Fiber Bragg Grating Sensors: Design, Applications, and Comparison with Other Sensing Technologies

Abstract

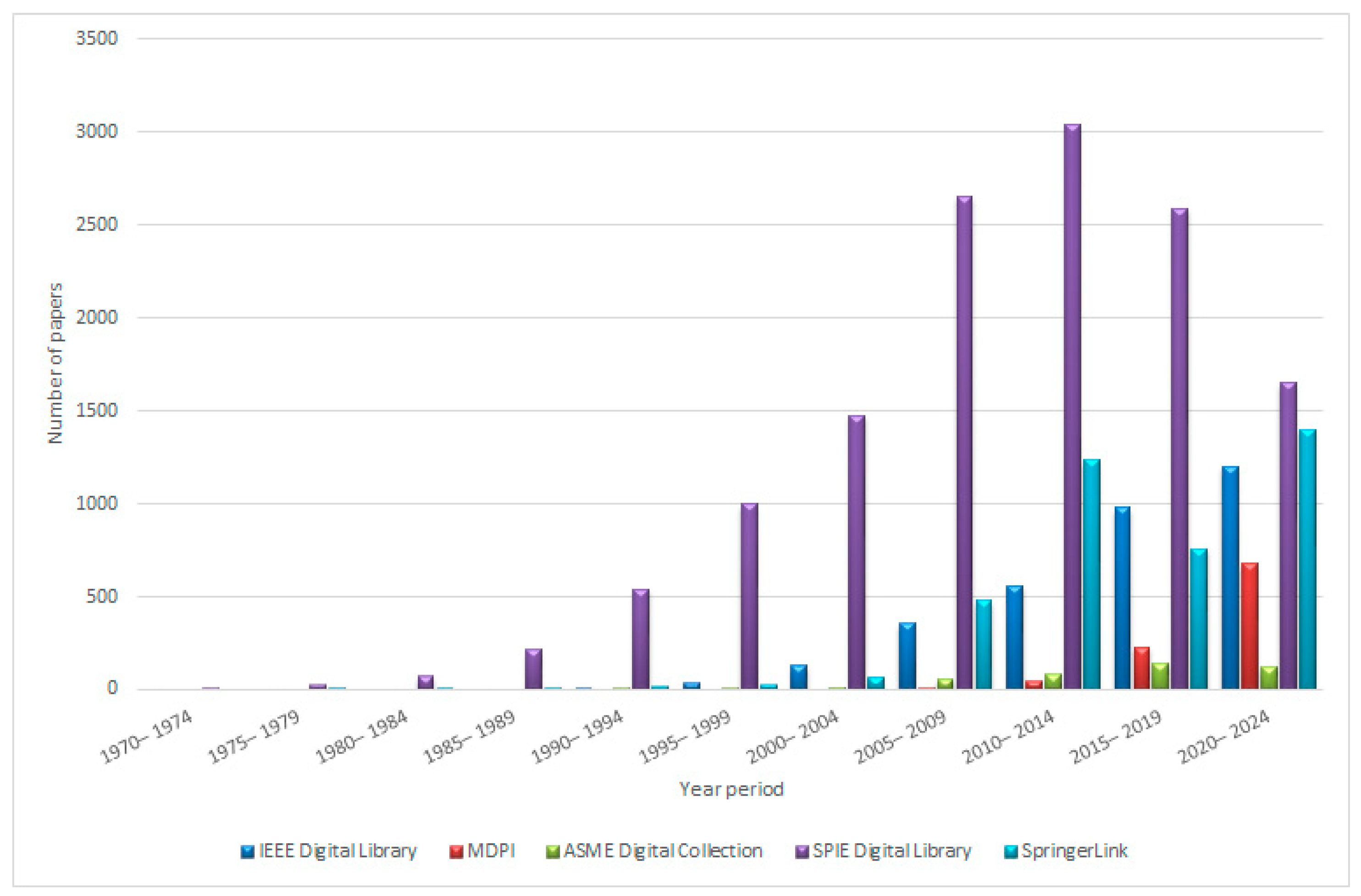

1. Introduction

2. FBG Technology Fundamentals

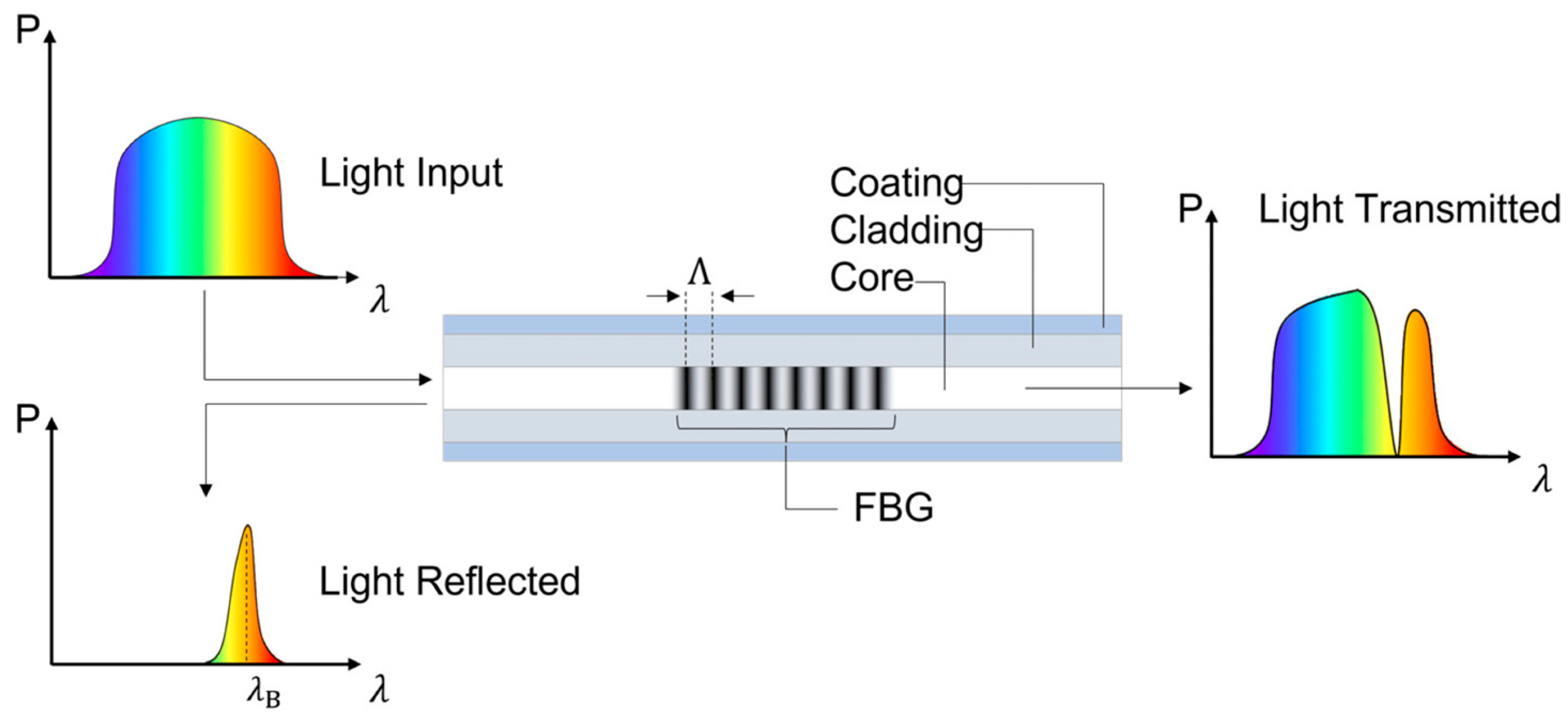

2.1. Principles of Operation

2.2. Advantages and Limitations of FBG Sensors

3. Design, Implementation, and Packaging Techniques

3.1. Sensor Design

3.2. Implementation Techniques

3.3. Packaging Techniques

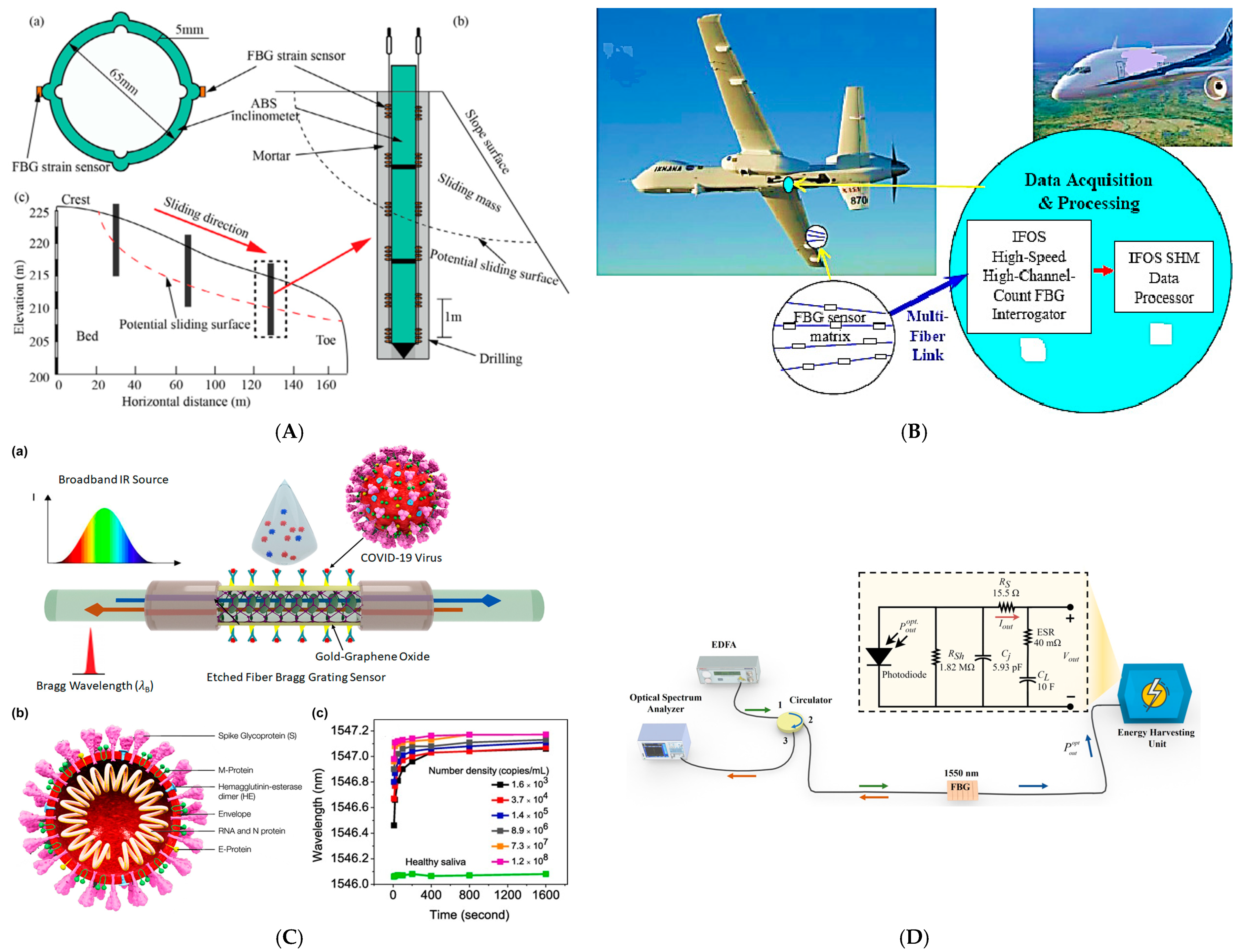

4. Applications Across Domains

4.1. Displacement Measurement

4.2. Liquid Level Monitoring

4.3. Temperature and Pressure Sensing

4.4. Strain Monitoring

4.5. Environmental and Biochemical Applications

5. Structural Health Monitoring Applications

5.1. High-Rise Building

5.2. Long-Term Monitoring of Concrete Bridges

6. Comparison with Other Sensing Technologies

6.1. FBG vs. Electronic Sensors

6.2. FBG vs. MEMS Sensors

6.3. FBG vs. Other Optical Fiber Sensors

7. Challenges and Future Directions

7.1. Cross-Sensitivity Issues: Temperature-Strain Interaction in FBG Sensors

7.2. Cost of Interrogation Systems: Strategies for Cost Reduction

7.3. FBG Interrogation Methods

7.4. Hybrid FBG-MEMS Devices

7.5. Enhancement of Sensing Elements in Surgical Robots

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Braunfelds, J.; Senkans, U.; Skels, P.; Janeliukstis, R.; Salgals, T.; Redka, D.; Lyashuk, I.; Porins, J.; Spolitis, S.; Haritonovs, V.; et al. FBG-Based Sensing for Structural Health Monitoring of Road Infrastructure. J. Sens. 2021, 2021, 8850368. [Google Scholar] [CrossRef]

- Lo Presti, D.; Cimini, S.; Massaroni, C.; D’Amato, R.; Caponero, M.A.; De Gara, L.; Schena, E. Plant Wearable Sensors Based on FBG Technology for Growth and Microclimate Monitoring. Sensors 2021, 21, 6327. [Google Scholar] [CrossRef] [PubMed]

- Rovera, A.; Tancau, A.; Boetti, N.; Dalla Vedova, M.D.L.; Maggiore, P.; Janner, D. Fiber Optic Sensors for Harsh and High Radiation Environments in Aerospace Applications. Sensors 2023, 23, 2512. [Google Scholar] [CrossRef] [PubMed]

- Riza, M.A.; Go, Y.I.; Harun, S.W.; Maier, R.R.J. FBG Sensors for Environmental and Biochemical Applications—A Review. IEEE Sens. J. 2020, 20, 7614–7627. [Google Scholar] [CrossRef]

- Rodrigues, C.; Félix, C.; Lage, A.; Figueiras, J. Development of a Long-Term Monitoring System Based on FBG Sensors Applied to Concrete Bridges. Eng. Struct. 2010, 32, 1993–2002. [Google Scholar] [CrossRef]

- Dalla Vedova, M.D.L.; Berri, P.C.; Maggiore, P.; Quattrocchi, G. Design and Development of Innovative FBG-Based Fiber Optic Sensors for Aerospace Applications. J. Phys. Conf. Ser. 2020, 1589, 012012. [Google Scholar] [CrossRef]

- López-Castro, B.; Haro-Baez, A.G.; Arcos-Aviles, D.; Barreno-Riera, M.; Landázuri-Avilés, B. A Systematic Review of Structural Health Monitoring Systems to Strengthen Post-Earthquake Assessment Procedures. Sensors 2022, 22, 9206. [Google Scholar] [CrossRef]

- Moyo, P.; Brownjohn, J.M.W.; Suresh, R.; Tjin, S.C. Development of Fiber Bragg Grating Sensors for Monitoring Civil Infrastructure. Eng. Struct. 2005, 27, 1828–1834. [Google Scholar] [CrossRef]

- Kuang, K.S.C.; Cantwell, W.J. Use of Conventional Optical Fibers and Fiber Bragg Gratings for Damage Detection in Advanced Composite Structures: A Review. Appl. Mech. Rev. 2003, 56, 493–513. [Google Scholar] [CrossRef]

- Lin, Y.B.; Chang, K.C.; Chern, J.C.; Wang, L.A. Packaging Methods of Fiber-Bragg Grating Sensors in Civil Structure Applications. IEEE Sens. J. 2005, 5, 419–424. [Google Scholar] [CrossRef]

- Wang, Z.; Hua, S.; Wang, D.; Xu, W.; Yang, S. Design and Verification of FBG Strain Gauge. J. Eng. 2019, 2019, 8535–8538. [Google Scholar] [CrossRef]

- Pashaie, R.; Shokrieh, M.M.; Vahedi, M.; Mirzaei, A.H.; Akbari, S. A Comparative Study of Residual Stress Measurement of Laminated Composites Using FBG Sensor, DIC Technique, and Strain Gauge. Opt. Quantum Electron. 2024, 56, 1790. [Google Scholar] [CrossRef]

- Bui, H.; Pham, T.B.; Nguyen, V.A.; Pham, V.D.; Do, T.C.; Nguyen, T.V.; Hoang, T.H.C.; Le, H.T.; Pham, V.H. Novel Method of Dual Fiber Bragg Gratings Integrated in Fiber Ring Laser for Biochemical Sensors. Meas. Sci. Technol. 2018, 29, 055105. [Google Scholar] [CrossRef]

- Yulianti, I.; Supa’at, A.S.M.; Idrus, S.M. Characterization of Fiber Bragg Grating Sensor for pH Measurement. In Proceedings of the 2014 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Besacon, France, 8–11 July 2014; pp. 1163–1166. [Google Scholar]

- Kahandawa, G.C.; Epaarachchi, J.; Wang, H.; Lau, K.T. Use of FBG Sensors for SHM in Aerospace Structures. Photonic Sens. 2012, 2, 203–214. [Google Scholar] [CrossRef]

- Hegde, G.; Asokan, S.; Hegde, G. Fiber Bragg Grating Sensors for Aerospace Applications: A Review. ISSS J. Micro Smart Syst. 2022, 11, 257–275. [Google Scholar] [CrossRef]

- Falcetelli, F.; Martini, A.; Di Sante, R.; Troncossi, M. Strain Modal Testing with Fiber Bragg Gratings for Automotive Applications. Sensors 2022, 22, 946. [Google Scholar] [CrossRef]

- Liang, X.; Chen, S.; Huang, H.; Liu, W. Study on Sensitivity Improving of Fiber Bragg Grating Based pH Sensor. Photonic Sens. 2014, 4, 28–33. [Google Scholar] [CrossRef]

- Liang, W.; Huang, Y.; Xu, Y.; Lee, R.K.; Yariv, A. Highly Sensitive Fiber Bragg Grating Refractive Index Sensors. Appl. Phys. Lett. 2005, 86, 151122. [Google Scholar] [CrossRef]

- Namiq, M.F.; Ibsen, M. Simple Technique of Determining the Fibre Diameter during Etching. Opt. Express 2018, 26, 32908. [Google Scholar] [CrossRef]

- Bennion, I.; Williams, J.A.R.; Zhang, L.; Sugden, K.; Doran, N.J. UV-Written in-Fibre Bragg Gratings. Opt. Quantum Electron. 1996, 28, 93–135. [Google Scholar] [CrossRef]

- He, J.; Xu, B.; Xu, X.; Liao, C.; Wang, Y. Review of Femtosecond-Laser-Inscribed Fiber Bragg Gratings: Fabrication Technologies and Sensing Applications. Photonic Sens. 2021, 11, 203–226. [Google Scholar] [CrossRef]

- Mihailov, S.; Grobnic, D.; Hnatovsky, C.; Walker, R.; Lu, P.; Coulas, D.; Ding, H. Extreme Environment Sensing Using Femtosecond Laser-Inscribed Fiber Bragg Gratings. Sensors 2017, 17, 2909. [Google Scholar] [CrossRef] [PubMed]

- Ioannou, A.; Kalli, K. Femtosecond Laser Inscribed Fiber Bragg Gratings Based on Precise Spatial Apodization. Opt. Lett. 2023, 48, 1826. [Google Scholar] [CrossRef]

- Luo, X.; Rahman, A.; Madhav, K.V.; Siefke, T.; Krämer, R.G.; Richter, D.; Zeitner, U.D.; Nolte, S.; Roth, M.M. Novel Phase Masks with Overlapping Regions to Fabricate Fiber Bragg Gratings for Filtering Sky Emission Lines. In Proceedings of the Advances in Optical and Mechanical Technologies for Telescopes and Instrumentation VI, Yokohama, Japan, 16–22 June 2024; Navarro, R., Jedamzik, R., Eds.; SPIE: St Bellingham, WA, USA, 2024; p. 235. [Google Scholar]

- Mihailov, S.J.; Ding, H.; Hnatovsky, C.; Walker, R.B.; Lu, P.; De Silva, M. Through-The-Coating Fabrication of Fiber Bragg Grating Relative Humidity Sensors Using Femtosecond Pulse Duration Infrared Lasers and a Phase Mask. Photonics 2023, 10, 625. [Google Scholar] [CrossRef]

- Chen, R.; He, J.; Xu, X.; Wu, J.; Wang, Y.; Wang, Y. High-Quality Fiber Bragg Gratings Inscribed by Femtosecond Laser Point-by-Point Technology. Micromachines 2022, 13, 1808. [Google Scholar] [CrossRef] [PubMed]

- Williams, R.J.; Voigtländer, C.; Marshall, G.D.; Tünnermann, A.; Nolte, S.; Steel, M.J.; Withford, M.J. Point-by-Point Inscription of Apodized Fiber Bragg Gratings. Opt. Lett. 2011, 36, 2988. [Google Scholar] [CrossRef] [PubMed]

- Mahakud, R.; Kumar, J.; Prakash, O.; Dixit, S.K.; Nakhe, S.V. FBG Inscription by a Biprism Interferometer: Analysis and Experiment. Appl. Phys. B 2015, 121, 283–295. [Google Scholar] [CrossRef]

- Kashaganova, G.; Kozbakova, A.; Kartbayev, T.; Togzhanova, K.; Alimseitova, Z.; Sergazin, G. Design of a Fiber Temperature and Strain Sensor Model Using a Fiber Bragg Grating to Monitor Road Surface Conditions. Inventions 2024, 9, 100. [Google Scholar] [CrossRef]

- Maiti, S.; Singh, V. Performance Analysis of Apodized Fiber Bragg Gratings for Sensing Applications. Silicon 2022, 14, 581–587. [Google Scholar] [CrossRef]

- Toba, M.; Mustafa, F.M.; Barakat, T.M. New Simulation and Analysis Fiber Bragg Grating: Narrow Bandwidth without Side Lobes. J. Phys. Commun. 2020, 4, 075018. [Google Scholar] [CrossRef]

- Wang, C.-H.; Chen, L.R.; Smith, P.W.E. Analysis of Chirped-Sampled and Sampled-Chirped Fiber Bragg Gratings. Appl. Opt. 2002, 41, 1654. [Google Scholar] [CrossRef] [PubMed]

- Robalinho, P.; Piaia, V.; Soares, L.; Novais, S.; Ribeiro, A.L.; Silva, S.; Frazão, O. Phase-Shifted Fiber Bragg Grating by Selective Pitch Slicing. Sensors 2024, 24, 6898. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, F.; Joe, H.-E.; Min, B.-K.; Jun, M.B.G. Characterization of Refractive Index Change and Fabrication of Long Period Gratings in Pure Silica Fiber by Femtosecond Laser Radiation. Opt. Laser Technol. 2015, 74, 119–124. [Google Scholar] [CrossRef]

- Zhang, N.; Turk, S.; Davis, C.; Chiu, W.K.; Boilard, T.; Bernier, M. Fatigue Performance of Type I and Type II Fibre Bragg Gratings Fabricated by Femtosecond Laser Inscription through the Coating. Sensors 2022, 22, 8812. [Google Scholar] [CrossRef] [PubMed]

- Burgmeier, J.; Waltermann, C.; Flachenecker, G.; Schade, W. Point-by-Point Inscription of Phase-Shifted Fiber Bragg Gratings with Electro-Optic Amplitude Modulated Femtosecond Laser Pulses. Opt. Lett. 2014, 39, 540. [Google Scholar] [CrossRef]

- Nadeem, M.D.; Raghuwanshi, S.K.; Kumar, S. Recent Advancement of Phase Shifted Fiber Bragg Grating Sensor for Ultrasonic Wave Application: A Review. IEEE Sens. J. 2022, 22, 7463–7474. [Google Scholar] [CrossRef]

- Werneck, M.M.M.; Allil, R.C.; De Nazaré, F.V. Calibrating Fiber Bragg Gratings for Temperature and Strain. In Fiber Bragg Gratings: Theory, Fabrication, and Applications; SPIE: St Bellingham, WA, USA, 2017; ISBN 978-1-5106-1386-7. [Google Scholar]

- Sahabutdinov, A.Z.; Kuznetsov, A.Z.; Nureev, I.I.; Morozov, O.G.; Faskhutdinov, L.M.; Petrov, A.V.; Kuchev, S.M. Calibration of Combined Pressure and Temperature Sensors. Int. J. Appl. Eng. Res. 2015, 10, 44948–44957. [Google Scholar]

- Breglio, G.; Cusano, A.; Irace, A.; Cutolo, A. Fiber Optic Sensor Arrays: A New Method to Improve Multiplexing Capability with a Low Complexity Approach. Sens. Actuators B Chem. 2004, 100, 147–150. [Google Scholar] [CrossRef]

- Sarkar, B.; Koley, C.; Roy, N.K.; Kumbhakar, P. Condition Monitoring of High Voltage Transformers Using Fiber Bragg Grating Sensor. Measurement 2015, 74, 255–267. [Google Scholar] [CrossRef]

- Caponero, M.A. Use of FBG Sensors in Advanced Civil Engineering Applications. J. Instrum. 2023, 18, C07020. [Google Scholar] [CrossRef]

- Elsherif, M.; Salih, A.E.; Muñoz, M.G.; Alam, F.; AlQattan, B.; Antonysamy, D.S.; Zaki, M.F.; Yetisen, A.K.; Park, S.; Wilkinson, T.D.; et al. Optical Fiber Sensors: Working Principle, Applications, and Limitations. Adv. Photonics Res. 2022, 3, 2100371. [Google Scholar] [CrossRef]

- Qin, H.; Tang, P.; Lei, J.; Chen, H.; Luo, B. Investigation of Strain-Temperature Cross-Sensitivity of FBG Strain Sensors Embedded Onto Different Substrates. Photonic Sens. 2023, 13, 230127. [Google Scholar] [CrossRef]

- Silveira, M.L.; Rocha, H.R.O.; Antunes, P.F.C.; André, P.S.B.; Segatto, M.E.V.; Frizera, A.; Díaz, C.A.R. An Optimized Self-Compensated Solution for Temperature and Strain Cross-Sensitivity in FBG Interrogators Based on Edge Filter. Sensors 2021, 21, 5828. [Google Scholar] [CrossRef]

- Wu, L.; Maheshwari, M.; Yang, Y.; Xiao, W. Selection and Characterization of Packaged FBG Sensors for Offshore Applications. Sensors 2018, 18, 3963. [Google Scholar] [CrossRef]

- Huang, A.-B.; Wang, C.-C.; Lee, J.-T.; Ho, Y.-T. Applications of FBG-Based Sensors to Ground Stability Monitoring. J. Rock Mech. Geotech. Eng. 2016, 8, 513–520. [Google Scholar] [CrossRef]

- Günday, A. Investigation of the Effects of Grating Length, Bragg Wavelength and Wavelength Shift on Temperature Sensitivity in Fiber Bragg Grating-Based Sensing Systems. Opt. Quantum Electron. 2024, 56, 290. [Google Scholar] [CrossRef]

- Cadusch, P.J.; Thompson, A.C.; Stoddart, P.R.; Wade, S.A. Modeling of Bend Effects on Fiber Bragg Gratings. In Proceedings of the Asia Pacific Optical Sensors Conference, Sydney, Australia, 31 January–3 February 2012; Canning, J., Peng, G., Eds.; SPIE: St Bellingham, WA, USA, 2012; p. 835114. [Google Scholar]

- Erdogan, T. Fiber Grating Spectra. J. Light. Technol. 1997, 15, 1277–1294. [Google Scholar] [CrossRef]

- Rodrigues, C.; Cavadas, F.; Félix, C.; Figueiras, J. FBG Based Strain Monitoring in the Rehabilitation of a Centenary Metallic Bridge. Eng. Struct. 2012, 44, 281–290. [Google Scholar] [CrossRef]

- Swanson, A.J.; Raymond, S.G.; Janssens, S.; Breukers, R.D.; Bhuiyan, M.D.H.; Lovell-Smith, J.W.; Waterland, M.R. Development of Novel Polymer Coating for FBG Based Relative Humidity Sensing. Sens. Actuators Phys. 2016, 249, 217–224. [Google Scholar] [CrossRef]

- Mishra, V.; Lohar, M.; Amphawan, A. Improvement in Temperature Sensitivity of FBG by Coating of Different Materials. Optik 2016, 127, 825–828. [Google Scholar] [CrossRef]

- Kang, D.H.; Park, S.O.; Hong, C.S.; Kim, C.G. The Signal Characteristics of Reflected Spectra of Fiber Bragg Grating Sensors with Strain Gradients and Grating Lengths. NDT E Int. 2005, 38, 712–718. [Google Scholar] [CrossRef]

- Dennison, C.R.; Wild, P.M. Enhanced Sensitivity of an In-Fibre Bragg Grating Pressure Sensor Achieved through Fibre Diameter Reduction. Meas. Sci. Technol. 2008, 19, 125301. [Google Scholar] [CrossRef]

- CR, U.K.; Samiappan, D.; Sudhakar, T. Development and Experimental Validation of a Nuttall Apodized Fiber Bragg Grating Sensor with a Hydrophobic Polymer Coating Suitable for Monitoring Sea Surface Temperature. Opt. Fiber Technol. 2020, 56, 102176. [Google Scholar] [CrossRef]

- Shen, R.; Zhang, J.; Wang, Y.; Teng, R.; Wang, B.; Zhang, Y.; Yan, W.; Zheng, J.; Du, G. Study on High-temperature and High-pressure Measurement by Using Metal-coated FBG. Microw. Opt. Technol. Lett. 2008, 50, 1138–1140. [Google Scholar] [CrossRef]

- Hong, C.-Y.; Zhang, Y.-F.; Zhang, M.-X.; Leung, L.M.G.; Liu, L.-Q. Application of FBG Sensors for Geotechnical Health Monitoring, a Review of Sensor Design, Implementation Methods and Packaging Techniques. Sens. Actuators Phys. 2016, 244, 184–197. [Google Scholar] [CrossRef]

- Chen, J.; Liu, B.; Zhang, H. Review of Fiber Bragg Grating Sensor Technology. Front. Optoelectron. China 2011, 4, 204–212. [Google Scholar] [CrossRef]

- Mihailov, S.J. Fiber Bragg Grating Sensors for Harsh Environments. Sensors 2012, 12, 1898–1918. [Google Scholar] [CrossRef]

- Werneck, M.M.; Allil, R.C.S.B.; Ribeiro, B.A.; de Nazaré, F.V.B.; Werneck, M.M.; Allil, R.C.S.B.; Ribeiro, B.A.; de Nazaré, F.V.B. A Guide to Fiber Bragg Grating Sensors. In Current Trends in Short- and Long-Period Fiber Gratings; IntechOpen: Rijeka, Croatia, 2013; ISBN 978-953-51-1131-3. [Google Scholar]

- Qiao, X.; Shao, Z.; Bao, W.; Rong, Q. Fiber Bragg Grating Sensors for the Oil Industry. Sensors 2017, 17, 429. [Google Scholar] [CrossRef]

- Li, T.; Guo, J.; Tan, Y.; Zhou, Z. Recent Advances and Tendency in Fiber Bragg Grating-Based Vibration Sensor: A Review. IEEE Sens. J. 2020, 20, 12074–12087. [Google Scholar] [CrossRef]

- Li, J.; Wang, H.; Sun, L.-P.; Huang, Y.; Jin, L.; Guan, B.-O. Etching Bragg Gratings in Panda Fibers for the Temperature-Independent Refractive Index Sensing. Opt. Express 2014, 22, 31917. [Google Scholar] [CrossRef]

- Shi, Q.; Wang, Y.; Cui, Y.; Xia, W.; Guo, D.; Wang, M. Resolution-Enhanced Fiber Grating Refractive Index Sensor Based on an Optoelectronic Oscillator. IEEE Sens. J. 2018, 18, 9562–9567. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, J.; Cai, S.; Zhang, Z.; Chen, X.; Guan, B.O.; Guo, T. Surface Plasmon Resonance Based on Multi-Angel Tilted Fiber Bragg Grating for Highly Sensitive and Wide Range Refractive Index Measurement. In Proceedings of the 2016 15th International Conference on Optical Communications and Networks (ICOCN), Hangzhou, China, 24–27 September 2016; pp. 1–3. [Google Scholar]

- Yang, S.; Homa, D.; Pickrell, G.; Wang, A. Fiber Bragg Grating Fabricated in Micro-Single-Crystal Sapphire Fiber. Opt. Lett. 2018, 43, 62. [Google Scholar] [CrossRef]

- Kuang, K.S.C.; Kenny, R.; Whelan, M.P.; Cantwell, W.J.; Chalker, P.R. Embedded Fibre Bragg Grating Sensors in Advanced Composite Materials. Compos. Sci. Technol. 2001, 61, 1379–1387. [Google Scholar] [CrossRef]

- Yan, W.; Ma, S.; Wang, H.; Zhang, X. Fiber Bragg Grating Online Packaging Technology Based on 3D Printing. Opt. Laser Technol. 2020, 131, 106443. [Google Scholar] [CrossRef]

- Zhao, J.; Dong, W.; Hinds, T.; Li, Y.; Splain, Z.; Zhong, S.; Wang, Q.; Bajaj, N.; To, A.; Ahmed, M.; et al. Embedded Fiber Bragg Grating (FBG) Sensors Fabricated by Ultrasonic Additive Manufacturing for High-Frequency Dynamic Strain Measurements. IEEE Sens. J. 2024, 24, 2853–2862. [Google Scholar] [CrossRef]

- Paloschi, D.; Polimadei, A.; Korganbayev, S.; Orsetti, V.; Mazzotta, C.; Cigada, A.; Caponero, M.A.; Saccomandi, P. Three-Dimensional-Printed Sensing Samples Embedding Fiber Bragg Gratings: Metrological Evaluation of Different Sample Materials and Fiber Coatings. IEEE Trans. Instrum. Meas. 2023, 72, 9506210. [Google Scholar] [CrossRef]

- Li, C.; Sun, L.; Xu, Z.; Wu, X.; Liang, T.; Shi, W. Experimental Investigation and Error Analysis of High Precision FBG Displacement Sensor for Structural Health Monitoring. Int. J. Struct. Stab. Dyn. 2020, 20, 2040011. [Google Scholar] [CrossRef]

- Thomas, J.; Rajanna, T.R.; Asokan, S. Temperature Compensated FBG Displacement Sensor for Long-Range Applications. IEEE Sens. Lett. 2020, 4, 5000104. [Google Scholar] [CrossRef]

- Cai, H.; Xiao, X.; Song, Q.; Sun, Q.; Yan, Z. Fiber Bragg Grating Displacement Sensor Based on Synchronous Deformation Sensing for Real-Time Monitoring of a Tunnel Lining. Appl. Opt. 2023, 62, 8299. [Google Scholar] [CrossRef]

- Xu, H.; Li, F.; Zhao, W.; Tian, X.; Du, Y.; Gao, Y. Fiber Optic Displacement Sensor Used in Railway Turnout Contact Monitoring System. Optoelectron. Lett. 2019, 15, 165–169. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, W.; Xiong, L.; Kuang, Y.; Wu, H.; Liu, H. Fiber Bragg Grating Displacement Sensor with High Abrasion Resistance for a Steel Spring Floating Slab Damping Track. Sensors 2018, 18, 1899. [Google Scholar] [CrossRef] [PubMed]

- Yao, Z.; Li, M.; Li, G.; Xing, M.; Chen, N. A High-Sensitivity Fiber Bragg Grating Sensor for Displacement Measurement in Structural Health Monitoring. Rev. Sci. Instrum. 2023, 94, 095008. [Google Scholar] [CrossRef] [PubMed]

- Consales, M.; Principe, S.; Iele, A.; Leone, M.; Zaraket, H.; Jomaa, I.; Cutolo, A.; Cusano, A. A Fiber Bragg Grating Liquid Level Sensor Based on the Archimedes’ Law of Buoyancy. J. Light. Technol. 2018, 36, 4936–4941. [Google Scholar] [CrossRef]

- De Almeida, G.G.; Barreto, R.C.; Seidel, K.F.; Kamikawachi, R.C. A Fiber Bragg Grating Water Level Sensor Based on the Force of Buoyancy. IEEE Sens. J. 2020, 20, 3608–3613. [Google Scholar] [CrossRef]

- Xu, D.; Feng, D.; Chen, Q.; Liu, G.; Qiao, X. Small-Sized Temperature and Pressure Sensors Based on Fiber Bragg Grating for Oil and Gas Wells. Sens. Actuators Phys. 2023, 357, 114397. [Google Scholar] [CrossRef]

- Laxmeshwar, L.S.; Jadhav, M.S.; Akki, J.F.; Raikar, P.; Raikar, U.S. Elemental Analysis of Wastewater Effluent Using Highly Sensitive Fiber Bragg Grating Sensor. Opt. Laser Technol. 2018, 105, 45–51. [Google Scholar] [CrossRef]

- Diaz, C.A.R.; Leal-Junior, A.G.; Andre, P.S.B.; Antunes, P.F.D.C.; Pontes, M.J.; Frizera-Neto, A.; Ribeiro, M.R.N. Liquid Level Measurement Based on FBG-Embedded Diaphragms with Temperature Compensation. IEEE Sens. J. 2018, 18, 193–200. [Google Scholar] [CrossRef]

- Zheng, Y.; Huang, D.; Shi, L. A New Deflection Solution and Application of a Fiber Bragg Grating-Based Inclinometer for Monitoring Internal Displacements in Slopes. Meas. Sci. Technol. 2018, 29, 055008. [Google Scholar] [CrossRef]

- Moslehi, B.; Black, R.J.; Faridian, F. Multifunctional Fiber Bragg Grating Sensing System for Load Monitoring of Composite Wings. In Proceedings of the 2011 Aerospace Conference, Big Sky, MT, USA, 5–12 March 2011; pp. 1–9. [Google Scholar]

- Bannur Nanjunda, S.; Seshadri, V.N.; Krishnan, C.; Rath, S.; Arunagiri, S.; Bao, Q.; Helmerson, K.; Zhang, H.; Jain, R.; Sundarrajan, A.; et al. Emerging Nanophotonic Biosensor Technologies for Virus Detection. Nanophotonics 2022, 11, 5041–5059. [Google Scholar] [CrossRef]

- Gunawan, W.H.; Marin, J.M.; Rjeb, A.; Kang, C.H.; Ashry, I.; Ng, T.K.; Ooi, B.S. Energy Harvesting Over Fiber From Amplified Spontaneous Emission in Optical Sensing and Communication Systems. J. Light. Technol. 2024, 42, 6511–6521. [Google Scholar] [CrossRef]

- Yu, Q.; Zhang, Y.; Dong, Y.; Li, Y.P.; Wang, C.; Chen, H. Study on Optical Fiber Bragg Grating Temperature Sensors for Human Body Temperature Monitoring. In Proceedings of the 2012 Symposium on Photonics and Optoelectronics, Shanghai, China, 21–23 May 2012; pp. 1–4. [Google Scholar]

- Majeed, A.F.; Murdas, I.A. Modern System for Blood Pressure and Temperature Monitoring Based on FBG Sensor. In Proceedings of the 2019 1st AL-Noor International Conference for Science and Technology (NICST), Sulimanyiah, Iraq, 25–29 October 2019; pp. 7–13. [Google Scholar]

- Xiao, F.; Chen, G.; Hulsey, J. Monitoring Bridge Dynamic Responses Using Fiber Bragg Grating Tiltmeters. Sensors 2017, 17, 2390. [Google Scholar] [CrossRef]

- Torres Górriz, B.; Rinaudo, P.; Calderón García, P.A. Comparison between Point and Long-gage FBG-based Strain Sensors during a Railway Bridge Load Test. Strain 2017, 53, e12230. [Google Scholar] [CrossRef]

- Iadicicco, A.; Natale, D.; Di Palma, P.; Spinaci, F.; Apicella, A.; Campopiano, S. Strain Monitoring of a Composite Drag Strut in Aircraft Landing Gear by Fiber Bragg Grating Sensors. Sensors 2019, 19, 2239. [Google Scholar] [CrossRef] [PubMed]

- Li, D.S.; Ren, L.; Li, H.N.; Song, G.B. Structural Health Monitoring of a Tall Building during Construction with Fiber Bragg Grating Sensors. Int. J. Distrib. Sens. Netw. 2012, 8, 272190. [Google Scholar] [CrossRef]

- Bai, Q.; Wang, Q.; Wang, D.; Wang, Y.; Gao, Y.; Zhang, H.; Zhang, M.; Jin, B. Recent Advances in Brillouin Optical Time Domain Reflectometry. Sensors 2019, 19, 1862. [Google Scholar] [CrossRef]

- Zrelli, A. Simultaneous Monitoring of Temperature, Pressure, and Strain through Brillouin Sensors and a Hybrid BOTDA/FBG for Disasters Detection Systems. IET Commun. 2019, 13, 3012–3019. [Google Scholar] [CrossRef]

- Sahota, J.K.; Gupta, N.; Dhawan, D. Fiber Bragg Grating Sensors for Monitoring of Physical Parameters: A Comprehensive Review. Opt. Eng. 2020, 59, 060901. [Google Scholar] [CrossRef]

- Pereira, K.; Coimbra, W.; Lazaro, R.; Frizera-Neto, A.; Marques, C.; Leal-Junior, A.G. FBG-Based Temperature Sensors for Liquid Identification and Liquid Level Estimation via Random Forest. Sensors 2021, 21, 4568. [Google Scholar] [CrossRef]

- Mondal, D.; Kavitha, B.S.; Vajresh Kumar, N.; Asokan, S. Functionalized Silver Nano Particle Coated E-FBG Sensor for Specific and Rapid Detection of Chromium in Drinking Water. IEEE Sens. J. 2024, 24, 28827–28834. [Google Scholar] [CrossRef]

- Yao, B.C.; Wu, Y.; Webb, D.J.; Zhou, J.H.; Rao, Y.J.; Pospori, A.; Yu, C.B.; Gong, Y.; Chen, Y.F.; Wang, Z.G. Graphene-Based D-Shaped Polymer FBG for Highly Sensitive Erythrocyte Detection. IEEE Photonics Technol. Lett. 2015, 27, 2399–2402. [Google Scholar] [CrossRef]

- Lei, M.; Zhang, Y.-N.; Han, B.; Zhao, Q.; Zhang, A.; Fu, D. In-Line Mach–Zehnder Interferometer and FBG with Smart Hydrogel for Simultaneous pH and Temperature Detection. IEEE Sens. J. 2018, 18, 7499–7504. [Google Scholar] [CrossRef]

- Rahme, M.; Tuthill, P.; Betters, C.; Large, M.; Leon-Saval, S. A New Gas Detection Technique through Cross-Correlation with a Complex Aperiodic FBG. Sci. Rep. 2024, 14, 9939. [Google Scholar] [CrossRef]

- Dalgamouni, S.; Benhaddou, D.; Brankovic, S. Developing a Gold Coated Fiber Brag Grating (FBG) Sensor to Monitor Chlorine Levels in Water. In Proceedings of the 2022 IEEE Photonics Conference (IPC), Vancouver, BC, Canada, 13–17 November 2022; pp. 1–2. [Google Scholar]

- Kurasawa, S.; Koyama, S.; Ishizawa, H.; Fujimoto, K.; Chino, S. Verification of Non-Invasive Blood Glucose Measurement Method Based on Pulse Wave Signal Detected by FBG Sensor System. Sensors 2017, 17, 2702. [Google Scholar] [CrossRef] [PubMed]

- Udos, W.; Tan, S.-H.; Lim, K.-S.; Low, M.-L.; Wei, H.; Ahmad, H. Signal Amplification Study for Gold-Coated Tilted Fiber Bragg Grating with Avidin-Biotin Sandwich Assay in the Detection of SARS-CoV-2. IEEE Sens. J. 2024, 24, 23878–23885. [Google Scholar] [CrossRef]

- Zhang, Q.; Xiong, Z. Crack Detection of Reinforced Concrete Structures Based on BOFDA and FBG Sensors. Shock. Vib. 2018, 2018, 6563537. [Google Scholar] [CrossRef]

- Poh, A.H.; Hassan, M.R.A.; Bakar, M.H.A.; Adikan, F.R.M.; Moghavvemi, M. Profile Morphology of Fiber Bragg Gratings During Initial Cracking: A Case Study on Proof Load Testing of an Arch Spandrel Segment. IEEE Sens. J. 2022, 22, 5678–5687. [Google Scholar] [CrossRef]

- Chan, T.H.T.; Yu, L.; Tam, H.Y.; Ni, Y.Q.; Liu, S.Y.; Chung, W.H.; Cheng, L.K. Fiber Bragg Grating Sensors for Structural Health Monitoring of Tsing Ma Bridge: Background and Experimental Observation. Eng. Struct. 2006, 28, 648–659. [Google Scholar] [CrossRef]

- Bai, J.; Zhao, D.; Zhang, X. Structural Health Monitoring of Smart Civil Structures Based on Fiber Bragg Grating Sensing Technology. In Proceedings of the 2011 2nd International Conference on Artificial Intelligence, Management Science and Electronic Commerce (AIMSEC), Deng Feng, China, 8–10 August 2011; pp. 635–638. [Google Scholar]

- Zhu, H.-H.; Yin, J.-H.; Zhang, L.; Jin, W.; Dong, J.-H. Monitoring Internal Displacements of a Model Dam Using FBG Sensing Bars. Adv. Struct. Eng. 2010, 13, 249–261. [Google Scholar] [CrossRef]

- Wang, M.; Chen, J.; Wei, H.; Song, B.; Xiao, W. Investigation on Seismic Damage Model Test of a High Concrete Gravity Dam Based on Application of FBG Strain Sensor. Complexity 2019, 2019, 7837836. [Google Scholar] [CrossRef]

- Ren, L.; Li, H.-N.; Li, X.; Zhou, J.; Xiang, L. Application of FBG Sensors in Rolled Concrete Dam Model. In Proceedings of the Smart Structures and Materials 2006: Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems, San Diego, CA, USA, 26 February–2 March 2006; Tomizuka, M., Yun, C.-B., Giurgiutiu, V., Eds.; SPIE: St Bellingham, WA, USA, 2006; p. 617436. [Google Scholar]

- Ren, C.; Sun, X.; He, M.; Tao, Z. Application of FBG Sensing Technology for Real-Time Monitoring in High-Stress Tunnel Environments. Appl. Sci. 2024, 14, 8202. [Google Scholar] [CrossRef]

- Li, Q.; He, Y.; Zhou, K.; Han, X.; He, Y.; Shu, Z. Structural Health Monitoring for a 600 m High Skyscraper. Struct. Des. Tall Spec. Build. 2018, 27, e1490. [Google Scholar] [CrossRef]

- Ni, Y.Q.; Wong, K.Y.; Xia, Y. Health Checks through Landmark Bridges to Sky-High Structures. Adv. Struct. Eng. 2011, 14, 103–119. [Google Scholar] [CrossRef]

- Liu, S.; Jiang, D. The Application of Structural Health Monitoring System Technology Using FBG to the No.2 Wuhan Bridge over the Yangtze River. In Proceedings of the Photonics and Optoelectronics Meetings (POEM) 2008: Fiber Optic Communication and Sensors, Wuhan, China, 24–27 November 2008; Jäger, D.S., Liu, D., Shum, P., Eds.; SPIE: St Bellingham, WA, USA, 2008; p. 72780O. [Google Scholar]

- Zhaoxia, W.; Dongmei, Y.; Zhiquan, L. Bridge Structure Monitoring System Based on Practical FBG. In Proceedings of the 2008 IEEE International Conference on Automation and Logistics, Qingdao, China, 1–3 September 2008; pp. 2714–2717. [Google Scholar]

- Alexakis, H.; Franza, A.; Acikgoz, S.; DeJong, M.J. Structural Health Monitoring of a Masonry Viaduct with Fibre Bragg Grating Sensors. In Proceedings of the IABSE Symposium 2019 Guimaraes, Towards a Resilient Built Environment—Risk and Asset Management, Guimarães, Portugal, 27–29 March 2019; pp. 1560–1567. [Google Scholar]

- Lin, Y.B.; Pan, C.L.; Kuo, Y.H.; Chang, K.C.; Chern, J.C. Online Monitoring of Highway Bridge Construction Using Fiber Bragg Grating Sensors. Smart Mater. Struct. 2005, 14, 1075–1082. [Google Scholar] [CrossRef]

- Bonopera, M.; Chang, K.-C.; Chen, C.-C.; Lee, Z.-K.; Sung, Y.-C.; Tullini, N. Fiber Bragg Grating–Differential Settlement Measurement System for Bridge Displacement Monitoring: Case Study. J. Bridge Eng. 2019, 24, 05019011. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, W.; Huang, Y.; Wang, H.; Jianping, H.; Huang, M.; Jinping, O. Optical Fiber Bragg Grating Sensor Assembly for 3D Strain Monitoring and Its Case Study in Highway Pavement. Mech. Syst. Signal Process. 2012, 28, 36–49. [Google Scholar] [CrossRef]

- Li, H.; Ou, J. The State of the Art in Structural Health Monitoring of Cable-Stayed Bridges. J. Civ. Struct. Health Monit. 2016, 6, 43–67. [Google Scholar] [CrossRef]

- Xiao, S.; Che, L.; Li, X.; Wang, Y. A Cost-Effective Flexible MEMS Technique for Temperature Sensing. Microelectron. J. 2007, 38, 360–364. [Google Scholar] [CrossRef]

- Mohammed, A.A.S.; Moussa, W.A.; Lou, E. High Sensitivity MEMS Strain Sensor: Design and Simulation. Sensors 2008, 8, 2642–2661. [Google Scholar] [CrossRef]

- Liu, X.; Yao, Y.; Ma, J.; Zhang, Y.; Wang, Q.; Zhang, Z.; Ren, T. Micro Packaged MEMS Pressure Sensor for Intracranial Pressure Measurement. J. Semicond. 2015, 36, 064009. [Google Scholar] [CrossRef]

- Pachava, V.R.; Kamineni, S.; Madhuvarasu, S.S.; Putha, K.; Mamidi, V.R. FBG Based High Sensitive Pressure Sensor and Its Low-Cost Interrogation System with Enhanced Resolution. Photonic Sens. 2015, 5, 321–329. [Google Scholar] [CrossRef]

- Li, R.; Chen, Y.; Tan, Y.; Zhou, Z.; Li, T.; Mao, J. Sensitivity Enhancement of FBG-Based Strain Sensor. Sensors 2018, 18, 1607. [Google Scholar] [CrossRef] [PubMed]

- Pal, D.; Kumar, A.; Gautam, A.; Thangaraj, J. FBG Based Optical Weight Measurement System and Its Performance Enhancement Using Machine Learning. IEEE Sens. J. 2022, 22, 4113–4121. [Google Scholar] [CrossRef]

- Tian, K.; Liu, Y.; Wang, Q. Temperature-Independent Fiber Bragg Grating Strain Sensor Using Bimetal Cantilever. Opt. Fiber Technol. 2005, 11, 370–377. [Google Scholar] [CrossRef]

- Frieden, J.; Cugnoni, J.; Botsis, J.; Gmür, T.; Ćorić, D. High-Speed Internal Strain Measurements in Composite Structures under Dynamic Load Using Embedded FBG Sensors. Compos. Struct. 2010, 92, 1905–1912. [Google Scholar] [CrossRef]

- Asri, M.I.A.; Hasan, M.N.; Fuaad, M.R.A.; Yunos, Y.M.; Ali, M.S.M. MEMS Gas Sensors: A Review. IEEE Sens. J. 2021, 21, 18381–18397. [Google Scholar] [CrossRef]

- Kim, B.-Y.; Lee, J.; Cho, Y.; Eoh, J.; Kim, H. Performance Test and Uncertainty Analysis of the FBG-Based Pressure Transmitter for Liquid Metal System. Nucl. Eng. Technol. 2022, 54, 4412–4421. [Google Scholar] [CrossRef]

- Galetto, M.; Schiavi, A.; Genta, G.; Prato, A.; Mazzoleni, F. Uncertainty Evaluation in Calibration of Low-Cost Digital MEMS Accelerometers for Advanced Manufacturing Applications. CIRP Ann. 2019, 68, 535–538. [Google Scholar] [CrossRef]

- Wu, W.; Liu, X. Investigation on High Temperature Characteristics of FBG Sensors. Optik 2015, 126, 2411–2413. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y.; Liao, C.; Wang, D.N.; Yang, M.; Lu, P. High-Temperature Sensing Using Miniaturized Fiber In-Line Mach–Zehnder Interferometer. IEEE Photonics Technol. Lett. 2010, 22, 39–41. [Google Scholar] [CrossRef]

- Rana, S.; Kandadai, N.; Subbaraman, H. Reflective Long Period Grating Based Temperature Sensor. In Proceedings of the Optical Components and Materials XVIII, Online Only, CA, USA, 6–12 March 2021; Digonnet, M.J., Jiang, S., Eds.; SPIE: St Bellingham, WA, USA, 2021; p. 43. [Google Scholar]

- Wang, Y.; Zheng, H.; Wu, H.; Huang, D.; Yu, C.; Lu, C. High-Sensitivity Distributed Temperature and Salinity Sensor Based on Frequency Scanning Φ-OTDR and Polyimide-Coated Polarization Maintaining Fiber. Opt. Laser Technol. 2024, 175, 110755. [Google Scholar] [CrossRef]

- Zheng, Y.; Chen, Y.; Zhang, Q.; Tang, Q.; Zhu, Y.; Yu, Y.; Du, C.; Ruan, S. High-Sensitivity Temperature Sensor Based on Fiber Fabry-Pérot Interferometer with UV Glue-Filled Hollow Capillary Fiber. Sensors 2023, 23, 7687. [Google Scholar] [CrossRef] [PubMed]

- James, S.W.; Tatam, R.P. Optical Fibre Long-Period Grating Sensors: Characteristics and Application. Meas. Sci. Technol. 2003, 14, R49. [Google Scholar] [CrossRef]

- Lee, C.-L.; Lee, L.-H.; Hwang, H.-E.; Hsu, J.-M. Highly Sensitive Air-Gap Fiber Fabry–Pérot Interferometers Based on Polymer-Filled Hollow Core Fibers. IEEE Photonics Technol. Lett. 2012, 24, 149–151. [Google Scholar] [CrossRef]

- Zhao, N.; Wang, Z.; Zhang, Z.; Lin, Q.; Yao, K.; Zhu, L.; Tian, B.; Zhao, L.; Yang, P.; Jiang, Z. Simultaneous Measurement of Temperature and Refractive Index Using Michelson Interferometer Based on Waist-Enlarged Fiber Bitaper. Micromachines 2022, 13, 658. [Google Scholar] [CrossRef]

- Iezzi, V.L.; Loranger, S.; Kashyap, R. High Sensitivity Distributed Temperature Fiber Sensor Using Stimulated Brillouin Scattering. Opt. Express 2017, 25, 32591. [Google Scholar] [CrossRef]

- Song, J.; Li, W.; Lu, P.; Xu, Y.; Chen, L.; Bao, X. Long-Range High Spatial Resolution Distributed Temperature and Strain Sensing Based on Optical Frequency-Domain Reflectometry. IEEE Photonics J. 2014, 6, 6801408. [Google Scholar] [CrossRef]

- Silva, M.S.P.E.; Alves, H.P.; Nascimento, J.F.D.; Martins-Filho, J.F. Impact of Pulse Width on the Sensitivity and Range of a Raman-Based Distributed Fiberoptic Temperature Sensor. J. Microw. Optoelectron. Electromagn. Appl. 2018, 17, 539–551. [Google Scholar] [CrossRef]

- Huang, J.-Y.; Van Roosbroeck, J.; Vlekken, J.; Martinez, A.B.; Geernaert, T.; Berghmans, F.; Van Hoe, B.; Lindner, E.; Caucheteur, C. FBGs Written in Specialty Fiber for High Pressure/High Temperature Measurement. Opt. Express 2017, 25, 17936. [Google Scholar] [CrossRef]

- Zheng, H.; Wu, H.; Wang, Y.; Shen, X.; Fang, Z.; Huang, D.; Dash, J.N.; Htein, L.; Cheng, X.; Tam, H.-Y.; et al. High-Sensitivity Distributed Optical Fiber Sensor for Simultaneous Hydrostatic Pressure and Temperature Measurement Based on Birefringent Frequency-Scanning φ-OTDR. Opt. Laser Technol. 2024, 175, 110756. [Google Scholar] [CrossRef]

- Liu, J.; Hou, Y.; Wang, J.; Zhong, G.; Zhang, L.; Zhuang, F.; Yu, L.; Wang, S. Multi-Parameter Demodulation for Temperature, Salinity and Pressure Sensor in Seawater Based on the Semi-Encapsulated Microfiber Mach-Zehnder Interferometer. Measurement 2022, 196, 111213. [Google Scholar] [CrossRef]

- Talataisong, W.; Wang, D.N.; Chitaree, R.; Liao, C.R.; Wang, C. Fiber In-Line Mach–Zehnder Interferometer Based on an Inner Air-Cavity for High-Pressure Sensing. Opt. Lett. 2015, 40, 1220–1222. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Wang, Y.; Liao, C.; Wang, Y.; He, J.; Fu, C.; Yang, K.; Bai, Z.; Zhang, F. Nano Silica Diaphragm In-Fiber Cavity for Gas Pressure Measurement. Sci. Rep. 2017, 7, 787. [Google Scholar] [CrossRef] [PubMed]

- Deng, L.; Jiang, C.; Hu, C.; Li, L.; Gao, J.; Li, H.; Sun, S.; Liu, C.; Shu, Y. Highly Sensitive Temperature and Gas Pressure Sensor Based on Long-Period Fiber Grating Inscribed in Tapered Two-Mode Fiber and PDMS. IEEE Sens. J. 2023, 23, 15578–15585. [Google Scholar] [CrossRef]

- Méndez, A.; Diatzikis, E. Fiber Optic Distributed Pressure Sensor Based on Brillouin Scattering. In Proceedings of the Optical Fiber Sensors, OSA, Cancún, Mexico, 23–27 October 2006; p. ThE46. [Google Scholar]

- Gu, H.; Dong, H.; Zhang, G.; He, J.; Xu, N.; Brown, D.J. Pressure Dependence of Brillouin Frequency Shift in Bare Silica Optical Fibers. Chin. Opt. Lett. 2012, 10, 100604. [Google Scholar]

- Du, C.; Wang, Q.; Zhao, Y. Long-Period Fiber Grating Sensor Induced by Electric-Arc Discharge for Dual-Parameter Measurement. Instrum. Sci. Technol. 2018, 46, 1–11. [Google Scholar] [CrossRef]

- Da Silva Falcão, B.; Giwelli, A.; Nogueira Kiewiet, M.; Banks, S.; Yabesh, G.; Esteban, L.; Kiewiet, L.; Yekeen, N.; Kovalyshen, Y.; Monmusson, L.; et al. Strain Measurement with Multiplexed FBG Sensor Arrays: An Experimental Investigation. Heliyon 2023, 9, e18652. [Google Scholar] [CrossRef]

- Wang, S.; Ma, Y.; Chen, W.; Wang, S.; Yi, Y.; Li, X.; Lu, C.; Zhang, S.; Geng, T.; Sun, W.; et al. Ultrasensitive Strain Sensor Based on Mach-Zehnder Interferometer with Bent Structures. J. Light. Technol. 2021, 39, 6958–6967. [Google Scholar] [CrossRef]

- Wu, H.; Guo, N.; Zhong, Z.; Guo, W.; Han, L.; Li, C.; Meng, D.; Yin, G.; Liu, T.; Zhu, T. High-Performance Distributed Dynamic Strain Sensing by Synthesizing φ-OTDR and BOTDR. Opt. Express 2023, 31, 18098. [Google Scholar] [CrossRef]

- Dong, X.; Luo, Z.; Du, H.; Sun, X.; Yin, K.; Duan, J. Highly Sensitive Strain Sensor Based on a Novel Mach–Zehnder Mode Interferometer with TCF-PCF-TCF Structure. Opt. Lasers Eng. 2019, 116, 26–31. [Google Scholar] [CrossRef]

- Li, L.; Xia, L.; Xie, Z.; Liu, D. All-Fiber Mach-Zehnder Interferometers for Sensing Applications. Opt. Express 2012, 20, 11109–11120. [Google Scholar] [CrossRef]

- Li, Y.; Khodaei, Z.S. Strain Measurement Consistency of Distributed Fiber Optic Sensors for Monitoring Composite Structures under Various Loading. Procedia Struct. Integr. 2024, 52, 709–718. [Google Scholar] [CrossRef]

- Sarkar, S.; Tarhani, M.; Eghbal, M.; Mehdi, S. Discrimination between Strain and Temperature Effects of a Single Fiber Bragg Grating Sensor Using Sidelobe Power. J. Appl. Phys. 2020, 127, 114503. [Google Scholar] [CrossRef]

- Alemohammad, H.R.; Foroozmehr, E.; Cotten, B.S.; Toyserkani, E. A Dual-Parameter Optical Fiber Sensor for Concurrent Strain and Temperature Measurement: Design, Fabrication, Packaging, and Calibration. J. Light. Technol. 2013, 31, 1198–1204. [Google Scholar] [CrossRef]

- Dey, K.; Vangety, N.; Roy, S. Machine Learning Approach for Simultaneous Measurement of Strain and Temperature Using FBG Sensor. Sens. Actuators Phys. 2022, 333, 113254. [Google Scholar] [CrossRef]

- Darwich, D.; Youssef, A.; Zaraket, H. Low-Cost Multiple FBG Interrogation Technique for Static Applications. Opt. Lett. 2020, 45, 1116. [Google Scholar] [CrossRef]

- Vermeiren, J.P.; Bentell, J.L.; De Gaspari, D.; Uwaerts, D.; Verbeke, P.; Vlekken, J. A 40 Ksamples/Sec Spectrometer Based FBG Interrogator Capable of Simultaneously Measuring More than 16 FBG Sensors. In Proceedings of the Fiber Optic Sensors and Applications VIII, Orlando, FL, USA, 25–29 April 2011; Mihailov, S.J., Du, H.H., Pickrell, G., Eds.; SPIE: St Bellingham, WA, USA, 2011; p. 80280G. [Google Scholar]

- Wuchrer, R.; Lautenschlager, G.; Metasch, R.; Rollig, M.; Fleischer, T.; Hartling, T. Filter-Based Interrogation of Fiber Bragg Grating Sensors. In Proceedings of the 2014 37th International Spring Seminar on Electronics Technology, Dresden, Germany, 7–11 May 2014; pp. 453–457. [Google Scholar]

- Zhang, P.; Cerecedo-Nunez, H.H.; Qi, B.; Pickrell, G.R.; Wang, A. Optical Time-Domain Reflectometry Interrogation of Multiplexing Low-Reflectance Bragg-Grating-Based Sensor System. Opt. Eng. 2003, 42, 1597–1603. [Google Scholar] [CrossRef]

- Agliullin, T.; Il’In, G.; Kuznetsov, A.; Misbakhov, R.; Misbakhov, R.; Morozov, G.; Morozov, O.; Nureev, I.; Sakhabutdinov, A. Overview of Addressed Fiber Bragg Structures’ Development. Photonics 2023, 10, 175. [Google Scholar] [CrossRef]

- Zhang, F.; Pei, H.; Song, H.; Zhu, H. Development of an FBG–MEMS-Based 3-D Principal Stress Monitoring Device in Soil. IEEE Sens. J. 2023, 23, 1972–1981. [Google Scholar] [CrossRef]

- Li, J.; Wang, X.; Wang, Y.; Wang, Z.; Wang, K.; Jiang, Y. Green Environmental Static Pressed Pile Penetration Mechanism Based on FBG-MEMS Joint Test Technology. Res. Sq. 2023; preprint. [Google Scholar]

- Liu, X.; Wang, Y.; Zhang, M. Application of Miniature FBG-MEMS Pressure Sensor in Penetration Process of Jacked Pile. Micromachines 2020, 11, 876. [Google Scholar] [CrossRef]

- Li, T.; Pei, Q.; Zhang, A.; Zhou, H.; Wang, L.; Tan, Y.; Zhou, Z. Multimode Proximal Force FBG-Based Sensors with High-Resolution for Catheter Surgical Robots. IEEE Trans. Instrum. Meas. 2023, 72, 4007512. [Google Scholar] [CrossRef]

- Lai, W.; Cao, L.; Tan, R.X.; Phan, P.T.; Hao, J.; Tjin, S.C.; Phee, S.J. Force Sensing with 1 Mm Fiber Bragg Gratings for Flexible Endoscopic Surgical Robots. IEEEASME Trans. Mechatron. 2020, 25, 371–382. [Google Scholar] [CrossRef]

- Li, T.; Chen, F.; Zhao, Z.; Pei, Q.; Tan, Y.; Zhou, Z. Hybrid Data-Driven Optimization Design of a Layered Six-Dimensional FBG Force/Moment Sensor with Gravity Self-Compensation for Orthopedic Surgery Robot. IEEE Trans. Ind. Electron. 2023, 70, 8568–8579. [Google Scholar] [CrossRef]

- Liu, Q.; Dai, Y.; Li, M.; Yao, B.; Zhang, J. FBG-Based Sensorized Surgical Instrument for Force Measurement in Minimally Invasive Robotic Surgery. IEEE Sens. J. 2024, 24, 11450–11458. [Google Scholar] [CrossRef]

| Parameter | Impact on Performance | Example Applications | Ref. |

|---|---|---|---|

| Grating Length | Shorter grating lengths (e.g., 2 mm) improve sensor stability and accuracy under strain gradients compared to longer lengths (e.g., 10 mm) | High-precision strain monitoring | [55] |

| Diameter | The small diameter enhances the sensitivity | Sensitive pressure measurements in medical application | [56] |

| Polymer Coatings | Increases humidity response | Humidity, temperature applications | [53,57] |

| Metal Coatings | Pressure sensitivity increased 19 times and temperature sensitivity doubled; measurable up to 40 MPa and 240 °C | Suitable for harsh environments such as oil wells monitoring | [58] |

| Sensor Type | Refractive Index Sensitivity | Refractive Index Range | Packaging Technique | Ideal Applications | Potential Challenges | Ref. |

|---|---|---|---|---|---|---|

| Etched FBG in Panda fiber | −1.492 nm/RI-unit (RIU) | 1.333 to 1.443 RIU | Chemical etching of the cladding | Temperature-independent refractive index sensing | Increased radiation loss | [65] |

| Optoelectronic oscillator with etched phase-shifted FBG | 530 MHz/RIU | 1.341 to 1.350 RIU | Cladding-etched PS-FBG | Biochemical and chemical RI sensing | Cross-sensitivity | [66] |

| Tilted FBG with gold coating | 523.41 nm/RIU | 1.15 to 1.143 RIU | Multi-angle tilted FBG with gold coating | Biochemical sensing in hard-to-reach places, in vivo measurements | Cross-sensitivity with temperature | [67] |

| Micro-sapphire FBG | 0.9–4.2 nm/RIU | 1.33 to 1.75 | Point-by-point inscription followed by wet etching | High-temperature sensing (up to 1400 °C) in harsh environments | Limited by material refractive index; nonlinear sensitivity | [68] |

| Application | Measurement Range (mm) | Sensitivity (pm/mm) | Environment | Benefits | Ref. |

|---|---|---|---|---|---|

| Civil Structures (Bridges, Dams) | 0–50 mm | 23.96 | Outdoor, dynamic | High durability, real-time monitoring, resistance to EMI | [73] |

| Long-range Industrial Applications | 0–150 mm | 23.80 | Harsh industrial environments (−40 to 120 °C) | High endurance, suitable for cyclic operations | [74] |

| Tunnel Monitoring | 0–25 mm | 19.48 | Tunnel linings | Real-time monitoring, high sensitivity, temperature compensation | [75] |

| Railway Infrastructure (Track Deformation) | 0–170 mm | 24.8 | High-speed rail systems | High precision, wide measurement range, real-time monitoring | [76] |

| Floating Slab Track | 0–90 mm | 34.32 | Alternating displacement, machinery equipment | High resolution (0.0029 mm) | [77] |

| Structural Health Monitoring: Crack Variation in Buildings | 0–110 mm | 39.47 | Structural components in power plants | High sensitivity, good linearity | [78] |

| Application | Measurement Range | Sensitivity | Environment | Benefits | Ref. |

|---|---|---|---|---|---|

| Industrial storage tanks | 0–0.25 m | 27 pm/cm | Corrosive liquids | Safety in explosive environments | [79] |

| Water level monitoring (rivers and reservoirs) | Up to 18 m | 43.5–155.7 pm/m | Reservoirs and rivers | Robust design, continuous monitoring, customizable sensitivity | [80] |

| Oil and gas industry | Pressure: 0–40 MPa, temperature: 25–200 °C | Pressure: 24.05 pm/MPa, temperature: 31.16 pm/°C | Harsh downhole environments (high temp, high pressure) | Small size (20 mm), high sensitivity | [81] |

| Industrial wastewater analysis | 95.73 ppm and 0.008 ppm | 0.76 pm/ppm (Cl), 38.6 pm/ppm (Pb) | Treated wastewater effluent | Accurate detection of chloride ions to prevent soil salinity. | [82] |

| Liquid level | Up to 10.54 m | 2.74 pm/mm | Industrial tanks | High sensitivity | [83] |

| Application | Temperature Range | Pressure Range | Temperature Sensitivity | Pressure Sensitivity | Refs. |

|---|---|---|---|---|---|

| Biomedical Monitoring | 35–45 °C | 102–219 mmHg | 23.4 pm/°C | 0.5 pm/mmHg | [88,89] |

| Oil and Gas | 25–200 °C | 0–40 MPa | 31.16 pm/°C | 24.05 pm/MPa | [81] |

| Application | Strain Range (με) | Sensitivity | Environment | Benefits | Refs. |

|---|---|---|---|---|---|

| Bridges | N/A | 1.15 pm/με | Dynamic bridge loads | High sensitivity, stability | [90,91] |

| Flexible Aerospace Parts | 0–2000 | ~1.2 pm/με | Dynamic aerospace conditions | Lightweight, durable | [92] |

| High-rise Buildings | 0–1000 | 0.5013 pm/με | High-rise construction | Reliable, low-maintenance | [93] |

| Application | Target Parameter | Measurement Range | Site | Benefits | Ref. |

|---|---|---|---|---|---|

| Environmental Applications | |||||

| Gas Detection | Acetylene (C2H2) | Differentiation of various C2H2 concentrations with high accuracy | Laboratory | Robust detection in mixed gas environments; minimal interference from contaminants. | [101] |

| Water Quality | Chlorine Concentration | 1–10 ppm | Freshwater | Highly efficient sensor for detecting low chlorine levels (1–10 ppm); suitable for medical applications (e.g., dialysis). | [102] |

| Biochemical Applications | |||||

| Clinical Glucose Monitoring | Glucose Levels (mg/dL) | Accurate glucose measurement up to 200 mg/dL | Radial Artery (Non-invasive) | Non-invasive, highly accurate glucose monitoring using pulse wave signals measured by FBG sensors. | [103] |

| SARS-CoV-2 Detection | Viral Load (copies/mL) | LOD reduced by ~70% from 100.05 to 29.97 copies/mL | Laboratory Setup | Highly sensitive with reduced LOD (∼70% improvement post amplification); specific for SARS-CoV-2 strains. | [104] |

| Parameter | FBG Sensors | MEMS Sensors | References |

|---|---|---|---|

| Sensitivity | Strain sensitivity: 6.2 pm/με Temperature sensitivity: 50.8 pm/K Pressure sensitivity: 90.6 pm/psi | Strain sensitivity: 0.03 mV/με Temperature sensitivity: 1.12 Ω/°C Pressure sensitivity: 0.009 mV/kPa. | [54,122,123,124,125,126] |

| Measurement Range | Pressure range: 0 to 40 psi Temperature range: −20 to 60 °C | Strain range: ±4000 με Temperature range: −50 to 50 °C | [123,125,127,128] |

| Measurement Speed | Strain measurement speed: 100 kHz | From 4 s to 46 min | [129,130] |

| Uncertainty | −3.63 to +3.47% | 0.6% | [131,132] |

| Parameter | FBG Sensors | Interferometric Sensors (e.g., Mach–Zehnder) | Long Period Grating Sensors | Distributed Sensors | References |

|---|---|---|---|---|---|

| Temperature Sensitivity | ~10–50 pm/°C | ~10–1700 pm/°C | ~30–100 pm/°C | 0.032–10 pm/°C | [54,88,133,134,135,136,137,138,139,140,141,142,143] |

| Pressure Sensitivity | 24–~13,100 pm/MPa | ~3.7 × 103–12 × 106 pm/MPa | ~−12–−18 nm/MPa | ~0.006–0.781 pm/MPa | [81,125,144,145,146,147,148,149,150,151] |

| Strain Sensitivity | 1.2–6.2 pm/με | ~1–165 pm/με | ~2–3 pm/με | ~1.2 pm/με | [92,126,142,152,153,154,155,156,157,158] |

| Interrogation Method | Principle | Cost | Applications | Ref. |

|---|---|---|---|---|

| Spectrometer-based Interrogation | Measures the spectrum of light reflected by the FBG to detect Bragg wavelength shifts. | High cost due to the need for high-performance components, offering precise measurements. | Research, high-precision sensing, industrial applications. | [163] |

| Wavelength-Shift Interrogation (Fixed Filter) | Uses a fixed optical filter to detect shifts in the FBG’s reflected wavelength. | Less expensive than spectrometers but may be less accurate; limited sensor capacity. | Applications with fewer sensors or where high precision is not critical. | [164] |

| Optical Time Domain Reflectometry | Uses time-domain measurements to locate and interrogate FBG sensors along a fiber. | More expensive than basic wavelength-shift systems; suitable for long-distance sensing or distributed sensors. | Large networks, long-distance sensing, structural health monitoring. | [165] |

| Addressed FBG Sensors | Assigns a unique address to each FBG sensor, allowing multiple sensors to share a single interrogator. | Significant cost reduction for large-scale networks by using one interrogator for many sensors. | Large-scale, distributed monitoring systems, such as environmental and structural health monitoring. | [166] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alhussein, A.N.D.; Qaid, M.R.T.M.; Agliullin, T.; Valeev, B.; Morozov, O.; Sakhabutdinov, A. Fiber Bragg Grating Sensors: Design, Applications, and Comparison with Other Sensing Technologies. Sensors 2025, 25, 2289. https://doi.org/10.3390/s25072289

Alhussein AND, Qaid MRTM, Agliullin T, Valeev B, Morozov O, Sakhabutdinov A. Fiber Bragg Grating Sensors: Design, Applications, and Comparison with Other Sensing Technologies. Sensors. 2025; 25(7):2289. https://doi.org/10.3390/s25072289

Chicago/Turabian StyleAlhussein, Alaa N. D., Mohammed R. T. M. Qaid, Timur Agliullin, Bulat Valeev, Oleg Morozov, and Airat Sakhabutdinov. 2025. "Fiber Bragg Grating Sensors: Design, Applications, and Comparison with Other Sensing Technologies" Sensors 25, no. 7: 2289. https://doi.org/10.3390/s25072289

APA StyleAlhussein, A. N. D., Qaid, M. R. T. M., Agliullin, T., Valeev, B., Morozov, O., & Sakhabutdinov, A. (2025). Fiber Bragg Grating Sensors: Design, Applications, and Comparison with Other Sensing Technologies. Sensors, 25(7), 2289. https://doi.org/10.3390/s25072289