Direct Writing of Quasi-Sinusoidal and Blazed Surface Relief Optical Transmission Gratings in Bi12GeO20, Er: LiNbO3 and Er: Fe: LiNbO3 Crystals by Nitrogen Ion Microbeams of 5 MeV and 10.5 MeV Energy

Abstract

:1. Introduction

2. Materials and Methods

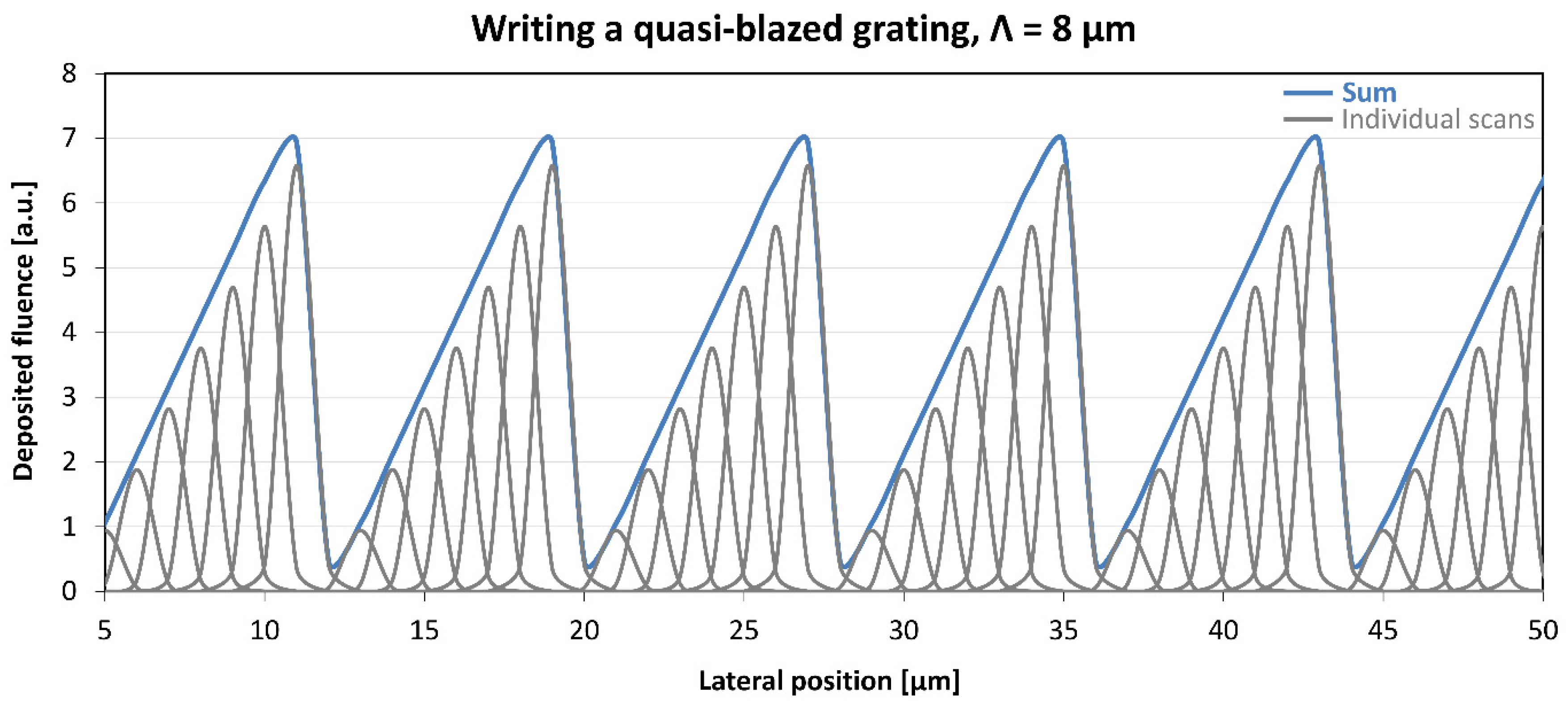

2.1. Design of the Gratings

2.2. Implantation of the Gratings

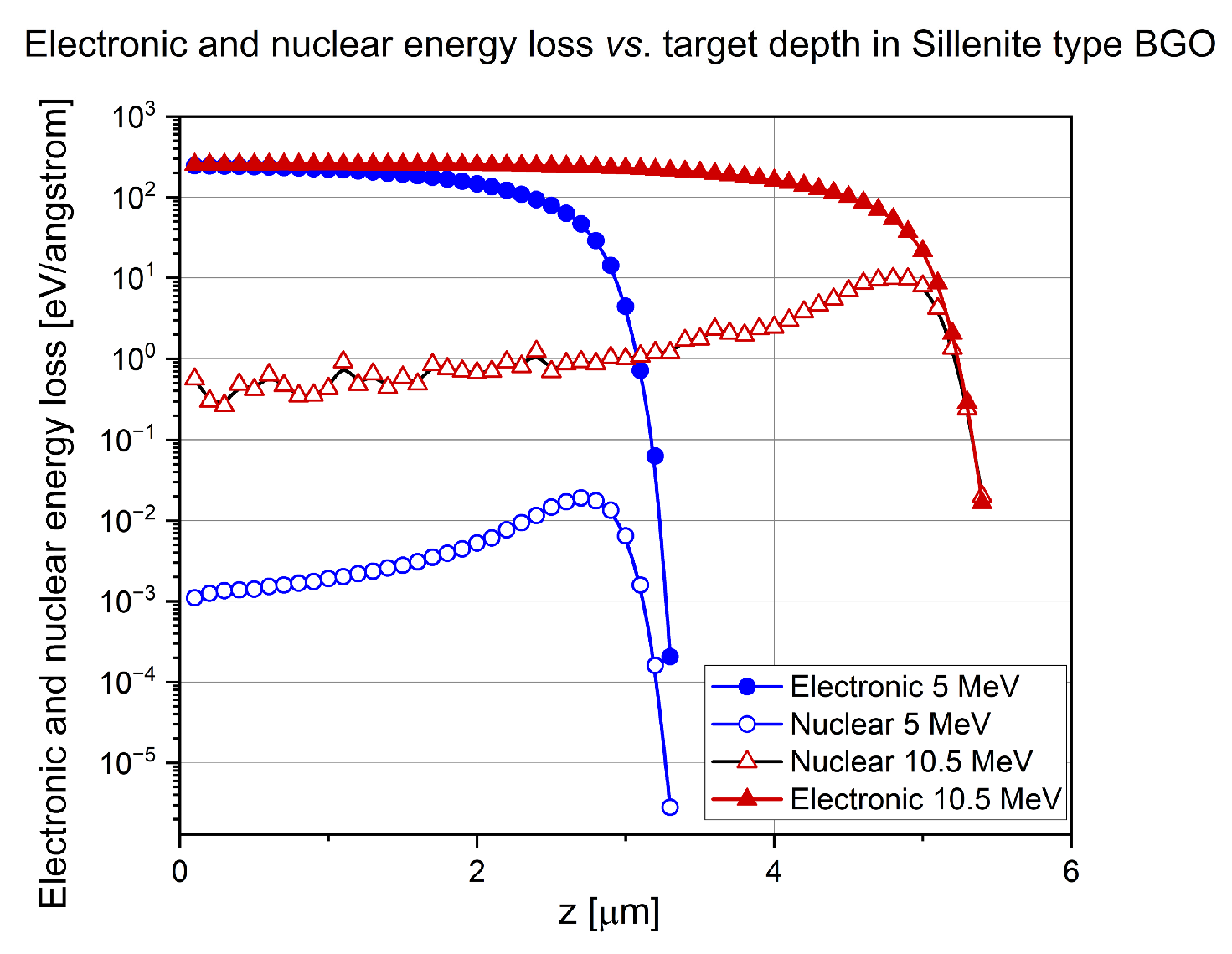

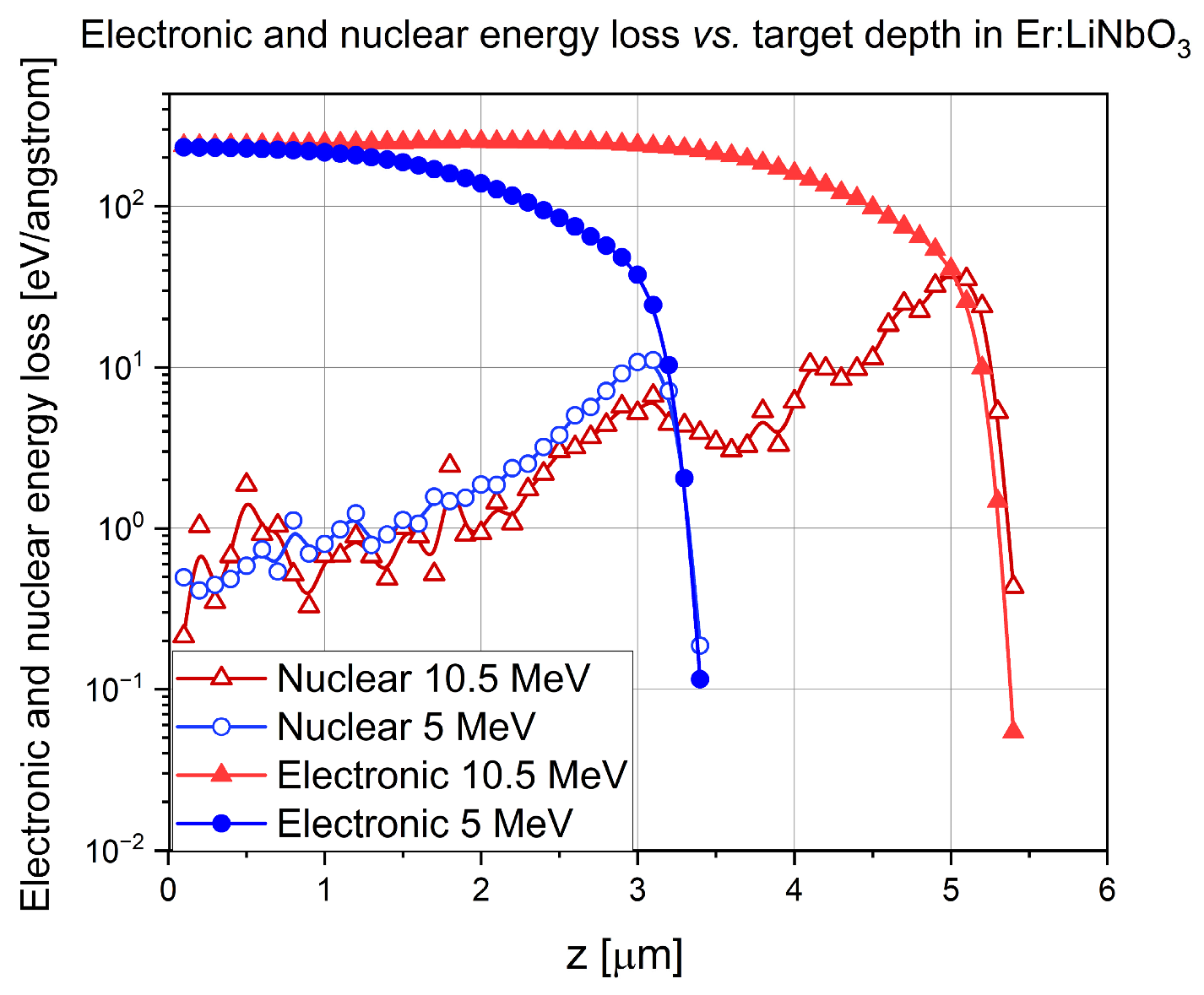

2.3. SRIM Simulations

3. Results

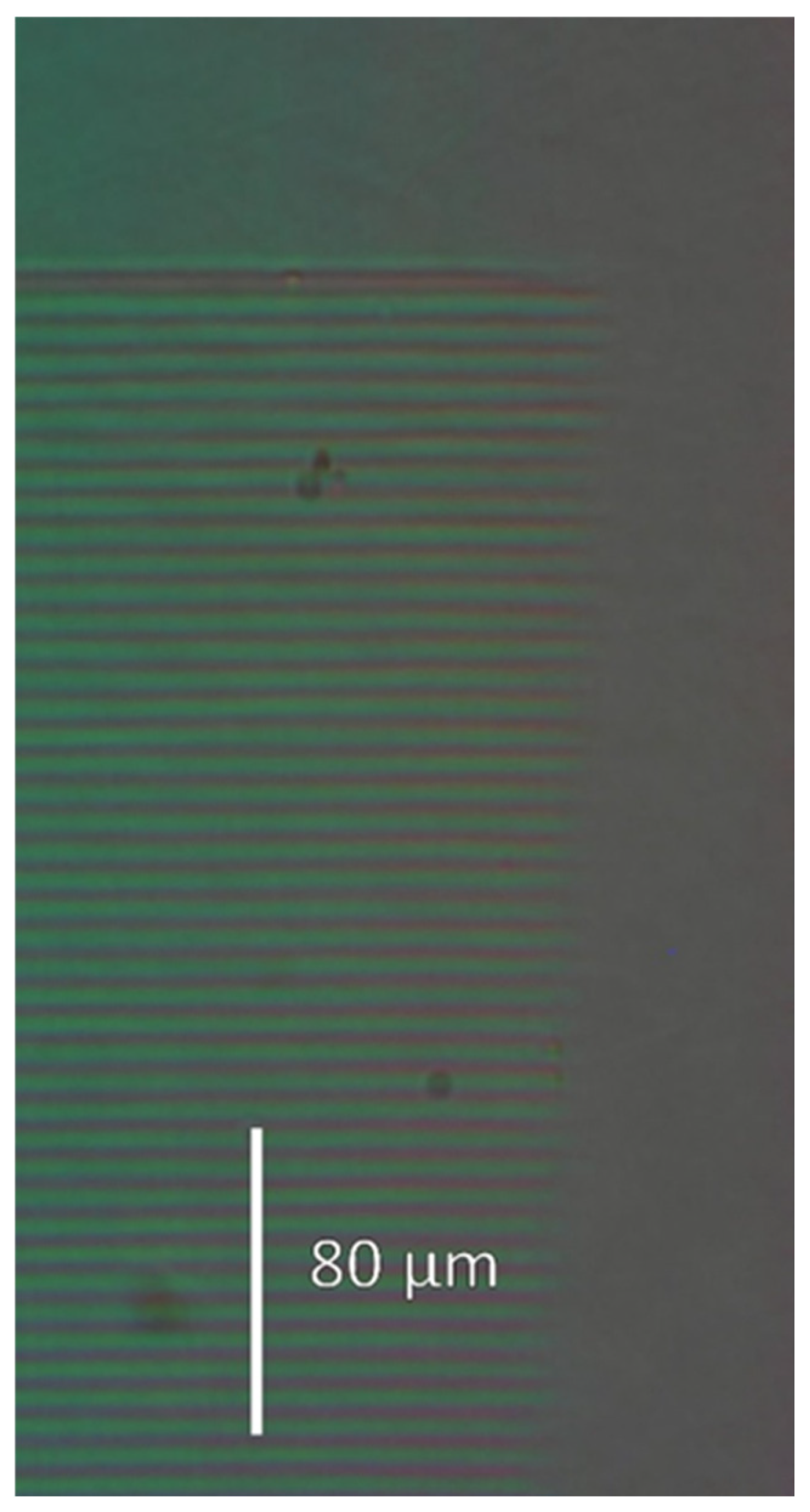

3.1. Microscopic Study of the Gratings

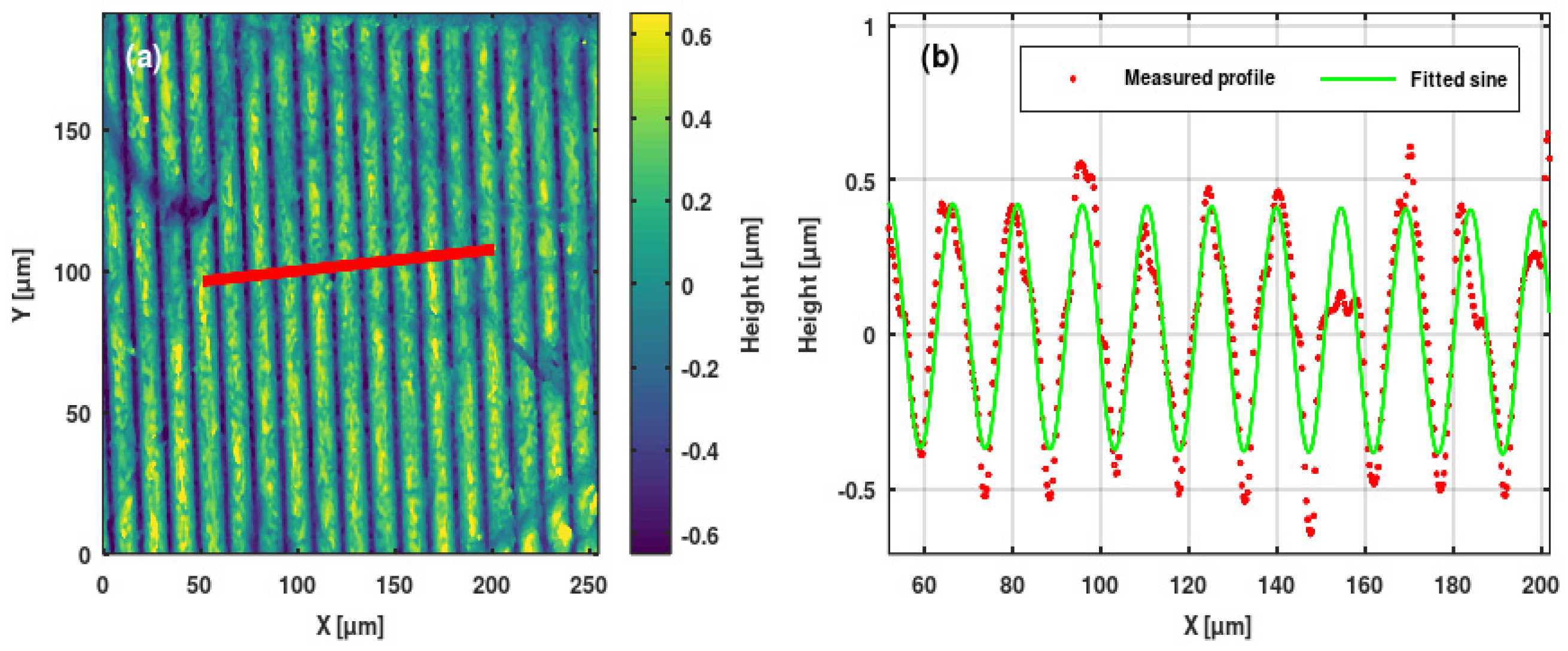

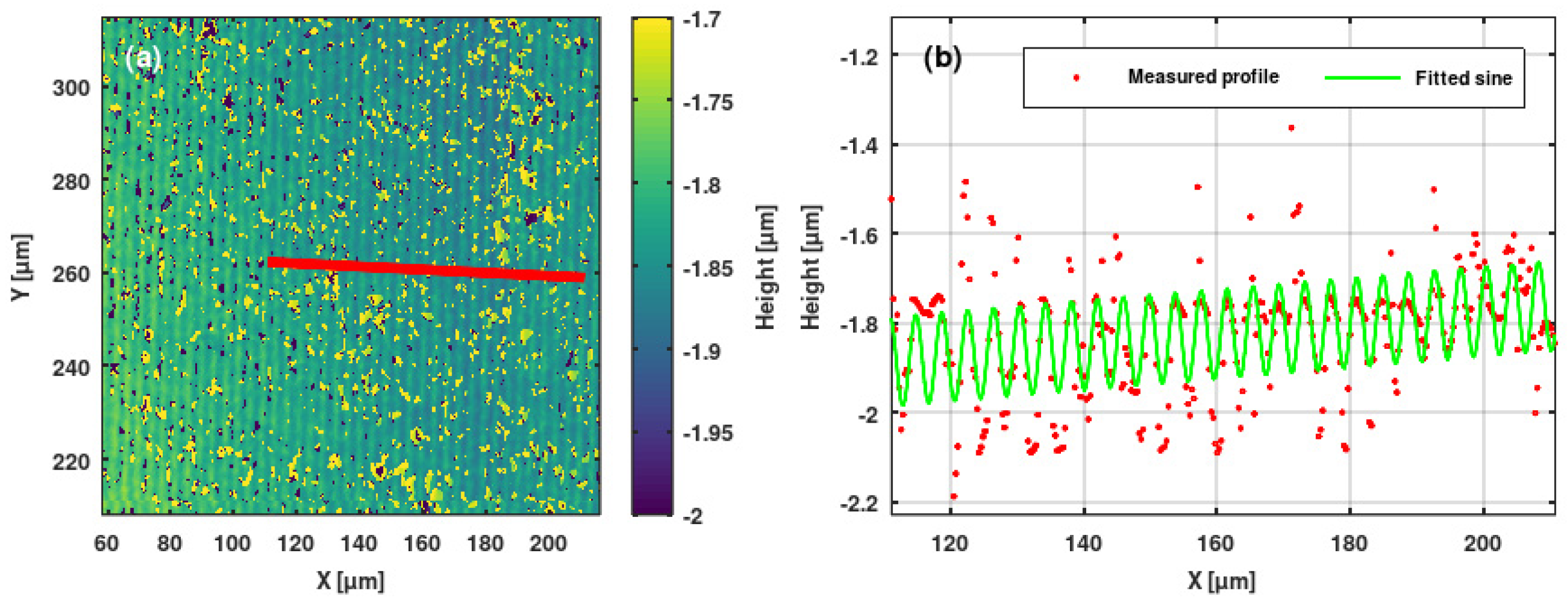

3.2. Microprofilometric Study of the Gratings and Analysis of the Grating Profiles

- In these experiments, a higher fluence resulted in higher peak-to-peak grating amplitude, when the ion energy and grating type were the same.

- Bi12GeO20 crystal implantations with the same fluence at an ion energy of 10.5 MeV produced much higher grating amplitudes than those performed at an ion energy of 5 MeV for both sinusoidal and blazed gratings. Namely, doubling the ion energy provided an increase of about 3.5 times in grating amplitude.

- At an ion energy of 5 MeV, the same fluences produced 1.5–2 times larger grating amplitudes in the Er: LiNbO3 than in the Bi12GeO20. However, in the case of Er: LiNbO3 crystal targets, the increase of the ion energy from 5 MeV to 10.5 MeV did not produce an increase in grating amplitude. Instead, the amplitudes of both the sinusoidal and blazed gratings decreased considerably. But it must be stressed that there was only one value of fluence for which comparison could be made.

- Further increasing the implanted fluence over 1015 ion/cm2 in the Er: Fe: LiNbO3 resulted in sinusoidal gratings of extremely large amplitude at an ion energy of 5 MeV. The peak-to-peak amplitude reached 800 nm for the GL4 grating, while surface damage was still minimal. Doubling the fluence produced a grating of an amplitude of 1600 nm, but with considerable surface damage.

3.3. Measurement and Calculation of the Diffraction Efficiencies

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wood, J. Ion Implantation. In Encyclopedia of Materials: Science and Technology; Elsevier: Amsterdam, The Netherlands, 2001; pp. 4284–4286. [Google Scholar] [CrossRef]

- Schineller, E.R.; Flam, R.P.; Wilmot, D.W. Optical Waveguides Formed by Proton Irradiation of Fused Silica. J. Opt. Soc. Am. 1968, 58, 1171. [Google Scholar] [CrossRef]

- Townsend, P.D.; Chandler, P.J.; Zhang, L. Optical Effects of Ion Implantation; Cambridge University Press: Cambridge, UK, 1994. [Google Scholar]

- Chen, F. Micro- and submicrometric waveguiding structures in optical crystals produced by ion beams for photonic applications. Laser Photon Rev. 2012, 6, 622. [Google Scholar] [CrossRef]

- Hartemann, P. Ion-implanted acoustic-surface-wave resonator. Appl. Phys. Lett. 1976, 28, 73. [Google Scholar] [CrossRef]

- Garvin, H.L.; Garmire, E.; Somekh, S.; Stoll, H.; Yariv, A. Ion Beam Micromachining of Integrated Optics Components. Appl. Opt. 1973, 12, 455–459. [Google Scholar] [CrossRef]

- Kurmer, J.P.; Tang, C.L. Ion implanted grating couplers for optical waveguides. Appl. Phys. Lett. 1983, 42, 146. [Google Scholar] [CrossRef]

- Hwang, H.-L.; Tang, R.-S.; Loferski, J.J.; Yang, Y.-C. Ion implanted Grating Type Si Solar Cells. Jpn. J. Appl. Phys. 1980, 19, 527. [Google Scholar] [CrossRef]

- Erickson, L.E.; Champion, H.G.; Albert, J.; Hill, K.O.; Malo, B.; Thériault, S.; Bilodeau, F.; Johnson, D.C. Fabrication of a variable diffraction efficiency phase mask by multiple dose ion implantation. J. Vac. Sci. Technol. B 1995, 13, 2940. [Google Scholar] [CrossRef]

- Orth, A.; Reithmaier, J.P.; Faller, F.; Forchel, A. Gain-Coupled Distributed-Feedback GaInAs-GaAs Laser Structures Defined by Maskless Patterning with Focused Ion Beams. IEEE Photonics Technol. Lett. 1995, 7, 845. [Google Scholar] [CrossRef]

- Orth, A.; Reithmaier, J.P.; Faller, F.; Forchel, A. First-order gain-coupled (Ga, In) As/(Al, Ga) As distributed feedback lasers by focused ion beam implantation and in situ overgrowth. J. Vac. Sci. Technol. B 1995, 13, 2714. [Google Scholar] [CrossRef]

- Orth, A.; Reithmaier, J.P.; Zeh, R.; Doleschel, H.; Forchel, A. First order gain-coupled GaInAs/GaAs distributed feedback laser diodes patterned by focused ion beam implantation. Appl. Phys. Lett. 1996, 69, 1906. [Google Scholar] [CrossRef]

- Yu, X.; Chen, X.; Milosevic, M.M.; Shen, W.; Topley, R.; Chen, B.; Yan, X.; Cao, W.; Thomson, D.J.; Saito, S.; et al. Ge Ion Implanted Photonic Devices and Annealing for Emerging Applications. Micromachines 2022, 13, 291. [Google Scholar] [CrossRef] [PubMed]

- Roberts, A.; von Bibra, M.L. Fabrication of Buried Silica Using Focused Channel Waveguides in Fused Silica Using MeV Proton Beam Irradiation. J. Light. Technol. 1996, 14, 2554. [Google Scholar] [CrossRef]

- Schrempel, F.; Witthuhn, W. P-LIGA: 3D-integration of microstructures with curved surfaces. Nucl. Instrum. Methods Phys. Res. B 1998, 139, 363–371. [Google Scholar] [CrossRef]

- Bettiol, A.A.; Sum, T.C.; Cheong, F.C.; Sow, C.; Rao, S.V.; van Kan, J.; Teo, E.; Ansari, K.; Watt, F. A progress review of proton beam writing applications in microphotonics. Nucl. Instrum. Methods Phys. Res. B 2005, 231, 364–371. [Google Scholar] [CrossRef]

- Glass, G.A.; Rout, B.; Dymnikov, A.D.; Greco, R.R.; Kamal, M.; Reinhardt, J.R.; Peeples, J.A. High energy focused ion beam lithography using P-beam writing. Nucl. Instrum. Methods Phys. Res. B 2005, 241, 397–401. [Google Scholar] [CrossRef]

- Huszank, R.; Szilasi, S.Z.; Rajta, I.; Csik, A. Fabrication of optical devices in poly(dimethylsiloxane) by proton microbeam. Opt. Commun. 2010, 283, 176–180. [Google Scholar] [CrossRef]

- Romanenko, O.; Havránek, V.; Malinsky, P.; Slepička, P.; Stammers, J.; Švorčík, V.; Macková, A.; Fajstavr, D. Effect of irradiation conditions by swift heavy ions on the microstructure and composition of PMMA. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2019, 461, 175–180. [Google Scholar] [CrossRef]

- Romanenko, O.; Jagerova, A.; Borodkin, A.; Havranek, V.; Mackova, A. One-step 3D microstructuring of PMMA using MeV light ions. EPJ Web Conf. 2022, 261, 02001. [Google Scholar] [CrossRef]

- Bányász, I.; Fried, M.; Dücső, C.; Vértesy, Z. Recording of transmission phase gratings in glass by ion implantation. Appl. Phys. Lett. 2001, 79, 3755–3757. [Google Scholar] [CrossRef]

- Bányász, I.; Fried, M.; Dücső, C.; Vértesy, Z. Phase grating fabrication in glass via ion implantation. Proc. SPIE 2003, 4944, 171–182. [Google Scholar] [CrossRef]

- García, G.; Martin, M.; Ynsa, M.D.; Torres-Costa, V.; Crespillo, M.L.; Tardío, M.; Olivares, J.; Bosia, F.; Peña-Rodríguez, O.; Nicolas, J.; et al. Process design for the manufacturing of soft X-ray gratings in single-crystal diamond by high-energy heavy-ion irradiation. Eur. Phys. J. Plus 2022, 137, 1157. [Google Scholar] [CrossRef]

- Bányász, I.; Rajta, I.; Havránek, V.; Pujol, M.C.; Bazsó, G.; Kármán, G.; Nagy, G. Fabrication of Quasi-Sinusoidal Surface Relief Optical Transmission Gratings in Pyrex and IOG Glasses by Implantation with Oxygen and Nitrogen Ion Microbeams of the 5–6 MeV Energy Range. ACS Omega 2024, 9, 30415–30424. [Google Scholar] [CrossRef] [PubMed]

- Bányász, I.; Rajta, I.; Nagy, G.U.L.; Zolnai, Z.; Havranek, V.; Pelli, S.; Veres, M.; Berneschi, S.; Nunzi-Conti, G.; Righini, G. Fabrication of optical channel waveguides in crystals and glasses using macro- and micro ion beams. Nucl. Instrum. Methods Phys. Res. Sect. B 2014, 331, 157–162. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM—The stopping and range of ions in matter (2010). Nucl. Instrum. Methods Phys. Res. Sect. B 2010, 268, 1818–1823. [Google Scholar] [CrossRef]

- Dessauer, F. Über einige Wirkungen von Strahlen. IV. Z. Physik 1923, 20, 288–298. (In German) [Google Scholar] [CrossRef]

- Jordan, P. Methods and results of radiobiology. Radiologica 1938, 3, 157. [Google Scholar]

- Seitz, F. On the disordering of solids by action of fast massive particles. Discuss. Faraday Soc. 1949, 5, 271–282. [Google Scholar] [CrossRef]

- Seitz, F.; Koehler, J.S. Displacement of Atoms during Irradiation. In Solid State Physics; Seitz, E., Turnbull, D., Eds.; Academic Press: London, UK; New York, NY, USA, 1956; Volume 2, p. 305. Available online: https://shop.elsevier.com/books/solid-state-physics/low/978-0-12-607702-5 (accessed on 19 January 2025).

- Klaumünzer, S.; Changlin, L.; Löffler, S.; Rammensee, M.; Schumacher, G. Plastic Flow of Vitreous Silica and Pyrex During Bombardment with Fast Heavy Ions. Nucl. Instrum. Methods Phys. Res. B 1989, 39, 665–669. [Google Scholar] [CrossRef]

- Trinkaus, H.; Ryazanov, A.I. Viscoelastic Model for the Plastic Flow of Amorphous Solids under Energetic Ion Bombardment. Phys. Rev. Lett. 1995, 74, 5072. [Google Scholar] [CrossRef]

- Klaumünzer, S.L. Plastic Flow of Amorphous Materials During Ion Bombardment. In Multiscale Phenomena in Plasticity: From Experiments to Phenomenology, Modelling and Materials Engineering; Lépinoux, J., Mazière, D., Pontikis, V., Saada, G., Eds.; NATO Science Series; Springer: Dordrecht, The Netherlands, 2000; Volume 367. [Google Scholar] [CrossRef]

- van Dillen, T.; Polman, A.; Onck, P.R.; van der Giessen, E. Anisotropic plastic deformation by viscous flow in ion tracks. Phys. Rev. B 2005, 71, 024103. [Google Scholar] [CrossRef]

- Sensofar. PLu 2300 Optical Surface Profiler, First Shown on Laser 2003. Available online: https://www.sensofar.com/launch-plu-2300/ (accessed on 19 January 2025).

- Lambda. Zygo NewView™ 7100. Available online: https://www.lambdaphoto.co.uk/zygo-newviewtm-7100.html (accessed on 19 January 2025).

- Raman, C.V.; Nath, N.S.N. The diffraction of light by high frequency sound waves: Part I. Proc. Indian Acad. Sci. Sect. A 1935, 2, 406–412. [Google Scholar] [CrossRef]

- de Jong, T.M.; de Boer, D.K.G.; Bastiaansen, C.W.M. Surface-relief and polarization gratings for solar concentrators. Opt. Express 2011, 19, 15127–15142. [Google Scholar] [CrossRef] [PubMed]

- Palmer, C. Diffraction Grating Handbook; MKS Instruments—Newport: Rochester, NY, USA, 2020; p. 118. Available online: https://www.researchgate.net/publication/339913143_DIFFRACTION_GRATING_HANDBOOK_eighth_edition (accessed on 19 January 2025).

- Kazanskiy, N.L.; Khonina, S.N.; Butt, M.A.; Kaźmierczak, A.; Piramidowicz, R. State-of-the-Art Optical Devices for Biomedical Sensing Applications—A Review. Electronics 2021, 10, 973. [Google Scholar] [CrossRef]

| Name of the Grating Groups | Sample Material | Implanted Ion and Charge State | Ion Beam Energy [MeV] | Ion Beam Lateral Dimensions [μm × μm] | Current Density in the Microbeam [10−3 A/cm2] | Implanted Fluence [ion/cm2] | Grating Constant (Λ) [µm] | Grating Profile |

|---|---|---|---|---|---|---|---|---|

| GN | Bi12GeO20 crystal | N3+ | 5 | 4 × 4 | 0.70 | 4 × 1014 | 16 | Saw-tooth |

| GP | Bi12GeO20 crystal | N3+ | 5 | 4 × 4 | 0.70 | 1 × 1014 | 16 | Saw-tooth |

| GQ, GR | Bi12GeO20 crystal | N3+ | 5 | 4 × 4 | 0.70 | 4 × 1014 | 16 | Sine |

| GS | Bi12GeO20 crystal | N3+ | 5 | 4 × 4 | 0.70 | 1 × 1014 | 16 | Sine |

| GZ06 | Bi12GeO20 crystal | N4+ | 10.5 | 4 × 4 | 1.0 | 4 × 1014 | 16 | Saw-tooth |

| GZ07 | Bi12GeO20 crystal | N4+ | 10.5 | 4 × 4 | 1.0 | 1 × 1014 | 16 | Saw-tooth |

| GZ08 | Bi12GeO20 crystal | N4+ | 10.5 | 4 × 4 | 1.25 | 4 × 1014 | 16 | Sine |

| GZ09 | Bi12GeO20 crystal | N4+ | 10.5 | 4 × 4 | 1.25 | 1 × 1014 | 16 | Sine |

| GH | Bi12GeO20 crystal | N4+ | 10.5 | 2.5 × 10 | 0.57 | 4 × 1014 | 16 | Sine |

| GL1 | Er:Fe:LiNbO3 crystal | N3+ | 5 | 2.5 × 20 | 0.57 | 5 × 1015 | 4 | Sine |

| GL2 | Er:Fe:LiNbO3 crystal | N3+ | 5 | 3 × 20 | 0.57 | 5 × 1015 | 16 | Sine |

| GL4 | Er:Fe:LiNbO3 crystal | N3+ | 5 | 3 × 20 | 0.57 | 1.4 × 1015 | 16 | Sine |

| GL6 | Er:Fe:LiNbO3 crystal | N3+ | 5 | 3 × 20 | 0.57 | 4 × 1014 | 16 | Sine |

| GT | Er:LiNbO3 crystal | N3+ | 5 | 4 × 4 | 0.57 | 4 × 1014 | 16 | Saw-tooth |

| GU | Er:LiNbO3 crystal | N3+ | 5 | 4 × 4 | 0.57 | 1 × 1014 | 16 | Saw-tooth |

| GV | Er:LiNbO3 crystal | N3+ | 5 | 4 × 4 | 0.57 | 4 × 1014 | 16 | Sine |

| GW | Er:LiNbO3 crystal | N3+ | 5 | 4 × 4 | 0.57 | 1 × 1014 | 16 | Sine |

| GZ02 | Er:LiNbO3 crystal | N4+ | 10.5 | 4 × 4 | 1.0 | 4 × 1014 | 16 | Saw-tooth |

| GZ03 | Er:LiNbO3 crystal | N4+ | 10.5 | 4 × 4 | 1.0 | 1 × 1014 | 16 | Saw-tooth |

| GZ04 | Er:LiNbO3 crystal | N4+ | 10.5 | 4 × 4 | 1.0 | 4 × 1014 | 16 | Sine |

| GZ05 | Er:LiNbO3 crystal | N4+ | 10.5 | 4 × 4 | 1.0 | 1 × 1014 | 16 | Sine |

| Name of the Grating | Name of the Sample | Implanted Ion | Energy of the Implanted Ion [MeV] | Implanted Fluence [ion/cm2] | Fitted Grating Amplitude [nm] | Measured First-Order Diffraction Efficiency |

|---|---|---|---|---|---|---|

| GS | Bi12GeO20 | N3+ | 5 | 1 × 1014 | 112 | 0.02 |

| GR | Bi12GeO20 | N3+ | 5 | 4 × 1014 | 158 | 0.0937 |

| GZ09 | Bi12GeO20 | N4+ | 10.5 | 1 × 1014 | 380 | 0.106 |

| GH | Bi12GeO20 | N4+ | 10.5 | 4 × 1014 | 436 | 0.1489 |

| GL4 | Er:Fe:LiNbO3 | N3+ | 5 | 1.4 × 1015 | 792 | 0.098 |

| GL2 | Er:Fe:LiNbO3 | N3+ | 5 | 5 × 1015 | 1600 | 0.032 |

| GW | Er:LiNbO3 | N3+ | 5 | 1 × 1014 | 180 | |

| GV | Er:LiNbO3 | N3+ | 5 | 4 × 1014 | 304 | 0.174 |

| GZ05 | Er:LiNbO3 | N4+ | 10.5 | 1 × 1014 | 0.0073 | |

| GZ04 | Er:LiNbO3 | N4+ | 10.5 | 4 × 1014 | 200 | 0.250 |

| Name of the Grating | Name of the Sample | Implanted Ion | Energy of the Implanted Ion [MeV] | Implanted Fluence [ion/cm2] | Fitted Grating Amplitude [nm] | Measured First-Order Diffraction Efficiency |

|---|---|---|---|---|---|---|

| GP | Bi12GeO20 | N3+ | 5 | 1 × 1014 | 90 | 0.0173 |

| GN | Bi12GeO20 | N3+ | 5 | 4 × 1014 | 126 | 0.0445 |

| GZ07 | Bi12GeO20 | N4+ | 10.5 | 1 × 1014 | 350 | 0.138 |

| GZ06 | Bi12GeO20 | N4+ | 10.5 | 4 × 1014 | 496 | 0.236 |

| GU | Er:LiNbO3 | N3+ | 5 | 1 × 1014 | ||

| GT | Er:LiNbO3 | N3+ | 5 | 4 × 1014 | 296 | 0.250 |

| GZ03 | Er:LiNbO3 | N4+ | 10.5 | 1 × 1014 | 0.0012 | |

| GZ02 | Er:LiNbO3 | N4+ | 10.5 | 4 × 1014 | 150 | 0.221 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bányász, I.; Nagy, G.; Havránek, V.; Pujol, M.C.; Nagyné Szokol, Á.; Kármán, G.; Magnusson, R.; Rajta, I. Direct Writing of Quasi-Sinusoidal and Blazed Surface Relief Optical Transmission Gratings in Bi12GeO20, Er: LiNbO3 and Er: Fe: LiNbO3 Crystals by Nitrogen Ion Microbeams of 5 MeV and 10.5 MeV Energy. Sensors 2025, 25, 804. https://doi.org/10.3390/s25030804

Bányász I, Nagy G, Havránek V, Pujol MC, Nagyné Szokol Á, Kármán G, Magnusson R, Rajta I. Direct Writing of Quasi-Sinusoidal and Blazed Surface Relief Optical Transmission Gratings in Bi12GeO20, Er: LiNbO3 and Er: Fe: LiNbO3 Crystals by Nitrogen Ion Microbeams of 5 MeV and 10.5 MeV Energy. Sensors. 2025; 25(3):804. https://doi.org/10.3390/s25030804

Chicago/Turabian StyleBányász, István, Gyula Nagy, Vladimir Havránek, Maria Cinta Pujol, Ágnes Nagyné Szokol, György Kármán, Robert Magnusson, and István Rajta. 2025. "Direct Writing of Quasi-Sinusoidal and Blazed Surface Relief Optical Transmission Gratings in Bi12GeO20, Er: LiNbO3 and Er: Fe: LiNbO3 Crystals by Nitrogen Ion Microbeams of 5 MeV and 10.5 MeV Energy" Sensors 25, no. 3: 804. https://doi.org/10.3390/s25030804

APA StyleBányász, I., Nagy, G., Havránek, V., Pujol, M. C., Nagyné Szokol, Á., Kármán, G., Magnusson, R., & Rajta, I. (2025). Direct Writing of Quasi-Sinusoidal and Blazed Surface Relief Optical Transmission Gratings in Bi12GeO20, Er: LiNbO3 and Er: Fe: LiNbO3 Crystals by Nitrogen Ion Microbeams of 5 MeV and 10.5 MeV Energy. Sensors, 25(3), 804. https://doi.org/10.3390/s25030804