Bio-Optimization of Chemical Parameters and Earthworm Biomass for Efficient Vermicomposting of Different Palm Oil Mill Waste Mixtures

Abstract

1. Introduction

Treatment Technologies of POME and Their Effects to the Environment

2. Materials and Methods

2.1. Materials

2.2. Experimental Set-Up

2.3. Statistical Analysis and Modelling

3. Results and Discussion

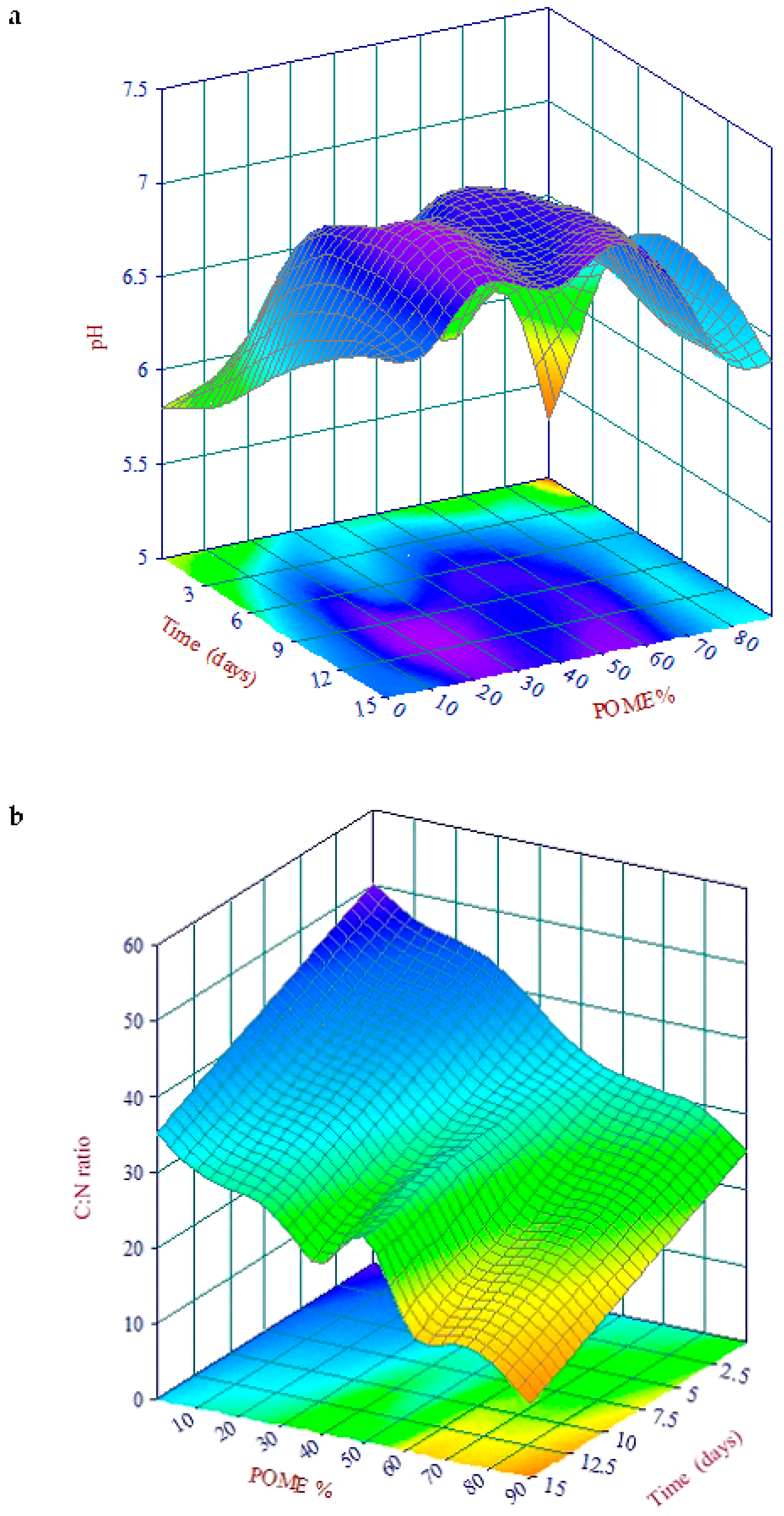

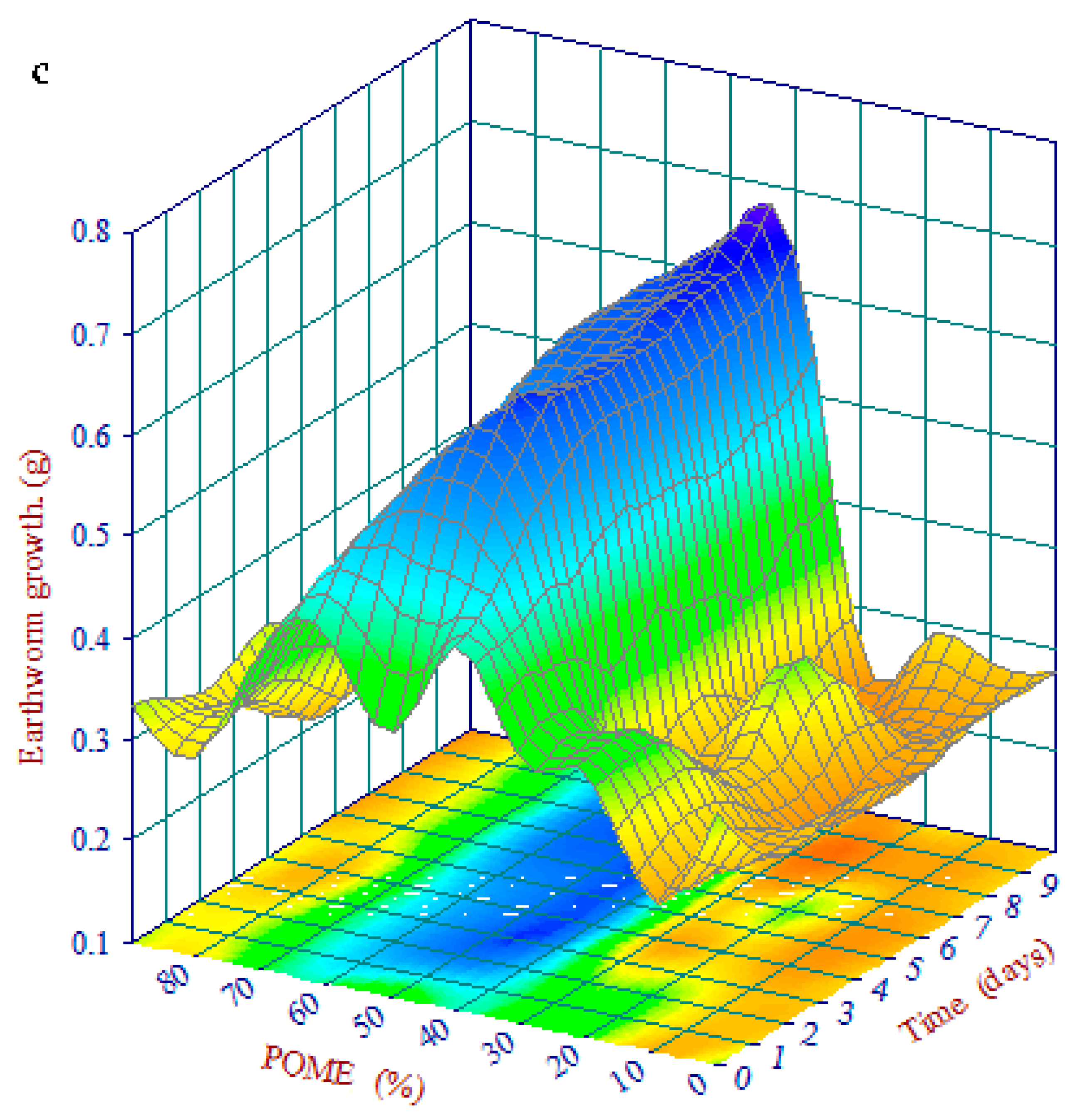

3.1. Effects of pH, C:N Ratio and Earthworm Biomass during the Vermicomposting Process

3.2. Mathematical Modelling of POME-PPF with Respect to pH, C:N Ratio and Earthworms

- R2 = 0.914; where

- = pH values; = Time (days); = POME (%);

- a = 4.038; b = 1.87; c = 4.24; d = −0.32; e = −4.72; f = −0.59;

- g = −0.00047; h = 1.49; i = 0.00067; j = −0.00085.

- R2 = 0.9785; where

- = C:N; = Time (days); = POME (%);

- a = 50.22; b = −1.066; c = 0.0145; d = −0.00056; e = −0.636; f = 0.032;

- g = −0.00098; h = 1.24; i = −5.56.

- R2 = 0.8123; where

- = earthworm growth (g); = Time (days); = POME (%);

- a = 8966.44; b = 0.027; c = 2.95; d = −6.58; e = 1.621; f = −0.296;

- g = 0.0227; h = −8967.75; wy = −2294.70.

3.3. Optimization of Vermicompost

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Abdul-Manan, A.F.; Baharuddin, A.; Chang, L.W. A detailed survey of the palm and biodiesel industry landscape in Malaysia. Energy 2014, 76, 931–941. [Google Scholar] [CrossRef]

- MPOB. Malaysian Oil Palm Statistics. Available online: http://bepi.mpob.gov.my/index.php/statistics/ export/138-export-2015/759-monthly-export-ofoil-palm products-2015.html2015 (accessed on 30 November 2015).

- Nieder, R.; Benbi, D.K.; Reichl, F.X. Reactive water-soluble forms of nitrogen and phosphorus and their impacts on environment and human health. In Soil Components and Human Health; Springer: Berlin, Germany, 2018; pp. 223–255. [Google Scholar]

- Gaur, S. An updated review on quantitative and qualitative analysis of water pollution in west flowing Tapi River of Gujarat, India. In Environmental Pollution; Springer: Berlin, Germany, 2018; pp. 525–547. [Google Scholar]

- Kamyab, H.; Friedler, F.; Klemes, J.J.; Chelliapan, S.; Rezania, S. Bioenergy production and nutrients removal by green microalgae with cultivation from agro-wastewater palm oil mill effluent (POME)—A review. Chem. Eng. Trans. 2018, 70, 2197–2202. [Google Scholar]

- Tabassum, S.; Zhang, Y.; Zhang, Z. An integrated method for palm oil mill effluent (POME) treatment for achieving zero liquid discharge—A pilot study. J. Clean. Prod. 2015, 95, 148–155. [Google Scholar] [CrossRef]

- Chin, M.J.; Poh, P.E.; Tey, B.T.; Chan, E.S.; Chin, K.L. Biogas from palm oil mill effluent (POME): Opportunities and challenges from Malaysia’s perspective. Renew. Sustain. Energy Rev. 2013, 26, 717–726. [Google Scholar] [CrossRef]

- Hojjat, M.; Salleh, M.A.M. Optimization of POME Anaerobic Pond. Eur. J. Sci. Res. 2009, 32, 455–459. [Google Scholar]

- Said, M.; Ahmad, A.; Mohammad, A.W.; Nor, M.T.M.; Abdullah, S.R.S. Blocking mechanism of PES membrane during ultrafiltration of POME. J. Ind. Eng. Chem. 2015, 21, 182–188. [Google Scholar] [CrossRef]

- Chong, Y.Y.; Thangalazhy-Gopakumar, S.; Gan, S.; Ng, H.K.; Lee, L.Y.; Adhikari, S. Kinetics and mechanisms for copyrolysis of palm empty fruit bunch fiber (EFBF) with palm oil mill effluent (POME) sludge. Energy Fuels 2017, 31, 8217–8227. [Google Scholar] [CrossRef]

- Yuan, H.; He, Z. Integrating membrane filtration into bioelectrochemical systems as next generation energy-efficient wastewater treatment technologies for water reclamation: A review. Biores. Technol. 2015, 195, 202–209. [Google Scholar] [CrossRef] [PubMed]

- Chu, W.; Yao, D.; Gao, N.; Bond, T.; Templeton, M.R. The enhanced removal of carbonaceous and nitrogenous disinfection by-product precursors using integrated permanganate oxidation and powdered activated carbon adsorption pretreatment. Chemosphere 2015, 141, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Baharuddin, A.S.; Rahman, N.A.A.; Shan, U.K.; Hassan, M.A.; Wakisaka, M.; Shirai, Y. Evaluation of pressed shredded empty fruit bunch (EFB)-palm oil mill effluent (POME) anaerobic sludge based compost using Fourier transform infrared (FTIR) and nuclear magnetic resonance (NMR) analysis. Afr. J. Biotechnol. 2011, 10, 8082–8289. [Google Scholar]

- Rupani, P.F.; Singh, R.P.; Ibrahim, M.H.; Esa, N. Review of current palm oil mill effluent (POME) treatment methods: vermicomposting as a sustainable practice. World Appl. Sci. J. 2010, 10, 1190–1201. [Google Scholar]

- Hayawin, Z.N.; Astimar, A.A.; Rashyeda, R.N.; Faizah, J.; Idris, J.; Ravi, N. Influence of frond, stem and roots of oil palm seedlings in vermicompost from oil palm biomass. J. Oil Palm Res. 2016, 28, 479–484. [Google Scholar] [CrossRef]

- Rupani, P.F.; Embrandiri, A.; Ibrahim, M.H.; Shahadat, M.; Hansen, S.B.; Mansor, N.N.A. Bioremediation of palm industry wastes using vermicomposting technology: Its environmental application as green fertilizer. 3 Biotech 2017, 7, 155. [Google Scholar] [CrossRef] [PubMed]

- Levenspiel, O. Chemical Reaction Engineering; John Wiley & Sons: Hoboken, NJ, USA, 1999. [Google Scholar]

- Benner, R.; Pakulski, J.D.; McCarthy, M.; Hedges, J.I.; Hatcher, P.G. Bulk chemical characteristics of dissolved organic matter in the ocean. Science 1992, 255, 1561–1564. [Google Scholar] [CrossRef] [PubMed]

- Talebi, A.; Teng, T.T.; Alkarkhi, A.F.; Ismail, N. Nickel ion coupled counter complexation and decomplexation through a modified supported liquid membrane system. RSC Adv. 2015, 5, 38424–38434. [Google Scholar] [CrossRef]

- Khan, A.A. Vermicomposting of Poultry Litter Using Eisenia Foetida. Ph.D. Thesis, Oklahoma State University, Stillwater, OK, USA, 2006. [Google Scholar]

- Komilis, D.; Evangelou, A.; Voudrias, E. Monitoring and optimizing the co-composting of dewatered sludge: A mixture experimental design approach. J. Environ. Manag. 2011, 92, 2241–2249. [Google Scholar] [CrossRef] [PubMed]

- Proietti, P.; Calisti, R.; Gigliotti, G.; Nasini, L.; Regni, L.; Marchini, A. Composting optimization: Integrating cost analysis with the physical-chemical properties of materials to be composted. J. Clean. Prod. 2016, 137, 1086–1099. [Google Scholar] [CrossRef]

- Rupani, P.F.; Embrandiri, A.; Ibrahim, M.H.; Shahadat, M.; Hansen, S.B.; Ismail, S.A.; Kadir, M.O.A. Recycling of palm oil industrial wastes using vermicomposting technology: Its kinetics study and environmental application. Environ. Sci. Pollut. Res. 2017, 24, 12982–12990. [Google Scholar] [CrossRef]

- Patil, J.H.; Sanil, P.H.; Malini, B.M.; Manoj, V.; Deepika, D.; Chaitra, D. Vermicomposting of water hyacinth with poultry litter using rotary drum reactor. J. Chem. Pharm. Res. 2012, 5, 2585–2589. [Google Scholar]

- Garg, V.; Gupta, R. Optimization of cow dung spiked pre-consumer processing vegetable waste for vermicomposting using Eisenia fetida. Ecotoxicol. Environ. Saf. 2011, 74, 19–24. [Google Scholar] [CrossRef]

- Yadav, A.; Garg, V. Vermicomposting-an effective tool for the management of invasive weed Parthenium hysterophorus. Biores. Technol. 2011, 102, 5891–5895. [Google Scholar] [CrossRef] [PubMed]

- Guerra-Rodríguez, E.; Vazquez, M.; Diaz-Raviña, M. Dynamics of physicochemical and biological parameters during the co-composting of chestnut burr/leaf litter with solid poultry manure. J. Sci. Food Agric. 2001, 81, 648–652. [Google Scholar] [CrossRef]

- Satisha, G.; Devarajan, L. Effect of amendments on windrow composting of sugar industry pressmud. Waste Manag. 2007, 27, 1083–1091. [Google Scholar] [CrossRef] [PubMed]

- Garg, V.K.; Suthar, S.; Yadav, A. Management of food industry waste employing vermicomposting technology. Biores. Technol. 2012, 126, 437–443. [Google Scholar] [CrossRef] [PubMed]

- Ismail, S.A. Vermicomposting: The Biology of Earthworms; Orient Longman Imited: Chennai, India, 1997. [Google Scholar]

- Singh, D.; Suthar, S. Vermicomposting of herbal pharmaceutical industry waste: Earthworm growth, plant-available nutrient and microbial quality of end materials. Biores. Technol. 2012, 112, 179–185. [Google Scholar] [CrossRef] [PubMed]

- Suthar, S.; Singh, S. Vermicomposting of domestic waste by using two epigeic earthworms (Perionyx excavatus and Perionyx sansibaricus). Int. J. 2008, 5, 99–106. [Google Scholar] [CrossRef]

- Rupani, P.F.; Ibrahim, M.H.; Ismail, S.A. Vermicomposting biotechnology: Recycling of palm oil mill wastes into valuable products. Int. J. Recycl. Org. Waste Agric. 2013, 2, 10. [Google Scholar] [CrossRef]

| S.O.V. | S.S. | d.f. | M.S. | F | p-Value |

|---|---|---|---|---|---|

| (pH) | |||||

| Model | 24.33 | 39 | 0.62 | 4.47 | <0.0001 |

| A-Day | 16.03 | 3 | 5.34 | 39.11 | <0.0001 |

| B-Mixture | 5.78 | 9 | 0.64 | 4.70 | <0.0001 |

| AB | 2.51 | 27 | 0.093 | 0.68 | 0.8685 |

| Pure Error | 10.93 | 80 | 0.14 | ||

| Total | 35.26 | 119 | |||

| (C:N) | |||||

| Model | 11,421.86 | 39 | 292.87 | 216.82 | <0.0001 |

| A-Day | 3516.43 | 3 | 1172.14 | 867.78 | <0.0001 |

| B-Mixture | 7808.85 | 9 | 867.65 | 642.35 | <0.0001 |

| AB | 96.57 | 27 | 3.58 | 2.65 | 0.0004 |

| Pure Error | 108.06 | 80 | 1.35 | ||

| Total | 11,529.92 | 119 | |||

| (EW) | |||||

| Model | 2.78 | 39 | 0.071 | 42.76 | <0.0001 |

| A-Day | 2.22 | 3 | 0.74 | 444.54 | <0.0001 |

| B-Mixture | 0.29 | 9 | 0.032 | 19.19 | <0.0001 |

| AB | 0.27 | 27 | 0.009947 | 5.98 | <0.0001 |

| Pure Error | 0.13 | 80 | 0.001668 | ||

| Total | 2.92 | 119 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rupani, P.F.; Alkarkhi, A.F.M.; Shahadat, M.; Embrandiri, A.; EL-Mesery, H.S.; Wang, H.; Shao, W. Bio-Optimization of Chemical Parameters and Earthworm Biomass for Efficient Vermicomposting of Different Palm Oil Mill Waste Mixtures. Int. J. Environ. Res. Public Health 2019, 16, 2092. https://doi.org/10.3390/ijerph16122092

Rupani PF, Alkarkhi AFM, Shahadat M, Embrandiri A, EL-Mesery HS, Wang H, Shao W. Bio-Optimization of Chemical Parameters and Earthworm Biomass for Efficient Vermicomposting of Different Palm Oil Mill Waste Mixtures. International Journal of Environmental Research and Public Health. 2019; 16(12):2092. https://doi.org/10.3390/ijerph16122092

Chicago/Turabian StyleRupani, Parveen Fatemeh, Abbas F. M. Alkarkhi, Mohammad Shahadat, Asha Embrandiri, Hany S. EL-Mesery, Hongcheng Wang, and Weilan Shao. 2019. "Bio-Optimization of Chemical Parameters and Earthworm Biomass for Efficient Vermicomposting of Different Palm Oil Mill Waste Mixtures" International Journal of Environmental Research and Public Health 16, no. 12: 2092. https://doi.org/10.3390/ijerph16122092

APA StyleRupani, P. F., Alkarkhi, A. F. M., Shahadat, M., Embrandiri, A., EL-Mesery, H. S., Wang, H., & Shao, W. (2019). Bio-Optimization of Chemical Parameters and Earthworm Biomass for Efficient Vermicomposting of Different Palm Oil Mill Waste Mixtures. International Journal of Environmental Research and Public Health, 16(12), 2092. https://doi.org/10.3390/ijerph16122092