Response Characteristics of Pressure-Sensitive Conductive Elastomer Sensors Using OFC Electrode with Triangular Wave Concavo-Convex Surfaces

Abstract

:1. Introduction

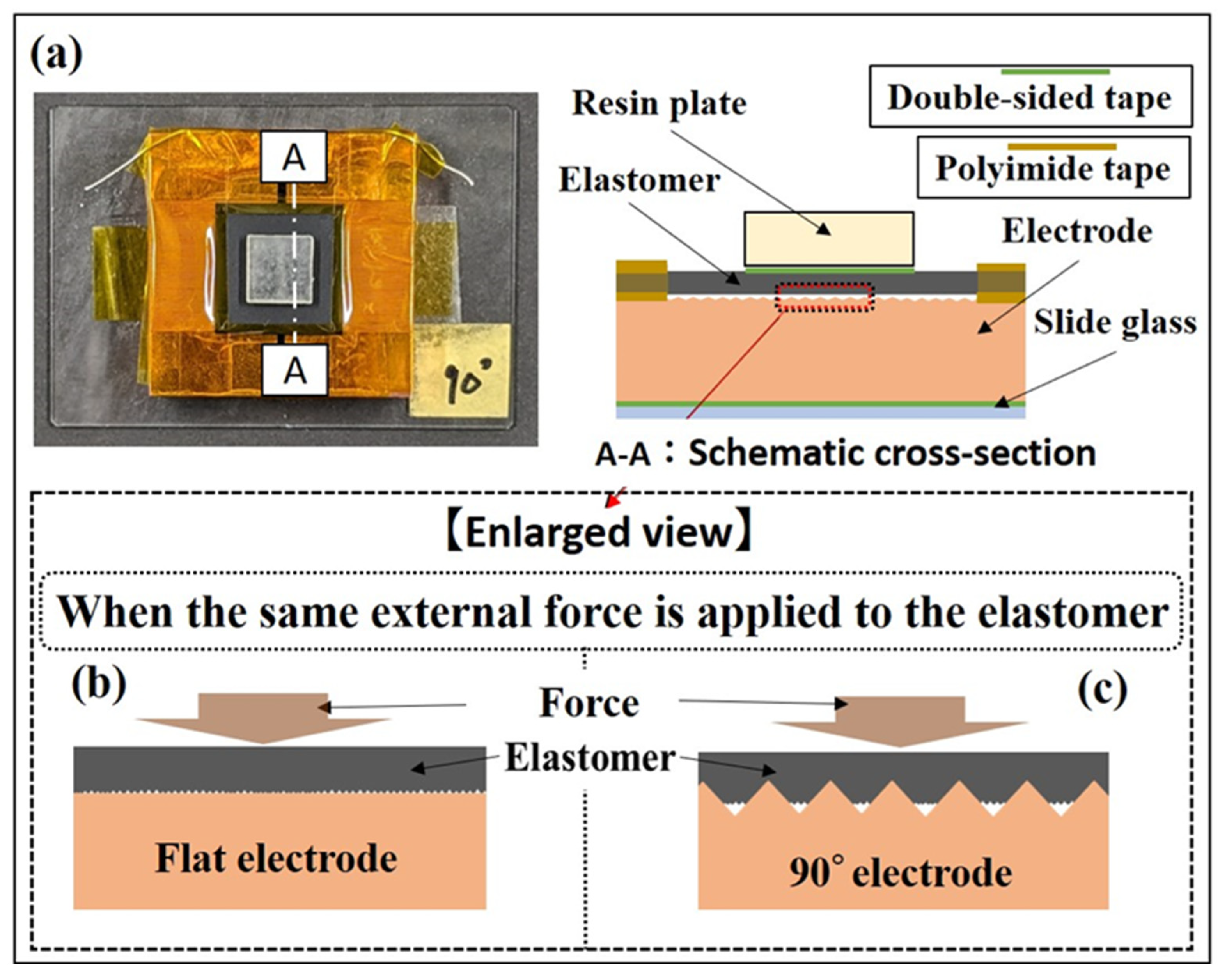

2. Materials and Methods

2.1. Material Selection

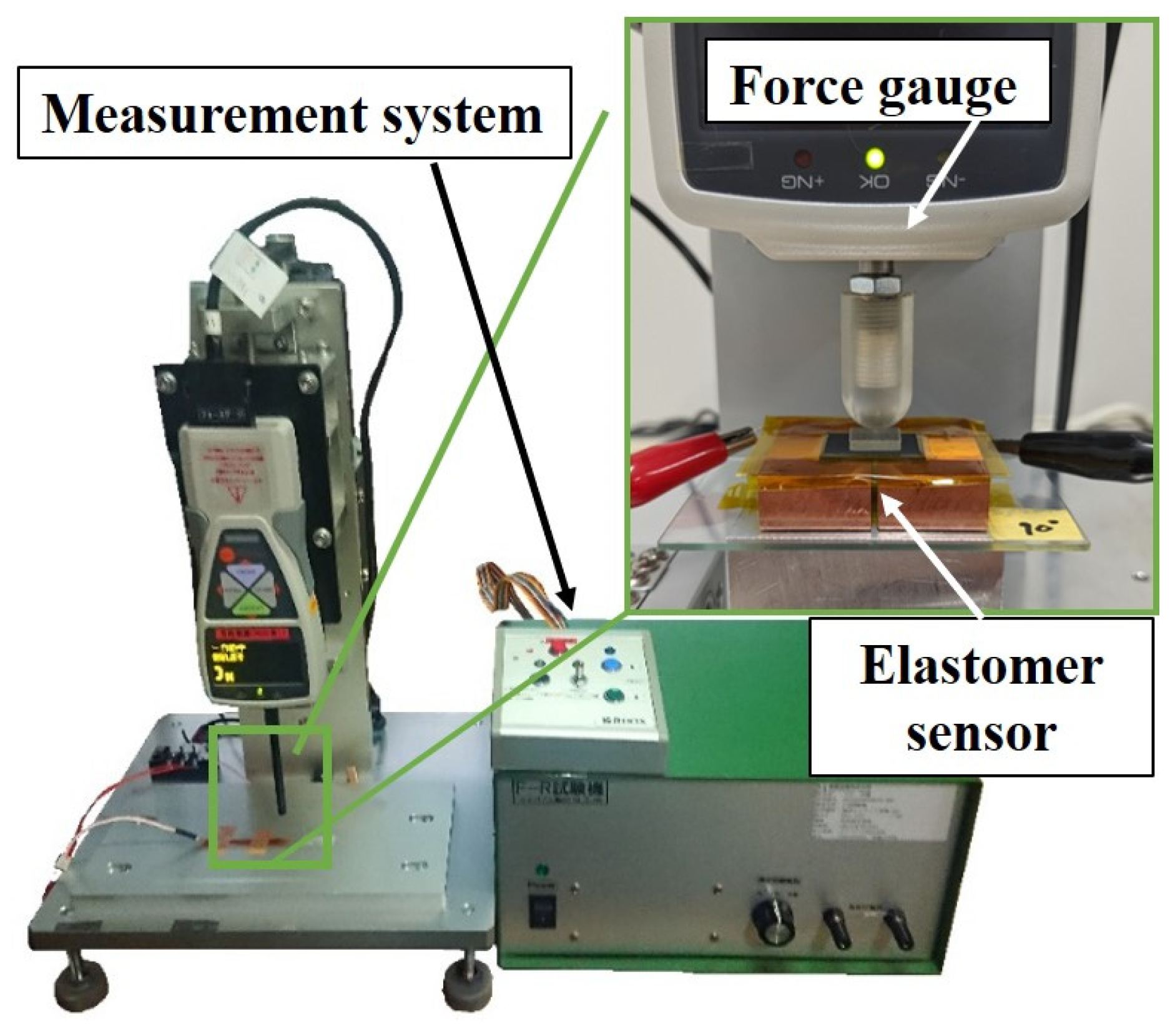

2.2. Acquisition Method of Quasi-Static Characteristics of Elastomer Sensors

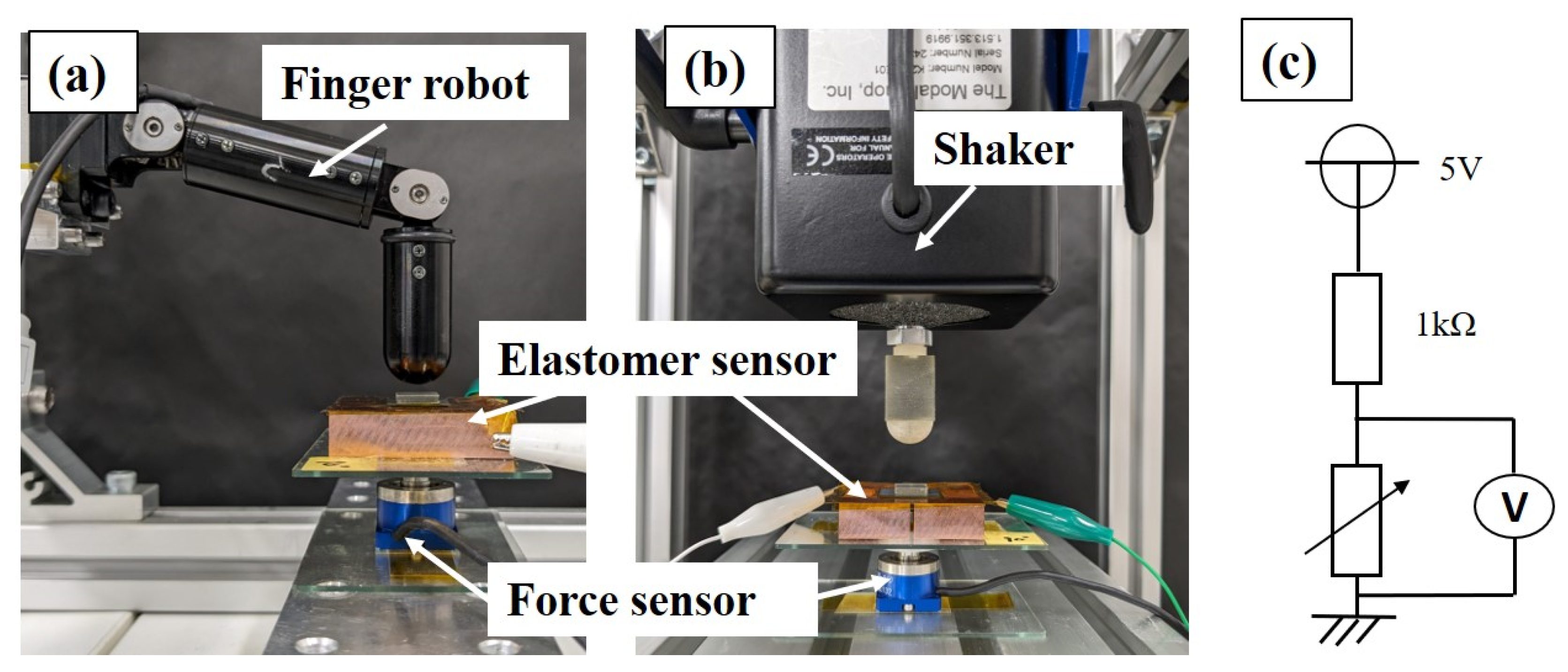

2.3. Acquisition Method of Dynamic Characteristics of Elastomer Sensors

3. Result

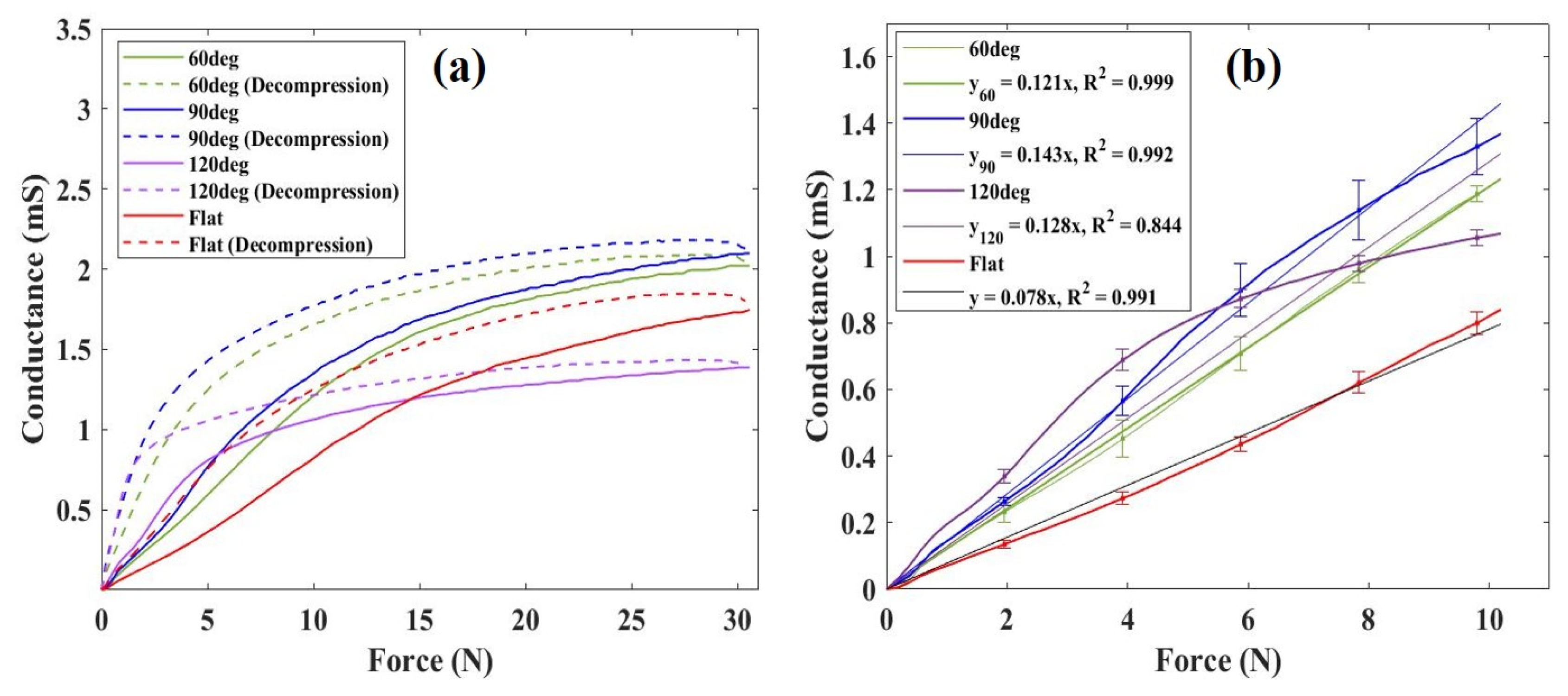

3.1. Quasi-Static Characteristics

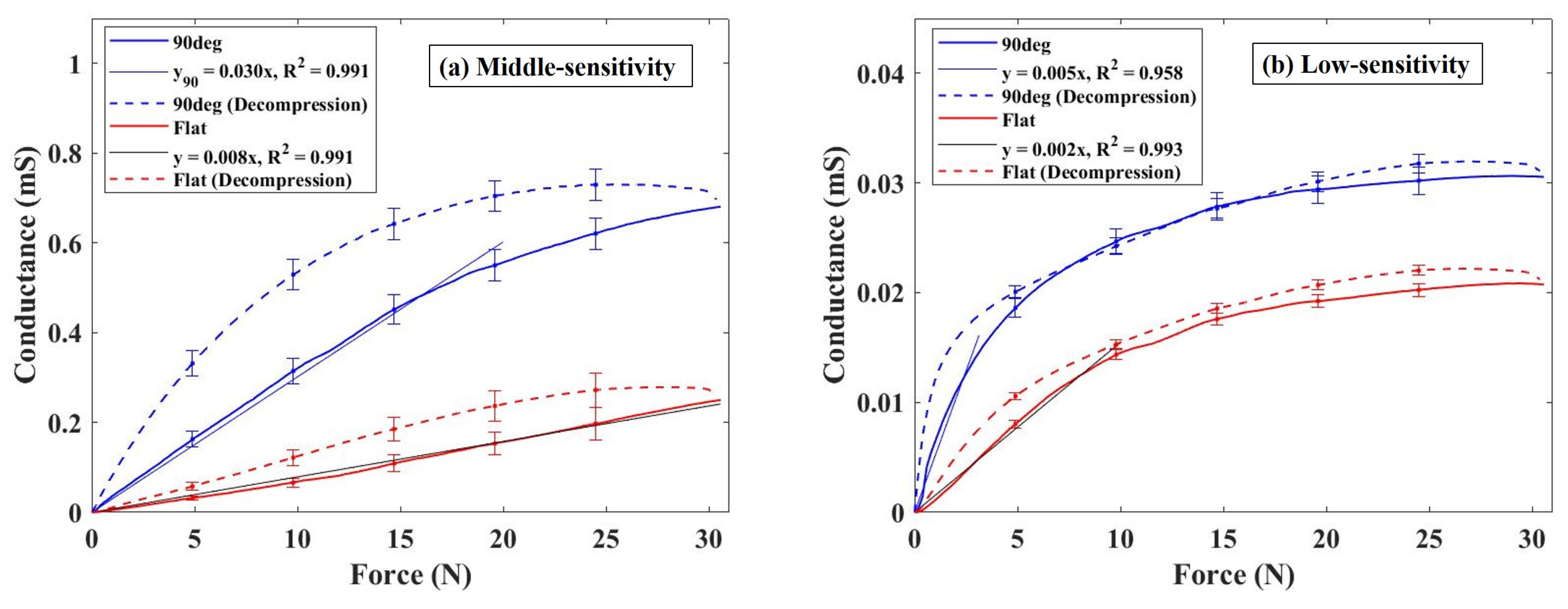

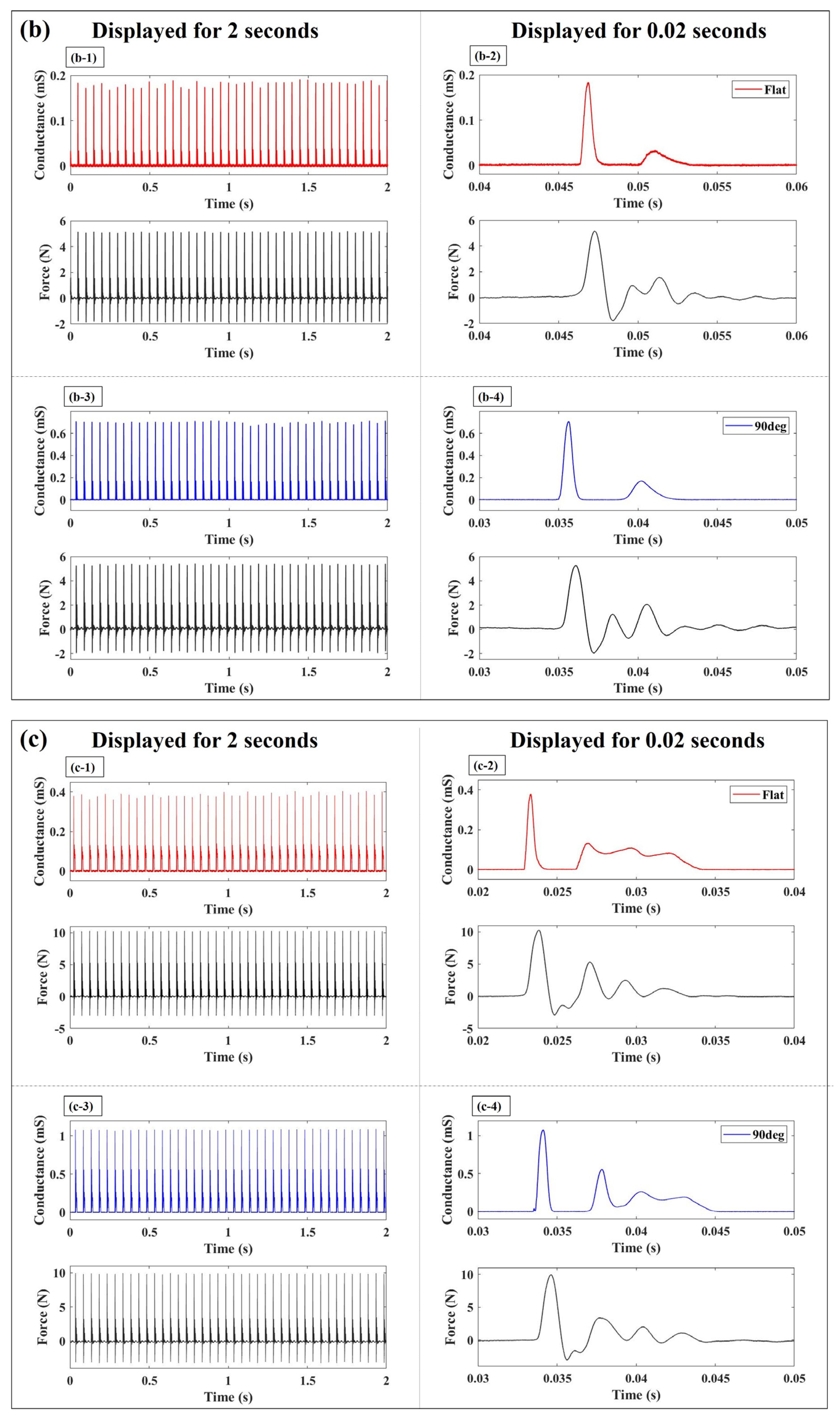

3.2. Comparison of Sensor Response Using Elastomers with Different Conductive Properties

3.3. Dynamic Characteristics

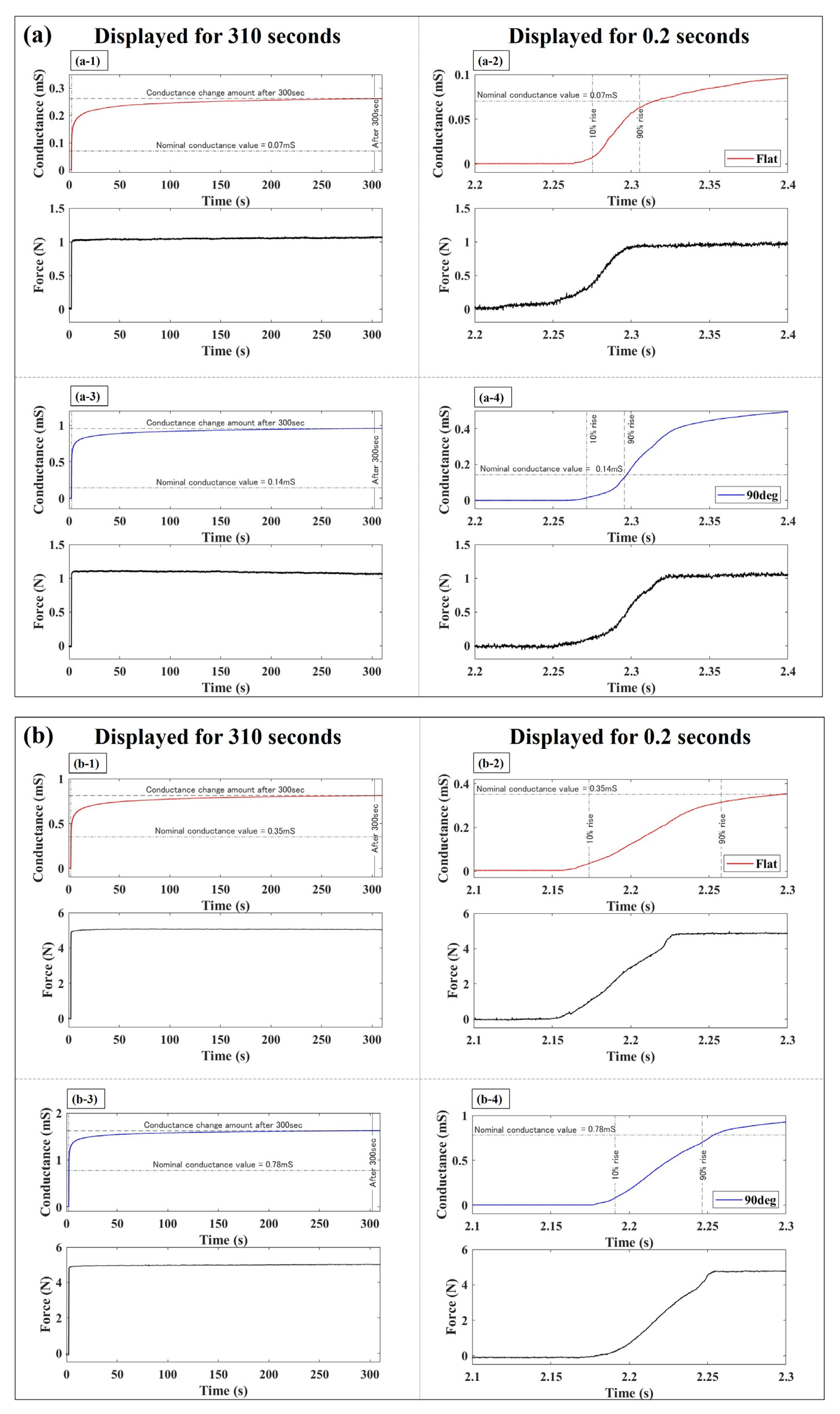

3.3.1. Sensor Response Evaluation by Step-like Inputs

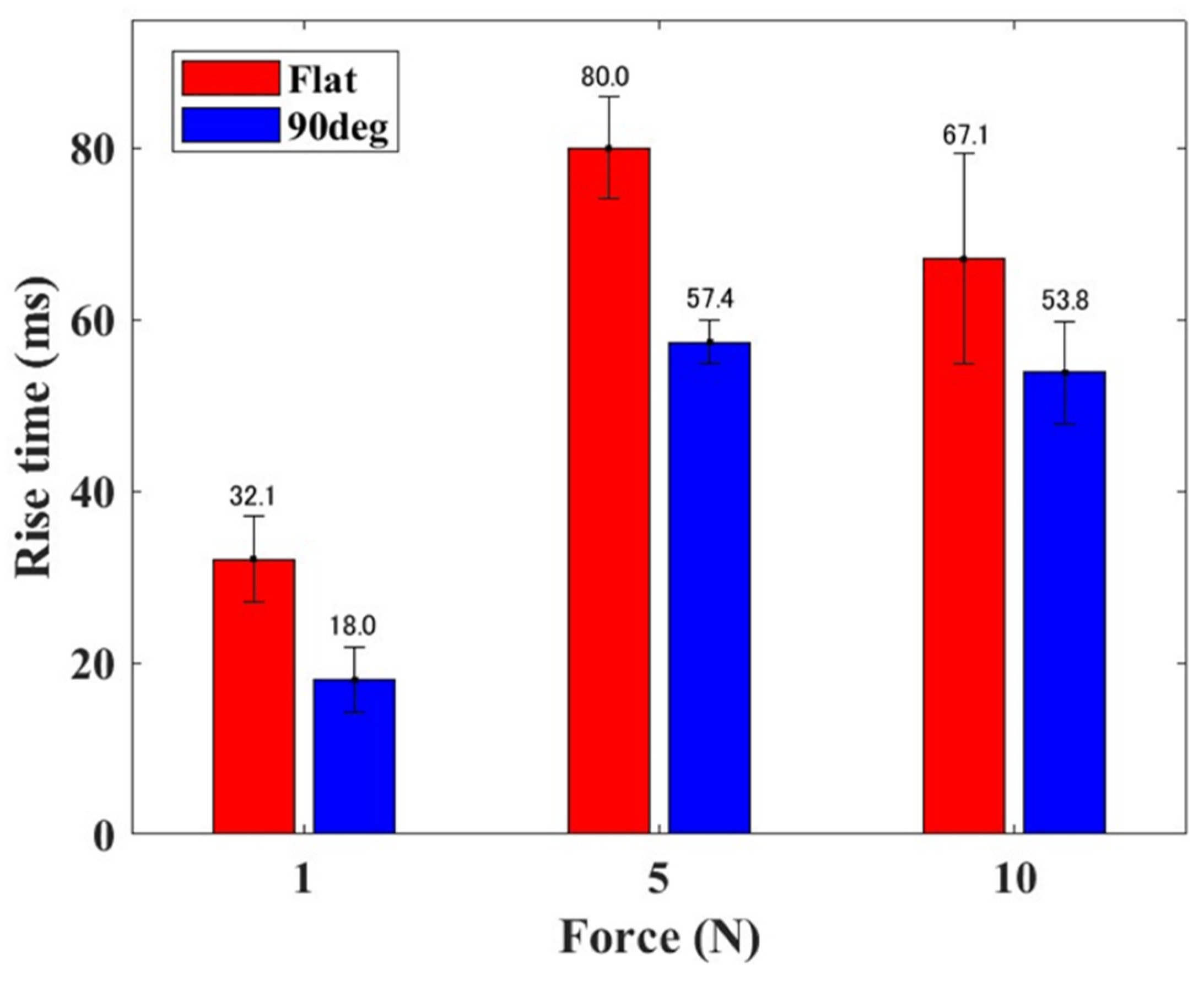

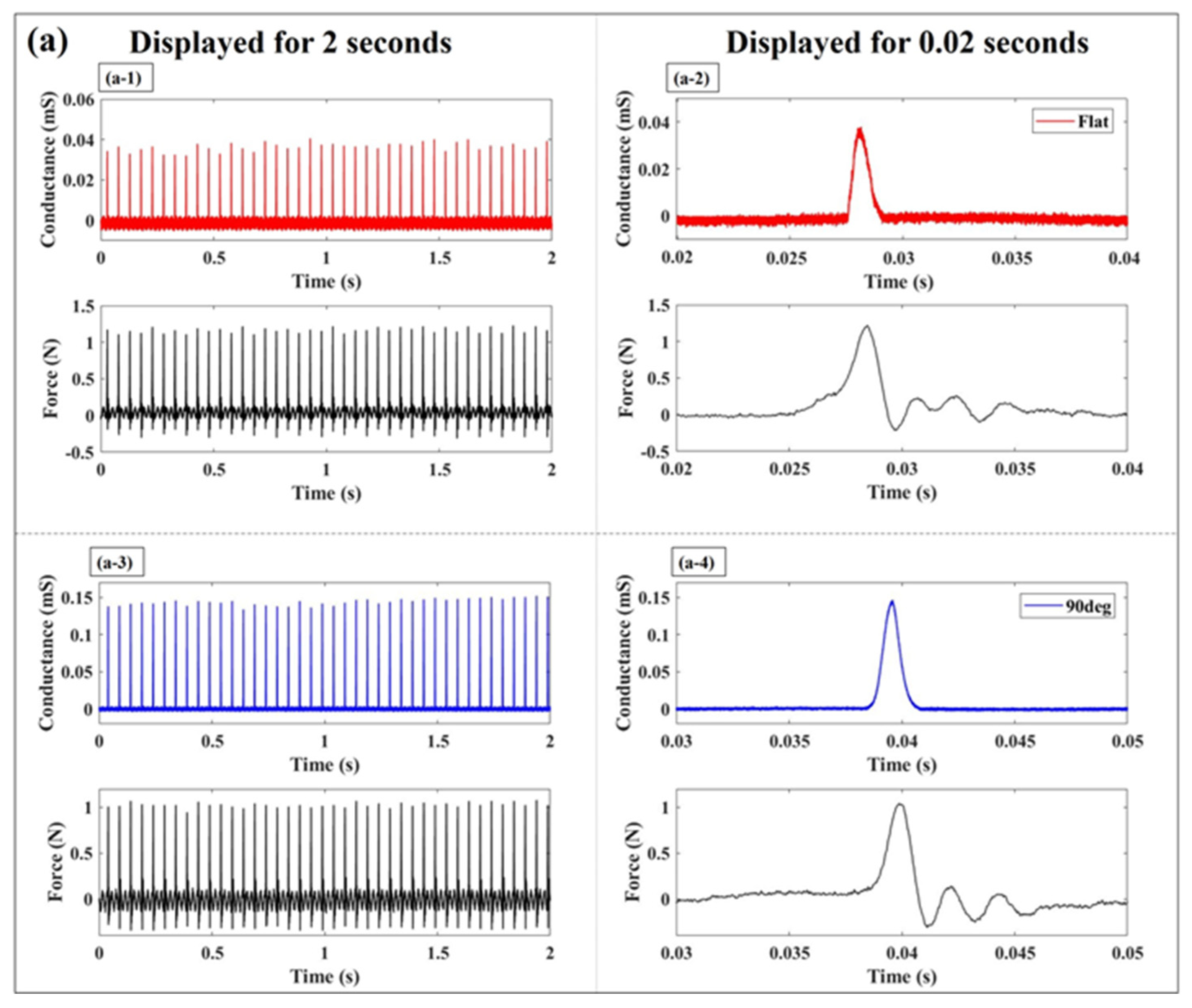

3.3.2. Sensor Response Evaluation by Periodic Impulse-like Inputs

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhan, F.; Chen, G.; Hickner, M.A.; Logan, B.E. Novel anti-flooding poly(dimethylsiloxane) (PDMS) catalyst binder for microbial fuel cell cathodes. J. Power Sources 2012, 218, 100–105. [Google Scholar] [CrossRef]

- Wang, W.; Xiang, C.; Zhu, Q.; Zhong, W.; Li, M.; Yan, K.; Wang, D. Multistimulus Responsive Actuator with GO and Carbon Nanotube/PDMS Bilayer Structure for Flexible and Smart Devices. ACS Appl. Mater. Interfaces 2018, 10, 27215–27223. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Wan, S.; Heng, Y.; Wang, S.; Yang, J.; Dong, Y.; Fu, Y.; Ni, Q. Double layered design for electromagnetic interference shielding with ultra-low reflection features: PDMS including carbon fibre on top and graphene on bottom. Compos. Sci. Technol. 2023, 231, 109797. [Google Scholar] [CrossRef]

- Liu, H.; Fu, R.; Su, X.; Wu, B.; Wang, H.; Xu, Y.; Liu, X. Electrical insulating MXene/PDMS/BN composite with enhanced thermal conductivity for electromagnetic shielding application. Compos. Commun. 2021, 23, 100593. [Google Scholar] [CrossRef]

- Nour, M.; Berean, K.; Griffin, M.J.; Matthews, G.I.; Bhaskaran, M.; Sriram, S.; Kalantar-Zadeh, K. Nanocomposite carbon-PDMS membranes for gas separation. Sens. Actuators B 2012, 161, 982–988. [Google Scholar] [CrossRef]

- Liu, H.; Sun, K.; Guo, X.L.; Liu, Z.L.; Wang, Y.H.; Yang, Y.; Yu, D.; Li, Y.T.; Ren, T.L. An Ultrahigh Linear Sensitive Temperature Sensor Based on PANI: Graphene and PDMS Hybrid with Negative Temperature Compensation. ACS Nano 2022, 16, 21527–21535. [Google Scholar] [CrossRef]

- Vafaiee, M.; Ejehi, F.; Mohammadpour, R. CNT-PDMS foams as self-powered humidity sensors based on triboelectric nanogenerators driven by finger tapping. Sci. Rep 2023, 13, 370. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Zhang, B.; Duan, J.; Guo, H.; Tang, J. Flexible pressure sensor with Ag wrinkled electrodes based on PDMS substrate. Sensors 2016, 16, 2131. [Google Scholar] [CrossRef] [PubMed]

- Kou, H.; Zhang, L.; Tan, Q.; Liu, G.; Lv, W.; Lu, F.; Dong, H.; Xiong, J. Wireless flexible pressure sensor based on micro-patterned Graphene/PDMS composite. Sens. Actuators A 2018, 277, 150–156. [Google Scholar] [CrossRef]

- Li, S.; Dong, K.; Li, R.; Huang, X.; Chen, T.; Xiao, X. Capacitive pressure sensor inlaid a porous dielectric layer of superelastic polydimethylsiloxane in conductive fabrics for detection of human motions. Sens. Actuators A 2020, 312, 112106. [Google Scholar] [CrossRef]

- Wang, F.; Tan, Y.; Peng, H.; Meng, F.; Yao, X. Investigations on the preparation and properties of high-sensitive BaTiO3/MwCNTs/PDMS flexible capacitive pressure sensor. Mater. Lett 2021, 303, 130512. [Google Scholar] [CrossRef]

- Hwang, J.; Kim, Y.; Yang, H.; Oh, J.H. Fabrication of hierarchically porous structured PDMS composites and their application as a flexible capacitive pressure sensor. Compos. B 2021, 211, 108607. [Google Scholar] [CrossRef]

- Yin, M.J.; Yin, Z.; Zhang, Y.; Zheng, Q.; Zhang, A.P. Micropatterned elastic ionic polyacrylamide hydrogel for low-voltage capacitive and organic thin-film transistor pressure sensors. Nano Energy 2019, 58, 96–104. [Google Scholar] [CrossRef]

- Zhang, K.; Shi, X.; Chen, J.; Xiong, T.; Jiang, B.; Huang, Y. Self-healing and stretchable PDMS-based bifunctional sensor enabled by synergistic dynamic interactions. Chem. Eng. J. 2021, 412, 128734. [Google Scholar] [CrossRef]

- Zheng, Q.; Jia, C.; Sun, F.; Zhang, M.; Wen, Y.; Xie, Z.; Wang, J.; Liu, B.; Mao, Y.; Zhao, C. Ecoflex Flexible Array of Triboelectric Nanogenerators for Gait Monitoring Alarm Warning Applications. Electronics 2023, 12, 3226. [Google Scholar] [CrossRef]

- Schmitz, A.; Bansho, Y.; Noda, K.; Iwata, H.; Ogata, T.; Sugano, S. Tactile object recognition using deep learning and dropout. In Proceedings of the 2014 IEEE-RAS International Conference on Humanoid Robots, Madrid, Spain, 18–20 November 2014; pp. 1044–1050. [Google Scholar] [CrossRef]

- Yuan, W.; Zhu, C.; Owens, A.; Srinivasan, M.A.; Adelson, E.H. Shape-independent hardness estimation using deep learning and a GelSight tactile sensor. arXiv 2017, arXiv:1704.03955. [Google Scholar] [CrossRef]

- Gao, Z.; Ren, B.; Fang, Z.; Kang, H.; Han, J.; Li, J. Accurate recognition of object contour based on flexible piezoelectric and piezoresistive dual mode strain sensors. Sens. Actuators A 2021, 322, 113121. [Google Scholar] [CrossRef]

- Tsuji, S.; Kohama, T. Using a convolutional neural network to construct a pen-type tactile sensor system for roughness recognition. Sens. Actuators A 2019, 219, 7–12. [Google Scholar] [CrossRef]

- Keser, S.; Hayber, Ş.E. Fiber optic tactile sensor for surface roughness recognition by machine learning algorithms. Sens. Actuators A 2021, 332, 113071. [Google Scholar] [CrossRef]

- Drimus, A.; Kootstra, G.; Bilberg, A.; Kragic, D. Design of a flexible tactile sensor for classification of rigid and deformable objects. Robot. Auton. Syst. 2014, 62, 3–15. [Google Scholar] [CrossRef]

- Pohtongkam, S.; Srinonchat, J. Tactile object recognition for humanoid robots using new designed piezoresistive tactile sensor and DCNN. Sensors 2021, 21, 6024. [Google Scholar] [CrossRef] [PubMed]

- Teshigawara, S.; Tsutsumi, T.; Suzuki, Y.; Shimojo, M. High speed and high sensitivity slip sensor for dexterous grasp-ing. J. Robot. Mechatron. 2012, 24, 298–310. [Google Scholar] [CrossRef]

- Frenkel, J. On the electrical resistance of contacts between solid conductors. Phys. Rev. 1930, 36, 1604–1618. [Google Scholar] [CrossRef]

- Canavese, G.; Stassi, S.; Fallauto, C.; Corbellini, S.; Cauda, V.; Camarchia, V.; Pirola, M.; Pirri, C.F. Piezoresistive flexible composite for robotic tactile applications. Sens. Actuators A 2014, 208, 1–9. [Google Scholar] [CrossRef]

- Lantada, A.D.; Lafont, P.; Sanz, J.L.M.; Munoz-Guijosa, J.M.; Otero, J.E. Quantum tunnelling composites: Characterisation and modelling to promote their applications as sensors. Sens. Actuators A 2010, 164, 46–57. [Google Scholar] [CrossRef]

- Qin, R.; Li, X.; Hu, M.; Shan, G.; Seeram, R.; Yin, M. Preparation of high-performance MXene/PVA-based flexible pressure sensors with adjustable sensitivity and sensing range. Sens. Actuators A 2022, 338, 113458. [Google Scholar] [CrossRef]

- Wang, L.; Ding, T.; Wang, P. Effects of conductive phase content on critical pressure of carbon black filled silicone rubber composite. Sens. Actuators A 2007, 135, 587–592. [Google Scholar] [CrossRef]

- Wang, L.; Xu, C.; Li, Y. Piezoresistive response to changes in contributive tunneling film network of carbon nanotube/silicone rubber composite under multi-load/unload. Sens. Actuators A 2013, 189, 45–54. [Google Scholar] [CrossRef]

- Hu, S.; Xiang, Y.; Sun, Z.; Fu, X.; Liu, Q.; Lou, D.; Hu, T.; Ping Wong, C.P.; Zhang, R. Highly flexible composite with improved Strain-Sensing performance by adjusting the filler network morphology through a soft magnetic elastomer. Compos. A 2022, 163, 107188. [Google Scholar] [CrossRef]

- Hussain, M.; Choa, Y.H.; Niihara, K. Fabrication process and electrical behavior of novel pressure-sensitive composites. Compos. A 2001, 32, 1689–1696. [Google Scholar] [CrossRef]

- Bloor, D.; Graham, A.; Williams, E.J.; Laughlin, P.J.; Lussey, D. Metal-polymer composite with nanostructured filler particles and amplified physical properties. Appl. Phys. Lett. 2006, 88, 102103. [Google Scholar] [CrossRef]

- Li, R.; Gou, X.; Zhou, M.; Yang, A.P.; Li, P.; Shou, M.; Liao, C.; Wang, X. Modeling and validation of multifield coupled self-sensing characteristics of magnetorheological elastomer for vibration isolators. Mater. Des. 2022, 217, 110636. [Google Scholar] [CrossRef]

- Fujihara, T.; Cho, H.B.; Kanno, M.; Nakayama, T.; Suzuki, T.; Jiang, W.; Suematsu, H.; Niihara, K. Three-dimensional structural control and analysis of hexagonal boron nitride nanosheets assembly in nanocomposite films induced by electric field concentration. Jpn. J. Appl. Phys. 2014, 53, 02BD12. [Google Scholar] [CrossRef]

- Park, J.; Lee, Y.; Hong, J.; Ha, M.; Do Jung, Y.; Lim, H.; Kim, S.Y.; Ko, H. Giant tunneling piezoresistance of composite elastomers with interlocked microdome arrays for ultrasensitive and multimodal electronic skins. ACS Nano 2014, 8, 4689–4697. [Google Scholar] [CrossRef]

- Jung, Y.; Jung, K.K.; Kim, D.H.; Kwak, D.H.; Ahn, S.; Han, J.S.; Ko, J.S. Flexible and highly sensitive three-axis pressure sensors based on carbon nanotube/polydimethylsiloxane composite pyramid arrays. Sens. Actuators A 2021, 331, 113034. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, Y.; Zhu, P.; Han, F.; Zhu, Y.; Sun, R.; Wong, C.P. Flexible and Highly Sensitive Pressure Sensor Based on Microdome-Patterned PDMS Forming with Assistance of Colloid Self-Assembly and Replica Technique for Wearable Electronics. ACS Appl. Mater. Interfaces 2017, 9, 35968–35976. [Google Scholar] [CrossRef] [PubMed]

- Pan, L.; Chortos, A.; Yu, G.; Wang, Y.; Isaacson, S.; Allen, R.; Shi, Y.; Dauskardt, R.; Bao, Z. An ultra-sensitive resistive pressure sensor based on hollow-sphere microstructure induced elasticity in conducting polymer film. Nat. Commun. 2014, 5, 3002. [Google Scholar] [CrossRef] [PubMed]

- Ji, B.; Mao, Y.; Zhou, Q.; Zhou, J.; Chen, G.; Gao, Y.; Tian, Y.; Wen, W.; Zhou, B. Facile Preparation of Hybrid Structure Based on Mesodome and Micropillar Arrays as Flexible Electronic Skin with Tunable Sensitivity and Detection Range. ACS Appl. Mater. Interfaces 2019, 11, 28060–28071. [Google Scholar] [CrossRef] [PubMed]

- Katagiri, T.; Ngo, N.C.T.; Togawa, Y.; Kodama, S.; Kawahara, K.; Umemoto, K.; Miyoshi, T.; Nakayama, T. Investigation of Contact Surface Changes and Sensor Response of a Pressure-Sensitive Conductive Elastomer. Electronics 2023, 12, 4532. [Google Scholar] [CrossRef]

- Abaddi, M.A.; Sasso, L.; Dimaki, M.; Svendsen, W.E. Fabrication of 3D nano/microelectrodes via two-photon-polymerization. Microelectron. Eng. 2012, 98, 378–381. [Google Scholar] [CrossRef]

- Brown, M.A.; Zappitelli, K.M.; Singh, L.; Yuan, R.C.; Bemrose, M.; Brogden, V.; Miller, D.J.; Smear, M.C.; Cogan, S.F.; Gardner, T.J. Direct laser writing of 3D electrodes on flexible substrates. Nat. Commun. 2023, 14, 3610. [Google Scholar] [CrossRef] [PubMed]

- Beidaghi, M.; Chen, W.; Wang, C. Electrochemically activated carbon micro-electrode arrays for electrochemical micro-capacitors. J. Power Sources 2011, 196, 2403–2409. [Google Scholar] [CrossRef]

| Flat Electrode | 90° Electrode | ||||||

|---|---|---|---|---|---|---|---|

| Force (N) | Nominal conductance value (mS) | Peak conductance at impulse-like inputs (mS) | Peak conductance ratio (%) | Nominal conductance value (mS) | Peak conductance at impulse-like inputs (mS) | Peak conductance ratio (%) | Magnification |

| 1 | 0.07 | 0.04 | 57 | 0.14 | 0.15 | 107 | 3.75 |

| 5 | 0.35 | 0.183 | 52 | 0.78 | 0.71 | 91 | 3.88 |

| 10 | 0.84 | 0.38 | 45 | 1.36 | 1.08 | 79 | 2.84 |

| Characteristic | Comparison Contents | Main Results |

|---|---|---|

| Quasi-static | Effects of differences in electrode surface shape on conductance | In the pressure-sensitive range up to 30 N, higher conductance was obtained with the 60° electrode and the 90° electrode compared to the flat electrode. |

| Sensitivity up to 10 N when pressurized | Compared to the flat electrode, the sensitivity improved the most with the 90° electrode, increasing by 1.83 times. | |

| Variability of sensor response | Compared to the flat electrode, the standard deviation of the sensor response increased with the 90° electrode. | |

| Adaptability of the 90° electrode to elastomers with different conductive properties | For all of the elastomers with different conductive properties used in this experiment, higher conductance was obtained up to 30 N when using the 90° electrode compared to the flat electrode. | |

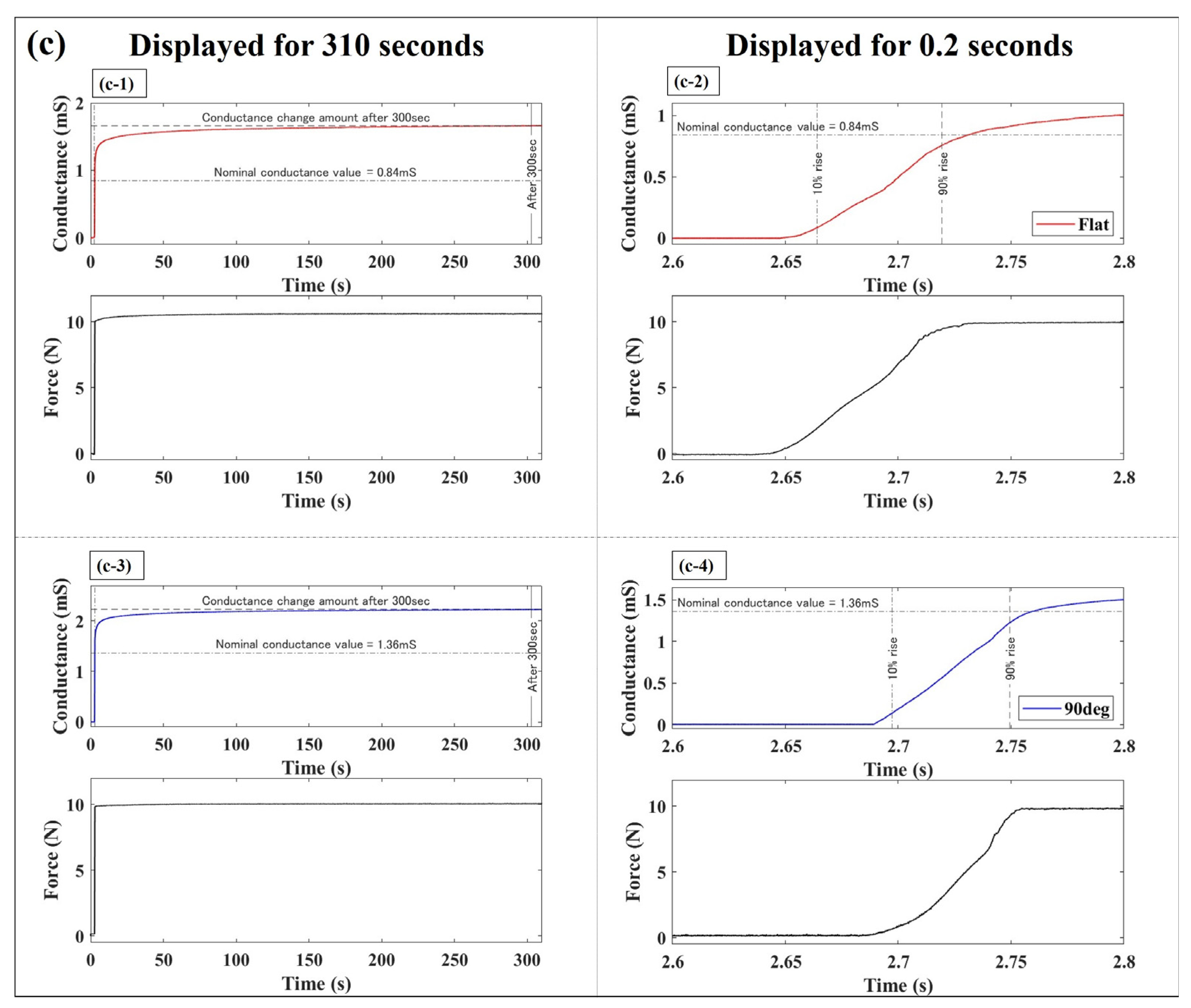

| Dynamic | Conductance creep amount | Compared to the flat electrode, the 90° electrode increased conductance creep amount. |

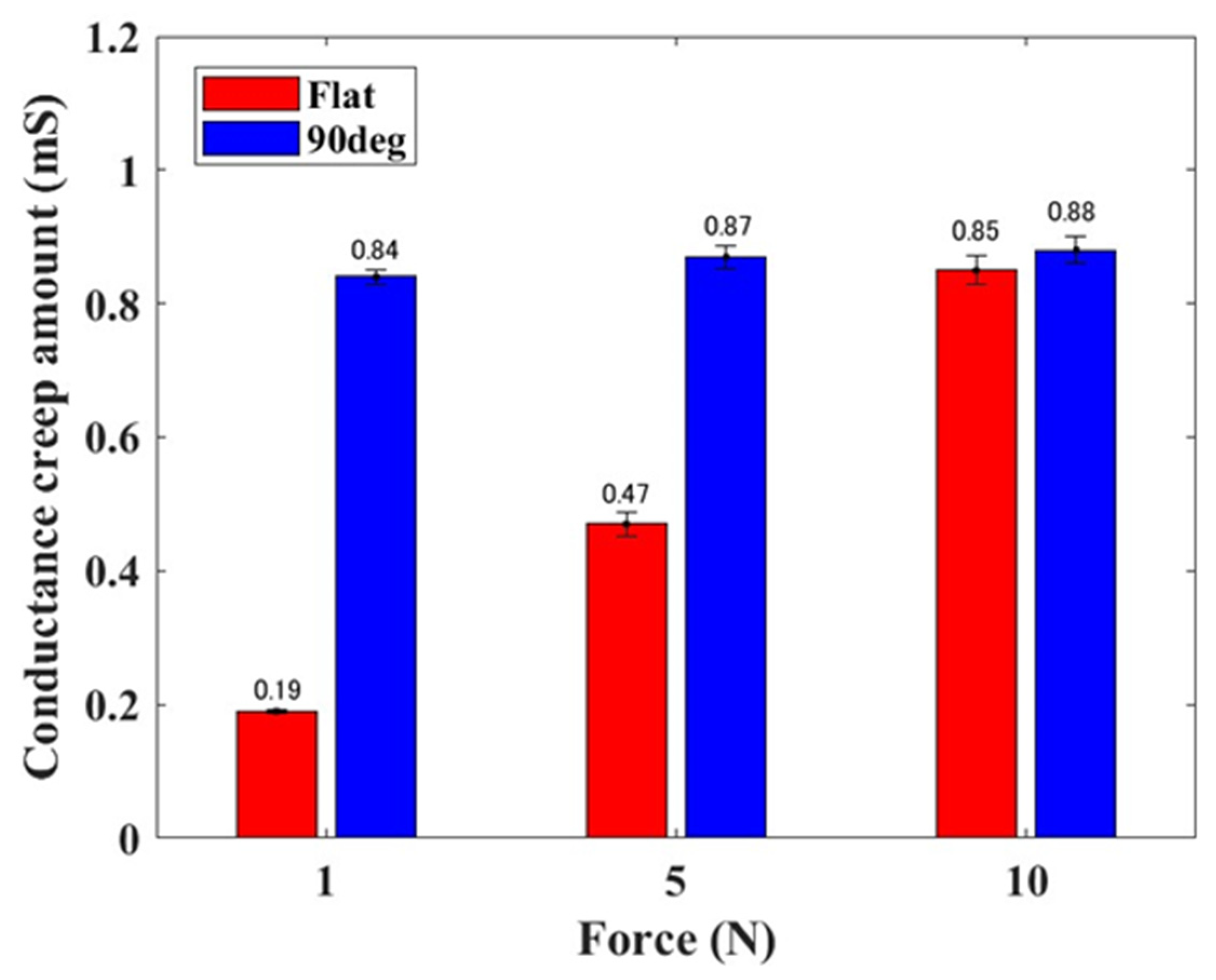

| Rise time | Compared to the flat electrode, the 90° electrode shortened the rise time. | |

| Peak conductance by impulse-like input | Compared to the flat electrode, the 90° electrode achieved conductance more than 2.84 times higher. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Katagiri, T.; Kodama, S.; Kawahara, K.; Umemoto, K.; Miyoshi, T.; Nakayama, T. Response Characteristics of Pressure-Sensitive Conductive Elastomer Sensors Using OFC Electrode with Triangular Wave Concavo-Convex Surfaces. Sensors 2024, 24, 2349. https://doi.org/10.3390/s24072349

Katagiri T, Kodama S, Kawahara K, Umemoto K, Miyoshi T, Nakayama T. Response Characteristics of Pressure-Sensitive Conductive Elastomer Sensors Using OFC Electrode with Triangular Wave Concavo-Convex Surfaces. Sensors. 2024; 24(7):2349. https://doi.org/10.3390/s24072349

Chicago/Turabian StyleKatagiri, Takeru, Sogo Kodama, Kotaro Kawahara, Kazuki Umemoto, Takanori Miyoshi, and Tadachika Nakayama. 2024. "Response Characteristics of Pressure-Sensitive Conductive Elastomer Sensors Using OFC Electrode with Triangular Wave Concavo-Convex Surfaces" Sensors 24, no. 7: 2349. https://doi.org/10.3390/s24072349