Assessment of Triboelectric Nanogenerators for Electric Field Energy Harvesting

Abstract

:1. Introduction

2. Material and Methods

2.1. Hardware Design of the Energy Harvester

2.2. Sensing System

2.3. Data Processing

- To ensure reproducible results, the experiments should be performed in a controlled environment. In this regard, experimental tests of the harvesters were developed by fixing the laboratory temperature to standard temperature levels according to the National Institute of Standards and Technology, i.e., 20 °C. In addition, relative humidity was set to about 50%. Each harvest sample was registered by taking a full-HD color image with a 16-megapixel monocular camera (Logitech, Santiago de Chile, Chile) within a validated digit ranging from 0 to 9.

- The characterization of the TENG was conducted by interfacing the harvester with various resistors, and the resulting voltage was systematically measured. Voltage measurements were carried out using a Keithley 6514 electrometer (Keithley, Tektronix, Santiago de Chile, Chile) connected to an industrial computer. The electrometer, configured with an IEEE-488 bus provider (refer to the Keithley 6514 user manual for details), facilitated the acquisition of up to 500 sensor readings per second. To enhance precision and mitigate the impact of uncertainties, a series of ten measurements were performed. Subsequently, the computed values were determined by averaging the acquired sensor database.

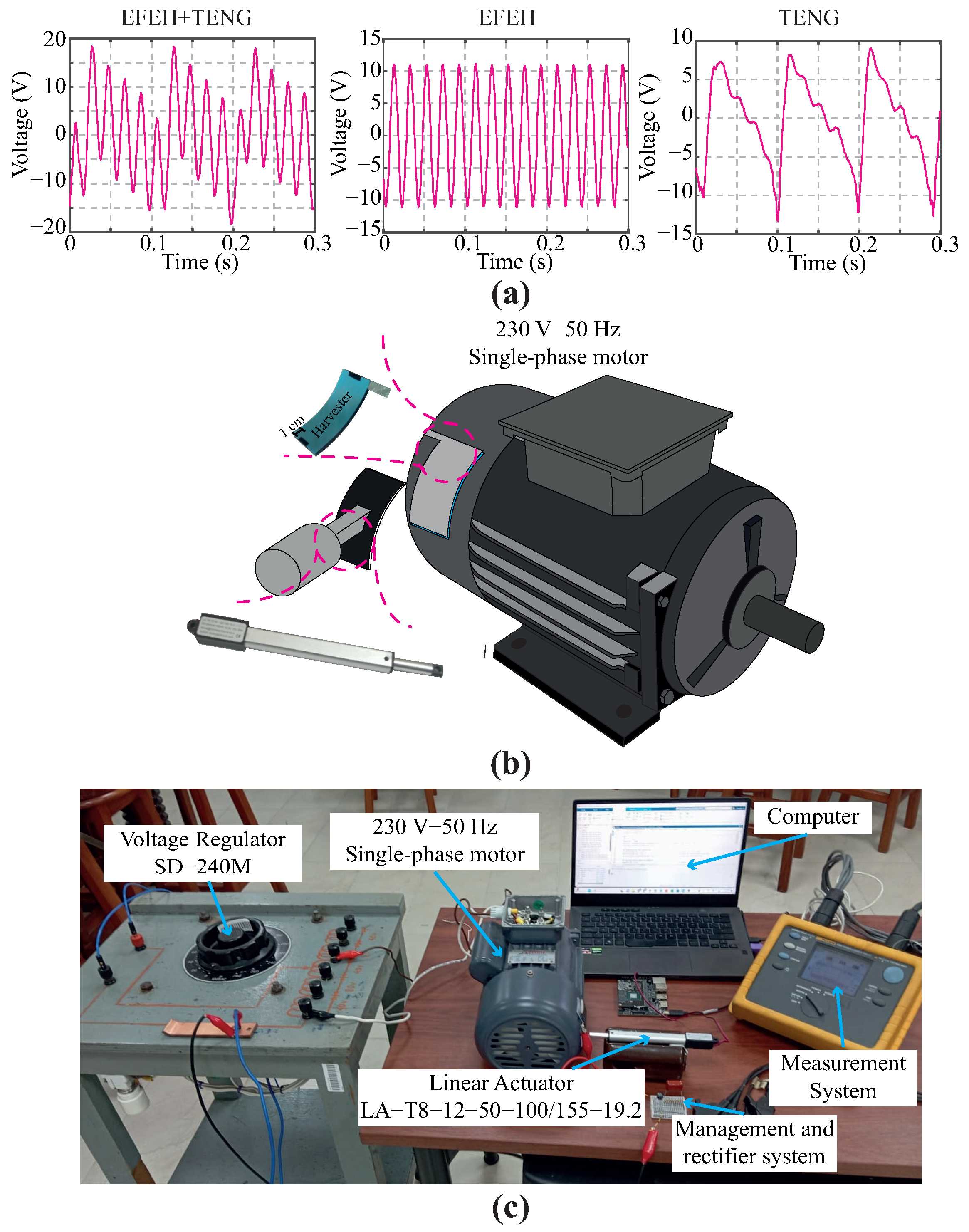

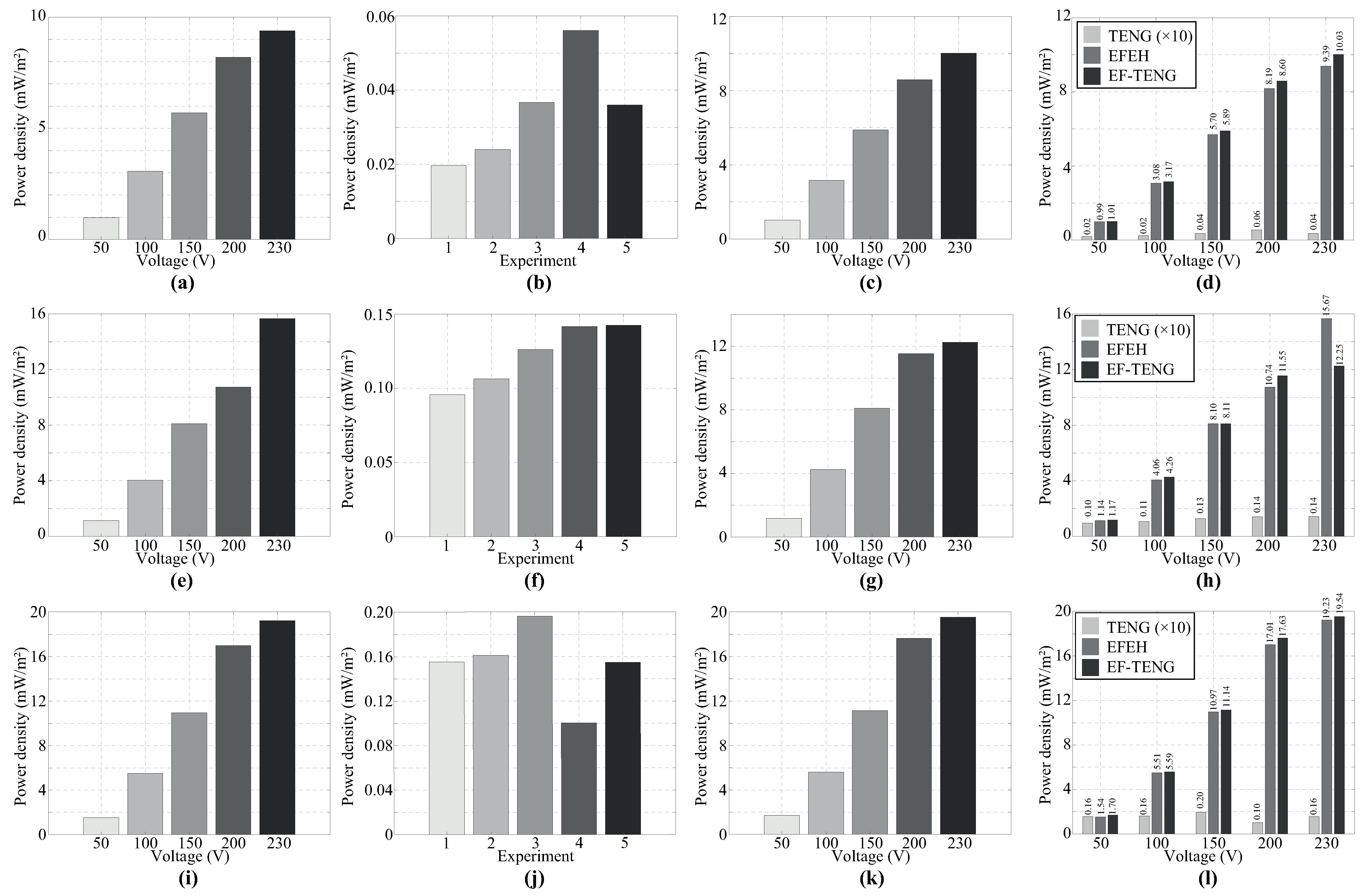

- To investigate the effects of electric field and oscillations in the energy harvester we evaluated the harvest performance in three different scenarios: (i) an EFEH, (ii) a TENG, and (iii) combining the former methods gathered in a hybrid device. Initially, the performance of the TENG as an EFEH was assessed. For this purpose, the linear motor was temporarily turned off. The second mode follows the working mechanism described in [43], i.e., the TENG operates in single-electrode mode. Finally, the third mode analyzed the hybrid behavior of the TENG, following guidelines described in Section 2.2.

- When running the trials, a critical thing to bear in mind is the practical harvester’s application. In this context, we investigate the performance of the harvesters in low-duty cycle applications. We have used the experience learned from previous experimental work to determine that the maximum frequency for reporting the status of smart-city assets is 30 min [28,42]. Here, the charging profile of a 4.7 F capacitor was acquired using a Keithley-6514 electrometer. The baud rate was 9600 bps since it is unnecessary to use a high sampling time.

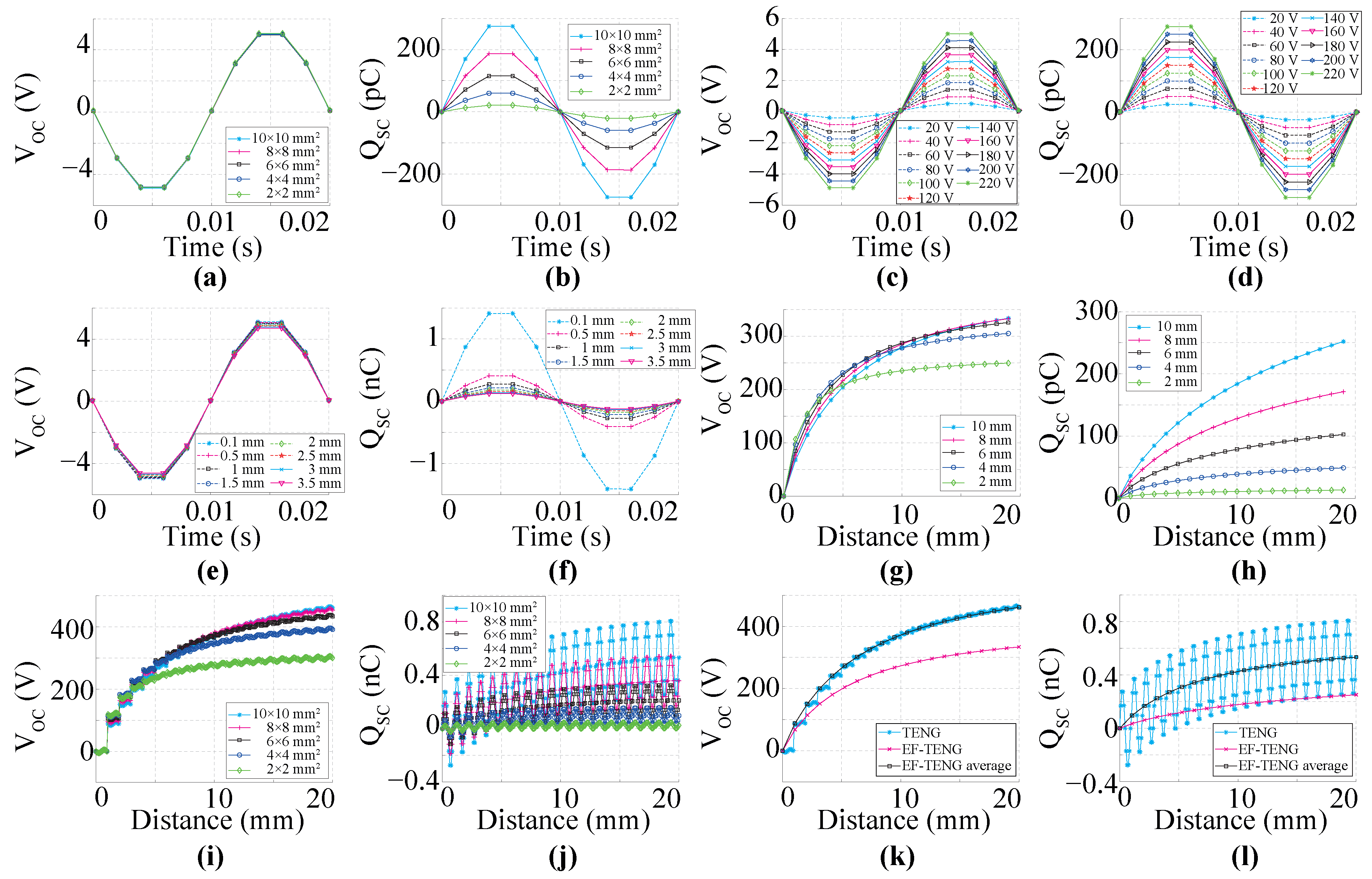

3. Simulation Results

4. Experimental Results

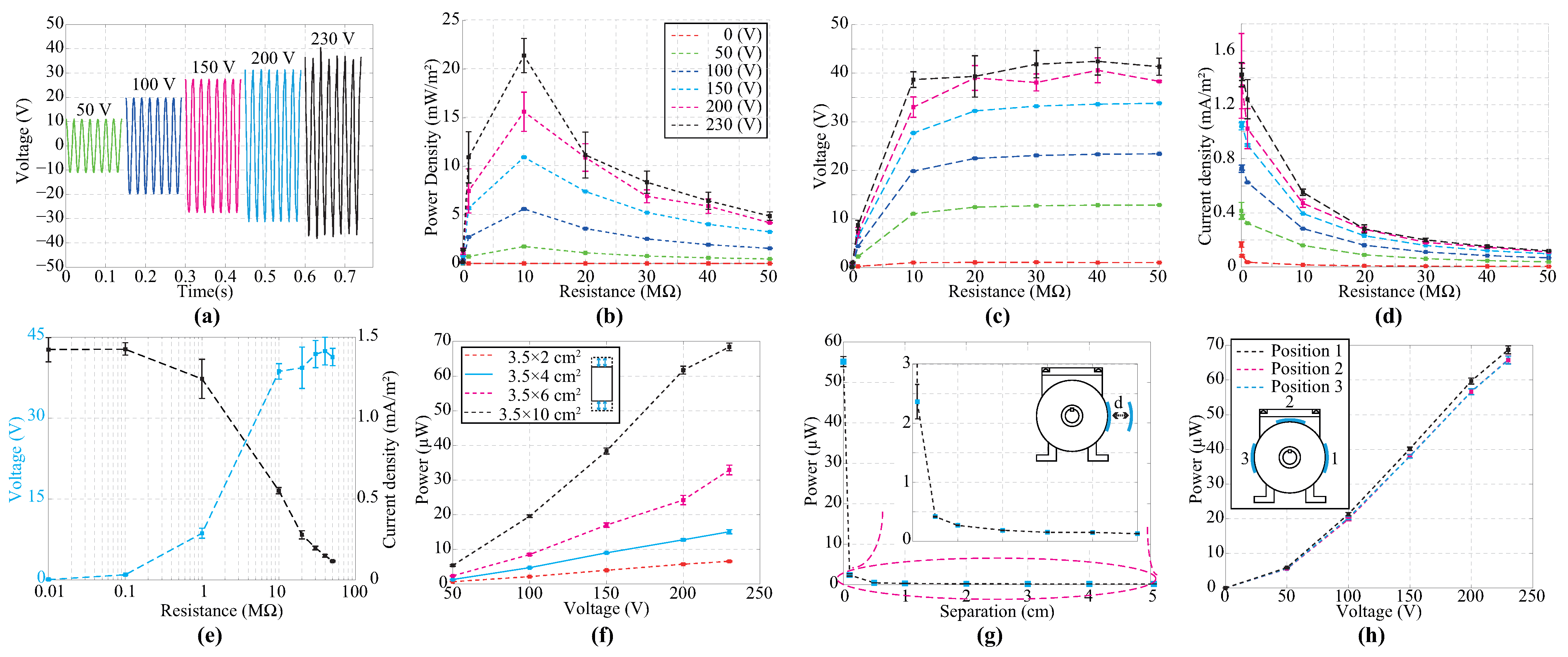

4.1. Assessment of the TENG as EFEH

4.2. Performance Comparison of the Harvesting Technologies

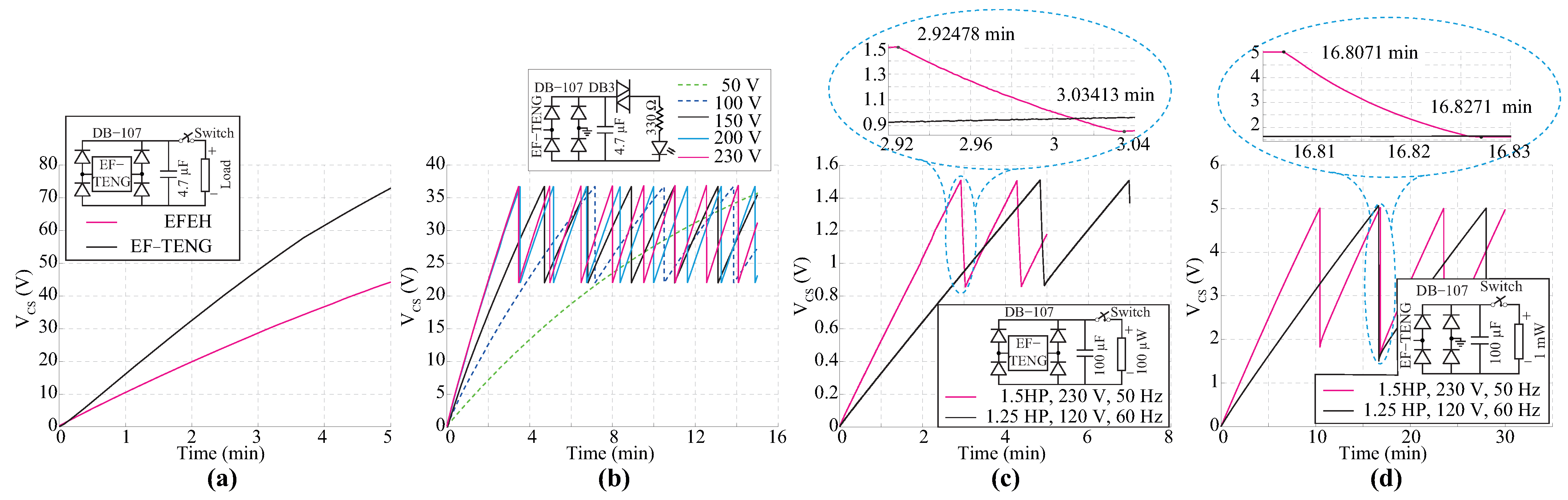

4.3. Application of the Energy Harvest Technology

- Based on the previous results from Section 4.1 and Section 4.2, a 3.5 × 10 cm2 TENG was designed, assembled and tested.

- The TENG was mounted on a 1.5 HP, 8 A, 230 VAC, 50 Hz single-phase motor. The motor works under nominal operation conditions and no-load conditions.

- A management electric circuit consists of a full-bridge rectifier and a storage capacitor, described in Section 2.1. Although the power density of the harvester depends on the capacitor value, we selected a 4.7 F test capacitor based on the power losses experimented in trials from Section 4.1 and Section 4.2. On the other hand, a 100 F electrolytic capacitor was used for the following experiments because of the low operating voltage of the connected loads.

- According to the analysis presented in Section 2.1, the voltage profile of the load is obtained during a 15-min test using a high-precision digital electrometer.

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Menendez, O.; Auat Cheein, F.A.; Rodriguez, J. Displacement Current-Based Energy Harvesters in Power Grids: Topologies and Performance Evaluation. IEEE Ind. Electron. Mag. 2021, 16, 52–66. [Google Scholar] [CrossRef]

- Deng, H.; Xiao, S.; Yang, A.; Wu, H.; Tang, J.; Zhang, X.; Li, Y. Advances in nanogenerators for electrical power system state sensing and monitoring. Nano Energy 2023, 115, 108738. [Google Scholar] [CrossRef]

- Bedi, G.; Venayagamoorthy, G.K.; Singh, R.; Brooks, R.R.; Wang, K.C. Review of Internet of Things (IoT) in Electric Power and Energy Systems. IEEE Internet Things J. 2018, 5, 847–870. [Google Scholar] [CrossRef]

- Dominguez, X.; Prado, A.; Arboleya, P.; Terzija, V. Evolution of knowledge mining from data in power systems: The Big Data Analytics breakthrough. Electric Power Syst. Res. 2023, 218, 109193. [Google Scholar] [CrossRef]

- Cao, J.; Emadi, A. Batteries Need Electronics. IEEE Ind. Electron. Mag. 2011, 5, 27–35. [Google Scholar] [CrossRef]

- Cetinkaya, O.; Akan, O.B. Electric-Field Energy Harvesting in Wireless Networks. IEEE Wirel. Commun. 2017, 24, 34–41. [Google Scholar] [CrossRef]

- Qiu, C.; Hu, Y.; Chen, Y.; Zeng, B. Deep Deterministic Policy Gradient (DDPG)-Based Energy Harvesting Wireless Communications. IEEE Internet Things J. 2019, 6, 8577–8588. [Google Scholar] [CrossRef]

- Zeeshan.; Panigrahi, B.K.; Ahmed, R.; Mehmood, M.U.; Park, J.C.; Kim, Y.; Chun, W. Operation of a low-temperature differential heat engine for power generation via hybrid nanogenerators. Appl. Energy 2021, 285, 116385. [Google Scholar] [CrossRef]

- Yang, P.K.; Lin, Z.H.; Pradel, K.C.; Lin, L.; Li, X.; Wen, X.; He, J.H.; Wang, Z.L. Paper-Based Origami Triboelectric Nanogenerators and Self-Powered Pressure Sensors. ACS Nano 2015, 9, 901–907. [Google Scholar] [CrossRef]

- Li, W.; Liu, G.; Jiang, D.; Wang, C.; Li, W.; Guo, T.; Zhao, J.; Xi, F.; Liu, W.; Zhang, C. Interdigitated Electrode-Based Triboelectric Sliding Sensor for Security Monitoring. Adv. Mater. Technol. 2018, 3, 1800189. [Google Scholar] [CrossRef]

- Yu, A.; Song, M.; Zhang, Y.; Zhang, Y.; Chen, L.; Zhai, J.; Wang, Z.L. Self-powered acoustic source locator in underwater environment based on organic film triboelectric nanogenerator. Nano Res. 2015, 8, 765–773. [Google Scholar] [CrossRef]

- Yu, B.; Fu, Y.; Wang, P.; Zhao, Y.; Xing, L.; Xue, X. Enhanced piezo-humidity sensing of a Cd–ZnO nanowire nanogenerator as a self-powered/active gas sensor by coupling the piezoelectric screening effect and dopant displacement mechanism. Phys. Chem. Chem. Phys. 2015, 17, 10856–10860. [Google Scholar] [CrossRef]

- Su, Y.; Xie, G.; Wang, S.; Tai, H.; Zhang, Q.; Du, H.; Du, X.; Jiang, Y. Self-powered humidity sensor based on triboelectric nanogenerator. In Proceedings of the 2017 IEEE SENSORS, Glasgow, UK, 29 October–1 November 2017; pp. 1–3. [Google Scholar] [CrossRef]

- Su, Y.; Xie, G.; Tai, H.; Li, S.; Yang, B.; Wang, S.; Zhang, Q.; Du, H.; Zhang, H.; Du, X.; et al. Self-powered room temperature NO2 detection driven by triboelectric nanogenerator under UV illumination. Nano Energy 2018, 47, 316–324. [Google Scholar] [CrossRef]

- Askari, H.; Hashemi, E.; Khajepour, A.; Khamesee, M.B.; Wang, Z.L. Towards self-powered sensing using nanogenerators for automotive systems. Nano Energy 2018, 53, 1003–1019. [Google Scholar] [CrossRef]

- Fu, Y.; Zang, W.; Wang, P.; Xing, L.; Xue, X.; Zhang, Y. Portable room-temperature self-powered/active H2 sensor driven by human motion through piezoelectric screening effect. Nano Energy 2014, 8, 34–43. [Google Scholar] [CrossRef]

- Yu, H.; He, X.; Ding, W.; Hu, Y.; Yang, D.; Lu, S.; Wu, C.; Zou, H.; Liu, R.; Lu, C.; et al. A Self-Powered Dynamic Displacement Monitoring System Based on Triboelectric Accelerometer. Adv. Energy Mater. 2017, 7, 1700565. [Google Scholar] [CrossRef]

- Lim, K.W.; Peddigari, M.; Park, C.H.; Lee, H.Y.; Min, Y.; Kim, J.W.; Ahn, C.W.; Choi, J.J.; Hahn, B.D.; Choi, J.H.; et al. A high output magneto-mechano-triboelectric generator enabled by accelerated water-soluble nano-bullets for powering a wireless indoor positioning system. Energy Environ. Sci. 2019, 12, 666–674. [Google Scholar] [CrossRef]

- Kwak, M.S.; Lim, K.W.; Lee, H.Y.; Peddigari, M.; Jang, J.; Jeong, C.K.; Ryu, J.; Yoon, W.H.; Yi, S.N.; Hwang, G.T. Multiscale surface modified magneto-mechano-triboelectric nanogenerator enabled by eco-friendly NaCl imprinting stamp for self-powered IoT applications. Nanoscale 2021, 13, 8418–8424. [Google Scholar] [CrossRef]

- Hajra, S.; Vivekananthan, V.; Sahu, M.; Khandelwal, G.; Joseph Raj, N.P.M.; Kim, S.J. Triboelectric nanogenerator using multiferroic materials: An approach for energy harvesting and self-powered magnetic field detection. Nano Energy 2021, 85, 105964. [Google Scholar] [CrossRef]

- Yuan, Z.; Wei, X.; Jin, X.; Sun, Y.; Wu, Z.; Wang, Z.L. Magnetic energy harvesting of transmission lines by the swinging triboelectric nanogenerator. Mater. Today Energy 2021, 22, 100848. [Google Scholar] [CrossRef]

- Li, W.; Liu, Y.; Wang, S.; Li, W.; Liu, G.; Zhao, J.; Zhang, X.; Zhang, C. Vibrational Triboelectric Nanogenerator-Based Multinode Self-Powered Sensor Network for Machine Fault Detection. IEEE ASME Trans. Mechatron. 2020, 25, 2188–2196. [Google Scholar] [CrossRef]

- Wu, C.; Zhou, Q.; Wen, G. Research on self-powered rotation speed sensor for drill pipe based on triboelectric-electromagnetic hybrid nanogenerator. Sens. Actuators A Phys. 2021, 326, 112723. [Google Scholar] [CrossRef]

- Yang, H.; Pang, Y.; Bu, T.; Liu, W.; Luo, J.; Jiang, D.; Wang, Z.L. Triboelectric micromotors actuated by ultralow frequency mechanical stimul. Nat. Commun. 2019, 10, 2309. [Google Scholar] [CrossRef]

- Zeng, X.; Yang, Z.; Wu, P.; Cao, L.; Luo, Y. Power Source based on Electric Field Energy Harvesting for Monitoring Devices of High-voltage Transmission Line. IEEE Trans. Ind. Electron. 2020, 68, 7083–7092. [Google Scholar] [CrossRef]

- Yang, F.; Du, L.; Yu, H.; Huang, P. Magnetic and Electric Energy Harvesting Technologies in Power Grids: A Review. Sensors 2020, 20, 1496. [Google Scholar] [CrossRef]

- Huertas, J.S.C.; Tavares, M.C. Analyzing Rural Electrification Topologies Based on Induced Voltage at Insulated Shielding Wires. IEEE Trans. Power Deliv. 2019, 34, 53–62. [Google Scholar] [CrossRef]

- Cetinkaya, O.; Akan, O.B. Electric-Field Energy Harvesting From Lighting Elements for Battery-Less Internet of Things. IEEE Access 2017, 5, 7423–7434. [Google Scholar] [CrossRef]

- Menéndez, O.; Kouro, S.; Pérez, M.; Cheein, F.A. Mechatronized maximum power point tracking for electric field energy harvesting sensor. AEU Int. J. Electron. Commun. 2019, 110, 152830. [Google Scholar] [CrossRef]

- Yan, D.; Li, J.; Zhang, J.; Tian, X.; Ou, D.; Gu, J. A capacitive electric-field energy harvester with double-layer copper foil for 220V power line. J. Phys. Conf. Ser. 2020, 1585, 012002. [Google Scholar] [CrossRef]

- Chen, B.; Tang, W.; Wang, Z.L. Advanced 3D printing-based triboelectric nanogenerator for mechanical energy harvesting and self-powered sensing. Mater. Today 2021, 50, 224–238. [Google Scholar] [CrossRef]

- Khandelwal, G.; Maria Joseph Raj, N.P.; Kim, S.J. Materials Beyond Conventional Triboelectric Series for Fabrication and Applications of Triboelectric Nanogenerators. Adv. Energy Mater. 2021, 11, 2101170. [Google Scholar] [CrossRef]

- Niu, Z.; Cheng, W.; Cao, M.; Wang, D.; Wang, Q.; Han, J.; Long, Y.; Han, G. Recent advances in cellulose-based flexible triboelectric nanogenerators. Nano Energy 2021, 87, 106175. [Google Scholar] [CrossRef]

- Margaronis, K.; Busolo, T.; Nair, M.; Chalklen, T.; Kar-Narayan, S. Tailoring the triboelectric output of poly-L-lactic acid nanotubes through control of polymer crystallinity. J. Phys. Mater. 2021, 4, 034010. [Google Scholar] [CrossRef]

- Qiao, H.; Zhang, Y.; Huang, Z.; Wang, Y.; Li, D.; Zhou, H. 3D printing individualized triboelectric nanogenerator with macro-pattern. Nano Energy 2018, 50, 126–132. [Google Scholar] [CrossRef]

- Zou, H.; Zhang, Y.; Guo, L.; Wang, P.; He, X.; Dai, G.; Zheng, H.; Chen, C.; Wang, A.C.; Xu, C.; et al. Quantifying the triboelectric series. Nat. Commun. 2019, 10, 1427. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Wang, H.; Du, C.; Zhang, D.; Lin, H.; Chen, Y.; Xiong, J. Cellulose for Sustainable Triboelectric Nanogenerators. Adv. Energy Sustain. Res. 2022, 3, 2100161. [Google Scholar] [CrossRef]

- Wang, Z.L. On Maxwell’s displacement current for energy and sensors: The origin of nanogenerators. Mater. Today 2017, 20, 74–82. [Google Scholar] [CrossRef]

- Menéndez, O.; Villacrés, J.; Rivera, R.G.; Cheein, F.A. Analyzing the Capabilities of Electric Field Energy Harvesting Using Natural Leaves. IEEE Access 2021, 9, 158852–158861. [Google Scholar] [CrossRef]

- Menéndez, O.; Romero, L.; Cheein, F.A. Serial Switch Only Rectifier as a Power Conditioning Circuit for Electric Field Energy Harvesting. Energies 2020, 13, 5279. [Google Scholar] [CrossRef]

- Ghaffarinejad, A.; Hasani, J.Y.; Galayko, D.; Basset, P. Superior performance of half-wave to full-wave rectifier as a power conditioning circuit for triboelectric nanogenerators: Application to contact-separation and sliding mode TENG. Nano Energy 2019, 66, 104137. [Google Scholar] [CrossRef]

- Zanella, A.; Bui, N.; Castellani, A.; Vangelista, L.; Zorzi, M. Internet of Things for Smart Cities. IEEE Internet Things J. 2014, 1, 22–32. [Google Scholar] [CrossRef]

- Shao, J.; Willatzen, M.; Shi, Y.; Wang, Z.L. 3D mathematical model of contact-separation and single-electrode mode triboelectric nanogenerators. Nano Energy 2019, 60, 630–640. [Google Scholar] [CrossRef]

- Chang, K.; Kang, S.; Park, K.; Shin, S.; Kim, H.S.; Kim, H. Electric Field Energy Harvesting Powered Wireless Sensors for Smart Grid. J. Electr. Eng. Technol. 2012, 7, 75–80. [Google Scholar] [CrossRef]

- Santos, J.F.D.; Tshoombe, B.K.; Santos, L.H.B.; Araújo, R.C.F.; Manito, A.R.A.; Fonseca, W.S.; Silva, M.O. Digital Twin-Based Monitoring System of Induction Motors Using IoT Sensors and Thermo-Magnetic Finite Element Analysis. IEEE Access 2023, 11, 1682–1693. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, K.; Shi, Y.; Li, Z.; Zhao, D.; Pi, Y.; Cui, Y.; Zhou, X.; Zhang, Y.; Zhong, J. Electromagnetic energy harvesters based on natural leaves for constructing self-powered systems. Mater. Today Energy 2022, 29, 101131. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, W.; Liu, T.; Luo, B.; Qin, Y.; Gao, C.; Yuan, J.; Wang, S.; Nie, S. Multiscale Structural Triboelectric Aerogels Enabled by Self-Assembly Driven Supramolecular Winding. Adv. Funct. Mater. 2024, 2400476. [Google Scholar] [CrossRef]

- Shao, Y.; Du, G.; Luo, B.; Liu, T.; Zhao, J.; Zhang, S.; Wang, J.; Chi, M.; Cai, C.; Liu, Y.; et al. A Tough Monolithic-Integrated Triboelectric Bioplastic Enabled by Dynamic Covalent Chemistry. Adv. Mater. 2024, 2311993. [Google Scholar] [CrossRef] [PubMed]

- Gao, C.; Zhang, W.; Liu, T.; Luo, B.; Cai, C.; Chi, M.; Zhang, S.; Liu, Y.; Wang, J.; Zhao, J.; et al. Hierarchical porous triboelectric aerogels enabled by heterointerface engineering. Nano Energy 2024, 121, 109223. [Google Scholar] [CrossRef]

| Sensor/Instrument | Technical Specifications |

|---|---|

| Single-phase motor Imatesa, Santiago de Chile, Chile | Nominal Power: 1.10 kW Nominal speed: 2750 RPM Voltage supply: 230 V Operation frequency: 50 Hz |

| Creality Ender-Pro 3 3D printer Creality, Valparaíso, Chile | Printing size: 220 × 220 × 250 mm Filament: PLA Layer Thickness: 0.1–0.4 mm Print Precision: ±0.1 mm |

| Linear Actuator LA-T8-12-50-100/155-19.2 GoMotorWorld, Quito, Ecuador | Nominal voltage: 12 V Unload speed: 50 mm/s Load: 19.2 N Duty cycle: 10% |

| Voltage Regulator SD-240M Variac, Vaparaíso, Chile | Input voltage: 110–220 V Output voltage: 0–240 V Frequency: 50 Hz Maximum Power: 2 kVA |

| Management and rectifier circuit | −DB-107 full-bridge rectifier Comchip, Valparaíso, Chile Reverse voltage: 1000 V Voltage drop: 1.1 V Junction capacitor: 25 pF −4.7 F metalized polypropylene film capacitor Tinyair, Santiago de Chile, Chile Leakage current: 22 nF Maximum voltage: 103 V |

| Voltage (V) | Size Plate (cm × cm − cm2) | EFEH | TENG * | EF-TENG | Increase |

|---|---|---|---|---|---|

| Power (W) | Power (W) | Power (W) | % | ||

| 0 ** | 10 × 3.5 | 0.4986 ± 0.0649 | - | - | - |

| 50 | 2 × 3.5 | 0.6919 ± 0.0227 | 0.0138 ± 0.039 | 0.7065 ± 0.0377 | 2.11 |

| 4 × 3.5 | 1.3222 ± 0.0470 | 0.1565 ± 0.1412 | 1.4037 ± 0.1289 | 6.16 | |

| 6 × 3.5 | 2.3901 ± 0.0729 | 0.2010 ± 0.1533 | 2.4581 ± 0.1709 | 2.85 | |

| 10 × 3.5 | 5.3835 ± 0.2130 | 0.5434 ± 0.4633 | 5.9483 ± 0.4813 | 10.49 | |

| 100 | 2 × 3.5 | 2.1529 ± 0.4881 | 0.0168 ± 0.0063 | 2.2155 ± 0.0792 | 2.91 |

| 4 × 3.5 | 4.7411 ± 0.1244 | 0.2537 ± 0.2083 | 4.9630 ± 0.4060 | 4.68 | |

| 6 × 3.5 | 8.5167 ± 0.2768 | 0.2234 ± 0.2369 | 8.9482 ± 0.3978 | 5.07 | |

| 10 × 3.5 | 19.2855 ± 0.5903 | 0.5643 ± 0.5916 | 19.5761 ± 0.3576 | 1.51 | |

| 150 | 2 × 3.5 | 3.9898 ± 0.0843 | 0.0257 ± 0.0174 | 4.1245 ± 0.2507 | 3.38 |

| 4 × 3.5 | 9.0144 ± 0.1959 | 0.1868 ± 0.1184 | 9.0826 ± 0.6885 | 0.76 | |

| 6 × 3.5 | 17.0247 ± 0.6147 | 0.2652 ± 0.1772 | 17.0265 ± 1.3713 | 0.01 | |

| 10 × 3.5 | 38.3907 ± 0.8458 | 0.6876 ± 0.4987 | 39.0160 ± 2.3231 | 1.63 | |

| 200 | 2 × 3.5 | 5.7326 ± 0.1220 | 0.0393 ± 0.0269 | 6.0181 ± 0.2719 | 4.98 |

| 4 × 3.5 | 12.7761 ± 0.3057 | 0.1589 ± 0.1189 | 13.5376 ± 0.8585 | 5.96 | |

| 6 × 3.5 | 22.5497 ± 3.3033 | 0.2975 ± 0.2122 | 24.2505 ± 1.3204 | 7.54 | |

| 10 × 3.5 | 59.5426 ± 3.4157 | 0.3518 ± 0.3100 | 61.6962 ± 1.1257 | 3.62 | |

| 230 | 2 × 3.5 | 6.5748 ± 0.1647 | 0.0252 ± 0.0204 | 7.0184 ± 0.4396 | 6.75 |

| 4 × 3.5 | 15.1029 ± 0.5860 | 0.3291 ± 0.3181 | 16.0263 ± 1.2914 | 6.11 | |

| 6 × 3.5 | 32.9159 ± 1.37522 | 0.2996 ± 0.3374 | 25.7248 ± 4.450 | −21.85 | |

| 10 × 3.5 | 67.3201 ± 2.6583 | 0.5418 ± 0.5484 | 68.4114 ± 1.1034 | 1.62 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Menéndez, O.; Villacrés, J.; Prado, A.; Vásconez, J.P.; Auat-Cheein, F. Assessment of Triboelectric Nanogenerators for Electric Field Energy Harvesting. Sensors 2024, 24, 2507. https://doi.org/10.3390/s24082507

Menéndez O, Villacrés J, Prado A, Vásconez JP, Auat-Cheein F. Assessment of Triboelectric Nanogenerators for Electric Field Energy Harvesting. Sensors. 2024; 24(8):2507. https://doi.org/10.3390/s24082507

Chicago/Turabian StyleMenéndez, Oswaldo, Juan Villacrés, Alvaro Prado, Juan P. Vásconez, and Fernando Auat-Cheein. 2024. "Assessment of Triboelectric Nanogenerators for Electric Field Energy Harvesting" Sensors 24, no. 8: 2507. https://doi.org/10.3390/s24082507

APA StyleMenéndez, O., Villacrés, J., Prado, A., Vásconez, J. P., & Auat-Cheein, F. (2024). Assessment of Triboelectric Nanogenerators for Electric Field Energy Harvesting. Sensors, 24(8), 2507. https://doi.org/10.3390/s24082507