Effect of the Adhesive System on the Properties of Fiberboard Panels Bonded with Hydrolysis Lignin and Phenol-Formaldehyde Resin

Abstract

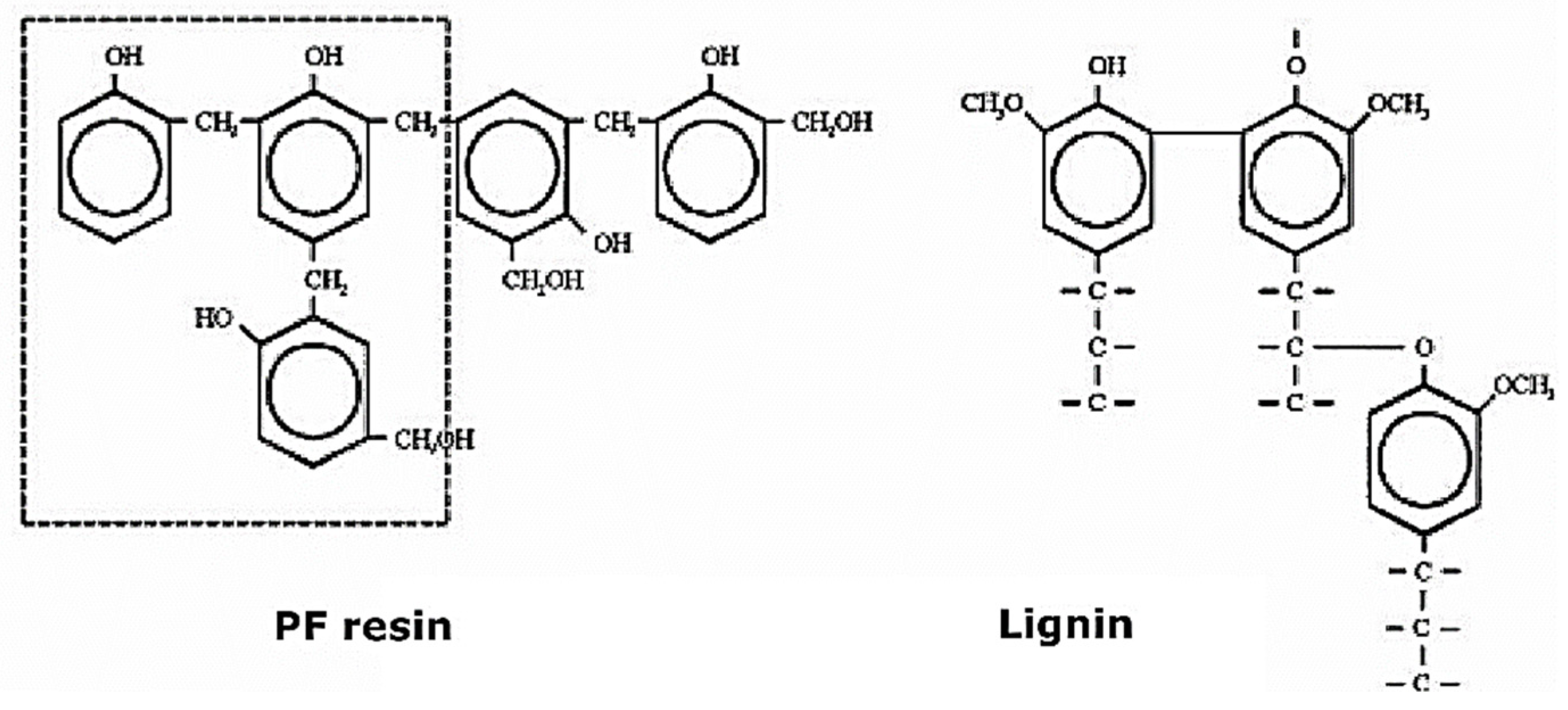

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, T.C.; Puad, N.A.D.; Selimin, M.A.; Manap, N.; Abdullah, H.Z.; Idris, M.I. An overview on development of environmental friendly medium density fibreboard. Mater. Today 2020, 29, 52–57. [Google Scholar] [CrossRef]

- Mirski, R.; Banaszak, A.; Bekhta, P. Selected Properties of Formaldehyde-Free Polymer-Straw Boards Made from Different Types of Thermoplastics and Different Kinds of Straw. Materials 2021, 14, 1216. [Google Scholar] [CrossRef]

- Popovic, M.; Momčilović, M.D.; Gavrilović-Grmuša, I. New standards and regulations on formaldehyde emission from wood-based composite panels. Zast. Mater. 2020, 61, 152–160. [Google Scholar] [CrossRef]

- Valyova, M.; Ivanova, Y.; Koynov, D. Investigation of free formaldehyde quantity in production of plywood with modified urea-formaldehyde resin. Int. J. Wood Des. Technol. 2017, 6, 72–76. [Google Scholar]

- Kristak, L.; Antov, P.; Bekhta, P.; Lubis, M.A.R.; Iswanto, A.H.; Reh, R.; Sedliacik, J.; Savov, V.; Taghiayri, H.; Papadopoulos, A.N.; et al. Recent Progress in Ultra-Low Formaldehyde Emitting Adhesive Systems and Formaldehyde Scavengers in Wood-Based Panels: A Review. Wood Mater. Sci. Eng. 2022. [Google Scholar] [CrossRef]

- FAO. Forest Product Statistics. Available online: http://www.fao.org/forestry/statistics/ (accessed on 24 March 2022).

- Kibleur, P.; Aelterman, J.; Boone, M.; Bulcke, J. Deep learning segmentation of wood fiber bundles in fiberboards. Compos. Sci. Technol. 2022, 221, 109287. [Google Scholar] [CrossRef]

- Puspaningrum, T.; Haris, Y.H.; Sailah, I.; Yani, M.; Indrasti, N.S. Physical and mechanical properties of binderless medium density fiberboard (MDF) from coconut fiber. IOP Conf. Ser. Earth Environ. Sci. 2020, 472, 012011. [Google Scholar] [CrossRef]

- Akgül, M.; Uner, B.; Çamlibel, O.; Ayata, Ü. Manufacture of Medium Density Fiberboard (MDF) Panels from Agri Based Lignocellulosic Biomass. Wood Res. 2017, 62, 615–624. [Google Scholar]

- Ferdosian, F.; Pan, Z.; Gao, G.; Zhao, B. Bio-Based Adhesives and Evaluation for Wood Composites Application. Polymers 2016, 9, 70. [Google Scholar] [CrossRef] [Green Version]

- Hemmilä, V.; Adamopoulos, S.; Karlsson, O.; Kumar, A. Development of sustainable bio-adhesives for engineered wood panels—A Review. RSC Adv. 2017, 7, 38604–38630. [Google Scholar] [CrossRef]

- Widsten, P.; Hummer, A.; Heathcote, C.; Kandelbauer, A. A preliminary study of green production of fiberboard bonded with tannin and laccase in a wet process. Holzforschung 2009, 63, 545–550. [Google Scholar] [CrossRef]

- Khalaf, Y.; El Hage, P.; Mihajlova, J.D.; Bargeret, A.; Lacroix, P.; El Hage, R. Influence of agricultural fibers size on mechanical and insulating properties of innovative chitosan-based insulators. Constr. Build. Mater. 2021, 278, 123071. [Google Scholar] [CrossRef]

- Wang, Z.; Kang, H.; Liu, H.; Zhang, C.; Wang, Z.; Li, J. Dual-Network Nanocross-linking Strategy to Improve Bulk Mechanical and Water-Resistant Adhesion Properties of Biobased Wood Adhesives. ACS Sustain. Chem. Eng. 2020, 8, 16430–16440. [Google Scholar] [CrossRef]

- Pizzi, A.; Papadopoulus, A.N.; Policardi, F. Wood Composites and Their Polymer Binders. Polymers 2020, 12, 1115. [Google Scholar] [CrossRef]

- Arias, A.; González-Rodríguez, S.; Vetroni Barros, M.; Salvador, R.; de Francisco, A.C.; Piekarski, C.M.; Moreira, M.T. Recent developments in bio-based adhesives from renewable natural resources. J. Clean. Prod. 2021, 314, 127892. [Google Scholar] [CrossRef]

- Tisserat, B.; Eller, F.J.; Mankowski, M.E. Properties of Composite Wood Panels Fabricated from Eastern Redcedar Employing Furious Bio-based Green Adhesives. BioResources 2019, 14, 6666–6685. [Google Scholar]

- Ghahri, S.; Pizzi, A.; Hajihassani, R. A Study of Concept to Prepare Totally Biosourced Wood Adhesives from only Soy Protein and Tannin. Polymers 2022, 14, 1150. [Google Scholar] [CrossRef]

- Mancera, C.; Mansouri, N.E.; Pelach, M.A.; Francesc, F.; Salvadó, J. Feasibility of incorporating treated lignins in fiberboards made from agricultural waste. Waste Manag. 2012, 1962–1967. [Google Scholar] [CrossRef]

- Santos, J.; Pereira, J.; Escobar-Avello, D.; Ferreira, I.; Vieira, C.; Magalhães, F.D.; Martins, J.M.; Carvalho, L.H. Grape Canes (Vitis vinifera L.) Applications on Packaging and Particleboard Industry: New Bioadhesive Based on Grape Extracts and Citric Acid. Polymers 2022, 14, 1137. [Google Scholar] [CrossRef]

- Kristak, L.; Ruziak, I.; Tudor, E.M.; Barbu, M.C.; Kain, G.; Reh, R. Thermophysical Properties of Larch Bark Composite Panels. Polymers 2021, 13, 2287. [Google Scholar] [CrossRef]

- Pizzi, A. Tannins: Prospectives and Actual Industrial Applications. Biomolecules 2019, 9, 344. [Google Scholar] [CrossRef] [Green Version]

- Dunky, M. Wood Adhesives Based on Natural Resources: A Critical Review Part III. Tannin- and Lignin-Based Adhesives. Rev. Adhes. Adhes. 2020, 8, 379–525. [Google Scholar]

- Anderson, I.; Anderson, B.; Avramidis, G.; Frichart, C.R. Handbook of Wood Chemistry and Wood Composites, 2nd ed.; Part III—Wood Composites; Taylor Francis Group: Abingdon, UK, 2013; pp. 255–511. [Google Scholar]

- Balakshin, M.; Capanema, E.A.; Zhu, X.; Sulaeva, I.; Potthast, A.; Rosenau, T.; Rojas, O.J. Spruce milled wood lignin: Linear, branched or cross-linked? Green Chem. 2020, 22, 3985–4001. [Google Scholar] [CrossRef]

- Iravani, S.; Varma, R.S. Greener synthesis of lignin nanoparticles and their applications. Green Chem. 2020, 22, 612. [Google Scholar] [CrossRef]

- Westin, M.; Simonson, R.; Östman, B. Kraft lignin wood fiberboards—The effect of kraft lignin addition to wood chips or board pulp prior to fiberboard production. Holz. Als. Roh.-Und Werkst. 2001, 58, 393–400. [Google Scholar] [CrossRef]

- Saffian, H.A.; Yamaguchi, M.; Ariffin, H.; Abdan, K.; Kassim, N.K.; Lee, S.H.; Lee, C.H.; Shafi, A.R.; Humairah Alias, A. Thermal, Physical and Mechanical Properties of Poly(Butylene Succinate)/Kenaf Core Fibers Composites Reinforced with Esterified Lignin. Polymers 2021, 13, 2359. [Google Scholar] [CrossRef]

- Solihat, N.N.; Sari, F.P.; Falah, F.; Ismayati, M.; Lubis, M.A.R.; Fatriasari, W.; Santoso, E.B.; Syafii, W. Lignin as an Active Biomaterial: A Review. J. Sylva Lestari 2021, 9, 1–22. [Google Scholar] [CrossRef]

- Parray, J.; Mir, M.; Shameen, N. Lignin Nanoparticles: Synthesis and Applications. In Nano-Technology Intervention in Agricultural Productivity; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2021; pp. 97–108. [Google Scholar]

- Euring, M.; Ostendorf, K.; Rühl, M.; Kües, U. Enzymatic Oxidation of Ca-Lignosulfonate and Kraft Lignin in Different Lignin-Laccase-Mediator-Systems and MDF Production. Front. Bioeng. Biotechnol. 2022, 9, 788622. [Google Scholar] [CrossRef]

- Antov, P.; Savov, V.; Mantanis, G.I.; Neykov, N. Medium-density fibreboards bonded with phenol-formaldehyde resin and calcium lignosulfonate as an eco-friendly additive. Wood Mater. Sci. Eng. 2021, 16, 42–48. [Google Scholar] [CrossRef]

- Antov, P.; Valchev, I.; Savov, V. Experimental and Statistical Modeling of the Exploitation Properties of Eco-Friendly MDF Trough Variation of Lignosulfonate Concentration and Hot-Pressing Temperature. In Proceedings of the 2nd International Congress of Biorefinery of Lignocellulosic Materials (IWBLCM 2019), Córdoba, Spain, 4–7 June 2019; pp. 104–109. [Google Scholar]

- Hemmila, V.; Hosseinpourpia, R.; Adamopoulos, S.; Eceiza, A. Characterization of Wood-based Industrial Biorefinery Lignosulfonates and Supercritical Water Hydrolysis Lignin. Waste Biomass Valor. 2020, 11, 5835–5845. [Google Scholar] [CrossRef] [Green Version]

- Savov, V.; Mihajlova, J. Influence of the Content of Lignosulfonate on Physical Properties of Medium Density Fiberboards. ProLigno 2017, 13, 247–251. [Google Scholar]

- Gonçalves, S.; Ferra, J.; Paiva, N.; Martins, J.; Carvalho, L.H.; Magalhães, F.D. Lignosulphonates as an Alternative to Non-Renewable Binders in Wood-Based Materials. Polymers 2021, 13, 4196. [Google Scholar] [CrossRef]

- Savov, V.; Valchev, I.; Antov, P. Processing Factors for Production of Eco-Friendly Medium Density Fibreboards Based on Lignosulfonate Adhesives. In Proceedings of the 2nd International Congress of Biorefinery of Lignocellulosic Materials (IWBLCM 2019), Córdoba, Spain, 4–7 June 2019; pp. 165–169. [Google Scholar]

- Savov, V.; Antov, P. Engineering the Properties of Eco-Friendly Medium Density Fibreboards Bonded with Lignosulfonate Adhesive. Drv. Ind. 2020, 71, 157–162. [Google Scholar] [CrossRef]

- Antov, P.; Savov, V.; Krišťák, Ĺ.; Réh, R.; Mantanis, G.I. Eco-Friendly, High-Density Fiberboards Bonded with Urea-Formaldehyde and Ammonium Lignosulfonate. Polymers 2021, 13, 220. [Google Scholar] [CrossRef]

- Antov, P.; Krišťák, Ĺ.; Réh, R.; Savov, V.; Papadopoulos, A.N. Eco-Friendly Fiberboard Panels from Recycled Fibers Bonded with Calcium Lignosulfonate. Polymers 2021, 13, 639. [Google Scholar] [CrossRef]

- Antov, P.; Savov, V.; Trichkov, N.; Krišťák, Ĺ.; Réh, R.; Papadopoulos, A.N.; Taghiyari, H.R.; Pizzi, A.; Kunecová, D.; Pachikova, M. Properties of High-Density Fiberboard Bonded with Urea–Formaldehyde Resin and Ammonium Lignosulfonate as a Bio-Based Additive. Polymers 2021, 13, 2775. [Google Scholar] [CrossRef]

- Bekhta, P.; Noshchenko, G.; Réh, R.; Kristak, L.; Sedliačik, J.; Antov, P.; Mirski, R.; Savov, V. Properties of Eco-Friendly Particleboards Bonded with Lignosulfonate-Urea-Formaldehyde Adhesives and pMDI as a Crosslinker. Materials 2021, 14, 4875. [Google Scholar] [CrossRef]

- Karthäuser, J.; Biziks, V.; Mai, C.; Militz, H. Lignin and Lignin-Derived Compounds for Wood Applications—A Review. Molecules 2021, 26, 2533. [Google Scholar] [CrossRef]

- Yotov, N.; Savov, V.; Valchev, I.; Petrin, S.; Karatotev, V. Study on possibility for utilization of technical hydrolysis lignin in composition of medium density fiberboard. Innov. Wood. Ind. Eng. Des. 2017, 6, 69–74. [Google Scholar]

- Limayem, A.; Ricke, S.C. Lignocellulosic biomass for bioethanol production: Current perspectives, potential issues and future prospects. Prog. Energy Combust. Sci. 2012, 38, 449–467. [Google Scholar] [CrossRef]

- Falah, F.; Lubis, M.A.R.; Fatriasari, W.; Sari, F.P. Utilization of Lignin from the Waste of Bioethanol Production as a Mortar Additive. J. Sylva Lestari 2020, 8, 326–339. [Google Scholar] [CrossRef]

- Gopalakrishnan, K.; Kim, S.; Ceylan, H. Lignin Recovery and Utilization. In Bioenergy and Biofuel from Biowastes and Biomass; American Society of Civil Engineers: Reston, VA, USA, 2010; pp. 247–278. [Google Scholar]

- Li, H.; Qu, Y.; Xu, J. Microwave-Assisted Conversion of Lignin. Prod. Biofuels Chem. Microwave. Biofuels Biorefineries 2015, 3, 61–68. [Google Scholar]

- Aracri, E.; Blanco, C.D.; Tzanov, T. An enzymatic approach to develop a lignin-based adhesive for wool floor coverings. Green Chem. 2014, 16, 2597. [Google Scholar] [CrossRef]

- Ariton, A.M.; Greanga, S.; Trinca, L.M.; Bors, S.I.; Ungureanu, E.; Malutan, T.; Popa, V. Valorization of lignin modified by hydroxymethylation to ensure birch veneer bioprotection. Cellul. Chem. Technol. 2015, 49, 765–774. [Google Scholar]

- El Mansouri, N.E.; Yuan, O.; Huang, F. Study of chemical modification of alkaline lignin by the glyoxalation reaction. BioResources 2011, 6, 4523–4536. [Google Scholar]

- Ghorbani, M.; Liebner, F.W.G.; van Herwijnen, H.; Pfungen, L.; Krahofer, M.; Budjav, E.; Konnerth, J. Lignin Phenol Formaldehyde Resoles: The Impact of Lignin Type on Adhesive Properties. BioResources 2016, 11, 6727–6741. [Google Scholar] [CrossRef] [Green Version]

- Nasir, M.; Asim, M.; Singh, K. Fiberboard Manufacturing from Laccase Activated Lignin Based Bioadhesive. In Eco-Friendly Adhesives for Wood and Natural Fiber Composites. Composites Science and Technology; Springer: Singapore, 2021; pp. 51–83. [Google Scholar]

- Valchev, I.; Savov, V.; Yordanov, I. Reduction of Phenol Formaldehyde Resin Content in Dry-Processed Fibreboards by Adding Hydrolysis Lignin. In Proceedings of the 2020 Society of Wood Science and Technology International Convention Renewable Resources for Sustainable and Healthy Future, Portorož, Slovenia, 12–15 July 2020; pp. 592–602. [Google Scholar]

- Valchev, I.; Yordanov, Y.; Savov, V.; Antov, P. Optimization of the Hot-Pressing Regime in the Production of Eco-Friendly Fibreboards Bonded with Hydrolysis Lignin. Period. Polytech. Chem. Eng. 2022, 66, 125–134. [Google Scholar] [CrossRef]

- Kumar, R.N.; Pizzi, A. Adhesives for Wood and Lignocellulosic Materials; Wiley Publishing House: Hoboken, NJ, USA, 2019; p. 491. [Google Scholar]

- Aristri, M.A.; Lubis, M.A.R.; Yadav, S.M.; Antov, P.; Papadopoulos, A.N.; Pizzi, A.; Fatriasari, W.; Ismayati, M.; Iswanto, A.H. Recent Developments in Ligninand Tannin-Based Non-Isocyanate Polyurethane Resins for Wood Adhesives—A Review. Appl. Sci. 2021, 11, 4242. [Google Scholar] [CrossRef]

- Handika, S.O.; Lubis, M.A.R.; Sari, R.K.; Laksana, R.P.B.; Antov, P.; Savov, V.; Gajtanska, M.; Iswanto, A.H. Enhancing Thermal and Mechanical Properties of Ramie Fiber via Impregnation by Lignin-Based Polyurethane Resin. Materials 2021, 14, 6850. [Google Scholar] [CrossRef]

- Malutan, M.; Nicu, R.; Popa, V.I. Contribution to the study of hydroxymetilation reaction of alkali lignin. Bioresurces 2008, 3, 13–20. [Google Scholar]

- Technical Association of the Pulp and Paper Industry. T 222 om-11 Acid-Insoluble Lignin in Wood and Pulp; Technical Association of the Pulp and Paper Industry: Peachtree Corners, GA, USA, 2011. [Google Scholar]

- Technical Association of the Pulp and Paper Industry. T 211 om-12 Ash in Wood, Pulp, Paper and Paperboard: Combustion at 525 Degrees C; Technical Association of the Pulp and Paper Industry: Peachtree Corners, GA, USA, 2012. [Google Scholar]

- Jivkov, V.; Elenska-Valchanova, D. Mechanical Properties of Some Thin Furniture Structural Composite Materials. In Proceedings of the 30th International Conference on Wood Science and Technology, Paris, France, 29–30 March 2019; pp. 86–94. [Google Scholar]

- Jivkov., V.; Petrova, B. Challenges for furniture design with thin structural materials. In Proceedings of the IFC2020, Trabzon, Turkey, 2–4 November 2020; pp. 113–123. [Google Scholar]

- Bertaud, F.; Tapin-Lingua, S.; Pizzi, A.; Navarrete, P.; Petit-Conil, M. Development of green adhesives for fibreboard manufacturing, using tannins and lignin from pulp mill residues. Cellul. Chem. Technol. 2012, 46, 449–455. [Google Scholar]

- Thaeng, D.; Mansouri, N.E.; Arbat, G.; Ngo, B.; Delgado-Aguilar, M.; Pelach, M.A.; Fullana-i-Palmer, P.; Matje, M. Fiberboards made from corn stalks thermomechanical pulp and kraft lignin as green adhesive. BioResources 2017, 12, 2379–2393. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.; Tang, L.; Zhang, W.; Lv, C.; Zheng, F.; Zhang, R.; Du, G.; Tang, B.; Liu, X. Enzymatic hydrolysis lignin derived from corn stover as an intrinsic binder for bio-composites manufacture: Effect of fiber moisture content and pressing temperature on boards’ properties. BioResources 2011, 6, 253–264. [Google Scholar] [CrossRef]

- EN 310:1999; Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization (CEN): Brussels, Belgium, 1999.

- EN 317:1998; Particleboards and Fibreboards—Determination of Swelling in Thickness after Immersion in Water. European Committee for Standardization (CEN): Brussels, Belgium, 1998.

- EN 323:2001; Wood-Based Panels—Determination of Density. European Committee for Standardization (CEN): Brussels, Belgium, 2001.

- EN 622-5:2010; Fibreboards—Specifications—Part 5: Requirements for Dry Process Boards. European Committee for Standardization (CEN): Brussels, Belgium, 2010.

- Vineeth, S.K.; Gadhave, R.V.; Gadekar, P.T. Chemical Modification of Nanocellulose in Wood Adhesive: Review. Open J. Polym. Chem. 2019, 9, 86–99. [Google Scholar] [CrossRef] [Green Version]

- Karagiannidis, E.; Markessini, C.; Athanassiadou, E. Micro-Fibrillated Cellulose in Adhesive Systems for the Production of Wood-Based Panels. Molecules 2020, 25, 4846. [Google Scholar] [CrossRef]

- Velasquez, J.A.; Ferrando, F.; Salvado, J. Effects of kraft lignin addition in the production of binderless fiberboard from steam exploded Miscanthus Sinensis. Ind. Crops Prod. 2003, 18, 17–23. [Google Scholar] [CrossRef]

- Bouajila, A.; Limare, A.; Joly, C.; Dole, P. Lignin plasticization to improve binderless fiberboard mechanical properties. Polym. Eng. Sci. 2005, 45, 809–816. [Google Scholar] [CrossRef]

- Okuda, N.; Hori, K.; Sato, M. Chemical changes of kenaf core binderless boards during hot pressing (I): Influence of the pressing temperature condition. J. Wood. Sci. 2006, 52, 244–248. [Google Scholar] [CrossRef]

- Okuda, N.; Hori, K.; Sato, M. Chemical changes of kenaf core binderless boards during hot pressing (II): Effects on the binderless board properties. J. Wood. Sci. 2006, 52, 249–254. [Google Scholar] [CrossRef]

- Suzuki, S.; Hiroyuki, S.; Park, S.-Y.; Saito, K.; Laemsak, N.; Okuma, M.; Iiyama, K. Preparation of binderless boards from steam exploded pulps of oil palm (Elaeis guneensis Jaxq.) fronds and structural characteristics of lignin and wall polysaccharides in steam exploded pulps to be discussed for self-bindings. Holzforschung 1998, 52, 417–426. [Google Scholar]

- Back, E. Oxidative activation of wood surfaces for glue bonding. For. Prod. J. 1991, 41, 30–36. [Google Scholar]

- Quintana, G.; Velasquez, J.; Betancourt, S.; Ganan, P. Binderless fiberboard from steam exploded banana bunch. Ind. Crops Prod. 2009, 29, 60–66. [Google Scholar] [CrossRef]

- Nasir, M.; Gupta, A.; Beg, M.D.H.; Chua, G.K.; Kumar, A. Physical and Mechanical Properties of Medium-Density Fibreboards Using Soy-Lignin Adhesives. J. Trop. For. Sci. 2014, 26, 41–49. [Google Scholar]

- Ammar, M.; Mechi, N.; Hidouri, A.; Elaloui, E. Fiberboards based on filled lignin resin and petiole fibers. J. Indian Acad. Wood Sci. 2018, 15, 120–125. [Google Scholar] [CrossRef]

- Hoareau, W.; Oliveira, F.B.; Grelier, S.; Siegmund, B.; Frollini, E.; Castellan, A. Fiberboards Based on Sugarcane Bagasse Lignin and Fibers. Macromol. Mater. Eng. 2006, 291, 829–839. [Google Scholar] [CrossRef]

- Tupciauskas, R.; Gravitis, J.; Abolins, J.; Veveris, A.; Andzs, M.; Liitia, T.; Tamminen, T. Utilization of lignin powder for manufacturing self-binding HDF. Holzforschung 2017, 71, 555–561. [Google Scholar] [CrossRef]

- Sihag, K.; Yadav, S.M.; Lubis, M.A.R.; Poonia, P.K.; Negi, A.; Khali, D.P. Influence of needle-punching treatment and pressureon selected properties of medium density fiberboard made of bamboo (Dendrocalamus strictus Roxb. Nees). In Wood Material Science & Engineering; Taylor and Francis Ltd.: London, UK, 2021. [Google Scholar] [CrossRef]

- Zakaria, R.; Bawon, P.; Lee, S.H.; Salim, S.; Lum, W.C.; Al-Edrus, S.S.O.; Ibrahim, Z. Properties of Particleboard from Oil Palm Biomasses Bonded with Citric Acid and Tapioca Starch. Polymers 2021, 13, 3494. [Google Scholar] [CrossRef]

- Rowell, R.; Gutzmer, D.; Sachs, I.; Kinney, R. Effects of alkylene oxide treatments on dimensional stability of wood. Wood Sci. 1976, 9, 51–54. [Google Scholar]

- Mantanis, G.I.; Young, R.; Rowell, R. Swelling of Wood. Part 1. Swelling in water. Wood Sci. Technol. 1994, 28, 119–134. [Google Scholar]

- Rozman, H.; Tan, K.; Kumar, R.; Abubakar, A.; Ishak, Z.; Ismail, H. The effect of lignin as a compatibilizer on the physical properties of coconut fiber-polypropylene composites. Eur. Polym. J. 2000, 36, 1483–1494. [Google Scholar] [CrossRef]

| Panel Type | Total Binders Content, % | PF Resin Content in the Adhesive System, % | Technical Hydrolysis Lignin Content in the Adhesive System, % | PF Resin Content Relative to Dry Fibers, % | Technical Hydrolysis Lignin Content Relative to Dry Fibers, % |

|---|---|---|---|---|---|

| A | 10 | 10 | 90 | 1.0 | 9.0 |

| B | 10 | 20 | 80 | 2.0 | 8.0 |

| C | 10 | 30 | 70 | 3.0 | 7.0 |

| D | 12 | 10 | 90 | 1.2 | 10.8 |

| E | 12 | 20 | 80 | 2.4 | 9.6 |

| F | 12 | 30 | 70 | 3.6 | 8.4 |

| Panel Type | Average/Mean/Value, kg·m−3 | Standard Deviation, kg·m−3 | Standard Error, kg·m−3 | Coefficient of Variation, % | Probability, % |

|---|---|---|---|---|---|

| A | 856 | 34 | 4 | 12 | 1.42 |

| B | 852 | 43 | 5 | 15 | 1.77 |

| C | 862 | 26 | 3 | 9 | 1.08 |

| D | 842 | 24 | 3 | 8 | 0.99 |

| E | 860 | 24 | 3 | 8 | 0.99 |

| F | 850 | 19 | 2 | 7 | 0.78 |

| Source of Variation | SS | df | MS | F | p-Value | Fcrit |

|---|---|---|---|---|---|---|

| Total binder content | 247.52 | 1 | 247.52 | 0.356 | 0.553 | 4.06 |

| PF resin content in the adhesive system | 393.16 | 2 | 196.58 | 0.282 | 0.755 | 3.21 |

| Error | 30,617.29 | 44 | 695.84 | |||

| Total | 31,257.97 | 47 |

| Property | Modulus of Elasticity (MOE) | Bending Strength (MOR) | Internal Bond (IB) Strength | Thickness Swelling (24 h) | Water Absorption (24 h) | |

|---|---|---|---|---|---|---|

| Regression Coefficient | ||||||

| B0 | −6920.667 | −51.867 | −2.260 | 60.538 | 111.152 | |

| B1 | 917.333 | 7.438 | 0.285 | −2.493 | −3.613 | |

| B2 | 230.450 | 0.395 | 0.018 | −0.410 | −0.530 | |

| B12 | −17.550 | – | −0.001 | – | – | |

| Fcal | 147.89 | 5882.68 | 974.77 | 37.892 | 29.039 | |

| F(0.05,3,2) | 19.164 | 19.164 | 19.164 | 19.164 | 19.164 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Savov, V.; Valchev, I.; Antov, P.; Yordanov, I.; Popski, Z. Effect of the Adhesive System on the Properties of Fiberboard Panels Bonded with Hydrolysis Lignin and Phenol-Formaldehyde Resin. Polymers 2022, 14, 1768. https://doi.org/10.3390/polym14091768

Savov V, Valchev I, Antov P, Yordanov I, Popski Z. Effect of the Adhesive System on the Properties of Fiberboard Panels Bonded with Hydrolysis Lignin and Phenol-Formaldehyde Resin. Polymers. 2022; 14(9):1768. https://doi.org/10.3390/polym14091768

Chicago/Turabian StyleSavov, Viktor, Ivo Valchev, Petar Antov, Ivaylo Yordanov, and Zlatomir Popski. 2022. "Effect of the Adhesive System on the Properties of Fiberboard Panels Bonded with Hydrolysis Lignin and Phenol-Formaldehyde Resin" Polymers 14, no. 9: 1768. https://doi.org/10.3390/polym14091768