Rapid Health Impact Assessment of a Proposed Poultry Processing Plant in Millsboro, Delaware

Abstract

:1. Introduction

1.1. Poultry Production and Impacts on the Environment and Human Health

1.2. Community Concerns about a Proposed Poultry Processing Plant in Delaware

1.3. Proposed Use of a Health Impact Assessment (HIA)

A systematic process that uses an array of data sources and analytic methods and considers input from stakeholders to determine the potential effects of a proposed policy, plan, program, or project on the health of a population and the distribution of those effects within the population. HIA provides recommendations on monitoring and managing those effects.

2. Materials and Methods

2.1. Screening

2.2. Scoping

2.3. Assessment

2.4. Reporting

3. Results

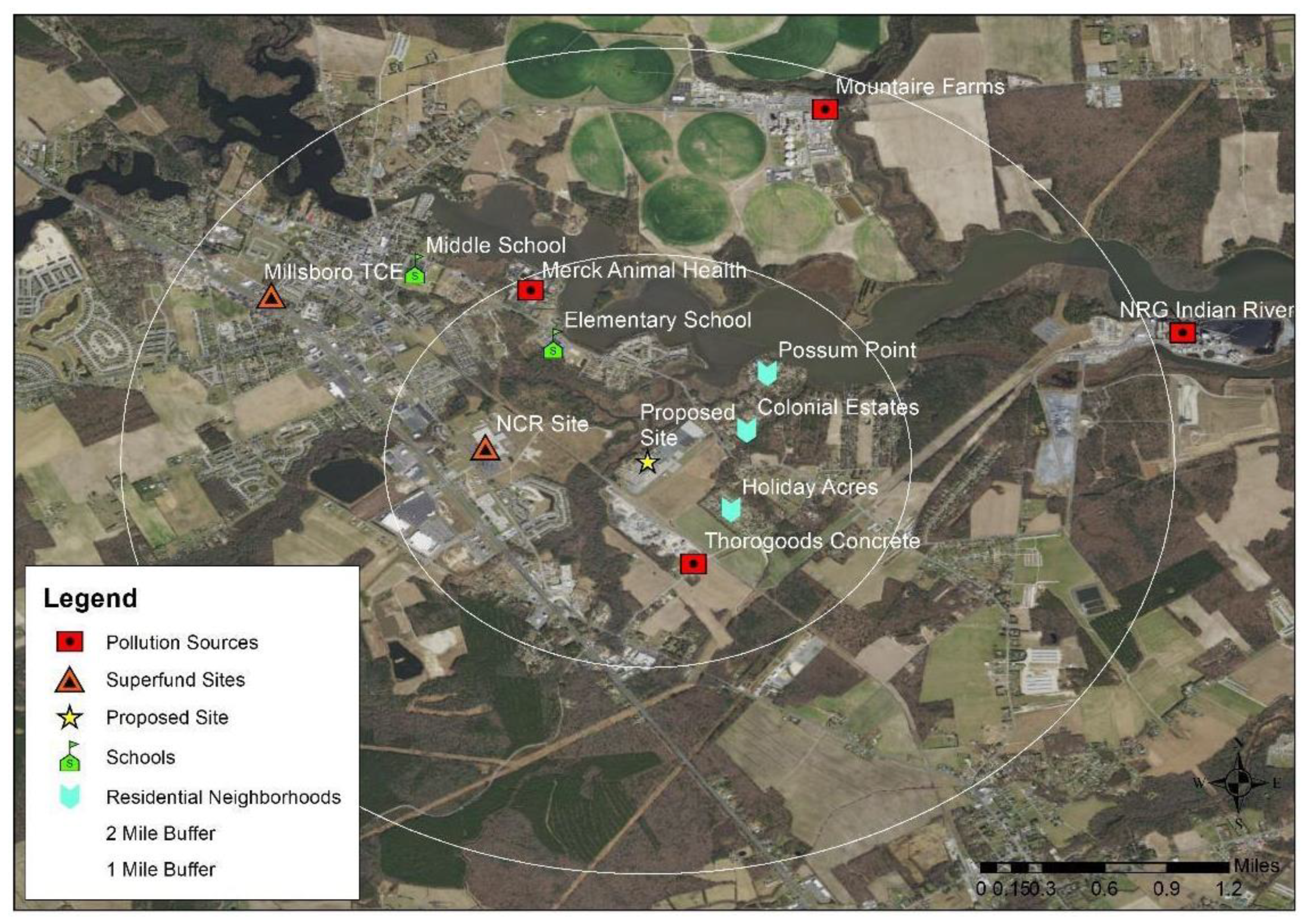

3.1. Geographic Analysis of Millsboro, Delaware

3.2. Sociodemographic Analysis

3.3. Baseline Environmental Assessment

3.4. Chemicals of Concern

3.5. Baseline Health Assessment

3.5.1. Respiratory Issues and Healthcare Access

3.5.2. Cancer

3.6. Impact Assessment

3.6.1. Exposures Related to Poultry Processing, Transport, and Waste Discharge

3.6.2. Odor Issues

3.6.3. Occupational Health

3.6.4. Traffic Concerns

3.6.5. Economic Benefits of the Proposed Processing Plant

4. Discussion

4.1. Key Findings

4.2. Challenges and Limitations Related to the Implementation of the Rapid HIA

4.3. Impact of the HIA

4.4. Value of the HIA in the US and beyond

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nahm, K.H. Current pollution and odor control technologies for poultry production. Avian Poult. Biol. Rev. 2003, 14, 151–174. [Google Scholar] [CrossRef]

- Silbergeld, E.K.; Graham, J.; Price, L.B. Industrial food animal production, antimicrobial resistance, and human health. Annu. Rev. Public Health 2008, 29, 151–169. [Google Scholar] [CrossRef] [PubMed]

- Wing, S.; Cole, D.; Grant, G. Environmental injustice in North Carolina’s hog industry. Environ. Health Perspect. 2000, 108, 225–231. [Google Scholar] [CrossRef] [PubMed]

- Rodić, V.; Perić, L.; DJukić-Stojčić, M.; Vukelić, N. The environmental impact of poultry production. Biotechnol. Anim. Husb. 2011, 27, 1673–1679. [Google Scholar] [CrossRef]

- Gerber, P.; Opio, C.; Steinfeld, H. Poultry Production and the Environment—A review; Animal Production and Health Division, Food and Agriculture Organization of the United Nations: Rome, Italy, 2007. [Google Scholar]

- Kalhor, T.; Rajabipour, A.; Akram, A.; Sharifi, M. Environmental impact assessment of chicken meat production using life cycle assessment. Inf. Process. Agric. 2016, 3, 262–271. [Google Scholar] [CrossRef] [Green Version]

- Clark, N.A.; Demers, P.A.; Karr, C.J.; Koehoorn, M.; Lencar, C.; Tamburic, L.; Brauer, M. Effect of Early Life Exposure to Air Pollution on Development of Childhood Asthma. Environ. Health Perspect. 2010, 118, 284–290. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bernstein, J.A.; Alexis, N.; Barnes, C.; Bernstein, I.L.; Nel, A.; Peden, D.; Diaz-Sanchez, D.; Tarlo, S.M.; Williams, P.B.; Bernstein, J.A. Health effects of air pollution. J. Allergy Clin. Immunol. 2004, 114, 1116–1123. [Google Scholar] [CrossRef] [PubMed]

- Chrischilles, E.; Ahrens, R.; Kuehl, A.; Kelly, K.; Thorne, P.; Burmeister, L.; Merchant, J. Asthma prevalence and morbidity among rural Iowa schoolchildren. J. Allergy Clin. Immunol. 2004, 113, 66–71. [Google Scholar] [CrossRef]

- Merchant, J.A.; Naleway, A.L.; Svendsen, E.R.; Kelly, K.M.; Burmeister, L.F.; Stromquist, A.M.; Taylor, C.D.; Thorne, P.S.; Reynolds, S.J.; Sanderson, W.T.; et al. Asthma and Farm Exposures in a Cohort of Rural Iowa Children. Environ. Health Perspect. 2005, 113, 350–356. [Google Scholar] [CrossRef]

- Cambra-López, M.; Aarnink, A.J.A.; Zhao, Y.; Calvet, S.; Torres, A.G. Airborne particulate matter from livestock production systems: A review of an air pollution problem. Environ. Pollut. 2010, 158, 1–17. [Google Scholar] [CrossRef]

- Chen, R.; Samoli, E.; Wong, C.M.; Huang, W.; Wang, Z.; Chen, B.; Kan, H. Associations between short-term exposure to nitrogen dioxide and mortality in 17 Chinese cities: The China Air Pollution and Health Effects Study (CAPES). Environ. Int. 2012, 45, 32–38. [Google Scholar] [CrossRef] [PubMed]

- Moore, P.A.; Daniel, T.C.; Sharpley, A.N.; Wood, C.W. Poultry manure management: Environmentally sound options. J. Soil Water Conserv. 1995, 50, 321–327. [Google Scholar]

- Burkholder, J.; Libra, B.; Weyer, P.; Heathcote, S.; Kolpin, D.; Thorne, P.S.; Wichman, M. Impacts of Waste from Concentrated Animal Feeding Operations on Water Quality. Environ. Health Perspect. 2007, 115, 308–312. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Burkholder, J.M.; Dickey, D.A.; Kinder, C.A.; Reed, R.E.; Mallin, M.A.; McIver, M.R.; Cahoon, L.B.; Melia, G.; Brownie, C.; Smith, J.; et al. Comprehensive trend analysis of nutrients and related variables in a large eutrophic estuary: A decadal study of anthropogenic and climatic influences. Limnol. Oceanogr. 2006, 51, 463–487. [Google Scholar] [CrossRef] [Green Version]

- Mallin, M.A.; Johnson, V.L.; Ensign, S.H.; MacPherson, T.A. Factors contributing to hypoxia in rivers, lakes, and streams. Limnol. Oceanogr. 2006, 51, 690–701. [Google Scholar] [CrossRef] [Green Version]

- Price Lance, B.; Lackey Leila, G.; Vailes, R.; Silbergeld, E. The Persistence of Fluoroquinolone-Resistant Campylobacter in Poultry Production. Environ. Health Perspect. 2007, 115, 1035–1039. [Google Scholar] [CrossRef] [PubMed]

- Nworie, A.; Onyema, A.S.; Okekpa, S.I.; Elom, M.O.; Umoh, N.O.; Usanga, V.U.; Ibiam, G.A.; Ukwah, B.N.; Nwadi, L.C.; Ezeruigbo, C.; et al. A Novel Methicillin-Resistant Staphylococcus Aureus T11469 and a Poultry Endemic Strain T002 (ST5) Are Present in Chicken in Ebonyi State, Nigeria. Biomed. Res. Int. 2017, 2017, 2936461. [Google Scholar] [CrossRef]

- Nachman, K.E.; Graham, J.P.; Price, L.B.; Silbergeld, E.K. Arsenic: A Roadblock to Potential Animal Waste Management Solutions. Environ. Health Perspect. 2005, 113, 1123–1124. [Google Scholar] [CrossRef] [Green Version]

- Sapkota, A.R.; Curriero, F.C.; Gibson, K.E.; Schwab, K.J. Antibiotic-Resistant Enterococci and Fecal Indicators in Surface Water and Groundwater Impacted by a Concentrated Swine Feeding Operation. Environ. Health Perspect. 2007, 115, 1040–1045. [Google Scholar] [CrossRef]

- Copeland, C. Animal Waste and Water Quality: EPA Regulation of Concentrated Animal Feeding Operations (CAFOs); Congressional Research Service, the Library of Congress: Washington, DC, USA, 2006. [Google Scholar]

- Wing, S.; Freedman, S.; Band, L. The potential impact of flooding on confined animal feeding operations in eastern North Carolina. Environ. Health Perspect. 2002, 110, 387–391. [Google Scholar] [CrossRef]

- Osterberg, D.; Wallinga, D. Addressing Externalities from Swine Production to Reduce Public Health and Environmental Impacts. Am. J. Public Health 2004, 94, 1703–1708. [Google Scholar] [CrossRef] [PubMed]

- Nicole, W. CAFOs and Environmental Justice: The Case of North Carolina. Environ. Health Perspect. 2013, 121, a182–a189. [Google Scholar] [CrossRef] [PubMed]

- Graham, J.P.; Nachman, K.E. Managing waste from confined animal feeding operations in the United States: The need for sanitary reform. J. Water Health 2010, 8, 646–670. [Google Scholar] [CrossRef] [PubMed]

- Grattan, L.M.; Oldach, D.; Perl, T.M.; Lowitt, M.H.; Matuszak, D.L.; Dickson, C.; Parrott, C.; Shoemaker, R.C.; Kauffman, C.L.; Wasserman, M.P.; et al. Learning and memory difficulties after environmental exposure to waterways containing toxin-producing Pfiesteria or Pfiesteria-like dinoflagellates. Lancet 1998, 352, 532–539. [Google Scholar] [CrossRef]

- Burkholder, J.M.; Glasgow, H.B. Pfiesteria piscicida and other Pfiesreria-like dinoflagellates: Behavior, impacts, and environmental controls. Limnol. Oceanogr. 1997, 42, 1052–1075. [Google Scholar] [CrossRef]

- Grattan, L.M.; Oldach, D.; Morris, J.G. Human Health Risks of Exposure to Pfiesteria piscicida. BioScience 2001, 51, 853–857. [Google Scholar] [CrossRef]

- Swinker, M.; Tester, P.; Attix, D.K.; Schmechel, D. Human health effects of exposure to Pfiesteria piscicida: A review. Microbes Infect. 2002, 4, 751–762. [Google Scholar] [CrossRef]

- Glasgow, H.; Burkholder, J.M.; Schmechel, D.E.; Tester, P.A.; Rublee, P.A. Insidious effects of a toxic estuarine dinoflagellate on fish survival and human health. J. Toxicol. Environ. Health 1995, 46, 501–522. [Google Scholar] [CrossRef] [Green Version]

- Shoemaker, R. Treatment of persistent Pfiesteria-human illness syndrome. MMJ 1998, 47, 64–66. [Google Scholar]

- United States Department of Agriculture (USDA). Delaware Agriculture. Available online: https://www.nass.usda.gov/Statistics_by_State/Delaware/index.php (accessed on 20 July 2018).

- Delaware Department of Natural Resources and Environmental Control (DNREC). Mountaire Millsboro Violations. Available online: http://www.nav.dnrec.delaware.gov/DEN3/Detail/FacilityDetail.aspx?id=10153227&panel=General (accessed on 20 July 2018).

- Quigley, R.; Den Broeder, L.; Furu, P.; Bond, A.; Cave, B.; Bos, R. Health Impact Assessment International Best Practice Principles; Special publication series No. 5; International Association for Impact Assessment: Fargo, ND, USA, 2006. [Google Scholar]

- U.S. Census Bureau American Community Survey (ACS). Five-Year Estimates. Available online: https://www.census.gov/programs-surveys/acs (accessed on 19 July 2018).

- Health Resources and Services Administration. HRSA Shortage Designation: Health Professional Shortage Areas & Medically Underserved Areas/Populations. Available online: https://datawarehouse.hrsa.gov/topics/shortageareas.aspx (accessed on 15 April 2015).

- U.S. Environmental Protection Agency (EPA). Toxics Release Inventory Program. Available online: https://www.epa.gov/toxics-release-inventory-tri-program (accessed on 20 July 2018).

- Environmental Integrity Project and Earthjustice. Out of Control: Mounting Damages From Coal Ash Waste Sites; Environmental Integrity Project: Washington, DC, USA, 2010. [Google Scholar]

- NRG Energy Inc. DNREC & State of Delaware 07C-02-283FSS; NRG Energy Inc.: Houston, TX, USA, 2007. [Google Scholar]

- Center for Media and Democracy: SourceWatch Indian River Power Station. Available online: https://www.sourcewatch.org/index.php/Indian_River_power_station#cite_note-4 (accessed on 20 July 2018).

- Delaware Depfartment of Natural Resources and Environmental Control (DNREC). SIRB Report: NCR History. Available online: https://onlinedocs.dnrec.delaware.gov/docfinity/application/index.html?jessionid=34659BB4C6740F4B99597939EB7D7B51#module=viewer;docid=8a8a81ef378082a7013782e2110d6ac4 (accessed on 20 July 2018).

- BCM Eastern, Inc. Excavated Sludge Disposal Site Post Closure Monitoring and Groundwater Quality Assessment for NCR Corporation; BCM Eastern, Inc: Plymouth Meeting, PA, USA, 1984. [Google Scholar]

- US EPA. Superfund: National Priorities List (NPL). Available online: https://www.epa.gov/superfund/superfund-national-priorities-list-npl (accessed on 19 July 2018).

- Agency for Toxic Substances and Disease Registry Health Consultation. Millsboro TCE Public Comment Version; Agency for Toxic Substances and Disease Registry Health Consultation: Atlanta, GA, USA, 2012. [Google Scholar]

- US EPA. Water Permitting 101; Office of Wastewater Management: Denver, CO, USA. Available online: https://www3.epa.gov/npdes/pubs/101pape.pdf (accessed on 20 July 2018).

- BP Environmental, Inc. Limited Subsurface Investigation: AL-190-03 Pinnacle Foods Corporation; BP Environmental, Inc.: Easton, MD, USA, 2013. [Google Scholar]

- US EPA. Drinking Water Contaminants—Standards and Regulations. Available online: https://www.epa.gov/dwstandardsregulations (accessed on 20 July 2018).

- Delaware Health and Social Services. Drinking Water Watch: Public Water Systems Search Parameters V3.13. Available online: https://drinkingwater.dhss.delaware.gov/ (accessed on 20 July 2018).

- Zogorski, J.S.; Carter, J.M.; Ivahnenko, T.; Lapham, W.W.; Moran, M.J.; Rowe, B.L.; Squillace, P.J.; Toccalino, P.L. Volatile Organic Compounds in the Nation’s Ground Water and Drinking-Water Supply Wells; States Geological Survey (USGS): Reston, VA, USA, 2006; p. 101.

- Geographic Research, Inc. Healthcare Data. Available online: http://simplyanalytics.com/ (accessed on 15 April 2015).

- CleanAir. Task Force Death and Disease from Power Plants. Available online: http://www.catf.us/fossil/problems/power_plants// (accessed on 19 July 2018).

- Delaware Health and Social Services. Cancer Cluster Investigation: Indian River Area; Delaware Health and Social Services: Dover, DE, USA, 2007.

- Delaware Health and Social Services. Lung Cancer in Sussex County, Delaware: Findings from the Indian River Community-Level Survey (IRCLS); Delaware Health and Social Services: Dover, DE, USA, 2009.

- Farm Sanctuary. Highway Accidents Involving Farm Animals; Farm Sanctuary: Acton, CA, USA, 2006. [Google Scholar]

- Rule, A.M.; Evans, S.L.; Silbergeld, E.K. Food animal transport: A potential source of community exposures to health hazards from industrial farming (CAFOs). J. Infect. Public Health 2008, 1, 33–39. [Google Scholar] [CrossRef] [Green Version]

- Vecerek, V.; Grbalova, S.; Voslarova, E.; Janackova, B.; Malena, M. Effects of Travel Distance and the Season of the Year on Death Rates of Broilers Transported to Poultry Processing Plants. Poult. Sci. 2006, 85, 1881–1884. [Google Scholar] [CrossRef] [PubMed]

- International Finance Corporation. Environmental, Health, and Safety Guidelines for Poultry Processing; International Finance Corporation: Washington, DC, USA, 2007. [Google Scholar]

- Anderson, B.W.; McCauley, S.; Lewis, G.P.; Liao, M.K. Impacts of a Poultry Processing Plant on the Diversity of Escherichia coli Populations and Transferability of Tetracycline Resistance Genes in an Urban Stream in South Carolina. Water Air Soil Pollut. 2014, 225, 2030. [Google Scholar] [CrossRef]

- Heederik, D.; Sigsgaard, T.; Thorne, P.S.; Kline, J.N.; Avery, R.; Bønløkke, J.H.; Chrischilles, E.A.; Dosman, J.A.; Duchaine, C.; Kirkhorn, S.R.; et al. Health Effects of Airborne Exposures from Concentrated Animal Feeding Operations. Environ. Health Perspect. 2007, 115, 298–302. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schinasi, L.; Horton, R.A.; Guidry, V.T.; Wing, S.; Marshall, S.W.; Morland, K.B. Air Pollution, Lung Function, and Physical Symptoms in Communities Near Concentrated Swine Feeding Operations. Epidemiology 2011, 22, 208–215. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wing, S.; Horton, R.A.; Marshall, S.W.; Thu, K.; Tajik, M.; Schinasi, L.; Schiffman, S.S. Air pollution and odor in communities near industrial swine operations. Environ. Health Perspect. 2008, 116, 1362–1368. [Google Scholar] [CrossRef] [PubMed]

- Horton, R.A.; Wing, S.; Marshall, S.W.; Brownley, K.A. Malodor as a Trigger of Stress and Negative Mood in Neighbors of Industrial Hog Operations. Am. J. Public Health 2009, 99, S610–S615. [Google Scholar] [CrossRef]

- Wing, S.; Horton, R.A.; Rose, K.M. Air Pollution from Industrial Swine Operations and Blood Pressure of Neighboring Residents. Environ. Health Perspect. 2013, 121, 92–96. [Google Scholar] [CrossRef]

- Bertozzi, L.; Villafañe, J.H.; Capra, F.; Reci, M.; Pillastrini, P. Effect of an Exercise Programme for the Prevention of Back and Neck Pain in Poultry Slaughterhouse Workers. Occup. Ther. Int. 2015, 22, 36–42. [Google Scholar] [CrossRef]

- Bureau of Labor Statistics. The Occupational Outlook Handbook: Slaughterers, Meat Packers, and Meat, Poultry, and Fish Cutters and Trimmers. Available online: https://www.bls.gov/ooh/#tab-3 (accessed on 19 July 2018).

- Occupational Safety and Health Administration. Safety and Health Topics: Poultry Processing—Hazards and Solutions. Available online: https://www.osha.gov/SLTC/poultryprocessing/hazards.html (accessed on 19 July 2018).

- Kyeremateng-Amoah, E.; Nowell, J.; Lutty, A.; Lees, P.S.J.; Silbergeld, E.K. Laceration injuries and infections among workers in the poultry processing and pork meatpacking industries. Am. J. Ind. Med. 2014, 57, 669–682. [Google Scholar] [CrossRef]

- Donham, K.J.; Cumro, D.; Reynolds, S.J.; Merchant, J.A. Dose-response relationships between occupational aerosol exposures and cross-shift declines of lung function in poultry workers: Recommendations for exposure limits. J. Occup. Environ. Med. 2000, 42, 260–269. [Google Scholar] [CrossRef]

- Donham, K.J.; Cumro, D.; Reynolds, S. Synergistic Effects of Dust and Ammonia on the Occupational Health Effects of Poultry Production Workers. J. Agromedicine 2002, 8, 57–76. [Google Scholar] [CrossRef] [PubMed]

- The Johns Hopkins Center for a Livable Future (CLF). Personal Communication to Sussex County Board of Adjustments; The Johns Hopkins Center for a Livable Future (CLF): Baltimore, MD, USA, 2013. [Google Scholar]

- California EPA. Health Effects of Diesel Exhaust; California EPA: Sacramento, CA, USA, 2018.

- US EPA. Controlling Nonpoint Source Runoff from Roads, Highways and Bridges; US EPA: Washington, DC, USA, 1995.

- Vuocolo, A. 5 Essential Facts about Delaware’s $1.7 Billion Poultry Industry—DBT. Available online: https://www.delawarebusinesstimes.com/5-essential-facts-about-the-poultry-industry/ (accessed on 6 July 2019).

- Allen Harim gets OK for chicken processing plant in Millsboro. Available online: https://www.delmarvanow.com/story/news/local/delaware/2018/05/08/millsboro-chicken-processing-plant-approved/588636002/ (accessed on 6 July 2019).

- Mountaire Farms to Expand Millsboro Poultry Plant, Add New Jobs—WBOC-TV 16, Delmarvas News Leader, FOX 21. Available online: http://www.wboc.com/story/13445956/mountaire-farms-to-expand-millsboro-poultry-plant-add-new-jobs (accessed on 6 July 2019).

- Skóra, J.; Matusiak, K.; Wojewódzki, P.; Nowak, A.; Sulyok, M.; Ligocka, A.; Okrasa, M.; Hermann, J.; Gutarowska, B. Evaluation of Microbiological and Chemical Contaminants in Poultry Farms. Intern. J. Environ. Res. Public Health 2016, 13, 192. [Google Scholar] [CrossRef] [PubMed]

- Berrang, M.E.; Northcutt, J.K.; Cason, J.A. Recovery of Campylobacter from broiler feces during extended storage of transport cages. Poult. Sci. 2004, 83, 1213–1217. [Google Scholar] [CrossRef] [PubMed]

- Nadimpalli, M.; Rinsky, J.L.; Wing, S.; Hall, D.; Stewart, J.; Larsen, J.; Nachman, K.E.; Love, D.C.; Pierce, E.; Pisanic, N.; et al. Persistence of Livestock-Associated Antibiotic-Resistant Staphylococcus Aureus among Industrial Hog Operation Workers in North Carolina over 14 Days. Occup. Environ. Med. 2015, 72, 90–99. [Google Scholar] [CrossRef] [PubMed]

- Castillo, N.R.; Augusto, F.J.; Rinsky, J.L.; Resnick, C.; Carroll, K.C.; Rule, A.M.; Ross, T.; You, Y.; Price, L.B.; Silbergeld, E.K. Multidrug-Resistant and Methicillin-Resistant Staphylococcus Aureus (MRSA) in Hog Slaughter and Processing Plant Workers and Their Community in North Carolina (USA). Environ. Health Perspect. 2014, 122, 471–477. [Google Scholar]

- Wing, S. Social Responsibility and Research Ethics in Community-Driven Studies of Industrialized Hog Production. Environ. Health Perspect. 2002, 110, 437–444. [Google Scholar] [CrossRef] [PubMed]

- Wing, S.; Horton, R.A.; Muhammad, N.; Grant, G.R.; Tajik, M.; Thu, K. Integrating Epidemiology, Education, and Organizing for Environmental Justice: Community Health Effects of Industrial Hog Operations. Am. J. Public Health 2008, 98, 1390–1397. [Google Scholar] [CrossRef] [PubMed]

- Bourcier, E.; Charbonneau, D.; Cahill, C.; Dannenberg, A.L. An Evaluation of Health Impact Assessments in the United States, 2011–2014. Preve. Chronic Dis. 2015, 12, E23. [Google Scholar] [CrossRef] [PubMed]

- Winkler, M.S.; Krieger, G.R.; Divall, M.J.; Cissé, G.; Wielga, M.; Singer, B.H.; Utzinger, J. Untapped potential of health impact assessment. Bull. World Health Organ. 2013, 91, 298–305. [Google Scholar] [CrossRef] [PubMed]

- Andrew, L.; Dannenberg, M.D. A Brief History of Health Impact Assessment in the United States. Chron. Health Impact Assess. 2016, 1. [Google Scholar] [CrossRef]

- Buse, C.G.; Lai, V.; Cornish, K.; Parkes, M.W. Towards environmental health equity in health impact assessment: Innovations and opportunities. Int. J. Public Health 2019, 64, 15–26. [Google Scholar] [CrossRef] [PubMed]

- Salazar, M.A.; Pesigan, A.; Law, R.; Winkler, V. Post-disaster health impact of natural hazards in the Philippines in 2013. Glob. Health Action 2016, 9, 31320. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Winkler, M.S.; Krieger, G.R.; Divall, M.J.; Singer, B.H.; Utzinger, J. Health impact assessment of industrial development projects: A spatio-temporal visualization. Geospat. Health 2012, 6, 299–301. [Google Scholar] [CrossRef] [PubMed]

- Tetteh, D.; Lengel, L. The urgent need for health impact assessment: Proposing a transdisciplinary approach to the e-waste crisis in sub-Saharan Africa. Glob. Health Promot. 2017, 24, 35–42. [Google Scholar] [CrossRef] [PubMed]

- Yuen, T.K.; Payne-Sturges, D.C. Using Health Impact Assessment to Integrate Environmental Justice into Federal Environmental Regulatory Analysis. New Solut. 2013, 23, 439–466. [Google Scholar] [CrossRef] [PubMed]

| Facility | Distance from Harim Millsboro | Amount of Emissions | Types of Emissions/Pollution | History of Pollution |

|---|---|---|---|---|

| NRG Indian River Plant | 2 miles | 279,354 Lbs. (2013) [37] | Chemical—barium, manganese, vanadium, lead [37] | Coal ash dump—groundwater contaminated with arsenic, chromium, and thallium [38] Closed coal-fired units in 2011 and 2013 to meet consent order to limit mercury, sulfur dioxide, and nitrous oxide emissions [39,40,41,42] |

| Mountaire Millsboro Poultry Processing Plant | 2 miles | 3167 Lbs [43,44] | Hydrogen sulfide, manganese, copper [33,41] | Received 17 violations from DNREC for exceedances of CO, NH3, nitrous oxides, nitrates, and sulfur oxides [33] |

| NCR Superfund Site | 1 mile | None | Chromium, trichloroethylene (TCE) [41,42] | Wastewater with high levels of chromium treated and stored in unlined pits on site until 1980s; added to NPL in 1987 [41,42,43] |

| Millsboro TCE Superfund Site | 2 miles | None | TCE [44] | 2005—remediation occurred because TCE found entering groundwater; bottled water given to residents during this time [45] |

| Chemical | EPA Standards | Health Effects | EPA Carcinogen Analysis | Concentrations Found at Harim Millsboro |

|---|---|---|---|---|

| Arsenic * | Maximum Contaminant Level (MCL) of 0.010 mg/L for drinking water | Acute exposure—numbness, nausea, vomiting, or burning sensations in the hands and feet, cardiovascular effects, and fatigue Chronic exposure-dermatological damage | Yes—chronic exposure associated with an increased risk of lung, skin, kidney, bladder, and prostate cancer | Vary from 0.0005–18.2 mg/L [46] |

| Chloride * | Secondary Maximum Contaminant Level (SMCL) 2 of 250 mg/L for drinking water | No known health effects; can cause corrosion in metal pipes, thus increasing amount of heavy metals in water | No | Vary between 12–560 mg/L [46] |

| Chromium-3 and Chromium-6 * | MCL of 0.1 mg/L for drinking water | Ingestion—Skin irritation Acute inhalation—Respiratory issues Chronic inhalation—Bronchitis, pneumonia, decreased lung function, and nasal septum destruction | Chromium-6 carcinogenic when inhaled and possible carcinogen when ingested | Elevated at site, below MCL in sprayfields [46,47,48] |

| Cobalt | None | Oral exposure—Nausea, vomiting, vision problems, skin irritation, thyroid damage, heart problems, death Acute inhalation—Decreased lung function, congestion, edema, and hemorrhage Chronic inhalation—Severe respiratory and cardiovascular issues | Not classified for carcinogenicity | Not monitored in public wells; private wells nearby ranged from 0.0018–0.523 mg/L [46] |

| Hydrogen Sulfide * | None; Occupational Safety and Health Administration (OSHA) has set standards for occupational exposure | Acute exposure—nausea, headache, eye and respiratory tract irritation, death at extremely high concentrations (over 500 ppm) Chronic exposure—impaired vision and sense of smell, dizziness, possible neurological defects | Not classified for carcinogenicity | Not available for site; at nearby Mountaire Processing Plant, 76% of emissions [33] |

| Nitrate * | MCL of 10 mg/L for drinking water | Methemoglobinemia, neurological issues, death | Not classified nitrate for carcinogenicity | Two wells measured 4.2 and 9.9 mg/L [46] |

| Particulate Matter (PM2.5 and PM10) * | PM2.5 Primary—12 μg/m3 Secondary—15 μg/m3 24 h—35 μg/m3 PM10 24 h—150 μg/m3 | Acute exposure—cardiovascular and respiratory issues Chronic exposure—increased mortality among individuals with chronic heart or lung diseases | Designated carcinogenic for diesel particulate matter; likely to be carcinogenic to humans by inhalation | Not measured at site; nearest monitoring station in Seaford shows above National Ambient Air Quality Standards (NAAQS) |

| Volatile Organic Compounds (VOCs) * | MCL for Total Trihalomethanes (TTHM) in drinking water is 0.08 mg/L | Acute exposure—nose, throat, and eye irritation; vomiting; nausea; dizziness; headache; worsening of asthma symptoms Chronic exposure to high levels—liver, kidney, and central nervous system damage | Bromoform—Probable human carcinogen Chloroform—likely to be carcinogenic Dibromodichloromethane—not classifiable as carcinogenic | Chloroform, PCE, and TCE most common VOCs, found at site [49] |

| Trichloroethylene (TCE) | MCL for TCE in drinking water is 0.005 mg/L | Acute exposure via inhalation—dizziness, tiredness, headaches, loss of coordination, cognitive and neurological issues Acute exposure in large quantities in air—unconsciousness or premature death | Likely to be carcinogenic by all routes of exposure | 1.2 μg/L [46] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baskin-Graves, L.; Mullen, H.; Aber, A.; Sinisterra, J.; Ayub, K.; Amaya-Fuentes, R.; Wilson, S. Rapid Health Impact Assessment of a Proposed Poultry Processing Plant in Millsboro, Delaware. Int. J. Environ. Res. Public Health 2019, 16, 3429. https://doi.org/10.3390/ijerph16183429

Baskin-Graves L, Mullen H, Aber A, Sinisterra J, Ayub K, Amaya-Fuentes R, Wilson S. Rapid Health Impact Assessment of a Proposed Poultry Processing Plant in Millsboro, Delaware. International Journal of Environmental Research and Public Health. 2019; 16(18):3429. https://doi.org/10.3390/ijerph16183429

Chicago/Turabian StyleBaskin-Graves, Leah, Haley Mullen, Aaron Aber, Jair Sinisterra, Kamran Ayub, Roxana Amaya-Fuentes, and Sacoby Wilson. 2019. "Rapid Health Impact Assessment of a Proposed Poultry Processing Plant in Millsboro, Delaware" International Journal of Environmental Research and Public Health 16, no. 18: 3429. https://doi.org/10.3390/ijerph16183429

APA StyleBaskin-Graves, L., Mullen, H., Aber, A., Sinisterra, J., Ayub, K., Amaya-Fuentes, R., & Wilson, S. (2019). Rapid Health Impact Assessment of a Proposed Poultry Processing Plant in Millsboro, Delaware. International Journal of Environmental Research and Public Health, 16(18), 3429. https://doi.org/10.3390/ijerph16183429