Eddy Current Sensor Array for Electromagnetic Sensing and Crack Reconstruction with High Lift-Off in Railway Tracks

Abstract

1. Introduction

2. Method

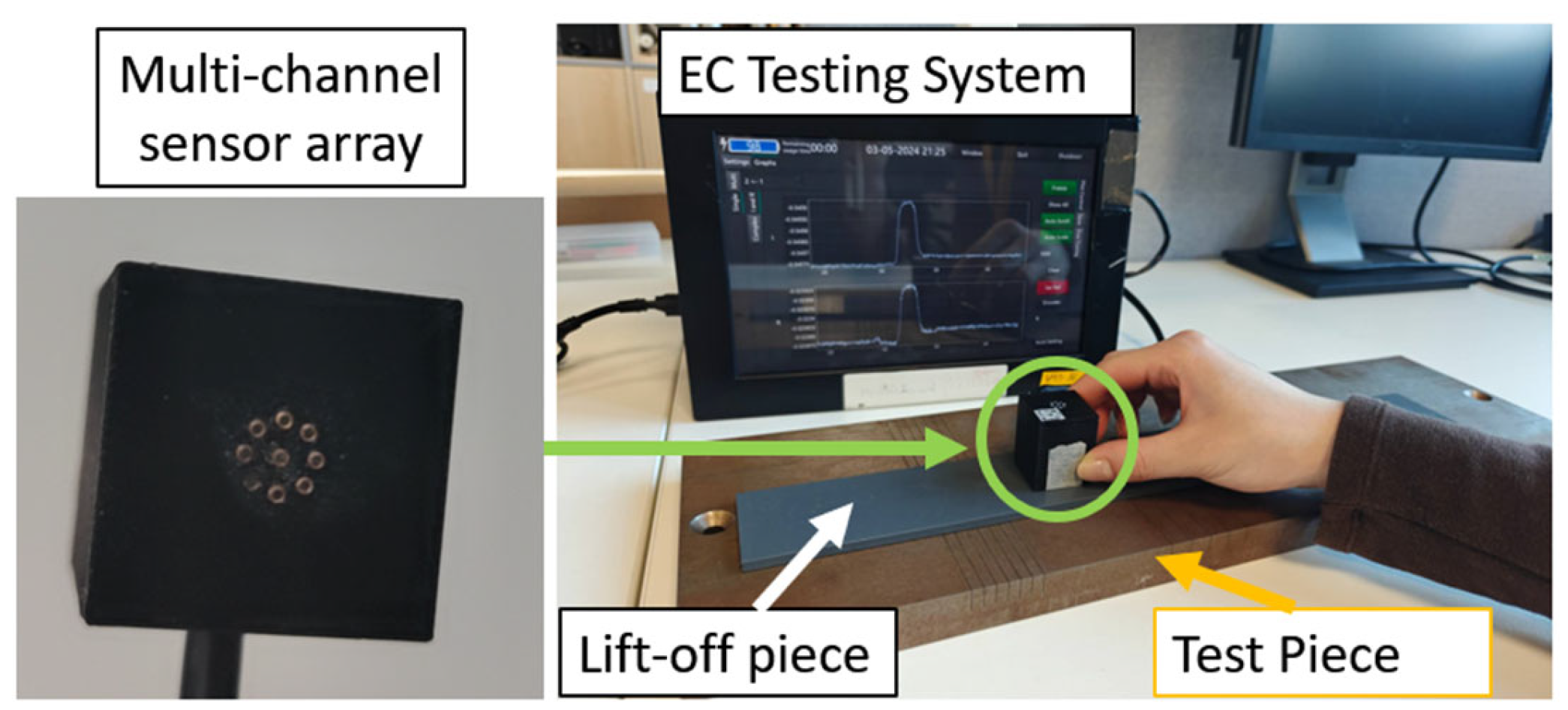

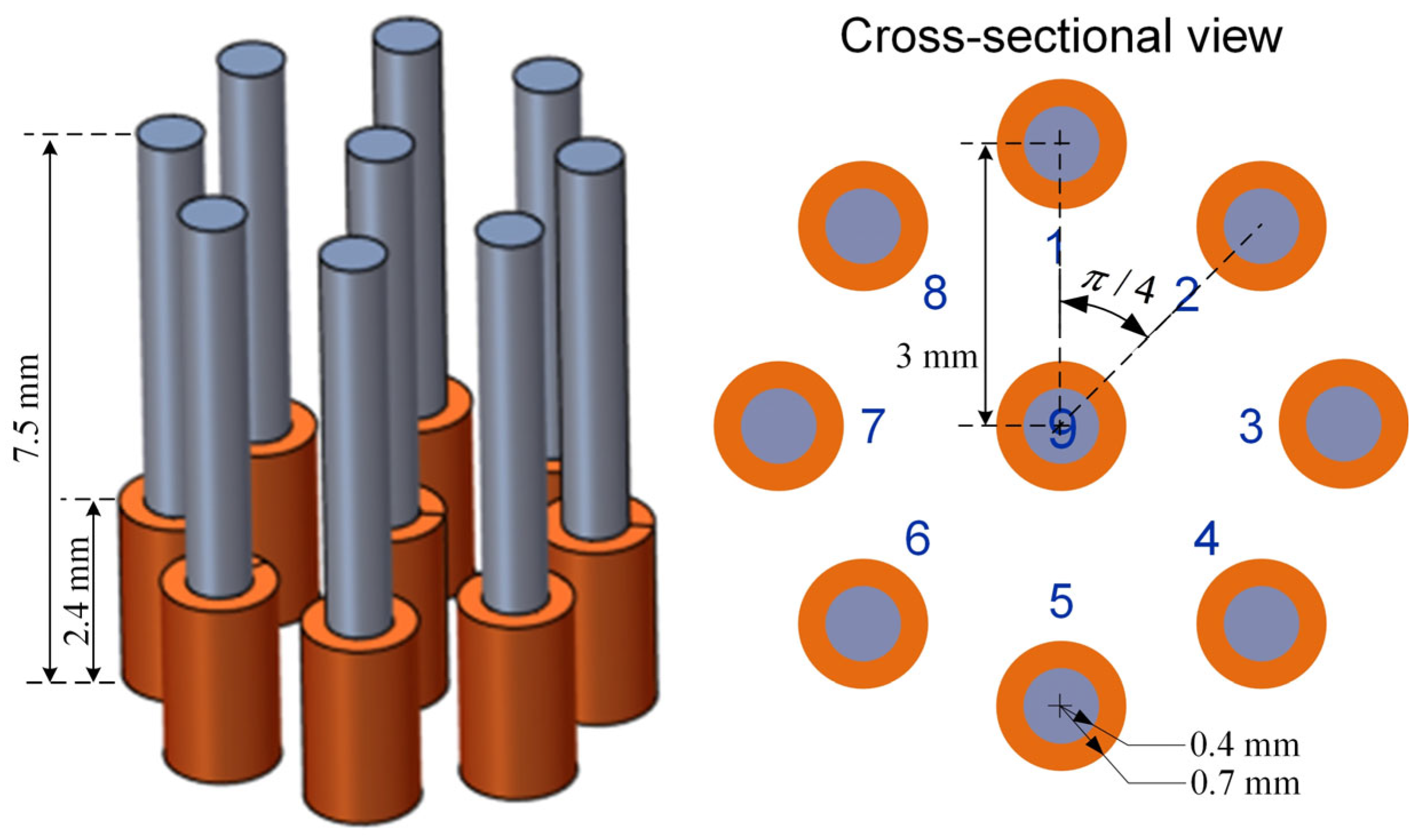

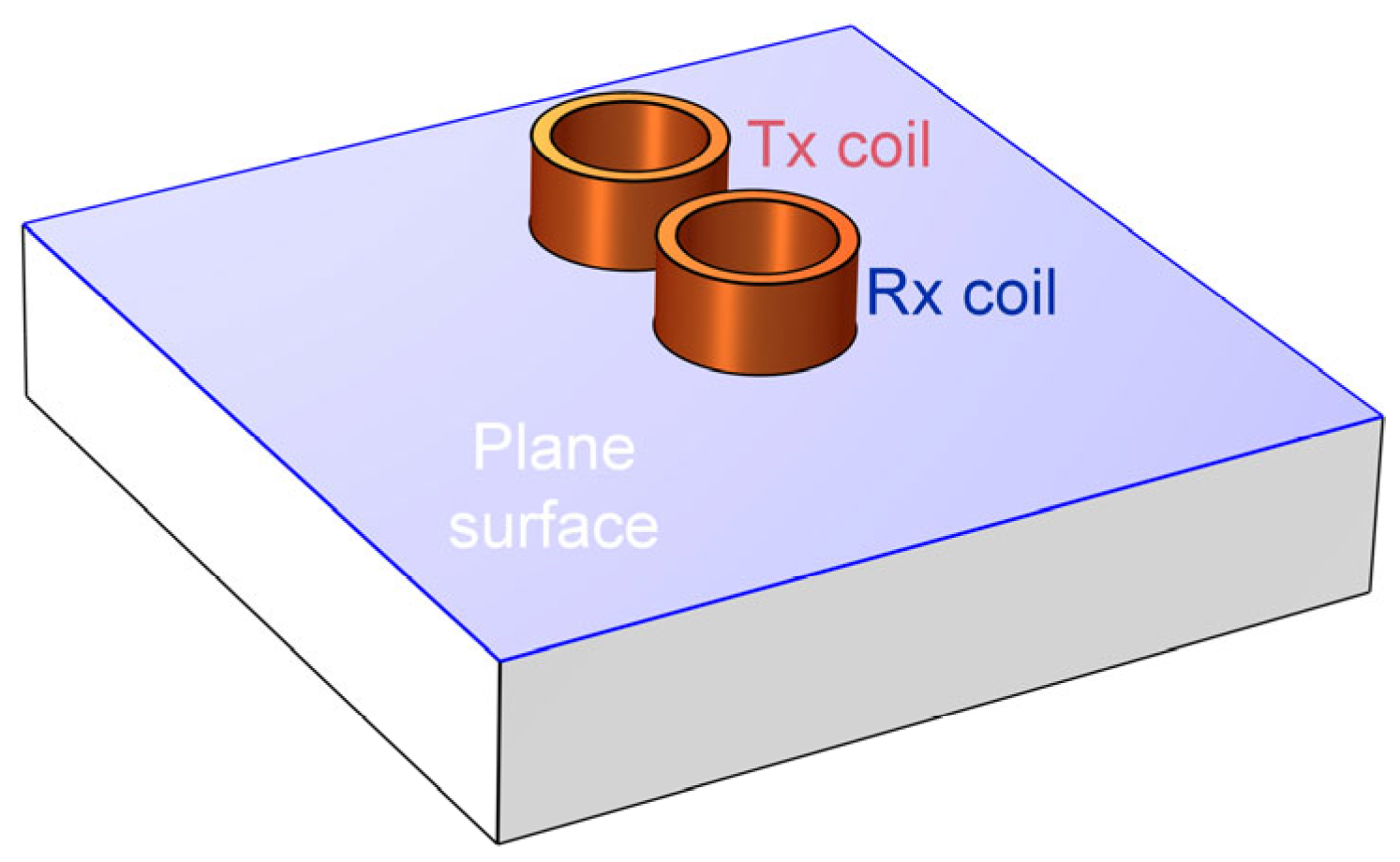

2.1. Measurement Setup for Rail Testing

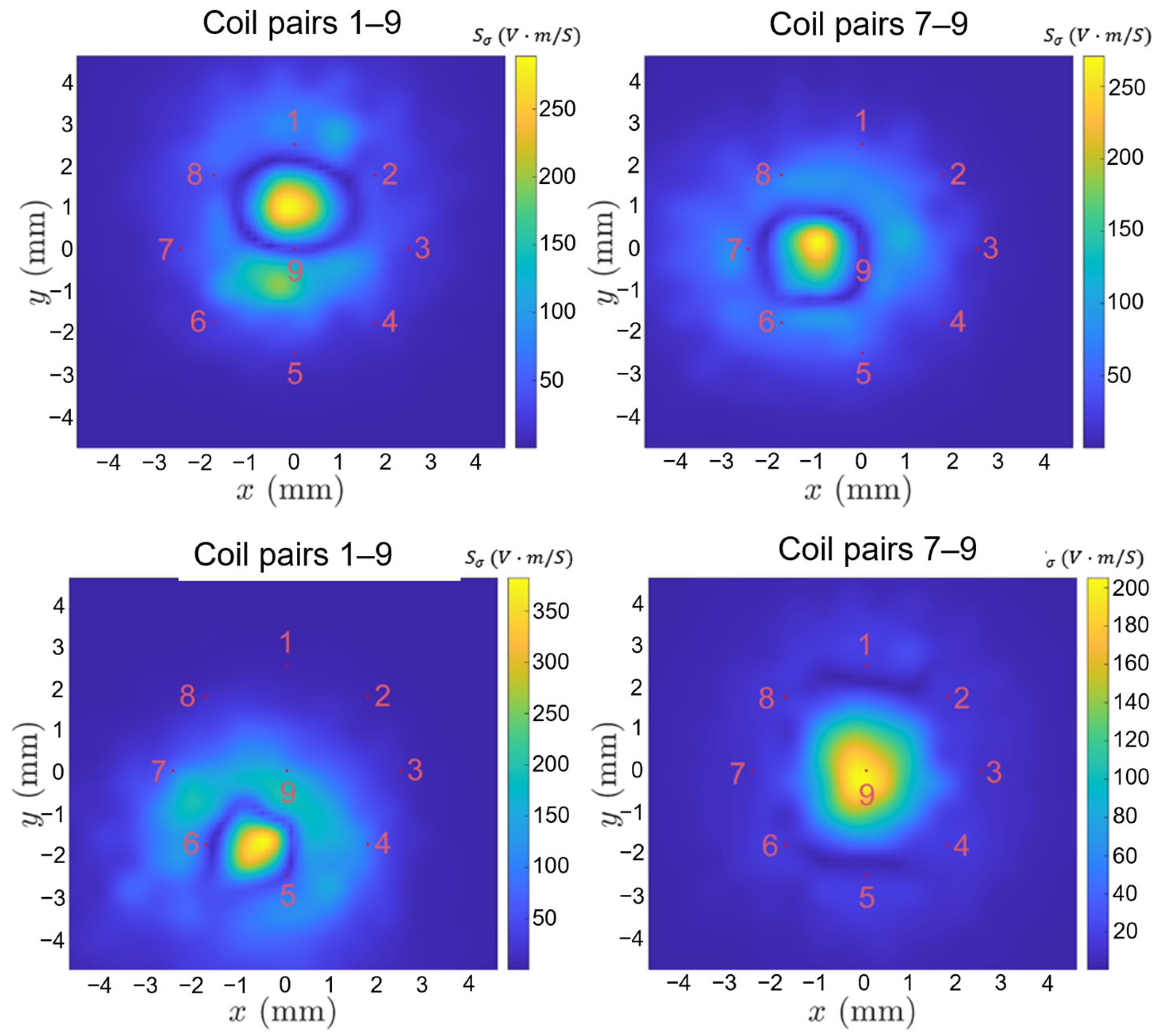

2.2. Forward Problem of Rail Testing

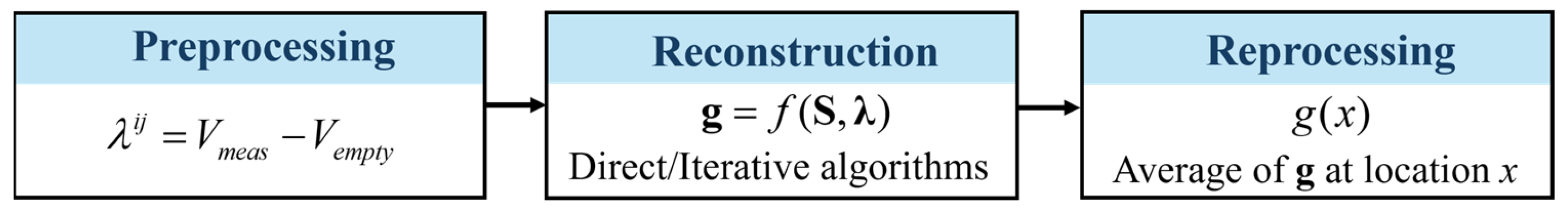

2.3. Inverse Problem of Crack Reconstruction

3. Results and Discussion

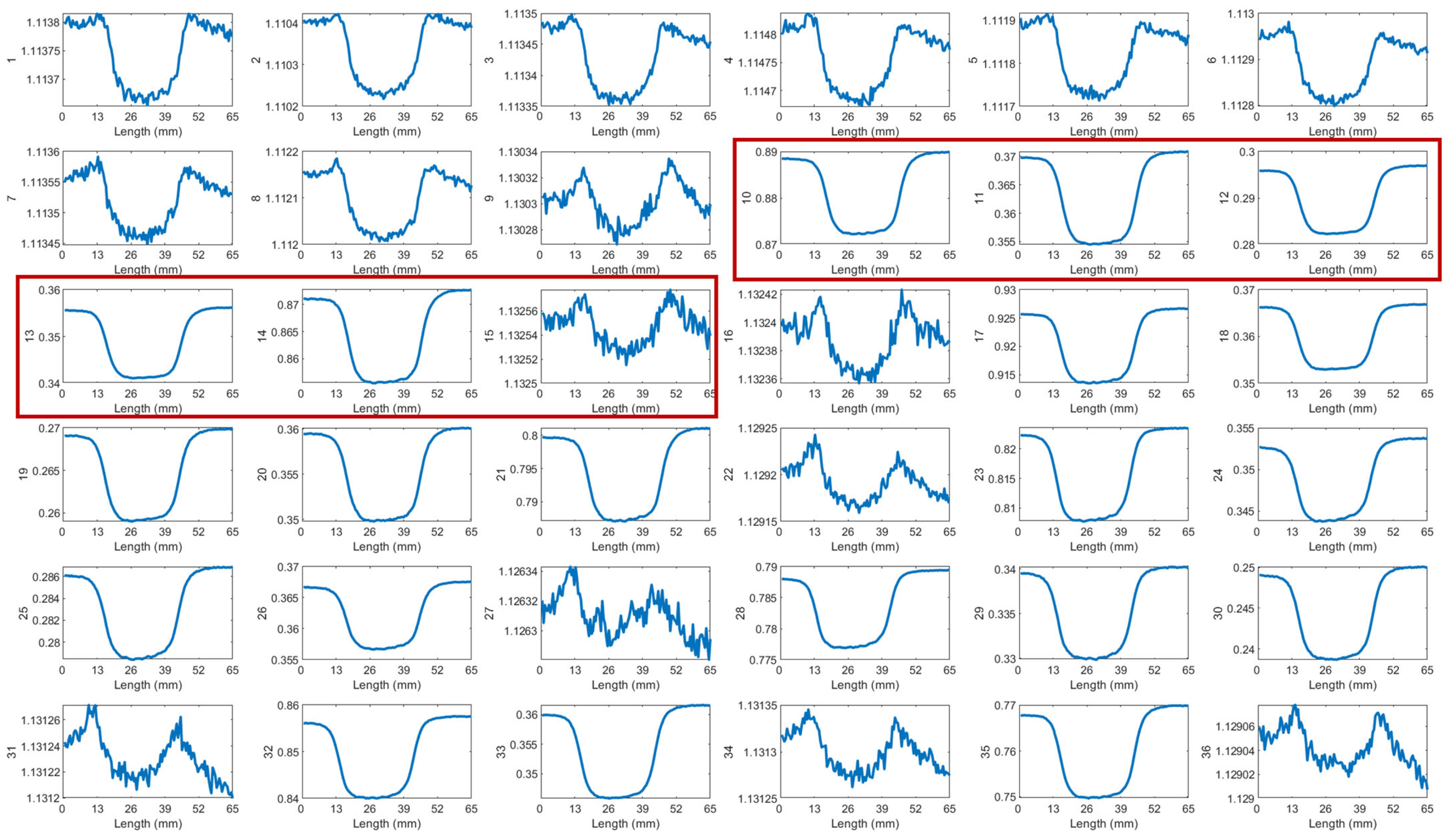

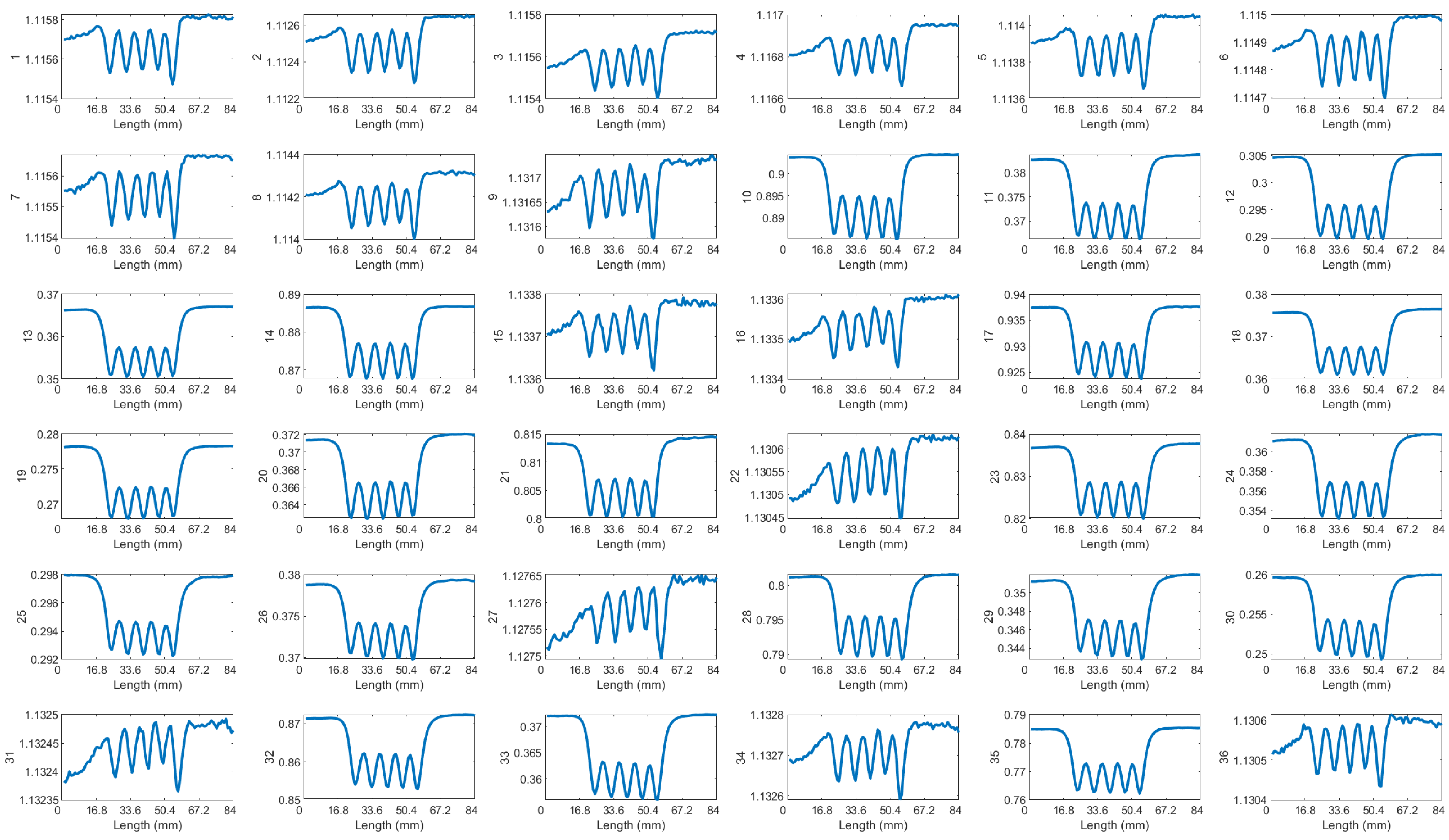

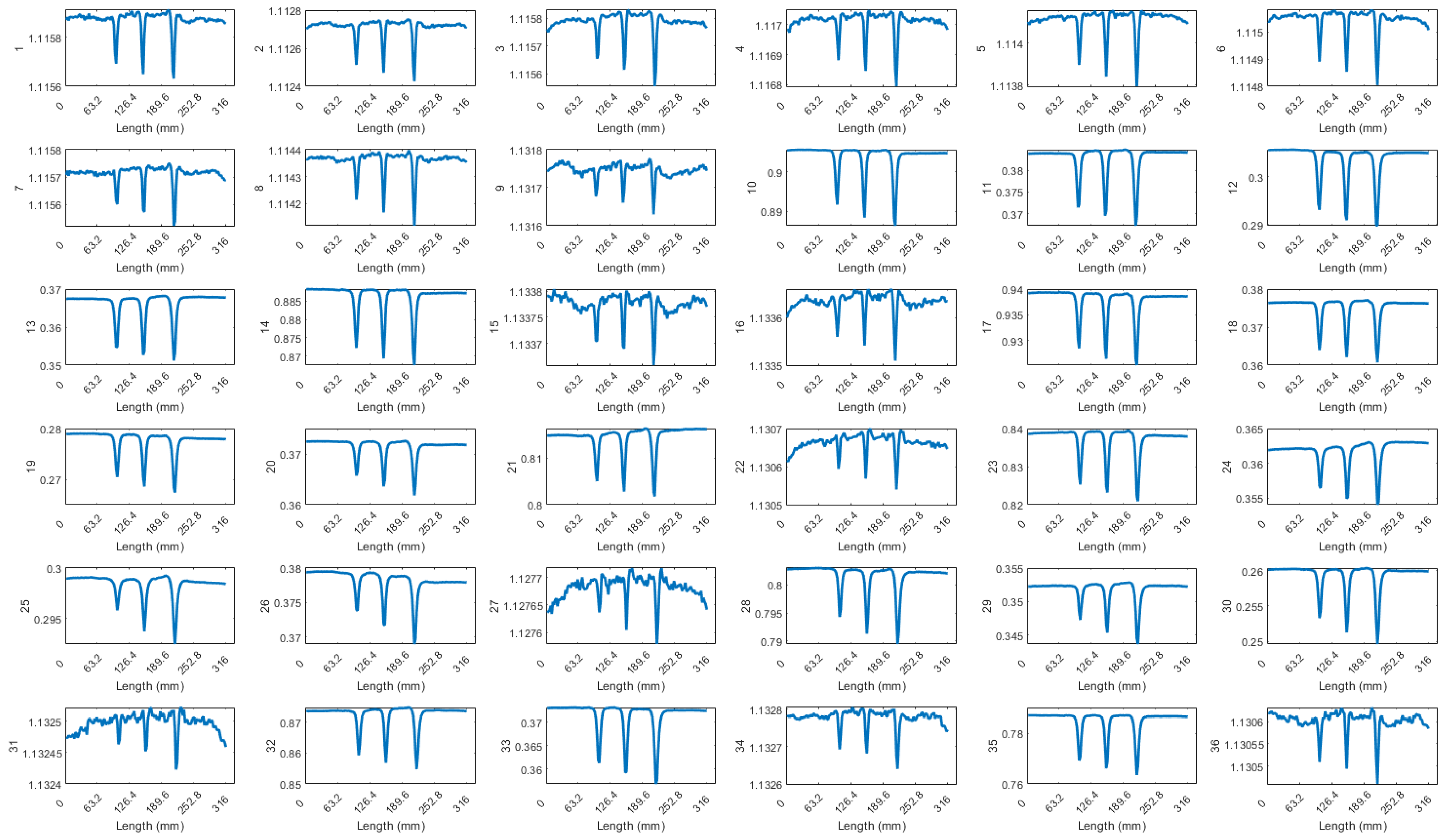

3.1. Received Data

3.2. Evaluation of Results Using Inverse Problems

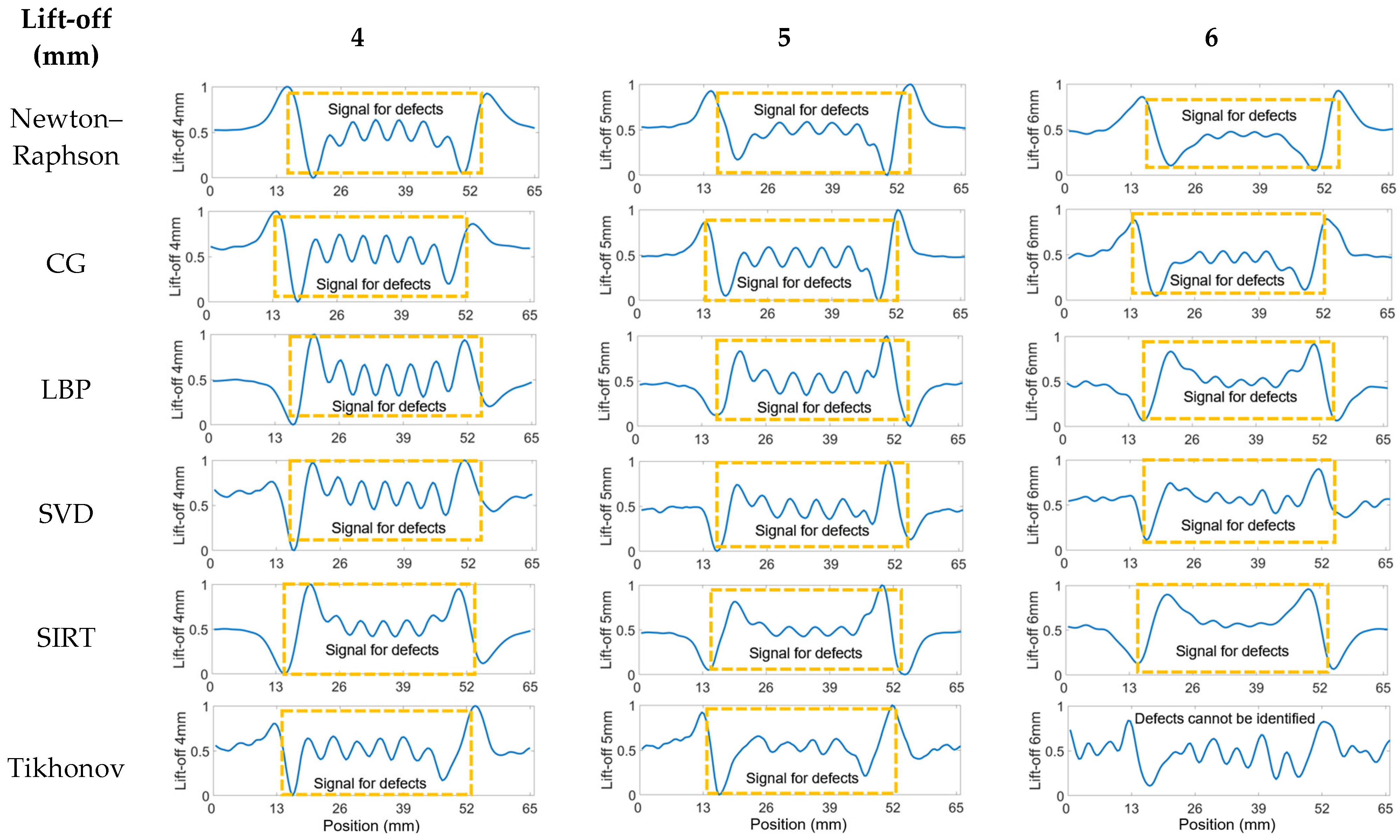

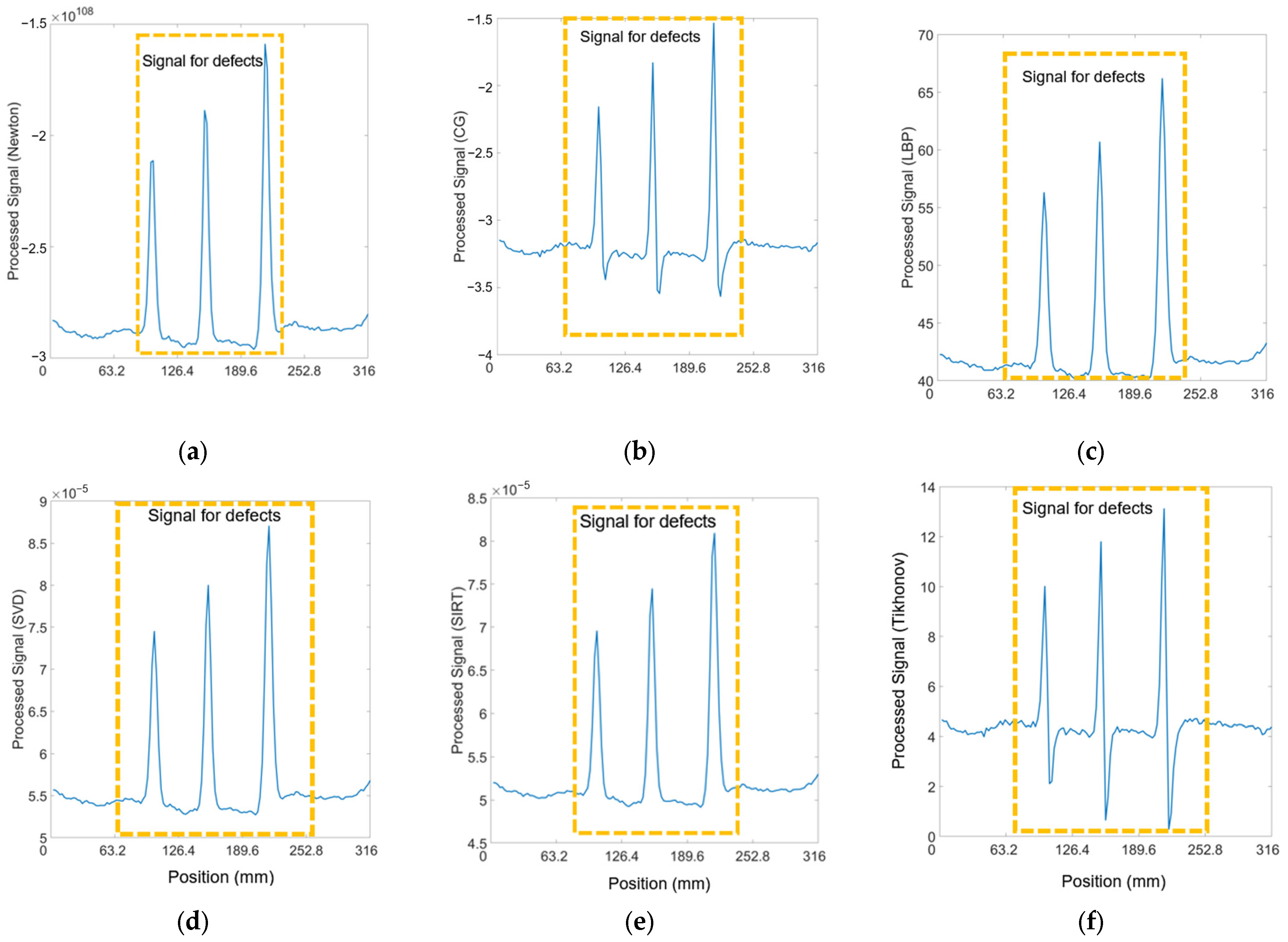

3.2.1. Seven Cracks with 5 mm Spacing

3.2.2. Five Cracks with 10 mm Spacing

3.2.3. Three Cracks with 6 mm, 9 mm, and 12 mm Depths

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Saunders, S.; Crocker, R.A. Pedestrian and Vehicle-Mounted System for Detecting RCF in Rail using Eddy Currents. In Proceedings of the 19th World Conference on Non-Destructive Testing, Munich, Germany, 13–17 June 2016. [Google Scholar]

- Haidemenopoulos, G.N.; Sarafoglou, P.I.; Christopoulos, P.; Zervaki, A.D. Rolling contact fatigue cracking in rails subjected to in-service loading. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 1161–1172. [Google Scholar] [CrossRef]

- Shen, J.; Zhou, L.; Warnett, J.; Williams, M.; Rowshandel, H.; Nicholson, G.; Davis, C. The influence of RCF crack propagation angle and crack shape on the ACFM signal. In Proceedings of the 19th World Conference on Non-Destructive Testing, Munich, Germany, 13–17 June 2016; pp. 1–9. [Google Scholar]

- Tillberg, J.; Larsson, F.; Runesson, K. A study of multiple crack interaction at rolling contact fatigue loading of rails. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2009, 223, 319–330. [Google Scholar] [CrossRef]

- Rajamäki, J.; Vippola, M.; Nurmikolu, A.; Viitala, T. Limitations of eddy current inspection in railway rail evaluation. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2018, 232, 121–129. [Google Scholar] [CrossRef]

- Mandache, C.; Brothers, M.; Lefebvre, V. Time domain lift-off compensation method for eddy current testing. NDT. Net 2005, 10, 1–7. [Google Scholar]

- Van Drunen, G.; Cecco, V.S. Recognizing limitations in eddy-current testing. NDT Int. 1984, 17, 9–17. [Google Scholar] [CrossRef][Green Version]

- Li, X.; Tian, G.; Li, K.; Zhang, Q.; Lu, X. Investigation of rolling contact fatigue cracks using the transmitter-receiver eddy current testing under moving conditions. Nondestruct. Test. Eval. 2024, 39, 614–633. [Google Scholar] [CrossRef]

- Xu, P.; Zhu, C.L.; Zeng, H.M.; Wang, P. Rail crack detection and evaluation at high speed based on differential ECT system. Measurement 2020, 166, 108152. [Google Scholar] [CrossRef]

- Kwon, S.G.; Lee, T.G.; Park, S.J.; Park, J.W.; Seo, J.M. Natural Rail Surface Defect Inspection and Analysis Using 16-Channel Eddy Current System. Appl. Sci. 2021, 11, 8107. [Google Scholar] [CrossRef]

- Blitz, J.; Willsttäter, V.J.; Oaten, S.R.; Hajian, N.T. Eddy-current surface-crack sizing in steel with high lift-off. NDT Int. 1987, 20, 105–110. [Google Scholar] [CrossRef]

- Sukhanov, D.; Zavyalova, K.; Kadurina, A. Method for enhancement of spatial resolution of eddy current imaging. Meas. Sci. Technol. 2019, 30, 065402. [Google Scholar] [CrossRef]

- Meng, X.; Lu, M.; Yin, W.; Bennecer, A.; Kirk, K.J. Evaluation of coating thickness using lift-off insensitivity of eddy current sensor. Sensors 2021, 21, 419. [Google Scholar] [CrossRef] [PubMed]

- Xu, P.; Zeng, H.; Qian, T.; Liu, L. Research on defect detection of high-speed rail based on multi-frequency excitation composite electromagnetic method. Measurement 2022, 187, 110351. [Google Scholar] [CrossRef]

- Xu, P.; Qian, T. High-speed rail defect detection using multi-frequency exciting 3D ACFM. Measurement 2024, 227, 114160. [Google Scholar] [CrossRef]

- Chady, T.; Lopato, P. Multi-Resolution Eddy Current Measurements, AIP Conference Proceedings. Am. Inst. Phys. 2007, 894, 370–377. [Google Scholar] [CrossRef]

- Chady, T.; Enokizono, M.; Todaka, T.; Tsuchida, Y.; Sikora, R. A Family of Matrix Type Sensors for Detection of Slight Flaws in Conducting Plates. IEEE Trans. Magn. 1999, 35, 3655–3657. [Google Scholar] [CrossRef]

- Shao, Y.; Meng, T.; Yu, K.; Xia, Z.; Huang, R.; Tao, Y.; Chen, Z.; Avila, J.R.S.; Yin, W. Automatic detection and imaging of rivet hole defects for aircraft structures with optimized sensor array using eddy current method and image analysis. IEEE Sens. J. 2022, 23, 4597–4606. [Google Scholar] [CrossRef]

- Yin, W.; Peyton, A.J. Sensitivity formulation including velocity effects for electromagnetic induction systems. IEEE Trans. Magn. 2009, 46, 1172–1176. [Google Scholar] [CrossRef]

- Cui, Z.; Wang, Q.; Xue, Q.; Fan, W.; Zhang, L.; Cao, Z.; Sun, B.; Wang, H.; Yang, W. A review on image reconstruction algorithms for electrical capacitance/resistance tomography. Sens. Rev. 2016, 36, 429–445. [Google Scholar] [CrossRef]

- Yang, W.; Peng, L. Image reconstruction algorithms for electrical capacitance tomography. Meas. Sci. Technol. 2002, 14, R1. [Google Scholar] [CrossRef]

- Su, B.; Zhang, Y.; Peng, L.; Yao, D.; Zhang, B. The use of simultaneous iterative reconstruction technique for electrical capacitance tomography. Chem. Eng. J. 2000, 77, 37–41. [Google Scholar]

- Liu, X.; Wang, Y. An improved conjugate gradient image reconstruction algorithm for electromagnetic tomography. Sens. and Imag. 2022, 23, 5. [Google Scholar] [CrossRef]

| Algorithm | |

| NR | |

| SIRT | , indicates the matrix-to-vector diag operator |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, Y.; Xia, Z.; Ding, Y.; Crocker, B.; Saunders, S.; Bai, X.; Peyton, A.; Conniffe, D.; Yin, W. Eddy Current Sensor Array for Electromagnetic Sensing and Crack Reconstruction with High Lift-Off in Railway Tracks. Sensors 2024, 24, 4216. https://doi.org/10.3390/s24134216

Shao Y, Xia Z, Ding Y, Crocker B, Saunders S, Bai X, Peyton A, Conniffe D, Yin W. Eddy Current Sensor Array for Electromagnetic Sensing and Crack Reconstruction with High Lift-Off in Railway Tracks. Sensors. 2024; 24(13):4216. https://doi.org/10.3390/s24134216

Chicago/Turabian StyleShao, Yuchun, Zihan Xia, Yiqing Ding, Bob Crocker, Scott Saunders, Xue Bai, Anthony Peyton, Daniel Conniffe, and Wuliang Yin. 2024. "Eddy Current Sensor Array for Electromagnetic Sensing and Crack Reconstruction with High Lift-Off in Railway Tracks" Sensors 24, no. 13: 4216. https://doi.org/10.3390/s24134216

APA StyleShao, Y., Xia, Z., Ding, Y., Crocker, B., Saunders, S., Bai, X., Peyton, A., Conniffe, D., & Yin, W. (2024). Eddy Current Sensor Array for Electromagnetic Sensing and Crack Reconstruction with High Lift-Off in Railway Tracks. Sensors, 24(13), 4216. https://doi.org/10.3390/s24134216