Environmental Assessment of a Hybrid Solar-Biomass Energy Supplying System: A Case Study

Abstract

:1. Introduction

2. Materials and Methods

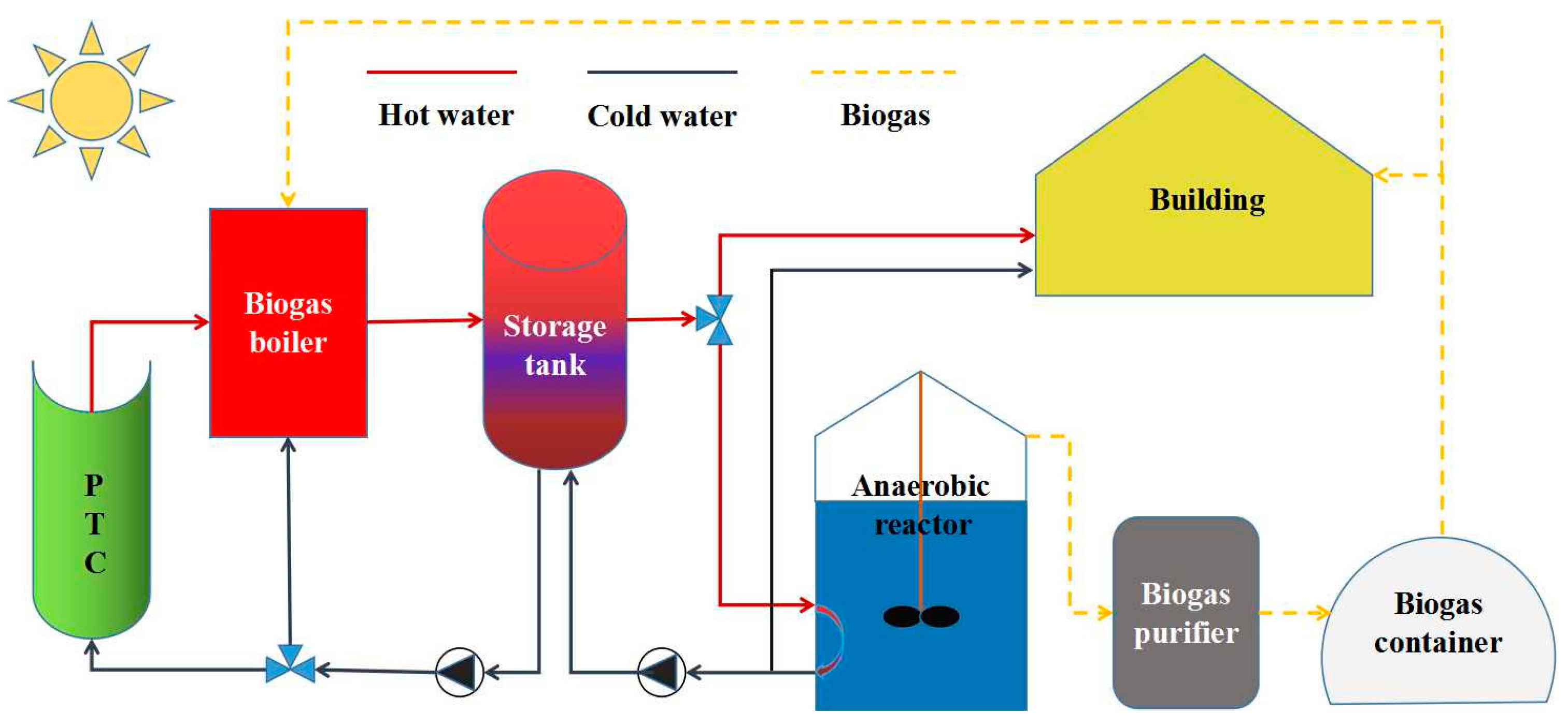

2.1. Case Study

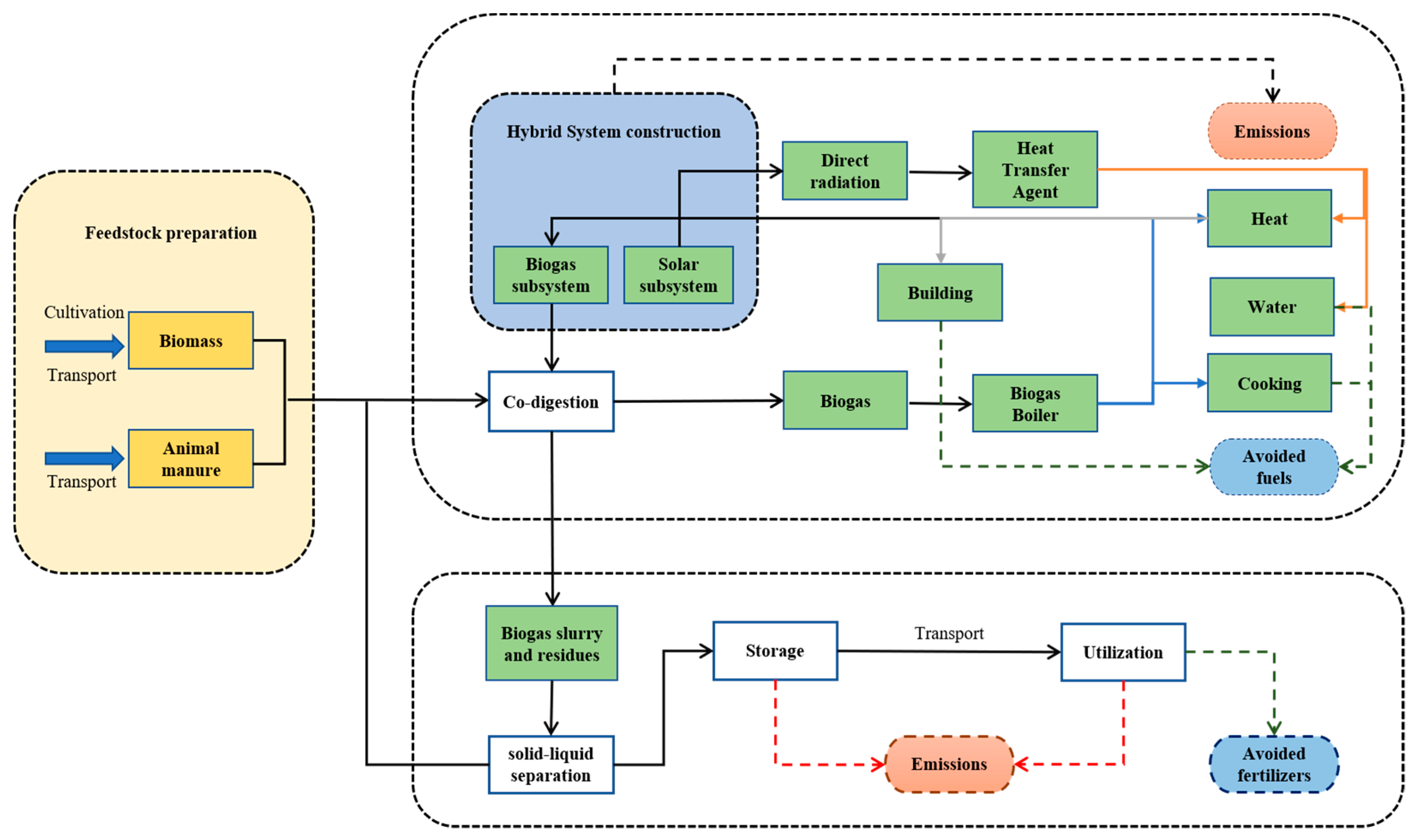

2.2. Life-Cycle Assessment

2.2.1. Goal and Scope Definition

2.2.2. Functional Unit

2.2.3. Data Source and Assessment Indicators

2.3. Life-Cycle Inventory Analysis

2.3.1. System Construction Stage

2.3.2. System Operation and Maintenance Stage

2.3.3. System Disassembling and Recycling Stage

3. Results and Discussion

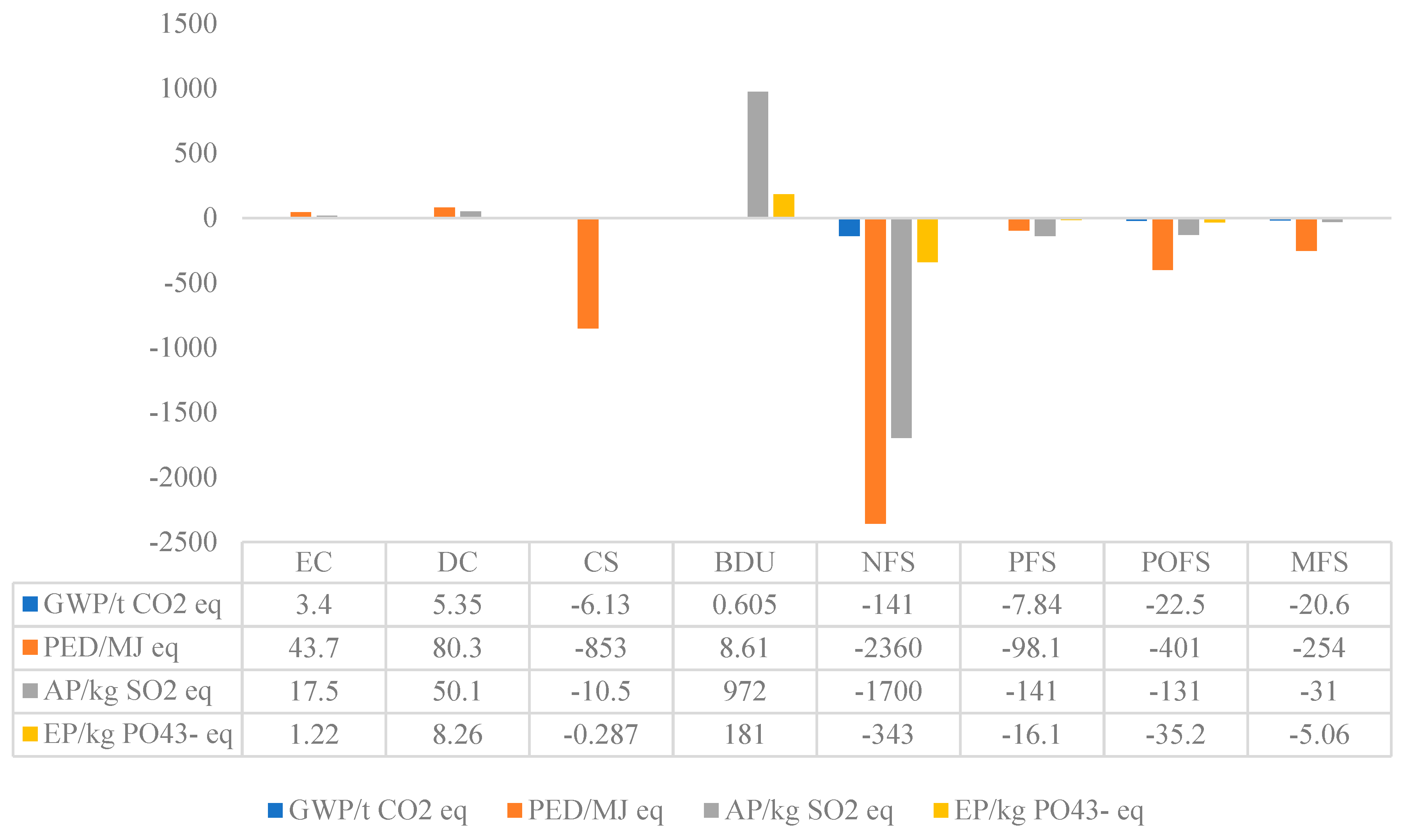

3.1. Comparison of Different Life-Cycle Stages

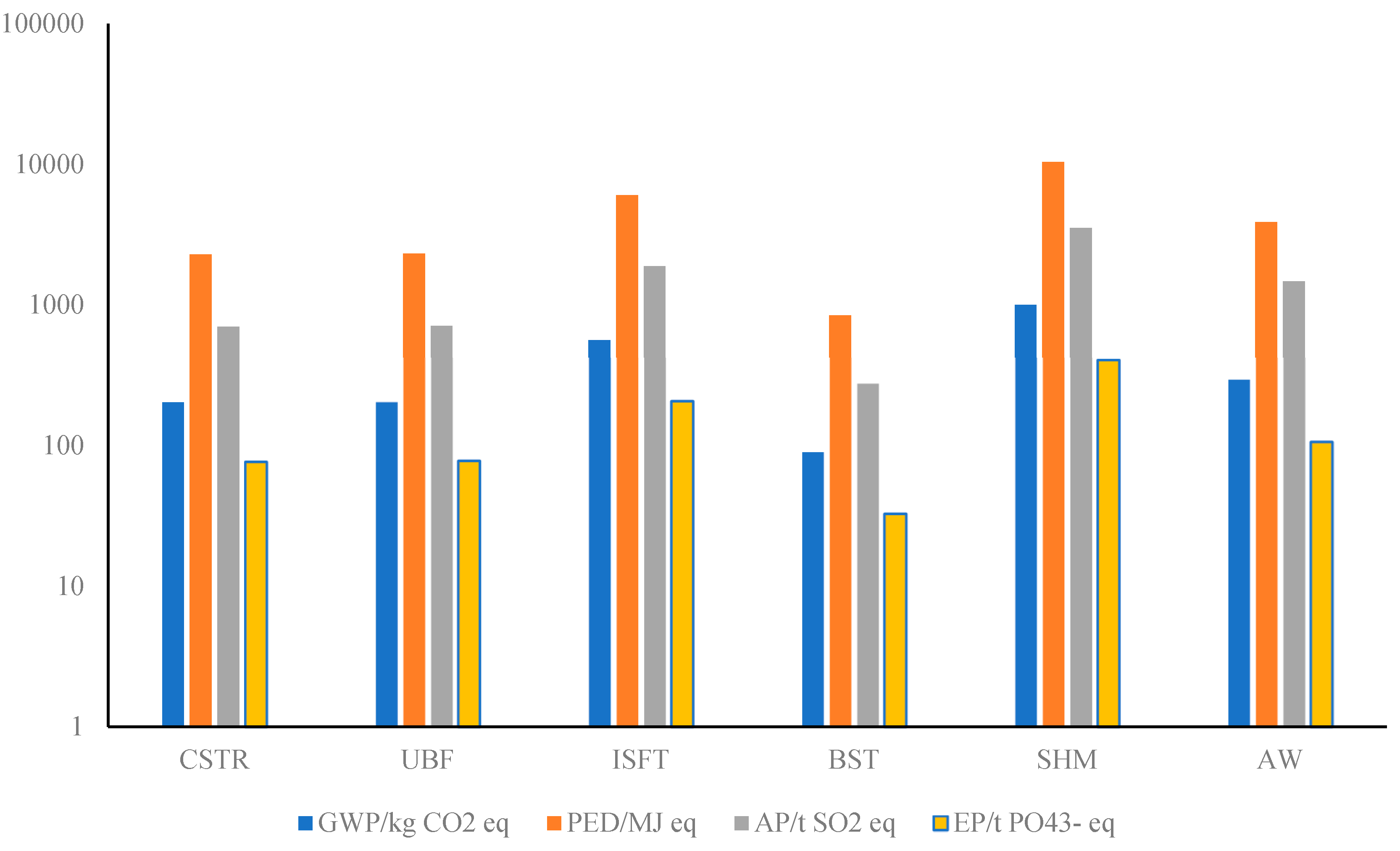

3.1.1. System Construction Stage

3.1.2. System Operation and Maintenance Stage

3.1.3. System Disassembling and Recycling Stage

3.2. Overall Environmental Evaluation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, B.; Wang, Q.; Wei, Y.M.; Li, Z.P. Role of renewable energy in China’s energy security and climate change mitigation: An index decomposition analysis. Renew. Sustain. Energy Rev. 2018, 90, 187–194. [Google Scholar] [CrossRef]

- Devabhaktuni, V.; Alam, M.; Depuru, S.S.S.R.; Green, R.C.; Nims, D.; Near, C. Solar energy: Trends and enabling technologies. Renew. Sustain. Energy Rev. 2013, 19, 555–564. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.-F.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Vivas, F.J.; Heras, A.D.L.; Segura, F.; Andújar, J.M. A review of energy management strategies for renewable hybrid energy systems with hydrogen backup. Renew. Sustain. Energy Rev. 2018, 82, 126–155. [Google Scholar] [CrossRef]

- Semaoui, S.; Arab, A.H.; Bacha, S.; Azoui, B. The new strategy of energy management for a photovoltaic system without extra intended for remote-housing. Sol. Energy 2013, 94, 71–85. [Google Scholar] [CrossRef]

- Robitaille, M.; Agbossou, K.; Doumbia, M. Modeling of an islanding protection method for a hybrid renewable distributed generator. In Proceedings of the Canadian Conference on Electrical and Computer Engineering, Saskatoon, SK, Canada, 1–4 May 2005. [Google Scholar]

- Zhang, X.; Yang, J.; Zhao, X. Optimal study of the rural house space heating systems employing the AHP and FCE methods. Energy 2018, 150, 631–641. [Google Scholar] [CrossRef]

- Bet Sarkis, R.; Zare, V. Proposal and analysis of two novel integrated configurations for hybrid solar-biomass power generation systems: Thermodynamic and economic evaluation. Energy Convers. Manag. 2018, 160, 411–425. [Google Scholar] [CrossRef]

- Sahoo, U.; Kumar, R.; Singh, S.K.; Tripathi, A.K. Energy, exergy, economic analysis and optimization of polygeneration hybrid solar-biomass system. Appl. Therm. Eng. 2018, 145, 685–692. [Google Scholar] [CrossRef]

- Delfiya, A.; Mohapatra, D.; Kotwaliwale, N.; Mishra, A.K. Effect of microwave blanching and brine solution pretreatment on the quality of carrots dried in solar-biomass hybrid dryer. J. Food Process. Preserv. 2017, 42, e13510. [Google Scholar] [CrossRef]

- Anvari, S.; Khalilarya, S.; Zare, V. Exergoeconomic and environmental analysis of a novel configuration of solar-biomass hybrid power generation system. Energy 2018, 165, 776–789. [Google Scholar] [CrossRef]

- Kang, Q.; Dewil, R.; Degrève, J.; Baeyens, J.; Zhang, H. Energy analysis of a particle suspension solar combined cycle power plant. Energy Convers. Manag. 2018, 163, 292–303. [Google Scholar] [CrossRef]

- Mehrpooya, M.; Khalili, M.; Sharifzadeh, M.M.M. Model development and energy and exergy analysis of the biomass gasification process (Based on the various biomass sources). Renew. Sustain. Energy Rev. 2018, 91, 869–887. [Google Scholar] [CrossRef]

- Ghasemi, A.; Heidarnejad, P.; Noorpoor, A. A novel solar-biomass based multi-generation energy system including water desalination and liquefaction of natural gas system: Thermodynamic and thermoeconomic optimization. J. Clean. Prod. 2018, 196, 424–437. [Google Scholar] [CrossRef]

- Greg, P. Techno-economic comparison of the levelised cost of electricity generation from solar PV and battery storage with solar PV and combustion of bio-crude using fast pyrolysis of biomass. Energy Convers. Manag. 2018, 171, 1573–1588. [Google Scholar]

- Krarouch, M.; Hamdi, H.; Lamghari, S.; Outzourhit, A. Simulation of floor heating in a combined solar-biomass system integrated in a public bathhouse located in Marrakech. IOP Conf. Ser. Mater. Sci. Eng. 2018, 353, 012005. [Google Scholar] [CrossRef]

- Wang, J.; Ying, Y. Energy, exergy and environmental analysis of a hybrid combined cooling heating and power system utilizing biomass and solar energy. Energy Convers. Manag. 2016, 124, 566–577. [Google Scholar] [CrossRef]

- Gustavsson, L.; Joelsson, A.; Sathre, R. Life cycle primary energy use and carbon emission of an eight-storey wood-framed apartment building. Energy Build. 2010, 42, 230–242. [Google Scholar] [CrossRef]

- Mclaren, D. A comparative global assessment of potential negative emissions technologies. Process Saf. Environ. Prot. 2012, 90, 489–500. [Google Scholar] [CrossRef]

- Xu, C.; Shi, W.; Hong, J.; Zhang, F.; Wei, C. Life cycle assessment of food waste-based biogas generation. Renew. Sustain. Energy Rev. 2015, 49, 169–177. [Google Scholar] [CrossRef]

- Budzianowski, W.M. Can ‘negative net CO emissions’ from decarbonised biogas-to-electricity contribute to solving Poland’s carbon capture and sequestration dilemmas? Energy 2011, 36, 6318–6325. [Google Scholar] [CrossRef]

- Jury, C.; Benetto, E.; Koster, D.; Schmitt, B.; Welfring, J. Life Cycle Assessment of biogas production by monofermentation of energy crops and injection into the natural gas grid. Biomass Bioenergy 2010, 34, 54–66. [Google Scholar] [CrossRef]

- Distefano, T.D.; Belenky, L.G.; Safferman, S.; Lioa, W.; Saffron, C. Life-cycle analysis of energy and greenhouse gas emissions from anaerobic biodegradation of municipal solid waste. J. Environ. Eng. 2009, 135, 1097–1105. [Google Scholar] [CrossRef]

- David, S.; Maclean, H.L.; Bradley, S. Electricity production from anaerobic digestion of household organic waste in Ontario: Techno-economic and GHG emission analyses. Environ. Sci. Technol. 2012, 46, 1233–1242. [Google Scholar]

- Thomassen, M.A.; Dalgaard, R.; Heijungs, R.; Boer, I. Attributional and consequential LCA of milk production. Int. J. Life Cycle Assess. 2008, 13, 339–349. [Google Scholar] [CrossRef] [Green Version]

- Ogunjuyigbe, A.S.O.; Ayodele, T.R.; Akinola, O.A. Optimal allocation and sizing of PV/Wind/Split-diesel/Battery hybrid energy system for minimizing life cycle cost, carbon emission and dump energy of remote residential building. Appl. Energy 2016, 171, 153–171. [Google Scholar] [CrossRef]

- Nojavan, S.; Majidi, M.; Zare, K. Performance improvement of a battery/PV/fuel cell/grid hybrid energy system considering load uncertainty modeling using IGDT. Energy Convers. Manag. 2017, 147, 29–39. [Google Scholar] [CrossRef]

- Khare, V.; Nema, S.; Baredar, P. Solar–wind hybrid renewable energy system: A review. Renew. Sustain. Energy Rev. 2016, 58, 23–33. [Google Scholar] [CrossRef]

- Gan, L.K.; Shek, J.K.H.; Mueller, M.A. Hybrid wind-photovoltaic-diesel-battery system sizing tool development using empirical approach, life-cycle cost and performance analysis: A case study in Scotland. Energy Convers. Manag. 2015, 106, 479–494. [Google Scholar] [CrossRef]

- Lajunen, A.; Lipman, T. Lifecycle cost assessment and carbon dioxide emissions of diesel, natural gas, hybrid electric, fuel cell hybrid and electric transit buses. Energy 2016, 106, 329–342. [Google Scholar] [CrossRef]

- Hassani, S.; Saidur, R.; Mekhilef, S.; Taylor, R.A. Environmental and exergy benefit of nanofluid-based hybrid PV/T systems. Energy Convers. Manag. 2016, 123, 431–444. [Google Scholar] [CrossRef]

- Asdrubali, F.; Baldinelli, G.; D’Alessandro, F.; Scrucca, F. Life cycle assessment of electricity production from renewable energies: Review and results harmonization. Renew. Sustain. Energy Rev. 2015, 42, 1113–1122. [Google Scholar] [CrossRef]

- Ozturk, M.; Ozek, N.; Batur, H.; Koc, M. Thermodynamic and life cycle assessment of flat-plate collector, photovoltaic system and photovoltaic thermal collector. Int. J. Exergy 2012, 11, 229–251. [Google Scholar] [CrossRef]

- ISO. ISO 14040 International Standard. Environmental Management–Life Cycle Assessment–Principles and Framework; International Organisation for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.P.; Suh, S.; Weidema, B.P.; Pennington, D.W. Life cycle assessment: Part 1: Framework, goal and scope definition, inventory analysis, and applications. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef]

- Bartolozzi, I.; Rizzi, F.; Frey, M. Are district heating systems and renewable energy sources always an environmental win-win solution? A life cycle assessment case study in Tuscany, Italy. Renew. Sustain. Energy Rev. 2017, 80, 408–420. [Google Scholar] [CrossRef]

- Astrup, T.F.; Tonini, D.; Turconi, R.; Boldrin, A. Life cycle assessment of thermal Waste-to-Energy technologies: Review and recommendations. Waste Manag. 2015, 37, 104–115. [Google Scholar] [CrossRef] [Green Version]

- Alberola-Borràs, J.-A.; Baker, J.; De Rossi, F.; Vidal, R.; Beynon, D.; Hooper, K.E.; Watson, T.M.; Mora-Seró, I. Perovskite Photovoltaic Modules: Life Cycle Assessment of Pre-industrial. Prod. Process 2018, 9, 542–551. [Google Scholar]

- Soares, W.M.; Athayde, D.D.; Nunes, E.H.M. LCA study of photovoltaic systems based on different technologies. Int. J. Green Energy 2018, 15, 577–583. [Google Scholar] [CrossRef]

- Flysjö, A.; Henriksson, M.; Cederberg, C.; Ledgard, S.; Englund, J.E. The impact of various parameters on the carbon footprint of milk production in New Zealand and Sweden. Agric. Syst. 2011, 104, 459–469. [Google Scholar] [CrossRef]

- Battini, F.; Agostini, A.; Boulamanti, A.K.; Giuntoli, J.; Amaducci, S. Mitigating the environmental impacts of milk production via anaerobic digestion of manure: Case study of a dairy farm in the Po Valley. Sci. Total Environ. 2014, 481, 196–208. [Google Scholar] [CrossRef]

- Mezzullo, W.G.; Mcmanus, M.C.; Hammond, G.P. Life cycle assessment of a small-scale anaerobic digestion plant from cattle waste. Appl. Energy 2013, 102, 657–664. [Google Scholar] [CrossRef] [Green Version]

- Styles, D.; Dominguez, E.M.; Chadwick, D. Environmental balance of the UK biogas sector: An evaluation by consequential life cycle assessment. Sci. Total Environ. 2016, 560–561, 241–253. [Google Scholar] [CrossRef] [PubMed]

- Ramírez Arpide, R.; Demirer, G.; Gallegos-Vázquez, C.; Hernández-Eugenio, G.; Santoyo, H.; Espinosa-Solares, T. Life cycle assessment of biogas production through anaerobic co-digestion of nopal cladodes and dairy cow manure. J. Clean. Prod. 2018, 172, 2313–2322. [Google Scholar] [CrossRef]

| Items | Unit | Pig Manure |

|---|---|---|

| HRT | d | 20 |

| Feedstock decomposition | % DM | 24.47 |

| % ODM | 17.29 | |

| Methane | Vol.% CH4 | 55 |

| Methane yield | m3/ t VS | 350 |

| Biogas yield | m3/d | 240 |

| Digestate (solid) | t/d | 4.81 |

| Digestate (liquid) | t/d | 62.51 |

| Recycled slurry | t/d | 40 |

| Concentration of system | % TS | 8 |

| GWP/kg CO2 eq | PED/MJ eq | AP/kg SO2 eq | EP/kg PO43− eq | |

|---|---|---|---|---|

| Rebar recycling | −5.10 × 10−2 | −0.754 | −2.11 × 10−4 | −1.98 × 10−5 |

| Bracket recycling | −2.71 × 10−2 | −0.397 | −1.06 × 10−4 | −1.46 × 10−5 |

| Glass recycling | −8.12 × 10−4 | −9.36 × 10−3 | −1.26× 10−5 | −1.18 × 10−6 |

| Wastes landfill | 2.57 | 3.39 | 1.22 × 10−3 | 3.37 × 10−2 |

| Transportation | 79.6 | 1560 | 0.829 | 0.138 |

| Total | 82.1 | 1560 | 0.830 | 0.172 |

| Stage | Item | GWP/kg CO2 eq | PED/MJ eq | AP/kg SO2 eq | EP/kg PO43− eq |

|---|---|---|---|---|---|

| System construction | Total impact | 2360 | 25,800 | 8.57 | 0.91 |

| Total impact reduction | 0 | 0 | 0 | 0 | |

| Net impact | 2360 | 25,800 | 8.57 | 0.91 | |

| System operation and maintenance | Total impact | 9390 | 133,000 | 1040 | 190 |

| Total impact reduction | −198,000 | −3,960,000 | −2010 | 399 | |

| Net impact | −188,000 | −3,830,000 | −975 | −209 | |

| System disassembling and recycling | Total impact | 82.2 | 1570 | 0.83 | 0.17 |

| Total impact reduction | −0.08 | −1.16 | 0 | 0 | |

| Net impact | 82.1 | 1560 | 0.83 | 0.17 | |

| Lifespan | Total impact | 11,800 | 160,000 | 1050 | 191 |

| Total impact reduction | −198,000 | −3,960,000 | −2010 | 399 | |

| Net impact | −186,000 | −3,800,000 | −966 | −208 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Sun, J.; Ma, J.; Xu, F.; Qiu, L. Environmental Assessment of a Hybrid Solar-Biomass Energy Supplying System: A Case Study. Int. J. Environ. Res. Public Health 2019, 16, 2222. https://doi.org/10.3390/ijerph16122222

Zhang C, Sun J, Ma J, Xu F, Qiu L. Environmental Assessment of a Hybrid Solar-Biomass Energy Supplying System: A Case Study. International Journal of Environmental Research and Public Health. 2019; 16(12):2222. https://doi.org/10.3390/ijerph16122222

Chicago/Turabian StyleZhang, Congguang, Jiaming Sun, Jieying Ma, Fuqing Xu, and Ling Qiu. 2019. "Environmental Assessment of a Hybrid Solar-Biomass Energy Supplying System: A Case Study" International Journal of Environmental Research and Public Health 16, no. 12: 2222. https://doi.org/10.3390/ijerph16122222

APA StyleZhang, C., Sun, J., Ma, J., Xu, F., & Qiu, L. (2019). Environmental Assessment of a Hybrid Solar-Biomass Energy Supplying System: A Case Study. International Journal of Environmental Research and Public Health, 16(12), 2222. https://doi.org/10.3390/ijerph16122222