Easy-to-Use MOX-Based VOC Sensors for Efficient Indoor Air Quality Monitoring

Abstract

:1. Introduction

2. Related Works

3. Materials and Methods

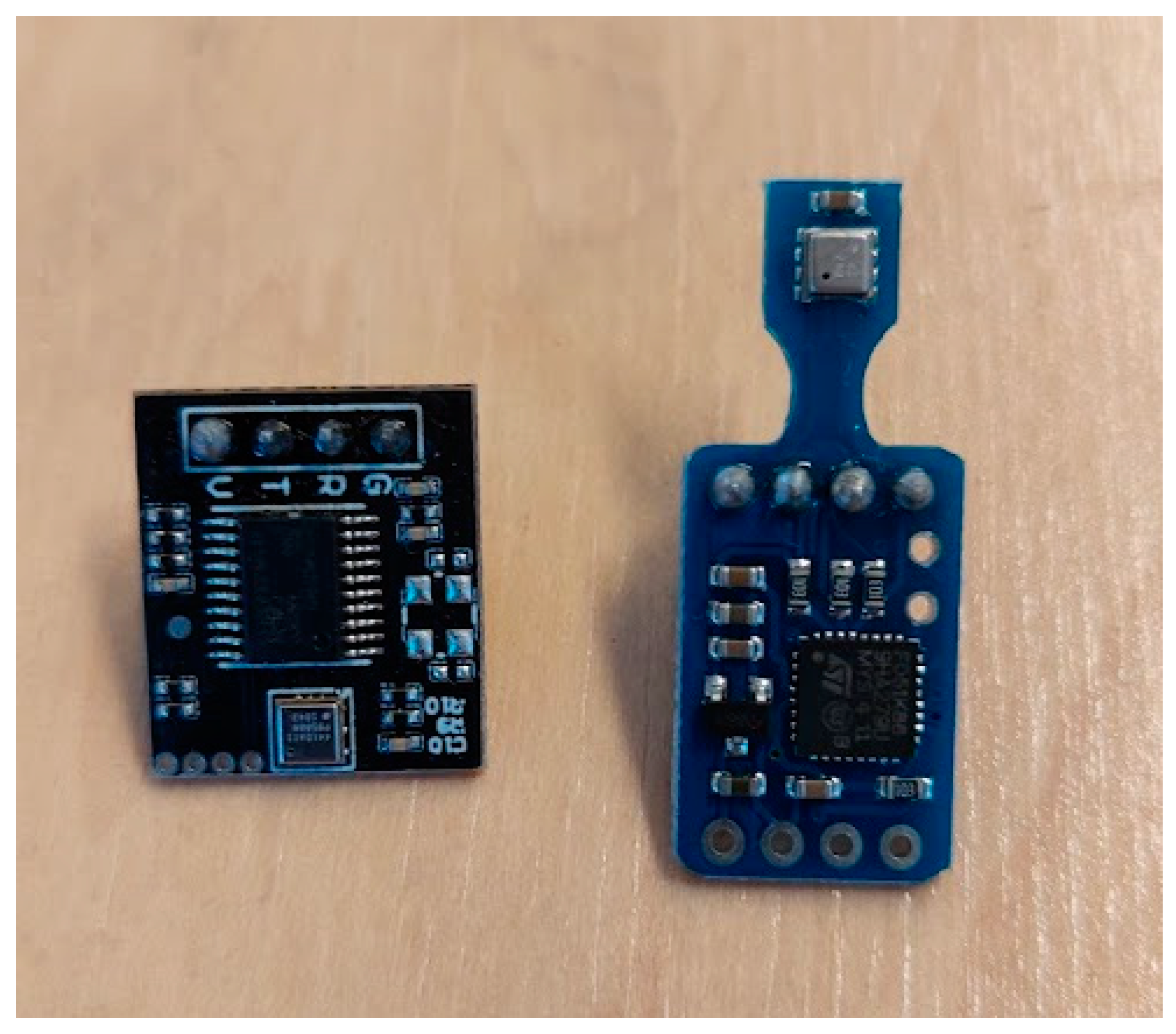

3.1. Sensors

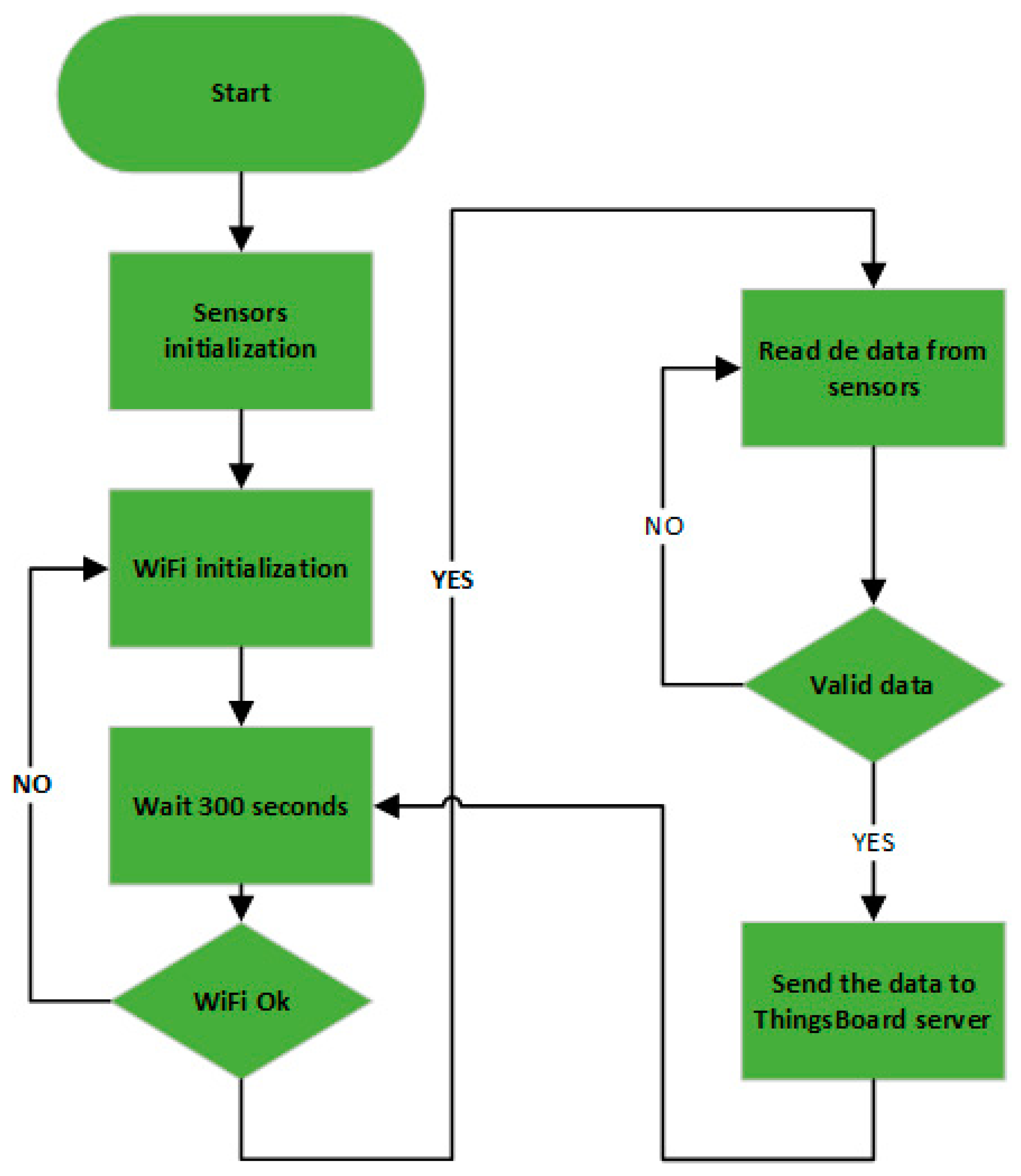

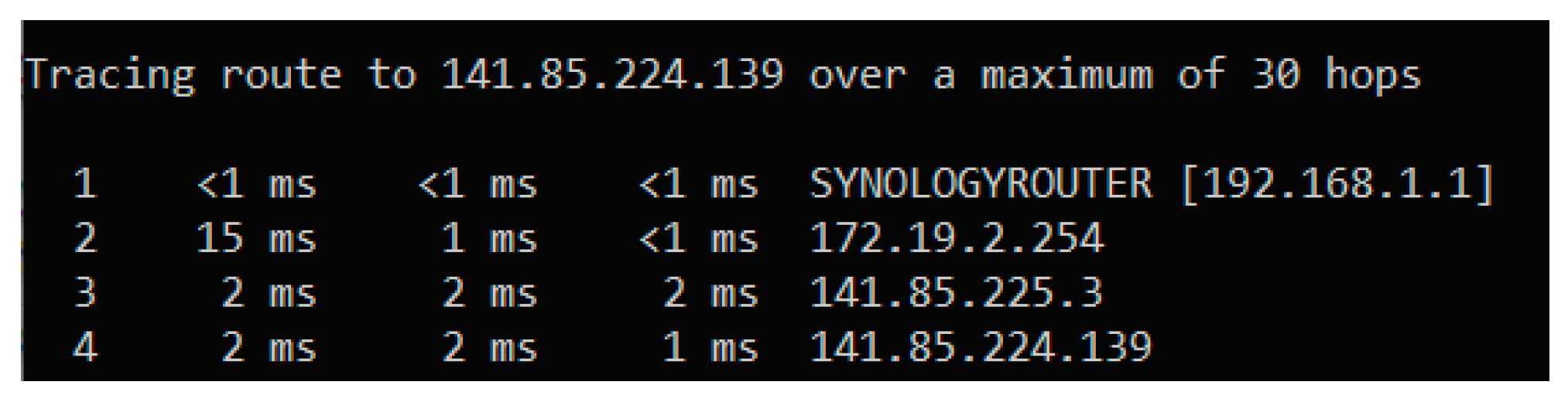

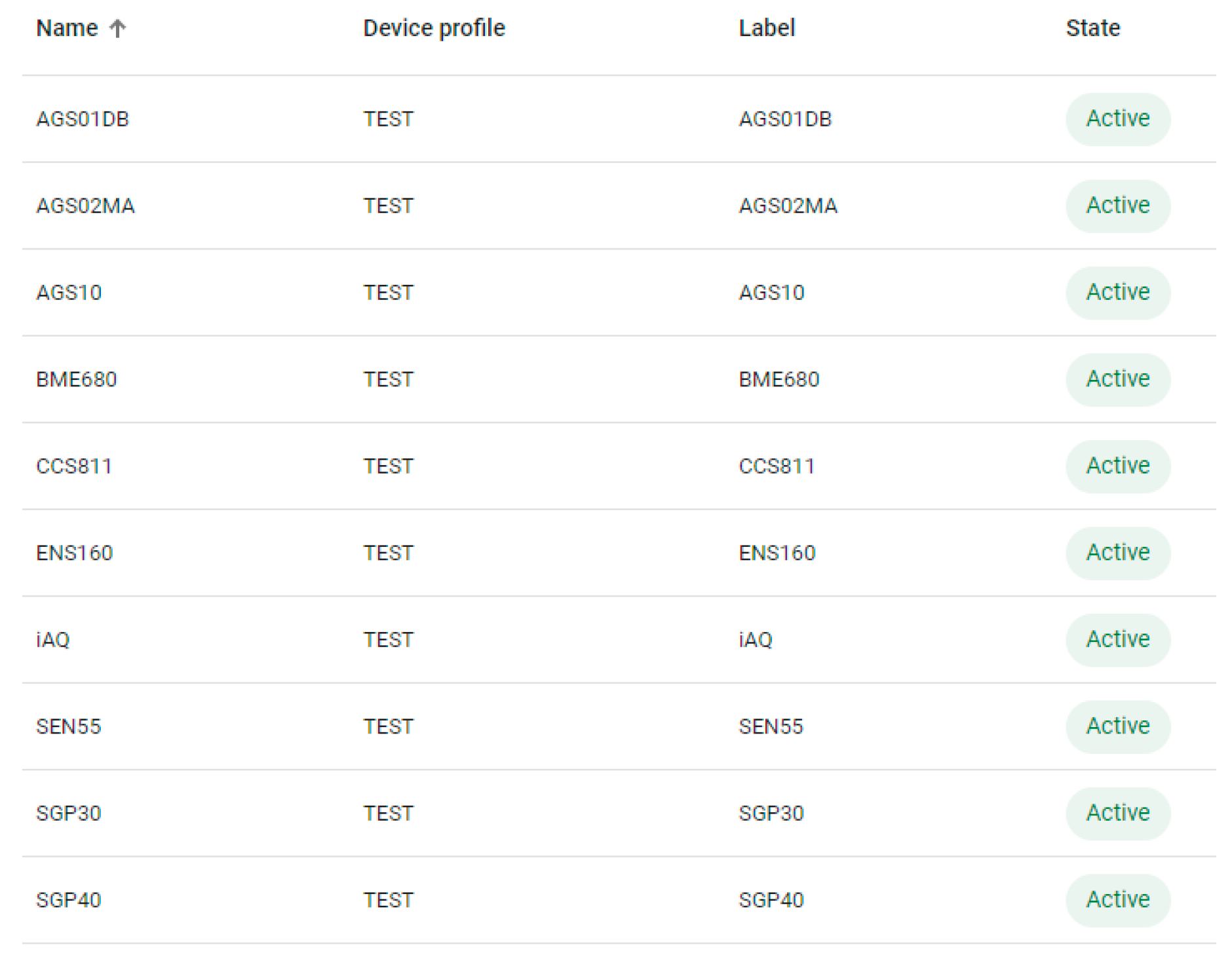

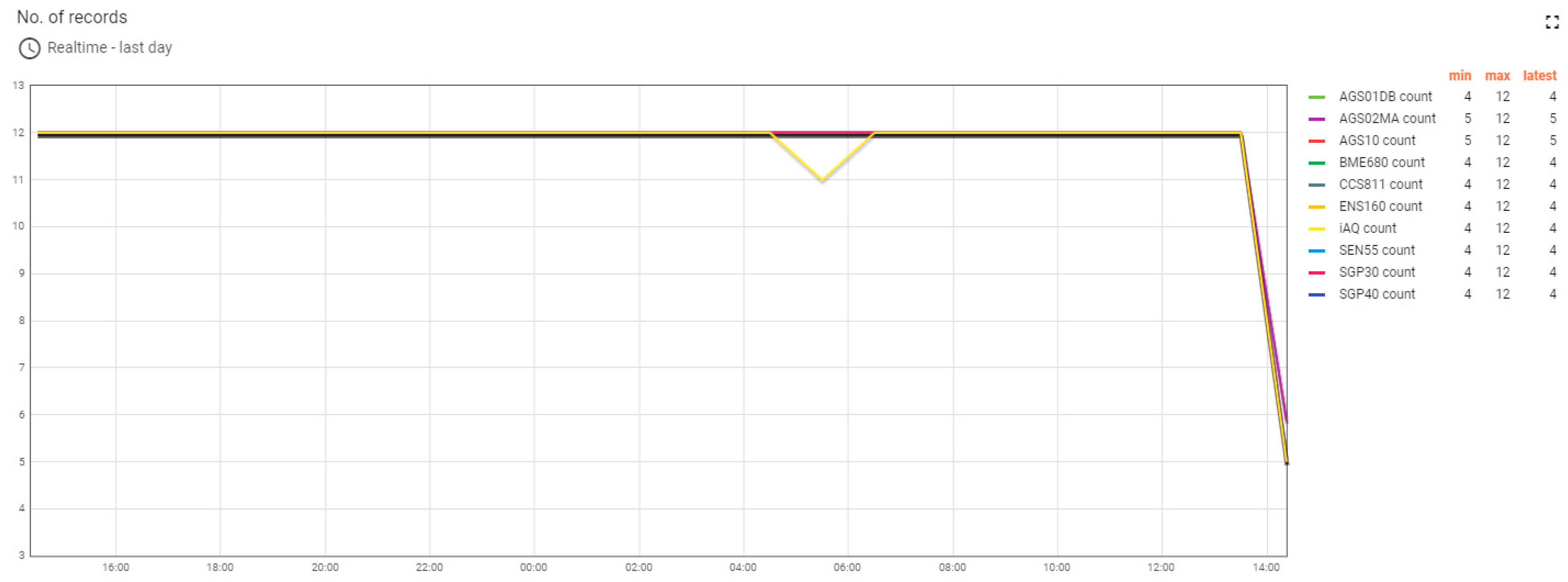

3.2. The Test Environment

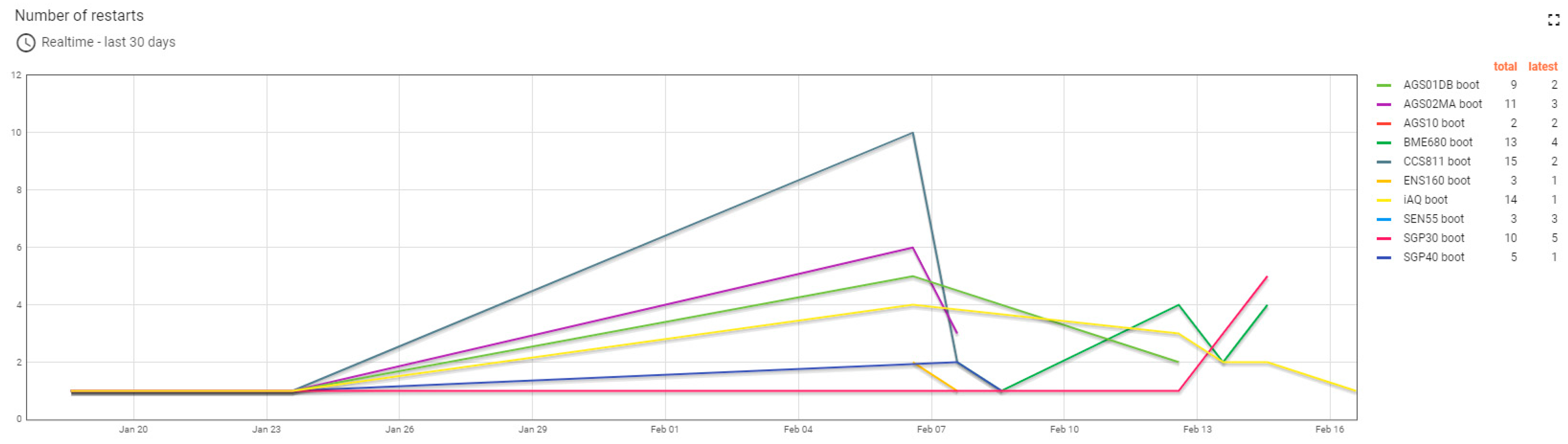

3.3. Tests

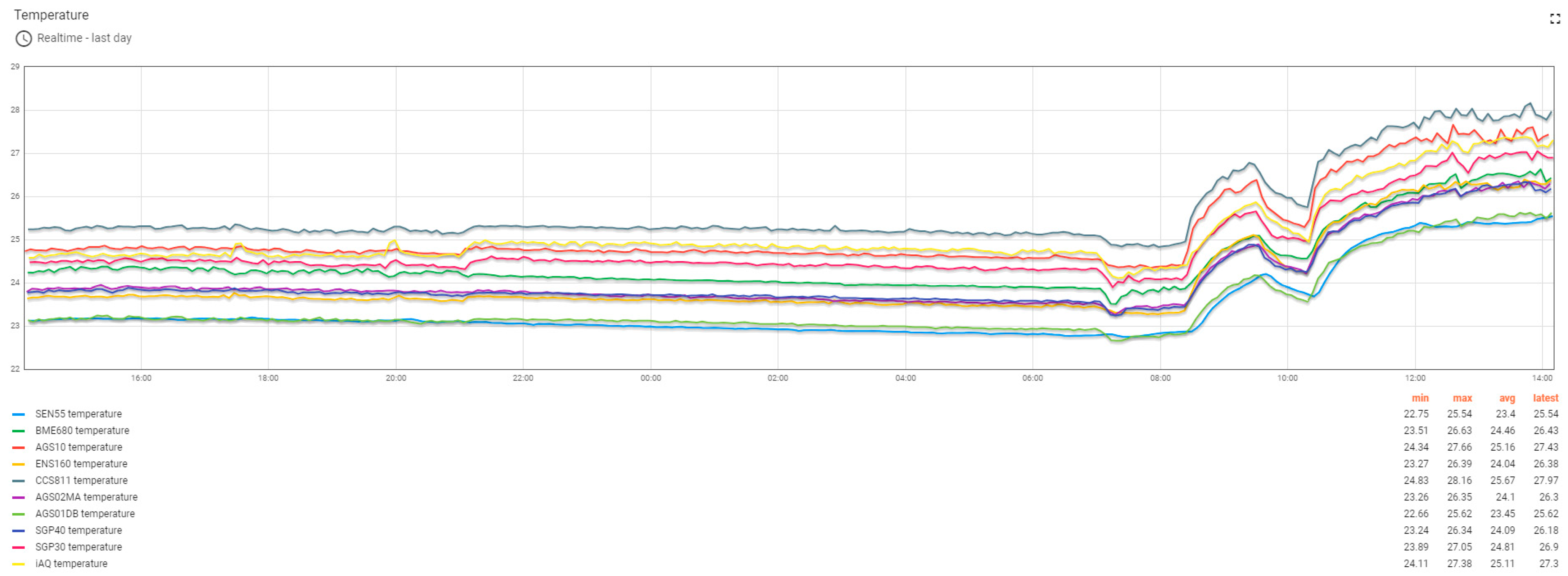

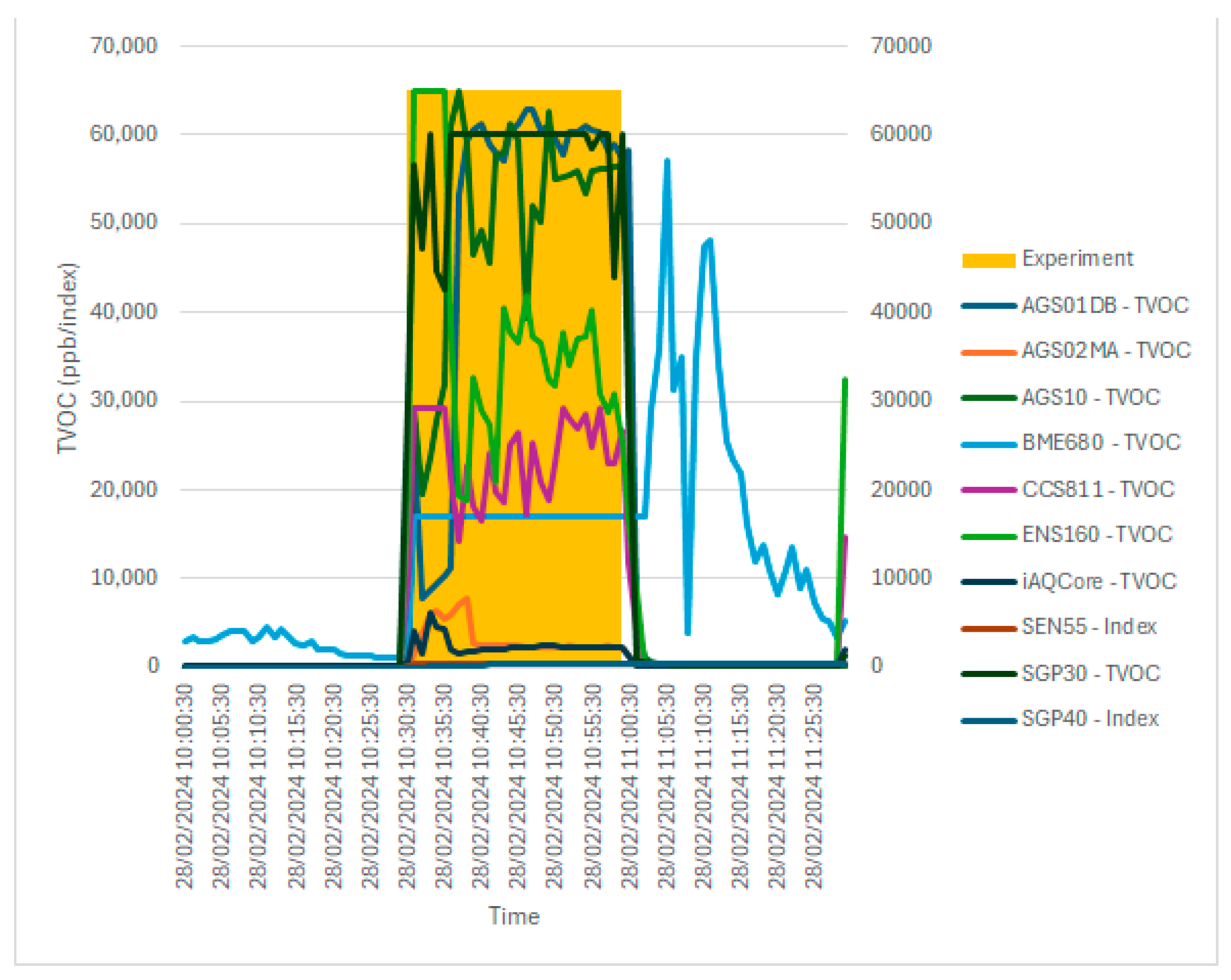

4. Results and Discussion

4.1. Statistical Analysis of Recorded Data

4.2. Correlation Analysis between Recorded Time Series

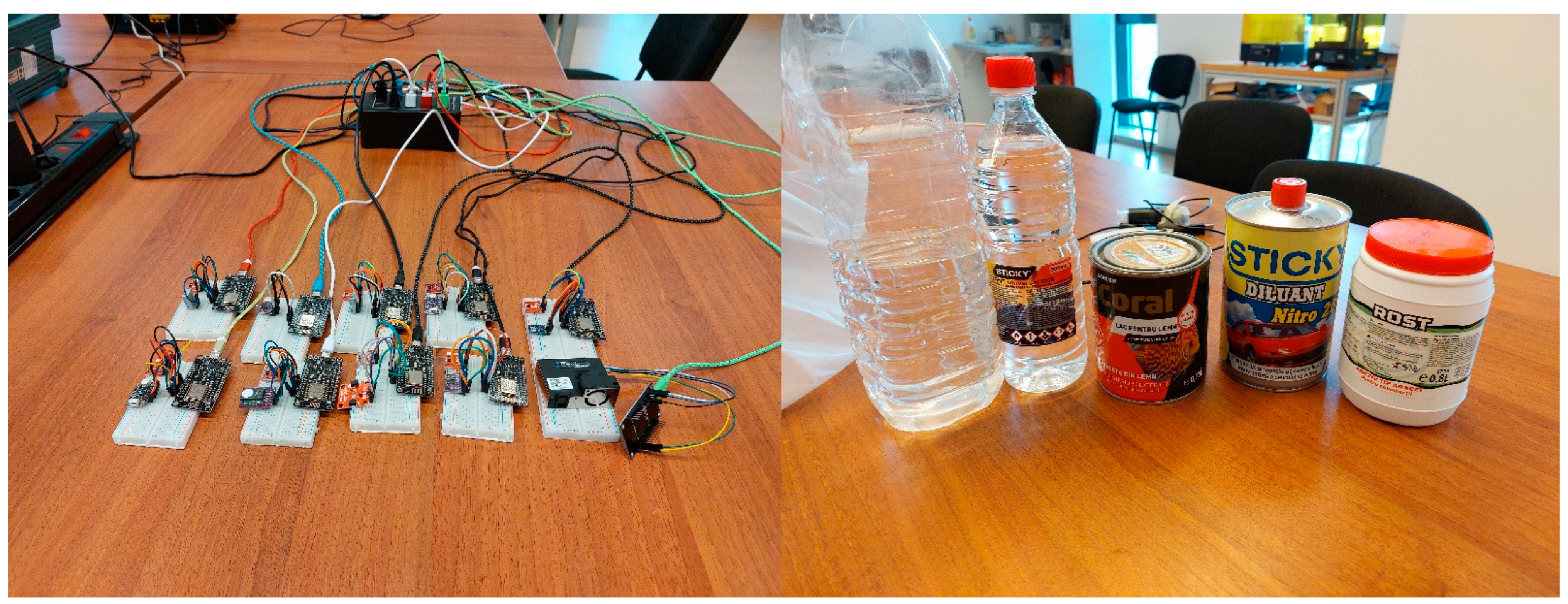

4.3. Sensor Testing to Various Common Polluting Agents

4.4. Concentration vs. Index

4.5. Trends in the Development of MOX-Based Sensors for TVOC/VOC Measurement

5. Conclusions

- initial burn-in time for sensors and start-up time (warm-up).

- establishing a reference level (baseline) by exposure to a good quality environment (clean air) when initializing the sensor.

- the lifetime of the sensor.

- measurement compensation depending on other environmental parameters (for example, temperature and humidity).

- respecting the measurement range and recognizing the phenomenon of upper saturation, unlike the temperature parameter where the upper measurement limit is not normally reached; in the case of indoor gas accumulation, there is a risk of higher concentrations than the sensor can measure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Commission. Indoor Air Pollution: New EU Research Reveals Higher Risks than Previously Thought. Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_03_1278 (accessed on 1 February 2024).

- United States Environmental Protection Agency. What Are the Trends in Indoor Air Quality and Their Effects on Human Health? Available online: https://www.epa.gov/report-environment/indoor-air-quality (accessed on 1 February 2024).

- Pietraru, R.N.; Adochiei, F.-C.; Costea, I.M. Winter in Europe 2022–2023—Concerns About the Effects of The Energy Crisis on Indoor Environmental Quality and Public Health. In Proceedings of the E-Health and Bioengineering Conference (EHB), Iasi, Romania, 17–18 November 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Pietraru, R.N.; Adochiei, F.-C.; Costea, I.M.; Bănică, C.K. Comfort vs Health: A Winter Snapshot of Indoor Air Quality During the Energy Crisis. In Proceedings of the 13th International Symposium on Advanced Topics in Electrical Engineering (ATEE), Bucharest, Romania, 23–25 March 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Khorramifar, A.; Karami, H.; Lvova, L.; Kolouri, A.; Łazuka, E.; Piłat-Rożek, M.; Łagód, G.; Ramos, J.; Lozano, J.; Kaveh, M.; et al. Environmental Engineering Applications of Electronic Nose Systems Based on MOX Gas Sensors. Sensors 2023, 23, 5716. [Google Scholar] [CrossRef] [PubMed]

- Dennler, N.; Rastogi, S.; Fonollosa, J.; van Schaik, A.; Schmuker, M. Drift in a popular metal oxide sensor dataset reveals limitations for gas classification benchmarks. Sens. Actuators B Chem. 2022, 361, 131668. [Google Scholar] [CrossRef]

- Chang, I.-S.; Byun, S.-W.; Lim, T.-B.; Park, G.-M. A Study of Drift Effect in a Popular Metal Oxide Sensor and Gas Recognition Using Public Gas Datasets. IEEE Access 2023, 11, 26383–26392. [Google Scholar] [CrossRef]

- Bergomi, A.; Mangia, C.; Fermo, P.; Genga, A.; Comite, V.; Guadagnini, S.; Ielpo, P. Outdoor trends and indoor investigations of volatile organic compounds in two high schools of southern Italy. Air Qual. Atmos. Health 2024. [Google Scholar] [CrossRef]

- Varzaru, G.; Zarnescu, A.; Ungurelu, R.; Secere, M. Dismantling the confusion between the equivalent CO2 and CO2 concentration levels. In Proceedings of the 2019 11th International Conference on Electronics, Computers and Artificial Intelligence (ECAI), Pitesti, Romania, 27–29 June 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Jia, Y.; Zheng, X.; Guan, J.; Tan, X.; Chen, S.; Qi, B.; Zheng, H. Investigation of indoor total volatile organic compound concentrations in densely occupied university buildings under natural ventilation: Temporal variation, correlation and source contribution. Indoor Built Environ. 2021, 30, 838–850. [Google Scholar] [CrossRef]

- European Commission. Joint Research Centre, European collaborative action ‘Indoor air quality and its impact on man. In Total Volatile Organic Compounds (TVOC) in Indoor Air Quality Investigations; Luxembourg Office for Official Publlicatons of the European Communities: Luxembourg, 1997; ISBN 92-828-1078-X. [Google Scholar]

- European Commission. Joint Research Centre, European collaborative action ‘Urban air, indoor environment and human exposure’. In Risk Assessment in Relation to Indoor Air Quality; Luxembourg Office for Official Publlicatons of the European Communities: Luxembourg, 2000; ISBN 92-828-9284-0. [Google Scholar]

- Indoor Air Quality Guidelines for selected Volatile Organic Compounds (VOCs) in the UK. Available online: https://assets.publishing.service.gov.uk/media/5d7a2912ed915d522e4164a5/VO__statement_Final_12092019_CS__1_.pdf (accessed on 1 February 2024).

- Saffell, J.; Nehr, S. Improving Indoor Air Quality through Standardization. Standards 2023, 3, 240–267. [Google Scholar] [CrossRef]

- Shrivastava, P.; Bhatnagar, A.; Desai, J.; Gajjar, S. DDAS: Distributed Data Acquisition System using Wireless Sensor Networks. In Proceedings of the 2019 IEEE 16th India Council International Conference (INDICON), Rajkot, India, 13–15 December 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Ferencz, P.K.; Domokos, J. IoT Sensor Data Acquisition and Storage System Using Raspberry Pi and Apache Cassandra. In Proceedings of the 2018 International IEEE Conference and Workshop in Óbuda on Electrical and Power Engineering (CANDO-EPE), Budapest, Hungary, 20–21 November 2018; pp. 000143–000146. [Google Scholar] [CrossRef]

- Kamat, P.; Shah, M.; Lad, V.; Desai, P.; Vikani, Y.; Savani, D. Data Acquisition Using IoT Sensors for Smart Manufacturing Domain. In Innovations in Information and Communication Technologies (IICT-2020); Singh, P.K., Polkowski, Z., Tanwar, S., Pandey, S.K., Matei, G., Pirvu, D., Eds.; Advances in Science, Technology & Innovation; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Nishanth, A.; Praveen, A.; Vijayabaskar; Ravi, T. Manual and Automatic Control of Appliances Based on Integration of WSN and IOT Technology. In Mobile Radio Communications and 5G Networks; Marriwala, N., Tripathi, C., Jain, S., Kumar, D., Eds.; Lecture Notes in Networks and Systems; Springer: Singapore, 2022; Volume 339. [Google Scholar] [CrossRef]

- Faheem, M.; Fizza, G.; Ashraf, M.W.; Butt, R.A.; Ngadi, M.A.; Gungor, V.C. Big Data acquired by Internet of Things-enabled industrial multichannel wireless sensors networks for active monitoring and control in the smart grid Industry 4.0. Data Brief 2021, 35, 106854. [Google Scholar] [CrossRef]

- Mabrouki, J.; Azrour, M.; Dhiba, D.; Farhaoui, Y.; Hajjaji, S.E. IoT-based data logger for weather monitoring using arduino-based wireless sensor networks with remote graphical application and alerts. Big Data Min. Anal. 2021, 4, 25–32. [Google Scholar] [CrossRef]

- Ali, I.; Ahmedy, I.; Gani, A.; Munir, M.U.; Anisi, M.H. Data Collection in Studies on Internet of Things (IoT), Wireless Sensor Networks (WSNs), and Sensor Cloud (SC): Similarities and Differences. IEEE Access 2022, 10, 33909–33931. [Google Scholar] [CrossRef]

- Rajawat, A.S.; Bedi, P.; Goyal, S.B.; Alharbi, R.A.; Aljaedi, A.; Jamal, S.S.; Shukla, P.K. Fog Big Data Analysis for IoT Sensor Application Using Fusion Deep Learning. Math. Probl. Eng. 2021, 2021, 6876688. [Google Scholar] [CrossRef]

- Gaura, E.I.; Brusey, J.; Allen, M.; Wilkins, R.; Goldsmith, D.; Rednic, R. Edge Mining the Internet of Things. IEEE Sensors J. 2013, 13, 3816–3825. [Google Scholar] [CrossRef]

- Idrees, Z.; Zou, Z.; Zheng, L. Edge Computing Based IoT Architecture for Low Cost Air Pollution Monitoring Systems: A Comprehensive System Analysis, Design Considerations & Development. Sensors 2018, 18, 3021. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, N.; Meena, C.S.; Raj, B.P.; Saini, L.; Kumar, A.; Gopalakrishnan, N.; Kumar, A.; Balam, N.B.; Alam, T.; Kapoor, N.R.; et al. Indoor air quality improvement in COVID-19 pandemic: Review. Sustain. Cities Soc. 2021, 70, 102942. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez, D.; Urbieta, I.R.; Velasco, A.; Campano-Laborda, M.A.; Jimenez, E. Assessment of indoor air quality and risk of COVID-19 infection in Spanish secondary school and university classrooms. Build. Environ. 2022, 226, 109717. [Google Scholar] [CrossRef] [PubMed]

- Elsaid, A.M.; Ahmed, M.S. Indoor Air Quality Strategies for Air-Conditioning and Ventilation Systems with the Spread of the Global Coronavirus (COVID-19) Epidemic: Improvements and Recommendations. Environ. Res. 2021, 199, 111314. [Google Scholar] [CrossRef] [PubMed]

- Alonso, M.J.; Moazami, T.N.; Liu, P.; Jørgensen, R.B.; Mathisen, H.M. Assessing the indoor air quality and their predictor variable in 21 home offices during the Covid-19 pandemic in Norway. Build. Environ. 2022, 225, 109580. [Google Scholar] [CrossRef] [PubMed]

- Sajeev, V.; Anand, P.; George, A. Chapter 12—Indoor air pollution, occupant health, and building system controls-a COVID-19 perspective. In Hybrid and Combined Processes for Air Pollution Control; Assadi, A., Amrane, A., Nguyen, T.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 291–306. ISBN 9780323884495. [Google Scholar] [CrossRef]

- Tagliabue, L.C.; Cecconi, F.R.; Rinaldi, S.; Ciribini, A.L.C. Data driven indoor air quality prediction in educational facilities based on IoT network. Energy Build. 2021, 236, 110782. [Google Scholar] [CrossRef]

- Shrubsole, C.; Dimitroulopoulou, S.; Foxall, K.; Gadeberg, B.; Doutsi, A. IAQ guidelines for selected volatile organic compounds (VOCs) in the UK. Build. Environ. 2019, 165, 106382. [Google Scholar] [CrossRef]

- Piasecki, M.; Kozicki, M.; Firląg, S.; Goljan, A.; Kostyrko, K. The Approach of Including TVOCs Concentration in the Indoor Environmental Quality Model (IEQ)—Case Studies of BREEAM Certified Office Buildings. Sustainability 2018, 10, 3902. [Google Scholar] [CrossRef]

- Epping, R.; Koch, M. On-Site Detection of Volatile Organic Compounds (VsOCs). Molecules 2023, 28, 1598. [Google Scholar] [CrossRef]

- Fanti, G.; Borghi, F.; Spinazzè, A.; Rovelli, S.; Campagnolo, D.; Keller, M.; Cattaneo, A.; Cauda, E.; Cavallo, D.M. Features and Practicability of the Next-Generation Sensors and Monitors for Exposure Assessment to Airborne Pollutants: A Systematic Review. Sensors 2021, 21, 4513. [Google Scholar] [CrossRef] [PubMed]

- Collier-Oxandale, A.M.; Thorson, J.; Halliday, H.; Milford, J.; Hannigan, M. Understanding the ability of low-cost MOx sensors to quantify ambient VOCs. Atmos. Meas. Tech. 2019, 12, 1441–1460. [Google Scholar] [CrossRef]

- Alonso, M.J.; Madsen, H.; Liu, P.; Jorgensen, R.B.; Jorgensen, T.B.; Christiansen, E.J.; Myrvang, O.A.; Bastien, D.; Mathisen, H.M. Evaluation of low-cost formaldehyde sensors calibration. Build. Environ. 2022, 222, 109380. [Google Scholar] [CrossRef]

- Horstmann, J.; Ramsbeck, M.; Bosse, S. Analog Sensor Signal Processing and Analog-to-Digital Conversion. In Material-Integrated Intelligent Systems-Technology and Applications: Technology and Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2018; pp. 257–280. [Google Scholar] [CrossRef]

- Mende, M.; Begoff, P. Sensors with Digital Output—A Metrological Challenge. In Proceedings of the International Congress of Metrology 22002, Paris, France, 24–26 September 2019. [Google Scholar] [CrossRef]

- Chen, J.; Huang, S. Analysis and Comparison of UART, SPI and I2C. In Proceedings of the 2023 IEEE 2nd International Conference on Electrical Engineering, Big Data and Algorithms (EEBDA), Changchun, China, 24–26 February 2023; pp. 272–276. [Google Scholar] [CrossRef]

- VOC AGS01DB. Available online: http://www.aosong.com/userfiles/files/media/AGS01DB气体传感器模块说明书V10.pdf (accessed on 10 January 2024).

- Datasheet AGS02MA. Available online: http://www.aosong.com/userfiles/files/media/Datasheet%20AGS02MA.pdf (accessed on 10 January 2024).

- Datasheet AGS10. Available online: http://www.aosong.com/userfiles/files/Datasheet%20AGS10.pdf (accessed on 10 January 2024).

- BME680—Datasheet. Available online: https://www.bosch-sensortec.com/media/boschsensortec/downloads/datasheets/bst-bme680-ds001.pdf (accessed on 10 January 2024).

- CCS811 Datasheet (PDF)—Ams AG. Available online: https://pdf1.alldatasheet.com/datasheet-pdf/view/1047395/AMSCO/CCS811.html (accessed on 10 January 2024).

- ENS160 datasheet. Available online: https://www.sciosense.com/wp-content/uploads/2023/12/ENS160-Datasheet.pdf (accessed on 10 January 2024).

- iAQ-Core Indoor Air Quality Sensor Module. Available online: https://www.alldatasheet.com/datasheet-pdf/pdf/861959/AMSCO/IAQ-CORE.html (accessed on 10 January 2024).

- Datasheet SEN5x. Available online: https://sensirion.com/media/documents/6791EFA0/62A1F68F/Sensirion_Datasheet_Environmental_Node_SEN5x.pdf (accessed on 10 January 2024).

- Datasheet SGP30. Available online: https://sensirion.com/media/documents/984E0DD5/61644B8B/Sensirion_Gas_Sensors_Datasheet_SGP30.pdf (accessed on 10 January 2024).

- Datasheet SGP40. Available online: https://sensirion.com/media/documents/296373BB/6203C5DF/Sensirion_Gas_Sensors_Datasheet_SGP40.pdf (accessed on 10 January 2024).

- ISO 16000-29:2014; (En): Indoor Air—Part 29: Test Methods for VOC Detectors. ISO: Geneva, Switzerland, 2014.

- Sensirion Datasheet, SGP40 Testing Guide. Available online: https://sensirion.com/media/documents/2EF11DC4/6164523B/Sensirion_Gas_Sensors_Datasheet_GAS_AN_SGP40_Quick_Testing_Guide_D1.pdf (accessed on 26 February 2024).

- Zhang, M.; Sun, M.; Lai, P.; Zhu, Z. Distributed Environmental Parameter Measurement System Based on TMS320F28335. In Proceedings of the 2019 12th International Congress on Image and Signal Processing, BioMedical Engineering and Informatics (CISP-BMEI), Suzhou, China, 19–21 October 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Suresh, K.C.; Prabha, R.; Hemavathy, N.; Sivarajeswari, S.; Gokulakrishnan, D.; Jagadeesh kumar, M. A Machine Learning Approach for Human Breath Diagnosis with Soft Sensors. Comput. Electr. Eng. 2022, 100, 107945. [Google Scholar] [CrossRef]

- Al-Okby, M.F.R.; Junginger, S.; Roddelkopf, T.; Huang, J.; Thurow, K. Ambient Monitoring Portable Sensor Node for Robot-Based Applications. Sensors 2024, 24, 1295. [Google Scholar] [CrossRef] [PubMed]

- Kuncoro, C.B.D.; Asyikin, M.B.Z.; Amaris, A. Smart-Autonomous Wireless Volatile Organic Compounds Sensor Node for Indoor Air Quality Monitoring Application. Int. J. Environ. Res. Public Health 2022, 19, 2439. [Google Scholar] [CrossRef] [PubMed]

- IKEA Vindstyrka Indoor Air Quality Monitor Review. Available online: https://breathesafeair.com/ikea-vindstyrka-review/ (accessed on 10 January 2024).

- Maciejewska, M.; Azizah, A.; Szczurek, A. Co-Dependency of IAQ in Functionally Different Zones of Open-Kitchen Restaurants Based on Sensor Measurements Explored via Mutual Information Analysis. Sensors 2023, 23, 7630. [Google Scholar] [CrossRef]

- Kim, M.; Kim, T.; Park, S.; Lee, K. An Indoor Multi-Environment Sensor System Based on Intelligent Edge Computing. Electronics 2023, 12, 137. [Google Scholar] [CrossRef]

- Feng, Z.; Zheng, L.; Liu, L.; Zhang, W. Real-Time PM2.5 Monitoring in a Diesel Generator Workshop Using Low-Cost Sensors. Atmosphere 2022, 13, 1766. [Google Scholar] [CrossRef]

- Palacín, J.; Clotet, E.; Rubies, E. Assessing over Time Performance of an eNose Composed of 16 Single-Type MOX Gas Sensors Applied to Classify Two Volatiles. Chemosensors 2022, 10, 118. [Google Scholar] [CrossRef]

- NodeMcu Connect Things EASY. Available online: https://www.nodemcu.com/index_en.html (accessed on 5 February 2024).

- ESP8266 A Cost-Effective and Highly Integrated Wi-Fi MCU for IoT Applications. Available online: https://www.espressif.com/en/products/socs/esp8266 (accessed on 5 February 2024).

- ThingsBoard Open-Source IoT Platform. Available online: https://thingsboard.io/ (accessed on 5 February 2024).

- Radu Nicolae, P.; Nicolae, M.; Mocanu, S.; Merezeanu, D.-M. Test measurements for ten MOX-based VOC sensors [Data set]. Zenodo 2024. [Google Scholar] [CrossRef]

- Compliance of Sensirion’s VOC Sensors with Building Standards. Available online: https://sensirion.com/media/documents/4B4D0E67/6520038C/GAS_AN_SGP4x_BuildingStandards_D1_1.pdf (accessed on 29 February 2024).

- ZMOD4410 Firmware Configurable Indoor Air Quality (IAQ) Sensor with Embedded Artificial Intelligence (AI). Available online: https://www.renesas.com/us/en/products/sensor-products/environmental-sensors/metal-oxide-gas-sensors/zmod4410-firmware-configurable-indoor-air-quality-iaq-sensor-embedded-artificial-intelligence-ai (accessed on 29 February 2024).

- Gas Sensor BME688. Available online: https://www.bosch-sensortec.com/products/environmental-sensors/gas-sensors/bme688/ (accessed on 29 February 2024).

- Sensirion Gas Index Algorithm. Available online: https://github.com/Sensirion/gas-index-algorithm (accessed on 29 February 2024).

- BSEC License. Available online: https://www.bosch-sensortec.com/media/boschsensortec/downloads/software/bme688_development_software/2023_04/license_terms_bme688_bme680_bsec.pdf (accessed on 29 February 2024).

| Sensor Name | Manufacturing Company | Target Physical Parameters | Initial Official Release/ Last Revision Date for Datasheet | Applications/Typical Applications (Extracted Directly from the Datasheet of Each Sensor) | |

|---|---|---|---|---|---|

| 1 | AGS01DB | Aosong Electronic 1 | TVOC | May 2018/July 2018 [40] | Air purifiers, home appliances, fresh air system. |

| 2 | AGS02MA | Aosong Electronic 1 | TVOC | July 2022 [41] | Air purifiers, home appliances, fresh air system. |

| 3 | AGS10 | Aosong Electronic 1 | TVOC | July 2022 [42] | Air purifiers, home appliances, fresh air system. |

| 4 | BME680 | Bosch 2 | Temp RH Pressure TVOV | June 2022 [43] | Indoor air quality, home automation and control, Internet of things, Weather forecast, GPS enhancement, Indoor navigation, Outdoor navigation, leisure and sports applications, Vertical velocity indication |

| 5 | CCS811 | ScioSense (AMS AG) 3 | TVOC eCO2 | December 2016 [44] | This device can be mainly used for indoor air quality monitoring in: Smart phones, Wearables, Home and Building automation, Accessories. |

| 6 | ENS160 | ScioSense 3 | TVOC eCO2 | November 2019/ March 2023 [45] | Building Automation/smart home/HVAC (Indoor air quality detection, Demand-controlled ventilation, Smart thermostats), Home appliances (Cooker hoods, Air cleaners/purifiers), IoT devices |

| 7 | IAQ Core | ScioSense (AMS AG) 3 | TVOC eCO2 | v1-00/April 2015 [46] | Smart Home, Internet of Things, HVAC, Thermostats |

| 8 | SEN55 | Sensirion 4 | Temp RH VOC NOx PM | January 2022/ March 2022 [47] | HVAC and Air Quality Applications |

| 9 | SGP30 | Sensirion 4 | TVOC eCO2 | May 2020 [48] | Indoor air quality applications. Easy integration into air purifier, demand-controlled ventilation, and IoT applications. |

| 10 | SGP40 | Sensirion 4 | VOC | July 2020/February 2022 [49] | Indoor air quality applications. Easy integration into air purifier s or demand-controlled ventilation systems. |

| Sensor Name | Dynamic Range | Resolution (ppm) | Accuracy (Compound Tested) | Response Time (s) | Cost ($) | Applications Examples/References | |

|---|---|---|---|---|---|---|---|

| 1 | AGS01DB [37] | 0–100 ppm | 0.1 [37] | 20% (ethanol) | ≥2 | <3$ | [52] |

| 2 | AGS02MA [38] | 0–100 ppm | Unspecified | 25% (ethanol) | ≥2 | <5$ | [53] |

| 3 | AGS10 [39] | 0–100 ppm | Unspecified | 25% (ethanol) | ≥2 | <3$ | No scientific research reported |

| 4 | BME680 [40] | 1–500 AQI | 1 AQI | 15% S2S (ethanol, bVOC) | <1 | <10$ | [54,55,56,57,58,59,60] |

| 5 | CCS811 [41] | 0–1187 ppb (TVOC), 400–8192 ppm (eCO2) | Unspecified 16-bit ADC | Not specified | 0.25 | <5$ | [6,7,9] |

| 6 | ENS160 [42] | 0–65,000 ppb (TVOC) 400–65,000 ppm (eCO2) 1–5 AQI | 1 ppb 1 ppm 1 AQI | 12% (hydrogen) | 1 | <10$ | [54] |

| 7 | IAQ Core [43] | 125–600 ppb (TVOC) 450–2000 ppm (eCO2) | Unspecified | Not specified | <10 | <20$ | [55] |

| 8 | SEN55 [44] | 1–500 AQI | Unspecified | 15% S2S (ethanol) | 1 | <30$ | [56] |

| 9 | SGP30 [45] | 0–60,000 ppb (TVOC) 400–60,000 ppm (eCO2) | 1, 6, 32 ppb 1, 3.9, 31 ppm | 15% (ethanol) 10% (hydrogen) | 1 | <10$ | [28,36,57,58] |

| 10 | SGP40 [46] | 1–500 AQI | Unspecified | 15% (ethanol) | 1 | <7$ | [54] |

| Sensor | Temperature AVG | Temperature MED | Temperature Mode | Temperature STD | Temperature MAX | Temperature MIN | Temperature Variation |

|---|---|---|---|---|---|---|---|

| AGS01DB (HTU21D) | 21.90 | 21.68 | 21.30 | 0.71 | 23.56 | 21.13 | 2.43 |

| AGS02MA (HTU21D) | 22.63 | 22.45 | 22.52 | 0.70 | 24.57 | 21.85 | 2.72 |

| AGS10 (HTU21D) | 22.86 | 22.62 | 22.62 | 0.70 | 24.79 | 22.11 | 2.68 |

| BME680 | 23.42 | 23.20 | 22.76 | 0.72 | 25.12 | 22.64 | 2.47 |

| CCS811 (HTU21D) | 23.36 | 23.12 | 23.10 | 0.62 | 25.22 | 22.57 | 2.66 |

| ENS160 (HTU21D) | 23.47 | 23.23 | 23.21 | 0.67 | 25.22 | 22.75 | 2.46 |

| IAQ (HTU21D) | 23.51 | 23.28 | 23.04 | 0.64 | 25.37 | 22.62 | 2.76 |

| SEN55 | 21.90 | 21.83 | 21.94 | 0.64 | 23.48 | 21.17 | 2.31 |

| SGP30 (HTU21D) | 23.30 | 22.96 | 22.88 | 0.66 | 25.44 | 22.40 | 3.03 |

| SGP40 (HTU21D) | 22.47 | 22.28 | 21.87 | 0.68 | 24.30 | 21.72 | 2.58 |

| Sensor | Humidity AVG | Humidity MED | Humidity Mode | Humidity STD | Humidity MAX | Humidity MIN | Humidity Variation |

|---|---|---|---|---|---|---|---|

| AGS01DB (HTU21D) | 35.31 | 35.61 | 38.17 | 2.57 | 39.33 | 30.28 | 9.05 |

| AGS02MA (HTU21D) | 33.39 | 33.58 | 35.82 | 2.49 | 37.34 | 28.16 | 9.17 |

| AGS10 (HTU21D) | 32.86 | 33.25 | 35.73 | 2.56 | 36.95 | 27.58 | 9.37 |

| BME680 | 30.59 | 30.81 | 32.84 | 2.04 | 33.91 | 26.63 | 7.28 |

| CCS811 (HTU21D) | 31.34 | 31.73 | 33.50 | 2.22 | 35.26 | 26.48 | 8.78 |

| ENS160 (HTU21D) | 23.56 | 23.99 | 21.60 | 2.05 | 26.96 | 19.34 | 7.62 |

| IAQ (HTU21D) | 24.06 | 24.42 | 25.93 | 1.99 | 27.48 | 19.76 | 7.72 |

| SEN55 | 35.41 | 35.35 | 37.64 | 1.92 | 38.56 | 31.48 | 7.08 |

| SGP30 (HTU21D) | 31.39 | 32.09 | 32.01 | 2.30 | 35.59 | 26.03 | 9.56 |

| SGP40 (HTU21D) | 34.51 | 34.78 | 35.52 | 2.25 | 38.14 | 29.88 | 8.27 |

| Name | TVOC AVG | TVOC MED | TVOC Mode | TVOC STD | TVOC MAX | TVOC MIN | TVOC Variation |

|---|---|---|---|---|---|---|---|

| AGS01DB | 115.39 | 0.00 | 0.00 | 208.68 | 710.00 | 0.00 | 710.00 |

| AGS02MA | 7.52 | 7.00 | 9.00 | 1.19 | 9.00 | 6.00 | 3.00 |

| AGS10 | 65.21 | 61.75 | 93.00 | 24.50 | 95.00 | 34.30 | 60.70 |

| BME680 | 16,436.84 | 3552.15 | 569.40 | 19,393.43 | 55,695.29 | 491.90 | 55,203.39 |

| CCS811 | 118.43 | 63.20 | 5.30 | 110.80 | 300.90 | 0.00 | 300.90 |

| ENS160 | 193.03 | 206.20 | 239.30 | 48.41 | 283.20 | 88.70 | 194.50 |

| IAQ | 385.83 | 418.70 | 527.50 | 172.26 | 608.40 | 125.70 | 482.70 |

| SEN55 (index) | 103.15 | 63.10 | 203.00 | 69.51 | 203.70 | 30.00 | 173.70 |

| SGP30 | 45.99 | 35.50 | 19.40 | 30.00 | 88.40 | 0.40 | 88.00 |

| SGP40 (index) | 62.53 | 22.55 | 12.00 | 60.93 | 163.00 | 10.00 | 153.00 |

| Name | eCO2 AVG | eCO2 MED | eCO2 Mode | eCO2 STD | eCO2 MAX | eCO2 MIN | eCO2 Variation |

|---|---|---|---|---|---|---|---|

| BME680 | 1524.47 | 1360.69 | 2565.33 | 756.54 | 2578.00 | 595.80 | 1982.20 |

| CCS811 | 1004.75 | 818.75 | 1609.80 | 499.17 | 1662.40 | 401.70 | 1260.70 |

| ENS160 | 680.06 | 700.55 | 736.30 | 64.85 | 785.50 | 529.60 | 255.90 |

| IAQ | 1395.63 | 1515.00 | 889.20 | 625.60 | 2204.20 | 451.50 | 1752.70 |

| SGP30 | 400.36 | 400.00 | 400.00 | 3.50 | 444.30 | 400.00 | 44.30 |

| TEMP | AGS01DB | AGS02MA | AGS10 | BME680 | CCS811 | ENS160 | iAQ-Core | SEN55 | SGP30 | SGP40 |

|---|---|---|---|---|---|---|---|---|---|---|

| AGS01DB | 1 | 0.991699 | 0.987383 | 0.998808 | 0.977116 | 0.992416 | 0.987442 | 0.989598 | 0.96967 | 0.993288 |

| AGS02MA | 0.991699 | 1 | 0.995103 | 0.994005 | 0.985002 | 0.993659 | 0.988735 | 0.986922 | 0.976414 | 0.999169 |

| AGS10 | 0.987383 | 0.995103 | 1 | 0.989818 | 0.989275 | 0.995974 | 0.985159 | 0.975833 | 0.980115 | 0.996597 |

| BME680 | 0.998808 | 0.994005 | 0.989818 | 1 | 0.978486 | 0.993353 | 0.986633 | 0.989896 | 0.970128 | 0.995062 |

| CCS811 | 0.977116 | 0.985002 | 0.989275 | 0.978486 | 1 | 0.991816 | 0.98805 | 0.966495 | 0.98973 | 0.985479 |

| ENS160 | 0.992416 | 0.993659 | 0.995974 | 0.993353 | 0.991816 | 1 | 0.9895 | 0.981098 | 0.982868 | 0.9955 |

| iAQ-Core | 0.987442 | 0.988735 | 0.985159 | 0.986633 | 0.98805 | 0.9895 | 1 | 0.979017 | 0.989641 | 0.989039 |

| SEN55 | 0.989598 | 0.986922 | 0.975833 | 0.989896 | 0.966495 | 0.981098 | 0.979017 | 1 | 0.95098 | 0.987 |

| SGP30 | 0.96967 | 0.976414 | 0.980115 | 0.970128 | 0.98973 | 0.982868 | 0.989641 | 0.95098 | 1 | 0.977026 |

| SGP40 | 0.993288 | 0.999169 | 0.996597 | 0.995062 | 0.985479 | 0.9955 | 0.989039 | 0.987 | 0.977026 | 1 |

| HUMID | AGS01DB | AGS02MA | AGS10 | BME680 | CCS811 | ENS160 | iAQ-Core | SEN55 | SGP30 | SGP40 |

|---|---|---|---|---|---|---|---|---|---|---|

| AGS01DB | 1 | 0.997315 | 0.996344 | 0.999184 | 0.993623 | 0.997465 | 0.996162 | 0.99658 | 0.99057 | 0.997765 |

| AGS02MA | 0.997315 | 1 | 0.998442 | 0.997851 | 0.995949 | 0.997568 | 0.996224 | 0.99638 | 0.991997 | 0.999659 |

| AGS10 | 0.996344 | 0.998442 | 1 | 0.996851 | 0.997926 | 0.998949 | 0.996054 | 0.994188 | 0.993994 | 0.998979 |

| BME680 | 0.999184 | 0.997851 | 0.996851 | 1 | 0.993964 | 0.997632 | 0.996084 | 0.996963 | 0.990946 | 0.99834 |

| CCS811 | 0.993623 | 0.995949 | 0.997926 | 0.993964 | 1 | 0.997851 | 0.996282 | 0.990138 | 0.996695 | 0.996277 |

| ENS160 | 0.997465 | 0.997568 | 0.998949 | 0.997632 | 0.997851 | 1 | 0.997114 | 0.993968 | 0.995201 | 0.998386 |

| iAQ-Core | 0.996162 | 0.996224 | 0.996054 | 0.996084 | 0.996282 | 0.997114 | 1 | 0.992865 | 0.996841 | 0.996676 |

| SEN55 | 0.99658 | 0.99638 | 0.994188 | 0.996963 | 0.990138 | 0.993968 | 0.992865 | 1 | 0.984124 | 0.996819 |

| SGP30 | 0.99057 | 0.991997 | 0.993994 | 0.990946 | 0.996695 | 0.995201 | 0.996841 | 0.984124 | 1 | 0.992529 |

| SGP40 | 0.997765 | 0.999659 | 0.998979 | 0.99834 | 0.996277 | 0.998386 | 0.996676 | 0.996819 | 0.992529 | 1 |

| TVOC | AGS01DB | AGS02MA | AGS10 | BME680 | CCS811 | ENS160 | iAQ-Core | SEN55 | SGP30 | SGP40 |

|---|---|---|---|---|---|---|---|---|---|---|

| AGS01DB | 1 | 0.254817 | 0.390833 | 0.532391 | 0.175483 | −0.00092 | 0.526315 | 0.338325 | 0.321577 | 0.012081 |

| AGS02MA | 0.254817 | 1 | 0.929027 | 0.85401 | 0.970279 | 0.686379 | 0.840928 | 0.941338 | 0.941555 | 0.923158 |

| AGS10 | 0.390833 | 0.929027 | 1 | 0.850293 | 0.91572 | 0.592695 | 0.957222 | 0.917506 | 0.889363 | 0.856209 |

| BME680 | 0.532391 | 0.85401 | 0.850293 | 1 | 0.847709 | 0.449376 | 0.832594 | 0.940817 | 0.894306 | 0.766756 |

| CCS811 | 0.175483 | 0.970279 | 0.91572 | 0.847709 | 1 | 0.641925 | 0.828203 | 0.968223 | 0.958003 | 0.973589 |

| ENS160 | −0.00092 | 0.686379 | 0.592695 | 0.449376 | 0.641925 | 1 | 0.40332 | 0.55786 | 0.640979 | 0.577431 |

| iAQ-Core | 0.526315 | 0.840928 | 0.957222 | 0.832594 | 0.828203 | 0.40332 | 1 | 0.873417 | 0.836406 | 0.75142 |

| SEN55 | 0.338325 | 0.941338 | 0.917506 | 0.940817 | 0.968223 | 0.55786 | 0.873417 | 1 | 0.97381 | 0.919811 |

| SGP30 | 0.321577 | 0.941555 | 0.889363 | 0.894306 | 0.958003 | 0.640979 | 0.836406 | 0.97381 | 1 | 0.89687 |

| SGP40 | 0.012081 | 0.923158 | 0.856209 | 0.766756 | 0.973589 | 0.577431 | 0.75142 | 0.919811 | 0.89687 | 1 |

| eCO2 | AGS01DB | AGS02MA | AGS10 | BME680 | CCS811 | ENS160 | iAQ-Core | SEN55 | SGP30 | SGP40 |

|---|---|---|---|---|---|---|---|---|---|---|

| AGS01DB | ||||||||||

| AGS02MA | ||||||||||

| AGS10 | ||||||||||

| BME680 | 1 | 0.962165 | 0.529631 | 0.928501 | −0.04209 | |||||

| CCS811 | 0.962165 | 1 | 0.630692 | 0.865876 | −0.03732 | |||||

| ENS160 | 0.529631 | 0.630692 | 1 | 0.390728 | 0.13529 | |||||

| iAQ-Core | 0.928501 | 0.865876 | 0.390728 | 1 | −0.00421 | |||||

| SEN55 | ||||||||||

| SGP30 | −0.04209 | −0.03732 | 0.13529 | −0.00421 | 1 | |||||

| SGP40 |

| eCO2/TVOC | AGS01DB | AGS02MA | AGS10 | BME680 | CCS811 | ENS160 | iAQ-Core | SEN55 | SGP30 | SGP40 |

|---|---|---|---|---|---|---|---|---|---|---|

| AGS01DB | ||||||||||

| AGS02MA | ||||||||||

| AGS10 | ||||||||||

| BME680 | 0.929904 | 0.927457 | 0.536933 | 0.9285 | 0.942818 | |||||

| CCS811 | 0.884055 | 0.986478 | 0.639984 | 0.865882 | 0.964221 | |||||

| ENS160 | 0.450441 | 0.630037 | 0.998313 | 0.390723 | 0.629599 | |||||

| iAQ-Core | 0.832609 | 0.828192 | 0.403321 | 1 | 0.836394 | |||||

| SEN55 | ||||||||||

| SGP30 | −0.07303 | −0.0507 | 0.151411 | −0.0042 | 0.016523 | |||||

| SGP40 |

| Pearson | AGS01DB | AGS02MA | AGS10 | BME680 | CCS811 | ENS160 | iAQ-Core | SEN55 | SGP30 | SGP40 |

|---|---|---|---|---|---|---|---|---|---|---|

| AGS01DB | 1 | 0.623073 | 0.9517841 | 0.216116 | 0.8212362 | 0.6610571 | 0.66004092 | 0.485318 | 0.910934 | 0.320382 |

| AGS02MA | 1 | 0.7785496 | 0.205455 | 0.806561 | 0.7884756 | 0.806492017 | 0.453133 | 0.816595 | 0.077032 | |

| AGS10 | 1 | 0.231299 | 0.894269 | 0.7597803 | 0.757723441 | 0.515935 | 0.962565 | 0.277967 | ||

| BME680 | 1 | 0.2129567 | 0.1916036 | 0.185304216 | 0.688824 | 0.225274 | 0.637923 | |||

| CCS811 | 1 | 0.9426917 | 0.91251034 | 0.522662 | 0.951564 | 0.20224 | ||||

| ENS160 | 1 | 0.941782659 | 0.485681 | 0.86903 | 0.111028 | |||||

| iAQ-Core | 1 | 0.455686 | 0.85121 | 0.105208 | ||||||

| SEN55 | 1 | 0.520766 | 0.889802 | |||||||

| SGP30 | 1 | 0.212892 | ||||||||

| SGP40 | 1 |

| Name | TVOC AVG | TVOC MED | TVOC Mode | TVOC STD | TVOC MAX | TVOC MIN | TVOC Variation |

|---|---|---|---|---|---|---|---|

| AGS01DB | 16,765.08 | 50.00 | 0.00 | 26,208.38 | 62,850.00 | 0.00 | 62,850.00 |

| AGS02MA | 1081.57 | 25.75 | 7.00 | 1802.50 | 7768.20 | 7.00 | 7761.20 |

| AGS10 | 16,696.98 | 98.50 | 48.00 | 24,533.03 | 64,897.00 | 39.50 | 64,857.50 |

| BME680 | 13,144.33 | 13,144.33 | 13,144.33 | 13,144.33 | 57,126.00 | 1071.00 | 56,055.00 |

| CCS811 | 8253.42 | 75.25 | 50.50 | 11,482.54 | 29,206.00 | 25.00 | 29,181.00 |

| ENS160 | 13,290.31 | 246.75 | 65,000.00 | 19,447.72 | 65,000.00 | 0.00 | 65,000.00 |

| IAQ | 988.51 | 988.51 | 127.50 | 1232.34 | 6246.50 | 125.00 | 6121.50 |

| SEN55 | 337.69 | 482.25 | 500.00 | 215.16 | 500.00 | 33.00 | 467.00 |

| SGP30 | 19,331.27 | 153.50 | 60,000.00 | 27,127.79 | 60,000.00 | 0.00 | 60,000.00 |

| SGP40 | 275.92 | 374.25 | 492.00 | 212.93 | 492.00 | 10.00 | 482.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pietraru, R.N.; Nicolae, M.; Mocanu, Ș.; Merezeanu, D.-M. Easy-to-Use MOX-Based VOC Sensors for Efficient Indoor Air Quality Monitoring. Sensors 2024, 24, 2501. https://doi.org/10.3390/s24082501

Pietraru RN, Nicolae M, Mocanu Ș, Merezeanu D-M. Easy-to-Use MOX-Based VOC Sensors for Efficient Indoor Air Quality Monitoring. Sensors. 2024; 24(8):2501. https://doi.org/10.3390/s24082501

Chicago/Turabian StylePietraru, Radu Nicolae, Maximilian Nicolae, Ștefan Mocanu, and Daniel-Marian Merezeanu. 2024. "Easy-to-Use MOX-Based VOC Sensors for Efficient Indoor Air Quality Monitoring" Sensors 24, no. 8: 2501. https://doi.org/10.3390/s24082501

APA StylePietraru, R. N., Nicolae, M., Mocanu, Ș., & Merezeanu, D.-M. (2024). Easy-to-Use MOX-Based VOC Sensors for Efficient Indoor Air Quality Monitoring. Sensors, 24(8), 2501. https://doi.org/10.3390/s24082501