Applications of Cd(Zn)Te Radiation Detectors in Non-Destructive Testing and Evaluation

Abstract

1. Introduction

2. Key Parameters of RTSD

2.1. Energy Resolution

2.1.1. Leakage Current

2.1.2. Charge Sharing in Energy Resolution Degradation

2.1.3. Charge Loss

2.2. Spatial Resolution

2.2.1. Charge Sharing in Spatial Resolution Degradation

2.2.2. Scatter

2.3. Time Resolution

2.4. Detector Efficiency

2.5. Form Factor

2.6. Electrode Designs to Alleviate Degradation Factors

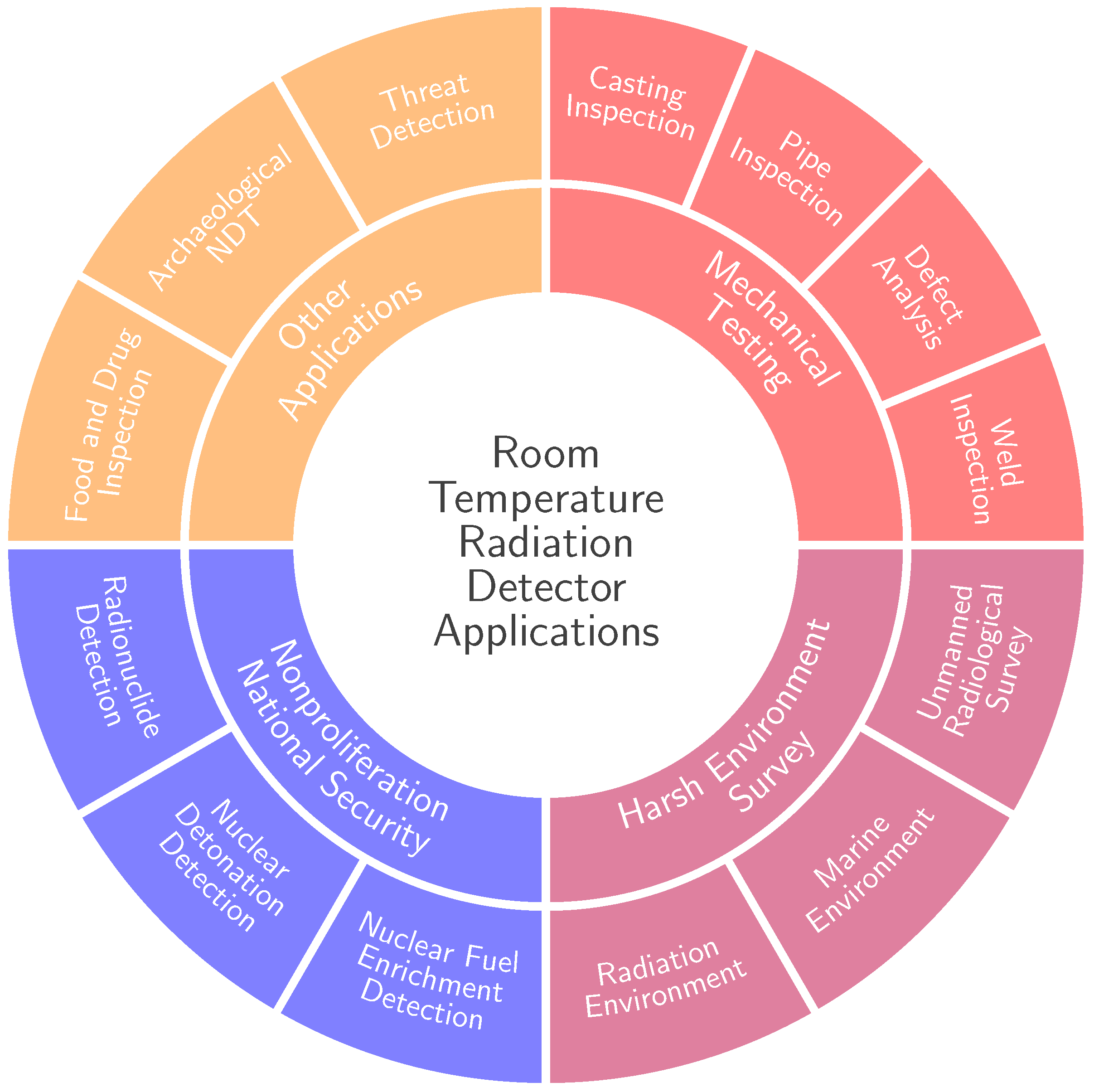

3. Applications

3.1. Imaging

3.1.1. Real Time Mechanical Tensile Testing

3.1.2. Carbon Fiber Reinforced Monitoring

3.1.3. Inspection of Pipes

3.1.4. Automotive Inline Welding Inspection

3.1.5. Casting Inspection

3.1.6. Threat Detection

Explosive Detection

Illicit Substance Detection

3.1.7. Material Decomposition

3.1.8. Density Measurements

3.1.9. Archaeological NDT

3.1.10. Nuclear Non-Proliferation and Security

3.1.11. Quantifying the Amount of Uranium in Nuclear Fuel

3.2. Spectroscopy

3.2.1. Explosive Detection

3.2.2. Unmanned Aerial Vehicle Radiological Surveying

3.2.3. Harsh Environment Survey

Marine Environment

Radiation Environment

3.2.4. Food and Drug Inspection

Compacted Pill Inspection

Material Decomposition in Meat Inspection

Heavy Metal Detection in Dried Fruit

3.2.5. Density Measurements

3.2.6. Nuclear Non-Proliferation and Security

Waste Barrel Identification

Nuclear Fuel Enrichment Detection

Nuclear Aerosol Detection

Special Nuclear Material Detection

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ASIC | Application-Specific Integrated Circuit |

| CEA | The French Alternative Energies and Atomic Energy Commission |

| IRFU | Institute of Research Into The Fundamental Laws of the Universe |

| CNVR | Contrast to Noise Variance Ratio |

| COMPUCEA | Combined Procedure for Uranium Concentration and Enrichment Assay |

| cps | Counts Per Second |

| CSA | Charge-Sharing Addition |

| CSD | Charge-Sharing Discrimination |

| CT | Computed Tomography |

| CTBT | Comprehensive Nuclear-Test-Ban Treaty |

| CTBTO | Comprehensive Nuclear-Test-Ban Treaty Organization |

| CUI | Corrosion Under Insulation |

| CZT | Cadmium Zinc Telluride |

| DOI | Depth of Interaction |

| EDXRD | Energy Dispersive X-ray Diffraction |

| FOV | Field of View |

| fps | Frames Per Second |

| FWHM | Full Width at Half Maximum |

| GADDOX | Gadolinium Oxysulfide |

| HPGe | High Purity Germanium |

| IQI | Image Quality Indicators |

| MDA | Minimum Detectable Activity |

| MDC | Minimum Detectable Counts |

| NAA | Neutron Activation Analysis |

| NDT&E | Non-Destructive Testing and Evaluation |

| PE | Polyethylene |

| PMMA | Polymethyl methacrylate |

| PMT | Photomultiplier Tube |

| POM | Polyoxymethylene |

| PTFE | Polytetrafluoroethylene |

| RTSD | Room Temperature Semiconductor Detector |

| SNM | Special Nuclear Material |

| SPECT | Single Photon Emission Computed Tomography |

| SUGI | Submarine Gamma Imager |

| TECZT | Two Element CZT |

| TNT | Trinitrotoluene |

| XRD | X-ray Diffraction |

References

- Menaria, T.; Kumar, M. Review on radiographic imaging modalities for non-destructive testing and evaluation (NDT & E). In Proceedings of the International Conference on Sustainable Computing in Science, Technology and Management (SUSCOM), Jaipur, India, 26–28 February 2019; Amity University Rajasthan: Rajasthan, India, 2019. [Google Scholar]

- Del Sordo, S.; Abbene, L.; Caroli, E.; Mancini, A.M.; Zappettini, A.; Ubertini, P. Progress in the Development of CdTe and CdZnTe Semiconductor Radiation Detectors for Astrophysical and Medical Applications. Sensors 2009, 9, 3491–3526. [Google Scholar] [CrossRef] [PubMed]

- Alam, M.D.; Nasim, S.S.; Hasan, S. Recent progress in CdZnTe based room temperature detectors for nuclear radiation monitoring. Prog. Nucl. Energy 2021, 140, 103918. [Google Scholar] [CrossRef]

- Li, Z.; Cheng, J.; Liu, F.; Wang, Q.; Wen, W.W.; Huang, G.; Wu, Z. Research on the Technological Progress of CZT Array Detectors. Sensors 2024, 24, 725. [Google Scholar] [CrossRef]

- Iniewski, K. CdTe and CdZnTe Materials: Material Properties and Applications, 1st ed.; Iniewski, K., Ed.; Springer Nature Switzerland: Cham, Switzerland, 2024. [Google Scholar]

- Russo, P.; Mettivier, G.; Pani, R.; Pellegrini, R.; Cinti, M.N.; Bennati, P. Imaging performance comparison between a scintillator based and a CdTe semiconductor based photon counting compact gamma camera. Med. Phys. 2009, 36, 1298–1317. [Google Scholar] [CrossRef] [PubMed]

- Abbene, L.; Del Sordo, S. CdTe Detectors. In Comprehensive Biomedical Physics; Newnes: Oxford, UK, 2014; Chapter 8.18. [Google Scholar]

- Cherry, S.R.; Sorenson, J.A.; Phelps, M.E. Radiation Detectors. In Physics in Nuclear Medicine; Elsevier: Amsterdam, The Netherlands, 2012; Chapter 7. [Google Scholar]

- Knoll, G.F. Semiconductor Diode Detectors. In Radiation Detection and Measurement; John & Wiley Sons Inc.: Hoboken, NJ, USA, 2010; Chapter 11. [Google Scholar]

- Moszyński, M.; Syntfeld-Każuch, A.; Swiderski, L.; Grodzicka, M.; Iwanowska, J.; Sibczyński, P.; Szczęśniak, T. Energy resolution of scintillation detectors. Nucl. Instrum. Methods Phys. Res. Sect. A 2016, 805, 25–35. [Google Scholar] [CrossRef]

- Bolotnikov, A.; Camarda, G.; Wright, G.; James, R. Factors limiting the performance of CdZnTe detectors. IEEE Trans. Nucl. Sci. 2005, 52, 589–598. [Google Scholar] [CrossRef]

- Buttacavoli, A.; Principato, F.; Gerardi, G.; Bettelli, M.; Zappettini, A.; Seller, P.; Veale, M.C.; Zanettini, S.; Abbene, L. Ballistic deficit pulse processing in cadmium–zinc–telluride pixel detectors for high-flux X-ray measurements. Sensors 2022, 22, 3409. [Google Scholar] [CrossRef]

- Spieler, H. Semiconductor Detector Systems; Oxford University Press: Oxford, UK, 2005; Volume 12. [Google Scholar]

- Redus, R.; Pantazis, J.; Huber, A.; Jordanov, V.; Butler, J.; Apotovsky, B. Fano factor determination for CZT. Mrs Online Proc. Libr. 1997, 487, 101. [Google Scholar] [CrossRef]

- Veale, M.C.; Booker, P.; Cross, S.; Hart, M.D.; Jowitt, L.; Lipp, J.; Schneider, A.; Seller, P.; Wheater, R.M.; Wilson, M.D.; et al. Characterization of the uniformity of high-flux CdZnTe material. Sensors 2020, 20, 2747. [Google Scholar] [CrossRef]

- Zhang, F.; Herman, C.; He, Z.; De Geronimo, G.; Vernon, E.; Fried, J. Characterization of the H3D ASIC readout system 3-D position sensitive CdZnTe detectors. IEEE Trans. Nucl. Sci. 2012, 59, 236–242. [Google Scholar] [CrossRef]

- Mele, F.; Quercia, J.; Abbene, L.; Benassi, G.; Bettelli, M.; Buttacavoli, A.; Principato, F.; Zappettini, A.; Bertuccio, G. Advances in high-energy-resolution CdZnTe linear array pixel detectors with fast and low noise readout electronics. Sensors 2023, 23, 2167. [Google Scholar] [CrossRef] [PubMed]

- Mescher, M.; Hoburg, J.; Schlesinger, T.; James, R. Analyses on the measurement of leakage currents in CdZnTe radiation detectors. IEEE Trans. Nucl. Sci. 1999, 46, 2289–2296. [Google Scholar] [CrossRef]

- Garson, A.; Li, Q.; Jung, I.V.; Dowkontt, P.; Bose, R.; Simburger, G.; Krawczynski, H. Leakage currents and capacitances of thick CZT detectors. In Proceedings of the 2007 IEEE Nuclear Science Symposium Conference Record, Honolulu, HI, USA, 28 October–3 November 2007; IEEE: Piscataway, NJ, USA, 2007; Volume 3, pp. 2258–2261. [Google Scholar]

- Veale, M.; Bell, S.; Duarte, D.; Schneider, A.; Seller, P.; Wilson, M.; Iniewski, K. Measurements of charge sharing in small pixel CdTe detectors. Nucl. Instrum. Methods Phys. Res. Sect. A 2014, 767, 218–226. [Google Scholar] [CrossRef]

- Koch-Mehrin, K.; Lees, J.; Bugby, S. A spectroscopic Monte-Carlo model to simulate the response of pixelated CdTe based detectors. Nucl. Instrum. Methods Phys. Res. Sect. A 2020, 976, 164241. [Google Scholar] [CrossRef]

- Dueñas, J.A.; Cobo, A.; Galtarossa, F.; Goasduff, A.; Mengoni, D.; Sánchez-Benítez, A. Energy Resolution from a Silicon Detector’s Interstrip Regions. Sensors 2024, 24, 2622. [Google Scholar] [CrossRef]

- Laštovička-Medin, G.; Rebarz, M.; Doknic, J.; Bozovic, I.; Kramberger, G.; Laštovička, T.; Andreasson, J. Exploring the interpad gap region in ultra-fast silicon detectors: Insights into isolation structure and electric field effects on charge multiplication. Sensors 2023, 23, 6746. [Google Scholar] [CrossRef]

- Banerjee, S.; Rodrigues, M.; Ballester, M.; Vija, A.H.; Katsaggelos, A.K. Learning-based physical models of room-temperature semiconductor detectors with reduced data. Sci. Rep. 2023, 13, 168. [Google Scholar] [CrossRef]

- Buttacavoli, A.; Principato, F.; Gerardi, G.; Cascio, D.; Raso, G.; Bettelli, M.; Zappettini, A.; Seller, P.; Veale, M.C.; Abbene, L. Incomplete charge collection at inter-pixel gap in low-and high-flux cadmium zinc telluride pixel detectors. Sensors 2022, 22, 1441. [Google Scholar] [CrossRef]

- Kim, J.C.; Anderson, S.E.; Kaye, W.; Zhang, F.; Zhu, Y.; Kaye, S.J.; He, Z. Charge sharing in common-grid pixelated CdZnTe detectors. Nucl. Instrum. Methods Phys. Res. Sect. A 2011, 654, 233–243. [Google Scholar] [CrossRef]

- Holstensson, M.; Partridge, M.; Buckley, S.E.; Flux, G.D. The effect of energy and source location on gamma camera intrinsic and extrinsic spatial resolution: An experimental and Monte Carlo study. Phys. Med. Biol. 2010, 55, 1735. [Google Scholar] [CrossRef]

- Zhu, Y.; Anderson, S.E.; He, Z. Sub-pixel position sensing for pixelated, 3-D position sensitive, wide band-gap, semiconductor, gamma-ray detectors. IEEE Trans. Nucl. Sci. 2011, 58, 1400–1409. [Google Scholar] [CrossRef]

- Schromm, T.; Beckmann, F.; Moosmann, J.; Berthe, D.; Pfeiffer, F.; Grosse, C. Challenges in non-destructive X-ray CT testing of riveted joints in the automotive industry. Discov. Appl. Sci. 2024, 6, 333. [Google Scholar] [CrossRef]

- He, Z.; Li, W.; Knoll, G.; Wehe, D.; Berry, J.; Stahle, C. 3-D position sensitive CdZnTe gamma-ray spectrometers. Nucl. Instrum. Methods Phys. Res. Sect. A 1999, 422, 173–178. [Google Scholar] [CrossRef]

- De Geronimo, G.; Zhu, Y.; Berry, J.E.; He, Z. Waveform-Sampling Front-End ASIC for 3D Position-Sensitive Detectors. IEEE Trans. Nucl. Sci. 2025. early access. [Google Scholar] [CrossRef]

- He, Z.; Li, W.; Knoll, G.; Wehe, D.; Du, Y. Effects of charge sharing in 3-D position sensitive CdZnTe gamma-ray spectrometers. Nucl. Instrum. Methods Phys. Res. Sect. A 2000, 439, 619–624. [Google Scholar] [CrossRef]

- Kim, J.W.; Joo, H.Y.; Choi, J.S.; Moon, J.H. Development and characterization of a portable multifunction radiation detector for radiological emergency preparedness. J. Korean Phys. Soc. 2023, 82, 98–106. [Google Scholar] [CrossRef]

- Carrascal, J.; Castilla, J.; Oller, J.; Díaz, A.; Vela, O.; Romero, L.; Pérez, J. Charge sharing and interaction depth corrections in a wide energy range for small pixel pitch CZT detectors. In Proceedings of the IEEE Nuclear Science Symposuim & Medical Imaging Conference, Knoxville, TN, USA, 30 October–6 November 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 3749–3755. [Google Scholar]

- Kim, J.C.; Kaye, W.R.; He, Z. Signal modeling of charge sharing effect in simple pixelated CdZnTe detector. J. Korean Phys. Soc. 2014, 64, 1336–1345. [Google Scholar] [CrossRef]

- Montémont, G.; Lux, S.; Monnet, O.; Stanchina, S.; Verger, L. Studying Spatial Resolution of CZT Detectors Using Sub-Pixel Positioning for SPECT. IEEE Trans. Nucl. Sci. 2014, 61, 2559–2566. [Google Scholar] [CrossRef]

- Yin, Y.; Chen, X.; Wu, H.; Komarov, S.; Garson, A.; Li, Q.; Guo, Q.; Krawczynski, H.; Meng, L.J.; Tai, Y.C. 3-D Spatial Resolution of 350 /spl mu/m Pitch Pixelated CdZnTe Detectors for Imaging Applications. IEEE Trans. Nucl. Sci. 2013, 60, 9–15. [Google Scholar] [CrossRef]

- Khalil, M.; Dreier, E.S.; Kehres, J.; Jakubek, J.; Olsen, U.L. Subpixel resolution in CdTe Timepix3 pixel detectors. J. Synchrotron Radiat. 2018, 25, 1650–1657. [Google Scholar] [CrossRef]

- Roque, G.; Schütz, M.K.; Fey, J.; Useche, J.S.; Fiederle, M.; Procz, S. Sub-pixel energy-weighting techniques for metallic contaminant highlighting in a pharmaceutical hard capsule using a Timepix3 CdZnTe hybrid pixel detector. J. Inst. 2022, 17, P10030. [Google Scholar] [CrossRef]

- Guerra, P.; Santos, A.; Darambara, D. An investigation of performance characteristics of a pixellated room-temperature semiconductor detector for medical imaging. J. Phys. Appl. Phys. 2009, 42, 175101. [Google Scholar] [CrossRef]

- Nakhostin, M. Optimizing timing performance of CdTe detectors for PET. Phys. Med. Biol. 2017, 62, N485. [Google Scholar] [CrossRef] [PubMed]

- Amrami, R.; Shani, G.; Hefetz, Y.; Pansky, A.; Wainer, N. Timing performance of pixelated CdZnTe detectors. Nucl. Instrum. Methods Phys. Res. Sect. A 2001, 458, 772–781. [Google Scholar] [CrossRef]

- Knoll, G.F. Radiation Detection and Measurement; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Wieczorek, H.; Goedicke, A.; Shao, L.; Petrillo, M.; Ye, J.; Vesel, J. Analytical model for pixellated SPECT detector concepts. In Proceedings of the IEEE Symposium Conference Record Nuclear Science 2004, Rome, Italy, 16–22 October 2004; IEEE: Piscataway, NJ, USA, 2004; Volume 4, pp. 2584–2588. [Google Scholar]

- Wilson, M.; Dummott, L.; Duarte, D.D.; Green, F.; Pani, S.; Schneider, A.; Scuffham, J.; Seller, P.; Veale, M. A 10 cm × 10 cm CdTe spectroscopic imaging detector based on the HEXITEC ASIC. J. Instrum. 2015, 10, P10011. [Google Scholar] [CrossRef]

- Szeles, C.; Cameron, S.E.; Ndap, J.O.; Chalmers, W.C. Advances in the crystal growth of semi-insulating CdZnTe for radiation detector applications. IEEE Trans. Nucl. Sci. 2002, 49, 2535–2540. [Google Scholar] [CrossRef]

- Goodman, D.I.; Streicher, M.; June, C.; Kitchen, B.; Wahl, C.G.; Driver, A.; Kaye, W. Energy Resolution and Efficiency Variations Across Commercial 3D Pixelated CdZnTe Crystals. In Proceedings of the 2022 IEEE Nuclear Science Symposium and Medical Imaging Conference (NSS/MIC), Milano, Italy, 5–12 November 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–3. [Google Scholar]

- Suzuki, K.; Seto, S.; Sawada, T.; Imai, K. Carrier transport properties of HPB CdZnTe and THM CdTe:Cl. IEEE Trans. Nucl. Sci. 2002, 49, 1287–1291. [Google Scholar] [CrossRef]

- McGregor, D.S.; He, Z.; Seifert, H.A.; Wehe, D.K.; Rojeski, R.A. Single charge carrier type sensing with a parallel strip pseudo-Frisch-grid CdZnTe semiconductor radiation detector. Appl. Phys. Lett. 1998, 72, 792–794. [Google Scholar] [CrossRef]

- Montémont, G.; Argues, M.; Verger, L.; Rustique, J. A capacitive Frisch grid structure for CdZnTe detectors. In Proceedings of the 2000 IEEE Nuclear Science Symposium. Conference Record (Cat. No. 00CH37149), Lyon, France, 15–20 October 2000; IEEE: Piscataway, NJ, USA, 2000; Volume 1, pp. 4–9. [Google Scholar]

- He, Z. Review of the Shockley–Ramo theorem and its application in semiconductor gamma-ray detectors. Nucl. Instrum. Methods Phys. Res. Sect. A 2001, 463, 250–267. [Google Scholar] [CrossRef]

- Luke, P. Unipolar charge sensing with coplanar electrodes-application to semiconductor detectors. IEEE Trans. Nucl. Sci. 1995, 42, 207–213. [Google Scholar] [CrossRef]

- Sturm, B.W.; He, Z.; Rhodes, E.A.; Zurbuchen, T.H.; Koehn, P.L. Coplanar grid CdZnTe detectors for space science applications. In Proceedings of the Hard X-Ray and Gamma-Ray Detector Physics VI, Denver, CO, USA, 3–4 August 2004; SPIE: Bellingham, WA, USA, 2004; Volume 5540, pp. 14–21. [Google Scholar]

- Luke, P.; Amman, M.; Lee, J.; Ludewigt, B.; Yaver, H. A CdZnTe coplanar-grid detector array for environmental remediation. Nucl. Instrum. Methods Phys. Res. Sect. A 2001, 458, 319–324. [Google Scholar] [CrossRef]

- Luke, P.N.; Amman, M.; Lee, J.S. Factors affecting energy resolution of coplanar-grid CdZnTe detectors. IEEE Trans. Nucl. Sci. 2004, 51, 1199–1203. [Google Scholar] [CrossRef]

- Bolotnikov, A.; Camarda, G.; Carini, G.; Fiederle, M.; Li, L.; McGregor, D.S.; McNeil, W.; Wright, G.; James, R. Performance characteristics of Frisch-ring CdZnTe detectors. IEEE Trans. Nucl. Sci. 2006, 53, 607–614. [Google Scholar] [CrossRef]

- Bao, L.; Zha, G.; Li, J.; Guo, L.; Dong, J.; Jie, W. CdZnTe quasi-hemispherical detector for gamma–neutron detection. J. Nucl. Sci. Technol. 2019, 56, 454–460. [Google Scholar] [CrossRef]

- Park, B.; Jung, K.; Kim, C. Fabrication and Evaluation of Spectroscopic Grade Quasi-hemispherical CdZnTe Detector. J. Radiat. Prot. Res. 2024, 49, 85–90. [Google Scholar] [CrossRef]

- Bale, D.S.; Szeles, C. Design of high-performance CdZnTe quasi-hemispherical gamma-ray CAPture plus detectors. In Proceedings of the Hard X-Ray and Gamma-Ray Detector Physics and Penetrating Radiation Systems VIII, San Diego, CA, USA, 14–17 August 2006; SPIE: Bellingham, WA, USA, 2006; Volume 6319, pp. 55–65. [Google Scholar]

- Malm, H.; Canali, C.; Mayer, J.; Nicolet, M.A.; Zanio, K.; Akutagawa, W. Gamma- ray spectroscopy with single- carrier collection in high- resistivity semiconductors. Appl. Phys. Lett. 1975, 26, 344–346. [Google Scholar] [CrossRef]

- Zhu, Y.; He, Z. Performance of Larger-Volume 40 × 40 × 10 and 40 × 40 × 15-mm3 CdZnTe Detectors. IEEE Trans. Nucl. Sci. 2021, 68, 250–255. [Google Scholar] [CrossRef]

- Bennett, P.; Shah, K.; Klugerman, M.; Squillante, M. High efficiency pixellated CdTe detector. Nucl. Instrum. Methods Phys. Res. Sect. A 1997, 392, 260–263. [Google Scholar] [CrossRef]

- Kuvvetli, I.; Budtz-Jorgensen, C. Pixelated CdZnTe drift detectors. IEEE Trans. Nucl. Sci. 2005, 52, 1975–1981. [Google Scholar] [CrossRef]

- Abbene, L.; Del Sordo, S.; Agnetta, G.; Biondo, B.; Caroli, E.; Mangano, A.; Russo, F.; Stephen, J.; Ventura, G.; Carlino, A.; et al. Investigation on pixellated CZT detectors coupled with a low power readout ASIC. In Proceedings of the 2008 IEEE Nuclear Science Symposium Conference Record, Dresden, Germany, 19–25 October 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 478–483. [Google Scholar]

- Rosenfeld, A.B. Semiconductor Detectors in Radiation Medicine: Radiotherapy and Related Applications. In Proceedings of the Radiation Detectors for Medical Applications; Tavernier, S., Gektin, A., Grinyov, B., Moses, W.W., Eds.; Springer: Dordrecht, The Netherlands, 2006; pp. 111–147. [Google Scholar] [CrossRef]

- Willemink, M.J.; Persson, M.; Pourmorteza, A.; Pelc, N.J.; Fleischmann, D. Photon-counting CT: Technical Principles and Clinical Prospects. Radiology 2018, 289, 293–312. [Google Scholar] [CrossRef]

- Flohr, T.; Petersilka, M.; Henning, A.; Ulzheimer, S.; Ferda, J.; Schmidt, B. Photon-counting CT review. Phys. Med. Eur. J. Med. Phys. 2020, 79, 126–136. [Google Scholar] [CrossRef]

- Chaudhari, A.J.; Badawi, R.D. Application-specific nuclear medical in vivo imaging devices. Phys. Med. Biol. 2021, 66, 10TR01. [Google Scholar] [CrossRef] [PubMed]

- Sharir, T.; Slomka, P.J.; Berman, D.S. Solid-State SPECT technology: Fast and furious. J. Nucl. Cardiol. 2010, 17, 890–896. [Google Scholar] [CrossRef]

- Karimeddini, D.; Bergmann, S. The state of the future is solid. J. Nucl. Cardiol. 2016, 23, 1288–1290. [Google Scholar] [CrossRef]

- Van den Wyngaert, T.; Elvas, F.; De Schepper, S.; Kennedy, J.A.; Israel, O. SPECT/CT: Standing on the shoulders of giants, it is time to reach for the sky! J. Nucl. Med. 2020, 61, 1284–1291. [Google Scholar] [CrossRef]

- Kumpova, I.; Vopalensky, M.; Fila, T.; Kytyr, D.; Vavrik, D.; Pichotka, M.; Jakubek, J.; Kersner, Z.; Klon, J.; Seitl, S.; et al. On-the-Fly Fast X-Ray Tomography Using a CdTe Pixelated Detector—Application in Mechanical Testing. IEEE Trans. Nucl. Sci. 2018, 65, 2870–2876. [Google Scholar] [CrossRef]

- Ballabriga, R.; Campbell, M.; Llopart, X. Asic developments for radiation imaging applications: The medipix and timepix family. Nucl. Instrum. Methods Phys. Res. Sect. A 2018, 878, 10–23. [Google Scholar] [CrossRef]

- Schumacher, D.; Antin, K.N.; Zscherpel, U.; Vilaça, P. Application of Different X-ray Techniques to Improve In-Service Carbon Fiber Reinforced Rope Inspection. J. Nondestruct. Eval. 2017, 36, 62. [Google Scholar] [CrossRef]

- Tartare, M. Dual and Multi-energy Radiography for CFRP Composites Inspection. In Proceedings of the European Conference on Non-Destructive Testing, Prague, Czech Republic, 6–10 October 2014. [Google Scholar]

- Gondrom, S.; Zhou, J.; Maisl, M.; Reiter, H.; Kröning, M.; Arnold, W. X-ray computed laminography: An approach of computed tomography for applications with limited access. Nucl. Eng. Des. 1999, 190, 141–147. [Google Scholar] [CrossRef]

- Rebuffel, V.; Rinkel, J.; Beldjoudi, G.; Brambilla, A. Material identification methods in spectral radiography using CdTe semiconductor detectors. In Proceedings of the International Symposium on Digital Industrial Radiology and Computed Tomography, Ghent, Belgium, 22–25 June 2015. [Google Scholar]

- Pincu, R. Digital radiography and its advantages in field NDT inspections today. In Proceedings of the 17 th World Conference on Non-Destructive Testing, Shanghai, China, 25–28 October 2008; pp. 25–28. [Google Scholar]

- Ewert, U.; Redmer, B.; Walter, D.; Thiessenhusen, K.U.; Bellon, C.; Nicholson, P.I.; Clarke, A.; Finke-Härkönen, K.P.; Scharfschwerdt, J.W.; Rohde, K. X-Ray Tomographic In-Service-Testing of Circumferential Pipe Welds—The European Project TomoWELD. In Proceedings of the World Conference on Non-Destructive Testing, Munich, Germany, 13–17 June 2016. [Google Scholar]

- Abdullah, J.; Yahya, R.; Senin, H.B.; Idris, N.H. Application of CdZnTe Gamma-Ray Detector for Imaging Corrosion under Insulation. In Proceedings of the 2nd International Conference on Solid State Science and Technology, Kuala Terengganu, Malaysia, 4–6 September 2006; pp. 74–79. [Google Scholar] [CrossRef]

- Walter, D.; Zscherpel, U.; Ewert, U. Photon Counting and Energy Discriminating X-Ray Detectors—Benefits and Applications. In Proceedings of the Digital Radiology and Radiography, Munich, Germany, 13–17 June 2016. [Google Scholar]

- ISO 17636-2; Non-Destructive Testing of Welds-Radiographic Testing-Part 2: X-and Gamma-Ray Techniques with Digital Detectors. International Organization for Standardization: Geneva, Switzerland, 2013.

- Bandara, A.; Kan, K.; Morii, H.; Koike, A.; Aoki, T. X-ray computed tomography to investigate industrial cast Al-alloys. Prod. Eng. Res. Devel. 2020, 14, 147–156. [Google Scholar] [CrossRef]

- Fey, J.; Procz, S.; Schütz, M.; Schoepff, V.; Carrel, F.; Useche, J.; Fauler, A.; Fiederle, M. CdTe sensor configurations for robot assisted photon counting gamma camera. J. Inst. 2021, 16, T07010. [Google Scholar] [CrossRef]

- Greenberg, J. X-Ray Diffraction Imaging: Technology and Applications; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Kosciesza, D.; Schlomka, J.P.; Meyer, J.; Montemont, G.; Monnet, O.; Stanchina, S.; Verger, L. X-ray diffraction imaging system for the detection of illicit substances using pixelated CZT-detectors. In Proceedings of the 2013 IEEE Nuclear Science Symposium and Medical Imaging Conference (2013 NSS/MIC), Seoul, Republic of Korea, 27 October 2013–2 November 2013; pp. 1–5, ISSN 1082-3654. [Google Scholar] [CrossRef]

- Rebuffel, V.; Rinkel, J.; Tabary, J.; Verger, L. New Perspectives of X-Ray Techniques for Explosive Detection Based on CdTe/CdZnTe Spectrometric Detectors. Int. Symp. Digit. Ind. Radiol. Comput. Tomogr. 2011, 2, 1–8. [Google Scholar]

- Chen, Y.; Wang, X.; Song, Q.; Xu, J.; Mu, B. Development of a high-energy-resolution EDXRD system with a CdTe detector for security inspection. AIP Adv. 2018, 8, 105113. [Google Scholar] [CrossRef]

- Greenberg, J.A.; Stryker, S.; Carpenter, J.; Kapadia, A.J. Concealed drug detection via fan beam coded-aperture x-ray diffraction imaging. In Proceedings of the Anomaly Detection and Imaging with X-Rays (ADIX) VI, Online, 12–16 April 2021; SPIE: Bellingham, WA, USA, 2021; Volume 11738, pp. 9–14. [Google Scholar] [CrossRef]

- Greenberg, J.A.; Carpenter, J.; Coccarelli, D.; Ding, Y.; Yang, S.; Fang, E.; Brumbaugh, K.; Gregory, C.; Ashok, A.; Kapadia, A.J.; et al. Design and analysis of a hybrid x-ray transmission and diffraction system. In Proceedings of the Anomaly Detection and Imaging with X-Rays (ADIX) VI, Online, 12–16 April 2021; SPIE: Bellingham, WA, USA, 2021; Volume 11738, pp. 15–25. [Google Scholar] [CrossRef]

- McCollough, C.H.; Rajendran, K.; Leng, S. Standardization and quantitative imaging with photon-counting detector CT. Investig. Radiol. 2023, 58, 451–458. [Google Scholar] [CrossRef]

- Zimmerman, J.; Poludniowski, G. Assessment of Photon-Counting Computed Tomography for Quantitative Imaging in Radiation Therapy. Int. J. Radiat. Oncol. Biol. Phys. 2024, in press. [CrossRef]

- Sellerer, T.; Ehn, S.; Mechlem, K.; Duda, M.; Epple, M.; Noël, P.B.; Pfeiffer, F. Quantitative dual-energy micro-CT with a photon-counting detector for material science and non-destructive testing. PLoS ONE 2019, 14, e0219659. [Google Scholar] [CrossRef] [PubMed]

- Nachtrab, F.; Weis, S.; Keßling, P.; Sukowski, F.; Haßler, U.; Fuchs, T.; Uhlmann, N.; Hanke, R. Quantitative material analysis by dual-energy computed tomography for industrial NDT applications. Nucl. Instrum. Methods Phys. Res. Sect. A 2011, 633, S159–S162. [Google Scholar] [CrossRef]

- Busi, M.; Mohan, K.A.; Dooraghi, A.A.; Champley, K.M.; Martz, H.E.; Olsen, U.L. Method for system-independent material characterization from spectral X-ray CT. NDT Int. 2019, 107, 102136. [Google Scholar] [CrossRef]

- Buttacavoli, A.; Principato, F.; Gerardi, G.; Cascio, D.; Raso, G.; Bettelli, M.; Zappettini, A.; Taormina, V.; Abbene, L. Window-Based Energy Selecting X-ray Imaging and Charge Sharing in Cadmium Zinc Telluride Linear Array Detectors for Contaminant Detection. Sensors 2023, 23, 3196. [Google Scholar] [CrossRef]

- Jumanazarov, D.; Alimova, A.; Ismoilov, S.K.; Atamurotov, F.; Abdikarimov, A.; Olsen, U.L. Method for the determination of electron density from multi-energy X-ray CT. NDT Int. 2024, 145, 103105. [Google Scholar] [CrossRef]

- Calza, C.; Oliveira, D.F.; Freitas, R.P.; Rocha, H.S.; Nascimento, J.R.; Lopes, R.T. Analysis of sculptures using XRF and X-ray radiography. Radiat. Phys. Chem. 2015, 116, 326–331. [Google Scholar] [CrossRef]

- Schreiner, M.; Frühmann, B.; Jembrih-Simbürger, D.; Linke, R. X-rays in art and archaeology: An overview. Powder Diffr. 2004, 19, 3–11. [Google Scholar] [CrossRef]

- Newman, R. Applications of x rays in art authentication: Radiography, x-ray diffraction, and x-ray fluorescence. In Proceedings of the Scientific Detection of Fakery in Art, San Jose, CA, USA, 29–30 January 1998; SPIE: Bellingham, WA, USA, 1998; Volume 3315, pp. 31–41. [Google Scholar] [CrossRef]

- Karch, J.; Bartl, B.; Dudak, J.; Zemlicka, J.; Krejci, F. Non-destructive imaging of fragments of historical beeswax seals using high-contrast X-ray micro-radiography and micro-tomography with large area photon-counting detector array. Micron 2016, 91, 22–28. [Google Scholar] [CrossRef]

- Regert, M.; Colinart, S.; Degrand, L.; Decavallas, O. Chemical Alteration and Use of Beeswax Through Time: Accelerated Ageing Tests and Analysis of Archaeological Samples from Various Environmental Contexts. Archaeometry 2001, 43, 549–569. [Google Scholar] [CrossRef]

- Bartl, B.; Trejbal, J.; Ďurovič, M.; Vašíčková, S.; Valterová, I. Analysis of efflorescence on surface of beeswax seals. J. Cult. Herit. 2012, 13, 275–284. [Google Scholar] [CrossRef]

- Pérot, B.; Jallu, F.; Passard, C.; Gueton, O.; Allinei, P.G.; Loubet, L.; Estre, N.; Simon, E.; Carasco, C.; Roure, C.; et al. The characterization of radioactive waste: A critical review of techniques implemented or under development at CEA, France. EPJ Nuclear Sci. Technol. 2018, 4, 3. [Google Scholar] [CrossRef]

- Estre, N.; Eck, D.; Pettier, J.L.; Payan, E.; Roure, C.; Simon, E. High-Energy X-Ray Imaging Applied to Nondestructive Characterization of Large Nuclear Waste Drums. IEEE Trans. Nucl. Sci. 2015, 62, 3104–3109. [Google Scholar] [CrossRef]

- Ziock, K.; Hailey, C.; Gosnell, T.; Lupton, J.; Harrison, F. A gamma-ray imager for arms control. IEEE Trans. Nucl. Sci. 1992, 39, 1046–1050. [Google Scholar] [CrossRef]

- Ziock, K. Principles and applications of gamma-ray imaging for arms control. Nucl. Instrum. Methods Phys. Res. Sect. A 2018, 878, 191–199. [Google Scholar] [CrossRef]

- Schmitt, K.; Ziock, K.P.; Daughhetee, J.; Laminack, A.; Mitchell, J.; Nwadeyi, V.; Gibbs, P. Implementation of a System of Gamma Imagers for Measuring Plutonium Holdup. In Proceedings of the INMM & ESARDA Joint Annual Meeting, Vienna, Austria, 22–26 May 2023; Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 2023. [Google Scholar]

- Brown, S.T.; Sobota, R.; Goodman, D.I.; Mason, J.R.; Tefft, D.; Williams, A.N.; Lambert, J.N.; Chichester, D.L. Improvement in Coded-Aperature Image Quality Using Continous Mask Rotation. In Proceedings of the INMM & ESARDA 2023 Joint Annual Meeting, Vienna, Austria, 22–26 May 2023. [Google Scholar]

- Brown, S.T.; Meert, C.A.; Fratila, S.; Stec, D.; Mason, J.R.; Goodman, D.I.; Willy, R.K. Detection and Localization of Concealed Mercury Using a Handheld CZT Spectrometer and Moderated Cf-252 Source. In Proceedings of the Waste Management Symposia, Cagliari, Italy, 9–13 October 2023. [Google Scholar]

- Gilbert, A.J.; McDonald, B.S.; Kasparek, D.M.; Wittman, R.S.; Gillis, W.C.; Clark, R.A.; Brayfindley, E.; Sweet, L.E. Quantitative uranium elemental reconstruction using spectral x-ray radiography. J. Appl. Phys. 2023, 134, 024902. [Google Scholar] [CrossRef]

- Gilbert, A.J.; McDonald, B.S.; Robinson, S.M.; Jarman, K.D.; White, T.A.; Deinert, M.R. Non-invasive material discrimination using spectral x-ray radiography. J. Appl. Phys. 2014, 115, 154901. [Google Scholar] [CrossRef]

- Kasparek, D.M.; McDonald, B.S.; Gilbert, A.J.; Wittman, R.S. Detector characterization for quantitative spectral radiography of uranium powder samples. Nucl. Instrum. Methods Phys. Res. Sect. A 2020, 954, 161413. [Google Scholar] [CrossRef]

- Veale, M.; Seller, P.; Wilson, M.; Liotti, E. HEXITEC: A high-energy X-ray spectroscopic imaging detector for synchrotron applications. Synchrotron Radiat. News 2018, 31, 28–32. [Google Scholar] [CrossRef]

- Berlizov, A.; Schachinger, A.; Roetsch, K.; Erdmann, N.; Schorlé, H.; Vargas, M.; Zsigrai, J.; Kulko, A.; Keselica, M.; Caillou, F.; et al. Feedback from operational experience of on-site deployment of bias defect analysis with COMPUCEA. J. Radioanal. Nucl. Chem. 2016, 307, 1901–1909. [Google Scholar] [CrossRef]

- Crespy, C.; Duvauchelle, P.; Kaftandjian, V.; Soulez, F.; Ponard, P. Energy dispersive X-ray diffraction to identify explosive substances: Spectra analysis procedure optimization. Nucl. Instrum. Methods Phys. Res. Sect. A 2010, 623, 1050–1060. [Google Scholar] [CrossRef]

- Vetter, K.; Barnowski, R.; Cates, J.W.; Haefner, A.; Joshi, T.H.Y.; Pavlovsky, R.; Quiter, B.J. Advances in Nuclear Radiation Sensing: Enabling 3-D Gamma-Ray Vision. Sensors 2019, 19, 2541. [Google Scholar] [CrossRef] [PubMed]

- Vetter, K. Multi-sensor radiation detection, imaging, and fusion. Nucl. Instrum. Methods Phys. Res. Sect. A 2016, 805, 127–134. [Google Scholar] [CrossRef]

- Pavlovsky, R.; Haefner, A.; Joshi, T.; Negut, V.; McManus, K.; Suzuki, E.; Barnowski, R.; Vetter, K. 3-D Radiation Mapping in Real-Time with the Localization and Mapping Platform LAMP from Unmanned Aerial Systems and Man-Portable Configurations. arXiv 2018, arXiv:1901.05038. [Google Scholar] [CrossRef]

- Martin, P.G.; Payton, O.D.; Fardoulis, J.S.; Richards, D.A.; Scott, T.B. The use of unmanned aerial systems for the mapping of legacy uranium mines. J. Environ. Radioact. 2015, 143, 135–140. [Google Scholar] [CrossRef]

- Aleotti, J.; Micconi, G.; Caselli, S.; Benassi, G.; Zambelli, N.; Bettelli, M.; Zappettini, A. Detection of Nuclear Sources by UAV Teleoperation Using a Visuo-Haptic Augmented Reality Interface. Sensors 2017, 17, 2234. [Google Scholar] [CrossRef]

- Kumar, K.P.; Sundaram, G.S.; Sharma, B.; Venkatesh, S.; Thiruvengadathan, R. Advances in gamma radiation detection systems for emergency radiation monitoring. Nucl. Eng. Technol. 2020, 52, 2151–2161. [Google Scholar] [CrossRef]

- Siltzovalis, G.; Lagaki, V.; Madesis, I.; Mertzimekis, T.J. Characterization of a CZT-based spectrometer for underwater operation via simulations and experiments. J. Inst. 2024, 19, P05008. [Google Scholar] [CrossRef]

- Ntouskos, V.; Tsironis, V.; Spanos, S.; Antoniou, C.; Mallios, A.; Karantzalos, K. Preliminary results from the Submarine Gamma Imager. J. Inst. 2024, 19, C03012. [Google Scholar] [CrossRef]

- Zhu, W.; Wu, j.; Zhao, R.; Tang, X.; Li, M. Evaluation of radiation leakage in X-ray security inspection machine using a CZT spectrometer. Radiat. Meas. 2024, 177, 107274. [Google Scholar] [CrossRef]

- Jianfeng, L.; Bin, L.; Lingxin, H.; Cida, Z.; Jianqing, F. Dose Rate Monitoring Based on the G (E) Function Method with In-situ NaI Spectrometry. J. Isot. 2022, 35, 304–310. [Google Scholar]

- Parra, J.S.U.; Roque, G.; Schütz, M.K.; Fiederle, M.; Procz, S. Investigations on the Performance of a 5 mm CdTe Timepix3 Detector for Compton Imaging Applications. Sensors 2024, 24, 7974. [Google Scholar] [CrossRef] [PubMed]

- Richtsmeier, D.; Guliyev, E.; Iniewski, K.; Bazalova-Carter, M. Contaminant detection in non-destructive testing using a CZT photon-counting detector. J. Inst. 2021, 16, P01011. [Google Scholar] [CrossRef]

- Perion, D.; Gaboriau-Borissenko, E.; Radisson, P. Material discrimination and imaging improvement using high count rate X-ray spectrometric detector for non-destructive testing and security applications. In Proceedings of the 2016 IEEE Nuclear Science Symposium, Medical Imaging Conference and Room-Temperature Semiconductor Detector Workshop (NSS/MIC/RTSD), Strasbourg, France, 29 October–6 November 2016; pp. 1–7. [Google Scholar] [CrossRef]

- Alvarez, R.E.; Macovski, A. Energy-selective reconstructions in X-ray computerised tomography. Phys. Med. Biol. 1976, 21, 733. [Google Scholar] [CrossRef]

- Landsberger, S. Neutron activation analysis of solid foods. In Handbook of Mineral Elements in Food; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2015; pp. 375–390. [Google Scholar] [CrossRef]

- Foley, A.; Mohanty, S.K.; Sjoden, G.E. Developing a basis for heavy metal in-situ detection using CZT. J. Inst. 2022, 17, P05026. [Google Scholar] [CrossRef]

- Ibrahim R V, S.; Musthafa, M.M.; Midhun, C.V.; Lily Cyriac, S.; Sajeev, S. Measurement and analysis of photonuclear reactions on thick target samples of biological importance. Indian J. Pure Appl. Phys. 2022, 58, 404–408. [Google Scholar] [CrossRef]

- Zambelli, N.; Zanettini, S.; Benassi, G.; Bettati, A.; Guidetti, A.; Zappettini, A. High Performance CZT Detectors for In-Line Non-destructive X-Ray Based Density Measurements. In Proceedings of the 2018 IEEE Nuclear Science Symposium and Medical Imaging Conference Proceedings (NSS/MIC), Sydney, NSW, Australia, 10–17 November 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Zambelli, N.; Benassi, G.; Zanettini, S. Absolute Density Determination and Compositional Analysis of Materials by Means of CdZnTe Spectroscopic Detectors. In Advanced X-Ray Radiation Detection: Medical Imaging and Industrial Applications; Iniewski, K.K., Ed.; Springer International Publishing: Cham, Switzerland, 2023; pp. 107–131. [Google Scholar] [CrossRef]

- Selivanova, A.; Hůlka, J.; Seifert, D.; Hlaváč, V.; Krsek, P.; Smutný, V.; Wagner, L.; Voltr, J.; Rubovič, P.; Češpírová, I.; et al. The use of a CZT detector with robotic systems. Appl. Radiat. Isot. 2020, 166, 109395. [Google Scholar] [CrossRef]

- Le Breton, R.; Limousin, O.; Daniel, G.; Diquelou, D.; Gutierrez, Y.; Hullo, J.I.; Paupe, J.P.; Mogear, V.; Serrano, P.; Tauzin, G.; et al. The Spid-X gamma camera: A miniature gamma ray integral field spectrometer for nuclear industry applications. Nucl. Instrum. Methods Phys. Res. Sect. A 2023, 1047, 167722. [Google Scholar] [CrossRef]

- Aloysius, N.; Geetha, M. A review on deep convolutional neural networks. In Proceedings of the 2017 International Conference on Communication and Signal Processing (ICCSP), Chennai, India, 6–8 April 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 0588–0592. [Google Scholar]

- Seo, H.; Oh, J.M.; Shin, H.S.; Kim, H.D.; Lee, S.K.; Lee, H.S.; Park, S.H. Burnup Measurement of Spent Fuel Assembly by CZT-based Gamma-Ray Spectroscopy for Input Nuclear Material Accountability of Pyroprocessing. IEEE Trans. Nucl. Sci. 2014, 61, 2169–2174. [Google Scholar] [CrossRef]

- Bell, M.J. ORIGEN: The ORNL Isotope Generation and Depletion Code; Technical Report ORNL-4628; Oak Ridge National Lab. (ORNL): Oak Ridge, TN, USA, 1973. [Google Scholar] [CrossRef]

- Mortreau, P.; Berndt, R. Determination of 235U enrichment with a large volume CZT detector. Nucl. Instrum. Methods Phys. Res. Sect. A 2006, 556, 219–227. [Google Scholar] [CrossRef]

- Ranjbar, L.; Farsoni, A.T.; Becker, E.M. 135Xe measurements with a two-element CZT-based radioxenon detector for nuclear explosion monitoring. J. Environ. Radioact. 2017, 169-170, 221–228. [Google Scholar] [CrossRef] [PubMed]

- Kalinowski, M.B.; Axelsson, A.; Bean, M.; Blanchard, X.; Bowyer, T.W.; Brachet, G.; Hebel, S.; McIntyre, J.I.; Peters, J.; Pistner, C.; et al. Discrimination of Nuclear Explosions against Civilian Sources Based on Atmospheric Xenon Isotopic Activity Ratios. Pure Appl. Geophys. 2010, 167, 517–539. [Google Scholar] [CrossRef]

- Dalnoki-Veress, F. Xenon and Particulates: A Qualitative Discussion of Sensitivity to Nuclear Weapon Components and Design; James Martin Center for nonproliferation Studies: Monterey, CA, USA, 2016; pp. 1–14. [Google Scholar]

- McIntyre, J.I.; Abel, K.H.; Bowyer, T.W.; Hayes, J.C.; Heimbigner, T.R.; Panisko, M.E.; Reeder, P.L.; Thompson, R.C. Measurements of ambient radioxenon levels using the automated radioxenon sampler/analyzer (ARSA). J. Radioanal. Nucl. Chem. 2001, 248, 629–635. [Google Scholar] [CrossRef]

- Prelovskii, V.V.; Kazarinov, N.M.; Donets, A.Y.; Popov, V.Y.; Popov, I.Y.; Skirda, N.V. The ARIX-03F mobile semiautomatic facility for measuring low concentrations of radioactive xenon isotopes in air and subsoil gas. Instrum. Exp. Tech. 2007, 50, 393–397. [Google Scholar] [CrossRef]

- Ringbom, A.; Larson, T.; Axelsson, A.; Elmgren, K.; Johansson, C. SAUNA—A system for automatic sampling, processing, and analysis of radioactive xenon. Nucl. Instrum. Methods Phys. Res. Sect. A 2003, 508, 542–553. [Google Scholar] [CrossRef]

- Bläckberg, L.; Fritioff, T.; Mårtensson, L.; Nielsen, F.; Ringbom, A.; Sjöstrand, H.; Klintenberg, M. Memory effect, resolution, and efficiency measurements of an Al2O3 coated plastic scintillator used for radioxenon detection. Nucl. Instrum. Methods Phys. Res. Sect. A 2013, 714, 128–135. [Google Scholar] [CrossRef]

- Kurvinen, K.; Smolander, P.; Pöllänen, R.; Kuukankorpi, S.; Kettunen, M.; Lyytinen, J. Design of a radiation surveillance unit for an unmanned aerial vehicle. J. Environ. Radioact. 2005, 81, 1–10. [Google Scholar] [CrossRef]

- Gadey, H.R.; Farsoni, A.T.; Czyz, S.A.; McGee, K.D. A stilbene - CdZnTe based radioxenon detection system. J. Environ. Radioact. 2019, 204, 117–124. [Google Scholar] [CrossRef] [PubMed]

- Cooper, M.W.; McIntyre, J.I.; Bowyer, T.W.; Carman, A.J.; Hayes, J.C.; Heimbigner, T.R.; Hubbard, C.W.; Lidey, L.; Litke, K.E.; Morris, S.J.; et al. Redesigned Î2–γ radioxenon detector. Nucl. Instrum. Methods Phys. Res. Sect. A 2007, 579, 426–430. [Google Scholar] [CrossRef]

- Streicher, M.; Brown, S.; Zhu, Y.; Goodman, D.; He, Z. A Method to Estimate the Atomic Number and Mass Thickness of Intervening Materials in Uranium and Plutonium Gamma-Ray Spectroscopy Measurements. IEEE Trans. Nucl. Sci. 2016, 63, 2639–2648. [Google Scholar] [CrossRef]

- Pozzi, S.A.; He, Z.; Hutchinson, J.; Jovanovic, I.; Lopez, R.; Ogren, K.; Nattress, J.; Shy, D.; Clarke, S.D. Detecting and characterizing special nuclear material for nuclear nonproliferation applications. Sci. Rep. 2023, 13, 10432. [Google Scholar] [CrossRef]

- Chen-Mayer, H.H.; Brown, S.; Yang, H. Feasibility study of Compton imaging for PGAA. J. Radioanal. Nucl. Chem. 2019, 322, 1729–1738. [Google Scholar] [CrossRef]

- Lecoq, P. Development of new scintillators for medical applications. Nucl. Instrum. Methods Phys. Res. Sect. A 2016, 809, 130–139. [Google Scholar] [CrossRef]

- N42.62-2023; IEEE Standard for Passive Imaging Radiation Devices (PIRDs) for the Localization and Identification of Radioactive and Nuclear Materials. IEEE: Piscataway, NJ, USA, 2023; pp. 1–30. [CrossRef]

- Harding, G. On screening for Special Nuclear Materials (SNMs) with X-ray diffraction. Radiat. Phys. Chem. 2010, 79, 597–602. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Whittemore, A.R.; Zannoni, E.M. Applications of Cd(Zn)Te Radiation Detectors in Non-Destructive Testing and Evaluation. Sensors 2025, 25, 1776. https://doi.org/10.3390/s25061776

Whittemore AR, Zannoni EM. Applications of Cd(Zn)Te Radiation Detectors in Non-Destructive Testing and Evaluation. Sensors. 2025; 25(6):1776. https://doi.org/10.3390/s25061776

Chicago/Turabian StyleWhittemore, Anthony R., and Elena Maria Zannoni. 2025. "Applications of Cd(Zn)Te Radiation Detectors in Non-Destructive Testing and Evaluation" Sensors 25, no. 6: 1776. https://doi.org/10.3390/s25061776

APA StyleWhittemore, A. R., & Zannoni, E. M. (2025). Applications of Cd(Zn)Te Radiation Detectors in Non-Destructive Testing and Evaluation. Sensors, 25(6), 1776. https://doi.org/10.3390/s25061776