Thickness Measurements with EMAT Based on Fuzzy Logic

Abstract

:1. Introduction

2. Theory

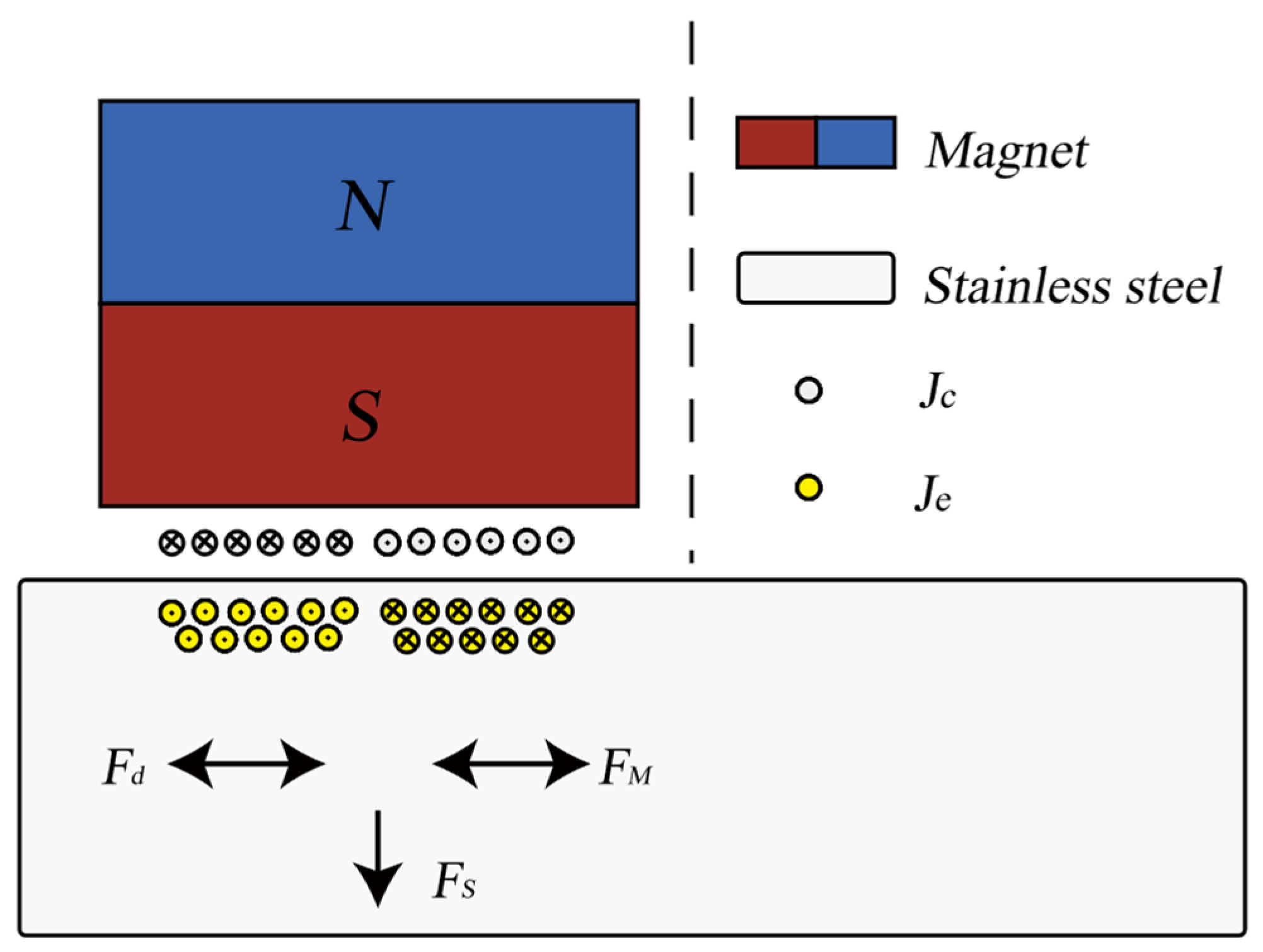

2.1. Transduction Mechanism

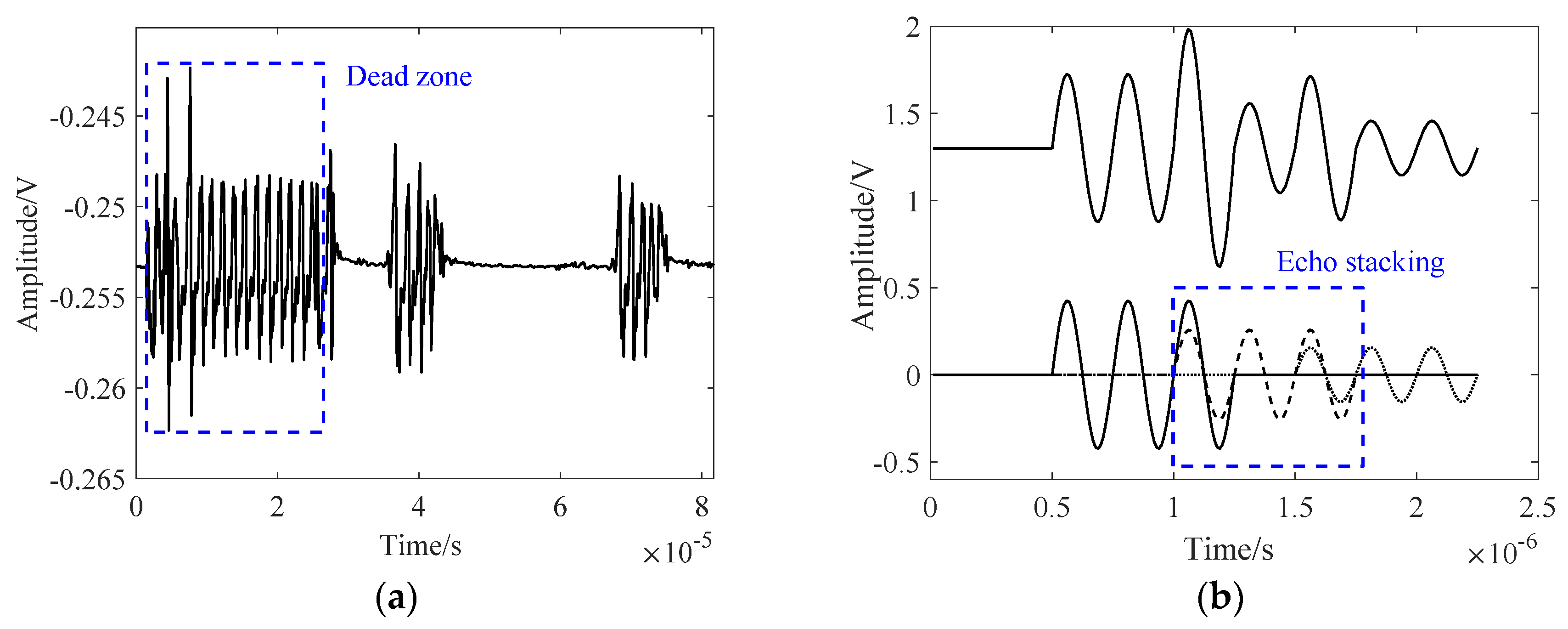

2.2. TOF Measurement

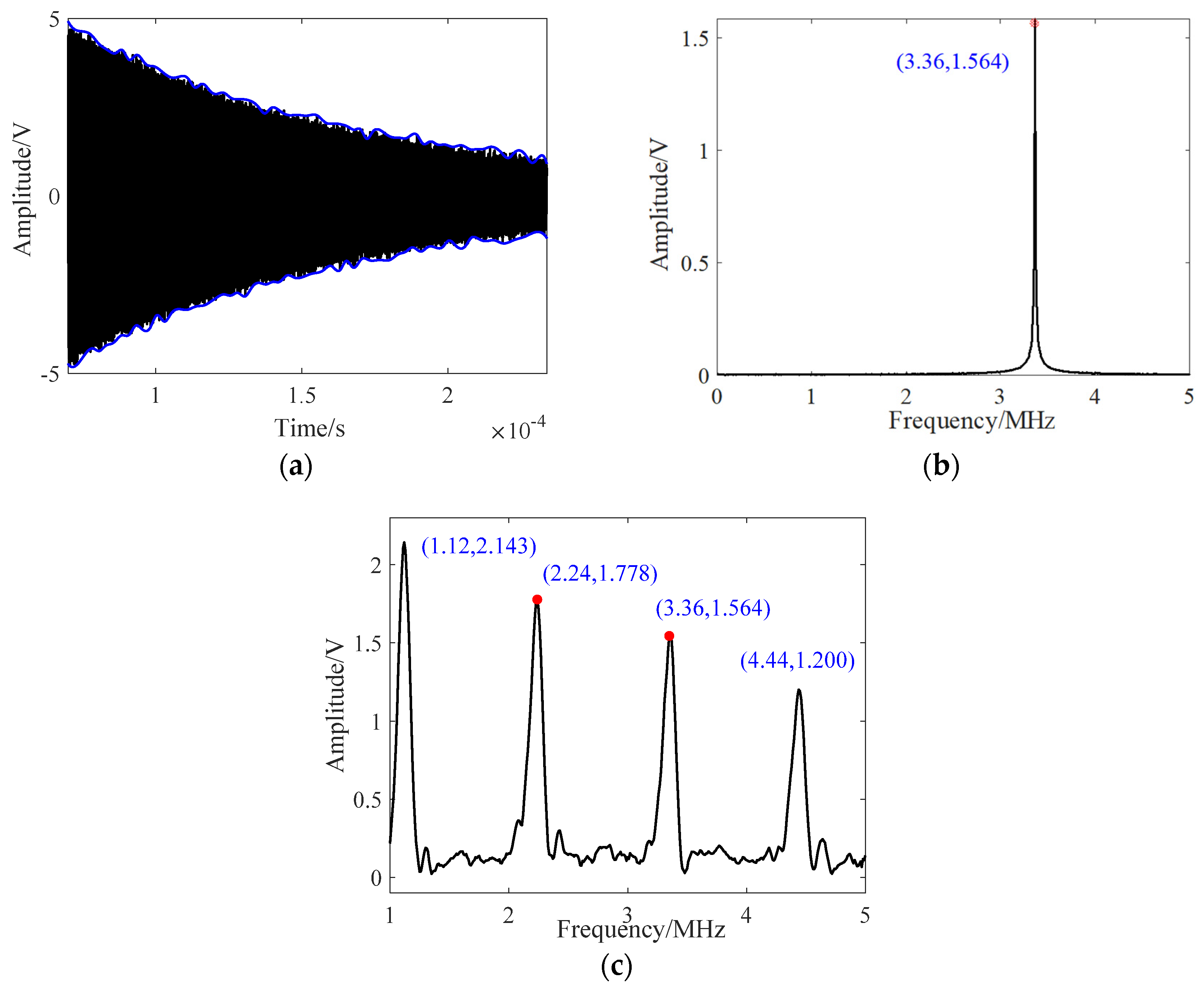

2.3. Resonance Measurement

2.4. Limitations and Solutions

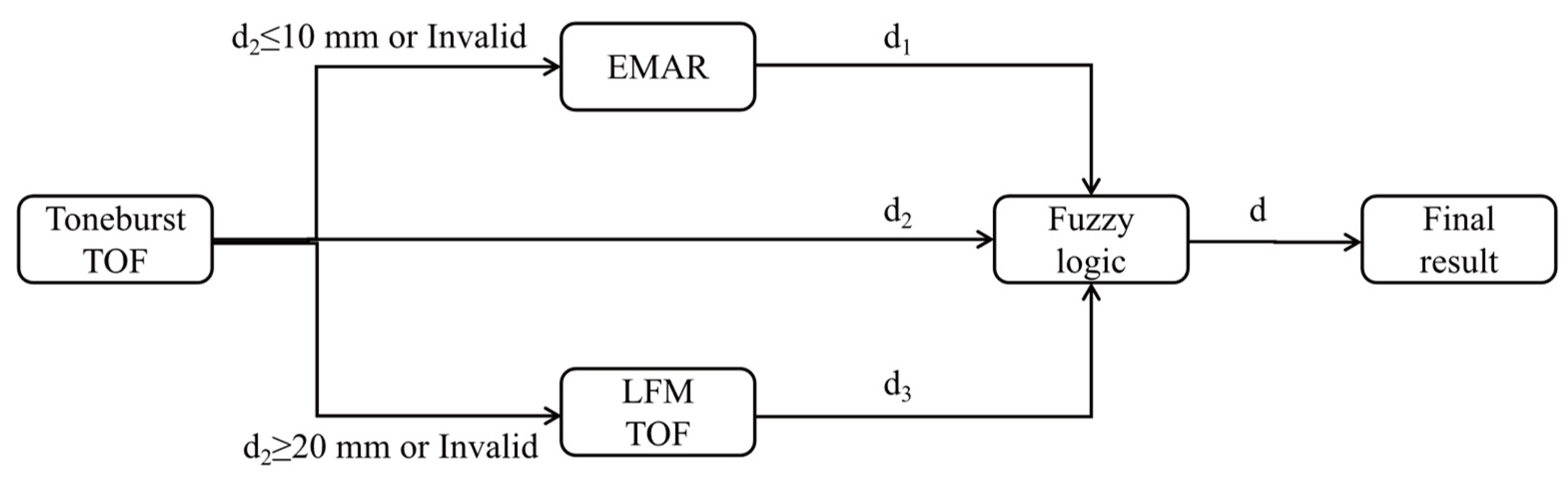

3. Fuzzy Logic Measurement

3.1. Fuzzy Logic Design

3.2. Principles of Fuzzy Logic and Thickness Measurement Process

4. Experiments

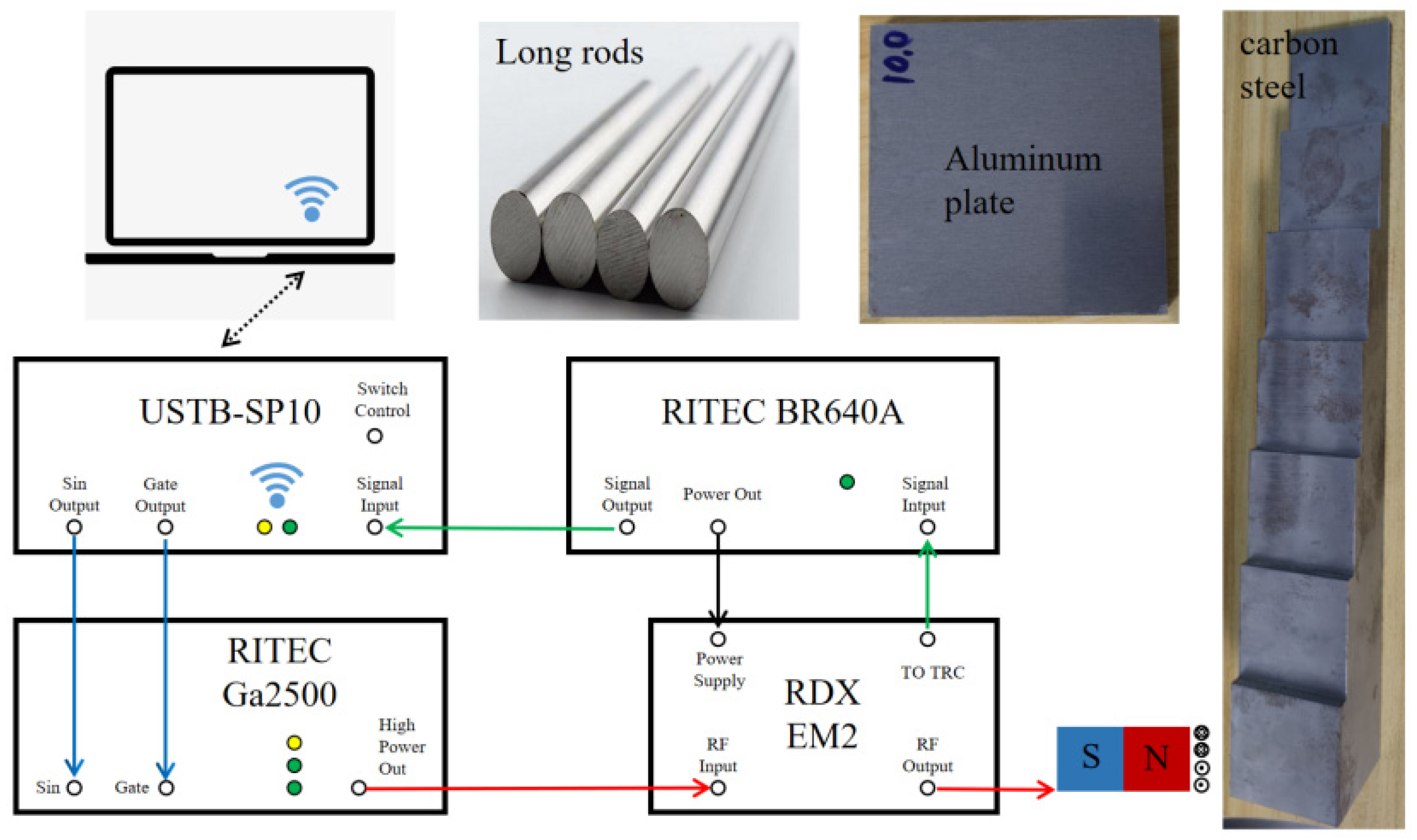

4.1. Experimental Setup

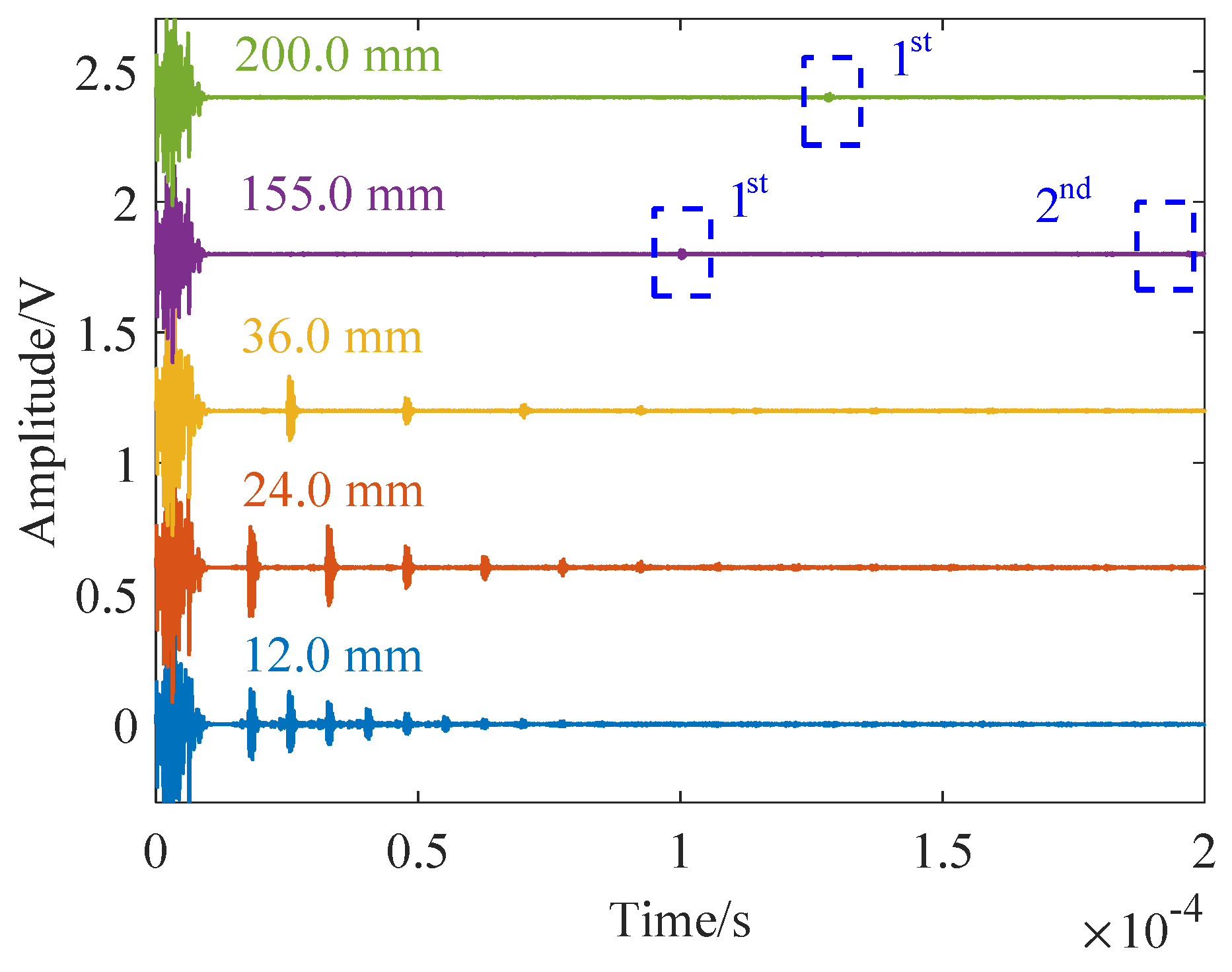

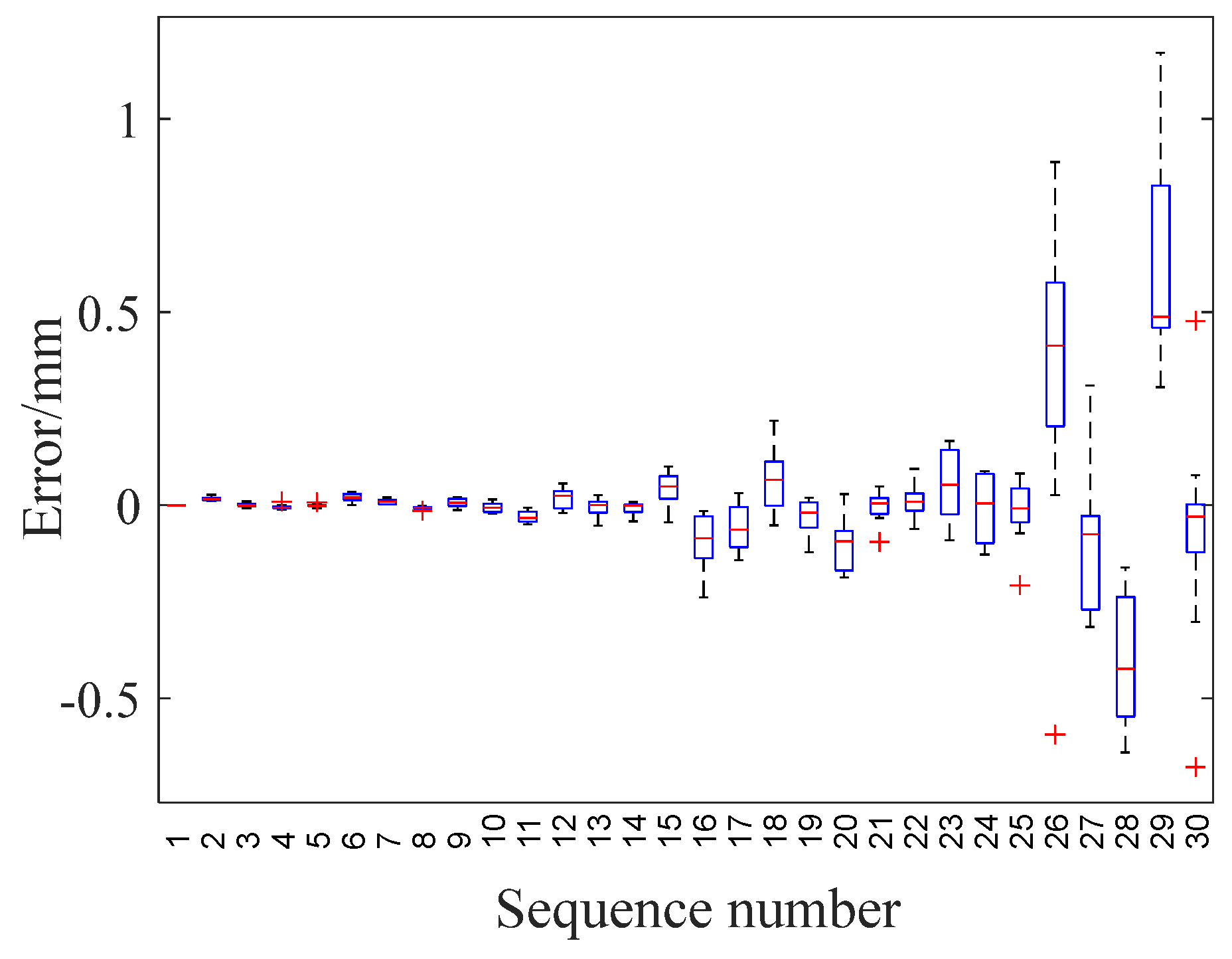

4.2. Experimental Verification

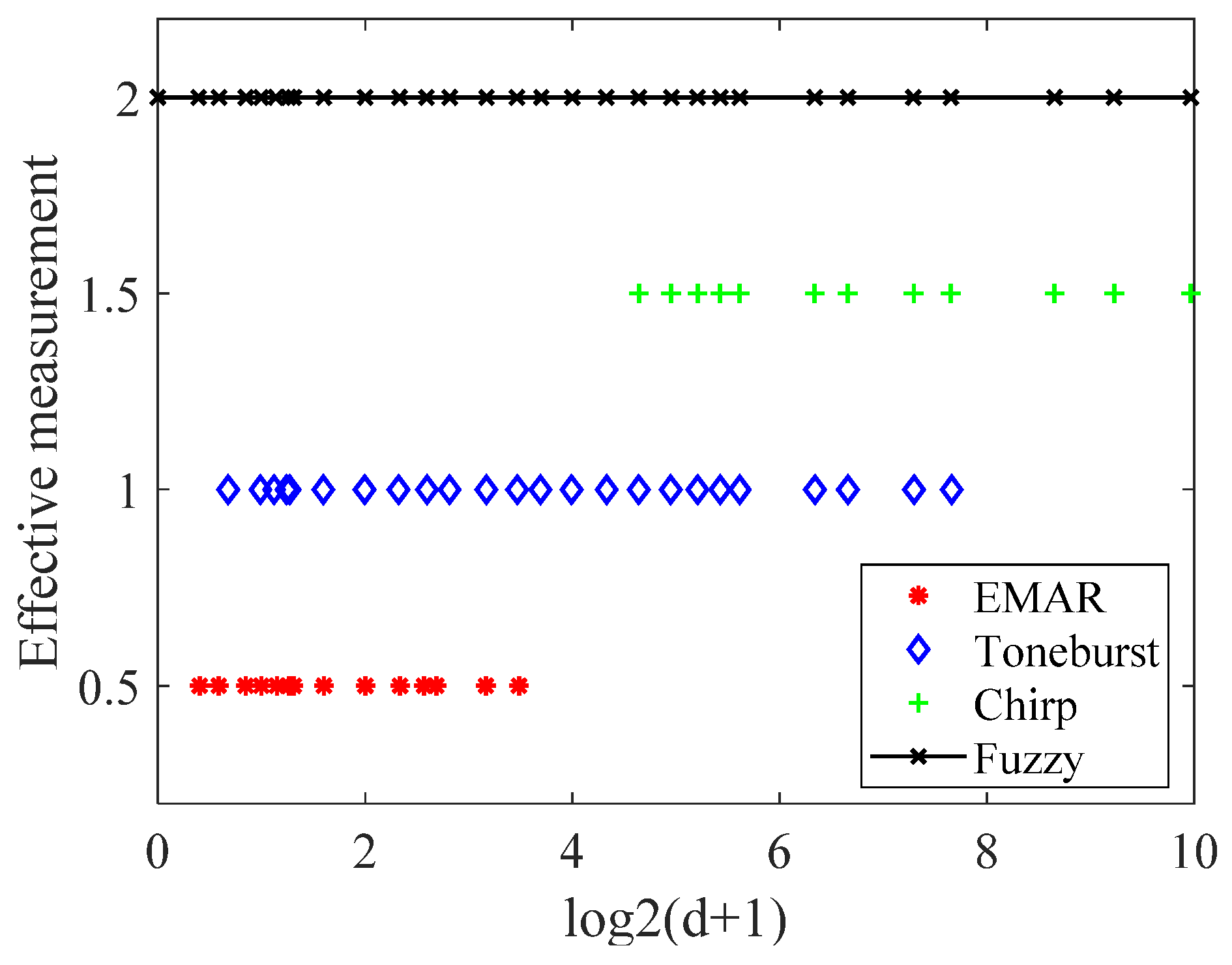

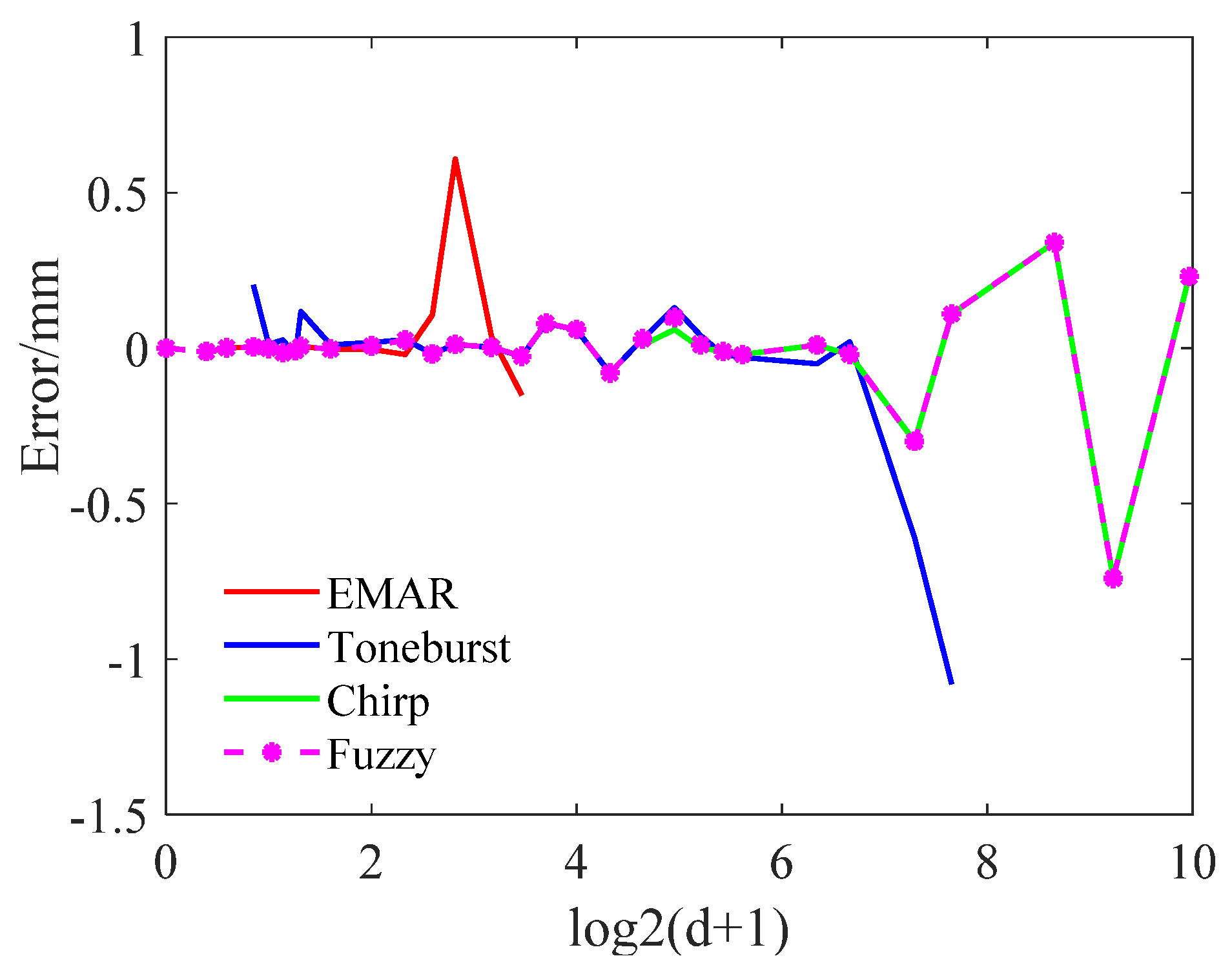

4.3. Fuzzy Logic Fusion

| Material | Thickness (mm) | Micrometer d (mm) | EMAR d1 (mm) | Toneburst d2 (mm) | LFM d3 (mm) | Fuzzy Judgment | Fuzzy Thickness Result (mm) | Fuzzy Error (mm) |

|---|---|---|---|---|---|---|---|---|

| Aluminum | 0.2 | 0.198 | - | - | - | - | 0.000 | - |

| 0.3 | 0.312 | 0.323 | - | - | S | 0.323 | 0.011 | |

| 0.5 | 0.504 | 0.503 | - | - | S | 0.503 | −0.001 | |

| 0.8 | 0.803 | 0.799 | 0.632 | - | S | 0.799 | −0.004 | |

| 1.0 | 0.996 | 0.997 | 0.984 | - | S | 0.997 | 0.001 | |

| 1.2 | 1.201 | 1.216 | 1.175 | - | S | 1.216 | 0.015 | |

| 1.4 | 1.394 | 1.402 | 1.416 | - | S | 1.402 | 0.008 | |

| 1.5 | 1.483 | 1.478 | 1.365 | - | S | 1.478 | −0.005 | |

| 2.0 | 2.035 | 2.038 | 2.024 | - | SM | 2.038 | 0.003 | |

| 3.0 | 3.003 | 3.007 | 2.985 | - | SM | 2.996 | −0.007 | |

| 4.0 | 4.029 | 4.049 | 4.001 | - | SM | 4.003 | −0.026 | |

| 5.0 | 5.030 | 4.924 | 5.048 | - | M | 5.048 | 0.018 | |

| 6.0 | 6.045 | 5.437 | 6.033 | - | M | 6.033 | −0.012 | |

| 8.0 | 8.004 | 7.966 | 8.001 | - | M | 8.001 | −0.003 | |

| 10.0 | 10.037 | 10.188 | 10.063 | - | M | 10.063 | 0.026 | |

| Carbon steel | 12.0 | 12.00 | - | 11.92 | - | M | 11.920 | −0.08 |

| 15.0 | 14.98 | - | 14.92 | - | M | 14.920 | −0.06 | |

| 19.0 | 19.04 | - | 19.12 | - | M | 19.120 | 0.08 | |

| 24.0 | 23.98 | - | 23.95 | 23.97 | M | 23.950 | −0.03 | |

| 30.0 | 30.02 | - | 29.89 | 29.96 | ML | 29.921 | −0.099 | |

| 36.0 | 36.00 | - | 35.96 | 36.00 | ML | 35.989 | −0.011 | |

| 42.0 | 42.00 | - | 42.02 | 42.01 | ML | 42.011 | 0.011 | |

| 48.0 | 48.00 | - | 48.03 | 48.02 | ML | 48.020 | 0.02 | |

| 80.0 | 80.04 | - | 80.09 | 80.03 | L | 80.030 | −0.01 | |

| 100.0 | 100.06 | - | 100.04 | 100.08 | L | 100.080 | 0.02 | |

| 155.0 | 155.69 | - | 156.30 | 155.99 | L | 155.990 | 0.3 | |

| 200.0 | 200.32 | - | 201.40 | 200.21 | L | 200.210 | −0.11 | |

| 400.0 | 401.90 | - | - | 401.56 | L | 401.560 | −0.34 | |

| 600.0 | 598.30 | - | - | 599.04 | L | 599.040 | 0.74 | |

| 1000.0 | 1000.40 | - | - | 1000.17 | L | 1000.170 | −0.23 |

4.4. Measurement Uncertainty

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ren, W.; Xu, K.; Dixon, S.; Zhang, C. A Study of Magnetostriction Mechanism of EMAT on Low-Carbon Steel at High Temperature. NDT E Int. 2019, 101, 34–43. [Google Scholar] [CrossRef]

- Jia, X.; Ouyang, Q. Optimal Design of Point-Focusing Shear Vertical Wave Electromagnetic Ultrasonic Transducers Based on Orthogonal Test Method. IEEE Sens. J. 2018, 18, 8064–8073. [Google Scholar] [CrossRef]

- He, M.; Shi, W.; Lu, C.; Chen, G.; Qiu, F.; Zhu, Y.; Liu, Y. Application of Pulse Compression Technique in High-Temperature Carbon Steel Forgings Crack Detection with Angled SV-Wave EMATs. Sensors 2023, 23, 2685. [Google Scholar] [CrossRef]

- Liu, T.; Pei, C.; Cai, R.; Li, Y.; Chen, Z. A Flexible and Noncontact Guided-Wave Transducer Based on Coils-Only EMAT for Pipe Inspection. Sens. Actuators A Phys. 2020, 314, 112213. [Google Scholar] [CrossRef]

- Rieger, K.; Erni, D.; Rueter, D. Examination of the Liquid Volume Inside Metal Tanks Using Noncontact EMATs from Outside. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2021, 68, 1314–1327. [Google Scholar] [CrossRef]

- Rieger, K.; Erni, D.; Rueter, D. Noncontact Reception of Ultrasound from Soft Magnetic Mild Steel with Zero Applied Bias Field EMATs. NDT E Int. 2022, 125, 102569. [Google Scholar] [CrossRef]

- Miao, H.; Li, F. Shear Horizontal Wave Transducers for Structural Health Monitoring and Nondestructive Testing: A Review. Ultrasonics 2021, 114, 106355. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Li, Z.; Kang, L.; Hu, X.; Zhang, X. Modeling and Comparison of Three Bulk Wave EMATs. In Proceedings of the IECON 2011—37th Annual Conference of the IEEE Industrial Electronics Society, Melbourne, VIC, Australia, 7–10 November 2011; pp. 2645–2650. [Google Scholar] [CrossRef]

- Diguet, G.; Miyauchi, H.; Takeda, S.; Uchimoto, T.; Mary, N.; Takagi, T.; Abe, H. EMAR Monitoring System Applied to the Thickness Reduction of Carbon Steel in a Corrosive Environment. Mater. Corros. 2022, 73, 658–668. [Google Scholar] [CrossRef]

- Trushkevych, O.; Edwards, R.S. Differential Coil EMAT for Simultaneous Detection of In-Plane and Out-of-Plane Components of Surface Acoustic Waves. IEEE Sens. J. 2020, 20, 11156–11162. [Google Scholar] [CrossRef]

- Cai, Z.; Li, Y. Optimization Design of Electromagnetic Ultrasonic Longitudinal Wave Transducer Based on Halbach Array. J. Electr. Eng. Technol. 2021, 36, 4408–4417. [Google Scholar]

- Pei, C.; Zhao, S.; Xiao, P.; Chen, Z. A Modified Meander-Line-Coil EMAT Design for Signal Amplitude Enhancement. Sens. Actuators A Phys. 2016, 247, 539–546. [Google Scholar] [CrossRef]

- Kang, L.; Dixon, S.; Wang, K.; Dai, J. Enhancement of Signal Amplitude of Surface Wave EMATs Based on 3-D Simulation Analysis and Orthogonal Test Method. NDT E Int. 2013, 59, 11–17. [Google Scholar] [CrossRef]

- Xu, X.; Tu, J.; Zhang, X. Study on the Characteristics of Common Electromagnetic Ultrasonic Coils for Steel Plate Thickness Measurement. China Test. 2020, 46, 5. [Google Scholar]

- Burrows, S.E.; Fan, Y.; Dixon, S. High Temperature Thickness Measurements of Stainless Steel and Low Carbon Steel Using Electromagnetic Acoustic Transducers. NDT E Int. 2014, 68, 73–77. [Google Scholar] [CrossRef]

- Wang, S.; Wang, S.; Liang, B.; Jiang, C.; Zhao, C.; Zhou, W. Research on Linear Frequency Modulation Pulse Compression in Electromagnetic Ultrasonic Thickness Measurement. In Proceedings of the 2020 IEEE Far East NDT New Technology & Application Forum (FENDT), Kunming, China, 20–22 November 2020; pp. 145–149. [Google Scholar] [CrossRef]

- Zhao, Y.; Ma, J.; Chen, J.W.; Ouyang, H.; Wang, M.H.; Zhao, P.; Zhang, B. Noncontact Method Applied to Determine Thickness of Thin Layer Based on Laser Ultrasonic Technique. Mater. Res. Innov. 2014, 18, S2-1081–S2-1085. [Google Scholar] [CrossRef]

- Qiu, J.; Ding, H.; Wang, S. Design of Pulse Electromagnet in Electromagnetic Ultrasonic Thickness Measurement Device for Steel Plate. China Test 2018, 44, 6. [Google Scholar]

- Guo, W.; Yu, Z.; Chui, H.-C.; Chen, X. Development of DMPS-EMAT for Long-Distance Monitoring of Broken Rail. Sensors 2023, 23, 5583. [Google Scholar] [CrossRef] [PubMed]

- Suresh, N.; Balasubramaniam, K. Quantifying the Lowest Remnant Thickness Using a Novel Broadband Wavelength and Frequency EMAT Utilizing the Cut-Off Property of Guided Waves. NDT E Int. 2020, 116, 102313. [Google Scholar] [CrossRef]

- Zhao, S.; Zhou, J.; Liu, Y.; Zhang, J.; Cui, J. Application of Adaptive Filtering Based on Variational Mode Decomposition for High-Temperature Electromagnetic Acoustic Transducer Denoising. Sensors 2022, 22, 7042. [Google Scholar] [CrossRef]

- Richards, M.A. Fundamentals of Radar Signal Processing, 1st ed.; McGraw-Hill: New York, NY, USA, 2005. [Google Scholar]

- Yusa, N.; Song, H.; Iwata, D. Probabilistic Evaluation of EMAR Signals to Evaluate Pipe Wall Thickness and Its Application to Pipe Wall Thinning Management. NDT E Int. 2021, 122, 102475. [Google Scholar] [CrossRef]

- Wang, J.; Wu, X.; Song, Y.; Sun, L. Study of the Influence of the Backplate Position on EMAT Thickness-Measurement Signals. Sensors 2022, 22, 8741. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Pei, C.; Cheng, X.; Zhou, H.; Xiao, P.; Chen, Z. Adhesive Debonding Inspection with a Small EMAT in Resonant Mode. NDT E Int. 2018, 98, 110–116. [Google Scholar] [CrossRef]

- Hirao, M.; Ogi, H. Electromagnetic Acoustic Transducers: Noncontacting Ultrasonic Measurements Using EMATs; Springer: Tokyo, Japan, 2017. [Google Scholar] [CrossRef]

- Ross, T.J. Fuzzy Logic with Engineering Applications; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Mendel, J.M. Fuzzy Logic Systems for Engineering: A Tutorial. Proc. IEEE 1995, 83, 345–377. [Google Scholar] [CrossRef]

- Kong, L.; Peng, X.; Chen, Y.; Wang, P.; Xu, M. Multi-sensor measurement and data fusion technology for manufacturing process monitoring: A literature review. Int. J. Extrem. Manuf. 2020, 2, 022001. [Google Scholar] [CrossRef]

- Lin, X.; Yu, Y.; Sun, C. A Decoupling Control for Quadrotor UAV Using Dynamic Surface Control and Sliding Mode Disturbance Observer. Nonlinear Dyn. 2019, 97, 781–795. [Google Scholar] [CrossRef]

| Manufacturer | Frequency (MHz) | Range (mm) | Thickness Measurement Error (mm) |

|---|---|---|---|

| Oktanta EM1401 | 3.5–5.5 | 2–200 | ±0.1 (thickness 2–200) |

| ACS A1270 | 3.0 | 1–100 | ±0.1 |

| Orisonic ETGmini-X2 | 4.0 | 1.5–300 | ±0.05 (thickness 1.5–10) ±0.01 + H/200 (thickness 10–500) |

| Ours | 0.5–5.0 | 0.3–1000 | ±0.03 (thickness 0.3–10) ±0.01 + H/300 (thickness 10–1000) |

| Hardware | Limitation | Frequency (MHz) | Problems |

|---|---|---|---|

| Power amplifier | Frequency | 0.05–20 | High frequency energy attenuation is serious |

| Weak signal amplifier | Filter | 0.5–5 | Bandpass filter |

| DAC | Refresh rate | 50 | The actual sine wave frequency is lower than 5 MHz |

| ADC | Sample rate | 50 | Restricted Nyquist sampling theorem |

| EMAT’s coil | Impedance matching frequency | 3 | Narrowband matches are flat around the center frequency |

| D | Fuzzy Logic |

|---|---|

| 0.3~1.5 | S |

| 1.5~2.5 | SM |

| 2.5~4.8 | M |

| 4.8~6 | ML |

| ≥6 | L |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Y.; Tian, S.; Jiang, J.; Lei, T.; Wang, S.; Lin, X.; Xu, K. Thickness Measurements with EMAT Based on Fuzzy Logic. Sensors 2024, 24, 4066. https://doi.org/10.3390/s24134066

Shi Y, Tian S, Jiang J, Lei T, Wang S, Lin X, Xu K. Thickness Measurements with EMAT Based on Fuzzy Logic. Sensors. 2024; 24(13):4066. https://doi.org/10.3390/s24134066

Chicago/Turabian StyleShi, Yingjie, Shihui Tian, Jiahong Jiang, Tairan Lei, Shun Wang, Xiaobo Lin, and Ke Xu. 2024. "Thickness Measurements with EMAT Based on Fuzzy Logic" Sensors 24, no. 13: 4066. https://doi.org/10.3390/s24134066