Optimization of Vehicle Routing for Waste Collection and Transportation

Abstract

:1. Introduction

2. Literature Review

2.1. Research about Waste Collection and Transportation

2.2. Research about Priority in a Vehicle Routing Problem (VRP)

2.3. Research about Algorithms

3. Model Formulation

3.1. Problem Description

- Each waste bin is only collected by one vehicle once.

- There is one disposal center.

- The vehicles must depart from the disposal center and go back to the disposal center when the task ends.

- There is single type of waste collection vehicle.

- The location of the disposal center and each waste bin are known.

- Each bin, , has a collection priority, which is determined in accordance with the passive influence of waste.

- A set of vehicles to collect waste, with a maximum capacity.

- A disposal center where vehicles star and end their trips.

- A set of waste bin filling level , for , where indicates the percentage of waste bin filled by waste.

3.2. Notation

3.3. Analysis of Objective Function

3.3.1. Total Distance

3.3.2. Total Greenhouse Gas (GHG) Emissions

3.3.3. Total Costs

3.4. Model Construction

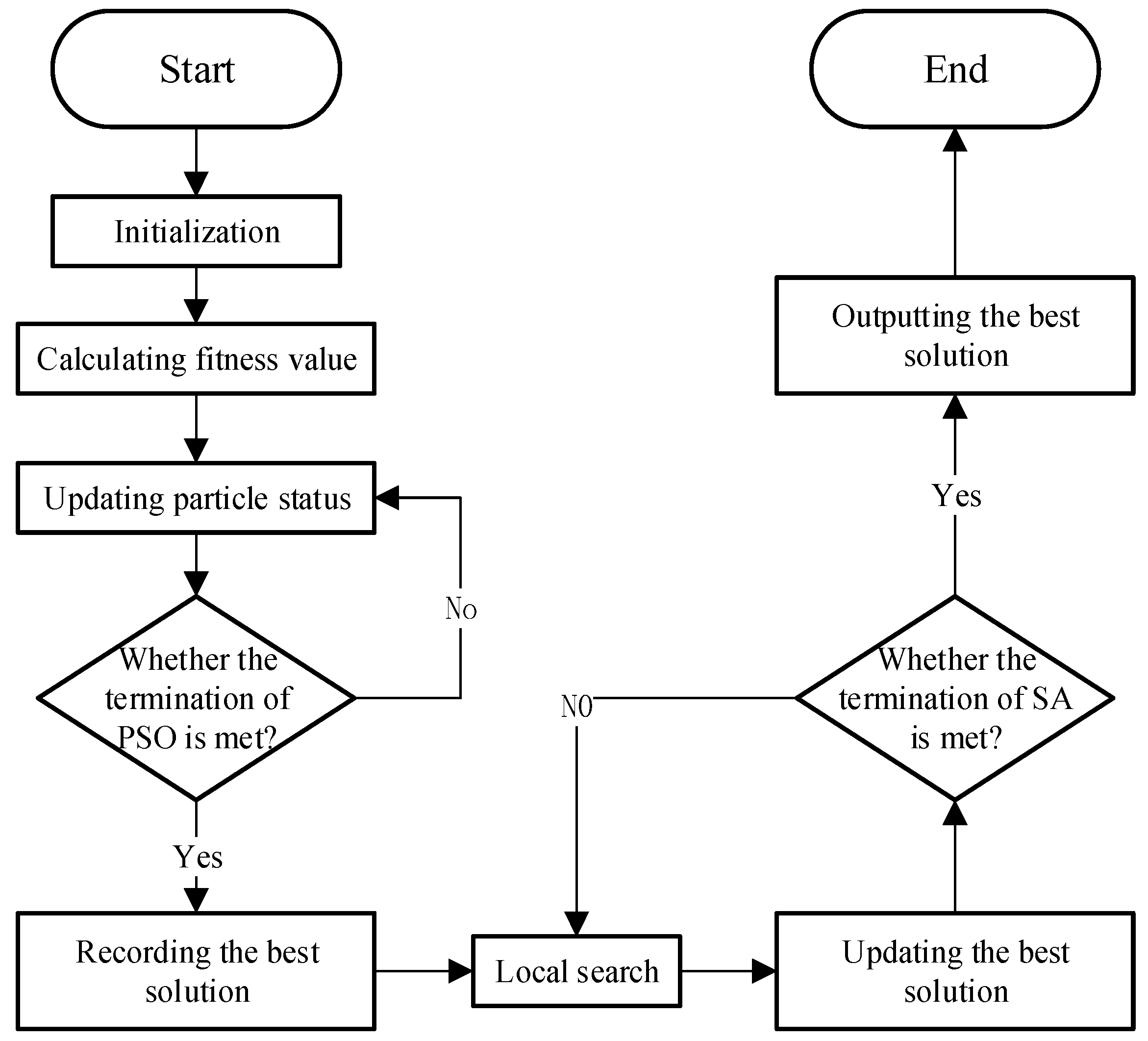

4. Algorithm

4.1. Algorithm Design

4.2. Particle Coding and Decoding

4.3. Constructing Initial Optimal Solution Based on Particle Swarm Optimization (PSO) Algorithm

4.3.1. Initialization and Fitness Function

- Initialization

- Fitness Function

4.3.2. Obtaining Optimal Solution

4.3.3. Particle Status Update

4.3.4. Terminating Condition

4.4. Local Search

4.5. Obtain Optimal Solution Using Simulated Annealing (SA) Algorithm

5. Numerical Experiment

5.1. Algorithm Experiment

5.1.1. Test Cases

5.1.2. Parameters Setting

5.1.3. Results of Algorithm Experiment

5.2. Model Experiment

5.2.1. Experimental Design

- Experiment about different objective functions;

- Experiment about collecting waste in conventional scenario in priority considered scenario;

- Experiment about different number of waste bins with high priority;

- Experiment about different waste filling levels;

- Experiment about different waste filling levels of general waste bins and different number of high priority waste bins.

5.2.2. Experimental Results

- Experiment about Objective Function

- Experiment about Conventional Scenario and Priority Considered Scenario

- Experiment about Different Number of High Priority Waste Bins

- Experiment about Different Waste Filling Levels (WFLs)

- Experiment about Different WFLs and Different Number of High-Priority Waste Bins

5.3. Analysis of Results

- (1)

- For experiment 1, the objectives of minimizing distance, minimizing GHG emissions and minimizing costs are compared. The objective of minimizing costs is the compromised one considering both distance and GHG emissions.

- (2)

- For experiment 2, PCS and CS are same in distance reduction, GHG emissions reduction and costs reduction, while PCS achieves a negative effect reduction of 42.3%.

- (3)

- For experiment 3, the negative effect increases as the number of waste bins with high priority is increasing.

- (4)

- For experiment 4, the higher the WFL, the lower the percentage of collected waste and the costs. However, excessive WFL can increase the risk of overflowing before the next collection.

- (5)

- For experiment 5, different distribution of various waste bins (waste bins with high priority, waste filling level of general waste bins) result in different negative effect, costs, vehicles utilization rate and so on. The WFL between 60% and 80% can obtain the optimal solution under different number of waste bins with high priority.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kharat, M.G.; Murthy, S.; Kamble, S.J.; Raut, R.D.; Kamble, S.S.; Kharat, M.G. Fuzzy multi-criteria decision analysis for environmentally conscious solid waste treatment and disposal technology selection. Technol. Soc. 2019, 57, 20–29. [Google Scholar] [CrossRef]

- Andrey, P.; Valentina, I.; Yuri, S. Strategic approaches to management in the field of solid municipal waste management. Talent Dev. Excell. 2020, 12, 700–709. [Google Scholar]

- Fernandez-Aracil, P.; Ortuno-Padilla, A.; Melgarejo-Moreno, J. Factors related to municipal costs of waste collection service in Spain. J. Clean. Prod. 2018, 175, 553–560. [Google Scholar] [CrossRef] [Green Version]

- Ferronato, N.; Torretta, V.; Ragazzi, M.; Rada, E.C. Waste mismanagement in developing countries: A case study of environmental contamination. UPB Sci. Bull. 2017, 79, 185–196. [Google Scholar]

- Cocarta, D.M.; Rada, E.C.; Ragazzi, M.; Badea, A.; Apostol, T.J.E.T. A contribution for a correct vision of health impact from municipal solid waste treatments. Environ. Technol. 2009, 30, 963–968. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Liu, X.; Hu, X.; Huang, G.; Meng, N. A genetic-algorithm-aided fuzzy chance-constrained programming model for municipal solid waste management. Eng. Optim. 2019, 1–17. [Google Scholar] [CrossRef]

- Expósito-Márquez, A.; Expósito-Izquierdo, C.; Brito-Santana, J.; Moreno-Pérez, J.A. Greedy randomized adaptive search procedure to design waste collection routes in La Palma. Comput. Ind. Eng. 2019, 137. [Google Scholar] [CrossRef]

- Nesmachnow, S.; Rossit, D.; Toutouh, J. Comparison of Multiobjective Evolutionary Algorithms for Prioritized Urban Waste Collection in Montevideo, Uruguay. Electron. Notes Discret. Math. 2018, 69, 93–100. [Google Scholar] [CrossRef]

- Ghiani, G.; Laganà, D.; Manni, E.; Triki, C. Capacitated location of collection sites in an urban waste management system. J. Waste Manag. 2012, 32, 1291–1296. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Abbasian, P.; Soltani, M.; Ghaffarian, S.A. Developing an applied algorithm for multi-trip vehicle routing problem with time windows in urban waste collection: A case study. Waste Manag. Res. 2019, 37, 4–13. [Google Scholar] [CrossRef] [Green Version]

- Tirkolaee, E.B.; Alinaghian, M.; Hosseinabadi, A.A.R.; Sasi, M.B.; Sangaiah, A.K. An improved ant colony optimization for the multi-trip Capacitated Arc Routing Problem. Comput. Electr. Eng. 2019, 77, 457–470. [Google Scholar] [CrossRef]

- Yaman, C.; Anil, I.; Jaunich, M.K.; Blaisi, N.I.; Alagha, O.; Yaman, A.B.; Gunday, S.T. Investigation and modelling of greenhouse gas emissions resulting from waste collection and transport activities. Waste Manag. Res. 2019, 37, 1282–1290. [Google Scholar] [CrossRef] [PubMed]

- Anagnostopoulos, T.; Kolomvatsos, K.; Anagnostopoulos, C.; Zaslavsky, A.; Hadjiefthymiades, S. Assessing dynamic models for high priority waste collection in smart cities. J. Syst. Softw. 2015, 110, 178–192. [Google Scholar] [CrossRef] [Green Version]

- Nuortio, T.; Kytöjoki, J.; Niska, H.; Bräysy, O. Improved route planning and scheduling of waste collection and transport. J. Expert Syst. Appl. 2005, 30, 223–232. [Google Scholar] [CrossRef]

- Jaeger, S.D.; Eyckmans, J.; Rogge, N.; Puyenbroeck, T.V.J.W.M. Wasteful waste-reducing policies? The impact of waste reduction policy instruments on collection and processing costs of municipal solid waste. Waste Manag. 2011, 31, 1429–1440. [Google Scholar] [CrossRef] [PubMed]

- Melakessou, F.; Kugener, P.; Alnaffakh, N.; Faye, S.; Khadraoui, D. Heterogeneous Sensing Data Analysis for Commercial Waste Collection. Sensors (Basel, Switzerland) 2020, 20, 978. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mamun, M.A.A.; Hannan, M.A.; Hussain, A.; Basri, H. Theoretical model and implementation of a real time intelligent bin status monitoring system using rule based decision algorithms. J. Expert Syst. Appl. 2016, 48, 76–88. [Google Scholar] [CrossRef]

- Ferrer, J.; Alba, E. BIN-CT: Urban waste collection based on predicting the container fill level. J. Biosyst. 2019, 186, 103962. [Google Scholar] [CrossRef] [Green Version]

- Shuang, X.; Li, G.; Ou, H.; Wu, W. Research and Demonstration of Dynamic Intelligent Logistics System of the Collection and Transportation Process of Giant Municipal Garbage. Lect. Notes Electr. Eng. 2015, 286, 39–50. [Google Scholar]

- Rada, E.C.; Grigoriu, M.; Ragazzi, M. Web oriented technologies and equipments for MSW collection. In Proceedings of the International Conference on Risk Management, Assessment and Mitigation, RIMA 2010, Bucharest, Romania, 20–23 April 2010; pp. 150–153. [Google Scholar]

- Kirschstein, T.; Meisel, F. GHG-emission models for assessing the eco-friendliness of road and rail freight transports. Transp. Res. Part B Methodol. 2015, 73, 13–33. [Google Scholar] [CrossRef]

- Behnke, M.; Kirschstein, T. The impact of path selection on GHG emissions in city logistics. Transp. Res. Part E-Logist. Transp. Rev. 2017, 106, 320–336. [Google Scholar] [CrossRef]

- Li, C.-Z.; Zhang, Y.; Liu, Z.-H.; Meng, X.; Du, J. Optimization of MSW collection routing system to reduce fuel consumption and pollutant emissions. Nat. Environ. Pollut. Technol. 2014, 13, 177–184. [Google Scholar]

- Mohsenizadeh, M.; Tural, M.K.; Kentel, E. Municipal solid waste management with cost minimization and emission control objectives: A case study of Ankara. Sustain. Cities Soc. 2020, 52. [Google Scholar] [CrossRef]

- Callao, C.; Martinez-Nunez, M.; Latorre, M.P. European Countries: Does common legislation guarantee better hazardous waste performance for European Union member states? Waste Manag. 2019, 84, 147–157. [Google Scholar] [CrossRef]

- Friege, H.; Kummer, B.; Steinhauser, K.G.; Wuttke, J.; Zeschmar-Lahl, B. How should we deal with the interfaces between chemicals, product and waste legislation? Environ. Sci. Eur. 2019, 31. [Google Scholar] [CrossRef] [Green Version]

- Nnorom, I.C.; Osibanjo, O. Overview of electronic waste (e-waste) management practices and legislations, and their poor applications in the developing countries. Resour. Conserv. Recycl. 2008, 52, 843–858. [Google Scholar] [CrossRef]

- Poykio, R.; Watkins, G.; Dahl, O. Evaluation of the utilization potential of debarking residue based on the requirements of Finnish waste legislation. Clean Technol. Environ. Policy 2019, 21, 463–470. [Google Scholar] [CrossRef]

- Faruqi, M.H.Z.; Siddiqui, F.Z. A mini review of construction and demolition waste management in India. Waste Manag. Res. 2020. [Google Scholar] [CrossRef]

- Alam, M.; Bahauddin, K.M.J.P.E.; Development, S. E-Waste In Bangladesh: Evaluating The Situation, Legislation And Policy And Way Forward With Strategy And Approach. Present Environ. Sustain. Dev. 2015, 9, 25–46. [Google Scholar] [CrossRef]

- Kaur, H.; Goel, S.J.M.; Studies, L. E-waste Legislations in India—A Critical Review. Manag. Labour Stud. 2016, 41, 63–69. [Google Scholar] [CrossRef]

- Dantzig, G.B.; Ramser, J.H. The Truck Dispatching Problem. Manag. Sci. 1959, 6, 80–91. [Google Scholar] [CrossRef]

- Beltrami, E.J.; Bodin, L.D. Networks and vehicle routing for municipal waste collection. Networks 1974, 4, 65–94. [Google Scholar] [CrossRef]

- Delgado-Antequera, L.; Caballero, R.; Sánchez-Oro, J.; Colmenar, J.M.; Martí, R. Iterated greedy with variable neighborhood search for a multiobjective waste collection problem. J. Expert Syst. Appl. 2020, 145, 113101. [Google Scholar] [CrossRef]

- Yadav, V.; Karmakar, S. Sustainable collection and transportation of municipal solid waste in urban centers. J. Sustain. Cities Soc. 2020, 53, 101937. [Google Scholar] [CrossRef]

- Miranda, P.A.; Blazquez, C.A.; Vergara, R.; Weitzler, S. A novel methodology for designing a household waste collection system for insular zones. Transp. Res. Part E-Logist. Transp. Rev. 2015, 77, 227–247. [Google Scholar] [CrossRef]

- Zhao, J.; Huang, L.; Lee, D.-H.; Peng, Q. Improved approaches to the network design problem in regional hazardous waste management systems. Transp. Res. Part E-Logist. Transp. Rev. 2016, 88, 52–75. [Google Scholar] [CrossRef]

- Abdallah, M.; Adghim, M.; Maraqa, M.; Aldahab, E. Simulation and optimization of dynamic waste collection routes. Waste Manag. Res. 2019, 37, 793–802. [Google Scholar] [CrossRef]

- De Bruecker, P.; Belien, J.; De Boeck, L.; De Jaeger, S.; Demeulemeester, E. A model enhancement approach for optimizing the integrated shift scheduling and vehicle routing problem in waste collection. Eur. J. Oper. Res. 2018, 266, 278–290. [Google Scholar] [CrossRef]

- Leggieri, V.; Haouari, M. A practical solution approach for the green vehicle routing problem. Transp. Res. Part E-Logist. Transp. Rev. 2017, 104, 97–112. [Google Scholar] [CrossRef]

- Heidari, R.; Yazdanparast, R.; Jabbarzadeh, A. Sustainable design of a municipal solid waste management system considering waste separators: A real-world application. Sustain. Cities Soc. 2019, 47. [Google Scholar] [CrossRef]

- Reddy, K.N.; Kumar, A.; Ballantyne, E.E.F. A three-phase heuristic approach for reverse logistics network design incorporating carbon footprint. Int. J. Prod. Res. 2019, 57, 6090–6114. [Google Scholar] [CrossRef]

- De Armas, J.; Melian-Batista, B.; Moreno-Perez, J.A.; Brito, J. GVNS for a real-world Rich Vehicle Routing Problem with Time Windows. Eng. Appl. Artif. Intell. 2015, 42, 45–56. [Google Scholar] [CrossRef]

- Molina, J.C.; Eguia, I.; Racero, J. An optimization approach for designing routes in metrological control services: A case study. Flex. Serv. Manuf. J. 2018, 30, 924–952. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, X.L.; Xu, M.Z.; Wang, Y.H.; Liu, Y. Vehicle routing problem based on a fuzzy customer clustering approach for logistics network optimization. J. Intell. Fuzzy Syst. 2015, 29, 1427–1442. [Google Scholar] [CrossRef]

- Solomon, M.M. Algorithms for the vehicle-routing and scheduling problems with time window constraints. Oper. Res. 1987, 35, 254–265. [Google Scholar] [CrossRef] [Green Version]

- Rau, H.; Budiman, S.D.; Widyadana, G.A. Optimization of the multi-objective green cyclical inventory routing problem using discrete multi-swarm PSO method. Transp. Res. Part E-Logist. Transp. Rev. 2018, 120, 51–75. [Google Scholar] [CrossRef]

- Wichapa, N.; Khokhajaikiat, P. Solving a multi-objective location routing problem for infectious waste disposal using hybrid goal programming and hybrid genetic algorithm. Int. J. Ind. Eng. Comput. 2018, 9, 75–98. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhao, Q.; Kaku, I.; Xu, Y. Development of a fuel consumption optimization model for the capacitated vehicle routing problem. Comput. Oper. Res. 2012, 39, 1419–1431. [Google Scholar] [CrossRef]

- Qin, G.; Tao, F.; Li, L.; Chen, Z. Optimization of the simultaneous pickup and delivery vehicle routing problem based on carbon tax. Ind. Manag. Data Syst. 2019, 119, 2055–2071. [Google Scholar] [CrossRef]

- Shen, L.; Tao, F.; Wang, S. Multi-Depot Open Vehicle Routing Problem with Time Windows Based on Carbon Trading. Int. J. Environ. Res. Public Health 2018, 15, 2025. [Google Scholar] [CrossRef] [Green Version]

- Qin, G.; Tao, F.; Li, L. A Vehicle Routing Optimization Problem for Cold Chain Logistics Considering Customer Satisfaction and Carbon Emissions. Int. J. Environ. Res. Public Health 2019, 16, 576. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shen, L.; Tao, F.; Shi, Y.; Qin, R. Optimization of Location-Routing Problem in Emergency Logistics Considering Carbon Emissions. Int. J. Environ. Res. Public Health 2019, 16, 2982. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, H.; Tao, F.; Qiao, Q.; Zhang, M. A Chance-Constrained Vehicle Routing Problem for Wet Waste Collection and Transportation Considering Carbon Emissions. Int. J. Environ. Res. Public Health 2020, 17, 458. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Sets | Unit | Description |

|---|---|---|

| Set of waste bins () | ||

| Waste disposal center | ||

| Set of vehicles () | ||

| Maximum load capacity of vehicle | ||

| Total distance of all vehicles | ||

| Total GHG emissions of all vehicles | ||

| Total cost of all vehicles | ||

| Cost of greenhouse gas (GHG) emissions per unit | ||

| Emission coefficient | ||

| Fuel consumption rate per unit distance | ||

| Fuel consumption rate per unit distance while vehicle is empty | ||

| Fuel consumption rate per unit distance while vehicle is at full load | ||

| Fuel consumption rate per unit distance with load of | ||

| Fuel consumption rate per unit distance while vehicle goes from waste bin to | ||

| GHG emissions | ||

| Collected waste at waste bin | ||

| Distance between waste bin and | ||

| s | Time of vehicle arriving at waste bin | |

| If waste bin has a high priority, . Otherwise, | ||

| Fixed cost of each vehicle | ||

| Price of fuel consumption | ||

| Variable | ||

| Whether a vehicle goes from waste bin to |

| Waste Bin Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | |

| 1 | 3 | 2 | 3 | 1 | 2 | 4 | 2 | 3 | 1 |

| Vehicle Number | Vehicle Route |

|---|---|

| 1 | 0-1-3-2-0 |

| 2 | 0-5-6-4-7-0 |

| 3 | 0-10-8-9-0 |

| Parameters of PSO | Description |

|---|---|

| Maximum number of iterations | |

| Length of particle code | |

| Number of population | |

| Learning factor1 | |

| Learning factor2 | |

| Acceleration factor 1 | |

| Acceleration factor 2 | |

| Maximum velocity | |

| Minimum velocity | |

| Particle range | |

| Inertia weight | |

| Inertia weight damping ratio |

| Problems | Case | Node | Capacity |

|---|---|---|---|

| Pro 1 | E-n22-k4 | 22 | 6000 |

| Pro 2 | E-n23-k3 | 23 | 4500 |

| Pro 3 | E-n30-k4 | 30 | 4500 |

| Pro 4 | E-n33-k4 | 33 | 8000 |

| Pro 5 | E-n51-k5 | 51 | 160 |

| Pro 6 | E-n76-k8 | 76 | 180 |

| Pro 7 | E-n76-k10 | 76 | 140 |

| Pro 8 | E-n101-k8 | 101 | 100 |

| Parameter | Value |

|---|---|

| 3.15 | |

| 0.16 | |

| 0.377 | |

| 0.025 | |

| 100 | |

| 8 |

| Parameter | Value |

|---|---|

| 1000 | |

| 20 | |

| 1.5 | |

| 1.5 | |

| 0.99 | |

| 200 | |

| 0.98 | |

| 1 | |

| 5 |

| Problems | PSO | LSHA | ||||

|---|---|---|---|---|---|---|

| Distance | GHG Emissions | Cost | Distance | GHG Emissions | Cost | |

| Pro 1 | 649.40 | 521.70 | 1738.01 | 603.72 | 467.87 | 1589.71 |

| Pro 2 | 946.06 | 737.81 | 2192.26 | 900.32 | 618.46 | 1886.17 |

| Pro 3 | 1161.74 | 884.11 | 2567.48 | 1091.85 | 783.08 | 2308.36 |

| Pro 4 | 1352.04 | 1028.88 | 3038.76 | 1210.99 | 971.73 | 2892.19 |

| Pro 5 | 1491.31 | 1211.97 | 3608.33 | 1383.12 | 1148.54 | 3402.13 |

| Pro 6 | 2331.47 | 1841.55 | 5622.99 | 2115.12 | 1746.72 | 4936.27 |

| Pro 7 | 2298.04 | 1746.65 | 5779.60 | 2089.77 | 1532.66 | 5043.73 |

| Pro 8 | 3152.75 | 2636.75 | 7562.42 | 2836.39 | 2339.05 | 6411.86 |

| Point | X Coordinate | Y Coordinate | Amount of Waste | Priority |

|---|---|---|---|---|

| Disposal Center | 4.8 | 4.74 | — | — |

| 1 | 0.98 | 0.08 | 626.87 | General |

| 2 | 3.6 | 1.05 | 566.31 | High |

| 3 | 3.35 | 2.68 | 772.5 | General |

| 4 | 1.92 | 4.27 | 913.9 | High |

| 5 | 2.46 | 4.55 | 918.5 | General |

| 6 | 3.87 | 1.67 | 916.67 | High |

| 7 | 0.74 | 2.35 | 601.86 | High |

| 8 | 2.43 | 0.01 | 772.21 | General |

| 9 | 0.36 | 1.55 | 937.47 | General |

| 10 | 3.94 | 2.43 | 560.5 | High |

| 11 | 1.97 | 1.31 | 928.18 | General |

| 12 | 1.18 | 3.42 | 949.89 | General |

| 13 | 0.4 | 4.56 | 608.93 | General |

| 14 | 0.4 | 2.85 | 538.49 | General |

| 15 | 4.64 | 1.33 | 737.11 | High |

| 16 | 1.02 | 4.64 | 917.51 | General |

| 17 | 4.78 | 0.32 | 734.7 | High |

| 18 | 1.7 | 3.13 | 706.88 | General |

| 19 | 0.3 | 0.54 | 751.37 | General |

| 20 | 1.72 | 2.58 | 562.72 | General |

| 21 | 3.02 | 4.78 | 566.14 | General |

| 22 | 3.06 | 1.36 | 935.24 | General |

| 23 | 2.78 | 2.63 | 801.48 | General |

| 24 | 2.73 | 3.56 | 632.65 | General |

| 25 | 1.01 | 1.07 | 932.4 | High |

| 26 | 3.94 | 4.13 | 529.05 | High |

| 27 | 1.74 | 0.69 | 728.88 | High |

| 28 | 4.86 | 2.19 | 861.1 | General |

| 29 | 0.58 | 3.88 | 669.5 | General |

| 30 | 3.56 | 3.52 | 700.61 | General |

| Parameter | Value |

|---|---|

| 100 | |

| Capacity | 3000 kg |

| Objective1-Distance | Objective2-GHG | Objective3-Cost | |

|---|---|---|---|

| Distance | 103.7554 | 109.4249 | 110.1329 |

| GHG Emissions | 83.1519 | 78.9363 | 82.6705 |

| Cost | 1208.129 | 1202.4465 | 1106.894 |

| Number | Routes | High Priority Waste Bin | Collection Order | Collection Time |

|---|---|---|---|---|

| 1 | {6,24,9,021,24,9,0} | 17 | 2nd | 30.54 |

| 2 | {0,15,11,7,0} | 15 | 1st | 11.38 |

| 7 | 3rd | 35.65 | ||

| 3 | {0,8,4,12,0} | 4 | 2st | 29.03 |

| 4 | {0,25,14,0} | 25 | 1st | 17.59 |

| 5 | {0,13,29,22,0} | - | - | - |

| 6 | {0,27,6,28,0} | 27 | 1st | 16.92 |

| 6 | 2nd | 29.74 | ||

| 7 | {0,23,16,30,0} | - | - | - |

| 8 | {0,5,26,10,0} | 26 | 2nd | 17.95 |

| 10 | 3rd | 28.62 | ||

| 9 | {0,3,2,0} | 2 | 2nd | 28.62 |

| 10 | {0,20,19,1,0} | - | - | - |

| Total | 246.03 | |||

| Number | Routes | High Priority Waste Bin | Collection Order | Collection Time |

|---|---|---|---|---|

| 1 | {0,27,5,11,0}. | 27 | 1st | 16.92 |

| 2 | {0,15,1,30,16,0} | 15 | 1st | 11.38 |

| 3 | {0,10,8,20,12,0} | 10 | 1st | 8.22 |

| 4 | {0,7,29,14,24,0} | 7 | 1st | 15.70 |

| 5 | {0,25,28,3,0} | 25 | 1st | 17.59 |

| 6 | {0,17,22,19,23,0} | 17 | 1st | 14.73 |

| 7 | {0,2,4,21,9,0} | 2 | 1st | 12.93 |

| 8 | 4 | 2nd | 30.04 | |

| 9 | {0,26,18,13,0} | 26 | 1st | 3.52 |

| 10 | {0,6,0} | 6 | 1st | 10.69 |

| Total | 141.72 | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Tao, F.; Yang, B. Optimization of Vehicle Routing for Waste Collection and Transportation. Int. J. Environ. Res. Public Health 2020, 17, 4963. https://doi.org/10.3390/ijerph17144963

Wu H, Tao F, Yang B. Optimization of Vehicle Routing for Waste Collection and Transportation. International Journal of Environmental Research and Public Health. 2020; 17(14):4963. https://doi.org/10.3390/ijerph17144963

Chicago/Turabian StyleWu, Hailin, Fengming Tao, and Bo Yang. 2020. "Optimization of Vehicle Routing for Waste Collection and Transportation" International Journal of Environmental Research and Public Health 17, no. 14: 4963. https://doi.org/10.3390/ijerph17144963