.; Wang, Y.; Tian, J.; Feng, J. A Ka-band one-dimensional beam scanning leaky-wave antenna based on liquid crystal. Sci. Rep. 2024, 14, 3937. [Google Scholar] [CrossRef] [PubMed]

- Deo, P.; Mirshekar-Syahkal, D. 60 GHz beam-steering slotted patch antenna array using liquid crystal phaseshifters. In Proceedings of the 2012 IEEE International Symposium on Antennas and Propagation, Chicago, IL, USA, 8–14 July 2012; pp. 1–2. [Google Scholar]

- Ma, S.; Zhang, S.-Q.; Ma, L.-Q.; Meng, F.-Y.; Erni, D.; Zhu, L.; Fu, J.-H.; Wu, Q. Compact planar array antenna with electrically beam steering from backfire to endfire based on liquid crystal. IET Microw, Antennas Propag 2018, 12, 1140–1146. [Google Scholar] [CrossRef]

- Sleasman, T.; Imani, M.F.; Xu, W.; Hunt, J.; Driscoll, T.; Reynolds, M.S.; Smith, D.R. Waveguide-fed tunable metamaterial element for dynamic apertures. Antennas Wirel. Propag. Lett 2015, 15, 606–609. [Google Scholar] [CrossRef]

- Manoochehri, O.; Farzami, F.; Erricolo, D.; Salari, M.A. A substrate integrated waveguide slot array with voltage-controlled liquid crystal phase shifter. In Proceedings of the 2018 IEEE International Symposium on Antennas and Propagation & USNC/URSI National Radio Science Meeting, Boston, MA, USA, 8–13 July 2018; pp. 2123–2124. [Google Scholar]

- Zografopoulos, D.C.; Ferraro, A.; Beccherelli, R. Liquid-crystal high-frequency microwave technology: Materials and characterization. Adv. Mat. Technol 2019, 4, 1800447. [Google Scholar] [CrossRef]

- Moessinger, A.; Marin, R.; Freese, J.; Mueller, S.; Manabe, A.; Jakoby, R. Investigations on 77 GHz tunable reflectarray unit cells with liquid crystal. In Proceedings of the 2006 First European Conference on Antennas and Propagation, Nice, France, 6–10 November 2006; pp. 1–4. [Google Scholar]

- Pavone, S.C.; Martini, E.; Caminita, F.; Albani, M.; Maci, S. Surface wave dispersion for a tunable grounded liquid crystal substrate without and with metasurface on top. IEEE Trans. Antennas Propag 2017, 65, 3540–3548. [Google Scholar] [CrossRef]

- Bellini, B.; Beccherelli, R. Modelling, design and analysis of liquid crystal waveguides in preferentially etched silicon grooves. J. Phys. D Appl. Phys. 2009, 42, 045111. [Google Scholar] [CrossRef]

- Torabi, E.; Erricolo, D.; Chen, P.Y. Reconfigurable beam-steerable leaky-wave antenna loaded with metamaterial apertures using liquid crystal-based delay lines. Opt. Express 2022, 30, 28966–28983. [Google Scholar] [CrossRef] [PubMed]

- Kamalzadeh, S.; Soleimani, M. A Novel SIW Leaky-Wave Antenna for Continuous Beam Scanning from Backward to Forward. Electronics 2022, 11, 1804. [Google Scholar] [CrossRef]

- Cheng, W.; Ni, J.; Song, C.; Ahsan, M.M.; Chen, X.; Nie, Z.; Liu, Y. Conical Statistical Optimal Near-Field Acoustic Holography with Combined Regularization. Sensors 2021, 21, 7150. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, Z.; McEvoy, P.; Ammann, M.J. A Wide Frequency Scanning Printed Bruce Array Antenna with Bowtie and Semi-Circular Elements. Sensors 2020, 20, 6796. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Fang, D.G.; Zhang, B. Dielectric loaded substrate integrated waveguide (SIW) H-plane horn antennas. IEEE Trans. Antennas Propag. 2009, 58, 640–647. [Google Scholar] [CrossRef]

- Heidari, H.R.; Rezaei, P.; Kiani, S. A monopulse array antenna based on SIW with circular polarization for using in tracking systems. AEU-Int. J. Electron. Commun. 2023, 162, 154563. [Google Scholar] [CrossRef]

- Bahrami, H.; Hakkak, M.; Pirhadi, A. Analysis and design of highly compact bandpass waveguide filter using complementary split ring resonators (CSRR). Prog. Electromagn. Res. 2008, 80, 107–122. [Google Scholar] [CrossRef]

- Han, X.; Liu, K.; Zhang, S. CSRR Metamaterial Microwave Sensor for Measuring Dielectric Constants of Solids and Liquids. IEEE Sens. J. 2024, 24, 14167–14176. [Google Scholar] [CrossRef]

| LC Model | |||||

|---|---|---|---|---|---|

| K15 | 2.57 | 2.3 | 10.5% | 0.0048 | 0.02 |

| E7 | 3.35 | 2.72 | 18.8% | 0.001 | 0.006 |

| TUD-566 | 3.16 | 2.4 | 24.1% | 0.002 | 0.006 |

| BL006 | 3.03 | 2.62 | 13.53% | 0.01 | 0.025 |

| MDA-05-893 | 2.65 | 2.24 | 15.47% | 0.01 | 0.025 |

| GT3-23001 | 3.3 | 2.5 | 24.2% | 0.0038 | 0.0143 |

| Parameters | W | W1 | W2 | W3 | W4 | W5 |

| Size/mm | 2 | 1.065 | 0.385 | 0.03 | 0.28 | 0.12 |

| Parameters | W6 | L | Lb | Lc | Lm | Ln |

| Size/mm | 3 | 8.6 | 2.8 | 1.45 | 0.2 | 0.3 |

| Parameters | Lg | H1 | H2 | H3 | H4 | - |

| Size/mm | 1.12 | 0.2 | 0.002 | 1.5 | 0.035 | - |

| Direction | Binary Discrete Amplitude-Weighted Sequences |

|---|---|

| 0° | 0, 1, 0, 1, 0, 1, 0, 1, 0, 0, 1, 0, 1, 0, 1, 0, 1, 0, 0, 1, 0, 1, 0, 1, 0, 1, 0, 0, 1, 0, 1, 0, 1, 0, 1, 0, 0, 1, 0, 1, 0, 1, 0, 1, 0, 0, 1, 0, 1, 0, 1, 0, 1, 0, 0, 1, 0, 1, 0, 1, 0, 1, 0, 0, 1, 0, 1, 0, 1, 0, 1, 0 |

| −20° | 0, 1, 0, 1, 1, 0, 1, 1, 0, 1, 0, 0, 1, 0, 0, 1, 0, 1, 1, 0, 1, 1, 0, 1, 0, 0, 1, 0, 0, 1, 0, 1, 1, 0, 1, 1, 0, 1, 0, 0, 1, 0, 0, 1, 0, 1, 1, 0, 1, 1, 0, 1, 0, 0, 1, 0, 0, 1, 0, 1, 1, 0, 1, 1, 0, 1, 0, 0, 1, 0, 0, 1 |

| 20° | 1, 0, 1, 0, 1, 0, 1, 0, 1, 0, 1, 0, 1, 0, 1, 0, 0, 1, 0, 1, 0, 1, 0, 1, 0, 1, 0, 1, 0, 1, 0, 1, 1, 0, 1, 0, 1, 0, 1, 0, 1, 0, 1, 0, 1, 0, 1, 0, 0, 1, 0, 1, 0, 1, 0, 1, 0, 1, 0, 1, 0, 1, 0, 1, 1, 0, 1, 0, 1, 0, 1, 0 |

| −30° | 0, 1, 0, 0, 1, 1, 0, 1, 1, 0, 1, 1, 0, 1, 1, 0, 0, 1, 0, 0, 1, 0, 0, 1, 0, 0, 1, 1, 0, 1, 1, 0, 1, 1, 0, 1, 1, 0, 0, 1, 0, 0, 1, 0, 0, 1, 0, 0, 1, 1, 0, 1, 1, 0, 1, 1, 0, 1, 1, 0, 0, 1, 0, 0, 1, 0, 0, 1, 0, 0, 1, 1 |

| 30° | 1, 0, 1, 0, 1, 0, 1, 1, 0, 1, 0, 1, 0, 1, 1, 0, 1, 0, 1, 0, 1, 1, 0, 1, 0, 1, 0, 1, 1, 0, 1, 0, 1, 0, 1, 1, 0, 1, 0, 1, 0, 1, 1, 0, 1, 0, 1, 0, 1, 1, 0, 1, 0, 1, 0, 1, 1, 0, 1, 0, 1, 0, 1, 1, 0, 1, 0, 1, 0, 1, 1, 0 |

| −52° | 0, 1, 1, 0, 0, 1, 1, 0, 0, 1, 1, 1, 0, 0, 1, 1, 0, 0, 1, 1, 0, 0, 1, 1, 0, 0, 1, 1, 0, 0, 0, 1, 1, 0, 0, 1, 1, 0, 0, 1, 1, 0, 0, 1, 1, 0, 0, 1, 1, 1, 0, 0, 1, 1, 0, 0, 1, 1, 0, 0, 1, 1, 0, 0, 1, 1, 0, 0, 0, 1, 1, 0 |

| −54° | 1, 0, 1, 1, 0, 1, 1, 0, 1, 1, 0, 1, 1, 0, 1, 1, 0, 1, 1, 0, 1, 1, 0, 1, 1, 0, 1, 1, 0, 1, 0, 0, 1, 0, 0, 1, 0, 0, 1, 0, 0, 1, 0, 0, 1, 0, 0, 1, 0, 0, 1, 0, 0, 1, 0, 0, 1, 0, 0, 1, 0, 0, 1, 0, 0, 1, 0, 0, 1, 0, 0, 1 |

| Preset Angle | −55° | −30° | −20° | 0° | 20° | 30° | 60° |

| Actual Angle | −52° | −29.2° | −19.5° | 0.3° | 21.5° | 29.6° | 54° |

| Angle Deviation | 3° | 0.8° | 0.5° | 0.3° | 1.5° | 0.4° | 6° |

| Gain (dB) | 9.16 dB | 10.09 dB | 10.67 dB | 10.55 dB | 9.47 dB | 11.65 dB | 8.52 dB |

| Preset Angle | −55° | −30° | −20° | 0° | 20° | 30° | 60° |

| Actual Angle | −51.7° | −29° | −19.4° | 0.1° | 21.1° | 30.7° | 53.8° |

| Angle Deviation | 3.3° | 1° | 0.6° | 0.1° | 1.1° | 0.7° | 6.2° |

| Gain (dB) | 8.719 dB | 9.502 dB | 9.931 dB | 10.304 dB | 9.386 dB | 10.892 dB | 8.216 dB |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, S.; Fang, S.; Fan, Y.; Li, Y.; Ma, Z.; Li, J. MCML-BF: A Metal-Column Embedded Microstrip Line Transmission Structure with Bias Feeders for Beam-Scanning Leakage Antenna Design. Sensors 2024, 24, 3467. https://doi.org/10.3390/s24113467

Hou S, Fang S, Fan Y, Li Y, Ma Z, Li J. MCML-BF: A Metal-Column Embedded Microstrip Line Transmission Structure with Bias Feeders for Beam-Scanning Leakage Antenna Design. Sensors. 2024; 24(11):3467. https://doi.org/10.3390/s24113467

Chicago/Turabian StyleHou, Shunhu, Shengliang Fang, Youchen Fan, Yuhai Li, Zhao Ma, and Jinming Li. 2024. "MCML-BF: A Metal-Column Embedded Microstrip Line Transmission Structure with Bias Feeders for Beam-Scanning Leakage Antenna Design" Sensors 24, no. 11: 3467. https://doi.org/10.3390/s24113467

APA StyleHou, S., Fang, S., Fan, Y., Li, Y., Ma, Z., & Li, J. (2024). MCML-BF: A Metal-Column Embedded Microstrip Line Transmission Structure with Bias Feeders for Beam-Scanning Leakage Antenna Design. Sensors, 24(11), 3467. https://doi.org/10.3390/s24113467